Fresadora tupí

Router

Défonceuse

Tischfräsmaschine

Fresatrice toupie

Fresadora tupia

Фрезер

FR277R / FR278R

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D’ EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D’ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

7

ENGLISH

FR277R ROUTER

FR278R ELECTRONIC ROUTER

(ILUSTRATIONS IN PAGE 39)

Important

Read these OPERATING INSTRUCTIONS

and the attached GENERAL SAFETY

INSTRUCTIONS LEAFLET carefully before

using the machine. Make sure you have

understood them before operating the

machine for the first time.

Keep both sets of instructions for any

future queries.

1. TECHNICAL DATA

Type.........................................................FR277R

Universal motor.........................................50/60 Hz

Input power..................................................1010W

No-load speed.......................................24,000/min

Standard chuck diameter.................................8 mm

Routing depth............................................0-50 mm

Maximum bit diameter...................................40 mm

Revolving depth gauge...3-position depth adjustment

Weight..........................................................2.9 Kg

Weighted equivalent continuous

acoustic pressure level A.............................................91 dBA

Acoustic power level A..................................................102 dBA

Uncertainty...................................................................K = 3 dbA

Wear ear protection!

Vibration total values..............................................ah: 4.4 m/s

2

Uncertainty....................................................................K: 1.5 m/s

2

Type........................................................FR278R

Universal motor.........................................50/60 Hz

Input power..................................................1300W

No-load speed.............................6,000-27,000/min

Standard chuck diameter.................................8 mm

Routing depth.............................................0-50 mm

Maximum bit diameter...................................40 mm

Revolving depth gauge..3-position depth adjustment

Weight.............................................................3 Kg

Weighted equivalent continuous

acoustic pressure level A.............................................91 dBA

Acoustic power level A..................................................102 dBA

Uncertainty...................................................................K = 3 dbA

Wear ear protection!

Sin embargo, el nivel de vibraciones puede llegar a ser

muy diferente al valor declarado en otras condiciones

de aplicación, con otros útiles de trabajo o con un

mantenimiento insuficiente de la herramienta eléctrica

y sus útiles, pudiendo llegar a resultar un valor mucho

más elevado debido a su ciclo de trabajo y modo de uso

de la herramienta eléctrica.

Por tanto, es necesario fijar medidas de seguridad de

protección al usuario contra el efecto de las vibraciones,

como pueden ser mantener la herramienta y útiles de

trabajo en perfecto estado y la organización de los

tiempos de los ciclos de trabajo (tales como tiempos

de marcha con la herramienta bajo carga, y tiempos de

marcha de la herramienta en vacío y sin ser utilizada

realmente ya que la reducción de estos últimos puede

disminuir de forma sustancial el valor total de exposición).

26. GARANTÍA

Todas las máquinas electroportátiles VIRUTEX, tienen

una garantía válida de 12 meses a partir del día de su

suministro, quedando excluidas todas las manipulaciones

o daños ocasionados por manejos inadecuados o por

desgaste natural de la máquina. Para cualquier reparación

dirigirse al servicio oficial de asistencia VIRUTEX S.A.

27. RECICLAJE DE LAS

HERRAMIENTAS ELÉCTRICAS

Nunca tire la herramienta eléctrica con el resto de resi-

duos domésticos. Recicle las herramientas, accesorios y

embalajes de forma respetuosa con el medio ambiente.

Respete la normativa vigente de su país.

Aplicable en la Unión Europea y en países europeos

con sistemas de recogida selectiva de residuos:

La presencia de esta marca en el producto o en el

material informativo que lo acompaña, indica que al

finalizar su vida útil no deberá eliminarse junto con

otros residuos domésticos.

Conforme a la Directiva Europea 2002/96/CE los usuarios

pueden contactar con el establecimiento donde adquirie-

ron el producto, o con las autoridades locales pertinentes,

para informarse sobre cómo y dónde pueden llevarlo

para que sea sometido a un reciclaje ecológico y seguro.

VIRUTEX se reserva el derecho de modificar sus productos

sin previo aviso.

8

wear a protective head-covering. When working outside,

wear non-skid footwear.

• In case the tool is blocked, immediately switch off the

tool and disconnect the plug.

• Clamp the workpiece.

• Guide only switched on tool towards the workpice.

Switch off the tool when you when you have lifted the

tool from the workpiece.

• Use only original parts and accessories.

4. PACKAGE CONTENTS

Router

Parallel guide

Compass

Wrench

Dust extraction adapter

Instructions for use, guarantee card

5. PREPARING THE TOOL FOR MILLING

Always disconnect the plug from power

source before making any adjustments

or changing any accessory.

6. DUST SUCTION

Milling and grinding wood generate sawdust and dust

that endanger safety and health. Using dust suction

prevents air pollution for breathing and makes easier

removal of wastes.

7. MOUNTING DUST EXTRACTION ADAPTER

Put the dust extraction adapter 15 (Fig. 2) baseplate 3

(Fig. 2) so that the twin column guide A (Fig. 2) is inside

the mouth of the dust extraction adapter.

Push the mouth with the right hand thumb in the

direction A (Fig. 2) towards the locking edge C so that

the lock D on the periphery is automatically cought in

the edge B (Fig. 2)

Connect the hose of a vacuum cleaner directly to the

dust extraction adapter 15 (Fig. 3), or connect it with a

suction hose with a turning connection for extracting

dust 4 (Fig. 3).

Fix the latter into the corresponding place below the

motor cover.

Mount the upper dust extraction adapter by pushing

it in the directions C until it snaps between the motor

gerabox and the motor cover. Then attach the lower

part of the hose to the dust extraction adapter 15 in

the direction D (Fig. 3).

Turning connection enables better view of the milling

area and setting the vacuum cleaner hose in the most

favourable position. The diameter of the dust extrac-

Vibration total values..............................................a

h

: 4.4 m/s

2

Uncertainty....................................................................K: 1.5 m/s

2

2. OPERATION RANGE

The router is a professional power tool intended for

surface milling of wood, plastics and aluminium. It is an

excellent tool for milling templates, contours, circles and

grooves, for making finishing laths and picture frames

and for engraving inscriptions.

3. SAFETY INSTRUCTIONS FOR

MACHINE OPERATION

Read the instructions for use and safety instructions

carefully before using the tool.

• Disconnect the plug before you perform any work

on the tool.

• Do not use the tool if the mains lead is damged. If the

mains lead is damaged while working, do not touch it

but immediately disconnect the plug.

• Always keep the mains lead away from moving parts

of the tool.

Direct the mais lead to the rear fo the tool.

• Use only extension cord that is intended for outdoor

use and equipped with a splash-proof coupling-socket.

Connect the tool via a fault current (FI) circuit beaker

with a triggering current of 30 mA maximum.

• Wires of the extension cable must have a minimum

section of 1,5 mm2 and the cable must be fully unwound.

• Plug in the tool only if the switch is turned off.

• Always wear personal protective equipment, glasses

and footwear.

• Always hold the router with both hands.

• Switch off the motor after you have finished milling.

• Before you put down the tool, loosen the router table.

• Always put down the tool on a horizontal and clean

surface.

• Do not put any other tools on the workpiece.

• Workpiece must be clean, without any rests of ma-

terials, sawdust...

• Work place should have adequte lights, it is forbiidden

to use the tool in rooms with inflammable substances

and gases, switch on/off the tool only by the switch and

not by disconnesting the plug.

• Be careful of screws, nails and other objects in the

workpiece while milling.

• Start working only when the tool has reached full speed.

• Be aware of the sudden impact when the FR277R and

FR278R power tool is switched on.

• Prevent unintentional switching on of the tool.

• Always use undamaged and sharp router bits.

• When you do not use the tool, store it in a dry place

protected from dust.

• Do not wear loose clothes of jewelry the tool could

take hold of and pull it towards it. If you have long hair,

9

tion adapter is 35 mm, which corresponds to hoses of

standard vacuum cleaners.

Using STANDARD DUST COLLECTOR ATTACHMENT

Ref.6446073 (optional), the router may be connected

to our AS182K, AS282K, AS382L aspirator or to any

other industrial aspirator via the aspiration connector.

8. REMOVING UPPER DUST

EXTRACTION ADAPTERS (Fig. 3)

With the hose can be removed by first taking off the hose

from the dust extraction adapter 15 in the direction E,

and then push with the left hand thumb the upper part

of the dust extraction adapter in the direction F (Fig. 3).

9. REMOVING LOWER DUST

EXTRACTION ADAPTERS (Fig. 2)

Take off the hose of the dust extraction adapter 4. Press

the lock D on the periphery of the adapter 15 that much

to release it and push in the direction of the arrow B.

Then take off the adapter (Fig. 2)

10. CHOOSING A ROUTER

Always use router bits of such diameters that

correspond the lock collet. The number of re-

volutions must not be higher then the allowed

speed of the router. It is forbidden to use

router bits of diamenters larger than 40 mm.

Carbide tipped bits (HM) are suitable for working hard

materials and enable higher cutting speeds.

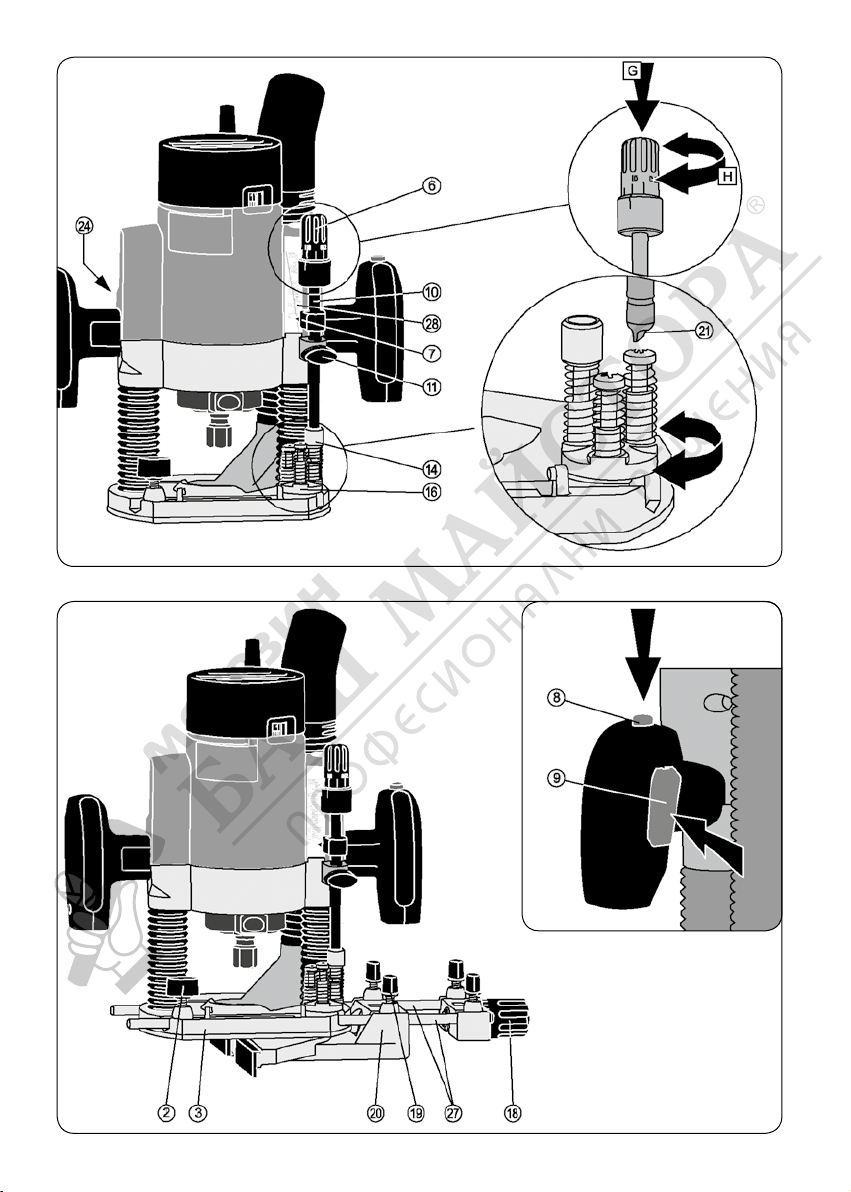

11. CLAMPING ROUTER BITS

Always disconnect the plug from power

source before making any adjustments

or changing any accessory.

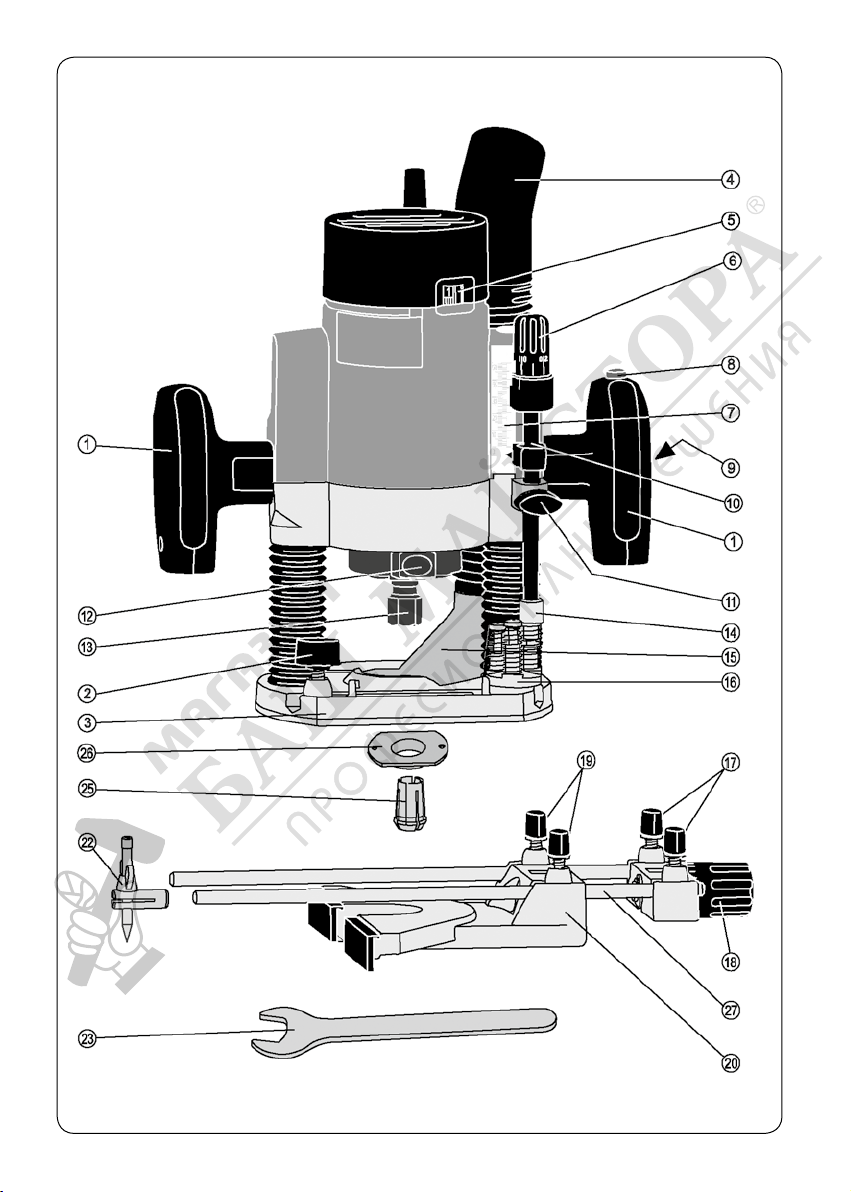

Clamp the bit with the collet 25 (Fig. 1) and the nut 13

(Fig. 1). The correct order for clamping bits:

• Unscrew the nut with the inserted collet on the spindle

by 1-2 threads.

• Insert a bit. The bit must be inserted at least 20 mm

deep. Pushing the lock-off button 12 (Fig. 1, 4) you block

the spindle, and then fasten the clamp nut 13 (Fig. 1)

with the fork wrench 23 (Fig. 1). Excessive fastening of

the nut can damage the thread on the spindle.

• Never drive in the clamp nut 13 till the end of the

shaft when there is no bit in the collet. Danger of

damaging the collet!

When removing the bit with one turn, first loosen the

clamp nut 13 (Fig. 1), and then continue unscrewing it

till the bit is completely loose.

12. CHANGING CLAMPING COLLET

Collet must be fixed in the clamp nut 13 (Fig. 10). When

you want to change it, pull it from the nut using a small

screwdriver which you insert between the nut and the

collet. Insert a new collet with a strong push into the

clamp nut (click).

Collet must be inserted in the nut in such

manner that the nut and the collet are

even at the front side.

13. FIXING ROUTER TABLE

Fix the router table to the desired height by the lever

24 (Fig. 5). Built-in telescopic spring returns the router

table in the original position after releasing the lever.

14. ROUGH DEPTH ADJUSTMENT

Always disconnect the plug from power

source before making any adjustments

or changing any accessory.

Set the depth of milling by the screws on the chip

deflector 16 (Fig. 6), together with the adjusting bit

10 (Fig. 6) by indicator 28 (Fig. 6). the three screws on

the chip deflector enable pre-setting of three depths

of milling. The range of setting is 50 mm.

Put the rpiter on the workpiece.

Release the lever 24 (Fig. 5) and slowly push down the

tool. When the router touches the surface, pull the

lever 24 (Fig. 5).

Turn the chip deflector 16 (Fig. 6) to the most favourable

depth of milling.

Unscrew the wing screw 11 (Fig. 6) and thereby you

loosen the movement of the adjusting bit 10.

Push down the adjusting bit 10 (Fig. 6) so that it is set

on the screw on the chip deflector.

Set the depth indicator 28 (Fig. 6) to 0.

Push the adjusting bit 10 (Fig. 6) upwards. When you

reach the desired depth on the scale 7 (Fig. 6), fasten

the wing screw 11 (Fig. 6).

Release the lever 24 (Fig. 5) and push the bit into the

new preadjusted position so that the adjusting bit 10

(Fig. 6) is laid on the screw and then pull the lever 24

(Fig. 5) again.

You must check the rough depth adjustmnet by a practical

test and then correct it if necessary.

15. FINE DEPTH ADJUSTMENT

10

Always disconnect the plug from power

source before making any adjustments

or changing any accessory.

Carry our fine depth adjustment if necessary. Having

set the rough depth adjustment you can set the desired

depth to 0.1 mm accurately by turning the knob of the

adjusting bit (1 line = 0.1 mm).

First release the lever 24 (Fig. 5). While you are pushing

the tool down, press the upper button of the adjusting

bit in the direction G (Fig. 6), so that it is laid on the

screw on the revorverskem nastavku 16 (Fig. 6). Adjust

the lower button with the upper one, then turn the

upper button in the direction H for a desired value. Pull

again the lever 24 (Fig. 5)

16. FINE DEPTH ADJUSTMENT WITH

THE ROUTER FIXED IN A TABLE

Support the adjusting bit 10 (Fig. 6) on the screw of the

chip deflector by a hollow screw and a spring.

Fasten the hollow screw 14 (Fig. 6) to the adjusting bit

10. Pay attention to put the screwdriver in the inside

of the adjusting bit into the groove of the screw below

the nut 14. Pushing the cover of the tool you set the

approximate depth of cut and fasten the screw 11 (Fig.

6). Fine depth adjustment is carried out by turning the

upper lever in the direction H (Fig. 6).

Check the accuracy by a practical test or correct it

correspondingly.

17. WORK WITH THE ROUTER

Always check that the supply voltage

is the same as the voltage indicated on

the nameplate.

Switch on/off.

Switch on: Press the lock-off button 8 (Fig. 8), and then

press the switch lever 9 (Fig. 8).

Continuous operation: When the tool is switched on,

push further button 8 and lock-off the switch. Press

button 8 and lever 9 to the end, then first release the

lever 9 and the then button 8.

Switch off: Pressing again the switch lever 9 you switch

off the tool.

18. FULL WAVE VARIABLE SPEED (TYPE FR278R)

Adjusting button 5 (Fig. 1) enables variable speed from

6000 to 27000 rpm.

Constant electronics

• Enables milling of all sorts of wood, laminates, plastics

and aluminium.

• Enables constant set number of revolutions at heavy

loads.

• Enables setting optimal working revolutions.

• Prolongs the service lives of routers.

• Soft start of the tool and overload protection.

• Enables corresponding adjustment and greater safety

when milling with rezkarji of large diameters.

Recommended table for choosing the number of revolu-

tions regarding the worked material and bit's diameter

Symbols of materials

Gypsum boards

Aluminium

Plastics

Panel

Softwood

Hardwood

Find out the corresponding number of revolutions by

a practical test.

19. USING PARALLEL GUIDE

Fix the parallel guide 20 (FIg. 7) by inserting the adjusting

bits in the holes in the base plate 3 (Fig. 7). and fasten

them to the desired depth by two wing screws 2 (Fig. 7).

Use knob 18 (Fig. 7) for more accurate depth adjustment

by fixing the two wing screws 17 and loosening wing

screws 19. Turning the button 18 you are moving the

bit away or close to the guide. When you fully turn the

nut, the distance changes by 1.25 mm. Fasten the two

screws 19 (Fig. 7) after the adjustment.

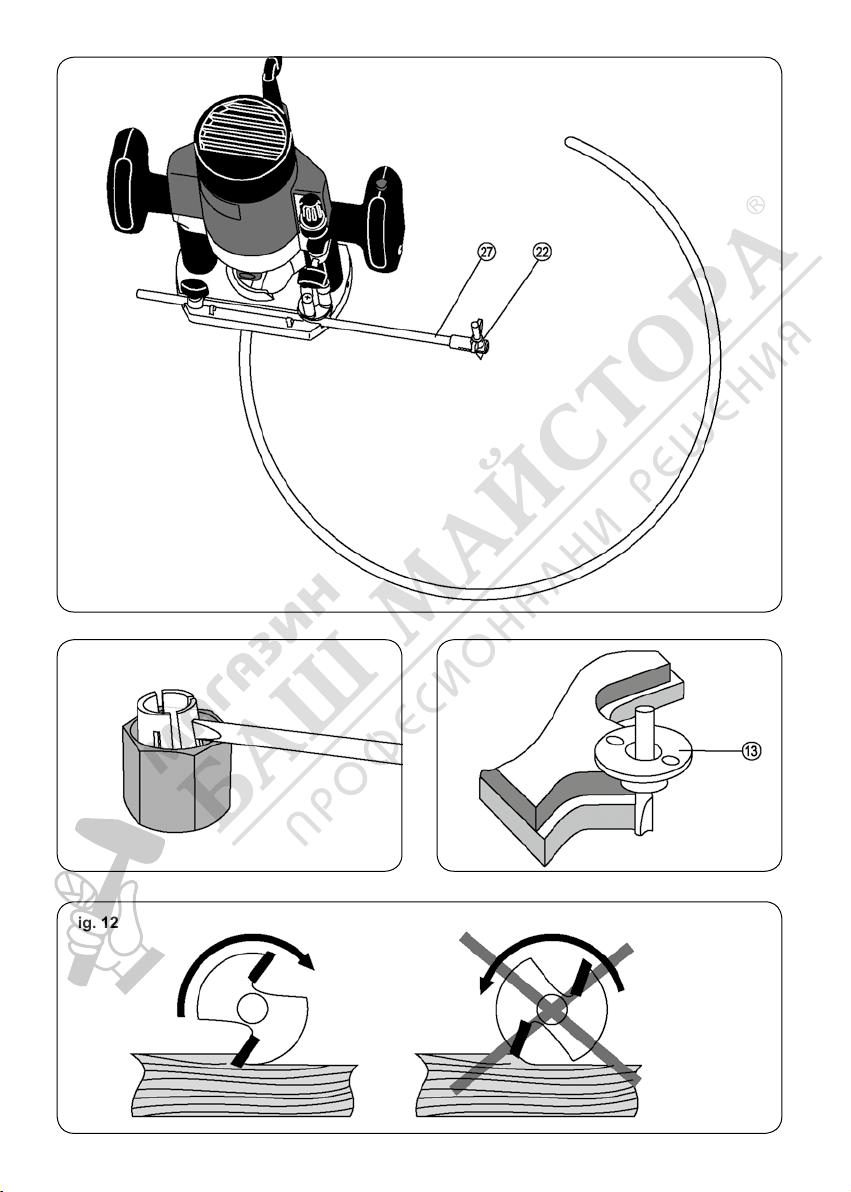

20. USE OF TEMPLATE GUIDES

Template guides are used for copy cutting of richly shaped

patterns. Selected template guide 26 (Fig. 1) is fixed to

base 3 (Fig. 1) using the two screws. When copying, a

diffrence in size between the template and the routed

item becomes apparent. The difference between the

radius of the template guide 13 (Fig. 11) and the radius

of the tool must always be taken into account when

preparing the template.

21. CIRCULAR MILLING WITH

COMPASSES (Fig. 9)

Fix the compasses 22 to one of the depth adjusters 27

fasten the point with a wing nut. Insert the composed

compasess into one of the holes in the baseplate of the

router. Set the desired distance between the router and

the compasses' point, and fasten it with a wing nut.

22. HOLDING AND GUIDING THE TOOL

Hold the tool with both hands while working. Switch

on the tool only when the router does not touch the

surface of the workpiece.

Before the router reaches the workpiece, the tool should

be switched on.

Do not apply pressure on the tool while working, let the

tool do the work for you.

Do not tilt the tool in order to avoid uneven milling.

Keep the ventilation slots uncovered.

Follow the next order when working with the router:

1. Choose abit and clamp it into the collet chuck.

2. Set the desired depth of milling.

3. Switch on the tool.

4. Push the motor downwards, pull the lock lever.

5. Start milling.

6. Release lock-off.

7. Switch off the tool.

Direction of moving the tool (Fig. 12)

While milling you must pay attention to the right

direction of moving the tool regarding the workpiece.

Move the router in the opposite direction of the bit's

turning (protitek).

Using chip deflector

When milling large depths, we recommend to mill in

stages by small depths odvzemi materiala. Using the

revolverskega nastavka, you can divide milling into

two or three stages.

Set the desired depth depth of milling to the maximum

depth of milling 16 (Fig. 1). Start the first two millings

at higher setting levels.

23. BRUSHES AND COLLECTOR

It is important to change the brushes when they reach

a minium length of 5 mm.

Changing brushes.

1. Disconnect the machine from the mains.

2. Remove screws from the cover.

3. Carefully remove electronic circuit (only in model

FR278R).

4. Take brush-holder and the brush.

5. Replace the brushes and replace the brush-holder

in its housing, ensuring that it exerts a slight pressure

on the collector.

6. Reassemble as indicated above. It is advisable to

operate the machine for about 15 minutes once the

brushes have been changed.

If burns or wear and tear are seen on the collector, it

is recommended that it should be repaired by VIRUTEX

technical service.

Never use emery paper for this operation.

24. OPTIONAL ACCESSORIES

The following optional accessories can be supplied:

7722116 Reducer of Ø 8 to 6 mm

7722115 Reducer of Ø 8 to 6.35 mm (1/4")

6446073 Standard dust collector attachment 3.5 m.

7722123 Dovetailing guide 26 mm.

7722161 Dovetailing guide 16 mm.

7722162 Dovetailing guide 34 mm.

7722160 AGB template guide for botton-hung fittings.

7722342 AGB template guide

7740117 Bit for AGB template.

25. NOISE AND VIBRATION LEVEL

The noise and vibration levels of this device have been

measured in accordance with European standard EN

60745-2-17 and EN 60745-1 and serve as a basis for comparison with other machines with similar applications.

The indicated vibration level has been determined for

the device’s main applications and may be used as an

initial value for evaluating the risk presented by exposure to vibrations. However, vibrations may reach levels

that are quite different from the declared value under

other application conditions, with other tools or with

insufficient maintenance of the electrical device or its

accessories, reaching a much higher value as a result

of the work cycle or the manner in which the electrical

device is used.

Therefore, it is necessary to establish safety measures

to protect the user from the effects of vibrations, such

as maintaining both the device and its tools in perfect

condition and organising the duration of work cycles

(such as operating times when the machine is subjected

to loads, and operating times when working with no-load,

in effect, not in use, as reducing the latter may have a

11

12

considerable effect upon the overall exposure value).

26. WARRANTY

All VIRUTEX power tools are guaranteed for 12 months

from the date of purchase, exlcuding any domage which

is a result of incorrect use or of natural wear and tear

on the machine. All repairs should be carried out by the

official VIRUTEX technical assistance service.

27. RECYCLING ELECTRICAL EQUIPMENT

Never dispose of electrical equipment with domestic was-

te. Recycle equipment, accessories and packaging in ways

that minimise any adverse effect on the environment.

Comply with the current regulations in your country.

Applicable in the European Union and in European

countries with selective waste collection systems:

If this symbol appears on the product or in the accom-

panying information, at the end of the product's useful

life it must not be disposed of with other domestic waste.

In accordance with European Directive 2002/96/EC, users

may contact the establishment where they purchased the

product or the relevant local authority to find out where

and how they can take the product for environmentally

friendly and safe recycling.

VIRUTEX reserves the right to modify its products

without prior notice.

FRANÇAIS

DÉFONCEUSE FR277R

DÉFONCEUSE ÉLECTRONIQUE FR278R

(FIGURES EN PAGE 39)

Important

Avant d'utiliser la machine, lisez attenti-

vement ce MANUEL D'INSTRUCTIONS et la

BROCHURE D'INSTRUCTIONS GÉNÉRALES

DE SÉCURITÉ qui vous sont fournis avec

cette machine. Assurez-vous de bien

avoir tout compris avant de commencer

à travailler sur la machine.

Gardez toujours ces deux manuels

d'instructions à portée de la main pour

pouvoir les consulter, en cas de besoin.

1. DONNÉES TECHNIQUES

Modèle.....................................................FR277R

Moteur universel........................................50/60 Hz

Puissance....................................................1010 W

Vitesse à vide.........................................24.000 /min

Diamètre pince standard.................................8 mm

Profondeur de fraisage...............................0-50 mm

Diamètre maximal de la fraise..........................40mm

Calibre de profondeu rotatif........réglage de profondeur

à 3 positions avec échelle

Poids...........................................................2,9 Kg

Niveau de pression acoustique

continu équivalent pondéré A..........................................91 dBA

Niveau de puissance acoustique A...............................102 dBA

Incertitude.....................................................................K = 3 dbA

Porter une protection acoustique!

Valeurs totales des vibrations..................................ah: 4,4 m/s

2

Incertitude..................................................................K: 1,5 m/s

2

Modèle.....................................................FR278R

Moteur universel........................................50/60 Hz

Puissance....................................................1300 W

Vitesse à vide...............................6.000-27.000/min

Diamètre pince standard................................8 mm

Profondeur de fraisage...............................0-50 mm

Diamètre maximal de la fraise..........................40mm

Calibre de profondeu rotatif..........réglage de profondeur

à 3 positions avec échelle

Poids..................................................................3 Kg

Niveau de pression acoustique

continu équivalent pondéré A..........................................91 dBA

Niveau de puissance acoustique A...............................102 dBA

Incertitude.....................................................................K = 3 dbA

Porter une protection acoustique!

Valeurs totales des vibrations..................................ah: 4,4 m/s

2

Incertitude..................................................................K: 1,5 m/s

2

2. EMPLOI

La défonceuse est un outil éléctrique professionnel conçu

pour le fraisage superficiel du bois, des masses artificielles

et de l'aluminium. C'est aussi un outil excellent pour le

fraisage des échantillons, des contours, des cercles et

des rainures, pour la fabrication des lattes de finition,

de listels et pour les gravures des inscriptions.

3. INSTRUCTIONS DE SÉCURITÉ POUR

LE MANIEMENT DE LA MACHINE

Avant de se mettre au travail lisez les instructions d'emploi

et conservez-les dans un lieu approprié.

Fig. 1

39

Fig. 2

Fig. 4

40

Fig. 3

Fig. 5

Fig. 6

Fig. 7

Fig. 8

41

Fig. 9

Fig. 10 Fig. 11

Fig. 12

Loading...

Loading...