Page 1

Lijadora de Banda

Blet sander

Ponçeuse a Bande

Bandschleifmaschine

Levigatrice a Nastro

Lixadeira de Cinta

Ленточная Шлифмашинка

AF11

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D’ EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D’ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

Page 2

2

C

A

B

C

C

NO/NON/NEIN/НЕТ

SI/YES/OUI/JA/ДА

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D'EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D'ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ

ПО

ЭКСПЛУАТАЦИИ

página/page

seite/pagina

страница

Fig. 3Fig. 1

Fig. 2

ESPAÑOL Lijadora de Banda AF11

3

ENGLISH AF11 Belt Sander

5

FRANÇAIS Ponçeuse a Bande AF11

6

DEUTSCH Bandschleifmaschine AF11

8

ITALIANO Levigatrice a Nastro AF11

9

PORTUGUÉS Lixadeira de Cinta AF11

11

РУССКИЙ AF11 Ленточная Шлифмашинка

12

Page 3

3

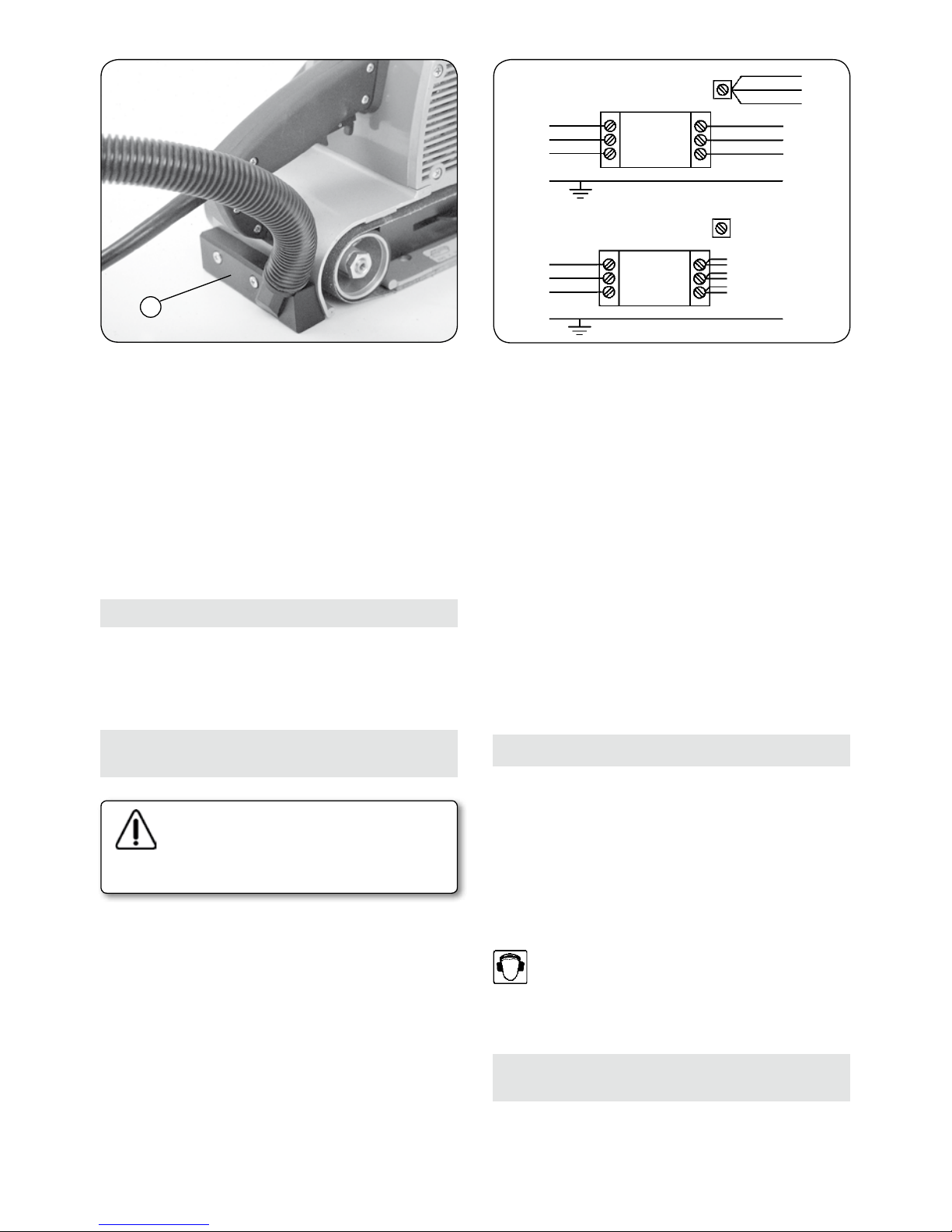

380 V III

220 V III

marrón (1)

amarillo (4) - verde (6)

amarillo (4) - verde (6)

1

2

3

azul (2)

negro (3)

amarillo V (4)

rojo U (5)

1

2

3

verde W (6)

amarillo X (4)

rojo Z (5)

azul (2)

negro (3)

marrón (1)

1

2

3

1

2

3

verde Y (6)

RED

(7)

RED

(7)

MOTOR

(8)

amarillo X V (4)

rojo Z U (5)

verde Y W (6)

MOTOR

(8)

D

ESPAÑOL

LIJADORA DE BANDA AF11

Nota importante

1. INSTRUCCIONES DE SEGURIDAD

PARA EL MANEJO DE LA LIJADORA

Lea atentamente el FOLLETO DE INSTRUCCIONES GENERALES DE SEGURIDAD,

que se adjunta con la documentación de

la máquina.

• Asegúrese antes de enchufar la máquina, que la tensión

de alimentación se corresponda con la indicada en la

etiqueta sujeta en el cable de alimentación.

• Comprobar al poner en marcha la lijadora, que el

sentido de giro de la banda, sea el indicado con la flecha

B (Fig. 1), si no es así, es preciso invertir, el orden de los

cables de conexión de la clavija de alimentación de red.

• Mantenga siempre las manos alejadas del área de

lijado, y sujete siempre la máquina por las empuñaduras.

• Use siempre recambios originales VIRUTEX.

• El polvo producido durante el lijado puede resultar

tóxico o nocivo para la salud (por ejemplo: pinturas

al plomo, algunas madera y metales). Se recomienda

utilizar siempre la conexión para la aspiración de polvo.

• Es necesario trabajar con aspiración de la viruta para

prolongar la vida de la banda y evitar posibles roturas

de la misma, y para una mayor salubridad.

• Emplear siempre protectores auditivos cuando se

utilicen Lijadoras de Banda.

2. CARACTERÍSTICAS TÉCNICAS

Potencia absorbida....................................................900W

Motor..........................................50 Hz ó 60 Hz

Velocidad de la banda....327 m/min ó 393 m/min

Dimensiones de la banda................690x100 mm

Superficie de lijado..........................175x100 mm

Peso........................................................9,7 Kg

Nivel de Presión acústica Ponderado A...........................79 dBA

Incertidumbre de la medición.......................................K = 3 dBA

¡Usar protectores auditivos!

Nivel total de emisión de vibraciones...................ah: <2,5 m/s

2

Incertidumbre de la medición.....................................K: 1,5 m/s

2

3. DESCRIPCIÓN GENERAL

DE LAS LIJADORAS AF11

Gran rendimiento para enrasados y desbastes. Su gran

superficie de lijado incrementa la productividad y permite

un acabado sin surcos. Dispone de unos topes internos

Marrón (1) Brown • Marron • Braun • Marrone • Castanho • Коричневый

Azul (2) Blue • Bleu • Blau • Blu • Azul • Голубой

Negro (3) Black • Noir • Schwarz • Nero • Preto • Черный

Amarillo (4) Yellow • Jaune • Gelb • Giallo • Amarelo • Желтый

Rojo (5) Red • Rouge • Rot • Rosso • Vermelho • Красный

Verde (6) Green • Vert • Grün • Verde • Verde • Зеленый

Red (7) Power • Resseau • Netz • Rete • Rede • Силовая линия

Motor (8) Motor • Moteur • Motor • Motore • Motor • Двигатель

Fig. 5

Fig. 4

Page 4

4

de carburo de tungsteno para evitar el deterioro de la

carcasa por desplazamiento de la banda.

Para obtener el máximo rendimiento se debe trabajar

aplicando exclusivamente el propio peso de la máquina

con lo que se consigue que la banda trabaje con la velocidad adecuada y el motor funcione a pleno rendimiento.

Al sobreforzar la máquina lo único que se consigue es

disminuir la velocidad de la banda con lo cual disminuye

también la capacidad de trabajo.

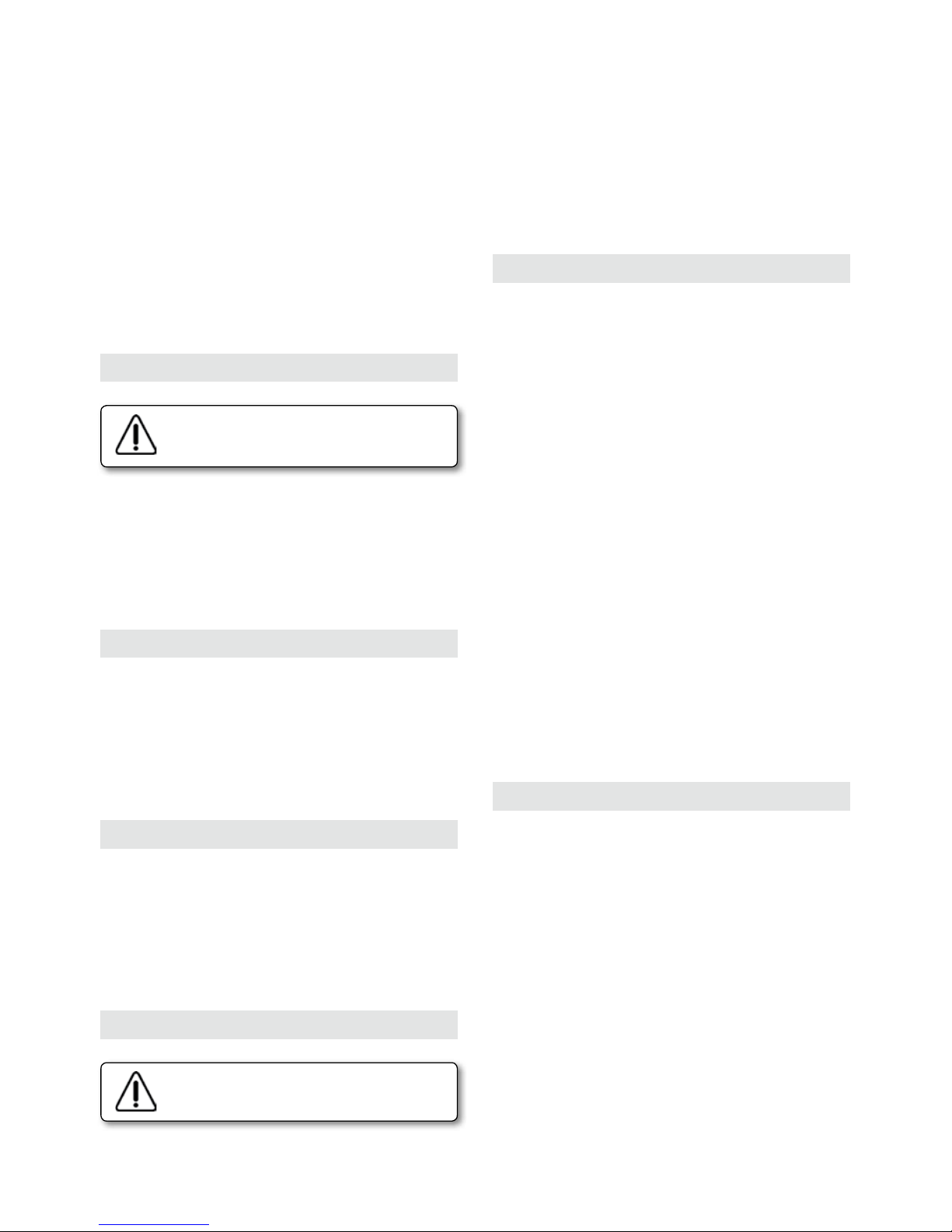

La máquina va provista de toma para aspiración D (Fig.

4), por la que puede conectarse, mediante el TUBO

ACOPLAMIENTO ASPIRADOR REF.6446073 (accesorio

opcional), a nuestro AS182K o AS282K, o a cualquier

aspirador industrial.

4. CAMBIO DE BANDA

Desconecte la máquina de la red eléctrica

antes de realizar esta operación.

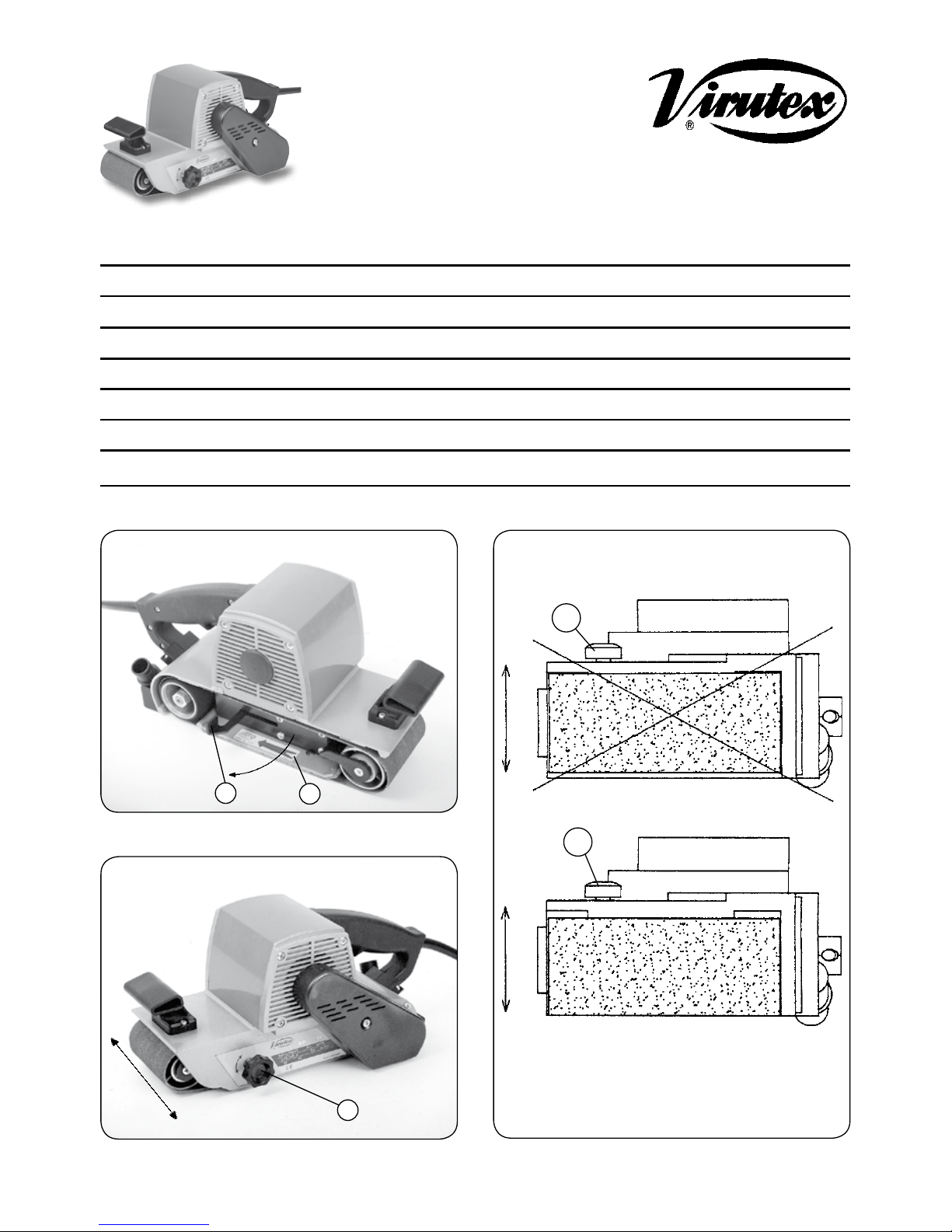

Para el cambio de la banda tirar de la palanca "A" tal

y como indica la (Fig. 1), retirar la banda gastada y

reemplazarla por otra original VIRUTEX, observando

que las flechas que llevan impresas en el interior sigan

el sentido de la flecha "B". Para fresar la banda seguir

la operación a la inversa.

5. CENTRAJE DE LA BANDA

Para el centraje de la banda (Fig. 2) se procederá girando

el pomo regulación "C", con la máquina en marcha, hasta

conseguir que la banda quede centrada. En ningún caso se

debe dejar que la banda roce con la carcasa de aluminio,

ya que dejaría de ser útil para el trabajo a realizar (Fig. 3)

Use bandas originales VIRUTEX (690x100), montándolas

de forma que queden tensadas y centradas.

6. BANDAS DISPONIBLES

Ref. Denominación

4491022 Banda 690x100 Grano 30

4491006 Banda 690x100 Grano 40

4491007 Banda 690x100 Grano 50

4491008 Banda 690x100 Grano 60

4491009 Banda 690x100 Grano 80

4491010 Banda 690x100 Grano 100

7. CAMBIO DE TENSIÓN

Desconecte la máquina de la red antes

de realizar esta operación.

Las máquinas salen conectadas de fábrica para trabajar,

a la tensión que se indica en la etiqueta del cable de

alimentación.

La tensión de trabajo puede cambiarse, siguiendo el

esquema de la (Fig. 5).

Siempre que efectué un cambio de la tensión de trabajo,

deberá comprobar que el sentido de giro de la banda,

coincida con el indicado con la flecha B, (Fig. 1) y si no

fuera así, deberá invertir el orden de los cables en la

clavija de conexión a la red.

8. NIVEL DE RUIDO

Los niveles de ruido y vibraciones de esta herramienta

eléctrica han sido medidos de acuerdo con la Norma

Europea EN 60745-2-4 y EN 60745-1 y sirven como base

de comparación con máquinas de semejante aplicación.

El nivel de vibraciones indicado ha sido determinado

para las aplicaciones principales de la herramienta,

y puede ser utilizado como valor de partida para la

evaluación de la exposición al riesgo de las vibraciones.

Sin embargo, el nivel de vibraciones puede llegar a ser

muy diferente al valor declarado en otras condiciones

de aplicación, con otros útiles de trabajo o con un

mantenimiento insuficiente de la herramienta eléctrica

y sus útiles, pudiendo llegar a resultar un valor mucho

más elevado debido a su ciclo de trabajo y modo de uso

de la herramienta eléctrica.

Por tanto, es necesario fijar medidas de seguridad de

protección al usuario contra el efecto de las vibraciones,

como pueden ser mantener la herramienta y útiles de

trabajo en perfecto estado y la organización de los

tiempos de los ciclos de trabajo (tales como tiempos

de marcha con la herramienta bajo carga, y tiempos de

marcha de la herramienta en vacío y sin ser utilizada

realmente ya que la reducción de estos últimos puede

disminuir de forma sustancial el valor total de exposición).

9. GARANTÍA

Todas las máquinas electroportátiles VIRUTEX, tienen

una garantía válida de doce meses a partir del día de

suministro, quedando excluidas todas las manipulaciones

o daños ocasionados por manejos inadecuados o por

desgaste natural de la máquina. Para cualquier reparación

dirigirse al Servicio Oficial de Asistencia Técnica VIRUTEX.

VIRUTEX se reserva el derecho de modificar sus productos

sin previo aviso.

Page 5

5

ENGLISH

AF11 BELT SANDER

Important note

1. SAFETY INSTRUCTIONS FOR

USE OF THE SANDER

Read carefully the GENERAL SAFETY INSTRUCTIONS LEAFLET, which is included

in the machine documentation.

• Before starting up the machine make sure that the

supply voltage is the same as that shown on the label

stuck to the supply cable.

• When turning on the sander, check that the belt turns

in the direction indicated by arrow B (Fig. 1). If not, the

order of the connection cables in the mains supply plug

must be inverted.

• Always keep hands clear of the sanding area, and

always hold the machine using the grips.

• Always use original VIRUTEX spares.

• The dust that accumulates during the sanding process

may prove to be toxic or harmful to the health (for

example, in the case of lead-based paints, certain woods

or metals). Use the dust collector connection at all times.

• It is necessary to work with dust collection in order to

prolong the life of the belt and prevent any breakages.

• Always wear earplugs when using belt sanders.

2. TECHNICAL CHARACTERISTICS

Input Power .....................................................................900 W

Motor ............................................................... 50 Hz or 60 Hz

Belt speed.................................... 327 m/min or 393 m/min

Belt size ...............................................................690x100 mm

Sanding surface ................................................175x100 mm

Weight .............................................................................. 9,7 Kg

Weighted equivalent continuous

acoustic pressure level A..................................................79 dBA

Uncertainty...................................................................K = 3 dbA

Wear ear protection!

Vibration total values...............................................ah: <2.5 m/s

2

Uncertainty..................................................................K: 1.5 m/s2

3. GENERAL DESCRIPTION OF THE AF11

Highly efficient for levelling and hewing. Its large sanding

area increases its productivity and gives a finish free from

grooves. It is equipped with internal tungsten-carbide

stops to avoid deterioration of the housing caused by

movement of the belt.

To obtain maximum efficiency you should work using

only the machine's own weight so that the belt works

at the correct speed determined by the motor at maximum efficiency. Overworking the machine only gives

rise to a reduction in belt speed which decreases the

working capacity.

The machine is equipped with a dust collector connection which can be used for connection to our AS182K,

AS282K dust collector or any industrial equivalent via

the DUST COLLECTOR ATTACHMENT TUBE (ref. 6446073/

optional accessorie).

4. CHANGING THE BELT

Disconnect the machine from the mains

before carrying out this operation

In order to change the belt pull lever "A" as indicated

in the (Fig. 1), remove the used belt and replace it with

another, original VIRUTEX belt, making sure that the

arrows printed on the inside are pointing in the same

direction as arrow "B". To secure the belt, repeat the

above procedure in reverse order.

5. CENTRING THE BELT

To centre the belt (Fig. 2) turn the regulating knob "C"

whilst the machine is running until the belt is centred.

Never allow the belt to rub against the aluminium casing

as it will then no longer be useable (Fig. 3).

Use original VIRUTEX belts (690x100) and fit them so

that they tensioned and centred.

6. AVAILABLE BELTS

Ref. Name

4491022 Belt 690x100 grain size 30

4491006 Belt 690x100 grain size 40

4491007 Belt 690x100 grain size 50

4491008 Belt 690x100 grain size 60

4491009 Belt 690x100 grain size 80

4491010 Belt 690x100 grain size 100

7. CHANGE OF VOLTAGE

Disconnect the machine from the mains

before performing this operation.

The machines leave the factory connected to operate at

the voltage indicated on the label stuck to the supply

cable. The working voltage may be changed by following

the plan in (Fig. 5).

Page 6

6

Whenever you change the working voltage, check that

the belt turns in the direction indicated by arrow B (Fig.

1). If not, invert the order of the cables in the plug for

connection to the mains.

8. NOISE AND VIBRATION LEVEL

The noise and vibration levels of this device have

been measured in accordance with European standard

EN 60745-2-4 and EN 60745-1 and serve as a basis

for comparison with other machines with similar

applications.

The indicated vibration level has been determined for

the device’s main applications and may be used as

an initial value for evaluating the risk presented by

exposure to vibrations. However, vibrations may reach

levels that are quite different from the declared value

under other application conditions, with other tools or

with insufficient maintenance of the electrical device

or its accessories, reaching a much higher value as a

result of the work cycle or the manner in which the

electrical device is used.

Therefore, it is necessary to establish safety measures

to protect the user from the effects of vibrations,

such as maintaining both the device and its tools in

perfect condition and organising the duration of work

cycles (such as operating times when the machine is

subjected to loads, and operating times when working

with no-load, in effect, not in use, as reducing the

latter may have a considerable effect upon the overall

exposure value).

9. WARRANTY

All VIRUTEX power tools are guaranteed for 12 months

from the date of purchase, excluding any damage which

is a result of incorrect use or of natural wear and tear

on the machine. All repairs should be carried out by the

official VIRUTEX technical assistance service.

VIRUTEX reserves the right to modify its products without prior notice.

FRANÇAIS

PONCEUSE A BANDE AF11

Remarque importante

1. INSTRUCTIONS DE SÉCURITÉ POUR

LE MANIEMENT DE LA PONCEUSE

Lire attentivement la BROCHURE

D'INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ jointe à la documentation de

la machine.

• Avant de brancher la machine, vérifier si la tension

d'alimentation correspond à celle indiquée sur l'étiquette

collée sur le câble d'alimentation.

• Vérifier en mettant en marche la ponceuse que le

sens de rotation de la bande est bien celui indiqué

par la flèche B (Fig. 1), s'il n'en est pas ainsi, il faudra

inverser l'ordre des câbles de connexion de la prise

d'alimentation de secteur.

• Prendre soin de ne pas mettre les mains sur la zone

de ponçage, et de toujours prendre la machine par la

poignée.

• Utiliser uniquement des pièces detaches d'origine

VIRUTEX.

• La poussière produite pendant le ponçage peut être

toxique ou nocive pour la santé (par exemple: celle des

peintures au plomb, de certains bois et métaux). Il est

recommandé de toujours utiliser la connexion pour

l'aspiration de la poussière.

• Il faut travailler avec un aspirateur de copeaux pour

prolonger la durée de vie de la bande et éviter des

cassures éventuelles de celle-ci.

• Toujours employer des protections auditives quand

on utilise des Ponceuses à Bande.

2. CARACTÉRISTIQUES

Puissance absorbée.......................................................900 W

Moteur............................................50 Hz ou 60 Hz

Vitesse de la bande.....327 m/min ou 393 m/min

Dimensions de la bande.........................690x100 mm

Surface de ponçage........................................175x100 mm

Poids........................................................................9,7 Kg

Niveau de pression acoustique

continu équivalent pondéré A..........................................79 dBA

Incertitude.....................................................................K = 3 dbA

Porter une protection acoustique!

Valeurs totales des vibrations..................................ah: <2,5 m/s

2

Incertitude..................................................................K: 1,5 m/s

2

Page 7

7

3. DESCRIPTION GÉNÉRALE

DES PONCEUSES AF11

Grand rendement pour arasages et dégrossissages. Sa

grande surface de ponçage augmente la productivité et

permet une finition sans sillons. Elle dispose de butées

internes au carbure de tungstène pour éviter la détérioration de la carcasse lors du déplacement de la bande.

Pour obtenir le rendement maximum, il faut travailler

en appliquant exclusivement le propre poids de la

machine, de manière à ce que la bande travaille à la

vitesse appropriée et que le moteur fonctionne à plein

rendement. Si on force la machine, la vitesse de la bande

diminue, ce qui diminue également la capacité de travail.

La machine est pourvue d'une buse d'aspiration, à laquelle

on peut brancher moyennant le TUBE D'ACCOUPLEMENT

D'ASPIRATEUR RÉF. 6446073 (accessoire en option),

notre aspirateur AS182K, AS282K, ou tout autre aspirateur industriel.

4. REMPLACEMENT DE LA BANDE

Débrancher la machine du secteur avant

de réaliser cette opération.

Pour remplacer la bande, tirer sur la levier A comme

il est indiqué sur la (Fig. 1), retirer la bande usée et la

remplacer par une d'origine VIRUTEX, en faisant en sorte

que les flèches qu'elle comporte à l'intérieur suivent le

sens de la flèche "B". Pour fixer la bande, faire la même

opération dans le sens inverse.

5. CENTRAGE DE LA BANDE

Pour le centrage de la bande (Fig. 2), on tournera le bouton

de réglage "C", avec la machine en marche, jusqu'à ce

que la bande soit bien centrée. Il ne faut surtout pas

laisser la bande frotter sur la carcasse d'aluminium car

sinon elle ne pourrait plus être utilisée pour le travail

à réaliser (Fig. 3).

Utiliser des bandes d'origine VIRUTEX (690x100), en les

montant de manière à ce qu'elles soient bien tendues

et centrées.

6. BANDES DISPONIBLES

Réf. Dénomination

4491022 Bande 690x100 Grain 30

4491006 Bande 690x100 Grain 40

4491007 Bande 690x100 Grain 50

4491008 Bande 690x100 Grain 60

4491009 Bande 690x100 Grain 80

4491010 Bande 690x100 Grain 100

7. CHANGEMENT DE TENSION

Débrancher la machine du secteur avant

de réaliser cette opération.

D'origine, les machines sont connectées pour travailler sous la tension indiquée sur l'étiquette du câble

d'alimentation. On peut changer la tension de travail

en suivant le schéma de la (Fig.5).

Après avoir effectué un changement de la tension de

travail, il faudra toujours vérifier que le sens de rotation

de la bande est bien celui indiqué par la flèche B (Fig. 1),

s'il n'en est pas ainsi, il faudra inverser l'ordre des câbles

sur la prise de branchement au secteur.

8. NIVEAU DE BRUIT ET DE VIBRATIONS

Les niveaux de bruit et de vibrations de cet appareil

électrique ont été mesurés conformément à la norme

européenne EN 60745-2-4 et EN 60745-1 et font

office de base de comparaison avec des machines aux

applications semblables.

Le niveau de vibrations indiqué a été déterminé pour

les principales applications de l’appareil, et il peut être

pris comme valeur de base pour l’évaluation du risque

lié à l’exposition aux vibrations. Toutefois, dans d’autres

conditions d’application, avec d’autres outils de travail

ou lorsque l’entretien de l’appareil électrique et de

ses outils est insuffisant, il peut arriver que le niveau

de vibrations soit très différent de la valeur déclarée,

voire même beaucoup plus élevé en raison du cycle de

travail et du mode d'utilisation de l'appareil électrique.

Il est donc nécessaire de fixer des mesures de sécurité

pour protéger l'utilisateur contre les effets des vibrations,

notamment garder l’appareil et les outils de travail en

parfait état et organiser les temps des cycles de travail

(temps de fonctionnement avec l’appareil en service,

temps de fonctionnement avec l’appareil à vide, sans être

utilisé réellement), car la diminution de ces temps peut

réduire substantiellement la valeur totale d’exposition.

9. GARANTIE

Tous les machines électro-portatives VIRUTEX ont une

garantie valable 12 mois à partir de la date d'achat, en

étant exclus toutes manipulations ou dommages causés

par des maniements inadéquats ou par l'usure naturelle

de la machine. Pour toute réparation, s'adresser au service

officiel d'assistance technique VIRUTEX.

VIRUTEX se réserve le droit de modifier ses produits

sans avis préalable.

Page 8

8

Leistungsfähig für's Bündogmachen und die Grobbearbeitung. Die große Schleiffläche erhöht die Produktivität

und ermöglicht eine rillenlose Bearbeitung. Die Maschine

ist innen mit Wolframkarbidanschlägen ausgestattet,

damit das Gehäuse durch die Bewegung des Schleifbands

nicht beschädigt wird.

Für optimale Leistungen bei der Arbeit nur das Eigengewicht der Maschine auf die zu schleifende Fläche

drücken lassen. So arbeitet das Band mit der richtigen

Geschwindigkeit und der Motor mit voller Leistung.

Wenn man zuviel Kraft anwendet, wird lediglich die

Bandgeschwindigkeit und damit auch die Arbeitskapazität verringert.

Die Maschine hat einen Sauganschluß, wo mit Hilfe

des ANSCHLUSSROHRS FÜR STANDARDSAUGER MIT

DER BEST. NR. 6446073 (WAHLWEISES ZUBEHÖR)

unser Sauger AS182K, AS282K oder irgendein anderer

Industriesauger angeschlossen werden Kann.

4. WECHSELN DES SCHLEIFBANDS

Ziehen Sie vor dieser Arbeit den Netzstecker.

Zum Wechseln des Bands wie auf der (Abb. 1) zu sehen

am Hebel A ziehen, das abgenutzte Band abnehmen

und durch ein anderes Original-VIRUTEX-Schleifband

ersetzen. Achten Sie dabei darauf, daß die auf der Innenseite des Bands aufgedruckten Pfeile in die gleiche

Richtung zeigen wie der Pfeil B. Zum Festmachen des

Bands genau umgekehrt vorgehen.

5. ZENTRIEREN DES SCHLEIFBANDS

Zum Zentrieren des Schleifbands (Abb. 2) dreht man

den Einstellknauf C bei laufender Maschine bis das

Band zentriert ist. Das Band darf auf keinen Fall am

Aluminiumgehäuse scheuern, da es sonst unbrauchbar

würde (Abb. 3).

Verwenden Sie Original-VIRUTEX-Schleifbänder

(690x100) und montieren Sie sie richtig gespannt und

zentriert.

6. LIEFERBARE SCHLEIFBÄNDER

Nr. Bezeichnung

4491022 Band 690x100, Körnung 30

4491006 Band 690x100, Körnung 40

4491007 Band 690x100, Körnung 50

4491008 Band 690x100, Körnung 60

4491009 Band 690x100, Körnung 80

4491010 Band 690x100, Körnung 100

7. SPANUNGSWECHSEL

DEUTSCH

BANDSCHLEIFMASCHINE AF11

WICHTIGER HINWEIS

1. SICHERHEITSHINWEISE FÜR DIE

ARBEIT MIT DER SCHLEIFMASCHINE

Lesen Sie die BROSCHÜRE MIT ALLGEMEINEN SICHERHEITSHINWEISEN, die

den Unterlagen zur Maschine beiliegt,

aufmerksam durch.

• Versichern Sie sich, daß die Spannung der auf dem

Typenschild angegebenen entspricht, bevor Sie die

Maschine Auf dem Etikett am Netzkabel.

• Überprüfen Sie, wenn Sie die Bandschleifmaschine

starten, daß sich das Band in Richtung des Pfeils B (Abb.

1) dreht. Ist das nicht der Fall, müssen die Kabel am

Netzstecker umgekehrt angeschlossen werden.

• Fassen Sie mit den Händen nie in die Nähe der

Schleiffläche, und halten Sie die Maschine immer an

den Griffen fest.

• Verwenden Sie immer Original- VIRUTEX-Ersatzteile.

• Der beim Schleifen entstehende Staub kann giftig

oder gesundheitsschädlich sein (zum Beispiel: Bleifarbe,

bestimmte Holz- und Metallarten). Es wird daher empfohlen, immer die Steckkupplung für die Absaugung

zu verwenden.

• Bei der Arbeit ist eine Spanabsaugung notwendig, um

die Lebensdauer des Schleifbands zu verlängern und

damit es nicht reißt.

• Bei der Verwendung von Bandschleifmaschinen ist ein

Gehörschutz zu tragen.

2. TECHNISCHE DATEN

Leistungsaufnahme .......................................................900 W

Motor.............................................................50 Hz und 60 Hz

Bandgeschwindigkeit 327 m/min und 393 m/min

Maße des Bands ................................................690x100 mm

Schleiffläche ......................................................175x100 mm

Gewicht.............................................................................9,7 Kg

Gewichteter akustischer Dauerdruckpegel A.......79 dBA

Unsicherheit..............................................................K = 3 dBA

Gehörschutz tragen!

Schwingungsgesamtwerte..............................ah: <2,5 m/s

2

Unsicherheit.........................................................K = 1,5 m/s

2

3. ALLGEMEINE BESCHREIBUNG

DER SCHLEIFMASCHINEN AF11

Page 9

9

ITALIANO

LEVIGATRICE A NASTRO AF11

Nota importante

1. ISTRUZIONI DI SICUREZZA

PER L'USO DELLA LEVIGATRICE

Leggere attentamente l'OPUSCOLO DI

ISTRUZIONI GENERALI DI SICUREZZA

allegato alla documentazione della

macchina.

• Verificare, prima di collegare la macchina alla rete

elettrica, che la tensione di alimentazione corrisponda

a quella indicata nell'etichetta attaccata al filo di

alimentazione.

• Quando si avvia la levigatrice, verificare che il senso

di rotazione del nastro sia quello indicato dalla freccia

B (Fig. 1); in caso contrario, è necessario invertire la

disposizione dei fili nella spina di collegamento alla

rete elettrica.

• Tenere semprele mani lontane dalla superficie da

levigare e afferrare sempre saldamente la macchina

dalle impugnature.

• Usare sempre ricambi originali VIRUTEX.

• La polvere che si forma durante la levigatura può

rivelarsi tossica o nociva per la salute (per esempio:

vernici al piombo, alcuni tipi di legno e di metallo). Si

raccomanda di usare sempre il raccordo di aspirazione

della polvere.

• Per prolungare la vita del nastro ed evitare che si rompa

bisognerà lavorare sempre con l'aspirazione inserita.

• Usare sempre protezioni per l'udito quando si lavora

con levigatrici a nastro.

2. CARATTERISTICHE

Potenza assorbita ..........................................................900 W

Motore ...............................................................50 Hz o 60 Hz

Velocità del nastro .....................327 m/min o 393 m/min

Dimensioni del nastro .....................................690x100 mm

Superficie di levigatura ..................................170x100 mm

Peso ....................................................................................9,7 Kg

Livello di pressione acustica continuo equivalente

ponderato A.......................................................................79 dBA

Incertezza della misura..................................................K = 3 dBA

Usare la protezione acustica!

Valori totali delle oscillazioni...............................ah: <2,5 m/s

2

Incertezza della misura...............................................K: 1,5 m/s

2

Ziehen Sie zuerst den Netzstecker.

Ab Werk sind die Maschinen für den Betrieb mit der

auf dem Etikett am Netzkabel angegebenen Spannung

angeschlossen. Die betriebsspannung kann geändert

werden, dabei ist der auf (Abb. 5) zu sehende Plan zu

befolgen.

Jedesmal wenn Sie die Betriebsspannung ändern, müssen

Sie überprüfen, daß sich das Band noch in Richtung des

Pfeils B (ABB. 1) dreht. Ist das nicht der Fall, müssen

Sie die Kabel am Netzstecker umgekehrt anschließen.

8. GERÄUSCHPEGEL UND VIBRATIONSSTÄRKE

Die Lärm- und Vibrationswerte dieses Elektrowerkzeugs

wurden in Übereinstimmung mit der europäischen

Norm EN 60745-2-4 und EN 60745-1 gemessen und

dienen als Vergleichsgrundlage bei Maschinen für

ähnliche Anwendungen.

Der angegebene Vibrationspegel wurde für die

wesentlichen Einsatzzwecke des Werkzeugs ermittelt

und kann bei der Beurteilung der Gefahren durch

die Aussetzung unter Vibrationen als Ausgangswert

benutzt werden. Die Vibrationswerte können sich

jedoch unter anderen Einsatzbedingungen, mit anderen

Arbeitswerkzeugen oder bei einer ungenügenden

Wartung des Elektrowerkzeugs oder seiner Werkzeuge

stark vom angegebenen Wert unterscheiden und

aufgrund des Arbeitszyklus und der Einsatzweise des

Elektrowerkzeugs einen bedeutend höheren Wert

aufweisen.

Es ist daher erforderlich, Sicherheitsmaßnahmen zum

Schutz des Anwenders vor den Vibrationen festzulegen.

Dazu können die Aufrechterhaltung des einwandfreien

Zustands des Werkzeugs und der Arbeitsutensilien sowie

die Festlegung der Zeiten der Arbeitszyklen gehören (wie

Laufzeiten des Werkzeugs unter Last und im Leerlauf,

ohne tatsächlich eingesetzt zu werden, wodurch die

Gesamtzeit der Vibrationsauswirkungen bedeutend

verringert werden kann).

9. GARANTIE

Alle Elektrowerkzeuge von VIRUTEX habe eine garantie

von 12 Monaten ab dem Lieferdatum. Hiervon ausgeschlossen sind alle Eingriffe oder Schäden aufgrund von

unsachgemässen Gebrauch oder natürlicher Abnutzung

des Geräts.

Wenden Sie sich im Falle einer Reparatur immer an den

zugelassenen Kundendiest von VIRUTEX.

VIRUTEX behält sich das Recht vor, die Produkte ohne

vorherige Ankündigung zu verändern.

Page 10

10

3. DESCRIZIONE GENERALE

DELLE LEVIGATRICI AF11

Grande rendimento nelle operazioni di spianatura e di

levigatura. La grande superficie di levigatura migliora la

produttività e permette di realizzare finiture perfettamente piane. Con margini interni in carburo di tungsteno

che evitando il deterioramento della carcassa dovuto

allo spostamento del nastro.

Per ottenere i migliori risultati non bisogna premere

sulla levigatrice, poiché è sufficiente il suo stesso peso.

In questo modo il nastro lavorerà alla giusta velocità e

il motore funzionerà a pieno rendimento. Se si esercita

un maggior peso sulla macchina, si otterrà solamente

che il nastro giri più piano: quindi, la capacità di lavoro

diminuirà.

La macchina è dotata di un attacco per aspirazione

esterna grazie al quale, tramite il TUBO COLLEGAMENTO

ASPIRATORE cod. 6446073 (accessori extra), è possibile

collegarla al nostro aspiratore AS182K, AS282K o a

qualsiasi aspiratore industriale.

4. CAMBIO DEL NASTRO

Prima di eseguire questa operazione, staccare la macchina dalla rete elettrica

Per sostituire il nastro, tirare la leva A e, come illustrato

nella (Fig. 1), estrarre il nastro consumato e sostituirlo

con un nastro originale VIRUTEX, sistemandolo in modo

che le frecce stampate all'interno siano disposte nel

senso della freccia B. Per fissare il nastro, ripetere la

stessa operazione in ordine inverso.

5. CENTRATURA DEL NASTRO

Per centrare il nastro (Fig. 2) girare la manopola di

regolazione C, con lamacchina in funzionamento, fino a

centrarlo. Evitare sempre che il nastro tocchi la carcassa

di alluminio, poiché si rovinerebbe e non servirebbe più

per il lavoro che si intende eseguire (Fig. 3).

Impiegare nastri originali VIRUTEX (690x100) e montarli

in modo che siano tesi e centrati.

6. NASTRI DISPONIBILI

Codice Denominazione

4491022 Nastro 690x100 grana 30

4491006 Nastro 690x100 grana 40

4491007 Nastro 690x100 grana 50

4491008 Nastro 690x100 grana 60

4491009 Nastro 690x100 grana 80

4491010 Nastro 690x100 grana 100

7. CAMBIO DELLA TENSIONE

Disinserire la macchina dalla rete elettrica

prima di eseguire questa operazione.

Le macchine sono predisposte di fabbrica per funzionare alla tensione indicata nell'etichetta del filo di

alimentazione.

La tensione di funzionamento può essere cambiata in

base allo schema della (Fig. 5).

Tutte le volte che si cambia la tensione di funzionamento,

occorre verificare che il senso di rotazione del nastro sia

quello indicato dalla freccia B (Fig. 1); in caso contrario,

è necessario invertire la disposizione dei fili nella spina

di collegamento alla rete elettrica.

8. LIVELLI DI RUMORE E DI VIBRAZIONI

I livelli di rumore e vibrazioni di questo apparato

elettrico sono stati misurati in conformità con la Norma

Europea EN 60745-2-4 e EN 60745-1 e fungono da

base di confronto con macchine per applicazioni simili.

Il livello di vibrazioni indicato è stato determinato

per le principali applicazioni dell’apparato e può

essere utilizzato come punto di partenza per la

valutazione dell’esposizione al rischio delle vibrazioni.

Ciononostante, il livello di vibrazioni può variare

notevolmente rispetto al valore dichiarato in altre

condizioni di applicazione, con altri strumenti di lavoro

o in caso di manutenzione insufficiente dell’apparato

elettrico e dei suoi strumenti, e può aumentare

notevolmente come conseguenza del ciclo di lavoro e

del modo d’uso dell’apparato elettrico.

Pertanto è necessario stabilire misure di sicurezza per

la protezione dell’utente dall’effetto delle vibrazioni,

ad esempio mantenendo l’apparato e gli strumenti

di lavoro in perfetto stato e pianificando i tempi dei

cicli lavorativi (ad esempio i tempi di funzionamento

dell’apparato sotto carico e i tempi di funzionamento

a vuoto quando l'apparato non viene realmente

utilizzato, dato che la riduzione di questi ultimi

può ridurre in modo sostanziale il valore totale

dell’esposizione).

9. GARANZIA

Tutte le macchine elettroportatili VIRUTEX hanno una

garanzia di 12 mesi valida a partire della data di consegna, con l'esclusione di tutte le manipolazioni o danni

derivanti da un uso inadeguato o dall'usura normale

della macchina.

Per qualunque riparazione rivolgersi al servizio autorizzato di assistenza tecnica VIRUTEX.

La VIRUTEX si riserva il diritto di modificare i propi

prodotti senza preaviso.

Page 11

11

PORTUGUÉS

LIXADEIRA DE CINTA AF11

Nota importante

1. INSTRUÇÕES DE SEGURANÇA

PARA A UTILIZAÇÃO DA LIXADEIRA

Leia atentamente o FOLHETO DE INSTRUÇÕES GERAIS DE SEGURANÇA que se

anexa juntamente com a documentação

da máquina.

• Antes de ligar a máquina, assegure-se de que a tensão

de alimentação eléctrica seja igual à que se encontra

indicada na etiqueta agarrada ao fio de alimentação.

• Ao pôr a lixadeira em funcionamento, verificar se o

sentido de rotação da cinta é o indicado pela seta B

(Fig. 1); se assim não for, torna-se necessário inverter

a ordem de ligação dos fios na ficha de ligação à rede

de corrente eléctrica.

• Mantenha sempre as mãos afastadas da área de lixagem e agarre sempre a máquina pelas empunhaduras.

• Use sempre sobressalentes originais VIRUTEX.

• O pó produzido durante a lixagem pode ser tóxico ou

nocivo para a saúde (por exemplo: pinturas efectuadas

com tintas à base de chumbo, algumas madeiras e alguns

metais). É sempre recomendável a utilização da conexão

para a aspiração do pó.

• Torna-se necessário trabalhar com a aspiração das

aparas, a fim de prolongar a vida da cinta e de evitar

possíveis rupturas da mesma.

• Empregar sempre protectores auditivos quando se

utilizam Lixadeiras de Cinta.

2. CARACTERISTICAS

Potência absorvida..........................................................900W

Motor..................................................................50 Hz o 60 Hz

Velocidade de lixa.......................327 m/min o 393 m/min

Dimensões da cinta...........................................690x100 mm

Superficie de lixagem..........................................175x100 mm

Peso.....................................................................................9,7 Kg

Nível de pressão acústica contínuo

equivalente ponderado A...............................................79 dBA

Incerteza.........................................................................K = 3 dBA

Usar protecção auricular!

Valores totais de vibração.....................................ah: <2,5 m/s

2

Incerteza........................................................................K: 1,5 m/s

2

3. DESCRIÇÃO GERAL DAS LIXADEIRAS AF11

Grande rendimento para nivelamentos e desbastes. A

sua grande superficie de lixagem faz incrementar a

produtividade e permite a obtenção de um acabamento

sem sulcos. Dispõe de uns topos internos de carbureto

de tungsténio, a fim de poder evitar a deterioração da

carcaça devido à deslocação da cinta.

Para obter o máximo rendimento, deve trabalhar-se aplicando exclusivamente o próprio peso da máquina, com a

qual se consegue que a cinta possa trabalhar à velocidade

adequada e o motor funcionar a pleno rendimento. Se

se aplicar um sobre-esforço à máquina, a única coisa

que se consegue é a diminuição da velocidade da cinta,

com o qual diminui também a capacidade de trabalho.

A máquina é provida de uma tomada de aspiração,

motivo pelo qual se pode ligá-la, por medio do TUBO DE

ACOPLAMENTO DE ASPIRADOR REF.6446073 (accesório

de opção), ao nosso Aspirador AS182K, AS282K, ou a

qualquer outro aspirador industrial.

4. SUBSTITUIÇÃO DA CINTA

Antes de realizar esta operação, desligue

a máquina da corrente eléctrica.

Para a substituição da cinta, puxe pela alavanca "A", tal

como se indica na (Fig. 1), retire a cinta gasta e substitua-a

por outra nova e original VIRUTEX, respeitando o facto

de que as setas que têm impressas no interior devem

seguir o sentido da seta "B". Para a fixação da cinta há

que seguir a mesma operação, mas na ordem inversa.

5. CENTRAGEM DA CINTA

Para a centragem da cinta (Fig. 2), proceder-se-á a

girar a manete de regulação "C", tendo a máquina em

funcionamento, até conseguir que a cinta possa ficar

centrada. Em nenhum caso se deve deixar a cinta roçar

na carcaça de alumínio, visto que deixaria de ser útil

para o trabalho a realizar (Fig. 3).

Use cintas originais VIRUTEX (690x100), montandoas de

forma a ficarem tensadas e centradas.

6. CINTAS DISPONIVEIS

Ref. Denominação

4491022 Cinta 690x100 Grão 30

4491006 Cinta 690x100 Grão 40

4491007 Cinta 690x100 Grão 50

4491008 Cinta 690x100 Grão 60

4491009 Cinta 690x100 Grão 80

4491010 Cinta 690x100 Grão 100

7. MUDANÇA DE TENSÃO

Page 12

12

РУССКИЙ

AF 11 ЛЕНТОЧНАЯ ШЛИФМАШИНКА

1. ИНСТРУКЦИЯ ПО БЕЗОПАСНОМУ

ИСПОЛЬЗОВАНИЮ ЛЕНТОЧНОЙ ШЛИФМАШИНКИ

Ознакомьтесь с инструкцией,

которая включена в пакет

документации станка.

• Перед подключением машины к сети,

убедитесь в том, что напряжение сети

соответствует указанному на машине.

• Во время включения машины проверьте,

что шлифовальная лента движется в

направлении, указанном стрелками В (рис.1).

Если это не так, измените схему подключения

проводов к внешнему источнику питания.

• Не допускайте попадания рук в рабочую

зону и всегда крепко держите машину.

• Всегда используйте только оригинальные

запчасти фирмы VIRUTEX.

• Пыль, образующаяся во время шлифования

может быть токсичной и опасна для здоровья

(например, краски, содержащие свинец или

некоторые виды металлов или дерева),

поэтому всегда при работе используйте

подключенный пылесос.

• Всегда одевайте шумопоглащающие

наушники при работе.

2. ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Мощность...................................................900W

Двигатель.....................................50 Hz или 60 Hz

Скорость шлифленты....327 м/мин или 393 м/мин

Размер шлифленты..........................690х100 мм

Площадь шлифования....................175х100 мм

Вес...............................................................9,7 кг

Эквивалентный уровень

акустического давления A........................79 дБ(A)

Диапазон колебания.............................K = 3 дБ(A)

Используйте индивидуальные

средства защиты слуха!

Уровень вибрации общий.................ah: <2,5 м/с

2

Диапазон колебания...............................K: 1,5 м/с

2

3. ОБЩЕЕ ОПИСАНИЕ ЛЕНТОЧНОЙ

ШЛИФМАШИНКИ AF 11

Высоко эффективна для выравнивания

поверхностей. Ее большая площадь

Antes de realizar esta operação, desligue

a máquina.

As máquinas saem da fábrica já ligadas para trabalhar

à tensão que se indica na etiqueta agarrada ao fio de

alimentação.

A tensão de trabalho pode ser mudada, de acordo com

o esquema da (Fig. 5).

Sempre que se efectuar uma mudança da tensão de

trabalho, dever-se-á verificar se o sentido de rotação da

faixa coincide com o indicado pela seta B (Fig. 1); se assim

não for, torna-se necessário inverter a ordem de ligação

dos fios na ficha de ligação à rede de corrente eléctrica.

8. NIVEL DE RUIDO E VIBRAÇÕES

Os níveis de ruído e vibrações desta ferramenta

eléctrica foram medidos de acordo com a Norma

Europeia EN 60745-2-4 e EN 60745-1 e servem como

base de comparação com uma máquina de aplicação

semelhante.

O nível de vibrações indicado foi determinado para

as principais aplicações da ferramenta e pode ser

utilizado como valor de partida para a avaliação da

exposição ao risco das vibrações. Contudo, o nível

de vibrações pode alcançar valores muito diferentes

do valor indicado noutras condições de aplicação,

com outros dispositivos de trabalho ou com uma

manutenção deficiente da ferramenta eléctrica e

respectivos dispositivos, podendo resultar num valor

muito mais elevado devido ao seu ciclo de trabalho e

modo de utilização.

Por conseguinte, é necessário estabelecer medidas de

segurança para protecção do utilizador contra o efeito

das vibrações, tais como a manutenção da ferramenta,

conservação dos respectivos dispositivos em perfeito

estado e organização dos períodos de trabalho (tais

como os períodos de trabalho com a ferramenta em

carga e períodos de trabalho com a ferramenta em

vazio e sem ser realmente utilizada, uma vez que a

redução da carga pode diminuir de forma substancial

o valor total da exposição).

9. GARANTIA

Todas as máquinas electro-portáteis VIRUTEX possuem

uma garantia válida por 12 meses contados a partir

do dia do seu fornecimiento, ficando dela excluídas

todas aquelas manipulações ou danos ocasionados por

utilizações não adequadas ou pelo desgaste natural da

máquina. Para qualquer reparação, há que se dirigir ao

Serviço Oficial de Assistência Técnica VIRUTEX.

A VIRUTEX reserva para si o direito de poder modificar

os seus productos, sin a necessidade de aviso prévio.

Page 13

13

шлифования позволяет увеличить

производительность и позволяет достичь

гладкой поверхности. Машинка оснащена

волфрамо-карбидными стопорами,

служащими для предотвращения износа

корпуса, причиной которого может послужить

движение ленты.

Для достижения оптимального эффекта

работайте на машине, используя лишь

ее вес, таким образом, лента будет

работать на оптимальной скорости,

выбранной двигателем автоматически с

максимальным эффектом. Перегрузка

машины послужит поводом для понижения

скорости движения ленты, понизив

соответственно работоспособность. Машинка

оснащена адаптером для подключения

пылеудаляющего аппарата, например,

нашего AS182 или AS282. Также возможно

подключение какого-либо подобного

промышленного пылесоса, используя ТРУБУ

ДЛЯ ПЫЛЕЗАБОРНОГО ПРИСПОСОБЛЕНИЯ

(6446073/дополнительный аксессуар).

4. ЗАМЕНА ШЛИФОВАЛЬНОЙ ЛЕНТЫ

Отключите машинку от сети.

Для того, чтобы заменить ленту, потяните

за рычаг "А", как показано на рисунке 1,

удалите использованную шлифленту и

замените ее новой, оригинальной фирмы

VIRUTEX, убедившись в том, что стрелки,

изображенные на внутренней стороне

совпадают в направлении со стрелками «В».

Чтобы закрепить ленту, повторите процедуру

в обратном порядке.

5. ЦЕНТРИРОВАНИЕ ШЛИФОВАЛЬНОЙ ЛЕНТЫ

Для центрирования ленты (рис.2) включите

машину и, поворачивая регулировочную

ручку «С», отцентрируйте ленту. Не

допускайте трения ленты об алюминиевый

корпус во избежание быстрого вывода из

строя шлифовальной ленты (рис.3).

Используйте оригинальные шлифовальные

ленты фирмы VIRUTEX (690х100) и

устанавливайте их таким образом,

чтобы лента была хорошо натянута и

отцентрирована.

6. ВОЗМОЖНЫЕ ШЛИФОВАЛЬНЫЕ ЛЕНТЫ

4491022 Лента 690х100 зернистость 30

4491006 Лента 690х100 зернистость 40

4491007 Лента 690х100 зернистость 50

4491008 Лента 690х100 зернистость 60

4491009 Лента 690х100 зернистость 80

4491010 Лента 690х100 зернистость 100

7. ИЗМЕНЕНИЕ НАПРЯЖЕНИЯ

Отсоедините машину от сети перед

выполнением данной операции.

Схема подключения инструмента

соответствует напряжению питания,

указанному на шильдике силового кабеля.

Рабочее напряжение может быть изменено,

согласно плану на рисунке 5.

Когда Вы будете менять рабочее напряжение,

проверьте, чтобы лента вращалась в

соответствии с направлением стрелок В

(рис.1). Если это не так, измените схему

подключения проводов к внешнему источнику

питания.

8. ШУМ И УРОВЕНЬ ВИБРАЦИИ

Уровень шума и вибрации этого устройства

были измерены в соответствии с

европейским стандартом EN 60745-2-4

и EN 60745-1 и служат основанием для

сравнения с другими машинами с подобными

характеристиками.

Обозначенный уровень вибрации был

определен для основных операций и может

использоваться как начальное значение для

того, чтобы оценить риски, возникающие

вследствие вибрации. Однако, колебания

могут достигнуть уровней, которые

отличаются от объявленного значения при

других условиях эксплуатации, с другими

инструментами или с недостаточным

техническим обслуживанием устройства

или его приспособлений, достигая намного

более высокой величины в результате цикла

работы или способа, которым используется

устройство.

Необходимо принять меры по обеспечению

безопасности пользователя от повышенной

вибрации, например, поддержание

устройства в чистоте и своевременное

техническое обслуживание устройства,

приспособлений и инструмента, а также

организация продолжительности циклов

работы (например, операционное время под

нагрузкой и время простоя, т.к. сокращение

последнего может существенно влиять на

Page 14

14

уровень вибрации)

9. ГАРАНТИЯ

Все изделия фирмы VIRUTEX имеют

гарантию 12 месяцев с момента поставки.

Гарантия не распространяется на ущерб

или повреждения, возникшие в результате

некорректного использования или

естественного износа изделия. Любой ремонт

должен выполняться на уполномоченных

станциях техобслуживания VIRUTEX.

Фирма VIRUTEX оставляет за собой право

на внесение изменений в свои изделия без

предварительного уведомления.

Page 15

Page 16

Virutex, S.A.

Antoni Capmany, 1

08028 Barcelona (Spain)

www.virutex.es

4096014 052013

http://www.virutex.es/registre

Acceda a toda la información técnica.

Access to all technical information.

Accès à toute l’information technique.

Zugang zu allen technischen Daten.

Accedere a tutte le informazioni tecniche.

Aceso a todas as informações técnicas.

Dostęp do wszystkich informacji technicznych.

Доступ ко всей технической информации.

Loading...

Loading...