Page 1

VR-6000VR-6000

OWNER©S MANUAL

MANUEL D©INSTRUCTIONS

MANUAL DE INSTRUCCIONES

VER 5 JAN 2005

842-410-000

Page 2

IN STRU CTIONS M ANUAL

Page 3

INSTRUCTIONS MA NUAL

INDEX

INDEX.............................................................................................................................................................................................................3

SAFETYSUMMARY............................................................................................................................................................................4

SAFETY INFORMATION.........................................................................................................................................................4

ELECTRICAL SHOCK HAZARDS 5

MOTI ON HA ZA RDS 5

FUM E HA ZARDS 5

HEAT/FRE EZI NG HAZA RDS 6

EXPLOSION/FLAMEHAZARDS 6

ADDITIONAL SAFETY INFORMATION........................................................................................................................6

INTRODUCTION..................................................................................................................................................................................7

GENERAL...........................................................................................................................................................................................7

CERTIF IC AT IO N...........................................................................................................................................................................7

ABOUT THIS MANUAL .............................................................................................................................................................7

ABOU T THE VIPER A/C AIR CONDITIONING SER VICE CENTER........................................................7

THE MACHINE.......................................................................................................................................................................................8

BAS IC COMPONE NTS............................................................................................................................................................8

CONTROLS AND CONTROL SYS TEM...................................................................................................................10

FUNCTION SELECTOR KEYBOARD.........................................................................................................................11

STATUS AND ALARM PANEL ..........................................................................................................................................12

MEA SUREMENT SETTING................................................................................................................................................13

VIPER VR-6000 SPECIFICATIONS..............................................................................................................................13

PREPAR ATION FOR USE........................................................................................................................................................13

GENERAL........................................................................................................................................................................................13

PREPARATION...........................................................................................................................................................................13

PREPARE THE REFRIGERANT STORAGE TANK..........................................................................................14

TRANSFER NEW REFRIGERANT TO THE STORAGE TANK...............................................................14

OPERATION INSTRUCTIONS.............................................................................................................................................1 6

RECOVER AND RECYCLE REFRIGERANT FROM AN AC SYSTEM...............................................16

REMOVING NON-CON DENS ABLE GASES.........................................................................................................16

VACUUM PHASE ........................................................................................................................................................................18

RECHARGE AN A/C SYSTEM.........................................................................................................................................18

3

Page 4

IN STRU CTIONS M ANUAL

RECOVERING THE REFRIGERANT IN THE HOSES...................................................................................19

MAINTENANCE..................................................................................................................................................................................20

REPLACING REFRIGERANT FILTER/DRYER...................................................................................................20

EMP TYING THE U SED OIL TANK................................................................................................................................21

CASE CARE...................................................................................................................................................................................21

AIR CONDITIONING HOSE MAINTENANCE.......................................................................................................21

CALIBRA TING THE ELECTRONIC SCALE............................................................................................................21

VACUUM PUMP ...........................................................................................................................................................................22

M.1) Oil t o p- up 22

M.2) Oil change 22

M.3) Deco n t amination 23

TROUBLE SHOOTING...........................................................................................................................................................24

RECO V ERY PROB L EMS 24

NO DISPL A Y WHE N MA IN POWER SWITCH IS ON 24

REF ILLI NG DOE S NOT FL OW 24

MANUFACTURER’S LIMITEDWARRANTY.............................................................................................................2 5

SAFETY SUMMARY

Congratulations on the purchase of your new VIPER VR-6000 Air Conditioning Service

Center. The following safety inform ation is provided as guidelines to help you operate your

new system under the safes t possible conditions. Any equipment that us es chemicals can

be potentiallydangerous to use when safetyor safe handling instructions are not known or

not followed. The following s afety instructions are to provide the us er with the information

neces sary for s afe use and operation. Please read and retain these instructions for the

co ntinued s afe use of your s ervice s y stem.

SAFET Y INFORMA TION

Every craftsman respects the tools with which theywork. They know that the tools repres ent

years of constantly improved designs and developments. The true crafts man also knows

that tools are dangerous if misused or abus ed. To reduce risk of discomfort, illness or even

death,read, understand and followthe following safetyinstructions . In addition, make certain

that anyone else that uses this equipment, understands and follows these s afety

instructions as well.

4

Page 5

INSTRUCTIONS MA NUAL

REA D ALL SAFETY INFORMA TION CAR EF UL LY before attempting to install, operate or

service this equipment. Failure to comply with thes e instructions could result in personal

injury and/or propertydamage.

RETAIN THEFOLLOWING SAFETYINFORMATION FOR FUTURE REFERENCE.

Publis hed s tandards onsafetyare available. Theyare listed in ADDITIONAL SAFETY

INFORMATION at the end of this SA FETYSUMMA RY.

TheNational Electrical Code, Occupational Safetyand Health Actregulations, local industrial

codes and local inspection requirem ents also provide a basis for equipment installation,

use and s ervice.

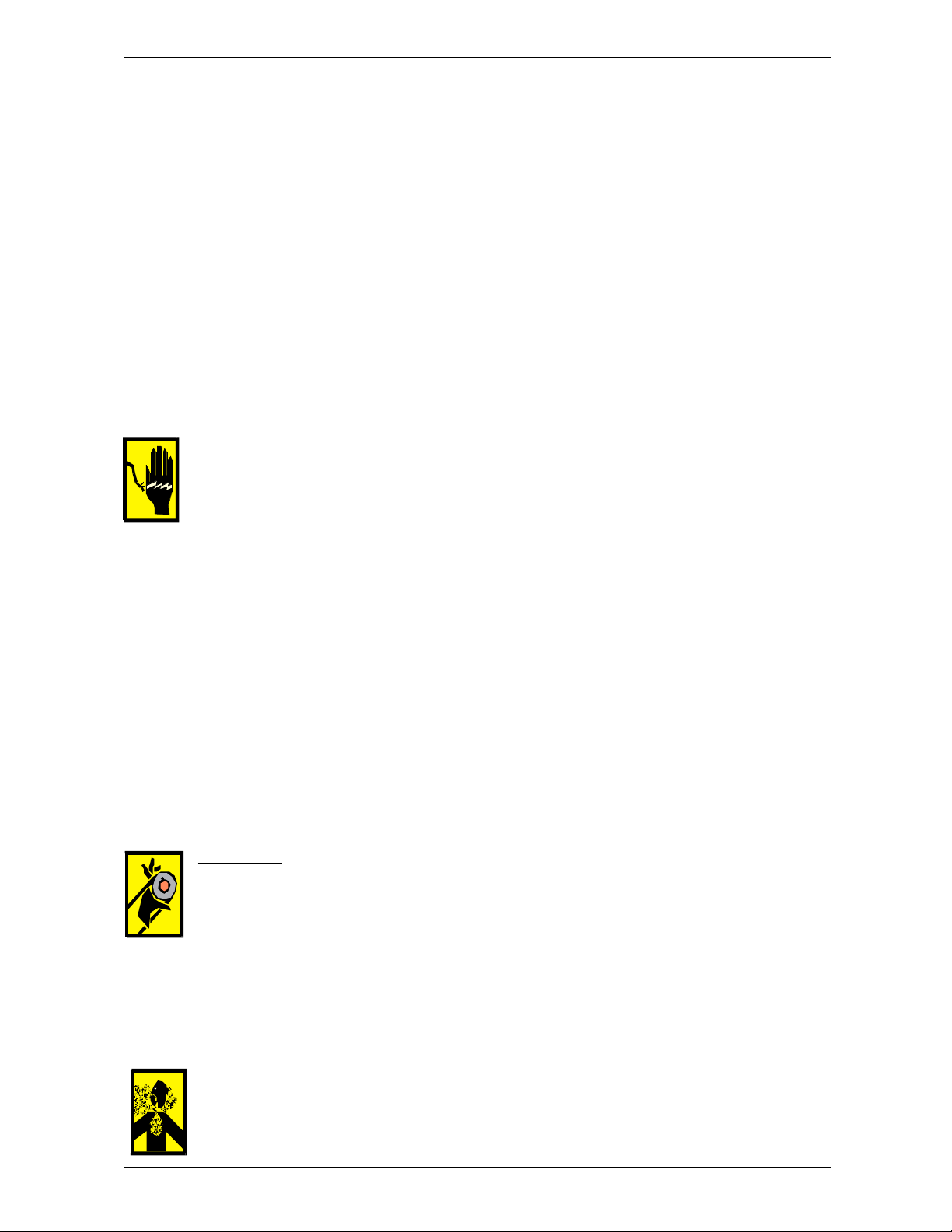

• The following safetyalert symbols identify im portant safety mess ages in this

manual.

• When you see one of the s ymbols s hown here, be alert to the possibility of

pers onal injuryand carefullyread them ess age that follows.

ELECTRICAL SHOCK HAZARDS

WAR NING:

• To reduce the risk of electric shock, unplug the air service center from the

outletbefore attempting any maintenance or cleaning. Turning off controls will

not reduce this risk.

• Do not operate the VR-6000 with a damaged cord or plug — replace the cord or plug

immediately. To reduce the risk of damage to electric plug and cord, disconnect

chargerbypulling on theplug ratherthan the cord.

• An extension cord should not be used unless absolutely necessary. Use of an

improper extens ion cord could resultin a risk of fire and electric shock. Ifextens ion cord

must be us ed, make s ure:

a. That pins on plug of extension cord are the s ame number, size, and shape as

thoseonplugonrecycler.

b.That extens ion cord is properly wired and ingood electrical condition;and

c. That the wire size is large enough forthe lengthof cord as specified below:

Length of cord in feet: 25 50 100 150

AWG size ofcord: 16 12 10 8

MOT ION HAZ ARDS

WAR NING:

• Engine parts that are in motion and unexpected movement of a vehicle can

injure or kill. When working near moving engine part, wear snug fit clothing

and keep hands and fingers away from moving parts. Keep hoses and tools

clear of moving parts. Always stay clear of m oving engine parts. Hoses and

tools can be thrown through the air ifnotkept clear ofmoving engineparts.

• The unexpected movement of a vehicle can injure or kill. When working on a vehicle,

always set the parking brake or block the wheels of the vehicle being s erviced.

FUME HAZARDS

WAR NING:

• FU MES , GASES, AND VAPORS CAN CAUSE D ISCOMFOR T, ILLNESS, AND

DEATH! To reducethe risk ofdiscomfort, illness, or death, read, unders tand,

and follow the following s afety instructions. In addition, make certain that

5

Page 6

IN STRU CTIONS M ANUAL

anyone else that uses this equipment, understands and follows thes e safety

instructions as well.

• Avoid breathing AC refrigerant and lubricant vapor m ist. Exposure may irritate eyes,

nose, and throat. To remove HFC-134a from the AC system, use service equipm ent

certified tomeet the requirem ents of SAE J2210 (HFC-134a recycling equipment).

• Additional health and safety information may be obtained from additional refrigerant

and lubricant m anufacturers.

• Always perform vehicle servi ce in a properly ventilated area. Never run an engine

withoutproper ventilationforits exhaust.

• Stop the recycling proces s if you develop momentary eye, nose, or throat irritation as

this indicates inadequate ventilation. Stop work and take necess ary steps to im prove

ventilation inthe work area.

HEAT/FREEZ ING HAZARDS

WAR NING:

• When under press ure, refrigerants become liquid. When accidentally

releas ed from the liquid state they evaporate and become gaseous. As they

evaporate,they can freeze or fros tbite tissue very rapidly. When these gases

are breathed, the lungs can be s eriously damaged. If sufficient quantities are

taken into the lungs, death can result. If you believe you have expos ed your lungs to

releas ed refrigerant, seek immediate medical assis tance.

• Refrigerants can cause frostbite and severe burns to exposed skin. Refrigerants are

under pressure and canbe forcibly sprayedin all directions ifcarelessly handled. Avoid

contact with refrigerants and always wear hand coverings and make certain other

exposed s kin is properly covered.

• Refrigerants can also s everely injure or cause permanent blindness to unprotected

eyes. Refrigerants are under press ure and can be forcibly s prayed in all directions if

carelessly handled. Avoid contact with refrigerants andalways wear safetygoggles.

EXPLOSION/FLAME HAZARDS

WAR NING:

• Never recover anything other than the approved refrigerants as specified on

theVR-6000. Alternate refrigerants m ay contain flam mables such as butane

or propaneand can explode or cause a fire. Recovering alternate refrigerants

will also void the warranty on your VIPER VR-6000.

• For generalsafetyreasons, attheend ofthe working day or in between services (when

services do not immediatelyfollow), s ee to it that all valves on hoses and tanks are

clos ed.

ADDIT ION AL SAFE T Y INFO R M AT IO N

For additionalinformation concerning s afety,refer tothe following s tandards.

ANSI Standard Z87.1 Safe Practice For Occupation And Educational Eye And Face

Protection obtainable from the American National Standards Institute, 11 W 42nd St, New

York, NY 10036, Telephone (212) 642-4900, Fax(212) 398-0023, www.ansi.org.

6

Page 7

INSTRUCTIONS MA NUAL

INTRODUCTION

GENERAL

Thank you for purchasing a VIPER VR-6000 Air Conditioning Service Center. Your VR-6000

is Underwriters Laboratories Inc.® approved, incompliance with SAE J 2210 (1991). We are

dedicated to s olvingthe issues surrounding the s afe containment and proper management

ofCFC’S.Your new VR-6000 incorporates the latest technology and state of the art features

toaid you in servicing air conditioning and refrigeration systems. We hope you get as much

enjoyment using this equipment as we diddesigning and building it.

CERTIFICA T ION

All technicians opening the refrigeration circuit in autom otive air conditioning systems must

now be certified in refri gerant recovery and recycling procedures to be in compliance with

Section 609 of the Clean Air Act Amendments of 1990. For inform ation on certification call

MACS Worldwide at (215) 631-7020.

ABO UT THIS MANUAL

This manual includes a SAFETY SUMMARY, machine PREPARATION FOR USE,

OPERATION procedures, and MAINTENANCE instructions , for the VIPER VR-6000 Air

Conditioning Service Center. Anyone intending to use the VR-6000 s hould becom e familiar

with ALL the information included in this manual (especiallythe SAFETYSUMMARY) before

attempting to us e it.

Bef ore operating this machine for the first time, per form all PREPA RATION FOR USE

instructions . Ifyour new machine is not properly prepared to perform a service, your service

data could be erroneous. In order to properly perform a complete air conditioning service,

follow all procedures in the order presented. Pleas e take the time to study this m anual

before operating the machine. Then keep this m anual clos e at hand for future reference.

Pleas e pay close attention to the SAFETY SUMMARY and all WARNINGS and CAUTIONS

provided throughout this m anual. To activate the published warranty, mail in the attached

warrantycard.

CAUTION: The VR-6000 is intended for indoor use only.

ABOUT THE VIPER A/C AIR CO NDITIONING SERVICE CENTER

The ozone layer around the earth’s atmos phere is a thin protective covering. It acts as a

shield against the sun’s destructiveultravioletrays. Without the ozone layer the very exis tence

of our planet would be in question. Scientific studies show that the ozone layer is being

destroyed at an alarming rate. It has been es tablished that emissions from refrigerants,

such as R-12, contain chlorofluorocarbons (CFC’s), which are the leading caus e of ozone

depletion. One CFC molecule has been s hown to destroyup to 100,000 ozone molecules.

Your VIPER VR-6000 incorporates a highly accurate electronic scale for determ ining

charging weights, etc. Other functions can also beperformed with the electronic scale as you

will discover during the operating procedures. Either standard or m etric units of measure

can be selected. Your new VIPER VR-6000 has been designed s pecifically touse R-134a, to

operatewithin theobjectives oftheMontreal Protocol.

7

Page 8

IN STRU CTIONS M ANUAL

THE MACHINE

BASIC COMPONENTS

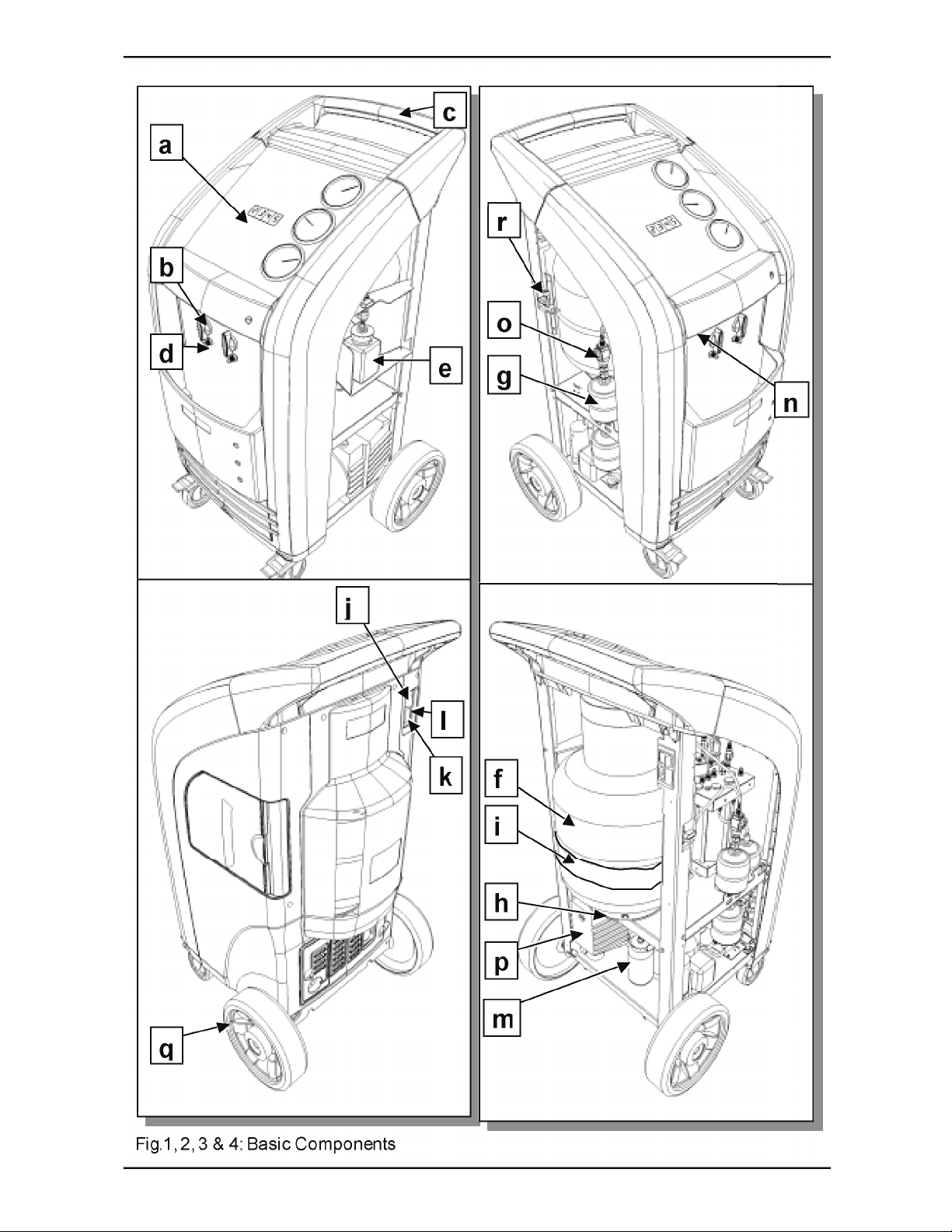

Refer tofig 1, 2, 3 & 4:

a) ControlConsole b) Valves

c) Handle d) High/Low Pressure Threaded Connectors

e) New Oil Container f) StorageTank

g) Desiccant Filters h) Electronic Scale

i) Heater Blanket j) Main Power Switch

k) Socket forElectrical Supply Plug l) Fuse

m) Used OilContainer n) Serial Port

o) Moisture Indicator p) Vacuum Pump

q) Wheels r) AirPurge Valve

8

Page 9

9

Page 10

IN STRU CTIONS M ANUAL

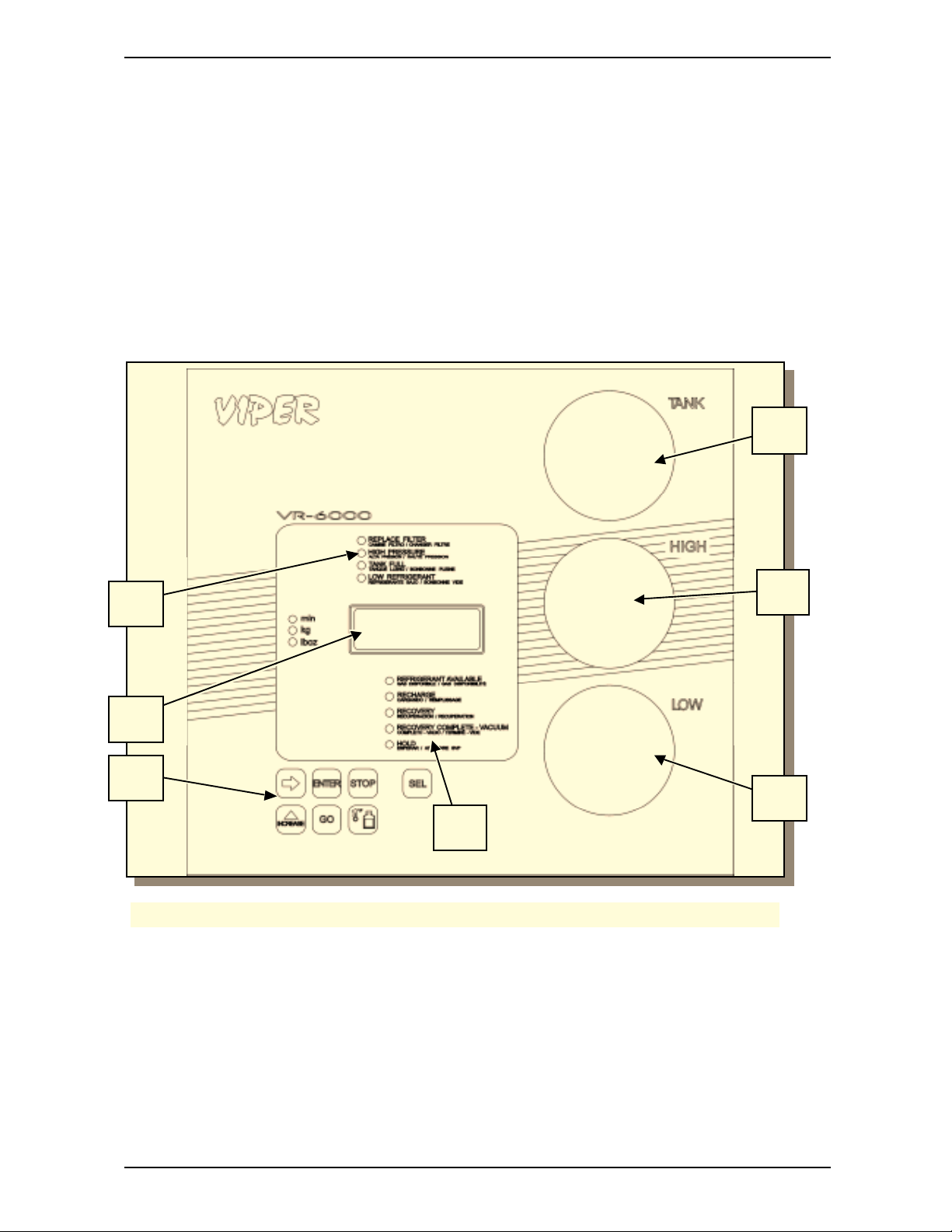

CONTROLS AND CONTROL SYSTEM

Refer toFig 5:

(A1) Lowpressure gauge forA/Csystem

(A2) High press ure gauge forA/C system

(A4) Pres sure gauge for s torage tank

(A6) Emergency/alarms panel

(A7) Display

(A8) Key pad controls

(A9) Operations selector panel

A4

A6

A7

A8

Fig.5: ControlPanel

A2

A1

A9

10

Page 11

INSTRUCTIONS MA NUAL

FUNCTION SELECTOR KEYBOARD

Refer toFig 6:

(T1) REFRIGERANTAVAILABLE LEDindicator: when lit, the display reports the weightof the

available refrigerantin the storage tank.

(T2) RECHARGE LED indicator (flashes during the CHARGING phase).

(T3) RECOVERYLED indicator (flashes during the RECOVERY phas e).

(T4) EVACUATE LED indicator (flas hes during the VACUUMphase).

(T5) HOLD: flashes at the end ofthe recovery during the OIL DISCHARGE phase.

(T6) SEL key: Selects the operation to be performed. Every time this keyis press ed one of

theLEDs from T1 through T4 will light in sequence; the LED alongside each operation

indicates that theoperation m ay be started or that it is being performed (flashing LED).

(T7) INCREA SE key: Each time this key is press ed dur ing the operations relative to set ting

thetime and the quantity, the value of the flas hing digit on the displaywill be increased

byone unit.

(T8) ARROW key: Each time this key is pres sed while a displayvalue is flas hing during the

operations relative to settingthe time and the quantity, a different digitwill be s elected for

modification (selected digit will flas h).

(T9) ENTER key: Pres sing this keywhen a LED corresponding to an operation is lit but not

flashing will permit modifying the evacuation time, and desired charging weight. After

setting the desiredvalue pres s the keyagain tocomplete the process.

(T10) GOkey: Press ing this keywill s tart theoperation indicated bythelighted LED

(T11) STOP key: Press ing this keywill stop the operation indicated bytheflashing LED.

(T12) °Fkey:Pres sing this keythedisplay will s how the bottle temperaturein Celsius degree

11

Page 12

IN STRU CTIONS M ANUAL

or Fahrenheit degree.

(T13) Display: According to the operation s elected, displays the evacuation time, tank

temperature, or weightof available refrigerant.

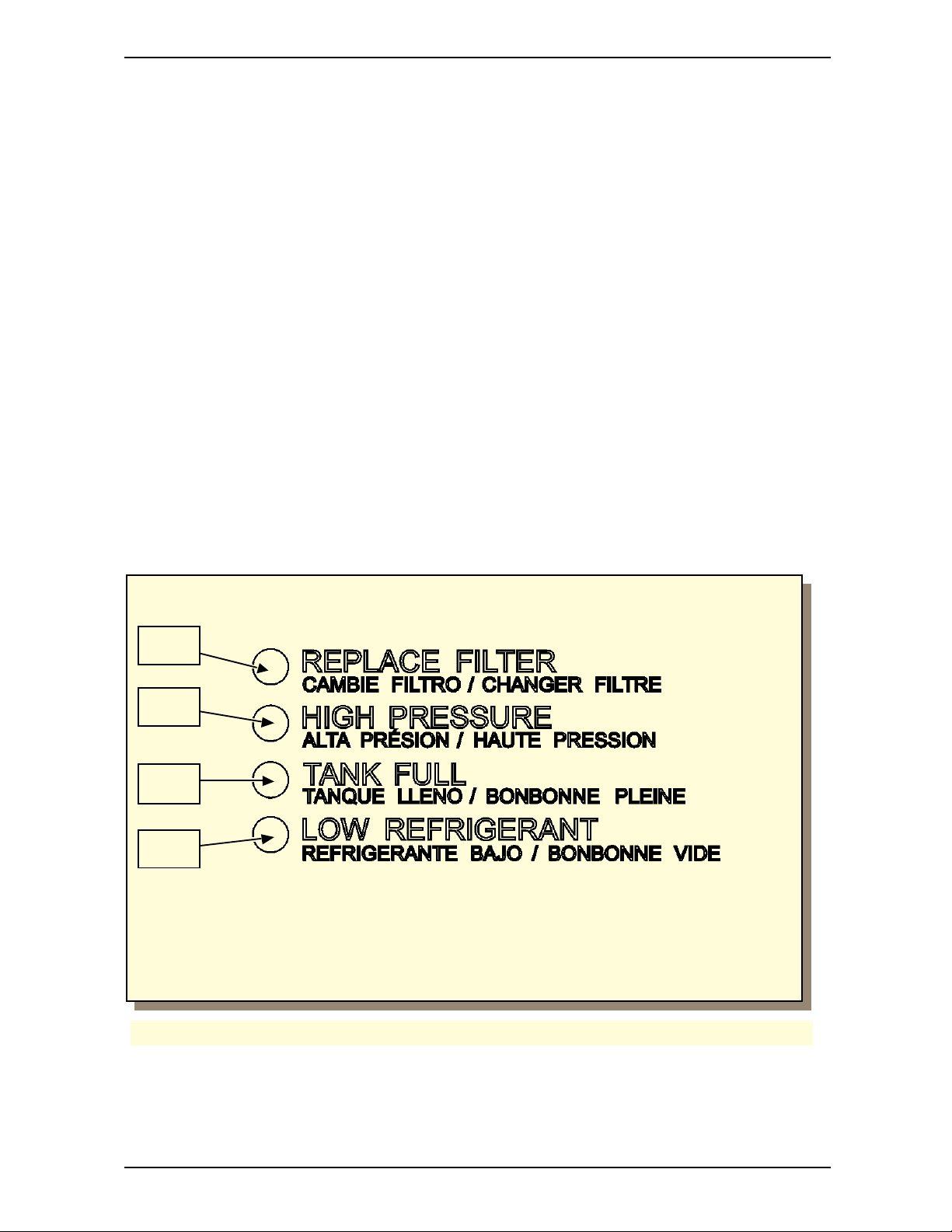

STATUS AND ALARM PANEL

See Fig 7:

(C1) REPLACE FILTER: the Low side refrigerant filter/dryer must be changed when the led

“REPLACE FILTER” lights up.When recovering new refrigerant this light m ay come on

prem aturely. Itm aybe reset bypres sing theSEL keywhile turning onthe machine.

(C2) HIGH PRESSURE: Lights and emits an acoustic signal when the press ure of the fluid

in the circuit exceeds 290 ps i (20 bar). The RECOVERY operation is automatically

interrupted. This will occur if you attempt to recover refrigerant with the tank valves

clos ed, and will require some disass embly to reset (s ee TROUBLE SHOOTING

section)

(C3) TANK FULL: Lights and emits an acous tic signal when the bottle is filled to more than

80% of maximum capacity, approximately 40 lbs. The RECOVERY operation is

automatically interrupted. You may use the CHARGING function to remove refrigerant

from the s torage tank.

(C4) LOW REFRIGERANT: Lights and emits an acoustic s ignal when the quantity of

refrigerant fluid contained in the bottle is low, near 4 lbs (~2 kg). You will need to add

additional refrigerantto continue with a CHARGING function.

C1

C2

C3

C4

Fig.7: Front v iews

12

Page 13

INSTRUCTIONS MA NUAL

MEASUREMENT SETTING

When power is turned on to your new VIPER VR-6000, the keypad displaywill show the gas

weight in the service tank. The display can be set to read in either metric or standard

measurements , proceed as follows:

• Switch off the VR-6000.

• Press the SEL, GO, and ENTER keys simultaneous ly while turning on the VR-6000.

Them achinewill change from one system ofunits ofmeasurementtothe other.

VIPER VR-6000 SPECIFICAT IONS

Electrical Input: 115 Vac, 8 A,60 Hz

Am bient Operating Temperature Range: 50° F (10° C) to120° F (48.9°C)

ApproximateShipping Weights: 170 lbs.

PREPARATION FOR USE

GENERAL

Your VIPER VR-6000 Air Conditioning Service Center is shipped completelyassembled and

100% pre-tested. Your VIPER VR-6000 needs to be prepared before it can be used to

s e rvice a v ehicle's ai r conditioning s ystem .

PREPARATION

Thefollowing s teps,forthe most part, are used only toprepare your VR-6000 for operation.

1. Remove the s hipping carton.

2. Lift outtheVR-6000 from the palletto the ground.

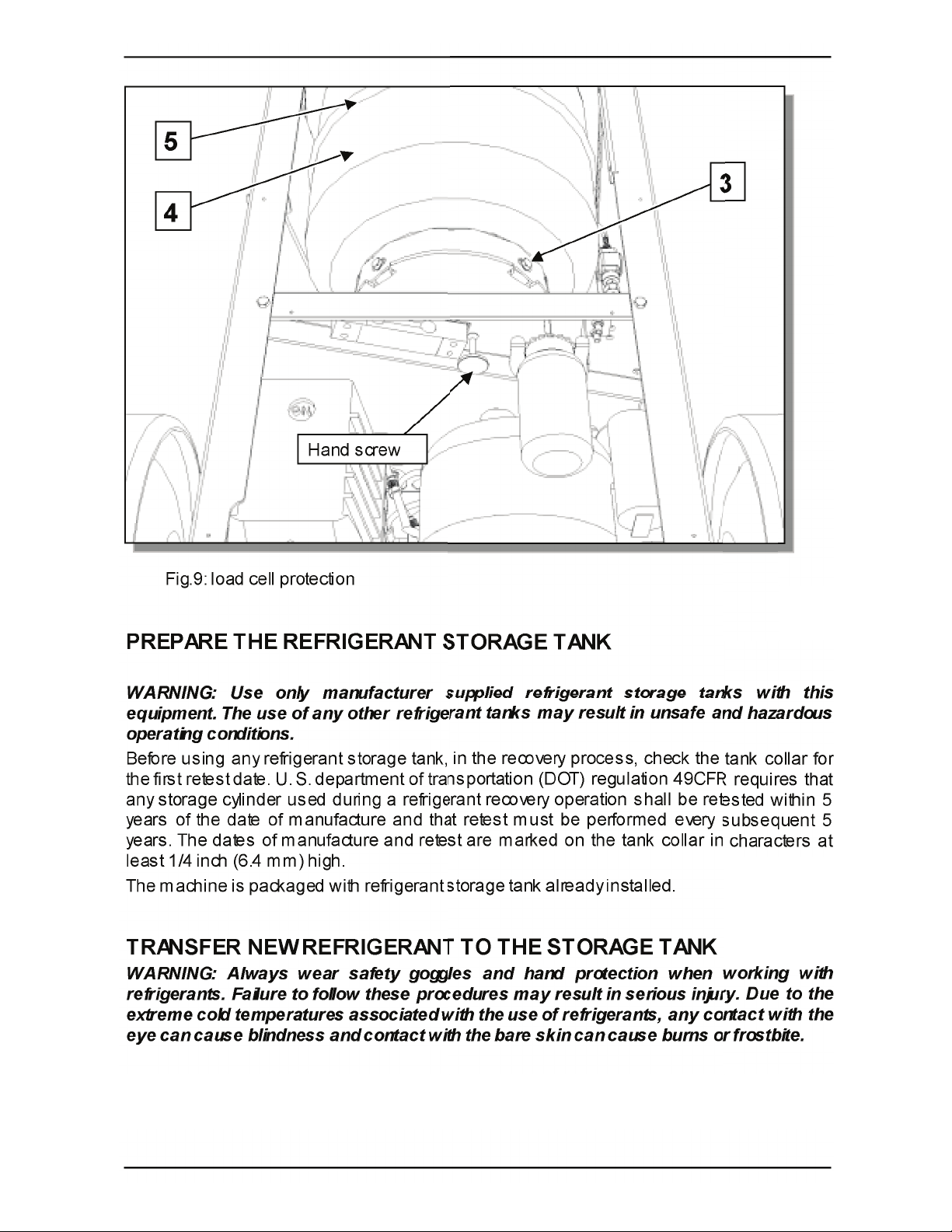

3. Loosen the scale hand screw (s ee Figure 9) that is under the scale platform. It is

tightened to preventdamage to thescale during shipment. Turn counter clockwis e six

full turns. Note: If youdo notloosen the scale hand screwunder the scale platform, the

scale will remain inoperable.

131415

Page 14

Page 15

Page 16

IN STRU CTIONS M ANUAL

OPERATION INSTRUCTIONS

RECOVER AND RECYCLE REFRIGERANT FROM AN AC SYSTEM

1. Be sure that the shutoffvalves are off prior toattaching to a vehicleAC s ystem.

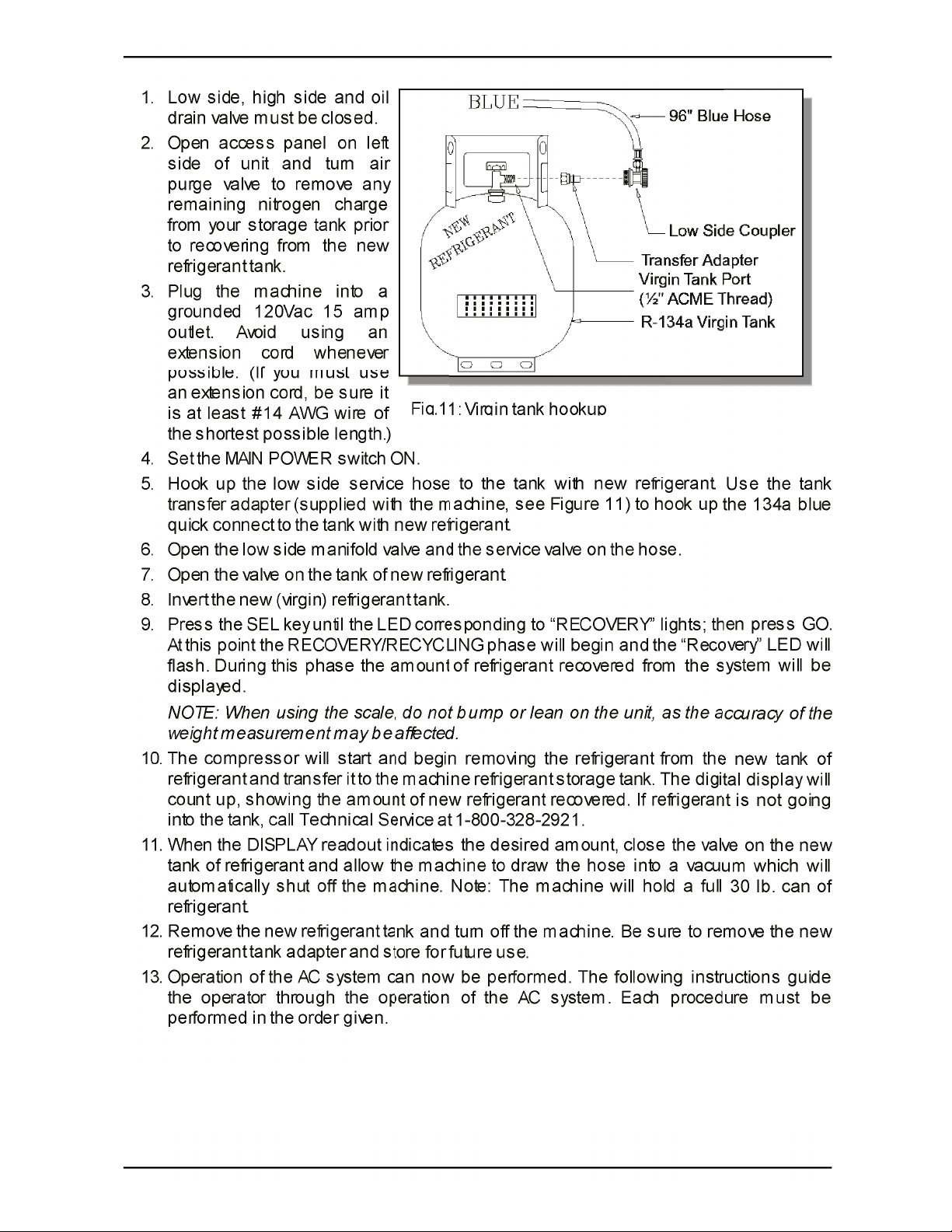

2. Attach themachine to the high and low sides of the AC system to be serviced. The R -

134a hoses have SAE approved s hut-off valves (quick disconnects). The hoses are

shut off when disconnected from the AC system and are open only when connected

with the knurledknobs turnedclockwise. Slide thecollar ofthe fitting back and pres s to

theappropriate fitting.

• Blue hose to the low side of AC system

• Red hose to thehigh s ide of AC system

3. Set MAIN POWER (k, Figure 3) ON.

4. Open the valves on the s ervice hoses by turning the knurled knob clockwise (Figure

12). This will allow refrigerant to flow tothe vehicle.

5. Observe the pressure readings on the low and high side manifold gauges. If the

readings are zero,then repair AC system leak orproceed to vacuum phas e.

6. Open the High Side andLow Side valves on the controlpanel ofthe machine.

7. Press and hold the SEL keyuntil the LED corresponding to “RECOVERY” lights; then

pres s GO. At this point the RECOVERY/RECYCLING phase will begin and the

“Recovery” LEDwill flas h.

8. During the RECOVERY/RECYCLING phas e the amount of refrigerant recovered from

thevehicle will be displayed. Upon completion of the recovery phase the machine will

stop and hold three m inutes.

9. During this time themachine automatically discharges the us ed oil. It will be necess ary

to m onitor this oil dumping to determ ine the am ount of oil that must be added to the

vehicle. When the oil discharge is complete, measure, record and em pty the oil

discharge bottle. This amount will be added to the AC system before charging. When

there is noincrease insystem pressure, the vacuum pump will start and evacuate the

input oil s eparator insidethe VR-6000.

10. If, during this 3-minute time period, the residual refri gerant left in the A/C system

caus es the pres sure to increase, themachine will automatically resume recovering the

refrigerant. When this phase is complete the machine will sound and audible alarm,

and switch to the REF RIGERANT A VAILA BLE display.

11. Clos e the High Side andLow Side panel valves.

12. Setthe MAIN POWER switchOFF.

13. Disconnect the machine if desired. (See DISCONNECTING THE MACHINE FROM A

VEHICL E.)

14. Make necess ary repairs tothe A/C system being serviced.

REMO VING NON-CONDENSABLE GASES

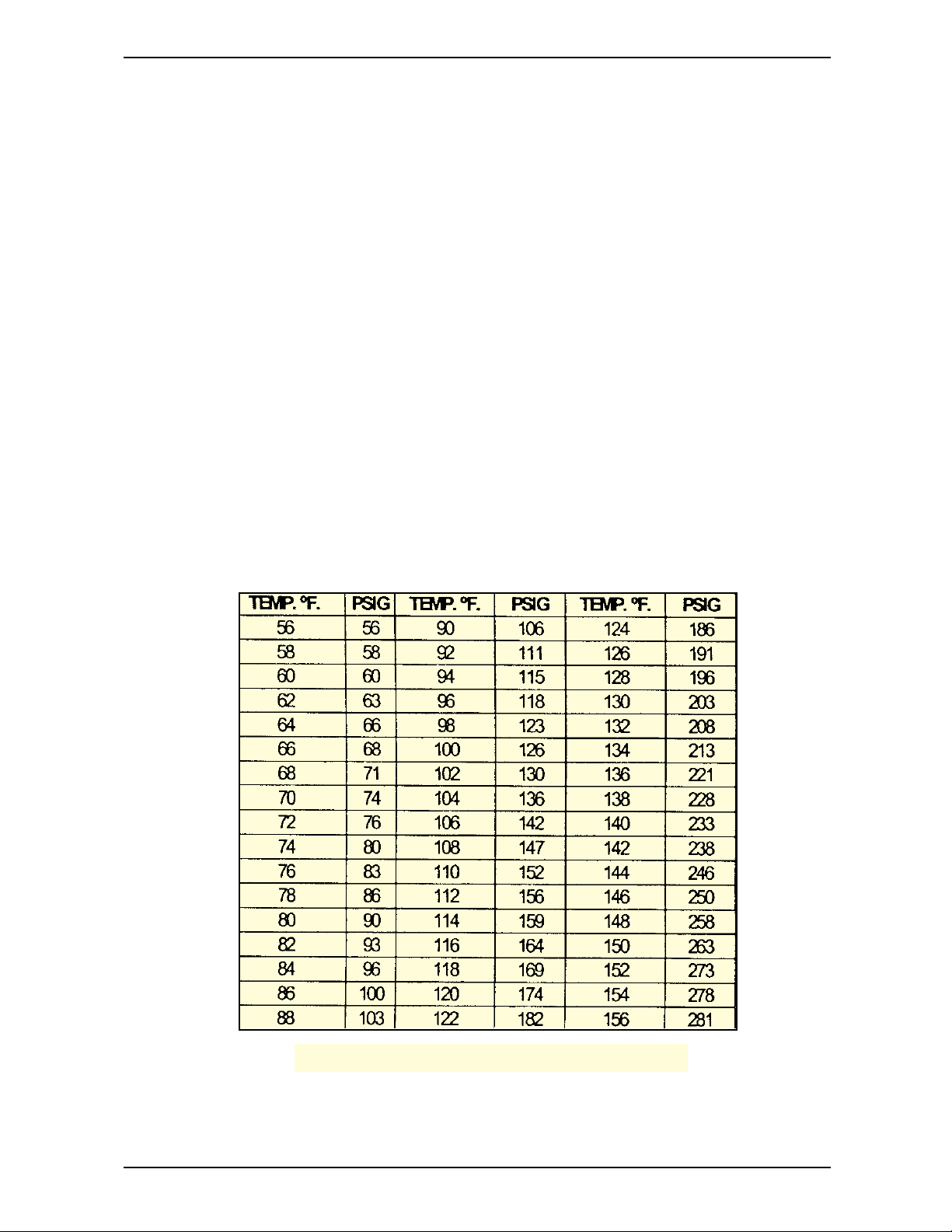

As non-condensable gases accumulate in the refrigerant storage tank, excessive pres sure

is created. The m ost noticeable symptom of excess press ure is a slow down of refrigerant

flow duringtherecovery process. Inm ost cases, you will not notice a reduction in refrigerant

recovery rate until the nominal press ure in the storage tank is 20 ps ig above the normal

pres sure, as listed on the purge chart. C he ck for non-condensable gases after each

recovery phase. The table provided below (Figure 13)is used to determine when an exces s

ofnon-condensable gases has accumulated in the refrigerants torage tank.

16

Page 17

INSTRUCTIONS MA NUAL

Proceedas follows:

“REFRIGERANT AVAILABLE” LED must light, if it is neces sary pres s the SEL key to switch

th e ligh t to “R EFRIGERANT AVA ILABL E” LED.

1. Press once the “°F” key in order to display the refrigerant tank temperature (in

Fahrenheit degree), press it a s econd time to display the temperature in Celsius

degree)

2. Read thestoragetank pressure ofthetank gauge

3. Find the temperature in the TEMP °F column for that tank then read the associated

PR ESSURE colum n in ps ig.

4. If the related TANK PRESSURE gauge (A4, fig.5) reads LOWER or EQUAL than the

nominal press ure listed in the table for the respective tank temperature, IT IS NOT

NECESSARY to vent the non-condensablegases from the tank.

5. If the related TANK PRESSURE gauge (A4, fig.5) reads HIGHER than the nominal

pres sure listed in the table for the respective tank temperature, you s hould vent the

non-condensable gases from the tank. This is accom plished byopening the air purge

valv e as shown in figures 1,2,3, & 4.

6. Press the STOP keyto exit the reading of the tank temperature

7. Slowly open the air purge valve (r,fig.2) counterclockwise (turn ~20 degree)

8. Once openedthe air purge valve r,(fig.2)check the tank press ure gauge and the value

shown bythe display.

9. Close the air purge valve when the tank pres sure comes down to the nominal

pres sure listed in the table.

Fig.13:Normal R-134° containerpressure chart

17

Page 18

IN STRU CTIONS M ANUAL

VACUUM PHASE

1. Upon completion of the RECOVERYphase it is poss i ble to start the vacuum phase by

opening the high- and low-pres sure valves, press ing the SEL key until the LED

corresponding to “EVACUATE”lights , andthen pressing GO. The vacuum time can be

set as follows. Press SEL until the“EVACUATE” LED lights, then press ENTER; at this

point the first digit on the left of the displaywill begin to flash. Pres s the INCREASE key

until the desired digit appears. Likewise, pres s the ARROW and INCREASE keys to

change the other digits. When s etting is complete, pres s the ENTER key to confirm the

vacuum time value.

2. During the vacuum phase, the display will clock its duration. Leave the machine

running until the displayreads 0000 and the pump stops autom atically.

3. Close all the valves and read the vacuum value on press ure gauges (A1) and (A2).

Wait for about 2 minutes, and then check that the pressure has not increased during

the interval. An increase in press ure s ignals leaks in the A/C system. Locate and

eliminate the leaks ; repeatthevacuum phase.

WARNING: Avoid breathing A/C refrigerant and lub ricant vapor mist. Exp osure may

irritate eyes, nose, and throat. To remove HFC-134a from the A/C system, use service

equipment certified to meet the requirements of SAE J2210 (HFC-134a recycling

eq uipment). Additional health and saf ety information may be obtained from add itional

refrigerant and lubricant manufacturers.

NE W OIL INJ ECTI ON

You caninjectvirgin lubricating oil into the vehicle A/C s ystem at this time. Make certain that

theOil ChargeBottle has sufficient quantity of oil. Cautiously open the Oil Charge valve until

thes ame amount of oilthatwas recovered in theRECOVERYAND RECYCLING operation is

removedfrom thecontainer and replaced back into the vehicle's A/C s ystem. The oil will be

drawn into the vehicle A/C s ystem bythe deep vacuum that was obtained while evacuating.

Thes ubsequent charging ofrefrigerantwill ensureall ofthe oilwill be charged from the lines

and hoses.

RECH AR GE AN A/ C SYST EM

WARNING: Always w ear safety goggles and hand protection when working with

refrigerants. Failure to follow these procedures may result in serious injury. Due to the

extreme cold temperatures associated with the use of refrigerants, any contact with the

eye can cause bli ndne ss and contact with the bare skin can cause burns or frostbite.

CAUTION: W hen charging a veh icle do not lean on the machine as this may affect the

scale readings. Inaccurate weight measurements may result. The vehicle system can

be damaged if weights are not measured accurat ely.

During this phase, the correct refrigerant charge is returned tothe vehicle’s A/C system.

1. Press the SELkeyuntil the“RECHARGE”LED lights.

2. Proceedas described below tosetthe quantity ofrefrigerant fluid to be charged. Press

the ENTER key. The firs t digit on the left of the display will begin to flash. Pres s the

INCREASE keyuntil thedesired valueappears. (Digits read in pounds and ounces, or

kilogram s.)Likewise, press the ARROW and INCREASE keys to change the values of

the other digits. Press ENTER when setting is completed to confirm the values . The

quantityof fluid required for filling the s ystem is usually reported on a data plate in the

engine compartm ent of the vehicle. If the quantity is not known, cons ult the relevant

system operating and maintenance m anuals.

18

Page 19

INSTRUCTIONS MA NUAL

3. Open the high- andlow-pressure valves (if previously closed) and press the GO key.

4. Themachine will s top automatically when the preset quantity has been charged. If the

A/C s ystem press ure increases to equal the tank press ure, and the charge is not

complete, it will be necessary to draw the remaining refrigerant into the system using

thevehicle compressor as outlined below.

5. Close the high- and low-pressure valves.

6. Start thevehicle motor andswitch on the A/C s ystem, and allow both to run for atleast 3

minutes. At this point thesystem will be at steady state and it will be possible to check

thehigh and low side values on therelative pres sure gauges .

7. Disconnect ONLY the high-press ure quick-connect coupling (if necessary, switch the

engine off). Then, with the A/C system still running, open the high and low press ure

taps toforce the A/C system to draw up the refrigerantcontained inthe hoses.

8. After about 1 (one) minute, disconnect the low-pres sure couplings of the VIPER VR-

6000 from the vehicle A/C system and switch off the engine.

WARNING: W hen removing hoses from the vehicle, use extreme caution. Wear gloves

and eye protection.Take care not to allow ref rigerant to ent er the eyes. Liquid refrigerant

wil l cau se severe burns and/or frostbi te to exposed skin, blindness if sprayed into the

eyes, andeven the possibility of death ifinhaled.

RECOVERING THE REFRIGERANT IN THE HOSES.

1. Set the MAIN POWER switch ON and open the high s ide and low side valves on the

front of the machine.

2. Press andhold theSEL keyuntil the LEDuntil the LED corresponding to “RECOVERY”

lights; then pres s GO. At this point the RECOVERY/RECYCLING phase will begin; the

“REC OVER Y” LED w ill fl as h.

3. When all of the refrigerant has been removed from the hoses, the machine will

automatically shut off and the lamp in thes witch will extinguish.To avoid going through

an “unneces sary and time consum ing oil dumpingphase”,press the stop keyas soon

as press ure in low press ure hose reaches zero.

4. Close the High Side Valve and Low Side Valve andturn off the m achine’s main power.

19

Page 20

IN STRU CTIONS M ANUAL

MAINTENANCE

REPLACING REFRIGERANT FILTER/DRYER

TheVIPER VR-6000 is equipped with two high side refrigerant filters/dryers and a low side

refrigerantfilter/dryer (see figure14). Inorder to maintain high qualityrecycled refrigerant:

• The low s ide refrigerant filter/dryer must be changed when the VR-6000 displays the

service alarm [SERV]and the led“REPLACE FILTER” lights up.

NOTE: When recovering new refrigerantas when the machine is first placed in service

this alarm will light abnormally early and may be cleared by pres sing the “SEL” key

while turningon themachine.

• The high-pres sure refrigerant filters/dryers m ust be replaced after approximately 30

hours of operation or 150 servicejobs.

ATTENTION: Use only Clore Automotive Filters Part No. 315-032-000 (Low )

andPart No. 315-035-666(High).

When changing the high pressure filters it is recomm ended that you disconnect the liquid

hose from thestorage tank (close the hose valve and the liquid tank valve first), and recover

the refrigerant from the machine with another m achine through the liquid hose. Then

proceed as described below:

1

2

3

Fig.14: Dryer filters

20

Page 21

INSTRUCTIONS MA NUAL

If the high and low gauges indicate positive pressure, then recover the refrigerant in the

hoses back into the storagetank.

1. Disconnect the machine from main power supply.

2. Puton gloves and s afetygoggles.

3. Remove the rear plas ticcover.

4. Close the valves on the storage tank.

5. Close the L.P. filter-tap. (3)

6. Working slowlyand carefully, unscrew the couplings atthe inlet and outlettothe filters.

7. Loosen thefilterclamps .

8. Replace thefilters, taking care to insertthem in thecorrect direction. (1,2)

9. Tighten the clamps and the couplings at the inlet and outletto the filters.

10. Open the valves on the s torage tank.

11. Open the L.P. filter- tap. (3)

12. Replace the rear plastic cover.

13. Reconnect and switch on the MACHINE.

14. During the firs t 10 seconds (when the service alarm [SERV] is displayed), press the

SEL key.

15. Type in thefiltercode 0014 tocancel thealarm (use the

16. Charge andrecover about 8 oz.of refrigerant to chargethe machine circuit.

17. SwitchofftheMACHINE

18. Disconnectthemachine from main power supply.

CAUTION: Replace the oldfilter with the new one as quickly as possible in order to avoid

possible con tami nation with the humidity inthe ambient air.

INCREASE and ARROW keys).

EMPTYING THE USED OIL TANK

This operation must be performed after everyrecovery.

Procedure: remove the tank from its lodging and unscrew the cap; empty the tank into a

container forused oils, Replace the cap and replace the container inits lodging.

CASE CARE

Ifthe case of the unit becomes soiled, clean with a m ild detergent and a clean rag. Do not

use solvents – some solvents may cause a deterioration of the material and harm your A/C

Service Center.

AIR CONDITIONING HOSE MAINTENANCE

Them anufacturer recomm ends that the hose s eals be checked periodically and replaced at

thebeginning of each season,at minimum. Contactyour local distributor when replacem ent

seals areneeded.

CALIBRATING THE ELECTRONIC SCALE

This operation s hould be performed when the s cale values displayed are out of line with

known values.The operations listed below must be performed with the maximum attention

and care. Always observe the precautions outlined in this section. Always place the weights

carefully on the scale plate, one at a time. Always place the weights the center of the scale

plate.Proceed as explained below tocalibrate the s cale (see fig. 1,2, 3, & 4). Disconnectthe

machinefrom m ain power supply. Procure a known reference weight (50 lbs). Remove the

plasticcover onthe rear of the m achineto access the machine bottle. Close the blue and red

valves on the storage tank. Remove the s torage tank locking bolts. Separate the heater

21

Page 22

IN STRU CTIONS M ANUAL

blanket(i) from the s torage tank (donot touch or disconnect the wires of the heater blanket).

Extreme care must be taken when removing the storage tank, so as to avoid pulling

wires loose anddamaging the copper tubing.

Remove the s torage tank (f) from its seat, leavingthe heater blanket around the s cale plate.

Rest the s torage tank on a stand at least 10” in height. Switch on the MACHINE. Be careful

not to touch any electrical wires . Wait at least 10 s econds and press STOP to s ilence the

alarm . Press the INCREASE and ARROW keys s imultaneously and hold down for about 5

seconds. The value displayed at this point will correspond to the scale zero value. Press

down lightlyon the s cale plate; the value should increase. If it does not, replace the charge

cell. Press the ENTER key to m emorize the value. In this phase, take care that nothing

touches the s cale plate). Place the reference weight (50 lbs) carefully at the center of the

scale plate andcheck that the displayed value increases accordingly. Press the SEL keyand

us e the INCREA SE & ARROW keys to typ e in the 4 figures of the ref erence weight. Press

ENTER. The display reading should be the reference weight minus the weight of the em pty

bottle (tare weight).

Remove the reference weight. Switch off the machine and disconnect from main power

supply. Replace the s torage tank in its s eat on the scale plate. Switch on the MACHINE,

taking care not to touch any electrical wires . Check calibration: place a known reference

weight onthe bottle and check that the displayed availability value increases bythe value of

theknown reference weight±2%. Removethe reference weight. Switch off the m achine and

disconnect from m ain s upply.Replace thestoragetank lockingbolts . Open the red and blue

storage tank valves. Replace the rear plas ticcover.

NOTE: In order to check the scale calibration the unit must be displaying a positive value for

REFRIGERANT AVAI LABLE,if the display is reading zero additional weight must be added

to the top of the tank to get a positive reading. The known weight is then added and the

change in weightis verified as the k nown weight.

VACUUM PUMP

Perform the operations listedbelow on a routine basis in order to ensure good operation of

thevacuum pump.

M.1) Oil top- u p

M.2) Oil change

M.3) Decontam in ation

When topping-up or replacing the pump oil, us e onlyVIPER No.793091Vacuum Pump Oil.

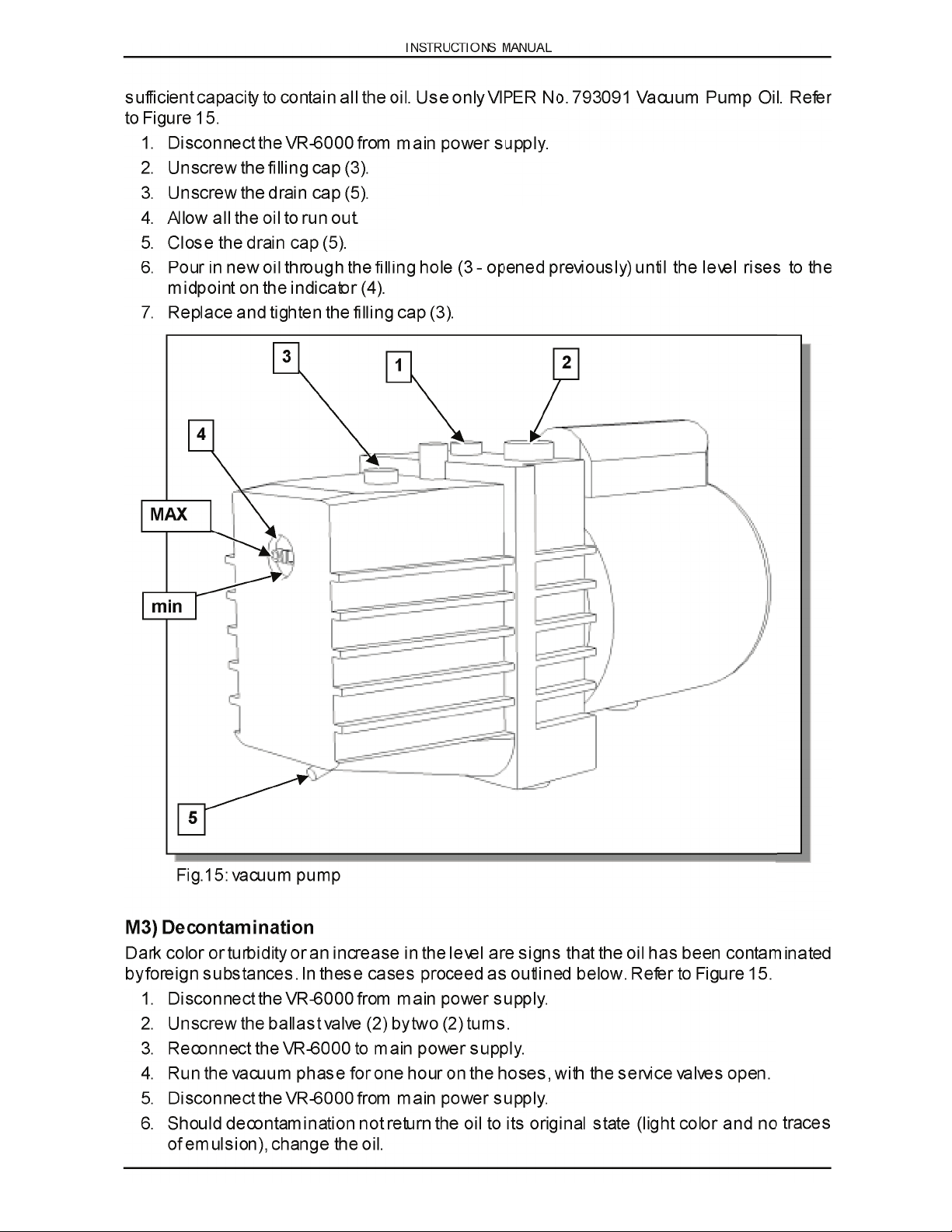

M.1) Oil top-up

This operation must be performed when the level of the oil falls to less than half on the

indicator (4 - Figure 15). To refill the oil, perform the steps listed below in the order given.

Refer toFigure 13.

1. Disconnect the VR-6000from m ain power supply.

2. Unscrew the filling cap (3).

3. Pour oil into the tank until theoil level is about half on theindicator (4).

4. Replace theoil cap (3)and tightendown.

M.2) Oil change

The vacuum pump oil must be replaced once a season and in any case every time the

refrigerant filters are replaced. The oil m ust also be changed whenever it changes color,

becom ing dark and turbid, since this is a s ign that it has been contaminated and has

absorbed humidity. Before beginning the oil change procedure, procure a container of

22

Page 23

23

Page 24

IN STRU CTIONS M ANUAL

TROUBLESHOOTING

RECOVERY PROBLEMS

Problem: “HIGH-PRESSURE”LED

Solution:

Be sure tank valves are open and hoses are properly connected to the tank. Check for the

pres ence ofair in the s torage tank (see air purge), if necessarypurge as required.

After a HIGH PRESSURE shutdown itwill be neces sarytoremove the back plastic cover and

manually reset the high pressure switch bypressing on the sm all red button on the top of the

pressureswitchlocatedonthetopofthemanifold.

Problem: “SERVICE” message

Solution:

Remove andreplacethe low side filter/dryer. SeeREPLACING THEFILTER/DRYER

Problem: When in RECOVERYdisplay shows error n°1 (ER01)

Solution:

TheA/C system is em pty, runEVACUATE

Problem: When in EVACUATE the displayshows error n°2 (ER02)

Solution:

The A /C system isn’t empty,run RECOVERY

NO DISPLAY WHEN MAIN POWER SWITCH IS ON

Problem: Blown main fuse

Solution:

Replace fuse 15A, located in the input power connector. A spare fuse is included in the

machine.

REF ILLING DOES NOT FLO W

Problem: Refrigerantsupplyempty orlow

Solution:

Add refrigerantto the tank, check thescale calibration.

Problem: Pres sure oftheA/Cs ystem equals the press ure ofthe bottle

Solution:

Close the high side tap, turn on the A/C system, let the compress or of the A/C system

recover the remaining refrigerant.

Problem: Tank valves closed.

Solution:

Open liquid(RED) valve and be sure hose is properly connected to the tank and theunit.

24

Page 25

INSTRUCTIONS MA NUAL

MANUFACTURER’S LIMITED WARRANTY

The m anufacturer warrants that for one year from the date of original retail purchase, it will

repair at no charge for parts and labor, this product proven defective in material or

workmanship. If, after reasonable efforts by the manufacturer, the product is deem ed not

repairable, The manufacturer will, at its option,refund the original purchase price or s upplya

replacem ent unit.

THE TERMS OF THE MANUFACTURER’S LIMITED WARRANTY CONSTITUTE THE

BUYER’S SOLE AND EXCLUSIVE REMEDY. THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIM ITED IN

DU RATION TO TH IS EXPR ESS WARRAN T Y.

AFTER ON E YEAR FR O M DATE OF PURCHASE, AL L RISK OF LOSS FROM WHA TEVER

REASON SHALL BE PUT UPON THE PURCHASER. THE MANUFACTURER SHALL NOT

BE LIABLE FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES UNDER ANY

CIRCUMSTANCES: MANUFACTURER’S LIABILITY, IF ANY, SHALL NEVER EXCEED THE

PURCHASE PRICE OF THIS MACHINE, REGARDLESS OF WHETHER LIABILITY IS

PREDICTED UPON BREACH OF WARRANTY (EXPRESS OR IMPLIED), NEGLIGENCE,

STRICT TORT OR ANYOTHER THEORY. THIS WARRANTY DOES NOT COVER LOSS OF

REFRIGERANTUNDER ANY CIRCUMSTANCE.

This warrantyextends to each person who acquires lawful ownership within one year of the

original retail purchase, but is void if the product has had any refrigerants other than R134a

or refrigerant sealants introduced, or has been abused, altered, misused or improperly

packaged and damaged when returned for repair. This warranty applies to the product only

and does not apply to any accessory items included with the product which are subject to

wear from us age; the replacem ent or repair of these item s shall be at the expense of the

owner. Some states/provinces do not permit the limitation of warranties or limitation of

cons equential or incidentaldamages, so the above disclaim er and limitation m ay not apply

toyou. This warranty gives youspecific legal rights, and you may also have other rights which

vary from s tate/province to state/province.

TO OBTAIN SER VICES UND E R THIS WAR RANT Y

1. Owner pays transportation charges to and from the address listed below or clos est

service center.

2. Owner may avoid transportation charges, if he/s he wishes , by calling AIR

CONDITIONING SERVICE CENTER REPAIR SERVICE, at the telephone number

below, for free diagnosis and immediate s hipment of replacem ent parts. The owner,

in this case, assumes the responsibilityforinstallation ofparts.

For answers to questions concerning use, out of warranty s ervice, or warranty/service

inform ation, contact:

FREETECHNICAL SUPPORT SERVICE1-800-328-2921

25

Page 26

MANUEL D’INSTR UCTIONS

INDEX

INDEX..........................................................................................................................................................................................................26

RÉSUMÉDES NORMESDE SÉCURITÉ..................................................................................................................2 7

INFORMATIONS SUR LA SÉCURITÉ.........................................................................................................................27

RISQUEDE DÉC HARGE ÉLE CTRI QUE 28

RISQUES LIÉ S A U MOU VEMENT 28

RISQUES DEFUMÉ ES 29

RISQUES LIÉ S À LA CHALEUR /AU FROID 29

RISQUES D’E XPLOSION / INC ENDI E 29

INFORMATIONS SUPPLÉMENTAIRES SUR LA SÉCURITÉ .....................................................................3 0

INTRODUCTION...............................................................................................................................................................................30

GÉNÉRALITÉS............................................................................................................................... .............................................30

CERTIF IC AT IO N........................................................................................................................................................................30

INFORMATIONS SUR CE MANUEL ............................................................................................................................3 0

RENSEIGNEMENTS SUR LA STATION DE RÉC UPÉRATION REC YCLA GE VIP ER.............3 1

LAMACHINE.........................................................................................................................................................................................3 1

COMPOSANTSFONDAMENTAUX..............................................................................................................................31

COMMANDES ET VOY ANTS...........................................................................................................................................33

clavier de sÉlection des fonctions..................................................................................................................................33

clavier de sÉlection des fonctions..................................................................................................................................34

PANNEAUVOYANTS ET ALARMES............................................................................................................................35

ENTRÉE MESURES.................................................................................................................................................................36

VIPER VR-6000 SPECIFICATIONS..............................................................................................................................36

PRÉPAR ATION À L’ EMPL O I ..................................................................................................................................................36

GÉNÉRALITÉS............................................................................................................................... .............................................36

PRÉPARATION...........................................................................................................................................................................36

TRA NSFÉRER DU RÉFRIGÉ RANT NEUF DANS LA BOUTEILLE DE STOCKAGE.................37

INSTRUCTIONS POUR LES INT ERVE NTIO NS.................................................................................................3 9

RÉCUPÉRATION/RECYCLAGE DE RÉFRIGÉRANT D’UN SYSTÈMEA/C....................................39

PURGE DES GAZ NON CONDENSABLES............................................................................................................40

PHASE DE VIDE.........................................................................................................................................................................41

RECHARGE D’UN SYS TÈME A/C............................................................................................................................... ..42

RÉCU PÉRATION DU RÉFRIGÉ RANT DAN S LES TUYAU X FLEXIBLES..........................................43

MAINTENANCE..................................................................................................................................................................................43

26

Page 27

MANUEL D’INSTR UCTIONS

REMPLACEMENT DESFILTRES DÉSHYDRATEURS..................................................................................4 3

VIDANGE DU RÉCIPIENT D’ HUILE USÉE...............................................................................................................45

LESOIN DUCAS........................................................................................................................................................................45

MAINTENANCE DES TUYAUXFLEXIBLES A/C..................................................................................................45

ÉTALONNAGE DE LA BALANCE ÉLE CTRONIQUE........................................................................................45

POMPEÀVIDE...........................................................................................................................................................................46

M.1) Rajout huile 46

M.2) Vidange huile 47

M.3) Déco n t amination 47

Recherche des pannes..........................................................................................................................................................47

PROBLÈMES DE RÉCUPÉRA TION 47

EN A LLUMAN T L’I NTER RUP TE UR PRI NCIP AL, RIE N N’ APP ARA Î T SUR L’ AFFICHAGE 48

LEREMPLISSAGENECIRCULEPAS 48

GAR ANTIE LIMITÉE DU FABRICA NT............................................................................................................................49

RÉSUMÉ DES NORMES DE SÉCURITÉ

Félicitations pour votre achat de la nouvelle la station de Récupération/Recyclage des

installations d’air climatisé VIPER VR-6000. Les inform ations sur la sécurité illustrées ciaprès s ont fournies comme lignes-guide pour vous aider à utilis er votre nouveau s ystème

dans des conditions de s écurité le plus possible maximum. Tout appareil qui utilis e des

substances chimiques peut être potentiellem ent dangereux à manier si les instructions de

sécurité de leur maniement ne sont pas connues ou s uivies. Les instructions de sécurité ciaprès s ont données envue de fournir à l’us ager les informations nécess aires pour utilis er

et m anier l’appareil en toute sécurité. Nous vous prions de bien vouloir lire et mémoriser

ces instructions pour utiliser votre s ystème de m aintenanceconstammenten toute s écurité.

INFORMATIONS SUR LASÉCURITÉ

Tout ouvrier respecte ses outils de travail. Il s ait que ces outils représentent des années

d’études en vue de leur am élioration et de leur développement constants. Le véritable

ouvrier sait également que les outils sont dangereux lorsqu’ils sont utilis és erronément ou

employés à des fins différentes. Pour diminuer les risques d’accidents, de maladies ou

même de m ort, il faut lire, comprendre, suivre et appliquer les instructions de sécurité ciaprès . Il faut également s’assurer que toute autre personne utilis ant cetappareil comprenne

etapplique également ces instructions de sécurité.

BIE N LIRE ATT ENTI VEMENT TOU TES LES INFORMA TIONS CON CE RN ANT LA SÉC URITÉ

avant d’essayer d’installer, manier ou réparer cet équipement. Le non-respect de ces

instructions peut entraîner des accidents auxpersonnes et/ou provoquer des dommages

auxchoses.

CONSERVER CES INFORMATIONS SUR LA SÉCURITÉ POUR TOUTE FUTURE

RÉFÉRENCE.

Les règlements et normes de sécurité publiés sont disponibles. Ils sont indiqués dans les

INFORMATIONS SUPPLÉMENTAIRES SUR LA SÉCURITÉ à la fin de ce RÉSUMÉ DES

NORMESDE SÉCURITÉ.

27

Page 28

MANUEL D’INSTR UCTIONS

Le Code National Électrique (les règlements en matière de sécuritésur les lieux de travail et

en matière de santé, les codes industriels locauxet les règlements locaux des Inspections

du Travail) fournissent des bases s upplémentaires pour l’installation, l’utilisation et la

maintenance des appareils et des outillages.

Les symboles d’avertiss ementci-après identifient les messages importants de cem anuel.

Lors que vous voyez l’un des symboles indiqués dans ce manuel, faites bien attention à la

possibilité d’un risqued’accident personnel et lire attentivementle message qui suit.

RISQUE DE DÉ CHARGE ÉLECTRIQUE

ATTEN TION :

• Pour diminuer le danger de décharge électrique, toujours débrancher la

machine du réseau avant d’entreprendre n’importe quelle opération

d’entretien et/ou de nettoyage. Tout simplement éteindre les interrupteurs de

commande ne diminuera pas cerisque.

• En cas d’endomm agements du câble ou de la prise d’alimentation, ne pas faire

marcher la stationde Récupération/Recyclage des installations d’air climatisé VIPER

VR-6000 et remplacer immédiatem ent le câble ou la prise. Pour diminuer tout risque

d’endomm agementdu câble et/ou de la prise, débrancher l’alimentateur en retirant la

pris e etnon en tirantle câble.

• L’utilisation d’une prolonge est déconseillée et ne devrait être utilisée qu’en cas de

néces sité absolue. L’utilis ation erronée d’un câble-prolonge pourrait être source de

risqued’incendie et/ou de décharge électrique. Encas de nécess ité d’utilis ation d’une

prolonge, toujours vérifier:

• que le nombre, les dimensions et la forme des contacts de la prise de la prolonge

sont identiques à ceux de la prise de l’appareil de recyclage.

• que la prolonge es t correctementcâbléeeten bonnes conditions électriques; et

• que par rapport à la longueur du câble, la dimension des conducteurs est

suffisamm ent grande et comme indiqué ci-après:

Longueur du câble en pieds: 25 50 100 150

Dimension AWG du câble: 16 12 10 8

RISQUES LIÉS AU MOUVEME NT

ATTEN TION :

• Les parties du m oteur en mouvem ent et tout mouvement inattendu et/ou

soudain du véhicule peuvent provoquer des bless ures et m ême la mort.

Lors que l’on travaille à proximité d’un moteur en mouvement, toujours porter des

vêtements près du corps et ne jamais approcher les doigts ou les mains près des

parties en mouvement. Ne jamais laiss er les tuyaux flexibles et/ou les outils à

proxim ité des parties en mouvement. Toujours rester éloigné des parties du m oteur

en mouvement.Les tuyauxflexibles et les outils peuvent être projetés en l’air si on les

laiss e à proxim ité des parties du m oteur en mouvement.

• Tout mouvement inattendu et/ou s oudaindu véhicule peut provoquer des bles sures et

même la mort. Lorsque l’on travaille sur un véhicule, toujours tirer le frein de

stationnem ent ou bloquer les roues du véhicule en cours d’opérations de

maintenance.

28

Page 29

MANUEL D’INSTR UCTIONS

RISQUES DE FUMÉES

ATTEN TION :

• FUMÉES , GAZ ET VAPEURS PEUVENT ENTRAÎNER DES MALAISES, DES

MALADIES ET LA MORT! Pour réduire le risque d’accident, maladie et/ou

décès , lire attentivement, bien comprendre et appliquer les instructions de sécurité

illustrées ci-après. Toujours contrôler que toute personne utilisant cet appareil

comprenne etse conforme auxinstructions de sécurité ci-après.

• Eviter de respirer vapeurs et aéros ol du liquide réfrigérant et du lubrifiant. Toute

exposition peut être cause d’irritation des yeux, du nez ou de la gorge. Pour retirer

l’HFC-134a du système de clim atis ation de l’air, utiliser des outils de m aintenance

munis du certificat de conformité aux prescriptions SAE J2210 (outillage pour le

recyclage del’HFC-134a).).

• Les renseignements et les informations supplémentaires sur la santé et la sécurité

peuvent être obtenus directement auprès des fabricants de réfrigérants et de

lubrifiants.

• Toujours effectuer les interventions sur un véhicule dans un local suffisamm ent aéré.

Ne jamais faire démarrer un moteur s ans une aération suffisante pour les gaz

d’échappement.

• En cas d’irritation momentanée des yeux, du nez ou de la gorge, interrompre les

opérations de recyclage car de telles irritations indiquent que l’aération es t

insuffis ante. Interrom pre le travail et adopter toutes les m esures en vue d’am éliorer

l’aérationdelazonedetravail.

RISQUES LIÉS À LA CHALEUR /AU FROID

ATTEN TION :

• Les réfrigérants deviennent liquides sous press ion. S’ils sont libérés

accidentellem ent ils passent del’état liquide à l’état gazeux en évaporant. En

cours d’évaporation,ces réfrigérants peuvent congeler les tissus et/ou provoquer des

gelures. S’ils s ont inhalés ils peuvent provoquer des lésions graves aux poumons. Ils

peuvent même provoquer la m ort en cas d’inhalation en quantité suffisante. Dans le

cas où vous pens ez que vos poumons ont été exposés à ce risque (gaz réfrigérant

libéré dans l’atmosphère) contactezim médiatement un médecin.

• Les réfrigérants peuvent provoquer de graves gelures et/ou brûlures de la peau. Les

réfrigérants s ont conservés s ous press ion et en cas de m aniement erroné peuvent

gicler violem ment. Eviter tout contact des réfrigérants avec la peau: toujours porter des

gants ets’ass urer que le reste de la peau soit suffisammentcouvert etdonc protégé.

• Les réfrigérants peuvent également entraîner de graves lésions des yeux non

protégés et même une cécité perm anente. Les réfrigérants sont cons ervés sous

pres sion eten cas de m aniement erroné peuvent gicler violemment. Eviter tout contact

des réfrigérants avec les yeux: toujours porter des lunettes de protection.

RISQUES D’E XPLOSION / INCENDIE

ATTEN TION :

• Ne jamais utilis er de réfrigérants différents de ceux dont l’emploi est

spécifiquement approuvé pour la station de Récupération/Recyclage des

installations d’air climatis é VIPER VR-6000. Les réfrigérants alternatifs peuvent

contenir des substances inflammables comm e le butane oule propane et peuvent par

29

Page 30

MANUEL D’INSTR UCTIONS

cons équent exploser ou provoquer un incendie. Toute utilisation de réfrigérants

alternatifs annulera également la garantie relative à la machine VIPER VR-6000.

• Pour des raisons de s écurité générale, contrôler que toutes les vannes et/ou robinets

montés s ur les tuyaux flexibles et les réservoirs s ont fermés : ce contrôle doit être

effectué à la fin de chaque journée de travail ou entre deux interventions d’entretien

(lorsqu’elles n’ont pas été effectuées immédiatement l’une après l’autre).

INFORMAT IONS SUPPLÉMENTAIRES SUR LASÉCURITÉ

Pour toute inform ation supplémentaire s ur la sécurité, s e reporter auxnorm es ci-après.

ANSI Standard Z87.1 Safe Practice For Occupational And Educational Eye And Face

Protection;disponible auprès de l’American National Standards Institute, 11 West 42nd St.,

New York, NY10036, Téléphone (212) 642-4900, Fax(212) 398-0023, www.ans i.org.

INTRODUCTION

GÉNÉRALITÉS

Merci d’avoir acheté notre station de Récupération/Recyclage des installations d’air

clim atis é VIPER VR-6000. Votre VR-6000 est approuvé par le Underwriters Laboratories

Inc.® en conformité avec les prescriptions de la SAE J 2210 (1991). Notre spécialité es t la

solution des problèmes relatifs à la conservation en toute sécurité et la gestion correcte des

CFC (gaz chlorofluorocarbones). Votre nouvelle m achine VR-6000 allie la technologie la

plus récente et les caractéris tiques en l’étatactuel de la technique pour vous aider dans vos

interventions de maintenance des systèmes de conditionnement et réfrigération de l’air.

Lors que vous utiliserez cette m achine, nous espérons que vous trouverez le même plaisir

que celui quenous avons éprouvé à la concevoir etla cons truire.

CERTIFICA T ION

Tout technicien qui ouvre lecircuitréfrigérantd’une installation de clim atis ation d’un véhicule

doit, aujourd’hui, avoir la certification relative aux procédures de récupération et recyclage

des réfrigérants, conformément au paragraphe 609du Clean Air Act Amendments de 1990.

Pour tout renseignement s ur cette certification contacter MACS Worldwide au numéro (215)

631-7020.

INFORMATIONS SUR CE MANUEL

Ce m anuel comprend un RÉSUMÉ DES NORMES DE SÉCURITÉ, les opérations de

PRÉPARATION À L’EMPLOI de la m achine ainsi que les instructions de MAINTENANCE,

relatives à la stationde Récupération/Recyclage des installations d’air climatisé VIPER VR-

6000. Toute personne qui désirese servir de la VR-6000 doit lire TOUTES les informations

contenues dans ce manuel avant d’essayer de l’utiliser (et tout particulièrement les

NORMESDE SÉCURITÉ).

Avant d’utiliser cette machine pour la prem ière fois, s e conformer à toutes les instructions

de PRÉPARATION ÀL’EMPLOI. Si votre nouvelle machine n’est pas correctement préparée

pour effectuer une intervention, vos données de service pourraient être erronées. Pour

effectuer une intervention complète de façon correcte sur une installation A/C, suivre toutes

les procédures dans l’ordreillustré. Nous vous prions de prendre tout le temps nécessaire

pour étudier ce m anuel avant de manœuvrer cette machine. Après l’avoir étudié, toujours

garder ce m anuel à portée de la main pour toute éventuelle consultation ultérieure.

Respecter très attentivement le contenu du RÉSUMÉ DES NORMES DE SÉCURITÉ ainsi

qu e tous le s AVERTISSEMEN TS et l es PR ÉCAUTION S il lus trés d a ns ce m anu el.

30

Page 31

MANUEL D’INSTR UCTIONS

Pour activer la garantie, envoyer le couponde garantie ci-joint.

ATTENTION: la V R-6000 est conçue pour être utilisée uniquementà l’intérieur.

RENSEIGNEMENT S SUR LA STATION DE RÉCUPÉRATION

RECYCLAGE VIPER

La couche d’ozone autour de l’atmosphère terres tre constitue un revêtement de protection

de faibleépaiss eur.Cette couche sert d’écran contre les radiations ultraviolettes émises par

le soleilet ayant un pouvoirdestructeur important. Sans la couche d’ozone, l’existence de la

vie sur notre planète serait en danger. Des études scientifiques m ontrent que la couche

d’ozone est en train de s e détruire à une vitess e alarm ante. Elles ont établi que les

émiss ions de réfrigérants , tels que l’R-12, contiennent des chlorofluorocarbones (CFC) qui

sont la cause principale de l’am incissementde la couche d’ozone. Il a été démontré qu’une

molécule de CFC peut détruire jusqu’à 100000 m olécules d’ozone. Votre VIPER VR-6000

comprend une balance électronique de haute précision en vue de déterminer les poids, les

quantités, les charges, les rempliss ages, etc. Cette balance électronique a également

d’autres fonctions comme vous le découvrirezlors des opérations que vous effectuerez. On

peut s électionner des unités de mesure anglo-saxonnes ou des unités de mesure

métriques. Votre nouvelle VIPER VR-6000 a été conçue s pécifiquement pour être utilisée

avec le R-134a, de façon à fonctionner conformément aux objectifs du Protocole de

Montré al .

LA MACHINE

COMPOSANTS FONDAMENTAUX

Voirfigures 1,2,3 & 4:

a) Pupitrede commande b) Robinets

c) Poignée d) Raccords filetés haute/bass e press ion

e) Récipienthuile neuve f) Bouteille de stockage

g) Filtres déshydrateurs h) Balance électronique

i) Couverture chauffante j) Interrupteur d’alim entation principale

k) Prise fiche alimentation électrique l) Fusible

m) Récipient huile usée n) Porte s érie

o) Indicateurd’humidité p) Pompe à vide

q) Roues r) Robinet purgeur air

31

Page 32

32

Page 33

MANUEL D’INSTR UCTIONS

COMM AN DES E T VOYAN T S

Se reporter à la Figure 5:

(A1) Manom ètre basse pres sion pour installation A/C

(A2) Manom ètre haute pres sion pour installation A/C

(A4) Manom ètre pres s i on bouteille de stockage

(A6) Tableauurgence/alarmes

(A7) Affichage

(A8) Commandes clavier numérique

(A9) Tableausélection opérations

A4

A6

A7

A8

Fig. 5:tableau de commande

A2

A1

A9

33

Page 34

MANUEL D’INSTR UCTIONS

clavier de sÉlecti on des fonctions

Se reporter à la Figure 6:

(T1) LEDDISPONIBILITÉ RÉFRIGÉRANT : lorsqu’il es t allum é, l’affichage visualis e le poids

de réfrigérant disponible dans la bouteille de stockage.

(T2) LEDREMPLISSAGE : clignote pendantla phase deREMPLISSAGE.

(T3) LEDRÉCUPÉRATION :clignote pendant laphase de RÉCUPÉRATION.

(T4) ÉVACUER : clignote pendantla phase de VIDE

(T5) LED ATTENDRE: clignote à la fin de la récupération pendant la phase de VIDANGE

HUILE.

(T6) touche SEL : sélectionne l’opération à effectuer. A chaque fois que cette touche est

pres sée, l’un des LED, de T1 à T4 s’allumera en s équence; le LED associé à chaque

opération indique que l’opération peut être commencée ou qu’elle est en cours (LED

clignotant).

(T7) toucheINCREASE: à chaque fois quecette touche est press ée pendant les opérations

de réglage du temps et de la quantité, la valeur du chiffre clignotant s ur l’affichage s era

augmentée d’une unité.

(T8) toucheFLÈCHE: à chaque fois que cette touche est press ée lors qu’une valeur affichée

clignote pendant les opérations de réglage du temps et de la quantité, un chiffre

différent sera s électionné pour être modifié (lechiffre sélectionné clignotera).

(T9) toucheENTER : en press ant cette touche lorsqu’un LED correspondant à une opération

est allum é mais ne clignote pas, permettra de modifier le temps de vide et le poids

désiré de rempliss age. Après avoir réglé la valeur désirée, appuyer à nouveau sur la

touchepour compléter l’opération.

(T10) touche GO: en press ant cette touche, l’opération indiquée par le LED allumé

34

Page 35

MANUEL D’INSTR UCTIONS

commencera

(T11) touche STOP: en pressant cette touche, l’opération indiquée par le LED allumé

s’arrêtera.

(T12) touche °F: en press ant cette touche, l’affichage montrera la température de la

bouteilles endegré Celsius ou endegré Fahrenheit.

(T13) Affichage: selon le type d’opération sélectionnée, il affiche le temps de vide, la

température de la bouteille ou le poids de réfrigérantdisponible.

PANNEAU VOYANTS ET ALARMES

Se reporter à la Figure 7:

(C1) REMPLACER FILTRE: le filtre déshydrateur de basse pres sion doit être remplacé

lors que le LED "REMPLACER FILTRE" s’allume. Lorsque l’on récupère un réfrigérant

neuf, ce voyant peut s’allumer plus vite. Pour le remettre à l’état initial, appuyer sur la

toucheSEL lorsqu’on allume la m achine.

(C2) HAUTE PRESSION: ce LEDs ’allume etémet un signal sonore lorsque la pression du

fluide dans le circuit dépas se 290 psi (20 bar). L'opération de RÉCUPÉRATION es t

automatiquement arrêtée. Ceci se passe lors que l’on es saye de récupérer le

réfrigérantavec les robinets de labouteille fermés et nécess ite quelques interventions

de démontage pour remettre en état initial. (voir paragraphe RECHERCHE DES

PANNES)

(C3) BOUTEILLE PLEINE:ce LEDs’allume etém et unsignal sonore lorsque la bouteille est

remplie à plus de 80% de sa capacité maximum, c’est-à-dire environ 40 lbs.

L'opérationde RÉCUPÉRATION est automatiquement arrêtée. Il est poss ible d’utilis er

la fonction REMPLISSAGE pour retirer leréfrigérantde la bouteille destockage.

C1

C2

C3

C4

Fig. 7: vues avant

(C4) BOUTEILLE VIDE: ce LED s’allume et émet un signal sonore lorsque la quantité de

liquide réfrigérant contenu dans la bouteille est faible, prochede 4 lbs (~2 kg). Il faudra

35

Page 36

MANUEL D’INSTR UCTIONS

ajouterdu réfrigérant pour continuer la fonction REMPLISSAGE.

ENTRÉE MESURES

En allumant votre nouvelle VIPER VR-6000, l’affichage m ontrera le poids /quantité de gaz

dans la bouteille. L’affichage peut être réglé pour lire des unités métriques ou des unités

anglo-saxonnes,en effectuant les opérations suivantes:

• Eteindre la VR-6000.

• Appuyer simultanément sur les touches SEL, GO , et ENTER en allumant la VR-6000.

La machine pass era d’un système d’unité de mesureà l’autre.

VIPER VR-6000 SPECIFICATIONS

Alimentation électrique: 115 Vac, 8 A,60 Hz

Intervallede travail à température ambiante: de 50°F (10° C) à 120° F (48.9° C)

Poids approximatif de transport: 170 lbs.

PRÉPARATION À L’EMPLOI

GÉNÉRALITÉS

Votre s tation de Récupération/Recyclage des installations d’air climatis é VIPER VR-6000

est livrée complètement assemblée et testée à 100%. Avant d’être utilis ée s ur un système

A/Cd’un véhicule, cette machine doit être préalablement préparée à l’emploi.

PRÉPARATION

La plupartdes phases ci-après s ont effectuées uniquement pour que la machine VR-6000

soit prête à fonctionner.

1. Enlever le carton d’emballage.

2. Soulever la machine VR-6000, la retirerde la palette etla poser parterre.

3. Desserrer l a vis de s écurité de la balance (Fig 9) qui avait été placée sous le plateau

de la balance pour éviter tout endomm agement de celle-ci pendant le transport.

Tourneropposé dans lesens des aiguilles d'une m ontre sixvirages pleins .

Nota: si la vis de sécurité de la balance n’est pas desserrée par en dessous du plateau, la

b alancene fonctionnera pas.

363738

Page 37

Page 38

Page 39

MANUEL D’INSTR UCTIONS

INSTRUCTIONS POUR LES INTERVENTIONS

RÉCUPÉRATION/RECYCLAGE DE RÉFRIGÉRANT D’UN SYSTÈM E

A/C

1. Avant de se raccorder au système A/Cdu véhicule, bien contrôler que les vannes des

raccords rapides sont fermées.

2. Raccorder la m achine à la haute et la bass e pression du système A/C en

maintenance.

3. Les tuyauxflexibles R-134a ont des vannes d’arrêt approuvées par les prescriptions

SAE (à déconnexion rapide). Les tuyaux flexibles sont autom atiquement fermés

lors qu’ils s ont déconnectés du s ystème A/C et ne s’ouvrent que lorsqu’ils s ont

raccordés avec les boutons m oletés tournés dans le sens des aiguilles d’une

montre. Faire coulisser le collier du raccord en arrière et le press er dans l’embout

adéquat.

• Tuyau flexible bleu dans leraccordde bass e pres sion du système A/C

• Tuyau flexible rouge dans le raccordde haute press ion du système A/C

4. Mettre l’interrupteur ALIMENTATION PRINCIPALE(k,Figure 3).

5. Ouvrir les vannes des tuyaux flexibles de service en tournant les boutons moletés

dans le sens des aiguilles d’une montre (Figure 12): ceci permettra au réfrigérant

d’affluer vers le véhicule.

6. Observer les lectures de press ion sur le niveau bas et haut guages divers latéral. Si

les lectures s ont zéro, alors fuite de système de A/C de réparation ou les bénéfices à

la phas e de vide.

7. Ouvrir les robinets de haute et de basse pres sion s itués sur le tableau de commande

de la machine.

8. Appuyer et garder enfoncée la touche SEL jusqu’à ce que le LED correspondant à

"Récupération" s ’allume; appuyer ensuite sur GO. A ce stade, la phase de

RÉCUPÉRATION/RECYCLAGEcommencera; le LED "Récupération"clignotera.

9. Pendant la phase de RÉCUPÉRATION/RECYCLAGE, la quantité de réfrigérant

récupérée par le système s era visualis ée sur l’affichage. Lorsque la phase de

récupération sera terminée, la machine s ’arrêtera et restera arrêtée pendant 3 (trois)

minutes.

10. Pendantcette phase,la machine vidange autom atiquementl’huileusée. Pour pouvoir

déterminer la quantité d’huile à rajouter dans le véhicule, il sera nécessaire de

contrôler le déversement de l’huile. Quand la décharge de pétrole est complète, la

mesure, enregistrer et vider la bouteille de décharge de pétrole. Cette quantité sera

ajoutée ausystème de A/C avant de charger. Quand il n'ya pas d'augmentation dans

la pression desystème, la pompe de vide commencera et évacuera la s éparateur de

pétroled'entrée dans le VR-6000.

11. Si, pendant ces 3 minutes, le fluide réfrigérant résiduel dans le système A/C devait

faire augm enter la press ion, la machine résumé autom atiquement à récupérer le

réfrigérant. Lorsque cette phase es t terminée, la machine ém ettra un signal sonore et

affichera DISPONIBILITÉ RÉFRIGÉRANT.

12. Fermer les robinets de haute et de basse pression situés sur le panneau de la

machine.

13. Mettre l’interrupteurALIMENTATION PRINCIPALE sur ÉTEINT.

14. Le cas échéant, débrancher la machine. (Se reporter au DÉBRANCHEMENT DE LA

39

Page 40

MANUEL D’INSTR UCTIONS

MACHINE D’UN VÉHICULE).

15. Effectuer les réparations nécessaires dusystème A/Cen m aintenance.

PURGE DES GAZNON CONDENSABLES

Lors que des gaz non condensables s ’accumulent dans la bouteille de stockage du

réfrigérant, une pression excess ive es t produite. Le s ymptôme le plus évident d’une

pres sion exces sive est le ralentis sement du flux du réfrigérant pendant la phase de

récupération. Dans la plupart des cas, vous ne remarquerez pas une diminution de la

vitesse de récupération du réfrigérant tant que la pres sion nominale sera de 20 ps ig audessus dela press ion normale, tel qu’indiquédans latable de purge. Contrôler l’existence

de gaz non condensables après chaque phase de récupération. Le tableau fourni (Figure

13) est utilis é pour déterm iner lors qu’un excès de gaz non condensables s ’est accumulé

dans la bouteille de stockage du réfrigérant.

Procéder de la façon s uivante:

“DISPONIBILITÉ RÉFRIGÉRANT” : ce LED doit s ’allumer. Si nécess aire, press er la touche

SELpour allum er le LED “DISPONIBILITÉ RÉFRIGÉRANT”.

1. Presser une fois la touche “°F” de façon à afficher la température de la bouteille de

réfrigérant(en degré Fahrenheit) ; pres ser une deuxième fois pour l’afficher en degré

Celsius.

2. Lire la pression de la bouteille de stockage sur le manomètre de la bouteille

3. Trouver la température dans la colonne TEMP °F/°C pour cette bouteille et lire la

colonne PRESSION associée enpsig.

4. Lors que le manomètre de PRESSION BOUTEILLE correspondant (A4, Figure 5)

indique une valeur INFÉRIEUREou ÉGALE à la pres sion nominale indiquée dans la

table pour la température respective de la bouteille, cela signifie qu’il NE FAUT PAS

faut purger les gaznon condensables de la bouteille.

5. Lors que le manomètre de PRESSION BOUTEILLE correspondant (A4, Figure 5)

indique une valeur SUPÉRIEURE à lapression nominale indiquée dans la table pour

la température respective de la bouteille, cela signifie qu’il FAUT purger les gaz non

condensables de la bouteille en ouvrant le robinet purgeur air, comme illustré

(Figures 1,2,3, et 4).

6. Appuyer sur la touche STOP pour sortirde la fonction lecturetempérature bouteille.

7. Ouvrir lentem ent le robinet purgeur air (r, Figure 2) en le tournant dans le sens

contraire des aiguilles d’une montre (tourner d’~20 degrés )

8. Après avoir ouvert le robinet purgeur air r, (Figure 2) contrôler le manomètre de

pres sion de la bouteille et la valeuraffichée s ur l’affichage.

9. Fermer le robinet purgeur air lorsque la pres sion de la bouteille es t inférieure à la

pres sion nominale indiquée dans latable (Figure 13):

40

Page 41

MANUEL D’INSTR UCTIONS

Fig. 13:Tablepression réservoir R-134°

PHASE DE VIDE

1. Lors que la phase de RÉCUPÉRATION estterminée, on peut faire démarrer la phas e

de vide en ouvrantles robinets de haute et de basse pression; appuyer sur la touche

SEL jusqu’à ce que le LED correspondant à “ÉVACUER” s’allume et en pres ser

ensuite la toucheGO. Le temps de vide peut être réglé de la façon s uivante. Appuyer