Viqua IHS12-D4, IHS22-D4, IHS22-E4 Owner's Manual

425 Clair Rd. W, Guelph, Ontario, Canada N1L 1R1

t. (+1) 519.763.1032 • f. (+1) 800.265.7246 (US and Canada only)

t. (+31) 73 747 0144 (Europe only) • f. (+1) 519.763.5069

e-mail: info@viqua.com

www.viqua.com

425 Clair Rd. W, Guelph, Ontario, Canada N1L 1R1

t. (+1) 519.763.1032 • f. (+1) 800.265.7246 (US et Canada seulement)

t. (+31) 73 747 0144 (Europe seulement) • f. (+1) 519.763.5069

Courriel : info@viqua.com

www.viqua.com

425 Clair Rd. W, Guelph, Ontario, Canadá N1L 1R1

t. (+1) 519.763.1032 • f. (+1) 800.265.7246 (solo EE. UU. y Canadá)

t. (+31) 73 747 0144 (solo Europa) • f. (+1) 519.763.5069

correo electrónico: info@viqua.com

www.viqua.com

425 Clair Rd. W, Guelph, Ontario, Canada N1L 1R1

t. (+1) 519.763.1032 • f. (+1) 800.265.7246 (US and Canada only)

t. (+31) 73 747 0144 (Europe only) • f. (+1) 519.763.5069

e-mail: info@viqua.com

www.viqua.com

Models:

IHS12-D4

IHS22-D4

IHS22-E4

Owner’s Manual

Powered by

520166-R_RevM

Congratulations on the purchase of your ultraviolet (UV) water disinfection

system! This system uses the most advanced UV technology on the market and is

designed to provide you with years of trouble free operation with minimal maintenance

required to protect your drinking water from microbiological contaminants.

To ensure ongoing disinfection of your water, UV lamps need to be replaced annually

with VIQUA factory-supplied replacem

ents. VIQUA lamps are the result of extensive

development resulting in a highly efficient disinfection platform with extremely stable UV

output over the entire 9000 hour lifetime. Its success has led to a proliferation of

non-genuine copies in the market.

The UV lamp is the heart of the disinfection system, and there should be no compromise

when it's time for a replacement.

Why should you insist on genuine factory supplied VIQUA replacement lamps?

• Use of wi

dely available, non-genuine, replacement lamps has been shown to damage

the control module of VIQUA UV disinfection equipment.

• An increasi

ng number of calls to VIQUA Technical Support are connected with

non-genuine lamps being used (unknowingly) as replacements.

• Damage arisi

ng from the use of non-genuine lamps poses a safety risk and is not

covered by equipment warranty.

• Unless the UV equi

pment is equipped with a UV sensor (monitor), it is not possible to

verify the UV (invisible) output of replacement lamps.

• Similar appearance to the origi

nal lamp and the presence of (visible) blue light does

not mean equivalent disinfection performance.

• VIQUA replacement lamp

s undergo rigorous performance testing and strict quality

control processes to ensure that the safety and performance certifications of the

original equipment are not compromised.

So, you can see that it's simply not worth the risk! Insist on genuine VIQUA replacement

lamps.

2 47

Garantía del fabricante

Sección 8 Garantía del fabricante

Nuestro compromiso

VIQUA se compromete a asegurar que su experiencia con nuestros productos y organización superen sus expectativas.

Hemos fabricado el sistema de desinfección UV según los más altos estándares y lo valoramos como cliente. Si necesitara

soporte técnico o tiene preguntas acerca de su sistema, póngase en contacto con nuestro equipo de soporte técnico en el

1.800.265.7246 o en technicalsupport@viqua.com. Estaremos encantados de ayudarle. Esperamos que disfrute de las

ventajas que ofrece un agua potable limpia y segura después de la instalación del sistema de desinfección VIQUA.

Cómo realizar una reclamación bajo garantía

Nota: Para maximizar el rendimiento de desinfección y la fiabilidad de su producto VIQUA, el sistema se debe

dimensionar, instalar y mantener adecuadamente. En el manual del propietario encontrará información de utilidad

sobre los parámetros de calidad del agua necesarios y los requisitos de mantenimiento.

En el caso de que se necesitara una reparación o reposición de piezas cubiertas bajo esta garantía, el proceso lo

gestionará el distribuidor. Si no está seguro de si un problema o fallo del sistema está cubierto por la garantía, póngase en

contacto con nuestro equipo de soporte técnico en el 1.800.265.7246 o por correo electrónico en la dirección

technicalsupport@viqua.com. Nuestro técnicos completamente formados le ayudarán a resolver el problema e identificar

una solución. Tenga a mano el número de modelo (tipo de sistema), la fecha de compra, el nombre del distribuidor al que

adquirió el producto VIQUA ("distribuidor de origen") y una descripción del problema que está experimentando. Para

establecer la prueba de compra al realizar una reclamación bajo garantía, ne cesitará su factura original, o bien deberá

haber completado y enviado su tarjeta de registro de producto por correo postal o en línea.

Cobertura específica de la garantía

La cobertura de la garantía es específica de la gama de productos de VIQUA. La cobertura de la garantía está sujeta a las

condiciones y limitaciones establecidas en la sección "Condiciones y limitaciones generales".

Garantía limitada de diez años para la cámara UV de VIQUA

VIQUA garantiza que la cámara UV del producto VIQUA estará libre de defectos de material y mano de obra durante un

período de diez (10) años desde la fecha de compra. Durante este período, VIQUA reparará o reemplazará, a su criterio,

toda cámara UV VIQUA defectuosa. Devuelva la pieza defectuosa a su distribuidor, quién procesará su reclamación.

Garantía limitada de tres años para los componentes eléctricos y de hardware

VIQUA garantiza que los componentes eléctricos (controlador) y de hardware estarán libres de defectos de material

y mano de obra durante un período de tres (3) años desde la fecha de compra. Durante este período, VIQUA reparará

o reemplazará, a su criterio, toda pieza defectuosa cubierta por la garantía. Devuelva la pieza defectuosa a su distribuidor,

quién procesará su reclamación.

Garantía limitada de un año para lámparas UV, vainas tubulares y sensores UV

VIQUA garantiza que las lámparas UV, las vainas tubulares y los sensores UV estarán libres de defectos de material

y mano de obra durante un período de un (1) año desde la fecha de compra. Durante este período, VIQUA reparará

o reemplazará, a su criterio, toda pieza defectuosa cubierta por la garantía. Su distribuidor procesará su reclamación

y ofrecerá consejos sobre si el artículo defectuoso se debe devolver para realizar un análisis de fallos.

Nota: Utilice únicamente lámparas y vainas tubulares de reposición VIQUA originales en el sistema. El incumplimiento de

este requisito podría poner en riesgo el rendimiento de la desinfección y afectar a la cobertura de la garantía.

Condiciones y limitaciones generales

Ninguna de las garantías anteriores cubre los daños provocados por el uso o mantenimiento inadecuados, accidentes,

actos de la naturaleza o arañazos e imperfecciones menores que no afectan materialmente el funcionamiento del

producto. Las garantías tampoco cubren los productos que no se han instalado según las instrucciones del manual del

propietario correspondiente.

Las piezas reparadas o reemplazadas según estas garantías serán cubiertas bajo garantía hasta el final del período de

garantía aplicable a la pieza original.

Las garantías anteriores no incluyen el coste de envío y manipulación de los artículos devueltos. Las garantías limitadas

que se describen anteriormente son las únicas garantías aplicables a la gama de productos VIQUA. En estas garantías

limitadas se describe el único recurso para todas las reclamaciones basadas en un fallo o defecto de cualquiera de estos

productos, ya sea que la reclamación se base en contrato, agravio (incluida la negligencia), responsabilidad estricta u otro.

Estas garantías reemplazan a todas las demás garantías escritas, orales, implícitas o reglamentari as. No corresponde, sin

limitación, ninguna garantía de comerciabilidad o aptitud para un propósito particular a ninguno de estos productos.

VIQUA no asume ninguna responsabilidad por lesiones o daños a la

propiedad causados por el uso o el mal uso de

cualquiera de los productos mencionados anteriormente. VIQUA no será de ningún modo responsable de los daños

especiales, incidentales, indirectos o consecuentes. La responsabilidad de VIQUA se limitará, en todos los casos, a la

reparación o reposición del producto o la pieza defectuosa y esta responsabilidad finalizará al finalizar el período de

garantía aplicable.

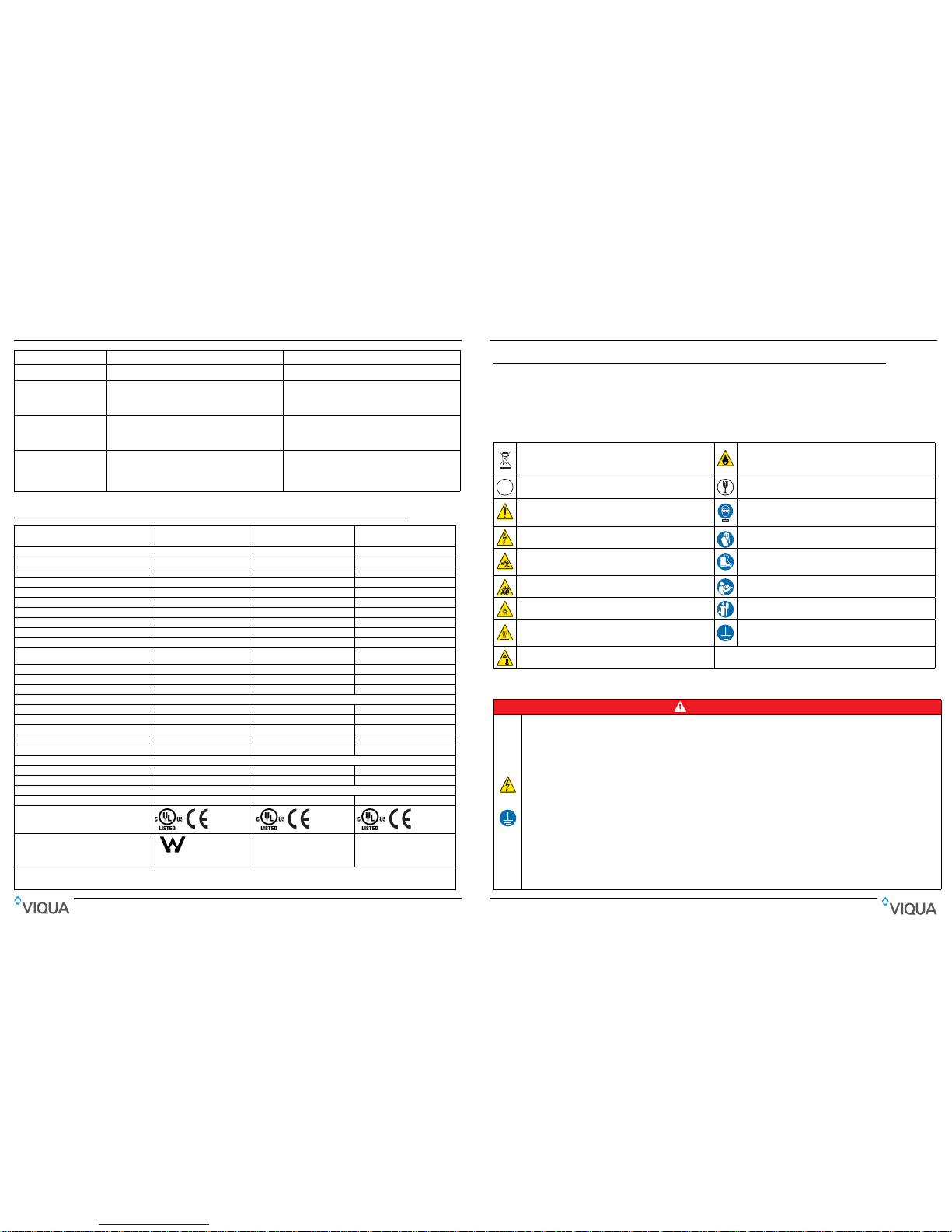

Section 1 Safety Information

Please read this entire manual before operating this equipment. Pay attention to all danger , warning, and caution statemen ts

in this manual. Failure to do so could result in serious personal injury or damage to the equipment.

Make sure that the protection provided by this equipment is not imp

aired. DO NOT use or install this equipment in any

manner other than that specified in the installation manual.

1.1 Potential Hazards:

Read all labels and tags attached to the system. Personal injury or damage to the system could occur if not observed.

Waste electrical and electronic equipment (WEEE). This symbol

indicates that you should not discard wasted electrical or electronic

equipment (WEEE) in the trash. For proper disposal, contact your

local recycling/reuse or hazardous waste center.

This symbol indicates not to store any combustible or flammable

material close to the system.

Hg

This symbol indicates there is Mercury present.

This symbol indicates that the contents of the transport package are

fragile and the package should be handled with care.

This is the safety alert symbol. Obey all safety messages that follow

this symbol to avoid potential injury. When on the equipment, refer to

the Operational and Maintenance manual for additional safety

This symbol indicates safety glasses with side protection is required

for protection against UV exposure.

This symbol indicates a risk of electrical shock and/or electrocution

exists.

This symbol indicates gloves must be worn.

This symbol indicates the marked equipment may contain a

component that can eject forcibly. Obey all procedures to safely

depressurize.

This symbol indicates safety boots must be worn.

This symbol indicates the system is under pressure.

This symbol indicates the operator must read all available

documentation to perform required procedures.

UV

This symbol indicates there is a potential UV hazard. Proper

protection must be worn.

Cu

This symbol indicates the plumber must use copper piping.

This symbol indicates the marked item could be hot and should not

be touched without care.

This symbol indicates that the system should only be connected to a

properly grounded, grounding-type controller receptacle that is

protected by a Ground Fault Circuit Interrupter (GFCI).

This symbol indicates there is a potential for VERY hot water when

flow is started.

Warning: T

his product may contain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

1.2 Safety Precautions:

DANGER

• Electric Shock: To avoid possible electric shock, special care should be taken since water is present near the electrical equipment. Unless a

situation is encountered that is explicitly addressed by the provided maintenance and troubleshooting sections, DO NOT attempt repairs yourself,

refer to an authorized service facility.

• GROUNDING: T

his product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electrical shock. This system is equipped with a cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the outlet is properly grounded. DO NOT modify the plug provided with this system – if it does not fit in

the outlet, have a proper outlet installed by a qualified electrician. DO NOT use any type of adapter with this system.

• GROUND FAULT CIRCUIT INTERRUPTER PROTECTION: T

o comply with the National Electrical Code (NFPA 70) and to provide additional

protection from the risk of electric shock, this system should only be connected to a properly grounded, grounding-type controller receptacle that is

protected by a Ground Fault Circuit Interrupter (GFCI). Inspect operation of GFCI as per manufacturer’s suggested maintenance schedule.

• DO N

OT operate the disinfection system if it has a damaged cord or plug, if it is malfunctioning or if it has been dropped or damaged in any

manner.

• DO NOT use this disinfection system for

other than intended use (potable water applications). The use of attachments not recommended or sold by

the manufacturer / distributor may cause an unsafe condition.

• DO N

OT install this disinfection system where it will be exposed to the weather or to temperatures below freezing.

• DO N

OT store this disinfection system where it will be exposed to the weather.

• DO N

OT store this disinfection system where it will be exposed to temperatures below freezing unless all water has been drained from it and the

water supply has been disconnected.

Failure to follow these instructions will result in serious in

jury or death.

Safety Information

46 3

Especificaciones

Sección 7 Especificaciones

Alarma Consulte Sección 5.1. Consulte Sección 5.1.

El sistema funciona pero las

pruebas de agua indican

contaminación bacteriana

• Los equipos instalados aguas abajo del sistema UV

funcionan como caldo de cultivo de agentes patógenos

• Hay agentes patógenos que residen en las líneas de

distribución posteriores al tratamiento UV

• Recontaminación de extremos sin salida de la canalización

• Asegurarse de que UV sea el último equipo de tratamiento.

• Asegurarse de que todas las líneas de distribución se

hayan desinfectado con cloro. Consulte Sección 3.2.

• Quitar los extremos sin salida de la canalización

y enjuagar con cloro. Consulte Sección 3.2.

El temporizador de la lámpara

no realiza ninguna lectura

• La unidad está desenchufada

• La toma de corriente de CA no tiene alimentación

• El cable de alimentación está dañado

• Una subida de tensión causó daños al conjunto eléctrico

• Enchufar la unidad a una toma de corriente de CA

• Reemplazar el fusible o restablecer el contacto

• Reemplazar el cable de alimentación

• Reemplazar el controlador y usar un protector de

sobretensiones (TVSS)

Fuga detectada en los filtros

• Junta tórica dañada, deteriorada o instalada de manera

incorrecta

• Cartucho de filtro no centrado

• Quitar el cárter, limpiar la junta tórica y las roscas.

Asegurarse de que la junta tórica se haya colocado

correctamente y volver a instalar

• Quitar el cárter, inspeccionar el cartucho para ver si está

dañado, volver a ensamblar asegurándose de que el

cartucho esté centrado

IHS12-D4 / IHS12-D4/2 /

IHS12-D4/2A

IHS22-E4 /

IHS22-E4/2

IHS22-D4 /

IHS22-D4/2

Parámetros de funcionamiento

Presión máxima de funcionamiento 100 PSI (689 kPa) 100 PSI (689 kPa) 100 PSI (689 kPa)

Presión mínima de funcionamiento 4 PSI (27,5 kPa) 4 PSI (27,5 kPa) 4 PSI (27,5 kPa)

Temperatura máxima del aire ambiental 50 ºC (122 ºF) 50 ºC (122 ºF) 50 ºC (122 ºF)

Temperatura mínima del aire ambiental 2 ºC (36 ºF) 50 ºC (122 ºF) 50 ºC (122 ºF)

Humedad máxima 95 % 95 % 95 %

Dureza máxima 120 ppm (7 granos por 3,79 litros) 120 ppm (7 granos por 3,79 litros) 120 ppm (7 granos por 3,79 litros)

Nivel máximo de hierro 0,3 ppm 0,3 ppm 0,3 ppm

Transmisión UV mínima 75 % 75 % 75 %

Caudales

Certificado de clase B NSF a una dosis de

16 mJ/cm

2

a 70 % TUV*

8,9 gpm (33,7 lpm) (2 m

3

/h) _ _

Caudal máximo a una dosis de 16 mJ/cm

2

** 16 gpm (60 lpm) (3,6 m3/h) N/A

1

16 gpm (60 lpm) (3,6 m3/h)

Caudal máximo a una dosis de 30 mJ/cm

2

** 12 gpm (45 lpm) (2,7 m3/h) 22 gpm (83 lpm) (4,95 m3/h) 22 gpm (83 lpm) (4,95 m3/h)

Caudal máximo a una dosis de 40 mJ/cm

2

** 9 gpm (34 lpm) (2 m3/h) 16 gpm (60 lpm) (3,6 m3/h) 9 gpm (34 lpm) (2 m3/h)

Eléctrico

Voltaje CA de 100 a 240 V CA de 100 a 240 V CA de 100 a 240 V

Frecuencia 50 a 60 Hz 50 a 60 Hz 50 a 60 Hz

Corriente máxima 0,5 Amp 0,85 Amp 0,5 Amp

Consumo eléctrico máximo 50 vatios 83 vatios 50 vatios

Potencia de la lámpara 40 vatios 70 vatios 40 vatios

Otros

Material de la cámara UV 304 SST 304 SST 304 SST

Entrada/salida NPT de 1,905 cm NPT de 2,54 cm NPT de 1,905 cm

Otros

Ciclo de vida nominal de la lámpara 1 año 1 año 1 año

Certificación del sistema UV

Solo IHS12-D4/2A

1

El caudal máximo lo determina el filtro de carbón.

*Caudales solo para IHS12-D4/2A.

**Los caudales que se muestran son a TUV del 95 %.

Síntoma Causa probable Posible solución

License# 035007

NSF International

CAUTION

• Carefully examine the disinfection system after installation. It should not be plugged in if there is water on parts not intended to be wet such as, the

controller or lamp connector.

• D

ue to thermal expansion concerns and potential material degradation due to UV exposer, it is recommended to use metal fittings and at least 10”

of copper pipe on the outlet of your UV chamber.

• T

he UV lamp inside the disinfection system is rated at an effective life of approximately 9000 hours. To ensure continuous protection, replace the

UV lamp annually.

• T

he UV system is not to be used or played with by children. Persons with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, are also not to handle the UV system unless they have been given supervision or instruction.

• EXTENSION CORDS: If an extensio

n cord is necessary, use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from this system. Use only extension cords that are intended for outdoor use. Use only extension cords having an

electrical rating not less than the rating of the system. A cord rated for less amperes or watts than this system rating may overheat. Exercise caution

when arranging the cord so that it will not be tripped over or pulled. DO NOT use damaged extension cords. Examine extension cord before using

and replace if damaged. DO NOT abuse extension cord. Keep extension cord away from heat and sharp edges. Always disconnect the extension

cord from the receptacle before disconnecting this system from the extension cord. Never yank cord to pull plug from outlet. Always grasp the plug

and pull to disconnect.

• SYSTEM PROTECTION:

To protect your Controller, a UL1449 certified (or equivalent) transient voltage surge suppressor is strongly

recommended.

• T

he UV lamp in this system conforms to the applicable provisions of the Code of Federal Regulations (CFR) requirements including, Title 21,

Chapter 1, Subchapter J, Radiological Health.

• R

ead and understand the Owner’s Manual before operating and performing any maintenance on this equipment.

1.3 Water Chemistry

Water quality is extremely important for the optimum performance of your UV system. The following levels are

recommended for installation:

* Where total hardness is less than 7 gpg, the UV unit should o

perate efficiently provided the quartz sleeve is cleaned

periodically. If total hardness exceeds 7 gpg, the wate r should be softened. If your water chemistry contains levels in excess

of those mentioned above, proper pre-treatment is recommended to correct these water problems prior to the installation of

your UV disinfection system. These water quality parameters can be tested by your local dealer, or by most private analytical

laboratories. Proper pre-treatment is essential for the UV disinfection system to operate as intended.

WAR N IN G

During extended periods of no water flow, the water in your chamber can become very hot (Approx. 60 °C) and potentially lead to scalding. It is

recommended to run your water until this hot water has been purged from your chamber. Do not allow water to contact your skin during this time. To

eliminate this condition, a temperature management valve can be installed at the outlet of your UV system.

Failure to follow these instructions could result in minor or moderate injury.

NOTICE

Water Quality and Minerals Level

Iron < 0.3 ppm (0.3 mg/L)

Hardness* < 7 gpg (120 mg/L)

Turbidity < 1 NTU

Manganese < 0.05 ppm (0.05 mg/L)

Tannins < 0.1 ppm (0.1 mg/L)

UV Transmittance > 75% (call factory for recommendations on applications where UVT < 75%)

Safety Information

4 45

Funcionamiento

Sección 5 Funcionamiento

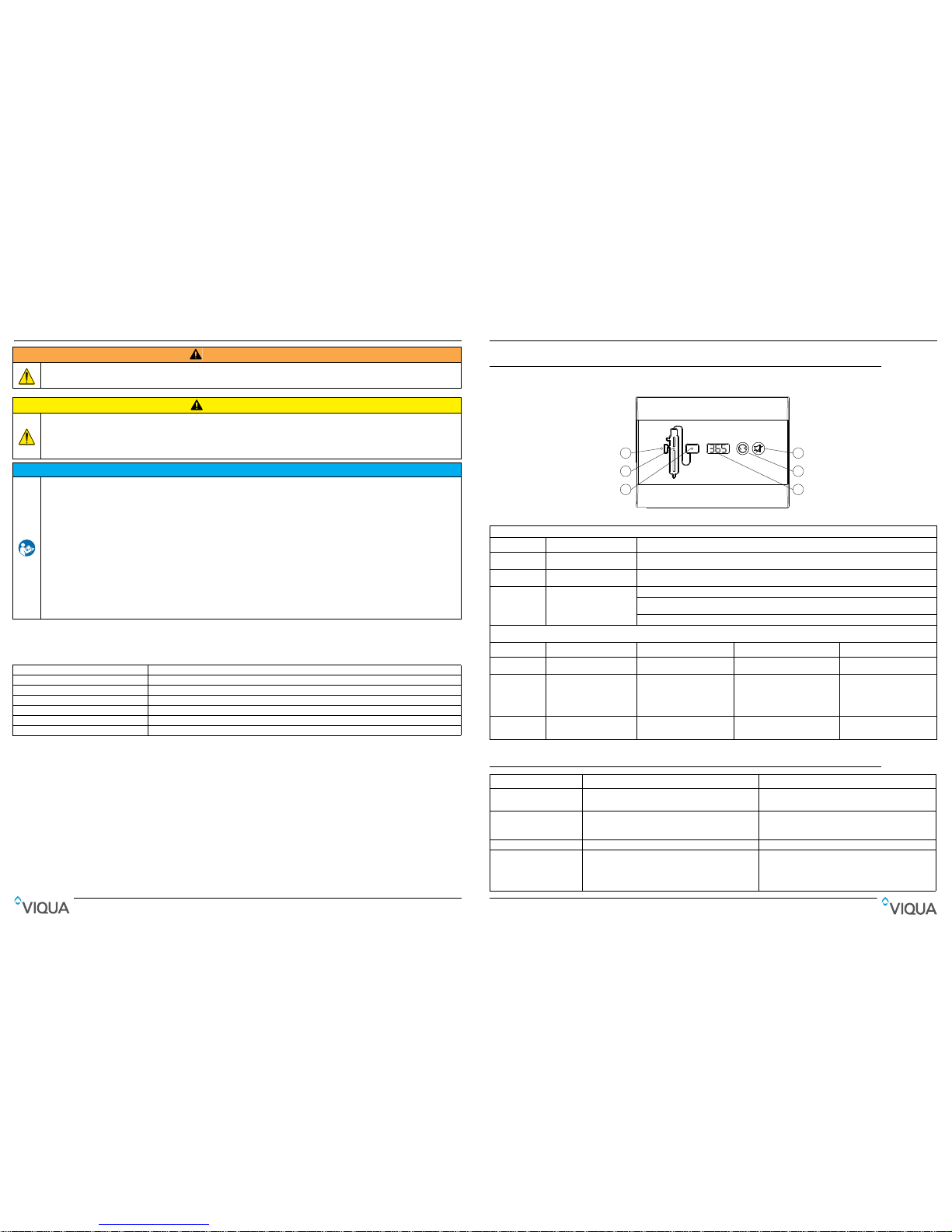

5.1 Controlador

Sección 6 Solución de problemas

Figura 3 Controlador

Botones y pantalla

Característica Descripción Función

A

Pantalla del temporizador de la

lámpara

Hace la cuenta atrás a partir de los 365 días para mostrar el momento de la reposición anua l de la lámpara.

B

Restablecimiento del

temporizador de la lámpara

Después de instalar una lámpara nueva, mantener pulsado durante cinco segundos para restablecer el

temporizador de la lámpara en 365.

C Silencio

Presionar para silenciar la alarma sonora.

Cuando la alarma se debe a la antigüedad de la lámpara, el botón Silencio silenciará la alarma sonora durante

7 días; esto se puede repetir un máximo de 4 veces. Luego, el botón se silenciará solo durante 24 horas.

Cuando la alarma se debe a algún otro problema, el botón Silenciar silenciará la alarma sonora durante 24 horas.

Luces indicadoras

LED Verde Amarillo Parpadea en rojo Rojo continuo

1

Opción no disponible en este

sistema

Opción no disponible en este

sistema

Opción no disponible en este

sistema

Opción no disponible en este

sistema

2

La lámpara funciona con

normalidad

Advertencia: La lámpara se

deberá reemplazar

próximamente

• Lámpara desconectada;

desconectar la alimentación,

volver a conectar la lámpara y

conectar el controlador

• Fallo de la lámpara;

reemplazar la lámpara

Lámpara inactiva debido a un

fallo del controlador

3

El controlador funciona con

normalidad

La temperatura del aire

alrededor del sistema es

demasiado cálida

Fallo del controlador; reemplazar el

controlador

Fallo del controlador; reemplazar

el controlador

Síntoma Causa probable Posible solución

Sin potencia

• Disparo del GFCI o contacto

• Supresor de tensiones transitorias (TVSS) dañado

• Controlador dañado

• Restablecer el GFCI o contacto.

• Reemplazar TVSS

• Reemplazar el controlador y usar TVSS

Disparo repetido del

GFCI o contacto

• La conexión entre la lámpara y el enchufe de la lámpara

está mojada

• Cortocircuito en el conjunto eléctrico

• Limpiar y secar las clavijas de la lámpara y el enchufe de

la lámpara; inspeccionar la unidad en búsqueda de fugas

o condensación

• Reemplazar el controlador

Fuga en la entrada o salida Hay una fuga en los accesorios de canalización con rosca

Limpiar las roscas, volver a sellar con cinta Teflon y volver a apretar

Fuga detectada en el área de

la cámara UV

• Condensación de aire húmedo en la cámara fría

(acumulación lenta)

• Junta tórica dañada, deteriorada o instalada de manera

incorrecta

• Conjunto de lámpara/vaina tubular no instalado

correctamente (demasiado o insuficientemente apretado)

• Controlar la humedad o cambiar la ubicación de la

unidad

• Inspeccionar la junta y reemplazar si está deteriorada

• Apretar el conjunto con la mano

3

2

1

C

B

A

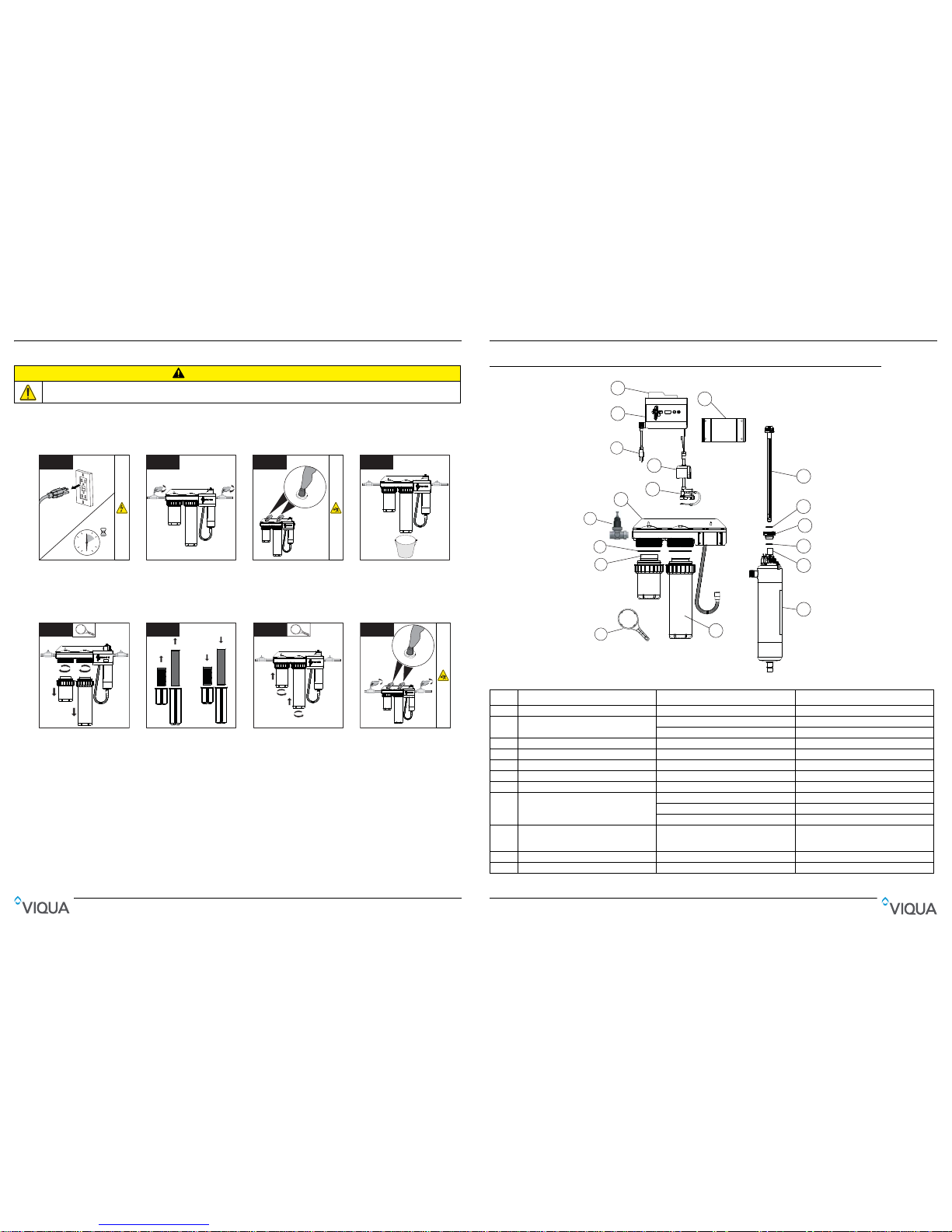

Section 2 General Information

1

2

3

9

6

5

10

14

13

12

13

16

15

17

4

8

11

7

Figure 1 System Components

Item Description Part Number UV System

1 Sump wrench WR40-50 Used on all systems.

2 Sediment filter

CMB-510-HF IHS12-D4, IHS12-D4/2, IHS12-D4/2A

CMB-520-HF IHS22-E4, IHS22-E4/2, IHS22-D4, IHS22-D4/2

3 O-ring OR40-50 Used on all systems.

4 Pressure reducing valve 410992-R IHS12-D4/2A

5Bracket - 6 Lamp cord - 7 Safety cap 603000 Used on all systems.

8 Power cord

602636 (120V) Used on all systems.

602637 (230V) Used on all systems.

260013 (Australian) Used on all systems.

9

Controller

(includes Controller mounting bracket,

Reference card, Safety cap, Lamp cord)

650713-007 Used on all systems.

10 Reference card 603069 Used on all systems.

11 Controller mounting bracket - -

General Information

44 5

4.3 Reposición de los cartuchos

Es recomendable cambiar los cartuchos de filtro periódicamente (3 a 4 veces al año) en función de la calidad y el uso del

agua. Una reducción gradual en la presión del agua después del dispositivo de filtrado es una indicación que los cartuchos

previos al filtro están llegando al final de su vida útil.

Procedimiento:

PRECAUCIÓN

Las carcasas del cárter serán pesadas.

1

0

30

15

45

10 mins

• Desconecte la fuente de

alimentación principal y deje

que la unidad se enfríe

durante 10 minutos.

2

• Corte el suministro de agua.

• Cierre los grifos.

3

• Pulse el botón de presión

para liberar la presión de los

cartuchos.

4

• Quite el tapón de drenaje de

la parte inferior del cárter

y coloque un cubo para

atrapar el agua.

• Vuelva instalar el tapón de

drenaje.

5

11

2

2

• Quite ambas carcasas con

una llave para filtros de agua.

6

Antiguo Nuevo

• Extraiga y descarte los

cartuchos viejos.

• Instale los cartuchos nuevos.

7

1

1

2

2

• Vuelva a instalar las

carcasas.

8

• Abra un grifo aguas abajo del

sistema.

• Restaure la alimentación y

active el suministro de agua.

• Cierre el grifo aguas abajo.

• Pulse el botón de presión

para purgar el aire.

Mantenimiento

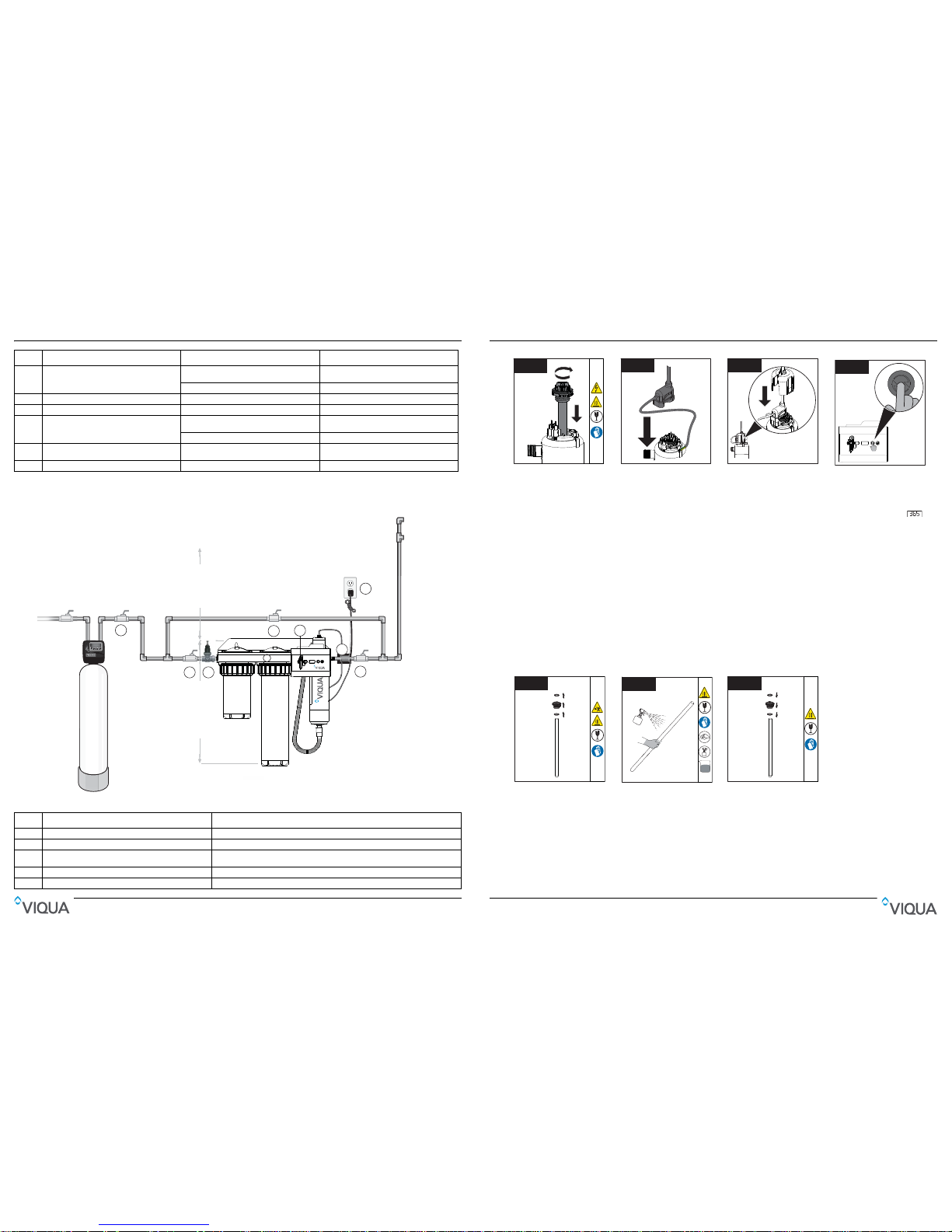

2.1 Dimensions and Layout

Main Water

Shut O

Optional By-Pass Assembly

Hot water pipe

Cold water pipe

1

2

4

7

16” Clearance for

lamp removal

6

3

8

9

Note: IHS12-D4/2A, IHS22-E4 and E4/2 come with quick connect fittings and PEX pipe.

MIN 4” from bottom of unit

for clearance for filter changes

25.5” Overall Length

Optional

Water

Softener

5

Figure 2 System - Dimension and Layout

12 Lamp (includes O-rings)

602805

IHS12-D4, IHS12-D4/2, IHS12-D4/2A,

IHS22-D4, IHS22-D4/2

602806 IHS22-E4, IHS22-E4/2

13 O-ring - Used on all systems.

14 Sleeve bolt 602665 Used on all systems.

15 Sleeve (includes O-rings)

602732

IHS12-D4, IHS12-D4/2, IHS12-D4/2A,

IHS22-D4, IHS22-D4/2

602733 IHS22-E4, IHS22-E4/2

16

UV Chamber (includes Chamber and Ring

clamp).

- Used on all systems.

17 Carbon filter C2-02 Used on all systems.

Item Description Function

1 Main water shut-off valve Allows for sampling of raw water.

2 Shut-off Valve Allows for ease of maintenance of whole home UV disinfection system.

3 Bypass shut-off valve

Bypass line and valve are optional. Intended to provide emergency water supply in the

event that the UV system is unavailable.

4 Shut-off valve Allows for ease of maintenance of whole home UV disinfection system.

5 Whole Home System Provides filtration and disinfection of the water.

Item Description Part Number UV System

General Information

6 43

4.2 Limpieza y reposición de la vaina tubular de cuarzo

Nota: Los minerales del agua van formando lentamente una capa en la vaina tubular de cuarzo de la lámpara. Esta capa

debe retirarse porque reduce la cantidad de luz UV que llega al agua, reduciendo de este modo el rendimiento de la

desinfección. Si la vaina tubular no puede limpiarse, deberá reemplazarse por otra.

Requisitos previos:

• Cortar el suministro de agua y drenar todas las líneas.

• Despresurizar el sistema. Colocar un paño pequeño debajo de la unidad para recoger el agua que pueda caer.

• Quitar la lámpara UV. Consulte Sección 4.1.

Procedimiento:

Notas: 1) Tras reemplazar la lámpara UV o la vaina tubular, realice el procedimiento de desinfección, consulte la Sección 3.2.

2) Si el sistema se desvía temporalmente o si se contamina después del sistema de desinfección, es necesario

completar el procedimiento de desinfección. Consulte Sección 3.2.

9

• Introduzca y asegure el

ensamblaje de la

lámpara/vaina tubular.

Nota: El apriete excesivo

romperá la vaina tubular

10

10

• Alinee las conexiones

girando la abrazadera de

anillo e instale el enchufe de

la lámpara.

11

11

• Introduzca la tapa de

seguridad.

1212

• Restaure la energía.

• Si se ha insertado la lámpara

nueva, mantenga pulsado el

botón de restablecimiento del

temporizador de la lámpara

durante 5 segundos. La

pantalla debería mostrar .

• Abra todos los grifos y las

entradas de agua. Luego

cierre todos los grifos

e inspeccione el equipo para

ver si hay fugas.

1

1

2

3

• Desenrosque el tornillo de la

vaina tubular y quite las

juntas tóricas de la vaina de

cuarzo.

2

Mild

Acid

• Limpie la vaina tubular de

cuarzo con un trapo empapado

en CLR, vinagre u otro ácido

blando y, a continuación,

aclárela con agua.

Nota: Si no es posible limpiar

la vaina tubular por completo

o si se raya o se quiebra,

reemplácela.

3

1

2

3

• Introduzca las juntas tóricas

y apriete el tornillo de la vaina

tubular en la vaina de cuarzo.

• Cuando haya finalizado el

servicio, realice los pasos que

aparecen en los requisitos

previos en orden inverso al

desmontaje.

Mantenimiento

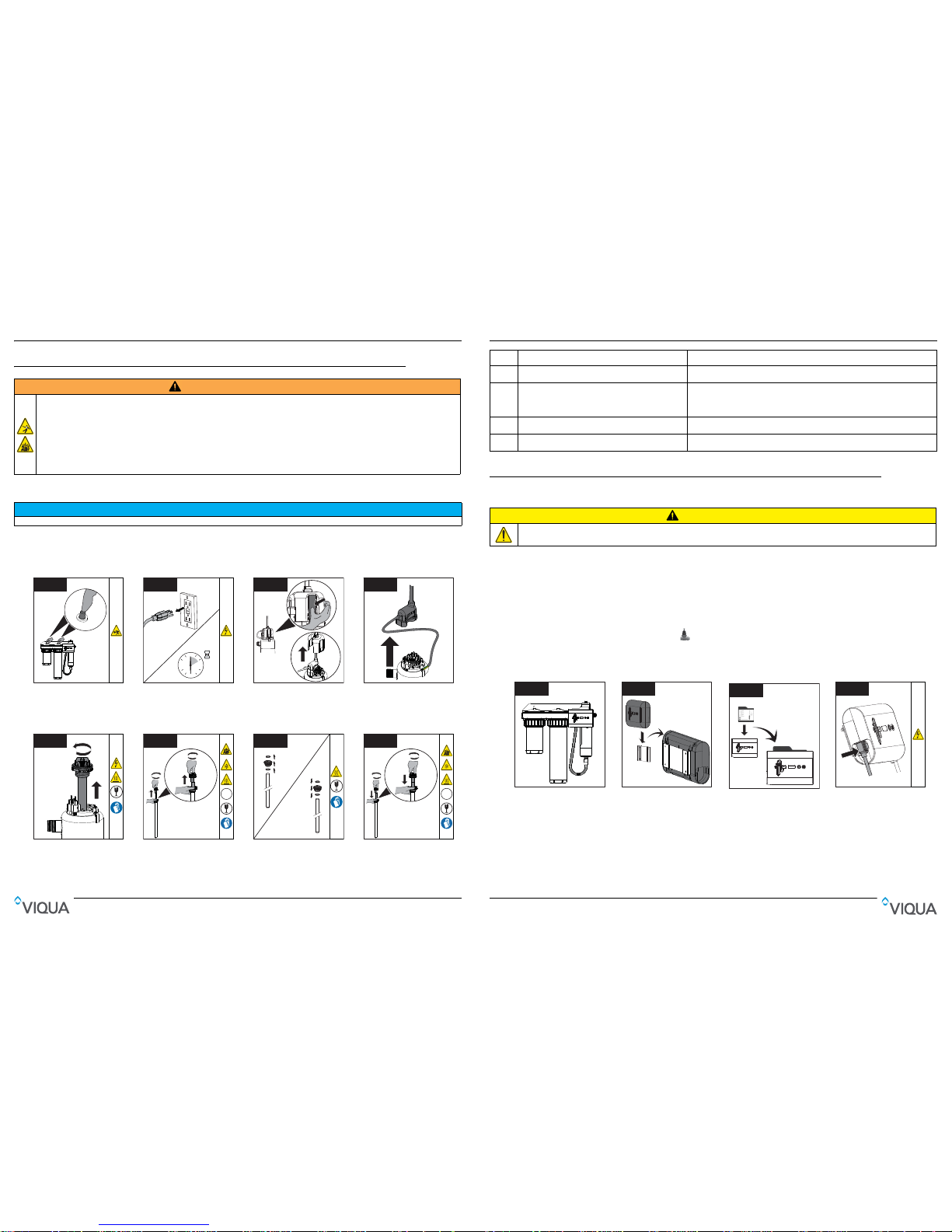

Section 3 Installation

3.1 Installing UV System

CAUTION

Prerequisites:

• Determ

ine appropriate indoor location of the controller and chamber, refer to Section 2.1.

• Make sur

e that the controller is installed higher than the chamber and away from all water sources.

• Ensur

e adequate clearance above chamber to allow for removal of the lamp and sleeve.

• Make sure to t

urn off the main water supply.

• Make all

necessary plumbing connections refer to Section 2.1.

Note: IHS1

2-D4/2A: For shipping purposes, the pressure reducing valve is shipped separately. Install it into the female

inlet and tighten by turning clockwise. A backflow device (n

ot included) is required to be installed downstream of the outlet,

in accordance with Watermark Certification Scheme (WMCS).

Procedure:

1

1

• Install the UV system on the

wall using lag bolts (not

supplied). Mounting holes are

located in the metal bracket.

2

• Slide controller onto mounting

bracket.

3

• Insert the reference card

between controller and

mounting bracket.

4

• Connect power cord to

controller.

• DO NOT connect the power

cord to the GFCI outlet at this

time.

6 Controller

Powers and controls the UV lamp and other devices. Provides human interface,

displaying information and allowing control inputs (such as muting the audible alarm).

7 Power source

Provides power to the controller. For safety reasons the outlet must be protected by a

Ground Fault Circuit Interrupter (GFCI).

Note: To protect the controller, a UL1449 certified (or equivalent) transient voltage surge

suppressor is required.

8 Pressure Reducing Valve:

Controls and maintains a preset desired reduced pressure regardless of variations in

upstream water pressure. (Only for IHS12-D4/2A)

9 Backflow device

A backflow (not included) device is required to be installed downstream of the outlet, in

accordance with the Watermark Certification Scheme (WMCS) (Only for IHS12-D4/2A).

Electronic controller must be connected to a Ground

Fault Protected Circuit (GFCI) receptacle. Ensure green ground wire ring terminal is securely

fastened to ground stud on UV chamber.

Item Description Function

Installation

42 7

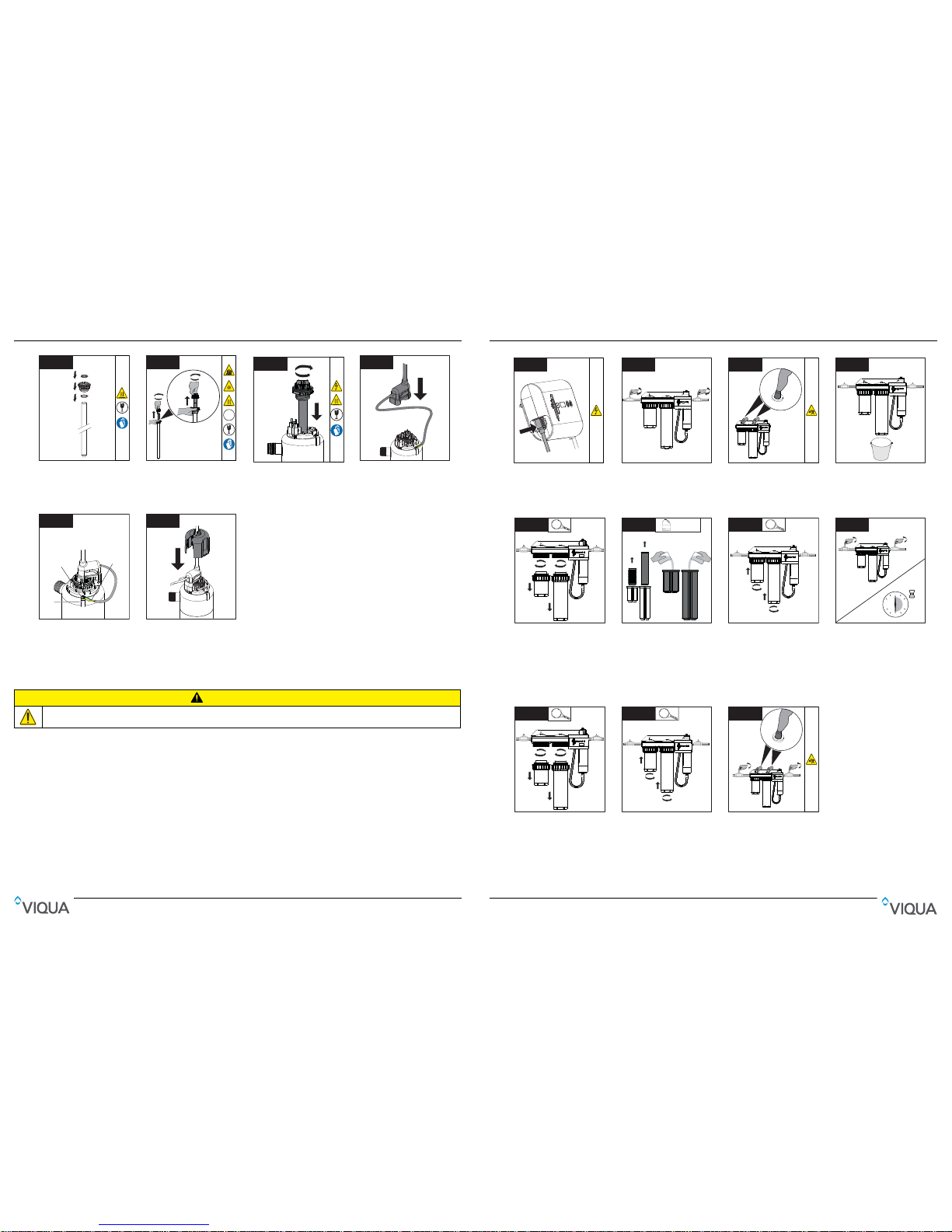

Sección 4 Mantenimiento

4.1 Reemplazo de la lámpara UV

La reposición de la lámpara es un procedimiento rápido y sencillo que no necesita herramientas especiales. Se debe

reemplazar la lámpara después de 9000 horas de funcionamiento continuo (un año aproximadamente) con el fin de

garantizar una desinfección adecuada.

Procedimiento:

ADVERTENCIA

• Desconecte siempre la corriente antes de llevar a cabo cualquier trabajo en el sistema de desinfección.

• Corte siempre el flujo de agua y libere la presión del agua antes de realizar el servicio.

• Examine con frecuencia el sistema de desinfección para asegurar que los indicadores de corriente estén encendidos y que no hay ninguna alarma.

• Reemplace la lámpara UV anualmente (o cada dos años si se trata de un uso casero temporal) para garantizar la máxima desinfección.

• Drene siempre la cámara al cerrar la temporada o al dejar la unidad en un área sujeta a temperaturas de congelación.

• Durante períodos prolongados sin flujo de agua, el agua del depósito se podría calentar excesivamente (aprox. 60 °C) y provocar quemaduras.

Se recomienda hacer correr el agua hasta que se haya drenado el agua caliente del depósito. Durante esta operación, evite que el agua entre en

contacto con la piel. Para eliminar esta condición, se puede instalar una válvula de control de la temperatura en la salida del sistema UV.

AV I S O

No utilice agua durante la reposición de la lámpara UV.

1

• Cierre todos los grifos

y suministros de agua.

• Pulse el botón de presión

para liberar la presión de los

cartuchos.

2

0

30

15

45

10 mins

• Desconecte la fuente de

alimentación principal y deje

que la unidad se enfríe

durante 10 minutos.

3

1

2

• Quite la tapa de seguridad

apretando la pestaña.

Nota: Asegúrese de que los

cables del enchufe de la lámpara

permanezcan conectados.

4

• Quite el enchufe de la lámpara.

Nota: Asegúrese de que los

cables de liberación de tensión

y conexión a tierra

permanezcan conectados.

5

2

1

• Gire el conjunto de

lámpara/vaina tubular hacia

la izquierda y tire de la

lámpara hacia arriba para

extraerla de la cámara.

6

Hg

UV

1

1

2

2

• Sostenga el perno de la vaina

tubular para extraer la

pestaña de la lámpara junto

con la lámpara UV.

7

1

2

3

1

2

3

•

Desenrosque el perno de la

vaina tubular y quite las dos

juntas tóricas de la vaina tubular.

•

Introduzca las dos juntas tóricas

y apriete el perno de la vaina

tubular contra la vaina tubular.

8

Hg

UV

2

2

1

1

• Instale y asegure la lámpara

nueva en la vaina tubular.

Nota: Si se aprieta

demasiado, se romperá la

vaina.

Mantenimiento

5

1

2

3

• Install the sleeve bolt with 2

new O-rings.

6

Hg

UV

1

1

2

2

• Install the lamp into sleeve

and hand tighten.

Note: Over tightening will

break the sleeve.

7

• Insert the lamp/sleeve

assembly into chamber,

screw hand tight.

Note: Over tightening will

break the sleeve.

8

• Align connections by rotating

the ring clamp and install the

lamp plug.

9

Locking

Screw

Ground

Lug

Ground and

strain relief

wires

• Attach ground and strain

relief wires from the lamp

plug to the ground lug on the

chamber. Secure both wires

with locking screw provided.

1010

• Insert the safety cap.

• Restore power.

• Open all faucets and turn on

water supply. Inspect for any

leaks.

3.2 Disinfection Procedure

CAUTION

UV disinfection is a physical disinfection process and does not add any potentially harmful chemicals to the water. As UV

does not provide a disinfection residual, it is imperative that the entire distribution system located after the UV be chemically

disinfected to ensure that the plumbing system is free from any bacteriological contaminants. The disinfection process must

be performed immediately after the UV unit is installed and repeated thereafter whenever the UV is shut down for service,

without power, or inoperative for any reason. The procedure for sanitizing the plumbing system is readily accomplished as

follows:

The sump housings will be heavy.

Installation

8 41

1

• Asegúrese de que el

controlador esté conectado

durante todo el proceso de

desinfección.

2

• Corte el suministro de agua.

• Cierre los grifos.

3

• Pulse el botón de presión

para liberar la presión de los

cartuchos.

4

• Quite el tapón de drenaje de

la parte inferior del cárter

y coloque un cubo para

atrapar el agua.

• Vuelva instalar el tapón de

drenaje.

5

11

2

2

• Quite las carcasas del cárter

con una llave para filtros de

agua.

6

Solución de

lejía de uso

doméstico al 5,25%

LEJÍA

x2 x2

1

2

• Quite los cartuchos y vierta

dos vasos de solución de

lejía de uso doméstico en las

carcasas del cárter.

Nota: NO utilice peróxido de

hidrógeno.

7

1

1

2

2

• Vuelva a instalar las

carcasas.

8

0

30

15

45

30 mins

• Abra todos los grifos

y encienda el suministro de

agua fría seguido de agua

caliente (si está disponible)

hasta que huela la lejía.

• Cierre todos los grifos

y permita que la lejía se

deposite en las líneas de

agua durante 30 minutos.

9

11

2

2

• Corte el suministro de agua.

• Extraiga ambas carcasas.

10

10

1

1

2

2

• Vuelva a instalar los

cartuchos y las carcasas.

11

11

• Limpie todas las salidas de

agua hasta que no huela a

lejía (5 minutos por lo menos).

• Pulse el botón de presión

para purgar el aire y finalizar

el procedimiento de

desinfección.

• Examine si hay fugas.

Desinfección

Loading...

Loading...