Page 1

Viper Shovelnose Wet Vac

Operating Instructions

Page 2

IMPORTANT!

Operator’s Manual

It is important that

you read the

operator’s

manual before

using any

machine.

This presentation will only outline

a few common issues that pertain

to the Viper Shovelnose Wet Vac.

Page 3

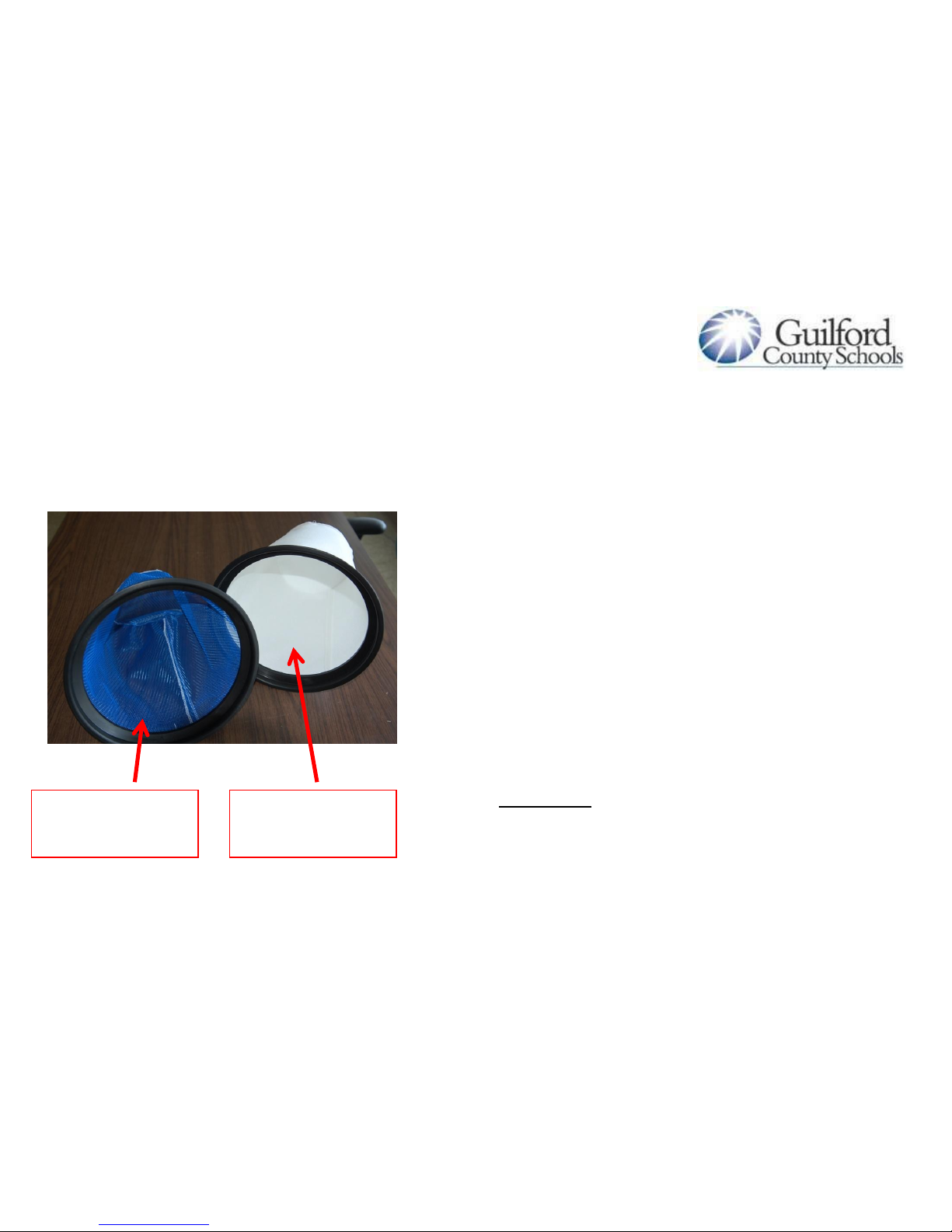

FILTERS

The Viper Wet Vac comes from the

factory with two filters—one for

WET pick up (BLUE mesh), and

one for DRY pick up (WHITE

cloth). DO NOT pick up wet

material with the WHITE filter

placed in the machine. If you

only use the machine for wet pick

up, it may be in your best interest

to discard the WHITE filter.

Filter for WET

pick-up

Filter for DRY

pick-up ONLY

Page 4

FILTERS

Place BLUE mesh filter inside tank.

The black gasket should rest on

the outside edge of the tank, and

vacuum head assembly should

be placed over the filter.

This filter is designed to keep foam

build-up from entering the

vacuum motor.

Page 5

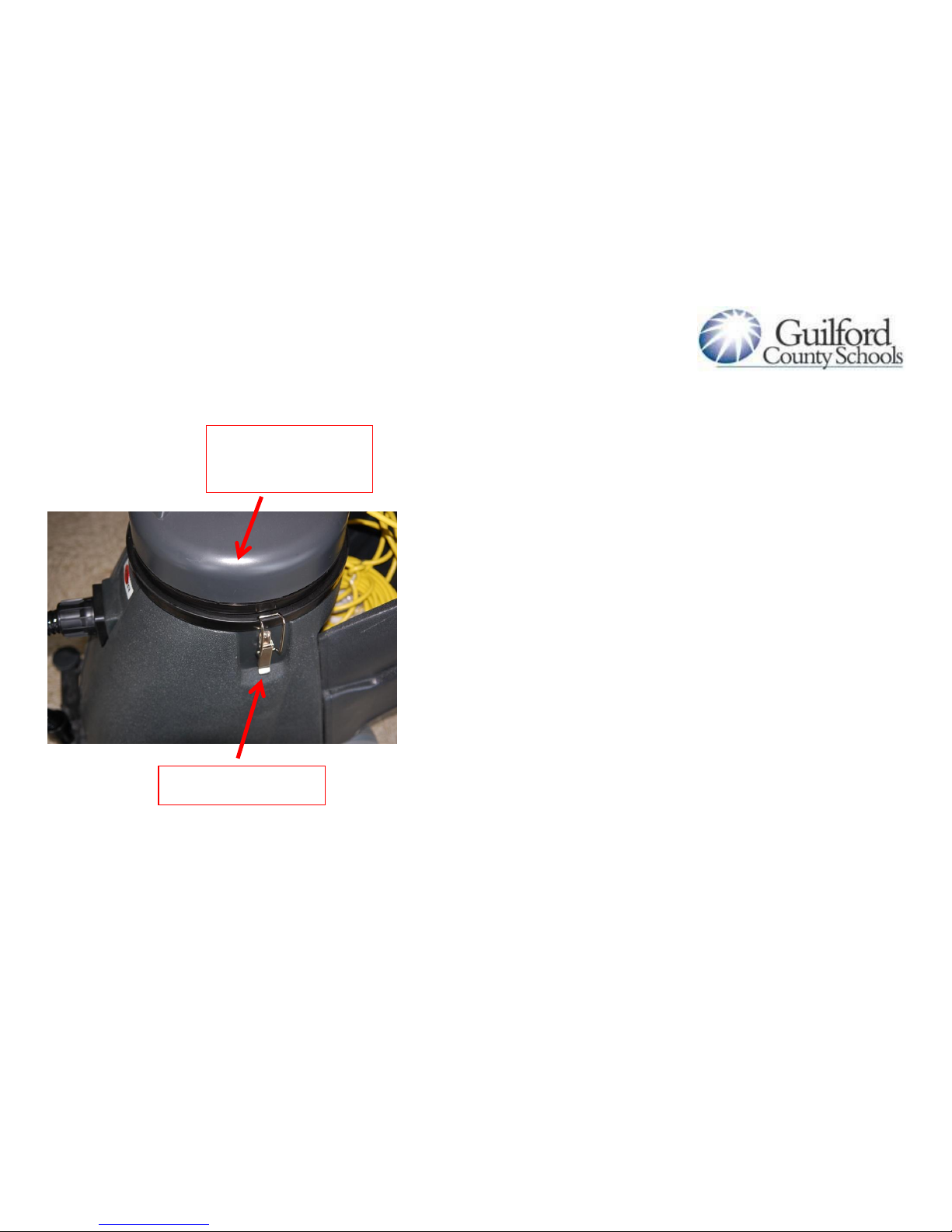

Vac-Motor Assembly

The vac-motor assembly should fit

easily over the tank. Latches are

often broken if the vac-motor

head is not properly seated on

the tank.

The latches are easily replaceable

with two screws.

Vac-Motor

Assembly

Latch

Page 6

Vac-Motor Assembly

The vac motor assembly should be

kept clean and dry at all times.

Water should not be allowed to

reach the “trumpet” (base).

Frequent emptying of the tank

will keep the vac motor from

being damaged by liquid.

Trumpet

Page 7

Ball Float Shut-Off

As a preventive measure, a ball

float shut-off is in place to keep

liquids out of the vacuum motor.

When the tank is full of liquid,

the ball will rise and you should

be able to hear the vac motor

“winding up”, like there is a clog.

This indicates that the tank is

full. However, FOAM BUILD-UP

WILL NOT ACTIVATE THE SHUTOFF!

Ball float

NOTE: “Shut-off” does not mean that the machine will power

off. It means that the vac motor air intake will be sealed—at

this point you should observe that the machine has lost

suction.

Page 8

When should I empty the

tank?

When the machine is about ¾ full,

empty the tank and properly

dispose of contents. As a rule,

do not pick up more than 10-12

gallons of solution at one time.

The red line in the photo shows the

approximate maximum fill-level.

Once that is reached, the

machine will need to be

emptied.

NOTE: Remember that FOAM will not activate the ball shut-

off. It is recommended by the manufacturer that “defoamer”

be used in the tank to dissipate foam from stripper and finish

solution.

Page 9

Excessive Foam Build-Up

and Overfilling

The Vacuum Air Intake filter screen

should remain free of any

obstruction. If it becomes clogged,

the vacuum is not going to function

properly and the motor will

overheat. This can be prevented by

proper emptying and using a

“defoamer” solution. If the

machine is overfilled, the liquid is

suctioned through this screen

directly into the vacuum motor. At

this point, it is likely that damage

has occurred.

Vacuum Air

Intake Filter

Screen

NOTE: If this area is clogged, it will cause the ball float shut-

off to activate immediately once the vacuum is powered on.

Page 10

Ground Plug

Do not operate a wet vac or any

other machine when this prong

is missing. This plug is most

often broken by not unplugging

the machine properly. Do not

unplug anything by pulling on

the cord.

Unplug electrical device by pulling

the PLUG from the outlet. If this

plug is missing, follow proper

procedures to have it replaced

immediately.

Ground

Page 11

Hose Assembly

After each use, remove the coupler

from the front of the machine

and rinse thoroughly. It is

helpful to add a lubricant to the

treads so that future removal will

be problem-free.

Coupler

Page 12

Hose Cuff

The hose cuff should be removed

after each use and rinsed

thoroughly. Floor strippers can

cause these to become brittle,

and cracking can occur in the

cuff. The vacuum will not

operate properly when the cuff

is not in good condition. These

can be easily replaced. The

custodial services department

has replacement cuffs should

you encounter this problem.

Hose Cuff

Page 13

Maintenance

1. Drain and rinse recovery tank after each use.

2. Clean ball float shut-off after each use.

3. Clean the outside of the machine with a mild

cleaner

4. Check the power cord for any damage

5. Rinse the squeegee blades with water and wipe

with a cloth.

6. Check the vacuum hose and dump hose for holes or

clogs.

7. Lubricate wheels and casters with a water-resistant

lubricant every month.

8. Check machine for loose or missing nuts or bolts,

and replace when necessary.

9. Clean the BLUE screen after each use to prevent

build-up, which will reduce air flow.

Page 14

Storage

1. Unplug machine from power

source

2. Store in upright position in a dry

area

3. Store with squeegee OFF the

ground

4. Store with the vacuum head off

unit so the tank can “breathe”

Loading...

Loading...