Page 1

User’s Guide

FS5i

Virtual Research Systems, Inc.

Page 2

December, 1995

The information contained in this publication is believed to be reliable, but Vir-

tual Research Systems, Inc. makes no warranties as to its accuracy or completeness.

Copyright 1995 Virtual Research Systems, Inc. All rights reserved.

Virtual Research Systems, Inc.

2326 Walsh Ave.

Santa Clara, CA 95051

phone: 408-748-8712

fax: 408-748-8714

e-mail:

info@virtualresearch.com

Page 3

FS5i

The

FS5i

is the integration of our top of the line FS5 HMD and our

FSCAN scan converter. The result is an HMD that accepts multiple signal

formats without the headache and expense of additional cabling. The

FS5i

maintains all of the functionality of the two separate devices, incorporating them

into a single, rack mountable enclosure. A new feature of the

FS5i

is a VGA

monitor output that replaces the field sequential monitor output of the

FS5.

This

allows the user to drive the HMD and a monitor without a VGA splitter or

additional cabling.(monitor out not available with field sequential input format.)

In addition, selectors for input formats and mono/stereo have been

relocated to the front panel.

The top cover of the enclosure need only be

opened to fine tune color

adjustments.(normally

not needed)

Initially, your

FS5i

will be shipped with separate manuals for the FS5 and

FSCAN. The functionality of the

FS5i

is the same as the separate units with the

above exceptions.

By following the guidelines in the separate manuals, one

should find the setup of the

FS5i

HMD to be simpler. A new, integrated

FS5i

manual will be shipped to you as soon as it is available. If you have any

questions or problems please contact Virtual Research for prompt assistance.

Page 4

Contents

ii

TABLE OF CONTENTS

INTRODUCTION TO THE FS5

SAFETY ISSUES

FS5 CONTROL BOX

Inputs

Video Input

outputs

MECHANICAL ADJUSTMENTS

Donning the

FS5

Interpupillary Distance (IPD)

Fore/Aft motion of shell

Display Height Adjustment

Overlap Adjustment

Ratchet Knobs

Headphones

Cable Positioning

OPTICS

POSITION SENSORS

Traeker Mounting

Reducing Tracker Jitter

PIN OUT INFORMATION

SYSTEM CONFIGURATION INFORMATION

23

Intergraph Platforms

23

1

2

14

14

15

15

16

16

17

17

17

18

19

19

21

22

Page 5

Contents iii

Division

ProVisionlO

System Configuration

SGI Reality Engine System Configuration

SGI Indigo2 Impact System Configuration

Other Systems and the F-Scan Converter

THE F-SCAN CONVERTER

26

TROUBLESHOOTING

27

24

24

25

25

Page 6

ChaDter

1 Introduction 1

Chapter 1

Introduction to the

FS5

FS5

is our new high performance head mount display (HMD) . At the heart of

the product are 1” cathode ray tubes (CRTs) capable of resolution and image

quality far superior to any available flat panel displays. The CRTs are black and

white tubes which run field sequentially; red, green and blue are created by

color shutters mounted in front of the CRTs. Although most users will drive

the

FS5

to VGA resolution, the CRTs are capable of up to 800 pixels horizon-

tally.

The

FS5

optical system excels as well. A custom design using

aspheric

sur-

faces on plastic elements allows us to achieve a

55”

field of view (FOV) while

maintaining sufficient eye relief for glasses wearers. By using plastic, we avoid

the weight problems of glass elements.

Mechanically, the FS5 retains many features developed and perfected in our

LCD product, the VR4. The rugged front shell protects the display components

and requires only two adjustments--interpupillary spacing and fore/aft positioning.The headband is a proven performer with thousands of hours of trouble free experience in the VR4. The high flex cable has an extruded jacket for

abrasion resistance.

Audio rises to a new level with the FS5. These Sennheiser closed cup head-

phones are the best compact headphone we have found.Whether your source

is simple monaural cues or top-of-the-line stereo, these headphones

will perform.

The FS5 control box has superior functionality as well.A set of front panel

LEDs

give instant status information. Brightness and contrast adjustments that

control both eyes together are also available on the front panel. Full right and

left RGB setup and gain adjustments are also easily accessed inside the control

box if fine tuning is desired.

Standard field sequential input is available from several image generators, in-

cluding SGI and Division. A similar field parallel format is available from

Intergraph platforms. Appropriate connectors are easily accessible at the control

box rear panel.

For other signal sources, an optional converter is available. The F-Scan Converter accepts either RS-170 RGB or

6OHz

VGA stereo signals and drives the

FS-5 directly.

The true test of any product is not the features list, but how it performs in your

application. We expect that the blend of features designed into FS5 will work

well for you. But if you have any questions or problems or special design requirements, please give us a call. We’ll do whatever we can resolve your questions and make your application successful.

Page 7

Chapter 2 Safety Issues 2

Chapter

2

Safety Issues

We take pride in building a safe product that will satisfy your requirements.

But the nature of our product--an electronic display device that you wear on

your head--creates the potential for problems. We strive to understand and

minimize the safety hazards associated with our head mount displays.

As an HMD user, you should understand those hazards too.

With that understanding, please make an informed decision about using this or any head mount

display product.

Blocked vision and hearing

By its nature, a head mount display blocks the user’s vision and hearing. The

danger of tripping over cables or other obstacles becomes a real concern while

immersed in the virtual world. As system manager, you must provide an environment that does not allow the. HMD user to fall or otherwise injure

him/herself. As a system user, you must survey your physical environment before entering the virtual environment to avoid problems. We recommend using

FS5

only while seated to avoid tripping hazards.

Eyestrain and other optical effects

FS5

will cause eyestrain if the interpupillary distance (IPD) is set incorrectly.

Like all head mounts, it is likely to cause some eyestrain effects even when correctly adjusted. This eyestrain stems from several causes, with perhaps the

most significant being the fixed focal plane which conflicts with the variable

depth cues present in the imagery. There is no technology we are aware of that

corrects this conflict.Other potential sources of eyestrain include optical aberrations, distortion, mismatch of computer imagery with mechanical configuration and display mismatch.

If you experience noticeable eyestrain, review and correct your mechanical ad-

justments and software configuration. If eyestrain persists, limit or end your

use of this device.

Lice/other pest transmission between users

Although we have not had any instances of user’s reporting lice transmission to

us, there has been at least one anecdotal report of lice transmission in a public

Page 8

Chapter 2 Safetv Issues 3

use HMD. There are sprays available that will kill lice on furniture and cloth-

ing. Two of these are RID and A-200. Both are available in drug stores. We

don’t have information on the effectiveness of these sprays on

HMDs

and encourage you to research this if you are considering a multiple user application.

These sprays are hazardous and you need to judge the benefits vs. risks of using them. Remember to read and follow the manufacturer’s directions.

Alcohol wipes are useful for cleaning the HMD between users. Alcohol will

remove skin oil and makeup that have transferred to the HMD. As far as we

know, alcohol has no effect on lice.

Electrical Shock Hazard

The desktop power supply produces

12V, -

12V and 5V DC.

All three voltages

are present in the control box. The HMD cable carries the 12V power to the

HMD. These voltages are too low to represent a significant hazard, even with

the control box open to make color adjustments.

The enclosure at the rear of the HMD contains high voltage circuitry required

for the CRTs. This enclosure should be opened only by trained, authorized

technicians.The voltage is sufficient to give a significant shock if contacted.

The voltage is also sufficient to arc across a few millimeter gap to any conductive surface--like a finger or tool. In our experience the shock from this voltage

is bothersome, but not dangerous because the current level is quite low. However, under worst case circumstances the effects would undoubtedly be more

severe (e.g. pacemaker users, etc.).

The top bar of the headband contains a cable bundle that carries these high voltages to the front of the HMD. Do not cut, drill, clamp or otherwise damage this

portion of the headband.

The front portion of the HMD consists of two display units within a shell.

The

wiring from the headband to the display units and the display units themselves

have the same voltage levels described above. There are no user accessible ad-

justments at the front of the HMD and no attempt should be made to insert fin-

gers, tools or other potentially damaging/conductive items into the front shell.

The shell should be removed only by trained, authorized technicians.

Extremely Low Frequency (ELF) and Very Low Frequency

(VLF) Emissions

Magnetic fields generated by electronic devices (Televisions, toasters, shavers,

household wiring, high voltage lines,

-etc,

etc, and

HMDs)

have been reported

to cause a number of severe health problems, including leukemia.

There is a

great deal of controversy at this time regarding the validity of these studies.

A

number of other studies have found no correlation between these emissions and

health risks.

Test equipment, a standard procedure and test limits for ELF and VLF

emis-

Page 9

Chapter 2 Safety Issues 4

sions for computer monitors have been developed in Sweden. While this test

seems relevant to head mount displays, the equipment is unsuitable for measuring the fields around miniature displays. There are no standard test procedures, equipment or standards for electronic devices other than computer

monitors.

Because there are so many unknowns surrounding this topic, we elected to

contract an expert in the field to develop test equipment and calibrate that

equipment for us. We have developed procedures for measuring the fields generated by our products using that equipment. After measuring the fields gener-

ated by our components, we add shielding and/or relocate components to mini-

mize the fields. This seems to be the prudent approach in view of the vast lack

of solid information in this area.

X-Ray Emissions

CRTs are capable of generating x-ray emissions under some circumstances.

Our CRTs operate at voltages below levels that produce x-ray emissions. The

CRT production process includes testing to verify this. The U.S. Food and

Drug Administration regulates CRT products to ensure adherence to x-ray emission standards. Our product information has been submitted to the FDA for review.

Further Information

If you have questions about any aspect of head mount display product safety,

please feel free to contact us directly. Our address, phone number and e-mail

address are listed at the front of this document.

Page 10

.

Chapter 3 Control Box 5

Chapter

3

FS5

Control Box

Box

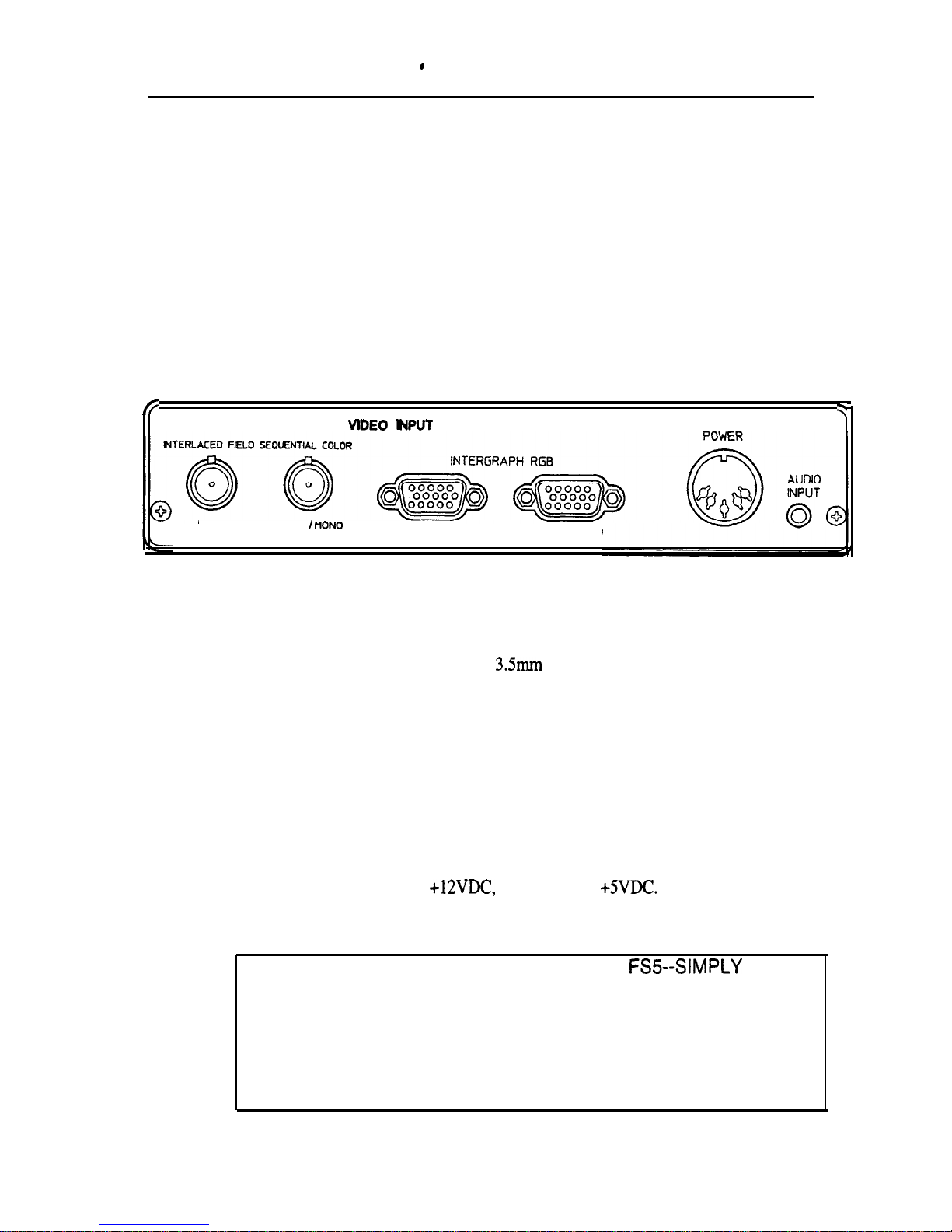

Inputs

FS5

control box inputs are located on the rear panel:

fi

3

VlDEO

INPUT

RIGHT

LEFT

I PION

RIGHT

LEFT I MONO

Control Box Rear Panel

Audio

The audio jack is a standard stereo

3.5mm

mini phone jack. The control box

passes the audio signal through directly to the FS5 headphones; there is no amplification or audio adjustment in the control box. Audio signal level supplied

to the control box should be the same signal that would be supplied directly to

stereo headphones.

Power

The control box requires

+12VDC,

-12VDC and

+SVDC.

A universal power

supply comes with FS5. The power plug on the FS5 is a 5 pin DIN plug.

CAUTION: IT IS EASY TO DESTROY YOUR

FSS--SIMPLY

PLUG

IN THE WRONG POWER SUPPLY AND TURN IT ON.

TO AVOID THIS UNHAPPY EXPERIENCE, ALWAYS CHECK FOR

THE COLOR MATCHED BAND ON THE POWER SUPPLY PLUG

AND THE COLOR PATCH ON THE CONTROL PANEL. IF THE

POWER SUPPLY DOESN’T HAVE A MATCHING BAND, DON’T

PLUG IT IN!

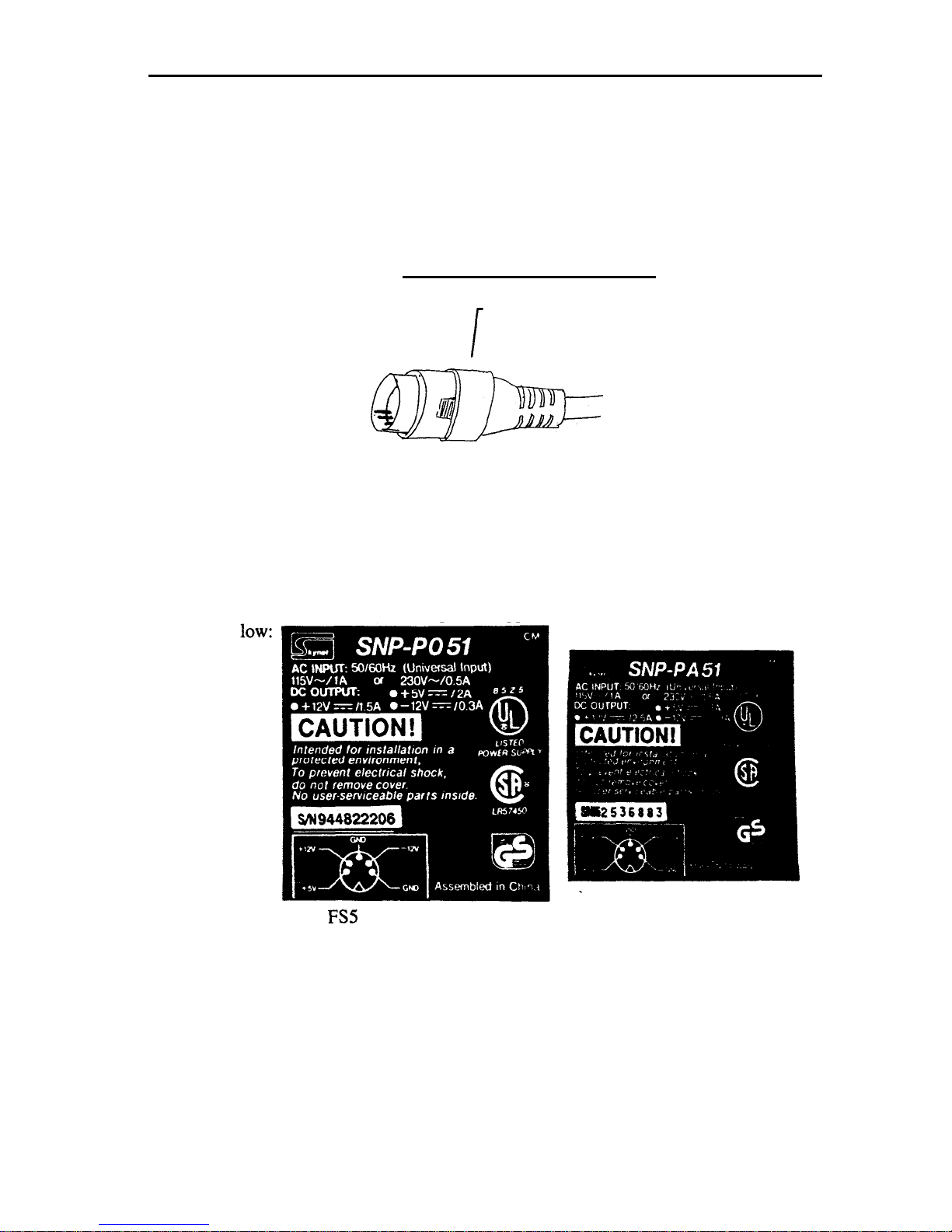

Page 11

Chapter 3 Control Box 6

Because the 5 pin DIN plug is used on many power supplies, there is a real

hazard of plugging the wrong power supply into the

FS5

control box. To re-

duce the risk of this, we have added a

REID

colored band to the

FS5

power

supply and a YELLOW colored band to the F-Scan power supply. Always

check for correct color matching before plugging in a power supply to avoid

making an expensive mistake.

Power SupplyQuick Identification

colored band

RED BAND --

FS5

Power Supply

YELLOW BAND -- F-Scan Power Supply

No Band-- Don’t use!

As a further verification of power

supplies,

compare the label to the copies below

be-

FS5

Power Supply

F-Scan Power Supply

One particular example of this problem is the Polhemus Fastrak which also uses

a 5 pin DIN plug. The Fastrak power supply outputs a higher voltage and can

damage the unit

Page 12

ChaDter

3 Control Box 7

Video Input

~

FS5

accepts three video signal formats:

1) Field sequential

3xRS

170 RGB composite

2)

3xRS170

RGB parallel

3) F-scan format

Background Information on Video Formats

RS170

RS 170 refers to a timing standard developed for television that uses an interlaced format with 525 lines per frame, 262.5 lines per field. Frame rate is

30Hz

while field rate is

60Hz.

Line rate is 15,575 Hz (262.5 lines X 60 fields).

RS170

RGB

The term RS170 RGB refers to red, green and blue on separate wires, with

RS 170 timing. RS 170 RGB also requires vertical and horizontal (or composite)

sync. We speak of 5 wire RS170 RGB (red, green, blue, horizontal sync and

vertical sync); 4 wire RS170 RGB (red, green, blue and composite sync) and 3

wire RS 170 RGB (red, green with sync and blue).

For reference, our previous generation

product--VR4--accepts

3 and 4 wire

RS170 RGB.

FS5

Video Formats

Field

Seaquential

3xRSl70 RGB

Composite

This signal is based on RS170 RGB, but is quite different.

Rather than

transmit red, green and blue in parallel, the three colors are transmitted in sequence. To transmit all the information, the rate of transmission is increased by

3x. The information is transmitted on one wire. To distinguish the three colors, a longer vertical sync pulse is sent before red. The color order is red,

green, blue.

The timing for this format is as follows:

full frame rate: 30 Hz (same as standard RS170)

full field rate:60Hz (same as standard RS 170)

individual color field rate:

18OHz

(3x full field rate)

line rate:

47,250Hz

(262.5 lines x 180 fields)

Because RS 170 is an interlaced format, there is some added complexity in defining the order of sending field one and field two. From a timing standpoint,

the most straightforward order of transmission is as follows:

R field 1

G field 2

B field 1

Page 13

Chader

3 Control Box 8

R field 2

G field 1

B field 2

This order maintains the field

1,

field 2, field 1, field 2 cycle that is defined in

RS170 timing. It avoids the timing problems that arise in using the following:

R field 1

G field 1

B field 1

R field 2

G field 2

B field 2.

However,

FS5

can accept either order.

Video input connectors are BNC type. Connectors are labeled ‘RIGHT’ for

right eye input while using stereo mode, and ‘LEFT/MONO’ for left eye in stereo mode, or for both eyes in mono mode. These inputs are 750hm terminated.

3xRS170

RGB Parallel (Intergraph RGB):

3x RS170 RGB

parallel describes yet another related video format. This format

is a 5 wire video (R, G, B, H sync and V sync) which is run at 3x RS170.

So

the timing is:

Full frame rate: 90

Hz

(3x RS 170)

Full field rate: 180 Hz (3x RS 170)

Color field rate:

18OHz

(3x RS170)

line rate:

47,250Hz

(262.5 lines x 180 fields)

This format has been created because some computer manufacturers (Intergraph

in particular) can generate video at 3x RS 170, but do not have hardware configured to support putting all three colors on one wire. To accommodate systems

like

Intergraph

we have developed circuitry to accept 3xRS 170 RGB parallel.

This signal is input on HD15 pin connectors. The FS5 does the work of selecting R, G and B in sequence internally.

The

pinout

of this connector is given in Appendix 1. Video inputs are 750hm

terminated. Sync inputs are unterminated.

F-Scan Format:

FS5 also accepts a field sequential format that is generated by the F-Scan converter. This format is most similar to the field sequential

3xRS-

170 RGB composite format described above. It differs only in that H sync and V sync are

transmitted on separate wires. The signal is transmitted over a 15 pin to 15 pin

video cable from the F-Scan converter to the FS5.

Page 14

Chapter 3 Control Box 9

The F-Scan Converter accepts

60Hz

VGA or RS 170 RGB. It converts these

signals to the F-Scan Format. This allows use of the

FS5

with graphics

sources that cannot generate an FS5 signal format.

For further information about the F-Scan Converter, contact Virtual Research.

outputs

Control box outputs are located on the front panel of the box.

II

SC

=

=c-=

= _ z f

_=.

g

?

--

Virtual

Research

=

a

:

ABCD

VR MONITOR

BRlGHTNESS0CONTRAST

0

Control box front panel

Monitor Output

One channel of monitor output is provided at the front of the control box. The

output is from the left eye input. RGB outputs are line driven and 75ohm terminated. Sync outputs are unterminated

TTL

level signals.

The output signal format is not standard and will not work with most monitors.

The signal is generated by taking the field sequential input used by the FS5, and

splitting it out onto separate red, green, blue, H sync and V sync lines. This

signal has a field rate of 180

Hz,

and the colors are only present on each third

field.

There is a drawback to this approach--because the monitor is only receiving

color signals in every third field, the picture has about l/3 the brightness of a

normal picture. For many applications, this is not a significant problem. But if

your application requires high monitor brightness, this approach would not be

recommended.

We have not done any extensive monitor evaluation, but we have not found any

monitors that are specified at 180 Hz field rate. And in fact, several monitors

we have tested will not accept this field rate.

However, we have discovered that some monitors will operate at this rate. In

our lab we have worked extensively with the Hitachi SuperScan pro 21”. Although it is specified only to

160Hz,

this monitor operates at up to

2OOHz.

Page 15

Chapter 3 Control Box 10

HMD Output

The HMD output is a

26

pin AMP connector.

Pinout

from this connector is

given in chapter

7

of this manual.

CAUTION: do not plug or unplug the HMD connector while power is

ON at the control box. Always power down the control box before disconnecting the HMD.

Status Indicator Lights

There are eight LED status indicator lights located on the front panel of the

FSS

control box. These lights are marked with letters A to H. The meaning of each

light is given in the following diagram:

A

B

C

D

ON: left eye ON: Left eye

*’

ON: 15 pin inputs ON: no horizontal

/,

horizontal

vertical, problem-- selected

sync. present at

frequency out of

HMD disconnected

OFF: BNC inputs

video input(s)

range

or no video

selected

ON: right eye

ON: Right eye

ON: 15 pin F-SCAN ON: monoscopic

horizontal

vertical problem-- input selected

OFF: stereoscopic

frequency out of

HMD disconnected

OFF: 15 pin

range

or no video

Intergraph input

selected

E

F

G

H

Overall Brightness and Contrast Adjustments

The brightness and contrast adjustments located on the front of the control box

will adjust both eyes together. For best image resolution, set brightness so

blacks are just black (rather than gray) and keep contrast low.For a standard

video input, the brightness can be adjusted so high that the entire image will go

to white. Although this should not damage the CRTs, it is a good practice to

avoid overdriving the CRTs this way.

Control Box Internal Adjustments

Selectors for mono/stereo input,

F-SCAN/Intergraph

input and individual display setup pots are located inside the control box. To access these adjustments,

you need to open the control box. To do this:

1. Turn off power at the control box.

Page 16

Chapter 3 Control Box 11

2.

Disconnect cables from front of control box.

3. Remove two Phillips screws as shown below from front panel of control

box:

4.

Remove the front panel and bezel from the control box.

5.

Slide the top cover forward and clear of the control box.

6.

Reconnect the HMD connector to the control box output.

To reassemble, reverse the above procedure. Be careful to slide the cover into

the correct channels on the control box base.

Use normal caution in working

with the exposed board regarding ESD (electrostatic discharge). The components are not highly susceptible to ESD, but can be damaged if normal precautions are not followed.

Page 17

Chapter 3 Control Box 12

Internal Adjustments are located as shown below:

F-Scan/lntergraph Select -,

Left Vertical

J

Adjustments

Color adjustments

The FS5 SETUP and GAIN pots have been factory set to give a matched output on your HMD. We use an oscilloscope to check output voltage levels for

each color. If you feel the colors are off, it is best to start slowly with changes.

You may find the mismatch is worse rather than better after casual tweaking.

If you do adjust colors, start first with SETUP pots. These are used to set

black level at an even black (rather than greenish black or reddish black for instance). Next use GAIN pots to set white levels (rather than reddish white,

etc.).

All adjustments may be made with power ON to the control box and the

HMD

operating. If you experience any problems, it is best to power down the control

box, wait a few seconds, then power up again.

Page 18

Chapter 3 Control Box 13

Video Input Format Switches

Switch positions as viewed looking down at board are as shown below:

t

Select BNC input

t

Select F-Scan Input

SW4

n

SW3

rl

c

Select 15 Pin input

i

Select Intergraph Input

t

Stereo Input

0

SW2

Mono Input

1

power switch

front of control box

Refer to chapter 8 for system configuration information and to the video input

section of this chapter for details of the specific input formats.

In most cases, we will factory set your video mode switches to match the sys-

tem you are planning to use. You should be able to use your

FS5

without any

initial changes to the mode switches.

Page 19

Chapter 4

Mechanical Adjustments 14

chapter

4

Mechanical Adjustments

Locations of mechanical adjustments are shown in the following drawing:

Donning the FS5

There are several things to consider when first donning the

FSS.

1. The top ratchet should be adjusted to bring the sides of the headband down

to the base of the ear. See diagram:

Page 20

Chapter 4

Mechanical Adjustments 15

2.

3.

4.

5.

The rear ratchet should sit below the base of the skull, as shown in the dia-

gram above.

The cable should fall down the user’s back--not over the shoulder. The ca-

ble weight provides counterbalancing for the display weight.

It is easier to don the

FS5

with the earphones in anup position--out of the

way. After the other adjustments are made, it is easy to bring the earphones

down. While pulling them down, pull them out away from the head to

avoid bending your ear.

IPD, display height, and fore/aft motion adjustments are performed together

to optimize the view.

lnterpupillary Distance (IPD)

IPD range = 48-73 mm. This range is sufficient to cover from 1st percentile

teenager women to 99th percentile adult men. It should also cover a large percent of younger children, but we don’t have statistical information on younger

population groups.

Adjust until both images are evenly visible. Close one eye to

confirm

the image

is centered in front of the other eye. Incorrect positioning of the IPD adjustment

will lead to eyestrain.

Fore/Aft motion of shell

Pull shell away for easy donning. Push toward face to maximize field of view

and to block ambient light. Eyeglasses can be worn with FS5, simply leave

fore/aft adjustment near the outer position.

Fore/aft motion is controlled by a detent set screw that is accessible through a

hole at the center of the aluminum bracket at the top inside of the shell.

It re-

quires a

.050’*

hex head wrench to adjust. This tool is provided with the FS5.

The location of the set screw is shown in the diagram below:

Captive

Fore/Aft Tension

Page 21

Chapter 4 Mechanical Adjustments 16

.

The adjustment is slightly easier to make if the fore/aft adjustment is in the close

position. Insert the hex head wrench in the hole shown in the diagram. Move

the tool around and rotate it until it seats itself in the set screw.Adjustment is

somewhat counter intuitive: Turn clockwise to loosen, counterclockwise to

tighten the adjustment.If the adjustment gets too loose, the front assembly will

slide off the headband. Be careful to avoid this.

Adjust so that tension is sufficient to keep the shell from sliding by itself, but

not so tight that a user must push or pull with any significant effort to move the

shell.

CAUTION: DO NOT OVER -TIGHTEN DETENT SCREW.

IF DETENT IS OVER -TIGHTENED, USERS MUST APPLY

EXCESSIVE INWARD FORCE TO MOVE SHELL TOWARD THE

FACE AND EYES. WHILE THIS FORCE IS APPLIED, DETENT MAY

DISENGAGE, CAUSING THE USER TO PUSH THE OPTICS INTO

HIS/HER FACE AND EYES RESULTING IN INJURY.

Display Height Adjustment

The entire shell structure can be moved vertically relative to the user’s face. To

do this, grasp the metal headband and move it up or down relative to the leather

covered forehead band. When display height is correctly adjusted, the top and

bottom of the CRT

.will

be equally visible.

Overlap Adjustment

This adjustment requires factory disassembly. Specify position when you or-

der, or return to Virtual Research for retrofitting.

Partial overlap setting requires stereo video inputs, but allows a wider field of

view than 100% overlap.

[As of this writing, the partial overlap position development work is incomplete.Some shell redesign work is needed to allow the outward tilt of the displays. Please contact Virtual Research for up to date information]

Page 22

Chapter 4 Mechanical Adjustments 17

Ratchet Knobs

Tension of ratchet knobs is adjustable by turning the Phillips screw at the center

of the knob.

Headphones

Headphones rotate around the knobs on the sides of the headband. When don-

ning the

FS5

unit, rotate the headphones above the headband. After video is

adjusted, pull the headphones down. This makes fitting faster and easier.

Rotation tension is controlled by tightening the knobs. Over tightening can

cause failure of the knob or the plastic bolt.

Cable Positioning

FS5 is designed to be lightweight and well balanced. The cable bundle provides a significant counterbalancing effect without adding weight to the product.

The cable bundle should drop directly down the user’s back. If the cable is

draped over the user’s shoulder,

FS5

will be front heavy.

The position sensor

cable should follow the cable bundle to add additional counterbalance weight

and to minimize the tangle of separate cables.

Page 23

Chapter 5 Optics 18

.Chapter

5

Optics

Avoid scratching the FS5 Optics.

FS5

optics are plastic and are prone to scratching. Eyeglass lenses and eyeglass

frames are especially likely to cause damage to your

FS5

optics.

FS5

is de-

signed with rubber bumpers around the lenses to minimize this contact. But the

bumpers won’t stop all contact, so be cautious when you wear glasses with

your FS5.

If this isn’t enough incentive, as your glasses damage the FS5 optics, the FS5

optics may damage you glasses. Be careful.

If worst comes to worst, FS5 lenses are factory replaceable. Contact Virtual

Research for details.

Eyeglasses:

Leave On or Remove?

In general, it is better to wear the FS5 without glasses. Without glasses, you

can bring the optics closer to your eye, but with glasses, you need to leave the

optics farther away. The optical exit pupil (the place in space where your eye

needs to be to see the screen clearly) is cone shaped and narrows farther from

the FS5 optics. As your eye moves farther from the lens, you need to be more

careful in adjusting the fit of the HMD to achieve good imagery.

The FS5 optical system is designed to place the image plane at about 5 ft

(1.5m).

If you wear glasses, but are able to see objects at 5 ft clearly, you will

find it is better to wear the FS5 without your glasses.If your vision is blurred

at 5 ft, you will probably find it is better to wear your glasses, even though you

are farther from the lens. If in doubt, try it both ways, then decide.

Bifocals can be a problem for HMD wearers. Near objects and far objects are

really all at the same distance, so bifocals tend to just get in the way.

While we can’t seriously recommend it, one customer has used HMD usage as

a work related reason that he required radial keratotomy and convinced his insurer to pay for the procedure that is normally not covered.

Lens Fogging

FS5 is supplied with a no-fog cloth to reduce fogging of lenses. To use it,

breath on the lens to create a fog, then gently wipe off with no-fog cloth.Keep

no-fog cloth in closed pouch so it doesn’t dry out. Reapply if fog reappears.

The no-fog cloth leaves a residue on the lens.A thin coating doesn’t have an

appreciable effect on image quality through the lens. But excessive application

will cause some degradation of image quality.

Page 24

Chapter 6 Position Sensors 19

chapter

Position

6

Sensors

Tracker Mounting

FS5

is designed to be used with a variety of position sensing options. The position sensor mounting bracket behind the top ratchet has mounting screws located for a Polhemus or Ascension receiver. The outer holes are sized for the

Ascension, while the inner holes fit the Polhemus.

Position Sensor Mounting Bracket

K

outer holes for ascension mount

c(.

inner holes for Polhemus mount

The mounting bracket holes are positioned so the tracker is turned 90” from the

HMD axis. Using this receiver position requires a software rotation of the receiver position.

Page 25

Chapter 6 Position Sensors 20

Tracker Rotation (Axes are those used by WorldToolKit)

UP

t-y)

t

line of sight (+Z)

90” rotation needed

some rotation about X maybe needed

left side (-X)

The correct position will have a 90” rotation about the Y axis. You should set

rotation about X after testing the system with no rotation.

Exact rotation about

X may depend on the user, although we have not worked enough with this to

be certain.

If your software has difficulty with this rotation, we can send you a mounting

plate with holes at 90” rotation from those shown above. For a quick fix, cus-

tomers have used velcro with adhesive backing.

The Logitech Ultrasonic tracker requires a triangular mounting hole pattern. We

can supply (at no charge) an adapter plate for the Logitech receiver.

Other trackers are becoming widely available.

If you would like to mount an-

other tracker on your

FS5,

let us know. We can probably supply basic hard-

ware for mounting. We are always glad to have feedback on your experience

with new trackers.

Position sensor cabling is most easily handled if you attach it to the

FS5

cable

bundle. This can be done with electrical tape wrapped at about 18” intervals

around both cables. However, this does leave some sticky residue when you

remove the tape. You can lay the smooth tapesurface against the cables and

finish by doubling the tape back on itself to avoid this residue. We don’t recommend plastic cable ties since they tend to snag on everything.

Page 26

Chapter 6 Position Sensors 21

Reducing Tracker Jitter

Electromagnetic trackers are prone to jitter. This effect can be subtle, or horrendous, depending on the conditions in which the tracker is used. A good

place to start is with a diagnostic setup.

Place the receiver and transmitter near

each other and well away from other possible sources of interference. We find

it is easiest to diagnose if we view a virtual scene on a large monitor and watch

for image jitter in that scene. Don’t use the HMD display for this; it’s hard to

move equipment while looking into an HMD and impossible to test for HMD

interactions. While watching the monitor, move the transmitter and receiver

apart and watch the jitter increase.

ambient jitter.

You should now-have a fair sense of your

Now bring suspect pieces of electronics or metal into the area of the receiver.

Turn the electronics on and off. Move the transmitter/receiver farther apart and

the electronics closer to the receiver, then try again. Notice how objects cause

warpage

of the electromagnetic field--causing the sensor output position to

change, as well as jitter.

Bring the

FS5

near the receiver. Notice that the jitter becomes severe when the

receiver is near the CRTs or the circuitry at the rear end of the HMD.

At the

tracker mount, the sensor should be nearly unaffected by the HMD.

Try the following jitter reduction steps if you are having problems:,

1.

2.

3.

4.

Keep the source and receiver as close together as possible. More than

anything else you do, the distance from source to receiver will effect you

performance.

Turn off or move away equipment that causes interference.

Monitors and

computers (especially computers that are partially open) produce fields that

will add jitter to your tracker.

Mount the transmitter above the receiver. This will maintain a clearer line

of sight from transmitter to receiver and reduce field

warpage

due to metal

parts of the FS5.

If the I-IMD seems to be a significant source of jitter or field

warpage,

mount the receiver on a plastic arm that moves it farther from the electronics

of the HMD. Use the diagnostic setup described above to figure out the po-

sition that works best for your situation.

Page 27

Chapter 7

Pin Out Information 22

Chapter 7

Pin Out Information

Interprauh Innut

and Monitor

Outuut

connector format

15 pin high density D female connector

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Signal

RedVideo

Green Video

Blue Video

Ilk

ground

ground

ground

ground

reserved for auto enable of intergraph mode--do not connect

ground

n/c

Ilk

horizontal

sync

verticalsync

reserved for auto enable of F-Scan mode--do not connect

Page 28

Chapter 8

System Configurations 23

Chapter

8

System Configuration Information

The following information is intended to help describe system configurations

that have been successfully used by Virtual Research, or by other

FS5

custom-

ers. If you find an alternative configuration works better or have problems with

a configuration described here, please let us know.

Intergraph Platforms

Virtual Research is currently using the following system configuration for

FS5

testing:

TDZ30 with two

GL2

graphics card sets

I-l

electromagnetic transmitter

0

Tracker

Box -

HDl Smak

to

HDl Smak

receiver for glove or wand

-

optional VGA distribution amp.

VGA loop through

cable supplkd

by Intergraph

I

I

use monitor out as alternative to VGA dist. amp.

HDl Smak

to

HDl Smale

Hitachi

SuperScan

Pro

21”

monitor

Our current system configuration uses a Polhemus Fastrak tracker and Sense8

WorldToolKit

software.

-

Page 29

Chapter 8 System Configurations 24

A special Intergraph driver is required to configure the GLZ boards to provide

180Hz

RS170 video output. As of this writing, that driver has not been for-

mally released. We are using a test version of the driver on our system.

It is not necessary to use two GLZ board in the system shown above.

If you

use one GLZ board, plug the GLZ output into the LEFT/MONO input of the

FS5

and move the MONO/STEREO switch to MONO.

Division Provision1 0 System Configuration

In preliminary tests with Division, we had no problem running the

FS5

directly

from the

PVlO

in mono and stereo modes.

As of this writing, Division is awaiting delivery of an FS5 for verification test-

ing with the FS5 prior to a formal release of the software driver.

Contact Division directly for further details of system configuration.

SGI Reality Engine System Configuration

We have tested the following system configuration to some extent:

electromagnetic transmitter

13W3

male to @NC

hakout csbk

Hitachi

SuperScan Pm

21” monitor

To deliver the correct video format to FS5, a new video output format (VOF) is

required.A tape with the VOF will be shipped with your FS5 if you are using

an Onyx. The format is titled

64Ox480_18Oiq.u.

L

Page 30

Chapter 8

System Configurations 25

The problem you are most likely to face is portrayal of imagery in black and

white on the HMD that should be in color. This problem results from a limitation of the SGI software to generate field sequential color. SGI engineers assure

us that the problem should not occur in windows that are generating graphic im-

ages, but we don’t have any real confirmation of this yet.

The Onyx multi-channel option (MCO) for the RE2 cannot drive the FS5. Al-

though it is theoretically possible, SGI efforts are focused on the RE3, which

will provide a more flexible support for products like the

FS5.

Unfortunately,

MC0 software for the RE2 is a lower priority. To run stereo from an

RE2

with

MCO, output VGA and use an F-Scan converter.

SGI Indigo2 Impact System Configuration

The Indigo2 Impact is not capable of driving the

FS5

directly. However, the

Impact Channel Option (ICO) which is still in development as of this writing,

will drive the

FS5

directly. It will be capable of stereo as well as mono.

We don’t yet have details of the exact system configuration.

Contact SGI for

further details on availability of the ICO.

Other Platforms and the F-Scan Converter

PC, Apple Macintosh, Sun, Evans and Sutherland, and SGI platforms not

named above are not currently able to output a video format directly

useable

by

the FS5. To allow a broad range of platforms to drive the FS5, we have devel-

oped the F-Scan Converter. See chapter 9 for further details on the F-Scan

Converter.

Page 31

Chapter 9 F-Scan Converter 26

Chapter 9

The F-Scan Converter

The F-Scan Converter will allow you to drive the

FS5

with a VGA or RS 170

RGB source. Input to the F-Scan Converter is one or two channels of video.

Video may be

3,4

or 5 wire.

Output from the F-Scan Converter is one or two

channels of field sequential video in

3xRS

170 RGB format.

VGA format video must be

6OHz,

640x480. Higher frame rates will not work.

RS 170 RGB is the same format accepted by the VR4. With an F-Scan Converter, you should be able to substitute an

FS5

directly for a VR4 in your appli-

cation.

Contact Virtual Research for further information on the F-Scan Converter.

Page 32

Chapter 10

Troubleshooting 27

Chapter 10

Troubleshooting

PROBLEM

yeen

power light not on at

control

box when switch is

In

power light blinks on and

off

HO VIDEO

no video at

HMD

Horizontal status light error

CHECK FOR

correct

power supply--check

color

coded ring on plug

power supply not plugged

into a live circuit

this is probably a serious

problem requiring factory

service. Try powering

down and back up. If the

problem persists or returns,

contact virtual research

check status lights--see descriptions of lights on manual page 10.

check that video source is

plugged into correct channel

of control box.

check input switch settings

inside control box for correct

configuration see page 13 of

manual

This is probably due to incorrect video format sent to

the

FS5.

Recheck your

video format. Check with

Hitachi monitor if available.

Monitor will show

47kHz,

180Hz if video timing is cor-

rect

COMMENTS

fuses

in

FS5

control box are

self resetting, so the problem

is not due to a blown fuse

If there is a short somewhere

in the circuit, the resettable

fuse may blow and reset repeatedly

Another quick test: Send the

signal to a regular monitor.

lf

you see a good image,

you are not sending

FS5

format, which will not work

on most monitors.

Page 33

Chapter 10 Troubleshooting 28

vertical

status light error

no video at HMD, status

ights show no problem with

ride0

left eye working, but right

eye

dark

ntergraph left eye working,

but

right eye dark

VIDEO

PRESENT BUT

NOT

CORRECT

Image appears all blotchy

with

colors changing

Video images present, but

hazy

overall

Displays are completely

bright white

intergraph image appears in

black and white

Shutter appears stuck on one

or two colors

commonly

due to HMD

un-

plugged

from control box.

Use

likely result of incorrect

video

feed to HMD. If

IMD

is plugged in, recheck

video

format.

adjust control box front

panel brightness and contrast

pots

rideo source may be sending

Ilack

image--check with

os-

:illoscope

or

180Hz

monitor

nay be in stereo mode when

:xpected

to be in mono

node

Intergraph graphics must be

:onfigured

for stereo and

dual display

This

is normal shutter

benavior when it is first turned

on.

The problem should

disappear within 30 seconds

CRT may be blooming.

Turn

down brightness and

contrast. The image quality

should improve

turn down brightness and

contrast at control box front

panel.

If this doesn’t help, you may

be sending an incorrect

video signal

control box is configured for

F-Scan input rather than

intergraph input. Check status

lights. Change SW 3 position

Power down HMD, wait a

few seconds, then power

UP*

horizontal

and vertical timing

If

video signal are correct

and

sync signals are present.

Maximum image quality will

always be achieved at the

lowest contrast level that is

acceptable.

Shutter can latch if power

down cycle is too short

Page 34

Chapter 10 Troubleshooting 29

on

SGI Onyx, portions or all

If

the scene are black and

vhite on the HMD

MECHANICAL IMAGE

PROBLEMS AND

IMAGE

MISMATCH

video

image is blurry at one

edge

or comer

corners

of image are lost

Colors

appear smeared or

ainbow

like at edges of

dis-

Ilay

One

eye is brighter than the

Ither,

or colors are different

in the two eyes

image in the two eyes are

different widths or are rotated relative to each other

images are different heights

this is a software limitation

of the SGI. Contact Virtual

Research for further details.

your eye is off to one side

from the exit pupil of the

optics. Try adjusting the

lPD

or vertical position of

the displays again.

your eye is too far from the

lens. Pull the shell closer to

your face.

this is a normal limitation of

the lens design. Different

light colors are bent differ-

ently by the lens. The effect, chromatic aberration, is

more severe the farther from

the center of the display

switch video signals if you

are running in stereo to see if

the problem is caused at the

control box, or at the computer

if the problem is control box

related, adjust SETUP and

GAIN pots inside control

box.

This is an image alignment

problem that requires factory

service. Please contact virtual research.

this can be adjusted at the

control box, but please contact virtual research before

making any adjustment

T-

This

is more of a problem

or those who wear

eye-

glasses.

If you are reading text, keep

it toward the center of the

display.

nake sure you have the

dis-

Ilays

aligned to your eyes

tnd

as close to your eyes as

)ossible

to limit all

aberra-

ions.

.mage

mismatch problems

will

cause eyestrain and

should

be fixed promptly

image mismatch problems

will cause eyestrain and

should be fixed promptly

Page 35

Chapter 10 Troubleshooting 30

stereo input, images aren’t

make sure everything is OK

image mismatch problems

fusing into one stereo image

with the HMD by testing in will cause eyestrain and

MONO mode. If this is OK

should be fixed promptly

and the problem persists, it

is due to software configuration. Adjust convergence/parallax as appropriate

MECHANICAL

PROBLEMS

front shell fore/aft motion

too loose or too tight

adjust detent screw at front

of headband--see manual for

instructions

HMD

seems front heavy

HMD cable and tracker cable

should fall down user’s

back, not over shoulder.

With cable at back, weight

should be centered

headband ratchet knobs too

adjust ratchet tightness with

loose or too tight

phillips

head screw at center

of ratchet knob

Loading...

Loading...