Viqua Sterilight S80, Sterilight SM80, Sterilight SV50 Owner's Manual

Owner’s Manual

S80, SM80, SV50

Ultraviolet Water Purification System

Congratulations. By purchasing this system, you

have taken the first step in ensuring safe drinking

water. Designed using the most advanced UV

technology available today, your UV system is

designed to provide you with years of trouble free

operation with minimal maintenance required.

Date of installation:

Installed by:

Installer phone#:

Serial #:

(Found on label on side of Power Supply)

KEY INFORMATION YOU SHOULD KNOW:

• A 5-micron (nominal) sediment filter must be installed upstream

of (before) any UV system.

• This product is for indoor use only. Keep all components clean

and dry.

• Clean the sleeve regularly for optimum performance.

Sterilight® SV50 model is USEPA UVDGM

2006 validated.

425 Clair Road West, Guelph, ON N1L 1R1 Canada

t. 519 763 1032 t.f. 1 800 265 7246 f. 519 763 5069 www.viqua.com

July 2010

P/N 520150-R revD

SAFETY INSTRUCTIONS

GROUNDING

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electrical shock. This system is equipped with a cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with

all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified

electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided

with this system – if it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not use any type of adapter

with this system.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electrical Code (NFPA 70) and to provide additional protection from the risk of electric shock, this

system should only be connected to a properly grounded, grounding-type power supply receptacle that is protected by a Ground

Fault Circuit Interrupter (GFCI). Inspect operation of GFCI as per manufacturers suggested maintenance schedule.

EXTENSION CORDS

If an extension cord is necessary, use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from this system. Use only extension cords that are intended for outdoor use. Use only extension

cords having an electrical rating not less than the rating of the system. A cord rated for less amperes or watts than this system

rating may overheat. Exercise caution when arranging the cord so that it will not be tripped over or pulled. Do not use damaged

extension cords. Examine extension cord before using and replace if damaged. Do not abuse extension cord. Keep extension cord

away from heat and sharp edges. Always disconnect the extension cord from the receptacle before disconnecting this system from

the extension cord. Never yank cord to pull plug from outlet. Always grasp the plug and pull to disconnect.

WARNING – To guard against injury, basic safety precautions should be observed, including the following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. DANGER – To avoid possible electric shock, special care should be taken since water is employed in the use of this system.

Unless a situation is encountered that is explicitly addressed by the provided maintenance and troubleshooting sections,

do not attempt repairs yourself; refer to an authorized service facility.

3. CAUTION - Do not operate with broken or faulty parts as this may result in exposure to ultraviolet radiation. Contact supplier

for replacement parts.

4. Do not operate the system if it has a damaged cord or plug, or if it is malfunctioning or if it has been dropped or damaged in

any manner.

5. Always unplug the system, shut off water flow and release water pressure before servicing or cleaning. Never yank cord to

remove from outlet; grasp the wall plug and pull to disconnect.

6. Do not use the system for other than intended use. The use of attachments not recommended or sold by the manufacturer may

cause an unsafe condition.

7. To prevent risk of electrical shock, connect this system only to a properly grounded, grounding-type power supply receptacle

that is protected by a Ground Fault Circuit Interrupter (GFCI). Inspect performance of GFCI as per manufacturer’s suggested

maintenance schedule. If an extension cord is used, ensure it is of a sufficient rating and accepts the plug from this system;

never use an adapter.

8. Visually inspect this system prior to installation. If the quartz sleeve or lamp is broken, cracked or damaged in any way,

do not use. Contact the supplier for replacement parts

9. Keep all connections dry and off the ground. Do not touch plug with wet hands.

10. The light emitted by the lamp will cause serious eye damage and burn unprotected skin. Do not plug system into an electrical

outlet without first properly securing the lamp into the chamber. Unplug the system prior to removing the lamp from the

chamber.

11. If the UV system malfunctions or fails, water must be boiled prior to consumption until the UV system is operational and the

water lines have been shocked. System failure is indicated by the system’s audible and visual alarms or the absence of any

indicator light.

12. Intended for indoor use only. System must not be exposed to weather elements. In seasonal applications, chamber must be

drained to prevent freezing.

13. Installation of this system must be in accordance with local plumbing and electrical codes as well as any and all applicable

regulations and laws.

14. SAVE THESE INSTRUCTIONS.

WARNING – To prevent risk of electrical shock, connect this system only to a properly grounded,

grounding-type power supply receptacle that is protected by a Ground Fault Circuit Interrupter. Pull

plug before servicing or replacing lamp. Keep all connections dry and off the ground. Do not touch

plug with wet hands.

WARNING – Do not look directly at UV lamp when it is operating. The light emitted by the lamp will

cause serious eye damage and burn unprotected skin.

WARNING – Read manual before installing or servicing this system. Only authorized personnel

possessing a strong understanding of this system should attempt to replace lamp or service this

system.

NOTE – Maximum pressure rating is 100 PSI (6.89 bar)

TABLE OF CONTENTS

Overview 4

Components 4

Specifications 5

Dimensions and layout 7

Installation 9

Installing the UV system 9

Disinfecting the water lines 11

Operation 14

Control panel 14

Troubleshooting 15

Low UV alarms 16

OVERVIEW

INSTALLATION WARRANTYMAINTENANCEOPERATION

Maintenance 17

Sleeve cleaning and lamp replacement 17

Fuse replacement 22

Warranty 23

OVERVIEW

INSTALLATIONWARRANTY MAINTENANCE OPERATION

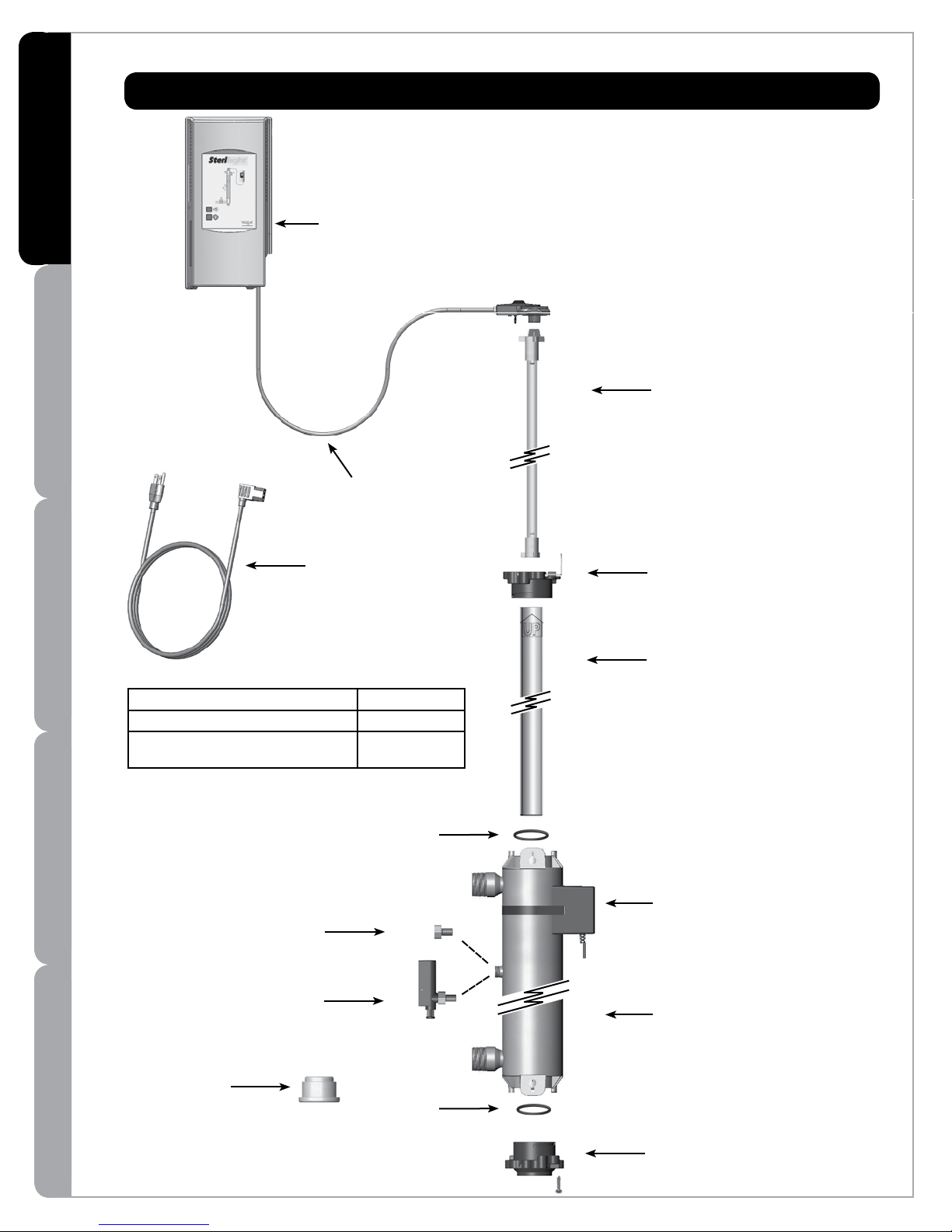

COMPONENTS

For replacement components please contact your

installer (listed on the front of this manual) or

contact VIQUA directly for a referral:

1 800 265 7246 (North America), 519 763 1032,

or info@viqua.com.

Power supply

SV50: Part #660023-R SM80: Part #660022-R S80: Part #660021-R

(power supply includes

lamp cord)

Lamp

SV50, SM80, S80:

Part #S37RL-AM

Lamp cord

Part #260174-R

Power cord

Part #602636 (120V)

Part #602637 (230V)

Accessory Part Number

2“ Solenoid Valve (option) 410898-R

CommCentre (option)

Remote Controller

270270-R

O-ring

Plug Kit

(Comes installed with

Basic Series chamber)

Sensor

(SV50 & SM80 only)

Part #440256-R

Top bolt & wireform

Part #602916 & 602896

Sleeve

SV50, SM80, S80: Part #QS-37

CoolTouchTM fan

Part #230438-R

Chamber

Sleeve removal

tool

Part #602988

Note: keep this tool with

system at all times.

4

O-ring

Bottom bolt (includes screw)

Part #603053

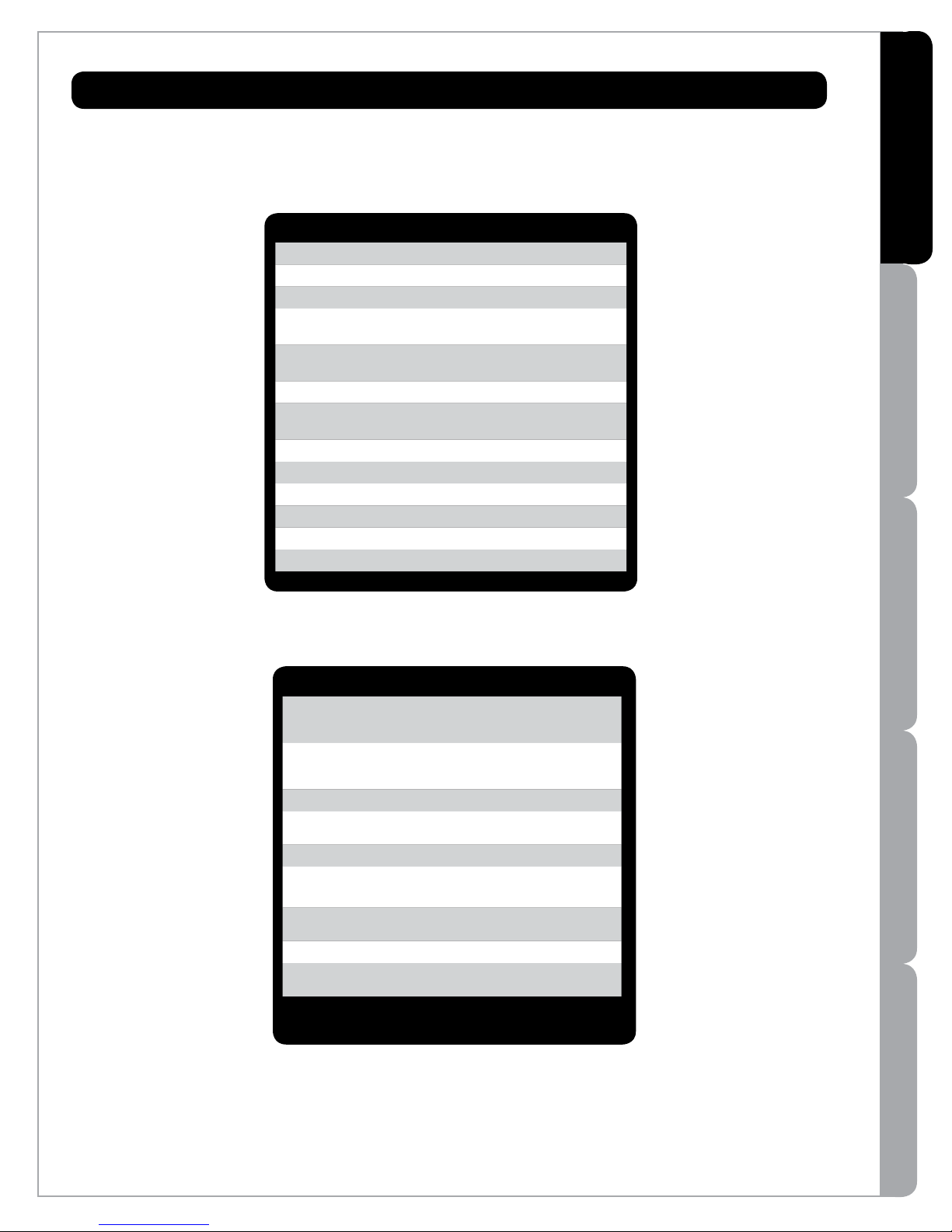

SPECIFICATIONS

General (All Models)

Operating Parameters

Maximum operating pressure 100 PSI (689 kPa)

Minimum operating pressure 4 PSI (27 kPa)

Maximum ambient air

temperature

Minimum ambient air

temperature

Maximum humidity 100%

Maximum hardness 120 ppm

Maximum iron 0.3 ppm

Minimum UVT 75%*

Installation Vertical ONLY

Other

Chamber material 316L SST

Rated service life of lamp 2 years

1040F (400C)

320F (00C)

(7 grains per gallon)

OVERVIEW

INSTALLATION WARRANTYMAINTENANCEOPERATION

* SV50 has a minimum UVT rating of 85%

SV50* SM80** S80**

Rated flow

dose of

30 mJ/cm

Rated flow

dose of

40 mJ/cm

Electrical

Voltage

Max. current 2.4 Amp 2.4 Amp 2.4 Amp

Max. power

consumption

Lamp power

consumption

Port Size

Inlet and

outlet

2

2

--

50 gpm

(189 lpm) -- --

100-240V

50-60Hz

230 Watts 230 Watts 230 Watts

200 Watts 200 Watts 200 Watts

2“ MNPT 2“ MNPT 2“ MNPT

up to 80 gpm

(265 lpm)

100-240V

50-60Hz

*Flow rates shown are at 85% UVT.

** Flow rates show are at 95% UVT.

up to 80 gpm

(265 lpm)

100-240V

50-60Hz

5

OVERVIEW

INSTALLATIONWARRANTY MAINTENANCE OPERATION

SPECIFICATIONS

SV50 SM80 S80

Color-coded plug and play

connections

Sensor with diagnostic test Yes Yes -CoolTouch fan Yes Yes Yes

Communications ports (two, RJ45) Yes Yes Yes

Solenoid valve Optional Optional Optional

Controls

Audible alarm mute button Yes Yes Yes

New lamp button Yes Yes Yes

Lamp age indicator Yes Yes Yes

Lamp operation indicator Yes Yes Yes

Power supply operation indicator Yes Yes Yes

Solenoid operation indicator Yes Yes Yes

Fan operation indicator Yes Yes Yes

Sensor reading indicator Yes Yes --

Yes Yes Yes

USEPA UVDGM 2006

(SV50 model only)

Other certifications

Yes -- --

6

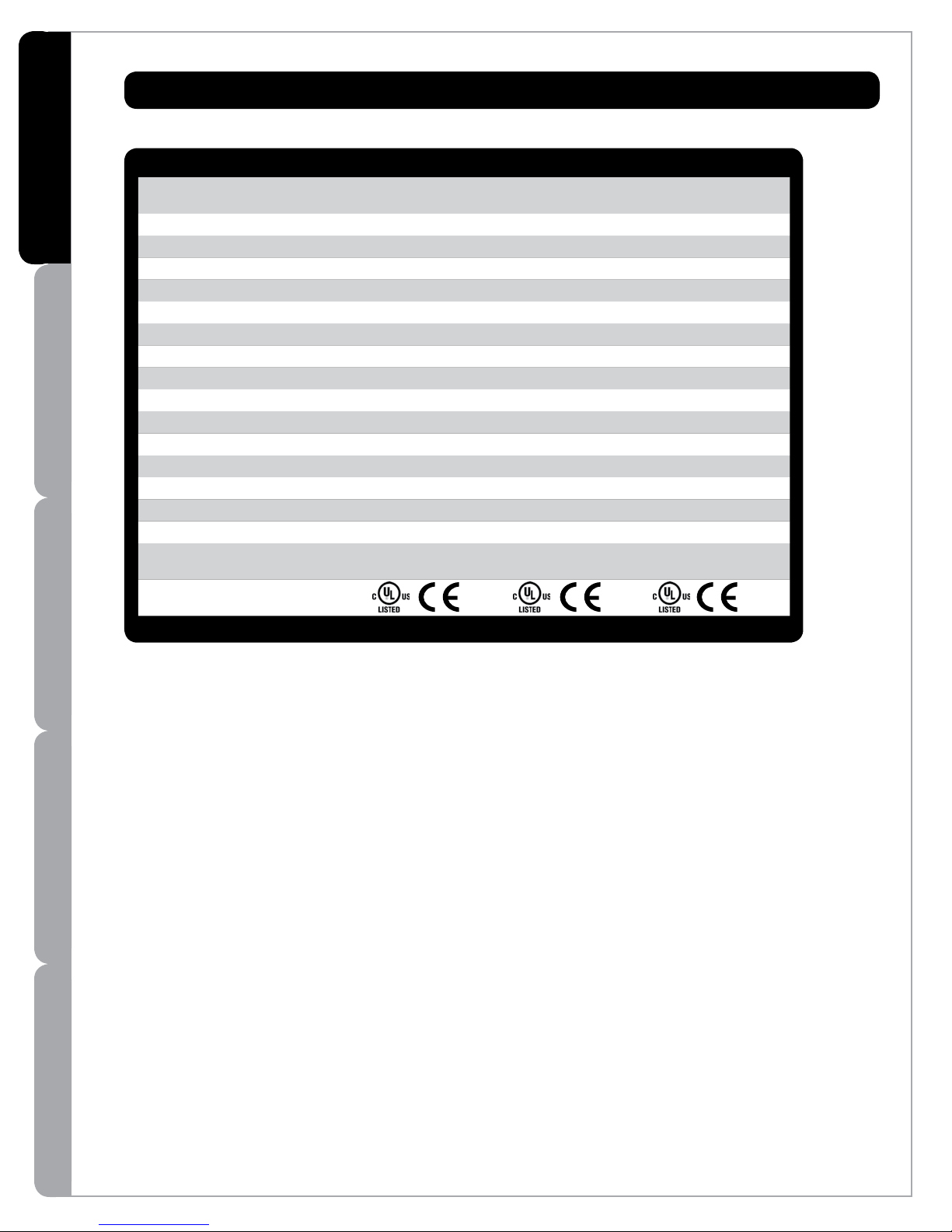

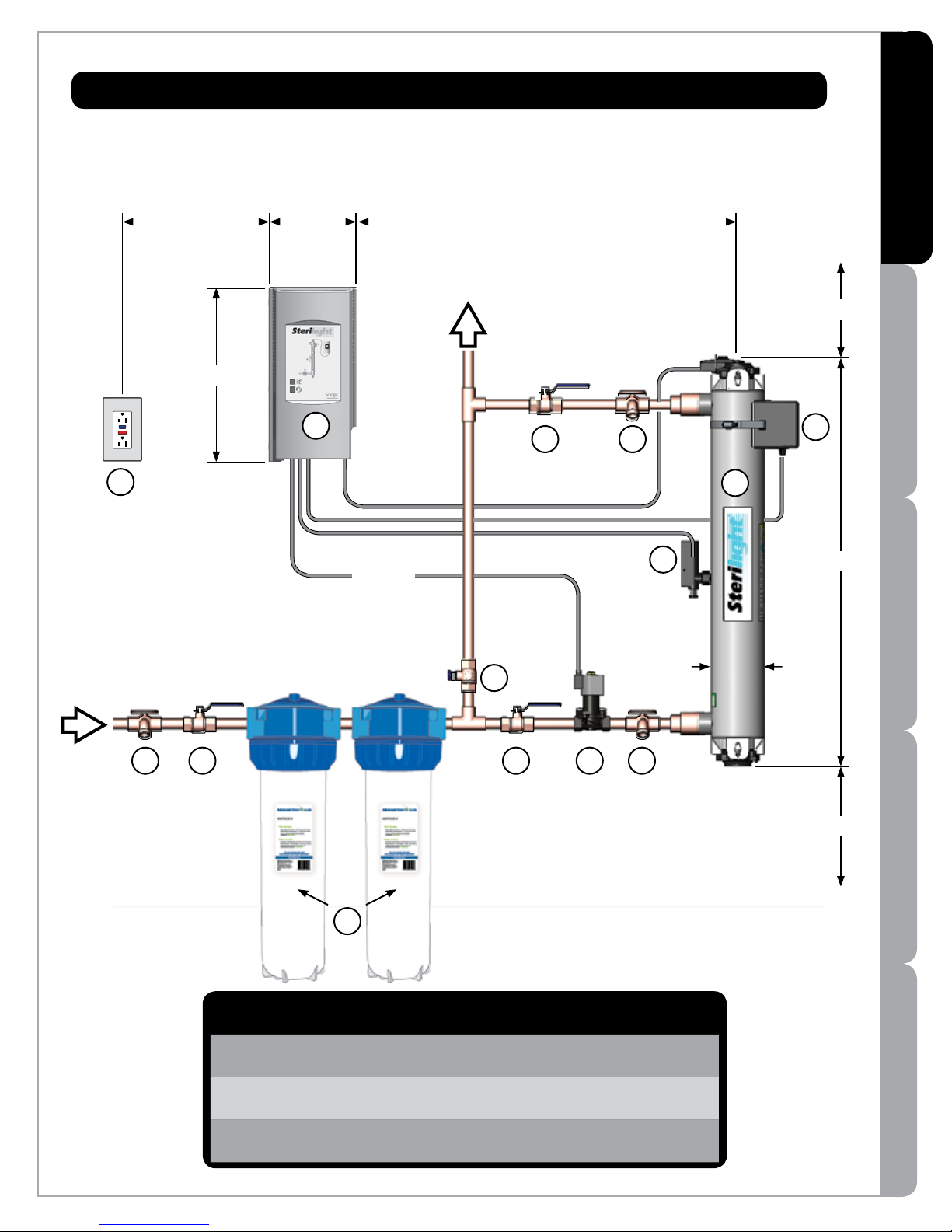

DIMENSIONS & LAYOUT

OVERVIEW

INSTALLATIONWARRANTY MAINTENANCE OPERATION

14

A B

C

13

72” (183cm

OUTLET

)

12

D

11

Clearance

for lamp

removal

L

10

9

8

L

INSTALLATION MAINTENANCEOPERATION

INLET

LModel

SV50 41"

(103cm)

SM80 41"

(103cm)

S80 41"

(103cm)

3

S

(min.)

12"

(30cm)4"(10cm)

12"

(30cm)4"(10cm)

12"

(30cm)4"(10cm)

4

5

61 2

Ø

7

Sampling and shut-off valves, fittings, and

pre-treatment equipment not included.

Ø D

(max.)

72"

(182cm)

72"

(182cm)

72"

(182cm)

6.5"

(16.5cm)

6.5"

(16.5cm)

6.5"

(16.5cm)

CBA

13"

(33cm)

13"

(33cm)

13"

(33cm)

(max.)

48"

(122cm)

48"

(122cm)

48"

(122cm)

S

7

OVERVIEW

INSTALLATIONWARRANTY MAINTENANCE OPERATION

Sample valve: Allows for sampling of raw water.

1

Shut-off valve: Required to allow maintenance of pre-treatment equipment.

2

Pre-treatment (illustrative only): For the UV system to operate effectively, the water should

3

meet certain water quality parameters, as outlined below. To meet these, pre-treatment of the

water may be required. Pre-treatment equipment must be installed BEFORE the UV chamber.

Pre-treatment systems can be comprised of one or more of the following elements: sediment

filters; carbon filters; iron removal systems; water softeners; cyst reduction filters, etc.

Water Quality Requirements:

Iron: < .3 PPM (.3 mg/L)

Hardness: < 120 PPM (7 Grains Per Gallon)

% UVT: > 75% (SM80, S80)

> 85% (SV50)

IMPORTANT:

A 5 micron (nominal) sediment filter must be installed

before the UV system and after any water softening equipment.

Bypass Shut-off valve: Bypass line and valve are optional. Intended to provide emergency water

4

supply in the event that the UV system is unavailable.

Shut-off valve: Required to allow maintenance of UV system.

5

Solenoid valve: Optional piece of equipment supplied by VIQUA - a Trojan Technologies

6

Company. Allows water supply to be shut-off when proper disinfection cannot be assured (2“

Solenoid available).

Note: If the ground from your electrical panel is tied to your copper water lines, and you are using a

solenoid valve, installation of an approved ground strap is required. This ground strap will maintain

continuity between the lines that have been cut to install the solenoid. Check your local electrical

code for the correct clamp and cable size.

Sample valve: Allows for sampling of water entering UV chamber; necessary in order to confirm

7

water being treated is of adequate quality.

Sensor: Monitors UV output to ensure proper dose (UV exposure) is being provided. Unique test

8

function allows verification of sensor performance.

UV chamber: Provides disinfection of the water. MUST BE INSTALLED VERTICALLY.

9

TM

CoolTouch

10

Sample valve: Allows for sampling of water immediately following UV treatment; necessary in

11

fan: Removes excess heat from water in chamber during periods without water flow.

order to confirm proper operation of UV system.

Shut-off valve: Required to allow maintenance of UV system.

12

Power supply: Powers and controls the UV lamp and other devices. Provides human interface,

13

displaying information and allowing control inputs (such as muting the audible alarm).

Power source: Provides power to the power supply. For safety reasons the outlet must be

14

protected by a Ground Fault Circuit Interrupter (GFCI). NOTE: to protect the power supply, a

UL1449 certified (or equivalent) transient voltage surge suppressor is required.

8

WARRANTYMAINTENANCE

Loading...

Loading...