Page 1

FR160P / FRE160P

Fresadora tupí

Router

Défonceuse

Tischfräsmaschine

Fresatrice toupie

Fresadora tupia

Ручной фрезер

Frezarka górnowrzecionowa

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D’ EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D’ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

INSTRUKCJA OBSŁUGI

Page 2

7

sorios y embalajes de forma respetuosa con el medio

ambiente. Respete la normativa vigente de su país.

Aplicable en la Unión Europea y en países europeos

con sistemas de recogida selectiva de residuos:

La presencia de esta marca en el producto o en el

material informativo que lo acompaña, indica que

al finalizar su vida útil no deberá eliminarse junto

con otros residuos domésticos.

Conforme a la Directiva Europea 2002/96/CE los

usuarios pueden contactar con el establecimiento

donde adquirieron el producto, o con las autoridades

locales pertinentes, para informarse sobre cómo y

dónde pueden llevarlo para que sea sometido a un

reciclaje ecológico y seguro.

VIRUTEX se reserva el derecho de modificar sus

productos sin previo aviso.

ENGLISH

FR160P-FRE160P ROUTER

(Ilustrations in page 43)

Important

Read these OPERATING INSTRUCTIONS

and the attached GENERAL SAFETY

INSTRUCTIONS LEAFLET carefully

before using the machine. Make sure

you have understood them before ope-

rating the machine for the first time.

Keep both sets of instructions for any

future queries.

1. TECHNICAL DATA

FR160P

Universal motor.........................................50/60 Hz

Input power................................................1,500 W

No-load speed.......................................25,000/min

Chuck collet Ø.............................................12 mm

Routing depth............................................0-60 mm

Revolving depth

gauge.......................6-position depth adjustment

Weight...........................................................5.4 Kg

Weighted equivalent continuous

acoustic pressure level A............................................92 dBA

Acoustic power level A.............................................103 dBA

Uncertainty...........................................................K = 3 dbA

Wear ear protection!

Vibration total values.................................a

h

: <2.5 m/s

2

Uncertainty..........................................................K: 1.5 m/s

2

FRE160P

Universal motor..........................................50 Hz

Input power................................................1,800 W

No-load speed............................11,500-23,000/min

Chuck collet Ø.............................................12 mm

Routing depth............................................0-60 mm

Revolving depth

gauge.......................6-position depth adjustment

Weight...........................................................5.4 Kg

Weighted equivalent continuous

acoustic pressure level A............................................92 dBA

Acoustic power level A............................................103 dBA

Uncertainty.............................................................K = 3 dbA

Wear ear protection!

Vibration total values........................................a

h

: <2.5 m/s

2

Uncertainty............................................................K: 1.5 m/s

2

2. OPERATION RANGE

The router is an electric appliance used for routing

wood and plastics. It is also very convenient for

trimming edges, cutting out of knots, copy cutting,

rebate cutting, making of frames and engraving.

Together with parallel guide, template followers,

compasses and profile cutters, it is an exceedingly

useful appliance.

3. SAFETY INSTRUCTIONS FOR

MACHINE OPERATION

Before using the router, carefully read

the GENERAL SAFETY INSTRUCTIONS

LEAFLET included with the machine

documentation.

- When changing tools or carrying out any other

operation near the cutting head, take your hand

from the on/off lever and unplug the machine from

Page 3

8

the mains.

- Use safety goggles when working with the router.

- Always guide the router with both hands, using

the machine's two handles.

- When you have finished working, disconnect the

motor and release the base before leaving the router.

- Always place the router on its base on a flat, clean

surface.

- Always start the router by using the main on/

off lever.

- Make sure that the router cannot be accidentally

knocked over.

- Always use cutter bits with the appropriate shaft

diameter for the chuck collet and the router speed

to be used.

- The specifications of the cutter bits in the VIRUTEX

range are especially suitable for use with this router;

we recommend using cutter bits from the wide

VIRUTEX range or bits with the same specifications.

4. STANDARD EQUIPMENT

The box contains the following items:

- FR160P - FRE160P router

- A/f service key: 24

- Ø 19 mm template guide for 26-mm pitch loops.

- Lateral fence assembly

- Dust collector connection

- Operating instructions and miscellaneous docu-

mentation.

- 6022387 Cutter bit 12 to 8 adaptor

- 6022388 Cutter bit 12 to 6 adaptor

5. STARTING UP THE MACHINE

This tool has an operating switch A (Fig. 1) in the

handle, enabling the machine to be turned on and

off without releasing it.

To prevent the machine from starting up accidentally,

the switch can only be operated when the lateral

safety catch B (Fig. 3) has been released. Once the

switch is in the on position, pressure need no longer

be applied to the safety catch.

Always make sure that the router is

not in contact with the part being

worked before operating the switch.

Once the machine has reached its

maximum speed, bring the machine

into contact with the material, and

stop the machine once it is completely

clear of the part. This will improve the

quality of the work.

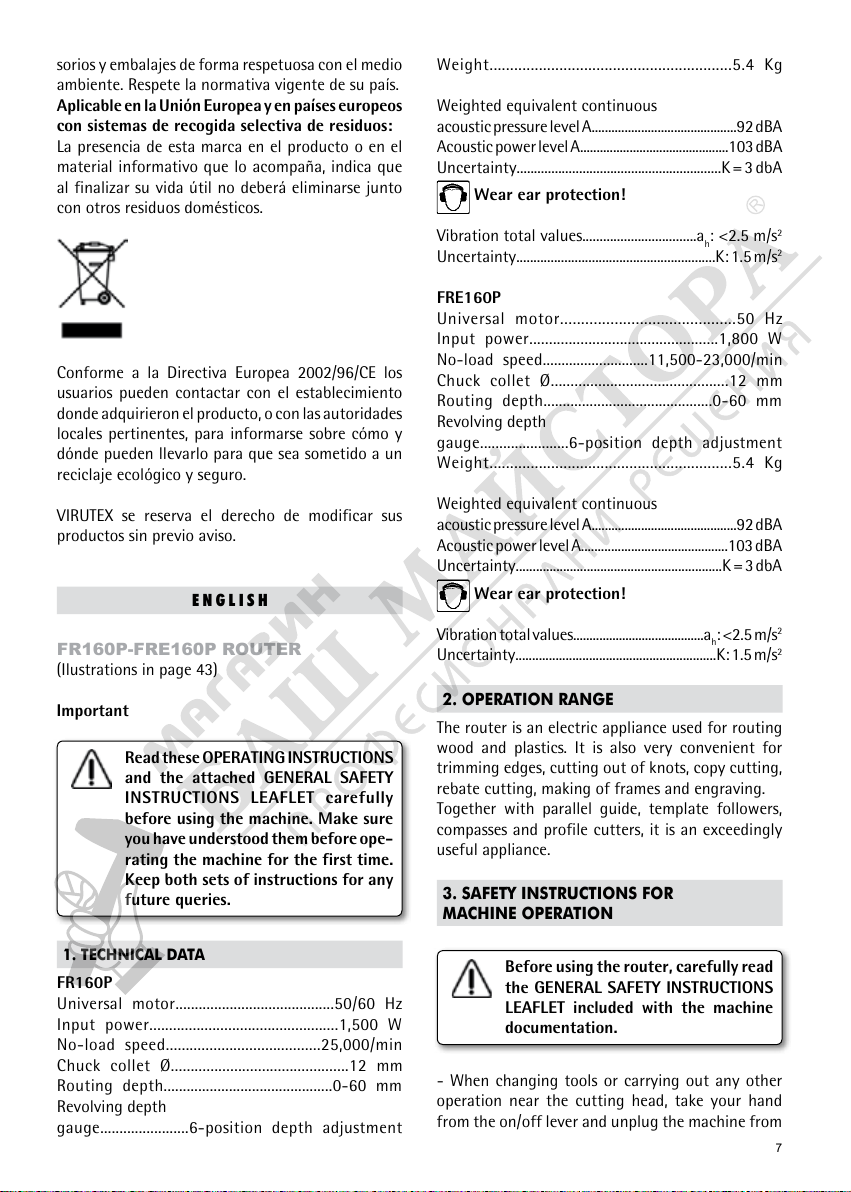

6. ADJUSTING THE SPEED 11,500 - 23,000

The surface router model FRE160P has an electronic

speed regulator C (Fig. 1) for adjusting the motor

speed, according to the size of cut and the hardness

of the material used. This ensures a better finish and

enhances the machine performance. To increase or

reduce the machine speed, turn the adjustment knob

to the right or left, depending on the task being

carried out. There are six reference numbers to assist

in setting the required speed.

The following table shows the position of the elec-

tronic speed regulator according to the diameter of

the bit and the material being worked with.

7. FITTING THE CUTTING TOOLS

Make sure that the router is disconnected

from the mains before attaching the

cutting tool.

To attach or remove the cutting tool, press the

router lock button E (Fig. 2) to prevent the shaft

from turning and loosen the chuck-holder nut F (Fig.

2) with service key G (Fig. 2) The chuck collet and

chuck-holder are attached together by pressure; you

should therefore make sure that the chuck collet is

properly positioned in the nut.

Insert the cutting tool H (Fig. 2) and, if necessary,

the corresponding bit adaptor I (Fig. 2) inside the

chuck-holder collet F (Fig. 2). Tighten the chuck

holder F (Fig. 2) tightly using the service key, while

keeping the lock button E (Fig. 2) pressed.

If you are using the 12 mm or 1/2" shaft bit, the

adaptor is not required. Always use bits with the

Page 4

9

shortest possible cutting length in order to reduce

the risk of the bit decentring. The bit, chuck collet

and adaptor should be completely clean before

attachment.

Do not leave the machine without a

cutting tool, as this exerts excessive

pressure on the chuck collet and can

damage the shaft housing.

Never start the machine while the bit

lock button is pressed.

8. BLOCKING OF THE BASE

The base may be locked in any position by turning

locking lever E (Fig. 3) in the counter-clockwise. The

action of the springs incorporated in the columns

means that when this lever is loosened the base

automatically returns to its highest position.

After use, always turn the switch to

the off position and release the base

using the locking lever J (Fig. 3) before

placing the router on a flat surface.

9. ADJUSTING THE DEPTH

ADJUSTING THE DEPTH. The depth is adjusted

by using the incorporated rack and pinion depth-

adjustment mechanism.

With the cutter bit face flush against the wood

surface, the penetration depth may be adjusted up

to 60 mm.

To unlock the depth rod K (Fig. 4) press down firmly

on adjustment knob L (Fig. 4) and turn it to raise or

lower the depth rod, if a greater or lesser cutting

depth is required. The gauged adjustment indicator

M (Fig. 4) can be moved separately from the knob, so

that it may be set to zero from any position using the

reference mark. When turning the knob after adjus-

ting the indicator, both elements will turn together,

there by indicating the degree to which the rod has

been moved. A full turn of the knob moves the rod

by 34 mm, with a maximum distance of 55 mm.

To hold the depth rod in the required position, release

the pressure from the adjustment knob. Next, to

ensure that the rod is firmly held in place, it should

be locked using fastening knob N (Fig. 4).

PRECISION ADJUSTMENT. If you wish to make

precision adjustments to the previously set depth,

simply turn adjustment knob O (Fig. 4). A full turn

of the knob moves the rod by 1 mm, with a maxi-

mum distance of 5 mm. Each division in the gauged

fine-adjustment indicator P (Fig. 4) represents an

advance of 0.1 mm.

MAKING DEEP CUTS. To safely make cuts that are

too deep to be made with a single pass, we recom-

mend making several successive cuts using the six

3-mm steps in the revolving depth turret Q (Fig. 4).

Lower the machine until the cutting bit is level with

the surface on which the router is resting. Use locking

knob J (Fig. 3) to hold the machine in this position.

Loosen fastening knob N (Fig. 4), then press down

and turn adjustment knob L (Fig. 4) until the depth

rod presses against the lower step of the revolving

depth turret, using fine adjustment if required. In

this position, turn depth indicator M (Fig. 4) until

position zero matches the reference mark. This

will be the starting position indicating the point at

which the bit comes into contact with the material.

Hold the rod in place with knob N (Fig. 4), release

the locking knob J (Fig. 3) and leave the machine in

the off position.

Loosen fastening knob N (Fig. 4), then press down

and turn adjustment knob L (Fig. 4), moving the

adjustment rod K (Fig. 4) upwards to the required cut

depth. Then use knob N once again to turn turret Q

(Fig. 4) until the highest step is below rod K (Fig. 4).

Make the first cut on the material. Turn the turret

Q to the next step and then make another cut, and

so on until the required depth is obtained when the

bottom step is reached.

10. LOCKING THE ROUTING DEPTH

To carry out several repetitive jobs in which the

router depth is always the same, it may be useful to

prevent the head from being released by accidentally

moving the locking knob J (Fig. 3). This may be done

by inserting two M8 nuts R (Fig. 3) in the threaded

shaft, one above and one below the head body. This

locks the head at any point along its depth setting.

When working with the router depth

locked, the tool will be permanently

outside the base surface. Therefore

the following actions must be taken:

- Wait until the machine has come to a complete stop

before setting it down on its base, on a flat surface,

with the cutting tool free.

- Remove nuts R (Fig. 3) to return to the normal

lock conditions using lever J (Fig. 3), once the job

is complete.

Page 5

10

11. USE OF PARALLEL GUIDE

The parallel guide is used for trimming edges and

cutting slots of different shapes, depending on the

profile shape. Hard metal cutter bits are particularly

useful for smoothing edges and lengthening the

working life of the bits.

The parallel guide S (Fig. 6) is inserted in the openings

on the base T (Fig. 6) and is held in place using the

two knobs U (Fig. 6).

NORMAL SQUARE ADJUSTMENT – Loosen the base

knobs U (Fig. 6), move the square to the required

position and then tighten the knobs in this position.

PRECISION ADJUSTMENT – Once the square has

been approximately positioned and held in place,

a further fine adjustment may be made. To do this,

loosen square fastening knob V (Fig. 6), turn the

adjustment knob W (Fig. 6) to the required measu-

rement, then tighten the square fastening knob V

(Fig. 6) again in this position. A full turn of the knob

moves the square by 1 mm, with a maximum distance

of 10 mm. The gauged fine-adjustment indicator X

(Fig. 6) can be moved separately from the knob, so

that it may be set to zero from any position using

the reference mark. When turning the knob W (Fig.

6) again after adjusting the indicator X (Fig. 6), both

elements will turn together, there by indicating the

degree to which the square has been moved, with

each division representing an advance of 0.1 mm.

12. USE OF TEMPLATE GUIDES

The template guides are used for routing with a wide

variety of shapes. The chosen template guide Y (Fig.

7) is held to the base T (Fig. 7) with the two screws Z

(Fig. 7). On making a copy, a difference between the

size of the template and the routed part will appear.

The difference between the radius of the template

guide and the cutting tool must always be taken into

account when making a template.

13. DUST COLLECTOR ATTACHMENT

To attach the dust collector connector A1 (Fig. 6),

place it in the central recess in base T (Fig. 6), with

the connection facing the back, and hold it in place

with screws B1 (Fig. 6). If trimming dovetails with the

Virutex PL11 model dovetailing attachment, guide

and position the dust collector connector as desired

so that the trimmer moves over the dovetailing

attachment better.

The dust collector connector A1 may be attached

either directly to the suction tubes of AS182K and

AS282K dust collectors, or else by using the smaller-

diameter and lighter 6446073 standard dust collector

attachment or 1746245 of 5 m, C1 (Fig. 6), which

can then be attached to AS182K and AS282K dust

collectors or any other industrial dust collector.

14. DUST COLLECTION NOZZLE SUPPLEMENT

To ensure that the suction of the machine is sufficient

when working with trimmer bits of less than 30 mm

in diameter, use the dust collection nozzle A1 (Fig. 6)

with the included supplement F1 (Fig. 6).

If you are using trimmer bits with a diameter of more

than 30 mm and up to 40 mm, remove the supplement

F1 (Fig. 6) from the dust collection nozzle A1 (Fig.

6) and work with only the nozzle. To re-attach the

supplement, simply press it firmly into the nozzle slot.

15. CHANGING THE BRUSHES

Make sure the machine is disconnected

from the mains before performing any

operation.

The brushes should be replaced when they have a

minimum length of 5 mm. To do this, remove the

covers D1 (Fig. 8) that hold the brushes E1 (Fig. 8) and

replace them with original VIRUTEX brushes, making

sure that they slide smoothly inside the guides.

It is advisable to allow the machine to run for 15

minutes unloaded after changing the brushes. When

changing the brushes, check the condition of the

collector. If it is burnt or juts out, it should be serviced

by a Virutex service technician.

16. LUBRITATION AND CLEANING

The machine is delivered fully lubricated from the

factory and does not require any special care during

its working life. It is important to clean the machine

carefully after use, using a dry air jet.

Maintain the supply cable in perfect operating

conditions.

17. OPTIONAL ACCESSORIES

The following optional accessories are available:

5000000 loop template PL11

6027103 Chuck collet Ø 12

6027106 Chuck collet Ø 1/2"

6022389 Cutter bit 1/2" to 3/8" adaptor

6022390 Cutter bit 1/2" to 1/4" adaptor

6446073 Standard dust collector attachment 2.25 m.

1746245 Dust collection connector 5 m

Page 6

11

Template guides:

7722168 Ø ext. 10 mm for 6 mm bits

7722120 Ø ext. 12 mm for 8 mm bits

7722121 Ø ext. 14 mm for 10 mm bits

7722122 Ø ext. 16 mm for 12 mm bits

7722169 Ø ext. 18 mm for 14 mm bits

7722118 Ø ext. 20 mm for 16 mm bits

7722119 Ø ext. 27 mm for 23 mm bits

7722114 Ø ext. 30 mm for 26 mm bits

Dovetail template guides:

7722161 For Ø 9.5 mm bit and 16 mm pitch plate

7722123 For Ø 15 mm bit and 26 mm pitch plate

7722162 For Ø 20 mm bit and 34 mm pitch plate

6040313 Carbide straight bit Ø 16

18. NOISE AND VIBRATION LEVEL

The noise and vibration levels of this device have

been measured in accordance with European stan-

dard EN 60745-2-17 and EN 60745-1 and serve as

a basis for comparison with other machines with

similar applications.

The indicated vibration level has been determined

for the device’s main applications and may be used

as an initial value for evaluating the risk presented

by exposure to vibrations. However, vibrations

may reach levels that are quite different from the

declared value under other application conditions,

with other tools or with insufficient maintenance

of the electrical device or its accessories, reaching a

much higher value as a result of the work cycle or

the manner in which the electrical device is used.

Therefore, it is necessary to establish safety measures

to protect the user from the effects of vibrations,

such as maintaining both the device and its tools

in perfect condition and organising the duration

of work cycles (such as operating times when the

machine is subjected to loads, and operating times

when working with no-load, in effect, not in use, as

reducing the latter may have a considerable effect

upon the overall exposure value).

19. WARRANTY

All VIRUTEX power tools are guaranteed for 12 months

from the date of purchase, exlcuding any domage

which is a result of incorrect use or of natural wear and

tear on the machine. All repairs should be carried out

by the official VIRUTEX technical assistance service.

20. RECYCLING ELECTRICAL EQUIPMENT

Never dispose of electrical equipment with domestic

waste. Recycle equipment, accessories and packaging

in ways that minimise any adverse effect on the

environment. Comply with the current regulations

in your country.

Applicable in the European Union and in European

countries with selective waste collection systems:

If this symbol appears on the product or in the ac-

companying information, at the end of the product's

useful life it must not be disposed of with other

domestic waste.

In accordance with European Directive 2002/96/EC,

users may contact the establishment where they

purchased the product or the relevant local authority

to find out where and how they can take the product

for environmentally friendly and safe recycling.

VIRUTEX reserves the right to modify its products

without prior notice.

FRANÇAIS

DÉFONCEUSE FR160P-FRE160P

(Figures en page 42)

Important

Avant d'utiliser la machine, lisez atten-

tivement ce MANUEL D'INSTRUCTIONS

et la BROCHURE D'INSTRUCTIONS

GÉNÉRALES DE SÉCURITÉ qui vous sont

fournis avec cette machine. Assurez-

vous de bien avoir tout compris avant de

commencer à travailler sur la machine.

Gardez toujours ces deux manuels

d'instructions à portée de la main pour

pouvoir les consulter, en cas de besoin.

1. DONNÉES TECHNIQUES

FR160P

Moteur universel........................................50/60 Hz

Puissance..................................................1.500 W

Vitesse à vide......................................25.000/min

Diamètre pince standard...............................12 mm

Profondeur de fraisage..............................0-60 mm

Page 7

Fig. 1

Fig. 2

Fig. 3

Fig. 5

Fig. 4

Fig. 6

42

Page 8

Fig. 7

Fig. 8

43

Page 9

Virutex, S.A.

Antoni Capmany, 1

08028 Barcelona (Spain)

www.virutex.es

6096443 102016

http://www.virutex.es/registre

Acceda a toda la información técnica.

Access to all technical information.

Accès à toute l’information technique.

Zugang zu allen technischen Daten.

Accedere a tutte le informazioni tecniche.

Aceso a todas as informações técnicas.

Dostęp do wszystkich informacji technicznych.

Доступ ко всей технической информации.

Loading...

Loading...