Page 1

User Manual

Viper XPT 6000

1-1

Page 2

Viper XPT-6000

Revision 6.12.15.1 – June 12, 2015

1-2

Page 3

Viper XPT-6000

Contents

1.0 SYSTEM OVERVIEW ..................................................................................................... 1

1.1 System Overview ....................................................................................................................................................... 2

2.0 GETTING STARTED ....................................................................................................... 5

2.1 Uncrating ...................................................................................................................................................................... 6

2.2 Stand Assembly .......................................................................................................................................................... 6

2.3 Connecting the Pre-Treatment Fluid Lines .................................................................................................... 6

2.3.1 Selecting Fluids for Spraying ........................................................................................................................... 8

2.4 Connecting Power ................................................................................................................................................... 11

2.5 Preparing Viper for Pre-Treatment ................................................................................................................. 12

3.0 USING THE TOUCH SCREEN INTERFACE ...................................................................... 13

3.1 Control Screen .......................................................................................................................................................... 14

3.1.1 Fluid Laydown ..................................................................................................................................................... 14

3.1.2 Spray Length ........................................................................................................................................................ 14

3.1.3 Spray Zones .......................................................................................................................................................... 15

3.1.4 Job Counter ........................................................................................................................................................... 15

3.2 Zones Screen ............................................................................................................................................................. 16

3.3 Counter Screen ......................................................................................................................................................... 16

3.3.1 Job Counter ........................................................................................................................................................... 17

3.3.2 Total Sprayed ....................................................................................................................................................... 17

3.4 Menu Screen .............................................................................................................................................................. 17

3.4.1 Fluid Maintenance ............................................................................................................................................. 18

3.4.2 Move Platen .......................................................................................................................................................... 18

3.4.3 General Settings .................................................................................................................................................. 18

3.4.4 Language ................................................................................................................................................................ 19

3.3.5 Customize Buttons ............................................................................................................................................. 20

4.0 Spraying a Garment ................................................................................................... 21

4.1 Loading a Garment ................................................................................................................................................. 22

4.2 Setting Spray Parameters .................................................................................................................................... 22

4.2.1 Setting the PT FLUID SPRAY value: ............................................................................................................ 22

4.2.2 Setting the SPRAY LENGTH value: .............................................................................................................. 22

4.2.3 Setting the SPRAY ZONES: .............................................................................................................................. 22

1-3

Page 4

Viper XPT-6000

4.2.4 Fluid Laydown ..................................................................................................................................................... 22

4.3 Starting Spray ........................................................................................................................................................... 23

4.4 Unloading and Curing/Drying Garment ........................................................................................................ 23

4.5 Pre-Treament Fluid Laydown Values ............................................................................................................. 23

5.0 MAINTENANCE .......................................................................................................... 25

5.1 Keeping the Viper Clean ....................................................................................................................................... 26

5.2 Daily Preventative Maintenance ....................................................................................................................... 26

5.2.1 - Nozzle/Spray Tip Maintenance ..................................................................................................................... 26

5.2.2 - Cleaning the Viper Nozzle Tips : ................................................................................................................... 27

5.2.3 - To Clean the Yellow Spray Suppressant Guards : ................................................................................. 28

5.3.4 Machine Body Maintenance ........................................................................................................................... 28

5.3 Weekly Preventative maintenance ............................................................................ 29

5.3.1 Nozzle/Spray Tip Maintenance .................................................................................................................... 29

5.3.2 Machine Body Maintenance ........................................................................................................................... 31

5.3.3 Internal Maintenance ....................................................................................................................................... 32

5.3.4 Flushing the Fluid System with Image Armor CLEANING SOLUTION ......................................... 33

6.0 Troubleshooting ........................................................................................................ 35

6 Troubleshooting ........................................................................................................................................................... 36

6.1 General Troubleshooting ..................................................................................................................................... 36

6.1.1 - The Viper will not turn on/doesn’t have any power: ........................................................................... 36

6.1.2 - The Viper will not spray pre-treatment fluid: ......................................................................................... 36

6.1.3 - The Spray Pattern is “blotchy” ....................................................................................................................... 36

6.1.4 - The Spray Pattern has gaps or appears to not be irregular: ............................................................. 37

6.1.5 - There are drips inside the spray chamber: .............................................................................................. 38

6.1.6 - I can’t load in any pre-treatment fluid or water: ................................................................................... 38

6.1.7 - Certain Spray Heads will not spray fluid: ................................................................................................. 39

6.1.8 - The moving platen shudders, grinds or binds when trying to move in or out or spraying: 39

7.0 Appendix .................................................................................................................. 41

7 Appendix.......................................................................................................................................................................... 42

7.1 Appendix A – Stand Assembly....................................................................................................................... 42

7.2 Appendix B – Pre-Treatment Fluid Laydown Values .......................................................................... 43

7.3 Appendix C – Valve and Fluid Connection Information ..................................................................... 44

7.4 Appendix D – Image Armor CLEANING SOLUTION: ............................................................................ 45

1-4

Page 5

Viper XPT-6000

7.5 Appendix E – Disassembling, Cleaning, and Reassembling the Brass Pressure Relief Valve

47

7.6 Appendix F – Disassembling, Cleaning, and Reassembling the Exit By-Pass Solenoid ......... 49

7.7 Appendix G – Disassembling, Cleaning, and Reassembling the Fluid Pump .............................. 51

7.8 Appendix H – Disassembling, Cleaning, and Reassembling the Spray Head Solenoid .......... 52

7.9 Appendix I – SPRAY TIP CLOGGING AND WEAR................................................................................... 54

7.10 Appendix J – Image Armor CLEANING SOLUTION: .............................................................................. 56

7.11 Appendix K – Pretreating Basics with the Viper XPT-6000 .............................................................. 58

1-5

Page 6

Viper XPT-6000

1-6

Page 7

1.0 SYSTEM OVERVIEW

1

Page 8

Viper XPT-6000

1.1 System Overview

WARNING!!! The Viper XPT is designed for applying pre-treatment fluid to apparel that will be used

for white ink direct-to-garment printing. User assumes all risks associated with the use of the

machine and the fluids run through the Viper XPT.

WARNING!!! Disconnect Viper from power source before any servicing of the machine to reduce

potential for shock.

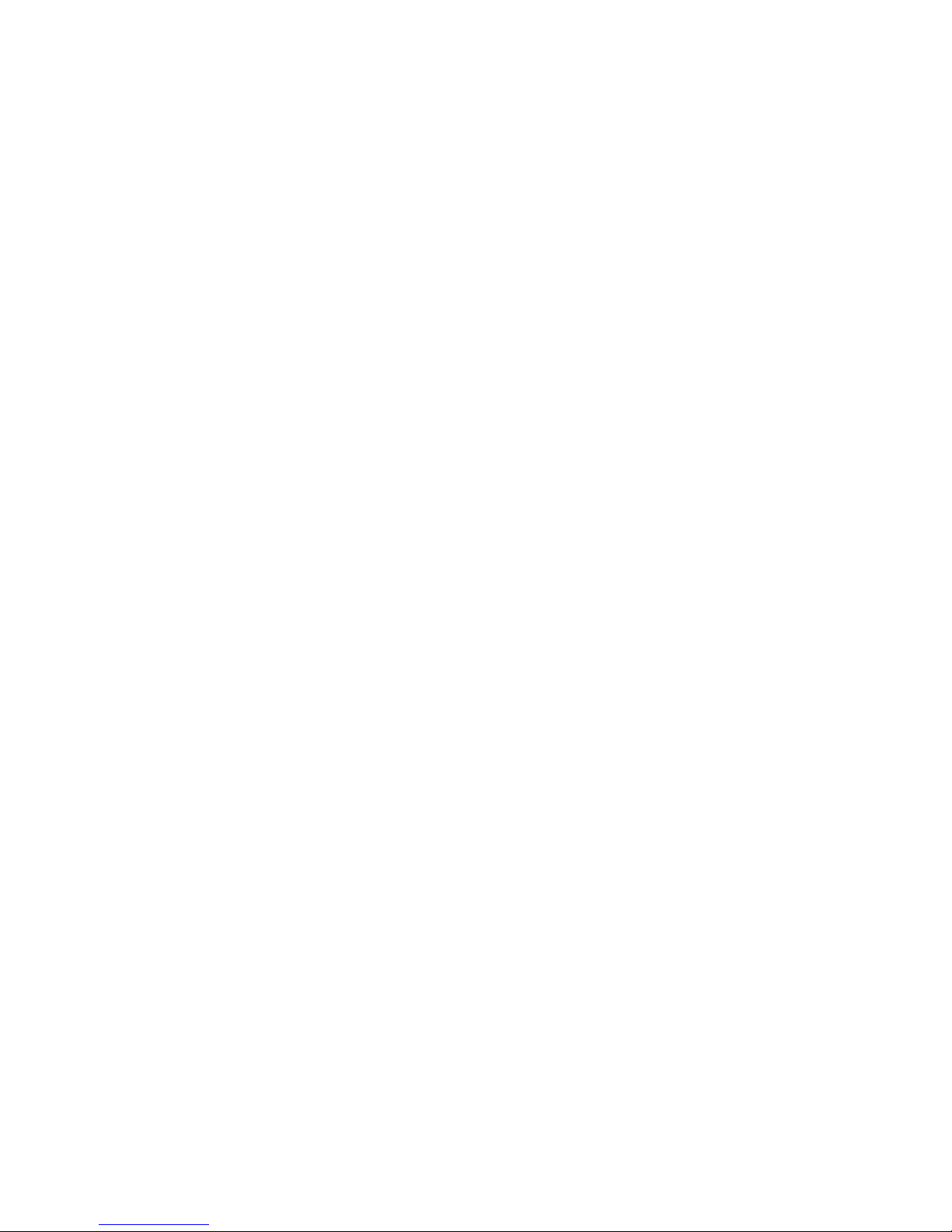

Viper XPT Specifications

Dimensions: 43.25” x 35.125” x 17” (109.85cm x 89.22cm x 40.32cm)

Weight: Viper 148 lbs. / 40lbs stand

110VAC (230VAC European model)

1.5 amps

Diaphragm pump with over pressure relief valve set to 60 psi

Other Information regarding the Viper:

2

Page 9

Viper XPT-6000

LABELS:

Keep all bodily parts and items away from and out of these areas.

Shock Hazard – 110V/220V input point. This is to warn that the

unit needs to be disconnected from the power source before servicing or cleaning the

machine.

Fuse Holder CAUTION – Warning for replacing the fuse with the

correct sized fuse (1.5 amp GMA type) and also to remind the user to disconnect the

machine from the power source prior to changing the fuse.

The Viper XPT-6000 is an industrial system to apply a pre-treatment solution to garments that are

to be printed on a digital inkjet garment printer. Features include:

Touch screen interface

Control of spray length and fluid laydown

Zone Spraying – save pretreatment by selecting zone / shirt size to be treated:

o Full Adult

o Left Chest

o Right Chest

o Youth

o Infant

o Independent Spray Head Control by the User

3

Page 10

Viper XPT-6000

Interchangeable Platens

o Adult

o Youth

o Infant

Minimal bounce and overspray of sprayed pre-treatment solution

Multi-lingual interface

Plug & Play – just power up the machine to start treating

Easy to load and unload garment on platen

Easy weekly maintenance

Job and total counters

Ideal and consistent pre-treatment solution lay-down

4

Page 11

2.0 Getting Started

2.0 GETTING STARTED

5

Page 12

Viper XPT-6000

CAUTION: The unit is heavy and requires at least two people to lift the Viper from the box

when placing it on the stand. Use proper lifting techniques.

Fig. 2.3 B – Firmly insert tube.

2.1 Uncrating

1. Remove the Viper’s included metal stand and assemble (See Section 2 below) before removing

Viper from shipping crate.

2. Once stand is assembled, remove excess cardboard from around Viper and lift unit straight off

crate and onto stand.

3. The Viper’s back will sit flush with the back of the stand, and the feet on the base will drop onto

the stand foot rests.

4. You can adjust the feet of the Viper by rotating the feet pads to either raise or lower the feet to

level the Viper as it sits on the metal stand.

2.2 Stand Assembly

Please see Appendix A, Stand Assembly, for stand assembly instructions.

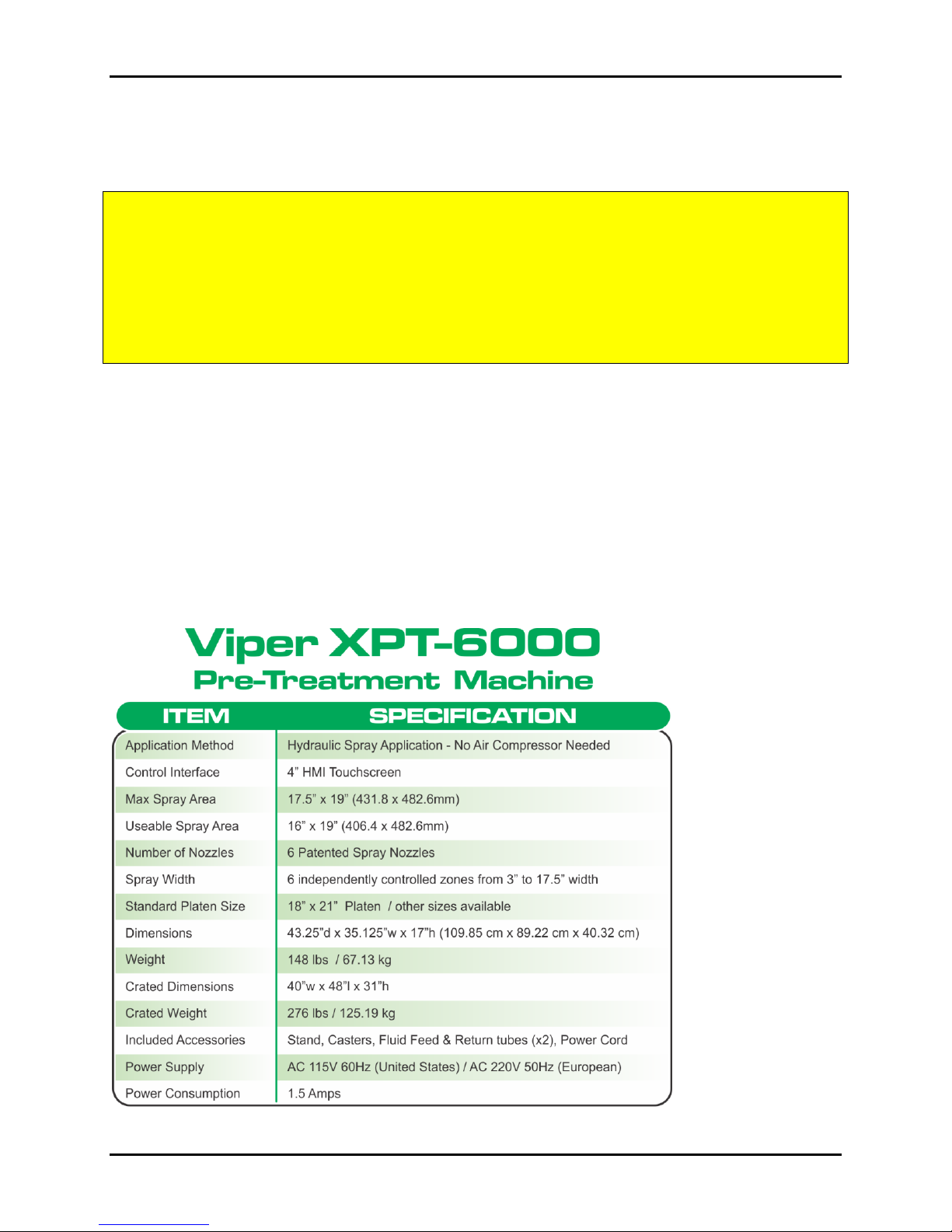

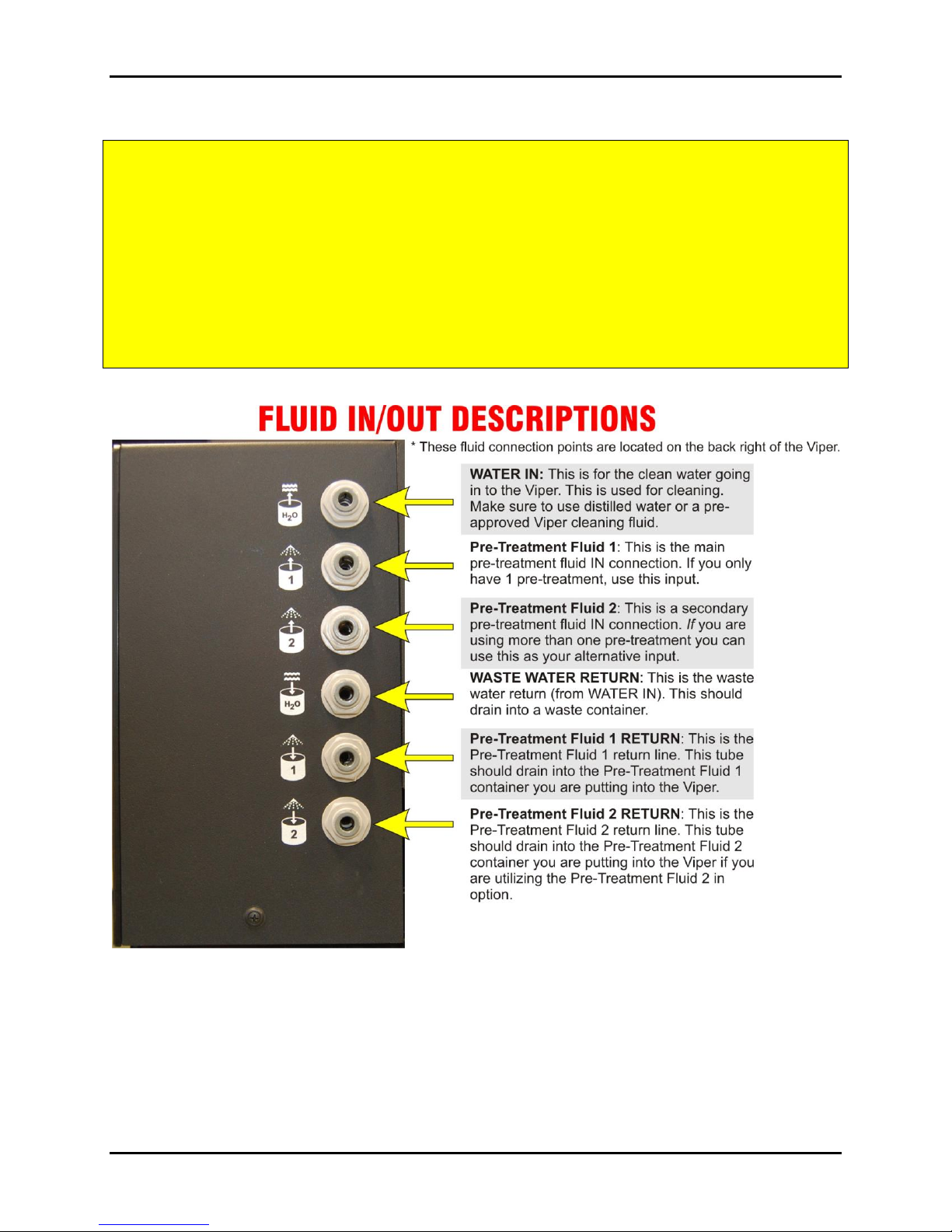

2.3 Connecting the Pre-Treatment Fluid Lines

1. Find the 4 included tubes and 2 clear filters and unpack.

2. Insert one tube in each of the following ports on the back of the

machine by inserting the tube firmly into the connector. (Figure

2.3B)

3. One tube will connect to the Water IN quick connect.

Make sure that the tube labeled IN is inserted into this port.

6

Page 13

Viper XPT-6000

CAUTION: REVERSING THIS FLUID OUT HOSE CAN RESULT IN A PRESSURE

BUILD UP THAT CAN BLOW THE CHECK VALVE OFF THE TUBE CONNECTION

POINT OR A TUBE CAN BURST IN THE SPRAY CABINET. USE EXTREME CAUTION

WHEN HOOKING THIS UP.

4. Another tube will connect to the Pre-Treatment 1 IN quick connect. Make sure that the

tube labeled IN is inserted into this port.

5. The third tube will connect to the Water Out/Waste quick connect.

6. The fourth tube will connect to the Pre-Treatment 1 OUT quick connect. The fluid out

tube for the pre-treatment has a clear check valve on one end. This end has a shorter hose tube

connected to the check valve. The SHORT end of the hose is what is placed into the pre-treatment

container.

7. Take the two supplied white rigid plastic tubes and thread the Water In and Pre-treatment 1 In

tubes through the white rigid plastic pipe. (The and ports on the back of the

machine)

8. Connect a clear filter to each of the two tubes you just put through the white rigid plastic pipe.

(The Water In and Pre-treatment 1 In ports).

9. Place the pre-treatment IN and OUT tubes in your pre-treatment solution containers. Place the

water IN tube in a container with water, and the water OUT in a waste container*.

7

Page 14

Viper XPT-6000

WARNING: It is highly recommended that you use distilled water for cleaning out routines

and Image Armor CLEANING SOLUTION for general maintenance in the Viper. Failure to do

so violates the warranty.

NOTE: * Pre-treatment, water and waste containers are not included. Use the pre-

treatment solution container, your own containers or order Viper branded containers,

available online from ViperXPT.com. Additional tubes for connecting a second pre-

treatment are also available.

** See Appendix 7.3 for detailed information on the Valve and Fluid Ports.

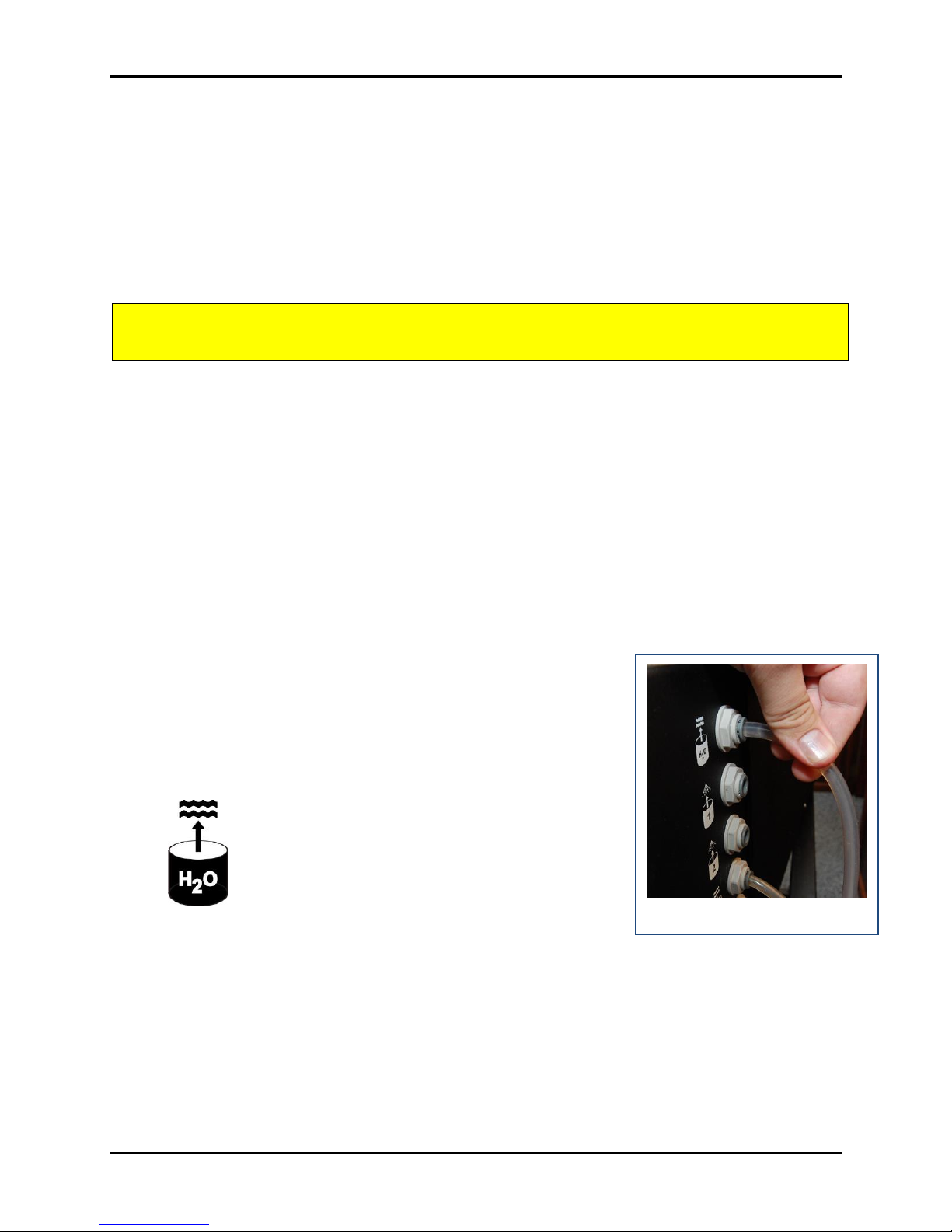

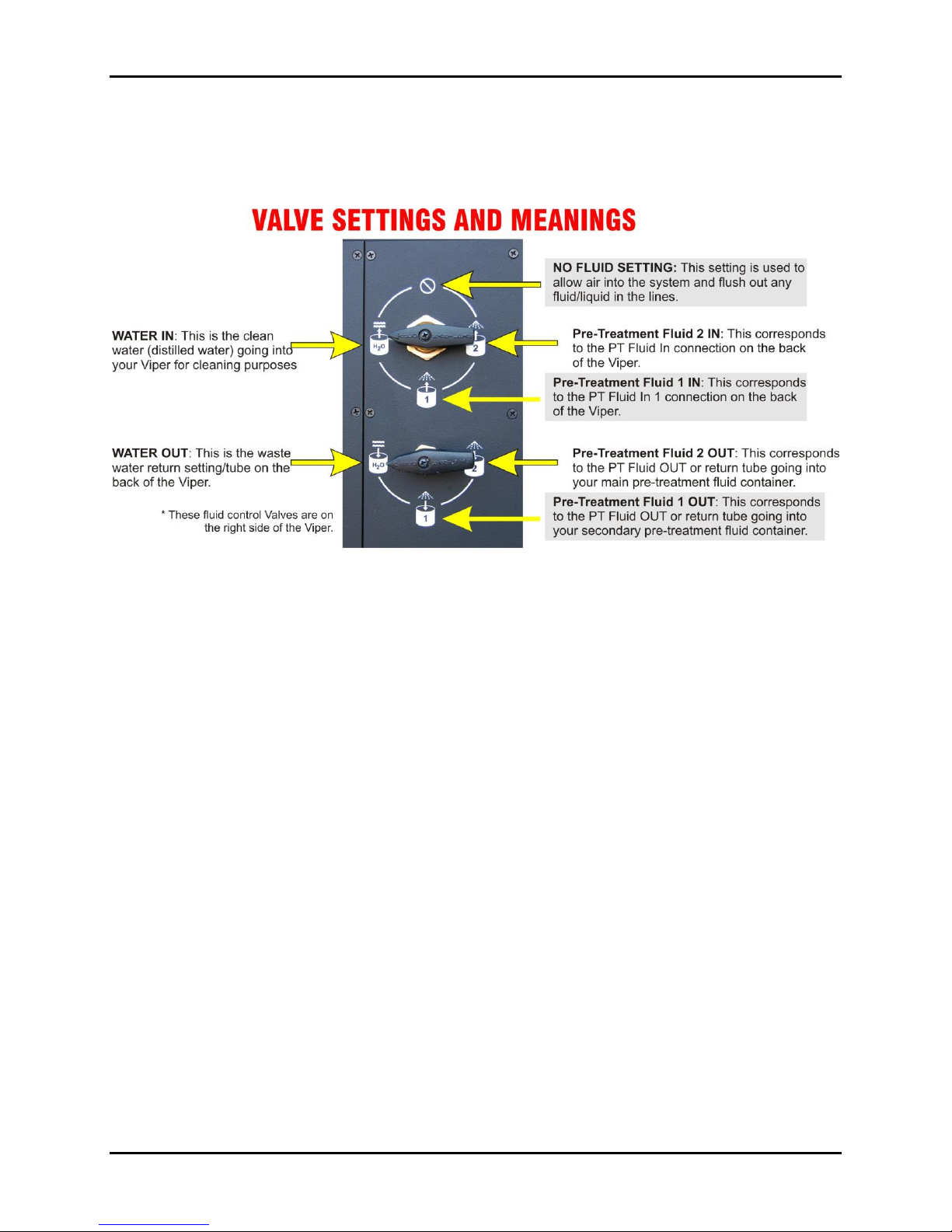

2.3.1 Selecting Fluids for Spraying

During the normal course of use you will need to select different fluids for different purposes. You can

select water for use in cleaning the Viper and flushing the fluid lines to keep your machine operating in

top condition.

8

Page 15

Viper XPT-6000

Here’s a quick guide to the Valves and how to use them.

The valve selector on the top allows you to select which fluid you would like to allow the Viper to use or

pull into the delivery system. There are 4 options for this valve:

Water In (used for cleaning the Viper)

Pre-Treatment Fluid 1

Pre-Treatment Fluid 2

None (allows air into the system to flush all fluids out of the fluid delivery system in the Viper).

The valve selector on the bottom is the return fluid (fluid out of the Viper) selector. This valve setting will

allow the fluid that is not used in the system to be returned to an external container. There are 3 options

for the bottom valve:

Waste Water Return

Pre-Treatment Fluid 1 Return

Pre-Treatment Fluid 2 Return

Normally you will position the top and bottom valve selectors to the same input/output selection choice.

To Select a Fluid:

1. Turn the top selector to the fluid of your choice.

2. Turn the bottom selector to the fluid of your choice.

9

Page 16

Viper XPT-6000

WARNING! Do not turn the bottom valve selector to the 12 o’clock position. This is not a valid option

and will result in the possibility of the Viper fluid delivery system over pressurizing and resulting in a

tube failure. This will create a wet mess in your machine you will have to clean up. Only position the

bottom valve in the 9 o’clock position (Waste water return), 6 o’clock position (Pre-Treatment 1 return)

or the 3 o’clock position (Pre-Treatment 2 return).

10

Page 17

Viper XPT-6000

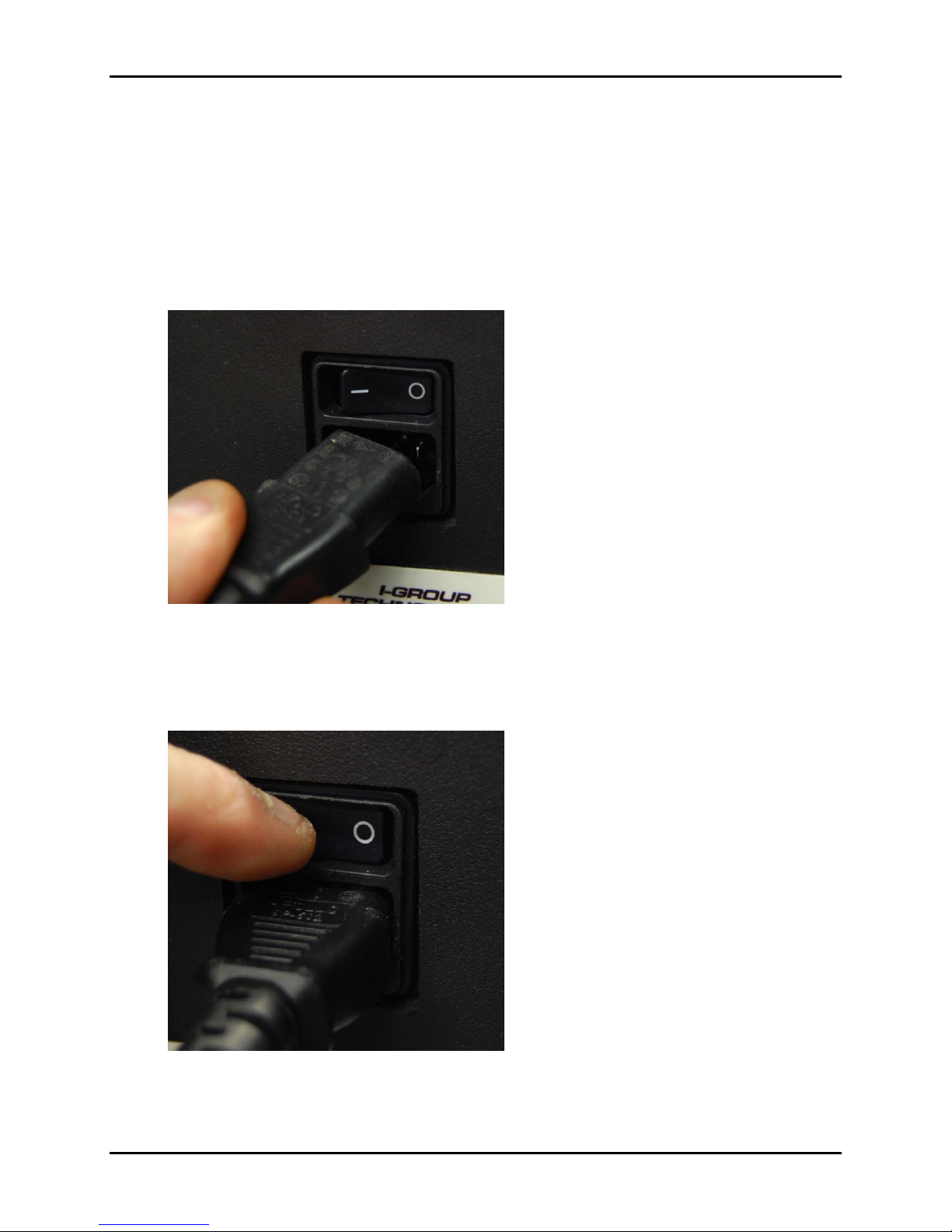

2.4 Connecting Power

1. Plug the power cable into the Viper’s power port, located on the right side of the machine, then

plug into a grounded outlet.

2. Power on the Viper XPT by toggling the power switch, located on the right side of the machine

above the power cord.

11

Page 18

Viper XPT-6000

2.5 Preparing Viper for Pre-Treatment

1. Eject the platen

2. On the touch screen, select the Menu tab at the top.

a. Select Platen In/Out option.

b. The platen will move in or out depending on the direction that it last traveled. If the

platen moves in, select the Platen In/Out button to move the platen back out.

3. Place the included yellow Sham-moo cloth on the platen once it is ejected

4. Select the Fluid Maintenance button on the menu screen, then select the Fill button

5. Follow the On-Screen instructions to complete the line fill.

12

Page 19

Viper XPT-6000

3.0 USING THE TOUCH

SCREEN INTERFACE

13

Page 20

Viper XPT-6000

3.1 Control Screen

The control screen is the main screen of the Viper’s

touch screen interface will load when the Viper is

powered on. This screen allows for change the

fluid laydown, the length of the spray, and zone of

the shirt that pre-treatment will be applied to. You

can also navigate to any of the menus by pressing

the tabs at the top of the screen.

3.1.1 Fluid Laydown

The fluid laydown option changes the amount of liquid that is sprayed. To change fluid laydown,

you can press the numerical display which will allow you to manually enter a fluid laydown value or

you can press one of the preset “buttons”.

If you press the numerical number display,

enter a fluid laydown value between 17 and

100 (17 being less, 100 being more). Press

enter to activate the value and close the popup.

Fluid laydown values control the amount of

fluid that is sprayed. For more information on

choosing the laydown value that is appropriate

for your application, please see section 4.2.1,

Choosing Fluid Amounts.

3.1.2 Spray Length

The spray length determines the length down the platen that fluid is sprayed. To change the spray

length, press the numerical value. On the popup input screen, enter the desired spray length in

inches. Press enter to activate the value and close the popup.

14

Page 21

Viper XPT-6000

You can also press the + or – increment buttons to increase or decrease the spray length values.

3.1.3 Spray Zones

The Viper is designed with 6 independently controllable spray heads. This allows you to save

money in pre-treating by reducing the amount of fluid laid down on the garment by “zoning” your

spray pattern.

The Viper has several built-in preset spray configurations. These configurations are changed simply

by pressing on the image of the Shirt on the main display screen. Each tap of the shirt will change to

the next available preset value and the spray length indicator on the shirt will also change to

visually indicate the new spray pattern.

These spray patterns are as follows:

● Full Adult

● Left Chest

● Right Chest

● Youth

● Infant

● Independent Spray Head Control by the User

You can also independently control each spray head by clicking on the Custom Spray Zone button to

the right of the T-Shirt icon to manually select each head to create your own spray patterns. See

section 3.2 for more information on this feature.

3.1.4 Job Counter

The job counter shows how many spray cycles have been completed for the current job. This value can

be reset from the Counter screen. See section 4.3 for more information.

15

Page 22

Viper XPT-6000

3.2 Zones Screen

The Zones screen (or tab) allows you to manually select and turn on specific spray heads on the Viper to

allow you to create a customized spray pattern. The heads are numbered 1 through 6 from left to right and

correlate to the spray heads as you stand in front of the Viper. Simply press the corresponding round

circle below the indicated head to turn it on, press it again to turn it off.

After you have selected the heads you want to turn on and spray, press the RETURN button. This will

return you to the Main User Screen and display a CUSTOM SPRAY PATTERN text in the t-shirt icon to

indicate you are in a custom spray pattern.

3.3 Counter Screen

The Counter Screen shows you the total number of garments sprayed since you have turned the machine

on as well as the total sprayed on the unit. You can only reset the JOB COUNTER by pressing the

RESET JOB COUNTER button.

16

Page 23

Viper XPT-6000

3.3.1 Job Counter

The JOB COUNTER shows the total number

of shirts sprayed since you turned the Viper on

or since you last pressed the RESET JOB

COUNTER button.

3.3.2 Total Sprayed

The total sprayed counter shows the total

number of sprays that have been completed on

the Viper XPT-6000. This counter cannot be reset.

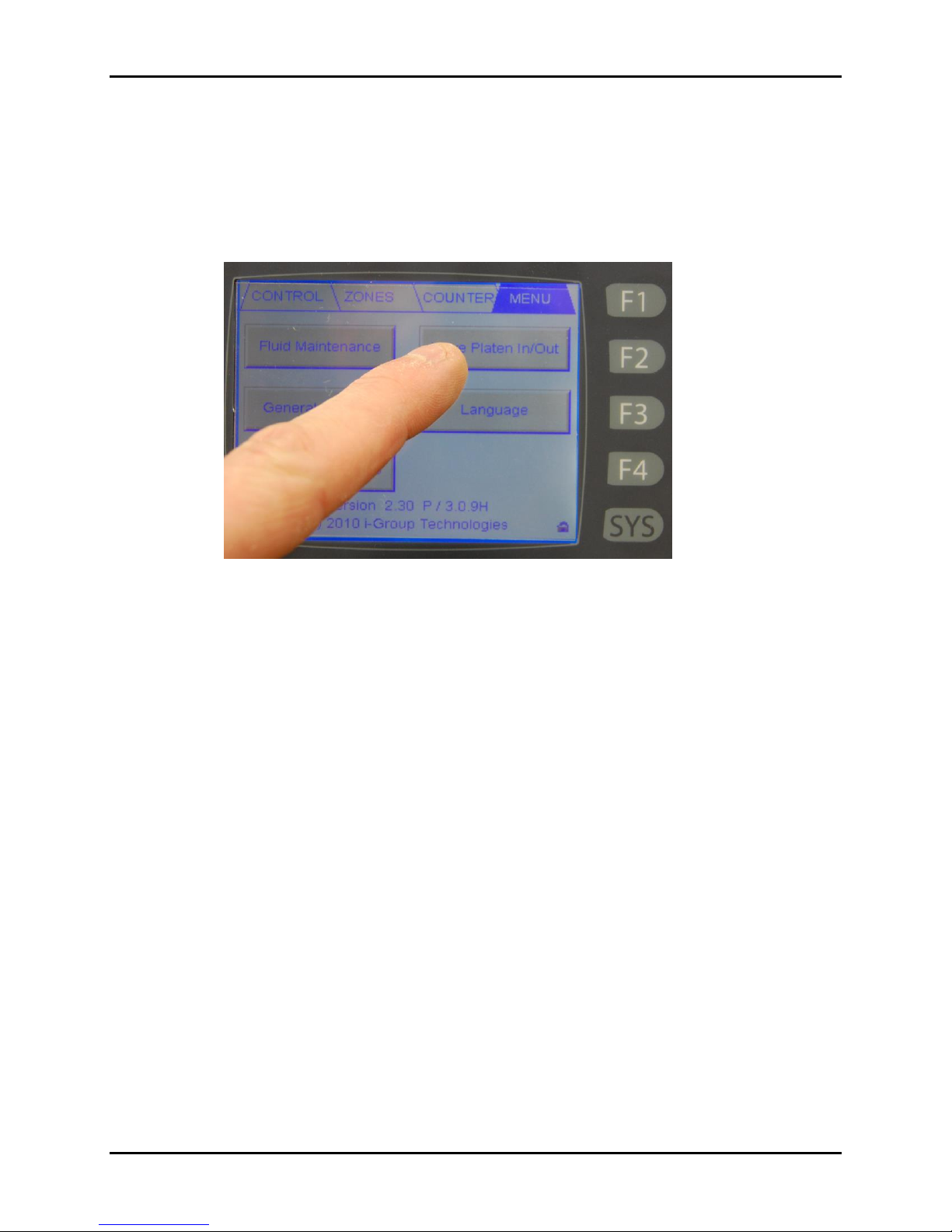

3.4 Menu Screen

The MENU tab screen contains several buttons that allow you to do general maintenance on the Viper as

well as changing the general settings on the touch screen, selecting the language to be displayed on the

touch screen as well as changing and setting the user modifiable PT Fluid laydown buttons.

17

Page 24

Viper XPT-6000

Figure 4.7 – The GENERAL SETTINGS options

3.4.1 Fluid Maintenance

The Fluid Maintenance button will provide you with several options to load, clean, empty and change

fluids within the Viper XPT. Specific fluid maintenance routines are explained the Maintenance section

of this manual.

3.4.2 Move Platen

By pressing the MOVE PLATEN IN/OUT button will cause the platen on the Viper to move either in or

out. If the platen is in the complete OUT position and you press the MOVE PLATEN IN/OUT button the

platen will be moved so that it is completely in the back of the unit. This is the preferred position for

storage when power is turned off to the Viper.

If the Platen is somewhere in between the full out position and the full in position, the platen will return to

the home starting point when the MOVE PLATEN IN/OUT button is pressed.

3.4.3 General Settings

The GENERAL SETTINGS button allows

you to set the following items on your Viper

control screen:

A MACHINE STATUS CODE is also

displayed on the GENERAL SETTINGS

screen. This is only used when trying to

diagnose a problem with the Viper and when

a certified Viper technician asks for it.

18

Page 25

Viper XPT-6000

Figure 4.7 – The BRIGHTNESS/CONTRAST

options settings.

Figure 4.7 – The DATE/TIME

options settings

Figure 3.4.4 – LANGUAGE button allows you to

select English, Spanish, French or German.

3.4.3.1 - Setting the Brightness/Contrast

When you press the SET BRIGHTNESS/

CONTRAST button you will be able to manually

set the brightness and contrast of the touchscreen.

Simply use your finger to drag the lever for each

option to increase or decrease the values to allow

you to easily view the touchscreen in under your

shop’s conditions.

3.4.3.2 - Setting the Date/Time

When you press the SET DATE/TIME button you will be

able to set the touch screen’s date and time that is

displayed on the main screen.

3.4.4 Language

By pressing the LANGUAGE button you

will be able either select:

English

Spanish

French

German

19

Page 26

Viper XPT-6000

Figure 4.5 – The CHANGE BUTTONS option

allows you to customize the PT Fluid spray button

values and display text.

3.3.5 Customize Buttons

The CUSTOMIZE LABELS screen allows you to

manually set the button labels found on the main

User Interface screen. These values are associated

with the “preset buttons” for the PT Fluid

Laydown on the main user screen. The text for the

buttons can contain up to 8 characters maximum.

The values associated with those buttons can be

preset to a value between 16 and 40. The higher

the value the more fluid is applied to the garment

when the machine is operated. Simply select the

button on the right side of each label or value

amount to bring up a data entry box where you can

type in the values you want for the selected item.

20

Page 27

Viper XPT-6000

4.0 SPRAYING A GARMENT

21

Page 28

Viper XPT-6000

4.1 Loading a Garment

There are two methods for loading a garment onto the Viper platen.

1. The shirt can be loaded onto the platen in a manner similar to loading a screen printing press.

Simply hold the shirt open so that the side of the shirt to be sprayed lies on top of the platen and

non-sprayed side lies on the platen support tray. This is the preferred method since you can more

easily smooth out the shirt to get rid of wrinkles.

2. The shirt can also just lay flat on top of the platen. This method can be used to load smaller shirts

that will not fit onto the adult platen; however it is more prone to misplacement and wrinkles.

4.2 Setting Spray Parameters

4.2.1 Setting the PT FLUID SPRAY value:

Before using the Viper each time you must set the PT FLUID LAYDOWN value by selecting it from one

of the preset buttons or by manually entering a PT FLUID LAYDOWN value in the in numerical display.

The higher the number, the more fluid is applied to the garment. A value of 17 will lay down a minimal

amount of fluid. A value of 100 will lay down the maximum amount allowed by the Viper.

4.2.2 Setting the SPRAY LENGTH value:

You will need to set the spray length value of the area to be pre-treated. Simply set a value of between 1”

and 19” in length. This should correspond to the image size you are printing. Just remember to allow for

about a 1” – 1.5” on the top and bottom for clearance when loading the pre-treated shirt onto your direct

to garment printer. This will give you some “wiggle room” in case you don’t position the shirt correctly

on the garment printer.

4.2.3 Setting the SPRAY ZONES:

You will also want to set the spray zone that is applicable for your design being printed. If you are doing a

left chest, you would only want to spray the left side of the shirt – not the whole width of the shirt.

4.2.4 Fluid Laydown

Where applicable, for each sub-function referenced within a section in 4.x, describe in detail and depict

graphically the sub-function name(s) referenced. Include screen captures and descriptive narrative.

22

Page 29

Viper XPT-6000

4.3 Starting Spray

To apply the pre-treatment to the shirt, make sure that the shirt is loaded correctly and all the settings are

appropriate, press the green START button. The Viper will pull the platen into the Viper and spray the

shirt.

NOTE: If there is an issue where you need to stop the machine immediately for any reason, press the red

EMERGENCY STOP button at any time. This will stop all motion of the Viper as well as turn all pumps

and solenoids to the off position.

4.4 Unloading and Curing/Drying Garment

Any shirt that has been pre-treated will need to be removed from the Viper and cured or “dried”. The

most common method of curing the pre-treatment is by using a heat press. Check with your

manufacturer’s pre-treatment instructions for the curing / drying of the pre-treatment.

4.5 Pre-Treatment Fluid Laydown Values

The chart in figure 4.5 is a sample representation of the amount of fluid laid down by the Viper XPT.

Though all pre-treatment fluid is going to weigh slightly differently, the chart will get you within general

guidelines. You must refer to the manufacturer’s pre-treatment guidelines for the proper amount of pretreatment to be applied to the garments. This may vary from manufacturer to manufacturer for lights and

darks or other types of pre-treatment solutions.

23

Page 30

Viper XPT-6000

Figure 4.5 – The above chart is a general representation of the amount of fluid laid down on the garment.

The most accurate way to measure the amount of fluid that the Viper is spraying for your particular pretreatment fluid is to use a gram scale. First weight the un-treated shirt and zero or tare out the gram scale.

Then pre-treat the shirt for the manufacturer’s recommended pre-treatment area and then re-weigh the

shirt. The resulting grams of PT fluid are how much the Viper sprayed for that particular PT FLUID

SETTING value.

24

Page 31

5.0 Maintenance

5.0 MAINTENANCE

25

Page 32

5.1 Keeping the Viper Clean

WARNING! Disconnect the Viper XPT from the power source by unplugging the power inlet cord

from the machine before doing any maintenance work or cleaning.

After use of the Viper, pre-treatment bounce will start to accumulate on the plastic deck and housing. It is

recommended that after each use that a damp rag or sponge is used and wipe down the plastic decking,

aluminum shirt support tray, and interior to keep the pre-treatment from accumulating. This will reduce

further maintenance and keep your machine running more smoothly.

You can also open the garage door of the unit to wipe down the insides of the spray chamber. A clean

Viper will give you many years of dependable service!

WARNING! To open the front “garage door” or the Viper use both hands and lift the garage door from

the middle of the door opening.

5.2 Daily Preventative Maintenance

5.2.1 - Nozzle/Spray Tip Maintenance

To keep the Viper’s fluid systems and spray tips functioning correctly, run the Viper’s Clean routine once

per day.

26

Page 33

Items needed:

1 L Distilled water

Waste bucket or container

1. Run the “Water In” hose to the distilled water. Run the “Water Out” hose to a waste bucket or

container.

2. Power on the Viper and select the Menu Screen (or press the F4 button).

3. From the Menu Screen, click the Fluid Maintenance button.

4. From the Fluid Maintenance screen, select the Clean button.

5. Follow all on-screen instructions

6. Discard wastewater after clean routine is complete

You also need to remove the absorbent Yellow Spray Suppressant Guards that lines the inside of the front

garage door and behind the spray bar. These yellow Spray Suppressant Guards collect over spray to help

keep your Viper cleaner and hold onto excess spray bounce. These are held in with Velcro.

5.2.2 - Cleaning the Viper Nozzle Tips:

After flushing the system with distilled water you will

want to use a very soft bristle toothbrush and clean the

nozzle tips using Image Armor CLEANING SOLUTION.

CLEANING THE NOZZLE TIPS IS NECESSARY TO

PREVENT ANY PRE-TREATMENT SOLUTION FROM

REMAINING ON THE NOZZLE TIPS AND DRYING OUT

CAUSING SPRAY PATTERN PROBLEMS. FAILURE TO DO THIS WILL RESULT IN NOZZLE TIPS THAT

MAY NOT BE ABLE TO BE CLEANED TO RETURN THE VIPER TO ITS ORIGINAL SPRAY PATTERN.

THE USER WILL THEN NEED TO PURCHASE A NEW TIP TO REPLACE NOZZLE TIPS THAT ARE THE

RESULT OF DRIED PRE-TREATMENT OR PRE-TREATMENT BUILDUP ON THE TIPS.

1. Take the toothbrush provided and some Image Armor CLEANING SOLUTION.

2. Starting with Nozzle Tip 1 unscrew the nut and take tip out of the machine.

3. Clean the tip with the wet tooth brush. Make sure to clean the entire tip thoroughly.

4. After cleaning Nozzle Tip 1, rinse the tooth brush off and re-wet.

5. Repeat Steps 2 and 3 until all the nozzle tips have been cleaned.

27

Page 34

6. Soak the tips in the small container provided with Image Armor CLEANING SOLUTION so that

the tips are completely submerged.

** NOTE: Sometimes stubborn dried deposits on the tips will cause distortions of the spray pattern.

Soaking the tips in the Image Armor CLEANING SOLUTION overnight and then repeating steps 1-4

above can help remove the deposits and restore clean spray patterns. Thoroughly rinse the tips off

with distilled water to remove any residue of the CLEANING SOLUTION.

5.2.3 - To Clean the Yellow Spray Suppressant Guards:

1. Remove the guards (fabric) from the inside of the garage door and from behind the spray heads

from the Velcro attachment points.

2. Rinse under warm water and squeeze to remove pre-treatment build up.

3. Repeat rinsing until no more pre-treatment is remaining in the suppression guards.

4. Wring dry.

5. You can heat press the suppression guards flat and to dry them out. Doing this will result in a

smooth, flat suppression guard to allow for easier installation back into the Viper.

6. Replace the suppression guards centering them on the provided Velcro strips.

a. Make sure the suppression fabric behind the spray bars hangs below the elbow (rear point

where the hinge connects) so that it hangs down below that elbow point by about ½”.

b. Insert the front suppression guard – centering it on the Velcro strip. You can leave this

hang down slightly below the front edge of the throat /opening of the garage door. At

least keep the guard even with the bottom of the front opening on the door to keep buildup of fluid from happening and resulting in potential drips of fluid on to your garments.

5.3.4 Machine Body Maintenance

To prevent pre-treatment buildup on the Viper, clean the machine’s body once per day, minimum. If the

unit is being used heavily and any pre-treatment fluid is building up on the deck or other body

components make sure to wipe these areas down before they get a chance to leak or drain into the

mechanical areas of the Viper.

Items needed: Image Armor CLEANING SOLUTION

1. Lift the “garage door” hood of the Viper.

28

Page 35

Figure 5.3.1 – Removing the spray tip nut. Be careful the o-ring doesn’t come out along with the nozzle

tip.

2. Using the Image Armor CLEANING SOLUTION, thoroughly clean all accessible surfaces of the

machine. Make sure to clean up any pre-treatment residue.

3. With the platen in the full out position you can remove the platen and reach back into the Viper to

clean the plastic in those areas. This will prevent buildup of residue inside the machine keeping

the machine running smoother.

5.3 WEEKLY PREVENTATIVE MAINTENANCE

5.3.1 Nozzle/Spray Tip Maintenance

If you have a persistent problem with a spray tip nozzle pattern you may need to remove the tip to try to

clean it more thoroughly or to remove any contaminants that might be clogging the tip.

Items needed: Toothbrush, distilled water, Image Armor CLEANING SOLUTION

1. Remove nozzle from spray head one at a time by loosening black nut. Be careful when removing

the spray tip as there is black O-ring that seals the tip to the spray head solenoid. Sometimes the

O-ring will come off with the spray tip. Other times it will remain in the spray solenoid. Be very

careful to NOT LOSE THIS O-RING OR THE HEAD WILL LEAK WHEN APPLYING PRETREAMTMENT.

29

Page 36

Figure 5.3.2 – Scrub the spray tips with Image

Armor CLEANING SOLUTION, then rinse with

warm soapy water and a tooth brush.

2. Gently scrub nozzle with the provided toothbrush and water until clean. Be sure to thoroughly

clean spray orifice. We also recommend using the Image Armor CLEANING SOLUTION to

scrub the tip with. The tip should be free from any buildup or pre-treatment residue.

NOTE: For tips that have stubborn build up on the tips or in the tips running the nozzle tips through your

dishwasher/Ultrasonic Cleaner might help. Make sure to use high temp water setting if available on your

dishwasher. This might help break up other deposits on your tips that the toothbrush might not be able to

remove otherwise. Additional replacement tips are available by calling i-Group Technologies.

3. Replace spray tip and black nut. When tightening the tip back into place make sure that it is at a slight

angle to the other tips. This angle should be about a 10 degree angle – refer to one of the other tips for

reference.

30

Page 37

Figure 5.3.3 – Replace the tip and black nut that holds the tip

4. Repeat with other nozzles.

5.3.2 Machine Body Maintenance

To prevent pre-treatment buildup on the Viper, clean the machine’s body once per day, minimum. If the

unit is being used heavily and any pre-treatment fluid is building up on the deck or other body

components make sure to wipe these areas down before they get a chance to leak or drain into the

mechanical areas of the Viper.

Items needed: Image Armor CLEANING SOLUTION

4. Lift the “garage door” hood of the Viper.

5. Using the Image Armor CLEANING SOLUTION, thoroughly clean all accessible surfaces of the

machine. Make sure to clean up any pre-treatment residue.

6. With the platen in the full out position you can remove the platen and reach back into the Viper to

clean the plastic in those areas. This will prevent buildup of residue inside the machine keeping

the machine running smoother.

31

Page 38

5.3.3 Internal Maintenance

You may find it necessary to access the transport system of the Viper. If this is necessary you will need to

remove the Garage Door and Rear Access Panel.

To Remove Garage Door and Rear Access Panel

Take off the Garage Door and remove all 8 of the screws holding the Rear Panel on.

To Access the Transport System

Once the Garage Door and Rear Access Panel are removed you will see the platen assembly and the

access panel on the Viper deck. To gain entry to the Transport System you’ll need to remove the platen

assembly and take off the access panel.

Removing the Bellows

To access the transport system for cleaning you will need to remove the bellows.

1. The bellows are held in position with Velcro.

2. To remove the front bellow, carefully lift the tabs from the connection points on the shoe. Once

that is free, you can carefully separate the Velcro from the bellows where they attach on the front

of the machine. Remove the rear bellow in the same fashion.

3. Once removed, the bellows can be rinsed under warm water to rinse off the pretreatment buildup.

Cleaning the Rail System

Use a clean, lint free; damp cloth can be used to wipe down the rail system completely removing any

residue of pretreatment. Ensure that the rails are cleaned completely even in the crevices. Also, clean the

rail guides that the platen shoe plate rest on. Completely clean any residue of pretreatment from these

rails. After that, apply a light white lithium grease to the screw drive. DO NOT apply grease to the rails!

This is a greaseless system.

Re-Assemble the Viper

Re-assemble the machine in the reverse order that it was disassembled.

32

Page 39

5.3.4 Flushing the Fluid System with Image

Armor CLEANING SOLUTION

The Image Armor CLEANING SOLUTION is designed to be

re-circulated through your Viper XPT-6000 via the H2O Fluid

IN and OUT ports. It is highly suggested that you utilize a 1

Quart container like the Image Armor CLEANING SOLUTION

1 Quart sized container as your re-circulation fluid holder.

How to Use the Image Armor CLEANING SOLUTION

1. Empty the Viper of pretreatment by running a Fluid Empty routine per on screen

instructions.

2. Place the water IN and OUT fluid lines into a container of Image Armor CLEANING

SOLUTION.

3. Run a Fluid FILL routine as per the Viper instructions.

4. To fully clean and maintain the Viper, run 3-5 cycles of the fluid FILL routine as per Step

3 above.

5. Empty the Viper of Image Armor CLEANING SOLUTION by running a Fluid Empty routine.

6. Place the water IN line back into a clean container of distilled water.

7. Place the water OUT line back into your waste water container.

8. Run two Fluid FILL routines per the Viper instructions using distilled water to remove the

residue of the CLEANING SOLUTION from the Viper’s lines, pump and spray heads.

9. Empty the water from the Viper using the Fluid EMPTY routine on the Viper.

10. You are ready to re-introduce pretreatment into the Viper and start pretreating.

Cleaning Schedule:

The Image Armor CLEANING SOLUTION should be run through the Viper pretreatment machine

once per week. This will help reduce the buildup of the pretreatment polymers in the fluid

system and can prevent additional maintenance.

Replacing the Image Armor CLEANING SOLUTION:

We recommend using 1 Quart of CLEANING SOLUTION for 4-6 maintenance cycles. After this

you should dispose of it according to your local laws.

33

Page 40

Notes:

1. Image Armor CLEANING SOLUTION and distilled water are the only approved CLEANING

SOLUTIONs for use in the Viper pretreatment machine. 2. Polymers can build up in your Viper and

collect in nozzle tips, spray heads, the pump or solenoids. 3. Refer to our Maintenance Sheets in the

Appendix for information on how to clean these parts. 4. Users should store the nozzle tips in the small

container provided with Image Armor CLEANING SOLUTION to help maintain cleaner, healthier tips

when not in use. 5. Rinse tips well with water before re-inserting into the Viper and using.

34

Page 41

6.0 TROUBLESHOOTING

35

Page 42

6 Troubleshooting

6.1 General Troubleshooting

6.1.1 - The Viper will not turn on/doesn’t have any power:

1. Check to ensure that the power cord is plugged into a working electrical outlet.

2. Check to ensure that the power switch is turned on.

3. If the above do not solve the issue, you may need to check the fuse located inside the Viper

control panel.

4. Remove all the screws on the side control panel.

5. The fuse is located to the left of the 24V power supply.

6. Open the fuse holder and remove the fuse.

7. If the fuse element is not intact, replace the fuse.

6.1.2 - The Viper will not spray pre-treatment fluid:

1. Ensure that you have loaded pre-treatment into the Viper. You can verify there is pre-treatment in

the lines by opening the garage door and looking at the fluid lines feeding the spray heads. If they

are empty there is no pre-treatment in the system. Load the pre-treatment according to the FLUID

MAINTENANCE section.

2. If you have pre-treatment in the machine, make sure the valves are set to the correct pre-treatment

solution settings – i.e. Pre-treatment 1 for both the top and bottom valves on the side of the Viper.

3. Listen to make sure that the pump kicks on when you try to spray a shirt. The pump should kick

on prior to the platen entering the Viper completely. It will sound slightly different and have a

“hum” to it. If you do not hear the pump kick on see the question IF THE PUMP DOESN’T

TURN ON.

6.1.3 - The Spray Pattern is “blotchy”

1. If you see a consistent area across the entire sprayed area that looks like the Viper is “skipping”

sprayed areas it is most likely that you are sucking air into the fluid system. Ensure that there is

plenty of pre-treatment fluid in the container and that the red filter is completely submerged in the

pre-treatment solution

36

Page 43

Figure 6.1 – If the pre-treatment solution is low and allowing

the Viper to suck in air, you will get a spray pattern like above.

6.1.4 - The Spray Pattern has gaps or appears to not be irregular:

If you experience an abnormal spray pattern it is possible there is an issue with the spray nozzle tips.

1. You can first try cleaning the spray tips with a toothbrush and warm, soapy water. Dip the

toothbrush in the water and firmly scrub the offending tip(s). Sometimes pre-treatment can

build up and “dry” on the tips causing irregular spray patterns.

2. You can remove the spray tips if necessary and run them through a dishwasher using high

temperature water. This will help clean the tips.

3. After removing the tips and they are dry you can hold the tip up to the light to see if the spray

tip orifice is un-obstructed. If it is obstructed and you can’t remove the obstruction through

regular cleaning you will need to replace the spray tip.

4. Make sure you are not in the CUSTOM SPRAY ZONE setting and have a spray head turned

off. It is possible to spray heads 1 and 2, skipping head 3, and spray heads 4 and 5. This will

leave a gap between heads 2 and 4 making it appear that there is a problem with the spray

pattern.

5. If you see a spray pattern as in Fig. 6.1 the most likely cause is that the pre-treatment solution

is running low and the Viper’s fluid intake filter is partially submerged and partially exposed

to the air. If this is the case, the air will be sucked into the Viper resulting in a “tire track”

type pattern with a more solid center. To remedy this fill your pre-treatment container with

more fluid or switch to a new container.

37

Page 44

6.1.5 - There are drips inside the spray chamber:

1. Open the garage door and wipe down the inside with a sponge and warm water.

2. Ensure that the yellow Sham-moo’s inside the spray chamber are not “soaked” with pre-

treatment solution. If they are, remove them, wash them out in a sink with warm water, wring

dry and allow to air dry. You can use a heat press to press them smooth again. Re-insert into

the Viper from the position you removed them:

3. The rear yellow Sham-moo should hang slightly below the 90 degree elbow of the back of the

garage door. This will prevent drips from forming on that angle and dripping onto the plastic

deck or shirt as it is spraying.

4. The front yellow Sham-moo should be at least even with the bottom of the opening of the

garage door. You can leave it hang down slightly lower to retain more of the spray bounce

inside the spray chamber.

5. Wipe down the spray heads with a damp sponge.

6. Wipe down the spray bar from and rear to remove any pre-treatment buildup.

6.1.6 - I can’t load in any pre-treatment fluid or water:

1. When loading in a fluid, make sure that you follow the on-screen instructions in the FLUID

MAINTENANCE routines.

2. Make sure that you do not have the PT FLUID IN valves in the 12:00 o’clock position (the

arrow on the handle pointing straight up) – this allows the Viper to suck air into the system to

flush it out – not pull in fluids.

3. Make sure that the pump is running when you run the fluid maintenance routines. If the pump

does not turn on, check our troubleshooting section on THE PUMP WILL NOT TURN ON.

4. It is possible that the by-pass solenoid has failed. The bypass solenoid is located in the pump

area of the Viper. If the cover is removed and you run the FLUID MAINTENANCE routine,

about 20 seconds into the routine the solenoid should turn on – you can visually verify it is

working as a red light will light up on the solenoid when it is running and you should see

fluid moving through the system (if there is any air in it. If the system is completely filled

with fluid the only way to tell if it is moving is if fluid is exiting the FLUID OUT outputs on

the back of the Viper.

5. It is possible that the pump, by-pass exit solenoid or other component may need to be taken

apart and cleaned. See Appendix for reference sheets on how to clean these parts.

38

Page 45

6.1.7 - Certain Spray Heads will not spray fluid:

1. If you have a spray head that will not spray, ensure that PT fluid is in the line going to that

spray head.

2. Next, ensure that you are in the CUSTOM SPRAY ZONE settings and select that spray head

only – return to the main menu to spray a shirt and ensure that you still can’t spray using that

head.

3. If you still can’t get a spray from the offending spray head after selecting it as the only head

to spray fluid, check the spray tip.

- Remove the spray tip from the spray head.

- Wash it out with water.

- Ensure that the orifice is not obstructed.

- If it is completely obstructed, replace the nozzle tip.

4. Ensure that the cable that runs from the control panel into the spray chamber is connected to

the offending spray head.

5. The spray head may need to be replaced. Call technical support for more information on how

to replace the spray head.

6.1.8 - The moving platen shudders, grinds or binds when trying to move in or out

or spraying:

There are generally two reasons why this might happen:

1. The platen has extended beyond the front proximity switch. This is the “home” position of

the Viper’s platen.

a) To remedy, turn the Viper’s power off.

b) Holding the platen support arm, gently push the platen tray support into the machine

about 6 inches.

c) Turn the Viper’s power back on.

d) Press the green START button or use the Platen Move In/Out button on the

touchscreen.

e) This will allow the Viper to “re-home” itself.

2. If the above does not resolve the shuddering or grinding then pretreatment has found its way

onto the rail system of the Viper. To clean this, see section 5.3.3 on Internal Maintenance and

the Appendix for more information on accessing and cleaning the rail system.

39

Page 46

NOTE: Most users will experience the binding issue at some point. It is better to be proactive with the

cleaning of the rails and bearings in the Viper to prevent any unwanted and unintentional down time. One

recommendation is that every 3000 sprays a wipe down and cleaning of the rails and bearings be done by

the user or at least every 6 months, whichever comes first.

40

Page 47

7.0 APPENDIX

41

Page 48

7 Appendix

7.1 Appendix A – Stand Assembly

42

Page 49

7.2 Appendix B – Pre-Treatment Fluid Laydown Values

The following chart is to be used as a guide. All pre-treatment values will vary slightly based on the pretreatment solution used. Use this chart as a guide. For the most accurate amount of fluid laydown use a

gram scale and weigh the shirt before spraying and after spraying. The difference between these two

weights is the amount of fluid in grams being laid down for the area being sprayed.

43

Page 50

7.3 Appendix C – Valve and Fluid Connection Information

44

Page 51

7.4 Appendix D – Image Armor CLEANING SOLUTION:

Description:

Image Armor CLEANING SOLUTION is designed to help

keep your Viper pretreatment machine running cleaner

and smoother. It helps break down the solids in the

pretreatment solution that can clog nozzles, spray

heads and tubes that can cause poor system

performance.

The Image Armor CLEANING SOLUTION is a non-

flammable, biodegradable, environmentally friendly, has low VOC, zero GWP, non-ozone

depleting, halide free and non-corrosive. Regular cleaning with the CLEANING SOLUTION will

help provide better, more consistent and even spray patterns over the life of your machine.

Use:

The Image Armor CLEANING SOLUTION is designed to be re-circulated through your Viper XPT-

6000 via the H2O Fluid IN and OUT ports. It is highly suggested that you utilize a 1 quart

container as your re-circulation fluid holder.

How to Use the Image Armor CLEANING SOLUTION

11. Empty the Viper of pretreatment by running a Fluid Empty routine per on screen instructions.

12. Place the water IN and OUT fluid lines into the 1 Quart container of Image Armor CLEANING SOLUTION.

13. Run a Fluid FILL routine as per the Viper instructions.

14. To fully clean and maintain the Viper, run 3-5 cycles of the fluid FILL routine as per Step 3 above.

15. Empty the Viper of Image Armor CLEANING SOLUTION by running a Fluid Empty routine.

16. Place the water IN line back into a clean container of distilled water.

17. Place the water OUT line back into your waste water container.

18. Run two Fluid FILL routines per the Viper instructions using distilled water to remove the residue of the

Anti-Venom from the Viper’s lines, pump and spray heads.

19. Empty the water from the Viper using the Fluid EMPTY routine on the Viper.

20. You are ready to re-introduce pretreatment into the Viper and start pretreating.

45

Page 52

Cleaning Schedule:

The Image Armor CLEANING SOLUTION should be run through the Viper pretreatment machine

once per week. This will help reduce the buildup of the pretreatment polymers in the fluid

system and can prevent additional maintenance.

Replacing the Anti-Venom CLEANING SOLUTION:

We recommend using 1 Quart of CLEANING SOLUTION for 4-6 maintenance cycles. After this

you should dispose of it according to your local laws.

Notes:

1. Image Armor CLEANING SOLUTION and distilled water are the only approved CLEANING SOLUTIONs for use in the Viper

pretreatment machine. 2. Polymers can build up in your Viper and collect in nozzle tips, spray heads, the pump or solenoids. 3.

Refer to our Maintenance Sheets for information on how to clean these parts. 4. Users can store the nozzle tips in a small

container of Image Armor CLEANING SOLUTION to help maintain cleaner, healthier tips when not in use. 5. Rinse tips well with

water before re-inserting into the Viper and using.

46

Page 53

Step 1: Use a crescent wrench to loosen the large nut

on the right side of the pressure relief valve as seen

above.

Step 2: Disassemble the pressure relief valve. Note the

spring. The piston is located in the body of the valve

directly underneath the 90 degree elbow tube fitting.

See #2 in the exploded view below.

Step 3: Ensure there are no polymers from the

pretreatment stuck in the body (#1 part below) or tube

fittings of the pressure relief valve.

Step 4: Also clean and remove any pretreatment from

the pressure setting side of the relief valve (#4 parts

below).

7.5 Appendix E – Disassembling, Cleaning, and Reassembling the Brass

Pressure Relief Valve

47

Page 54

Step 5: The picture above shows the pressure relief valve disassembled from left to right. Ensure that you DO NOT

loosen the smaller nut on #4. This holds the preset pressure setting for the valve. Adjusting this will adjust the

spray pressure and spray pattern. Thoroughly clean all parts #1 through #4. When reassembling, do not over

tighten #4 when retightening to the main body valve #1.

www.viperxpt.com

48

Page 55

Step 1: Remove the black

finger nut holding the

electromagnet portion of the

solenoid.

Step 2: Remove the

electromagnet.

Step 3: Unscrew the two

bolts holding the piston

cover plate in place.

Step 4: Remove the

piston cover plate.

Step 5: Remove the piston and spring

assembly.

Step 6: Note the position of the spring

insert when reassembling the exit

solenoid.

Step 7: Clean all parts and

inside the port as shown

above. That’s where

pretreatment can collect.

7.6 Appendix F – Disassembling, Cleaning, and Reassembling the Exit By-Pass

Solenoid

49

Page 56

Step 8: The picture above shows the disassembly process from Left to Right (#1 - #5). Thoroughly clean all

components with Image Armor CLEANING SOLUTION Maintenance Solution. Especially check the bottom of the

piston spring and the port the piston sits in. When re-assembling, the parts stack on top of each other in the

reverse order they were removed.

When putting the spring back into the piston, ensure it is correctly placed as seen in the picture to the left (#4).

50

Page 57

Step 1: Remove the

four screws holding

the pump cover plate

in place.

Step 2: Remove the top

pump cover plate.

Step 3: Remove the fluid

connector block which

also holds the main

diaphragm.

Step 4: Remove the pump gasket

and valve block.

7.7 Appendix G – Disassembling, Cleaning, and Reassembling the Fluid Pump

51

Page 58

Step 5: The above shows the disassembly

process from Left to Right (#1 - #6).

Thoroughly clean all components with Image

Armor CLEANING SOLUTION Maintenance

Solution and rinse with water. When re-

assembling the pump, the parts stack on top of

each other in the reverse order they were

removed. Please note that you must clean any

pre-treatment film from the diaphragms and

the valve ports, if clogged, as seen in #6 above.

When putting the diaphragm in the pump,

ensure it is placed with the “dip” in the

diaphragm on the bottom side. See picture to

left for clarification.

Step 1: Remove the black

spray tip nut that holds the

spray tip against the

solenoid.

Step 2: Using a 7/64” hex wrench

remove all 4 bolts that hold the spray

head solenoid together.

Step 3: Make sure to not lose the O-Ring

(it may stick to the nozzle tip) when

disassembling the unit.

7.8 Appendix H – Disassembling, Cleaning, and Reassembling the Spray Head

Solenoid

52

Page 59

Step 4: When separating

spray solenoid, note the

piston and spring position in

the piston shaft.

Step 5: Remove the piston and spring

from the lower portion of the spray

head and clean the piston, spring and

inside the plastic housing.

Step 6: Also clean the top electromagnet

housing of the spray solenoid.

Step 8: The picture above shows the spray head solenoid disassembled from left to right. Once the four screws are

removed the entire unit will disassemble as seen. Make sure to thoroughly clean every part seen above. Ensure

that no solidified pretreatment polymers are stuck in the tips (#4), the piston & spring (#5) plunger housing (#4),

and the electromagnet housing (#6). Reassemble in the reverse order as pictured above.

procedure can be completed while the spray solenoid is still mounted on the spray bar of the Viper.

NOTE: This cleaning

53

Page 60

Front of Spray Tip: Above is a

photo of a new spray tip for the

Viper XPT pretreatment

machine.

Close Up of Spray Tip Orifice: Here

is a clean and healthy spray tip

orifice. Notice how it is crisp and

sharp.

Polymer Stuck in Orifice of Tip: You can

see above there is a small piece of

pretreatment polymer stuck in the

orifice opening of the tip. This will cause

an erratic spray pattern.

Bottom of Spray Tip: Here you

can see the bottom side of a

new spray tip.

Close Up of Inside of a Clean Tip:

This is a close up photo of the inside

of a clean tip. There is no wear or

contaminants seen.

Polymer Stuck in Inside of Tip: Here you

can see a polymer chunk stuck in the

inside side of the orifice. This will cause

a “bad” spray pattern.

7.9 Appendix I – SPRAY TIP CLOGGING AND WEAR

54

Page 61

Spray Tip Wear and

Containments: Spray tips

are a wear item on the

pretreatment machine. It

is always a good idea to

have additional tips on

hand so you do not lose

production time while

waiting for a new tip to

arrive.

Tip wear will depend on

many factors including

pretreatment sprayed,

how often you spray, how

often you clean the tips

and how tips are handled.

See our Understanding the

Causes of Nozzle Wear

flyer for more information.

Good Spray Pattern: Above is

what a good spray pattern

should look like. Slightly heavier

in the middle with a feathered

edge on both the left and right

side.

Bad Spray Pattern: Above is a picture of the

spray pattern with some polymer stuck in the

tip. Bad spray patterns can vary widely. If your

spray pattern of a single nozzle does not look

like the Good Spray Pattern, it most likely is

either worn or has pretreatment built up on or

in the tip.

55

Page 62

7.10 Appendix J – Image Armor CLEANING SOLUTION:

The nozzle tips of any spray system are a wear item in the Viper XPT and will over time due to a

variety of factors, erode the spray tip causing poor spray patterns. Below are several of the

common factors that can cause spray tip degradation and poor pretreatment machine

performance.

1. Erosion: Erosion is the gradual removal of

nozzle material which causes the nozzle

orifice and internal flow passages to enlarge.

When this happens your spray pattern will

change and additional pretreatment will be

applied to the garment in comparison to

when the tip was new.

2. Corrosion: Some pretreatments that are used

in DTG printing are very highly corrosive. This

can cause the nozzle material to wear internally as well as externally, enlarging the

orifice and corroding the spray tip features causing irregular spray patterns.

3. Caking/Bearding: This is the build-up of

pretreatment material on the inside or

outer edges of the orifice. Most typically

if nozzle tips are not cleaned and flushed

daily, pretreatment can dry and build up

on the tips. Many times this is

imperceptible to the naked eye, but this

build-up can cause irregular spray

patterns by obstructing the orifice and/or

flow passages inside the tip.

4. Accidental Damage: Use of improper cleaning tools can result in scratches that can

affect nozzle performance and spray patterns. Dropping the tip during maintenance or

installation can also damage the nozzle tip causing irregular spray patterns. When

cleaning the Viper’s spray tips, use only a soft bristle toothbrush and Image Armor

56

Page 63

CLEANING SOLUTION. Make sure to rinse off with water after cleaning to help remove

any contaminants.

5. Clogging: Clogging is when unwanted solid

particles block the inside of the orifice and

cause distorted spray patterns. Most commonly

what happens in the Viper is as the polymers in

the pretreatment separate from solution they

can collect and, when the Viper is sprayed are

not able to be blown through the nozzle tip

where it can collect causing a clog and a bad

spray pattern.

57

Page 64

7.11 Appendix K – Pretreating Basics with the Viper XPT-6000

Methods of Applying Pretreatment

There are several ways you can pretreat shirts for Direct-to-Garment printing. The three main

methods are:

1. Using a roller and manually applying pretreatment to the selected area.

2. Utilizing a HPLV sprayer like a Wagner Power Sprayer.

3. An automated pretreating system like the Viper XPT-6000.

Pros and Cons of Each Application Method

1. Roller: Very precise in application area but extremely difficult to apply the correct

amount of pretreatment. No over spray whatsoever.

2. Spray Gun: Very difficult to apply precise amount of fluid. Additional wasted

pretreatment in overspray or bounce.

3. Automated Pretreatment Machine: With the Viper it allows for more precise

application of pretreatment by utilizing 6 independent spray zones (user defined). Much

more precise application of pretreatment fluid for consistent and repeatable results

from shirt to shirt. Minimized bounce and overspray.

Application Amounts of Pretreatment

The amount of pretreatment applied will vary based on a variety of factors:

1. Manufacturer’s Recommendations: The manufacturer’s recommendations are always

first and foremost for application. However, some manufacturers don’t necessarily have

solid recommendations.

2. The Shirt Color: We have found that darker shirts will require more pretreatment than

lighter shirts. The lighter the shirt, if excessive amounts of pretreatment are applied and

cured may result in scorching or a yellowing of the pretreated area.

3. Shirt Weight: The heavier the shirt, the more pretreatment in general will be needed in

comparison to the same colored shirt but of a lighter weight fabric. A 6.0 oz.

heavyweight dark shirt may require 26-32 grams of fluid while the same dark shirt in a

4.0 oz. fabric may require only 20-24 grams of pretreatment.

4. Shirt Composition: Depending on the composition of the shirt, this can also vary the

amount of pretreatment. A 50/50 shirt may require a different amount (usually less

pretreatment) than a 100% cotton shirt.

58

Page 65

5. Type of Pretreatment: Utilizing a white ink pretreatment versus a pretreatment for light

colored polyester fabrics will also result in a different amount of applied fluid

potentially.

General Rules of Application:

1. Variability: There is some leeway in the amount of fluid applied. However, too much or

too little pretreatment can be an issue depending on the garment and pretreatment

fluid being used. Generally, too little pretreatment is the most common issue.

2. Amounts Applied: Too much pretreatment can sometimes result in a crystallization of

the salts in the pretreatment fluid giving the shirt distinctive “white” specks in the

pretreated area.

3. Hovering: Depending on the manufacturer’s pretreatment, sometimes it is necessary to

“hover” your heat press above the treated shirt to start steaming off the pretreatment

fluid. Then, the final press can be applied. We have seen where not doing this really

results in the crystallization of the salts resulting in “white” specks. Note: Not all

pretreatments require you to hover to work correctly.

4. Cover Sheet: ALWAYS use a Teflon sheet or high quality craft or parchment type paper

(with release agent). You don’t want to pull up the shirt fibers after pressing. A nonsticky surface really helps reduce fiber pull-up.

5. Pressure: ALWAYS use the highest pressure you can on your heat press. A standard

manual heat press will work. A pneumatic heat press with 80 psi of pressure will work

even better.

6. PRESSURE IS THE KEY: The high pressure of the heat press does two things. It really

helps to drive out the moisture in the pretreatment solution. The second is the pressure

helps matte the fibers of the garment down really flat while the pretreatment is cured.

Once cured, the pretreatment helps hold those fibers down flat, giving an incredibly

smooth printing surface for better white ink printing.

7. CURING IS A MUST: A complete cure of the pretreatment is also a must. If the

pretreated garment has any moisture in it the final results of your white ink printing will

be less than satisfactory. The results can be poor colors, lower vibrancy and poor

washability.

8. Pre-Pretreating Garments: You can pretreat your garments for future use. The longer

the shirts sit around the more they will reabsorb moisture from the air. Always re-

heatpress your shirts prior to printing if you are not pretreating and immediately

printing the shirts.

59

Page 66

9. Shelf Life: Pretreated shirts do have a shelf life. Always use as quickly as possible. Do not

try to pretreat several weeks in advance. The fresher the pretreatment the better.

10. Shaking Your Pretreatment: Always shake your pretreatment container before using.

The polymers in the pretreatment can separate and settle onto the bottom of your

pretreatment container. This can result in an unbalanced mixture if applied giving

varying results for the final print and durability.

SHAKE, SHAKE, SHAKE

before using!

11. Mixtures: Always mix according to the manufacturer’s instructions. Failure to do so will

result in undesirable final prints. It will either be too strong or too weak – both resulting

in bad prints.

STARTING POINTS OF APPLICATION AMOUNTS:

For non-Brother Pretreatment:

- Heavyweight Dark Colors: 18-24 grams (A setting of 41-52 on the Viper Fluid

Laydown Amount)

- Heavyweight Light Colors: 15-20 grams (A setting of 32-45 on the Viper Fluid

Laydown Amount)

For Brother Pretreatment:

- Heavyweight Dark Colors: 26-30 grams (A setting of 55-70 on the Viper Fluid

Laydown Amount)

- Heavyweight Light Colors: 20-24 grams (A setting of 42-52 on the Viper Fluid

Laydown Amount)

Refer to the Viper Fluid Laydown Chart for complete fluid application amount correlations. You

may find that you will require less pretreatment applied as you experiment with the different

settings and conduct washability tests. Always record your results!

60

Page 67

61

Loading...

Loading...