Viqua S2Q-PA, S2Q-P/12VDC, S8Q-PA, S5Q-PA, S5Q-P/12VDC Owner's Manual

425 Clair Rd. W, Guelph, Ontario, Canada N1L 1R1

t. (+1) 519.763.1032 • f. (+1) 800.265.7246 (US and Canada only)

t. (+31) 73 747 0144 (Europe only) • f. (+1) 519.763.5069

e-mail: info@viqua.com

www.viqua.com

Models:

S2Q-PA, S5Q-PA, S8Q-PA, S2Q-P/12VDC,

S5Q-P/12VDC

NSF Standard 55 Class B

Validated Models:

SV5Q-PA, SV8Q-PA

Owner’s Manual

Powered by

System Tested and Certified by

NSF International against CSA

B483.1 and NSF/ANSI 55 for

Disinfection Performance, Class B

520104_RevL

Congratulations on the purchase of your ultraviolet (UV) water disinfection

system! This system uses the most advanced UV technology on the market and is

designed to provide you with years of trouble free operation with minimal maintenance

required to protect your drinking water from microbiological contaminants.

To ensure ongoing disinfection of your water, UV lamps need to be replaced annually

with VIQUA factory-supplied replacem

ents. VIQUA lamps are the result of extensive

development resulting in a highly efficient disinfection platform with extremely stable UV

output over the entire 9000 hour lifetime. Its success has led to a proliferation of

non-genuine copies in the market.

The UV lamp is the heart of the disinfection system, and there should be no compromise

when it's time for a replacement.

Why should you insist on genuine factory supplied VIQUA replacement lamps?

• Use of wi

dely available, non-genuine, replacement lamps has been shown to damage

the control module of VIQUA UV disinfection equipment.

• An increasi

ng number of calls to VIQUA Technical Support are connected with

non-genuine lamps being used (unknowingly) as replacements.

• Damage arisi

ng from the use of non-genuine lamps poses a safety risk and is not

covered by equipment warranty.

• Unless the UV equi

pment is equipped with a UV sensor (monitor), it is not possible to

verify the UV (invisible) output of replacement lamps.

• Similar appearance to the origi

nal lamp and the presence of (visible) blue light does

not mean equivalent disinfection performance.

• VIQUA replacement lamp

s undergo rigorous performance testing and strict quality

control processes to ensure that the safety and performance certifications of the

original equipment are not compromised.

So, you can see that it's simply not worth the risk! Insist on genuine VIQUA replacement

lamps.

2

Section 1 Safety Information

Please read this entire manual before operating this equipme nt. Pay attention to all dang er , warning, and caution statement s

in this manual. Failure to do so could result in serious personal injury or damage to the equipment.

Make sure that the protection provided by this eq uip m ent is not imp

aired. DO NOT use or install this equipment in any

manner other than that specified in the installation manual.

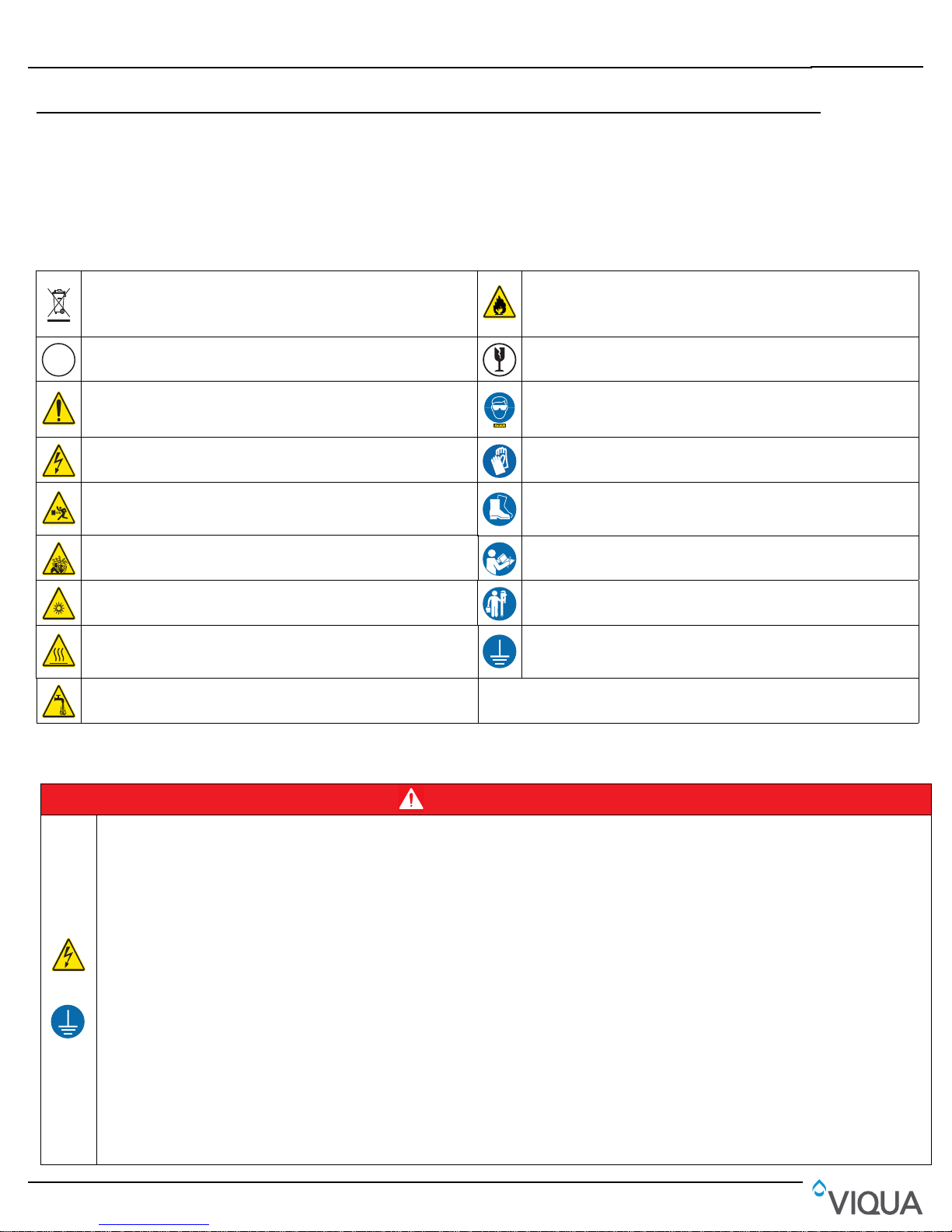

1.1 Potential Hazards:

Read all labels and tags attached to the system. Personal injury or damage to the system could occur if not observed.

Waste electrical and electronic equipment (WEEE). This symbol

indicates that you should not discard wasted electrical or electronic

equipment (WEEE) in the trash. For proper disposal, contact your

local recycling/reuse or hazardous waste center.

This symbol indicates not to store any combustible or flammable

material close to the system.

Hg

This symbol indicates there is Mercury present.

This symbol indicates that the contents of the transport package are

fragile and the package should be handled with care.

This is the safety alert symbol. Obey all safety messages that follow

this symbol to avoid potential injury. When on the equipment, refer to

the Operational and Maintenance manual for additional safety

This symbol indicates safety glasses with side protection is required

for protection against UV exposure.

This symbol indicates a risk of electrical shock and/or electrocution

exists.

This symbol indicates gloves must be worn.

This symbol indicates the marked equipment may contain a

component that can eject forcibly. Obey all procedures to safely

depressurize.

This symbol indicates safety boots must be worn.

This symbol indicates the system is under pressure.

This symbol indicates the operator must read all available

documentation to perform required procedures.

UV

This symbol indicates there is a potential UV hazard. Proper

protection must be worn.

Cu

This symbol indicates the plumber must use copper piping.

This symbol indicates the marked item could be hot and should not

be touched without care.

This symbol indicates that the system should only be connected to a

properly grounded, grounding-type controller receptacle that is

protected by a Ground Fault Circuit Interrupter (GFCI).

This symbol indicates there is a potential for VERY hot water when

flow is started.

Warning: T

his product may contain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

1.2 Safety Precautions:

DANGER

• Electric Shock: To avoid possible electric shock, special care should be taken since water is present near the electrical equipment. Unless a

situation is encountered that is explicitly addressed by the provided maintenance and troubleshooting sections, DO NOT attempt repairs yourself,

refer to an authorized service facility.

• GROUNDING: T

his product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electrical shock. This system is equipped with a cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the outlet is properly grounded. DO NOT modify the plug provided with this system – if it does not fit in

the outlet, have a proper outlet installed by a qualified electrician. DO NOT use any type of adapter with this system.

• GROUND FAULT CIRCUIT INTERRUPTER PROTECTION:

To comply with the National Electrical Code (NFPA 70) and to provide additional

protection from the risk of electric shock, this system should only be connected to a properly grounded, grounding-type controller receptacle that is

protected by a Ground Fault Circuit Interrupter (GFCI). Inspect operation of GFCI as per manufacturer’s suggested maintenance schedule.

• DO NOT oper

ate the disinfection system if it has a damaged cord or plug, if it is malfunctioning or if it has been dropped or damaged in any

manner.

• DO NOT use this disinfe

ction system for other than intended use (potable water applications). The use of attachments not recommended or sold

by the manufacturer / distributor may cause an unsafe condition.

• DO NOT inst

all this disinfection system where it will be exposed to the weather or to temperatures below freezing.

• DO NOT store th

is disinfection system where it will be exposed to the weather.

• DO NOT store th

is disinfection system where it will be exposed to temperatures below freezing unless all water has been drained from it and the

water supply has been disconnected.

Failure to follow these instructions will result in

serious injury or death.

Safety Information

3

CAUTION

• Carefully examine the disinfection system after installation. It should not be plugged in if there is water on parts not intended to be wet such as, the

controller or lamp connector.

• D

ue to thermal expansion concerns and potential material degradation due to UV exposure, it is recommended to use metal fittings and at least 10"

of copper pipe on the outlet of your UV chamber.

• T

he UV lamp inside the disinfection system is rated at an effective life of approximately 9000 hours. To ensure continuous protection, replace the

UV lamp annually.

• T

he UV system is not to be used or played with by children. Persons with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, are also not to handle the UV system unless they have been given supervision or instruction.

• EXTENSION CORDS: If an extensio

n cord is necessary, use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from this system. Use only extension cords that are intended for outdoor use. Use only extension cords having an

electrical rating not less than the rating of the system. A cord rated for less amperes or watts than this system rating may overheat. Exercise caution

when arranging the cord so that it will not be tripped over or pulled. DO NOT use damaged extension cords. Examine extension cord before using

and replace if damaged. DO NOT abuse extension cord. Keep extension cord away from heat and sharp edges. Always disconnect the extension

cord from the receptacle before disconnecting this system from the extension cord. Never yank cord to pull plug from outlet. Always grasp the plug

and pull to disconnect.

• SYSTEM PROTECTION:

To protect your Controller, a UL1449 certified (or equivalent) transient voltage surge suppressor is strongly

recommended.

• T

he UV lamp in this system conforms to the applicable provisions of the Code of Federal Regulations (CFR) requirements including, Title 21,

Chapter 1, Subchapter J, Radiological Health.

• R

ead and understand the Owner’s Manual before operating and performing any maintenance on this equipment.

1.3 Water Chemistry

Water quality is extremely important for the optimum performance of your UV system. The following levels are

recommended for installation:

* Where total hardness is less than 7 gpg, the UV unit should o

perate efficiently provided the quartz sleeve is cleaned

periodically. If total hardness exceeds 7 gpg, the water sho uld be sof t ened. If your water che mistry cont ai ns levels in excess

of those mentioned above, proper pre-treatment is re commended to correct these water problems prior to the installation of

your UV disinfection system. These water quality p arameters can b e tested by your local dealer, or by most private a nalytical

laboratories. Proper pre-treatment is essential for the UV disinfection system to operate as intended.

WAR NI NG

During extended periods of no water flow, the water in your chamber can become very hot (Approx. 60 °C) and potentially lead to scalding. It is

recommended to run your water until this hot water has been purged from your chamber. Do not allow water to contact your skin during this time. To

eliminate this condition, a temperature management valve can be installed at the outlet of your UV system.

Failure to follow these instructions could result in minor or moderate injury.

NOTICE

Water Quality and Minerals Level

Iron < 0.3 ppm (0.3 mg/L)

Hardness* < 7 gpg (120 mg/L)

Turbidity < 1 NTU

Manganese < 0.05 ppm (0.05 mg/L)

Tannins < 0.1 ppm (0.1 mg/L)

UV Transmittance > 75% (call factory for recommendations on applications where UVT < 75%)

Safety Information

4

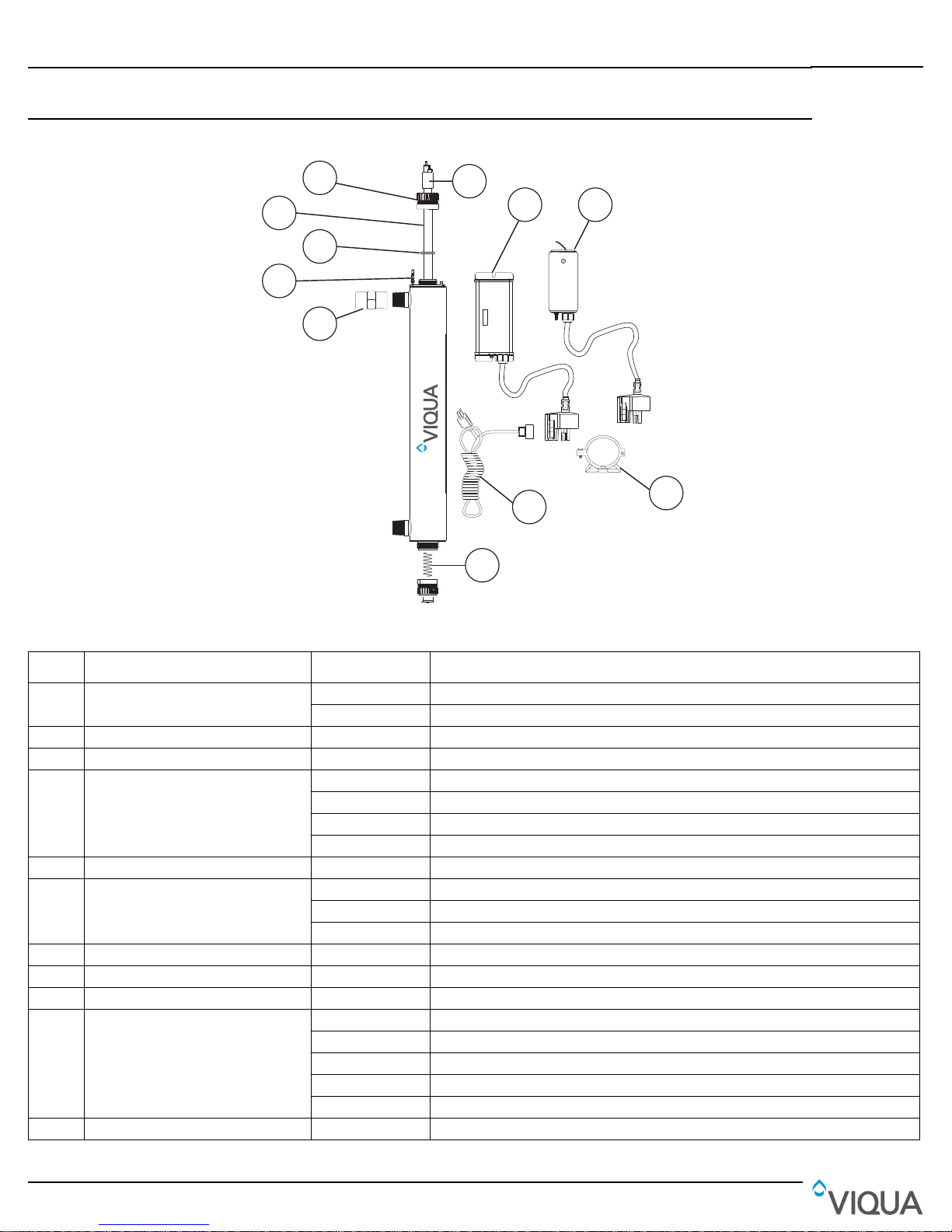

Section 2 General Information

2

3

4

5

6

7

8

9

10

11

1

Figure 1 System Components

Item Description Part Number UV Systems

1

Flow restrictor (Only for certified

models)

440263-R SV5Q-PA

440264-R SV8Q-PA

2 Lamp connector base 270276-R Used on all systems

3 O-ring 410867 Used on all systems

4

Open-ended, 214 fused quartz sleeves

with fire polished ends

QS-001 S1Q-PA

QS-330 S2Q-PA

QS-463 S5Q-PA, SV5Q-PA

QS-810 S8Q-PA, SV8Q-PA

5 Retaining nut RN -001 Used on all systems

6

Hard glass, coated Sterilumze

®

-EX UV

lamps for long, consistent life (9000

hours)

S330RL S2Q-PA

S463RL S5Q-PA, SV5Q-PA

S810RL S8Q-PA, SV8Q-PA

7 Controller (for 100-240V models only) BA-ICE-S S5Q-PA, S8Q-PA, SV5Q-PA, SV8Q-PA

8 Controller (for 12VDC models only) BA-RO/P/12 S2Q-P/12VDC, S5Q-P/12VDC

9 2.5” Mounting brackets 410958-R Used on all systems

10

IEC replacement power cords for

VIQUA ICE Controller (sold

separately)

260010 NORTH AMERICAN (NEMA 5-15P), 3-PRONG GROUNDED

602637 CONTINENTAL EUROPEAN (CEE 7/7) 2-PIN WITH GROUND, “SCHUKO”

260012 UK VERSION (BS 1363) 3-PRONG

GROUNDED (5 AMP FUSE)

260013 AUSTRALIAN VERSION (AS 3112) 3-PRONG GROUNDED

260019 NO CONNECTOR, 3-WIRE, BARE LEADS

11 Spring SP008 Used on all systems

General Information

5

Loading...

Loading...