Page 1

Page | 1

Page 2

Page | 2

Contents

1.0 Introduction ................................................................................................... 3

2.0 The Viper Mini MKII Kit Components .......................................................... 4

3.0 Viper Mini MKII Kits Components Assembled & Numbered ..................... 5

3.1 Viper Mini MKII Standard Kit ................................................................. 5

3.1.1 Viper Mini MKII Standard Complete 20KG Kit ............................... 5

3.1.2 Viper Mini MKII Standard Complete Collar .................................... 5

3.1.3 Viper Mini MKII Standard 20KG Pump Kit ..................................... 7

3.1.4 Viper Mini MKII Standard 20KG Complete Hose ........................... 8

3.2 Viper Mini MKII High Speed Kit ............................................................. 9

3.2.1 Viper Mini MKII HS Complete 20KG Kit ......................................... 9

3.2.2 Viper Mini MKII HS Complete Collar ............................................ 10

3.2.3 Viper Mini MKII HS Standard 20KG Pump Kit ............................. 11

3.2.4 Viper Mini MKII HS 20KG Complete Hose ................................... 12

4.0 Assembly Instructions ............................................................................... 13

5.0 Ratchet Strap Buckle Assemblies - Ref: AW107 ...................................... 16

6.0 Operating Instructions ............................................................................... 17

7.0 Lubricant Penetration ................................................................................. 19

8.0 Equipment Specifications .......................................................................... 20

9.0 Trouble Shooting ........................................................................................ 21

10.0 Safety Recommendations ........................................................................ 22

10.1 Caution Level Rating ......................................................................... 22

10.2 Viper Mini MKII Assembly and Use .................................................. 23

11.0 Guarantee .................................................................................................. 24

Page 3

Page | 3

1.0 Introduction

The VIPER MINI MKII Wire Rope Lubricator is an Australian designed and built

lubricator for wire rope sizes from 6mm (1/4”) to 36mm (1 7/16”). It provides fast

and effective single pass lubrication of wire ropes, eliminating the slow and

arduous task of manual lubrication. Lubrication of wire ropes with the Viper

system provides superior protection against corrosion and fretting wear by

forcing lubricant into the core of the wire rope while also coating the outer

strands. The use of the Viper Mini MKII WRL improves operator safety and

reduces the environmental impact of wire rope lubrication for any size operation.

1.1 Key features of the Viper Mini MKII WRL include:

1. Viper collar constructed from high grade aluminium with a high visibility

corrosion resistant coating.

2. Unique polyurethane seal design provides largest pressure contact area to

ensure maximum lubri cant pen etr ati o n.

3. Durable and wear resistant polyurethane seals last thousands of meters in

normal service.

4. Seal size range to cater for rope sizes 6mm to 36mm.

5. The Viper Mini MKII Standard Kit: 50:1 grease pump delivers lubricant at

up to 2.9kg per minute and pr ess ur es up to 5,000 psi.

The Viper Mini MKII High Speed Kit: 45:1 grease pump delivers lubricant

at up to 4.5kg per minute and pressures up to 5,000 psi.

6. Global distribution network which provides local customer support.

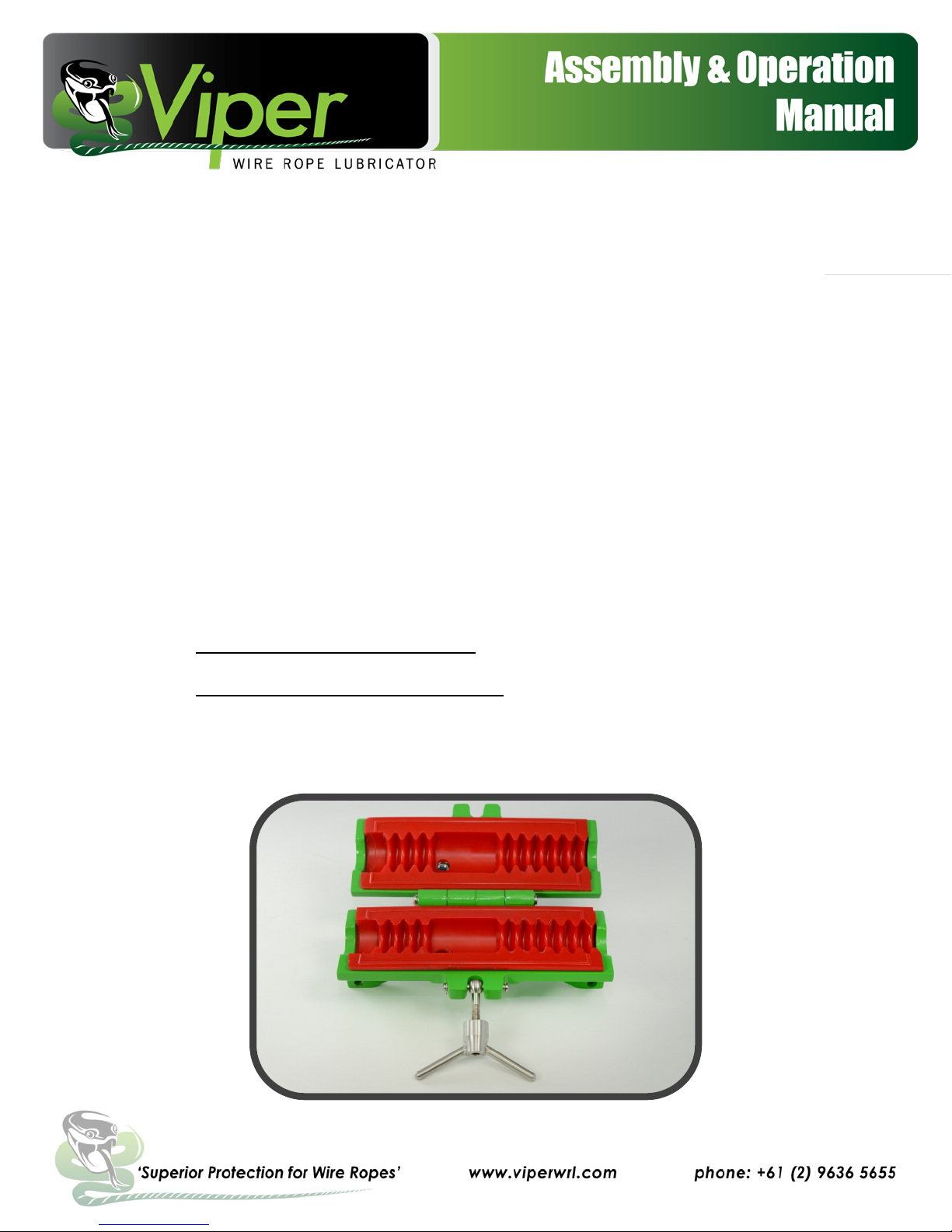

Viper Mini MKII collar with Seals in place

Page 4

Page | 4

2.0 The Viper Mini MKII Kit incl udes the following

components:

1) Viper lubricator collar, cast aluminium, includes lubricant delivery line quick

connect coupling.

2) High pressure high flow customized Viper 50:1 (Standard kit) or 45:1 (High

Speed Kit) grease pump to suit 20kg drum which comes preassembled with:

a) Air control valve

b) Air regulator with gauge

c) Male quick connect fitting

3) Four (4) metre, high pressure, 3/8” hydraulic hose complete with female quick

connect couplings on each end.

4) Two (2) x 2 metre ratchet straps rated to 500kg.

5) Four (4) x “Bow” shackles.

6) Heavy duty aluminium storage case with stainless steel fixtures.

7) Polyurethane seals (ordered separately)

a) Sized to suit specific size ropes - 6mm (1/4”) to 36mm (1 7/16”).

b) Refer to selection guide when ordering

8) Viper Wire Cleaners (optional accessory)

a) Available to suit a variety of ropes – Refer to selection guide when

ordering

Page 5

Page | 5

3.0 Viper Mini MKII K its Components Assembled &

Numbered

3.1 Viper Mini MKII Standard Kit

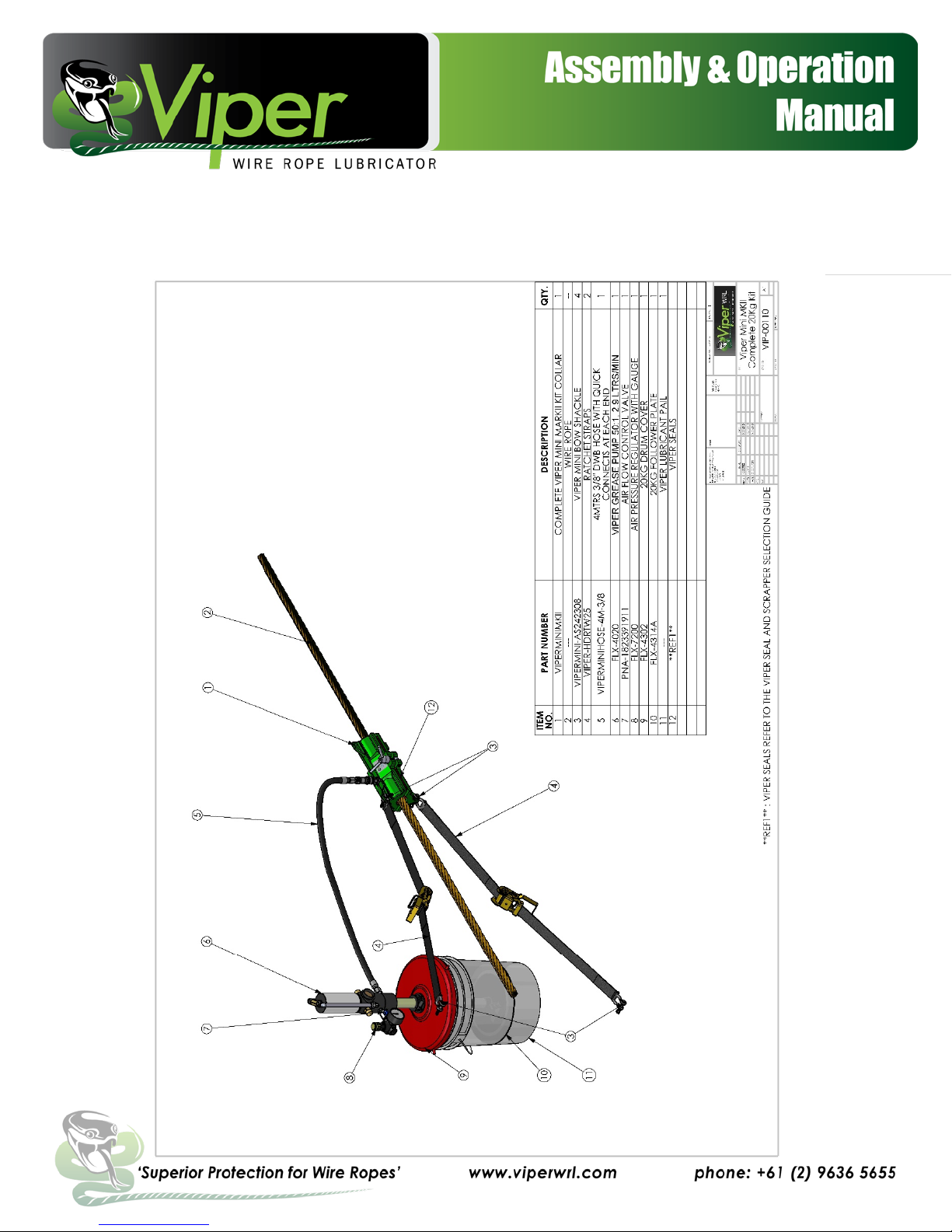

3.1.1 Viper Mini MKII Standard Complete 20KG Kit

Page 6

Page | 6

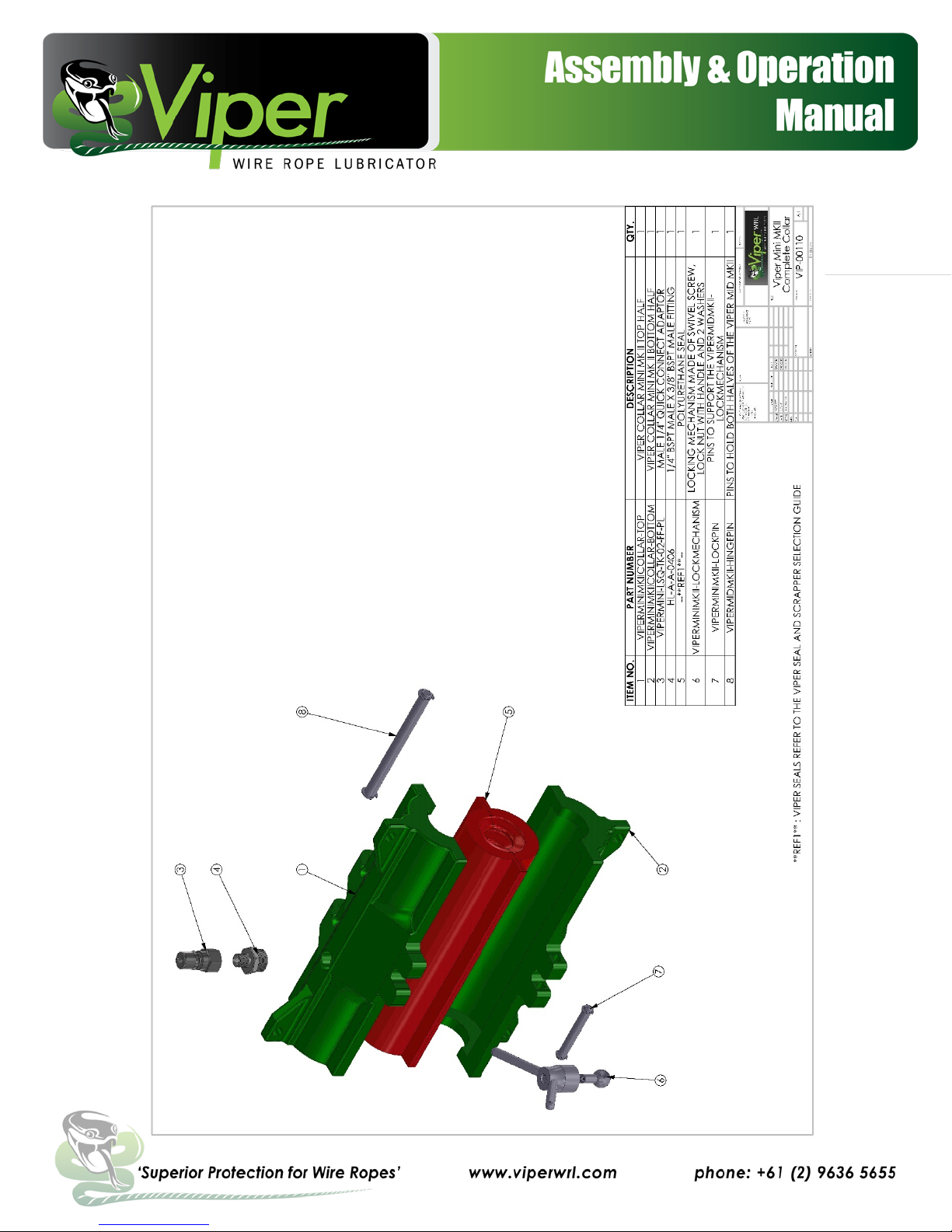

3.1.2 Viper Mini MKII Standard Collar

Page 7

Page | 7

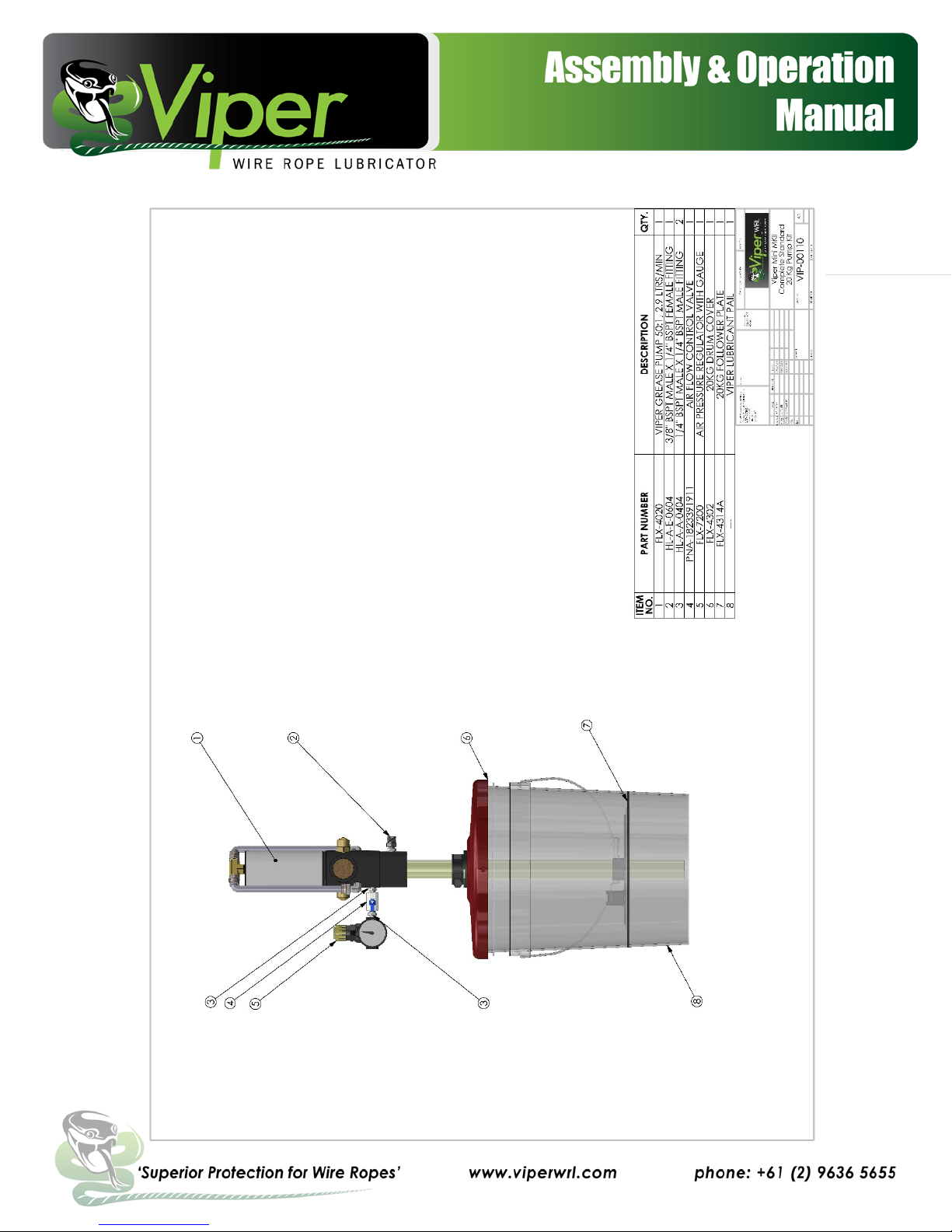

3.1.3 Viper Mini MKII Standard 20KG Pump Kit

Page 8

Page | 8

3.1.4 Viper Mini MKII Standard 20KG Hose

Page 9

Page | 9

3.2 Viper Mini MKII High Speed Kit

3.2.1 Viper Mini MKII HS 20KG Kit

Page 10

Page | 10

3.2.2 Viper Mini MKII HS Collar

Page 11

Page | 11

3.2.3 Viper Mini MKII HS 20KG Pump Kit

Page 12

Page | 12

3.2.4 Viper Mini MKII HS 20KG Complete Hose

Page 13

Page | 13

4.0 Viper Mini MKII Assemb ly Instructions (refer assembly video on website)

1. Remove all components from Viper aluminium carry case, unpack

from packing materials and lay out on a flat surface. Check all items

are present as per your purchase order.

2. Remove grease pump noting that the air inlet isol ati on v alve,

air regulator is preassembled onto the pump.

• Connect site specific compressed ai r connector to

the air regulator.

o Standard Pump

o High Speed Pump

3. Remove lid from lubricant container and place follower plate

onto the top of the lubricant. Press down firmly until the

follower plate comes in contact with the lubricant.

• Note the Viper lubricator should only be used with high

quality wire rope lubricants with a consistency of

NLGI #00 to #2.

4. Fit the drum cover over the top of the lubricant container and

tighten the three securing screws until they contact the

container.

5. Clamp the grease pump handle onto the grease pump body and

tighten the two screws.

6. Slide the grease pump shaft into the opening of the drum cover

and the follower plate. Push the grease pump down into the

grease until it touches the base of the gr eas e cont ainer.

7. Connect the high-pressure grease hose to the grease pump

outlet via the quick connect coupling.

o Standard Pump

o High Spee d Pump

Page 14

Page | 14

8. Remove the Viper collar from the packaging materials and loosen

the clamping bolt allowing the collar to open.

9. Fit the Viper seals into the Viper collar. Make certain that the

grease inlet holes on the seal and viper collar are aligned.

Note seals are sized to suit the wire rope as per the “Selection

guide”.

10. Clamp the lubricator collar fitted with seals around the wire rope

to be lubricated, tightening the toggles.

• Face the collar so that the hydraulic coupling is at the

rope inlet end when the rope is being moved through

the collar.

• Locate the collar so that the optimum length of wire

rope can be lubricated in a single pass, this is typically

close to the winch drum.

11. Connect the high-pressure lubricant delivery hose to the Viper

Collar using the quick connect coupler.

Page 15

Page | 15

12. To secure the Viper lubricator collar in place, use the nylon ratchet

straps and ‘Bow’ shackles.

• Secure one end of the ratchet strap to one of the lugs on the

wire entry end of the lubricator collar via a bow shackle.

Secure the other end to a suitable fixed position to prevent the

lubricator collar from travelling with the wire rope. Replicate

this using the second ratchet strap, bow shackle and lug on

the lubricator collar.

• Note the ratchet strap is in high tension and strain during

operation. Please ensure that all fittings are tightly secured

prior to operation.

• The lubricator collar must be able to move laterally during

operation to ensure even wire rope spooling on and off the

rope drum.

The Viper Mini MKII

Wire Rope Lubricator

is now assembled and

ready for use.

Page 16

Page | 16

5.0 Ratchet Strap Buckle Assemblies - Ref: AW107

Basic Steps of Operation

To Tighten:

1. Secure Hooks on either side of load.

2. Insert free end of strap through slot A and pull through excess webbing

3. Push down and pull up handle B to work the ratchet strap till strap is as tight as possible.

a. Do not over tighten, as the straps are only designed to maintain position of the Viper

Collar.

4. Ensure at least 2 to 3 revolutions of webbing are around centre cam A.

5. Push Handle B down to lock your Tie-Down.

To Release:

1. Pull back on quick release C and hold.

2. Pull handle B up and over to a fully open flat position.

3. Pull tie-down up to loosen strap and remove from slot A.

To be used as a guide only

Please note: Lubricate all moving parts on a regular basis.

Use and Care Instructions – Webbing Load Restraint Systems Ref: AW116

Use: The selected lashing system should be both strong enough and of the correct length for the mode of

use. Good lashing practice should always be followed; the fitting and removal operations of the lashing

should be planned before starting a journey. The lashing should be suitably

Pre-tensioned and regularly checked.

CAUTION: NOT TO BE USED FOR LIFTING

INSPECTION: Web lashings and any fittings or coupling components attached should be subject of frequent

visual inspection and regular examination by a competent person. Web lashings shall be withdrawn from

service if there is cause to doubt fitness for use.

MARKING: Use only legibly marked and labelled web lashing.

OVERLOADING: Lashing systems should not be overloaded. Mechanical aids such as levers or bars

should not be used unless they are specifically designed for use with the device.

PROTECTION: The webbing and labels should be protected against friction, abrasion and damage from

load with edge radii less than twice the webbing material thickness, using protective sleeves or corner

protectors.

SERVICEABILITY: Normal wear and tear can reduce the strength of the webbing assemblies. If webbing is

damaged by more than 10% of its original state due to abrasion, cuts, prolonged exposure to sunlight or

chemicals then it should be replaced. Similar, if tensioning devices such as hand ratchets and end fittings

are damaged by wear or corrosion they should be replaced.

RESPONSIBILITY: It is the responsibility of the owner, the driver and the person in charge of the loading to

ensure that a vehicle’s load restraint and attachments, and the load securing equipment, are serviceable

and strong enough for their application.

NOTE: The user of this strap assumes all risk and liability for its handling and use.

For further information please refer to the RTA ‘Load Restraint Guide’.

Page 17

Page | 17

6.0 Viper Mini MKII Wire Rope Lubric ator - Operating

Instructions

With the Viper Mini MKII Wire Rope Lubricator assembled and mounted

correctly as per the previous instructions, you are now ready to operate the

system and lubricate the nominated wire rope.

1. Open the air supply to the lubricant pump via th e air control valve. Check

that the air regulator is set to 7 bar. (105psi)

THE VIPER MINI MKII IS NOW CHARGED AND READY FOR OPERATION.

2. Start the wire rope moving through the Viper collar and then slowly open

the lubricant flow control valve. Continue to open until an even coating of

grease is visible on the wire rope exiting the collar.

• Speeds of up to 1,000 metres per hour are possible but this

depends on a number of factors, including the rope size, speed and

specific lubricant in use.

3. The lubricant flow can be controlled by adjusting the air pressure control

valve. And should be adjusted as required to provide the correct lubricant

flow rate into the lubricator collar and thereby onto and into the wire rope.

• If the lubricant flow rate is too high lubricant will begin leaking out of

the Viper collar at the rope entry point.

• Reduce the lubricant flow by adjusting air regulator. Alternatively

increase the wire rope speed through the lubricator collar until the

correct amount of lubricant appears on the wire rope.

4. Visually inspect the wire rope as it exits the collar to observe if full

lubricant coverage is being achieved.

• If insufficient coverage is being achieved, increase lubricant flow

rate by adjusting air pressure until an even coating is occurs.

• Alternatively reduce the rope speed until an even lubricant coating

occurs.

Page 18

Page | 18

Unlubricated wire rope

Rope lubricated with Viper WRL CG-0

5. If lubricant leakage occurs around the collar, check the collar is correctly

tightened and seals are fitted correctly.

6. An even balance between lubricant volume and wire rope travel speed is

required to achieve an even lubricant film combined with optimum

penetration.

7. Once the optimum lubricant coverage is achieved, run the complete rope

at a consistent speed though the Viper.

8. Note that the Viper collar with flexible seals is not a pressure vessel and is

not designed to hold pressure. The grease pressure is generated by both

the pump and the action of the rope travelling through the lubricant

chambers in the seal. The Viper grease pump should not be operated with

the wire rope stationary.

Page 19

Page | 19

7.0 Lubricant Penetrat ion

To inspect internal lubricant penetration a sharp spike or heavy-duty screwdriver

to open the wire rope. Alternatively, two pipe wrenches secured one metre apart,

and rotated in opposite directions will allow visual inspection.

Lubricant penetration to the wire rope core is often difficult due to the follow ing:

• Wire rope design, particularly anti-spin and locked core wire ropes.

• Dirty or contaminated wire ropes.

(Use of a Viper Wire Cleaner is recommended)

• Ropes contaminated with solid used lubricant coatings.

(Use of a Viper Wire Cleaner is recommended)

During the wire rope operation, the rope movement onto the drum and over

sheaves is known to assist with the lubric a nt penetration.

If an NLGI#2 grade grease is used it may be necessary to pre-heat the lubricant

at ambient temperatures below 5 degrees C (41 F) to ensure adequate

penetration. Check with lubricant suppliers for method of pre-heating and

individual lubricant specifications. Be sure that the lubricant used will adequately

protect your wire rope from corrosion and wear.

Page 20

Page | 20

8.0 Equipment Specifications

Drum Pump

Standard Kit High Speed Kit

Maximum operating air pressure 120 psi 120 psi

Pump ratio 50:1 45:1

Flow rate approximately 2,900 gram per min 4,500 gram per min

Volume of compressed Air 165 L/min at 7 bar 250L/min at 7 bar

Guideline pressures are as follows:

Air Pressure for all Wire Rope Diameters 4 - 7 bar (60-105 psi)

Viper Collar

• Cast aluminium construction with enhanced mechanical properties and

excellent resistance to corrosion, heat treated to T6.

• Lugs tested to withstand 800kg of resistance.

• Coating: 3 coat treatment.

• Salt – Spray Resistance to ASTM B117-73 - 2,000 hours

• Humidity Resistance to ASTM D2247 - 1,000 hours

Seals

• Estimated average operational life – 10,000+ meters

• Shelf life 2-3 years (based on correct storage)

• Chemically resistant to commercially available mineral wire rope lubricants.

• The lubricator seals may be washed with a mild petroleum cleaner.

• Do not leave the seals to soak in cleaning fluid which may be detrimental to

their composition.

• It is important to store the seals away from UV light, the seals will be harmed

if left for extended periods in sunlight.

• Seals should be kept in a sealed plastic bag as supplied.

(Note: Lubrication Engineers reserves the right to change specifications as and when required.)

Page 21

Page | 21

9.0 Trouble Shooting

1. NO LUBRICANT ON WIRE ROPE AFTER START UP

a) Check lubricant container content.

b) Check lubricator pump air shut-off valve is open.

c) Check air pressure on gauge.

d) Check lubricant control valve is open (for High Speed Kits

only).

2. INADEQUATE LUBRICANT COVERAGE

a) U ti l iz e lubr ic ant dr um heater or change to lighter viscosity if

ambient temperature is 5ºC or below.

b) Increase air pressure and hence lubricant flow, until correct

quantity of lubrication is on wire rope.

c) Reduce wire rope speed to ensure complete coverage.

3. TOO MUCH LUBRICANT ON WIRE ROPE

a) Reduce volume of lubricant via the flow control valve (for

………………………High Speed Kits only).

b) Increase wire rope speed through the lubricator collar.

c) Use a combination of both.

d) Investigate type of wire rope lubricant used.

e) Measure rope diameter and ensure correct seals in use.

4. LEAKING FROM COLLAR

a) T ighten collar clamp ing screws

b) Che ck correct Viper seal is being used for wire rope size.

c) Check air pressure reduce if required.

d) Adjust Lubricant flow rate air pressure.

e) Check condition of seals for any damage.

Page 22

Page | 22

10.0 Safety Recommendations

10.1 Caution Level Rating

• Before installation of the wire rope lubricator onto the cable, ensure the

work area is clean and safe to work in with adequate space around the

cable attachment point, for attachment of the Viper collar.

• Ensure buckles and straps, D shackles and attachment points used to

anchor the Viper Lubricator are rated for a mi nimum WWL of 500 kg.

• Check hydraulic hose, couplings air lines and fittings for damage or wear,

before connecting to grease pump and Viper lubricator collar. Carry out

visual inspection of the Viper collar to ensure it has not been damaged

during transport or handling. Damage to the casing that prevents it from

sealing correctly will severely reduce the unit’s ability to force lubricant to

the ropes core and could be a potential safety hazard.

• Always ensure the return grease line feeds to a container of suitable size for

receiving the excess grease from the Viper lubricator. Grease allowed to

flow from the return line without being captured may cause a serious slip or

environmental hazard.

• Note Lubricants vary in their hazard and environmental ratings, please

ensure Material Safety Data Sheets for all lubricants used with the Viper are

kept in close proximity to the kit. Lubrication Engineers recommend a copy

of the Lubricant in use MSDS is kept in the Aluminium carry case for

reference as required. Lubrication Engineers supply a copy of the Viper

WRL Coating Grease CG-0 MSDS with any kits that include this product.

Page 23

Page | 23

10.2 Viper Mini MKII Assembly and Use

Danger Rating

• Before attaching the Viper lubricator collar to the cable, you must ensure

the cable winch control has been locked out and tagged. Serious injury or

death may occur should the cable winching equipment be activated while

the Viper Lubricator is being fitted to the cable.

• When the Viper Lubricator has been assembled, attached to the Cable and

anchored in position, the lubrication system can be activated. While in

operation the grease pump can generate up to 5,500 PSI grease pressure.

Under no circumstances should the Viper collar be opened, or the grease

hose disconnected while under pressure as this can cause serious injury.

• While in operation the Viper Lubricator utilises both high pressure air, up to

120 PSI max and high pressure grease up to 5,500 PSI. Always wear

appropriate PPE (Personal Protective Equipment) while carrying out the

cable lubrication operation.

• Suggested PPE includes, safety glasses, leather gloves, safety boots, long

sleeved shirts, high visibility vest, hard hat and hearing protection.

• Lubrication Engineers recommend to only use pumps, fittings, hoses and

accessories supplied or recommended Lubrication Engineers. All of our

components have been tested to ensure they will work safely and effectively

for extended duty cycles. Using non-approved components may lead to

unexpected failure of the Viper Lubricator and / or its components causing

serious injury to maintenance personal.

Page 24

Page | 24

11.0 Viper Mini MKII Wire Rope Lubricator - Guarantee

The VIPER Mini MKII Wire Rope Lubricator Kit and all the components are

guaranteed for a period of 12 months from date of purchase against any fault of

manufacture or materi al failur e.

Fair wear and tear are expected of the unit and is not covered by warranty,

tearing of the seals due to broken wires or other obstructions are not covered by

this warranty.

Any parts to be claimed for warranty must be first returned to the Lubrication

Engineers for inspection prior to warranty being granted.

Commercially available wire rope lubricant NLGI 00-2.

(Approved Lubricants list available)

Viper WRL

2 / 14 Stoddart Road, Prospect,

New South Wales, Australia, 2148

Web – www.ViperWRL.com

Email – sales@ViperWRL.com

Ph: +61 2 9636 5655

Fax: +61 2 9636 8566

Loading...

Loading...