Page 1

User Manual

Original instructions

FANG 32T-EU

ENGLISH

DEUTSCH BEDİENUNGSANLEİTUNG......................................................................... 1-6, 27-48

FRANÇAİS MANUEL D’UTILISATION.......................................................................... 1-6, 49-69

NEDERLANDS GEBRUIKERS HANDLEIDING.................................................................. 1-6, 70-89

ITALIANO ISTRUZIONI PER L’USO...................................................................................

ESPAÑOL MANUAL DE USUARIO............................................................................... 1-6, 111-130

PORTUGUÊS MANUAL DO UTILIZADOR....................................................................... 1-6, 131-150

ΕΛΛΗΝΙΚΆ ΕΓΧΕΙΡΊ∆ΙΟ ΧΡΉΣΤΗ................................................................................. 1-6, 151-174

TÜRKÇE .............................................

ČESKÝ

POLSKI INSTRUKCJA OBSŁUGI..............................................................................

MAGYAR KEZELÉSI UTASÍTÁS..................................................................................

ROMÂNĂ MANUAL DE UTILIZARE...........................................................................

РУССКИЙ РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ.........................................................

БЪЛГАРСКИ РЪКОВОДСТВО НА ПОТРЕБИТЕЛЯ..............................................

DANSK BRU

SVENSKA BRUKSANVISNING 1-6,

NORSK 1-6,

SUOMI KÄYTTÄJÄN OPAS 1-6,

OPERATING LNSTRUCTIONS..................................................................... 1-6, 7-26

1-6, 90-110

KULLANIM KILAVUZU..................................

NÁVOD K OBSLUZE...................................................

GERMANUAL 1-6,

.....................................................................

.................................. 1-6, 197-216

.....................................................................

BRUKERHÅNDBOK

...................................................................

....................................................................

1-6, 175-196

1-6, 217-236

1-6, 237-256

1-6, 257-276

1-6, 277-297

1-6, 298-318

319-338

339-358

359-378

379-398

Company information:

www

.vipercleaning.eu

info-

eu@vipercleaning.com

VF84902EU REV:10 08 2018

Page 2

Page 3

1

Page 4

2

Page 5

3

Page 6

4

Page 7

5

Page 8

6

Page 9

USER MANUAL

ENGLISH

TABLE OF CONTENT

INTRODUCTION ......................................................................................................................................................................... 8

MANUAL PURPOSE AND CONTENTS

TARGET

HOW TO KEEP THIS MANUAL

DECLARATION OF CONFORMITY

IDENTIFICATION DATA

OTHER REFERENCE MANUALS

SPARE PARTS AND MAINTENANCE

CHANGES AND IMPROVEMENTS

PURPOSE AND INTENDED USE

CONVENTIONS

UNPACKING/DELIVERY........................................................................................................................................................... 9

SAFETY ......................................................................................................................................................................................... 9

SYMBOLS USED TO MARK INSTRUCTIONS

GENERAL INSTRUCTIONS

MACHINE DESCRIPTION ...................................................................................................................................................... 13

MACHINE STRUCTURE

……………………………………………………………………………………………………………………

…………………………………………………………………………………………

…………………………………………………………………………………………………

…………………………………………………………………………………………………………

……………………………………………………………………………………………

…………………………………………………………………………………………………

…………………………………………………………………………………

.. 8

... 8

……………………………………………………………………………………

………………………………………………………………………………………

……………………………………………………………………………………

………………………………………………………………………………………

…………………………………………………………………………………………

…………………………………………………………………………

.... 8

... 8

10

13

8

8

8

8

8

9

9

ACCESSORIES/OPTIONS

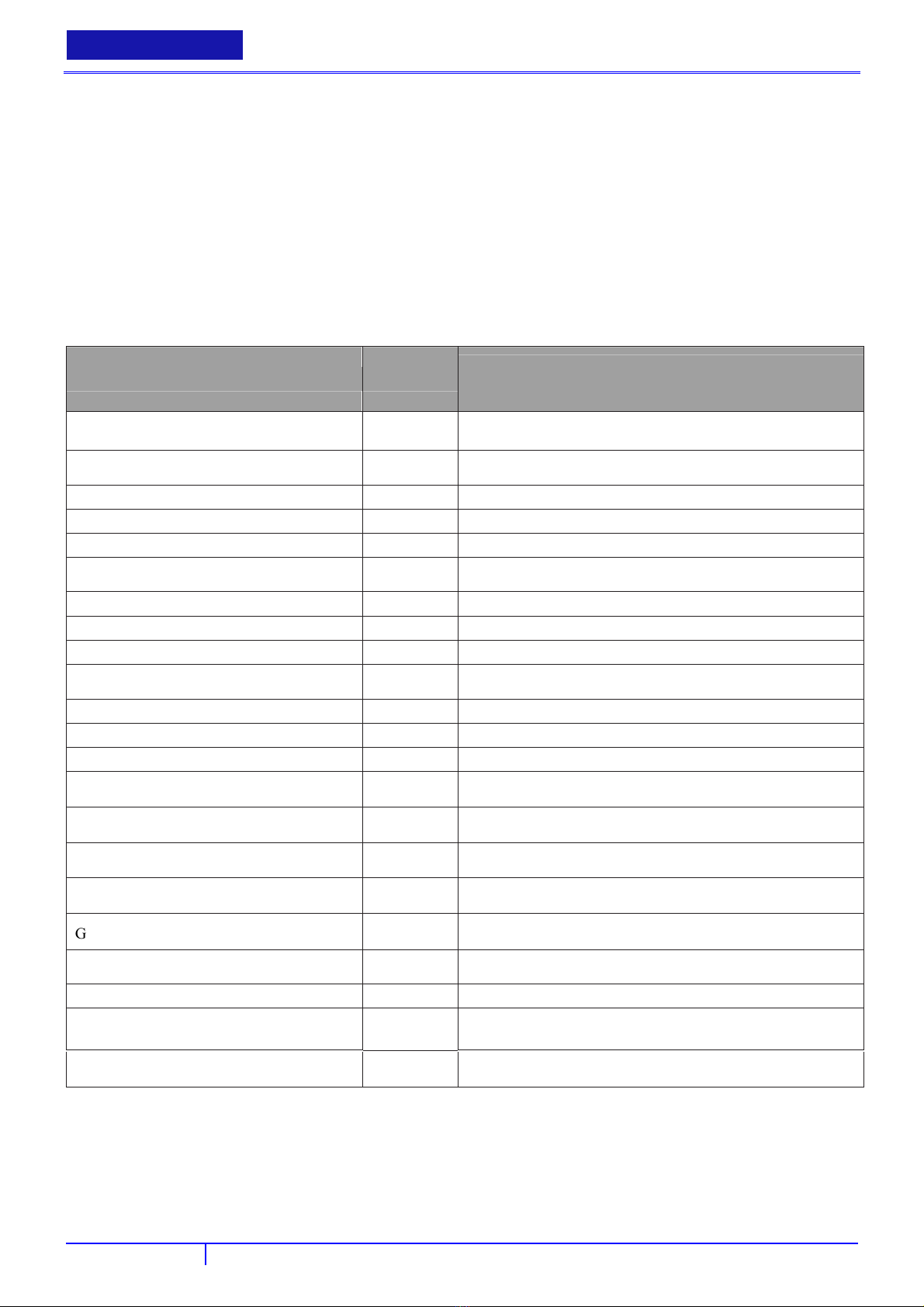

WIRING DIAGRAM (FANG32T-EU )

OPERATION ............................................................................................................................................................................... 17

BEFORE STARTING THE MACHINE

WHILE OPERATING MACHINE

MAINTENANCE ........................................................................................................................................................................ 23

DAILY MAINTENANCE

WEEKLY MAINTENANCE

MONTHLY MAINTENANCE

VACUUM SYSTEM MOTOR FILTER CLEANING

SOLUTION/CLEAN WATER FILTER CLEANING

SQUEEGEE BLADE CHECK AND REPLACEMENT

BRUSH/PAD CLEANING

TROBLESHOOTING ................................................................................................................................................................ 25

STORAGE ................................................................................................................................................................................... 26

RECYCLING THE CLEANER ................................................................................................................................................. 26

………………………………………………………………………………………………

………………………………………………………………………………

…………………………………………………………………………………

………………………………………………………………………………………

…………………………………………………………………………………………………

………………………………………………………………………………………………

……………………………………………………………………………………………

……………………………………………………………………

……………………………………………………………………

…………………………………………………………………

…………………………………………………………………………………………………

14

16

17

21

23

23

23

23

23

24

24

7

Page 10

ENGLISH

BETRİEBSANLEİTUNG

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and

au-tonomous way. It contains information about technical data, safety, operation, storage, maintenance, spare parts and

disposal. Before performing any procedure on the machine, the operators and qualified technicians must read this manual

carefully. Contact Viper in case of doubts concerning the interpretation of the instructions and for any further information.

TARGET

This manual is intended for operators and technicians qualified to perform the machine maintenance.

The operators must not perform procedures reserved for qualified technicians. Viper will not be answerable for damages

coming from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The User Manual must be kept near the machine, inside an adequate case, away from liquids and other substances that can

cause damage to it.

DECLARATION OF CONFORMITY

The declaration of conformity, supplied with the machine, certifies the machine conformity with the law in force.

NOTE

Two copies of the original declaration of conformity are provided together with the machine documentation.

The CE-declaration is printed in the Quick Start Guide.

IDENTIFICATION DATA

The machine model and serial number are marked on the plate.

This information is useful when requiring machine spare parts. Use the following table to write down the machine

identification data.

MACHINE mode..................................................................

MACHINE serial number.......................................................

OTHER REFERENCE MANUALS

− Service Manual (can be consulted at Viper Service Centers)

− Spare Parts List (see www.vipercleaning.eu)

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be performed out by qualified personnel or by Viper Service

Centers. Only original spare parts and accessories must be used. Contact Viper for service or to order spare parts and

accessories, specifying the machine model and serial number.

CHANGES AND IMPROVEMENTS

Viper constantly improves its products and reserves the right to make changes and improvements at its discretion without being

obliged to apply such benefits to the machines that were previously sold.

Any change and/or addition of accessories must be approved and performed by Viper.

PURPOSE AND INTENDED USE

All automatic cleaning machines are exclusively intended for the wet cleaning of water-resistant floor coverings in building

interiors.

8

Page 11

USER MANUAL

The automatic cleaning machines cannot be used for fitted carpet and carpet cleaning.

This appliance is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, offices and rental

businesses.

Any other use is considered as improper use. The manufacturer accepts no liability for any damage resulting from such use.

The risk for such use is borne solely by the user.

Proper use also includes proper operation, servicing and repairs as specified by the manufacturer.

Changes made to the automatic machines by the users themselves rule out the liability of the manufacturer for any resultant

damage.

Floor coverings are to be checked with regard to the suitability of this cleaning method before the use of the machine!

Note the surface pressure in the case of point-elastic floors, e.g. in gymnasiums!

The manufacturer accepts no liability for damage to the machine and the floor covering to be cleaned which is caused by the

use of the wrong brushes and cleaning agents.

ENGLISH

CONVENTIONS

Forward, backward, front, rear, left or right and up are intended with reference to the operator’s position, that is to say in

working position.

UNPACKING/DELIVERY

To unpack the machine, carefully follow the instructions on the packing.

When the machine is delivered, check that the packing and the machine were not damaged during transportation. In case of

visible damages, keep the packing and have it checked by the carrier that delivered it. Call the carrier immediately to fill in a

damage claim.

Check contents of package to ensure that the following items are included:

− machine

− squeegee assembly

− brush driver (and pad driver)

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precau-tions to safeguard people and property.

The operator’s cooperation is essential in order to prevent injury. No accident prevention program is effective without the total

coop-eration of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while

working or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and

prudent operator is the best guarantee against accidents and is essential for successful completion of any prevention program.

SYMBOLS USED TO MARK INSTRUCTIONS

DANGER!

Danger that leads directly to serious or irreversible injuries, or even death.

WARNING!

Danger that can lead to serious injuries or even death.

CAUTION!

Danger that can lead to minor injuries and damage.

9

Page 12

ENGLISH

NOTE

Indicates a remark related to important or useful functions.

BETRİEBSANLEİTUNG

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

The appliance must

− only be used by persons, who have been instructed in its correct usage and explicitly commissioned with the task of

operating it

− only be operated under supervision

− not be used by children

The workplace is behind the cleaner.

Do not use any unsafe work techniques.

Always guide the cleaner with both hands on the handle.

When the cleaner is stationary, switch off the brush unit immediately to prevent damage to the floor covering.

Switch off the appliance and disconnect the battery plug in the following situations:

− Prior to cleaning and servicing

− Prior to replacing components

− Prior to changing over the appliance

Use of the cleaner is subject to current national regulations. Besides the operating instructions and binding accident prevention

regu-lations valid in the country of use, observe recognized regulations for safe and proper work.

TRANSPORT

When transporting the cleaner in elevators

− observe current safety regulations, in particular with regard to carrying capacity.

OPERATION

In order to prevent unauthorized use of the appliance, the power source is to be switched off or locked, for example, by

removing the key of the power switch.

Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine moving parts.

Before using the machine, close all doors and/or covers.

The machine working temperature must be between 0°C and +40°C.

The humidity must be between 30% and 95%.

Do not use the machine as a means of transport.

In case of fire, use a powder fire extinguisher, not a water one.

Do not tamper with the machine safety guards and follow the ordinary maintenance instructions scrupulously.

Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged. Always keep the

openings free from dust, hairs and any other foreign material which could reduce the air flow.

Do not remove or modify the plates affixed to the machine.

If the machine is used according to the instructions, the vibrations are not dangerous. The machine vibration level is less than

2

2.5 m/s

The Hand/arm vibration levels are well below 2,5 m/s2 (measured according to ISO 5349), which is the limit for an 8 hour

continuous working period.

(98/37/EEC-EN 1033/1995).

10

Page 13

USER MANUAL

This machine must not be used on roads or public streets.

Viper machines can be used in combination with standard detergents which cannot damage any materials of Viper machines

(no use of solvents or other aggressive liquid materials). Viper will not pay any claims regarding using aggressive detergents in

Viper machines. If you need a special detergent for cleaning purposes, please contact your Viper dealer.

Pay attention during machine transportation when temperature is below freezing point. The water in the tank or in the hoses

could freeze and seriously damage the machine.

ENGLISH

MAINTENANCE

To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of this manual, must be

performed by the authorised personnel or by Viper Service Center.

Carefully read all the instructions before performing any maintenance/repair procedure.

Do not work under the lifted machine without supporting it with safety stands.

Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

GUARANTEE

Our general conditions of business are applicable with regard to the guarantee.

Unauthorised modifications to the appliance, the use of incorrect brushes and detergents in addition to using the appliance in a

way other than for the intended purpose exempt the manufacturer from any liability for the resulting damage.

TESTS AND APPROVALS

Electrical tests must be performed in accordance with the provisions of safety regulations (BGV A3) and to DIN VDE 0701

Part 1 and Part 3.

In accordance with DIN VDE 0702 these tests must be performed at regular intervals and after repairs or modifications.

ELECTRICAL COMPONENTS

DANGER

Batteries.

Risk of explosion.

Battery charging produces highly explosive hydrogen gas. Keep the tank assembly open during battery

charging and perform this procedure in well-ventilated areas and away from naked flames.

To reduce the risk of fire, electric shock, or injury, do not leave the machine unattended when it is

plugged in. Before performing any maintenance procedure, disconnect the battery charger cable from the

electrical mains.

Do not smoke while charging the batteries.

The use of non-genuine spare parts, accessories, batteries and chargers can impair the safety of the

appliance. Only use spare parts and accessories from Viper and use batteries and chargers which VIPER

recommend. When using non-certified and not recommended batteries and chargers, VIPER will not

cover the cost of damages (warranty) caused of this.

CAUTION

Battery charger.

Electric shock due to faulty mains connecting lead or charger cable.

Touching a faulty mains connecting lead or charger cable can result in serious or even fatal injuries.

Keep the battery away from sparks, flames and incandescent material. During the normal operation

explosive gases are released.

Before using the battery charger, ensure that frequency and voltage values, indicated on the machine

serial number plate, match the electrical mains voltage.

Do not damage the mains power lead (e.g. by driving over it, pulling or crushing it).

11

Page 14

ENGLISH

BETRİEBSANLEİTUNG

Regularly check whether the power cord is damaged or shows signs of ageing.

Have the faulty mains connecting lead replaced by your Viper service representative or a qualified

electrician prior to using the appliance again.

Do not pull or carry the machine by the battery charger cable and never use the battery charger cable as a

handle. Do not close a door on the battery charger cable, or pull the battery charger cable around sharp

edges or corners.

Keep the battery charger cable away from heated surfaces.

Do not charge the batteries if the battery charger cable or the plug are damaged. If the machine is not

working as it should, has been damaged, left outdoors or dropped into water, return it to the Service

Center.

STAIRS AND GRADIENTS

CAUTION

Risk of tipping and slipping on stairs and gradients.

When negotiating stairs and gradients, there is a risk of personal injuries and damage to property.

Do not negotiate steps.

Only use the appliance on level surfaces with a maximum gradient of 2 %.

FLOOR COVERINGS

CAUTION

Damage to sensitive floor coverings.

Particularly sensitive floor coverings can be damaged by cleaning.

Before using the cleaner, check whether floor coverings are suitable for this cleaning technique.

Beware of area compression in point-elastic floors, e.g. in gym halls.

Only use cleaning agents approved by Viper.

MATERIALS HAZARDOUS TO HEALTH

WARNING

Materials hazardous to health in floor coverings.

Floor coverings can contain materials that are hazardous to health, which dissolve during cleaning.

Do not clean floor coverings from which dusts or liquids that are hazardous to health can dissolve.

RISK OF EXPLOSION

WARNING

Flammable and explosive materials.

Risk of explosion in explosive atmosphere or areas where flammable and explosive materials are stored.

Do not operate the machine near dangerous, flammable and/or explosive powders, liquids or vapours.

SPARE PARTS AND ACCESSORIES

CAUTION

Non-genuine components and unsuitable detergents.

The use of non-genuine parts and unsuitable detergents can impair the safety of the appliance and lead to

damage.

Only use spare parts and accessories from Viper.

Only use the accessories and detergents supplied with the appliance or those specified in the operating

instructions.

2

1

Page 15

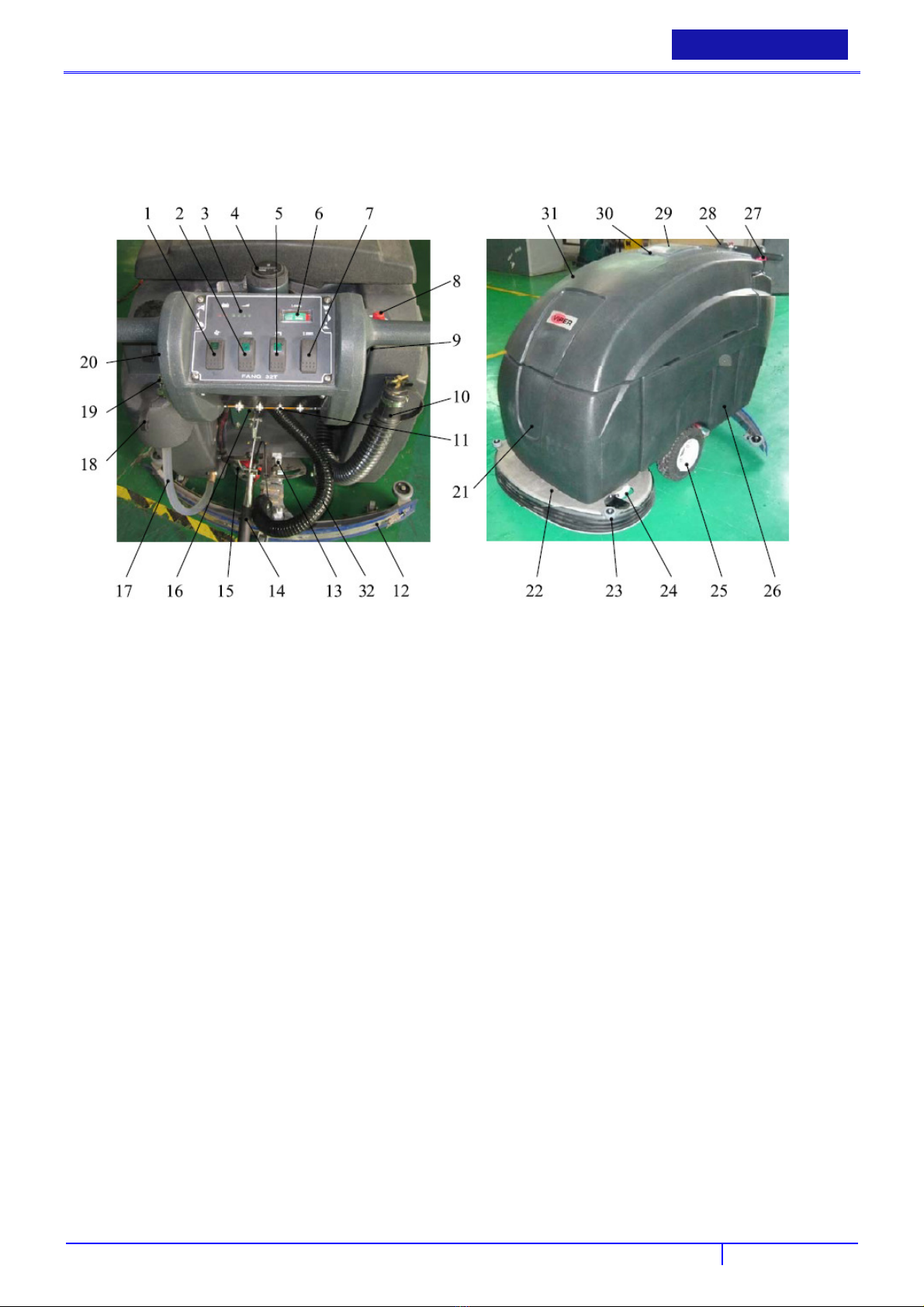

MACHINE DESCRIPTION

MACHINE STRUCTURE

USER MANUAL

ENGLISH

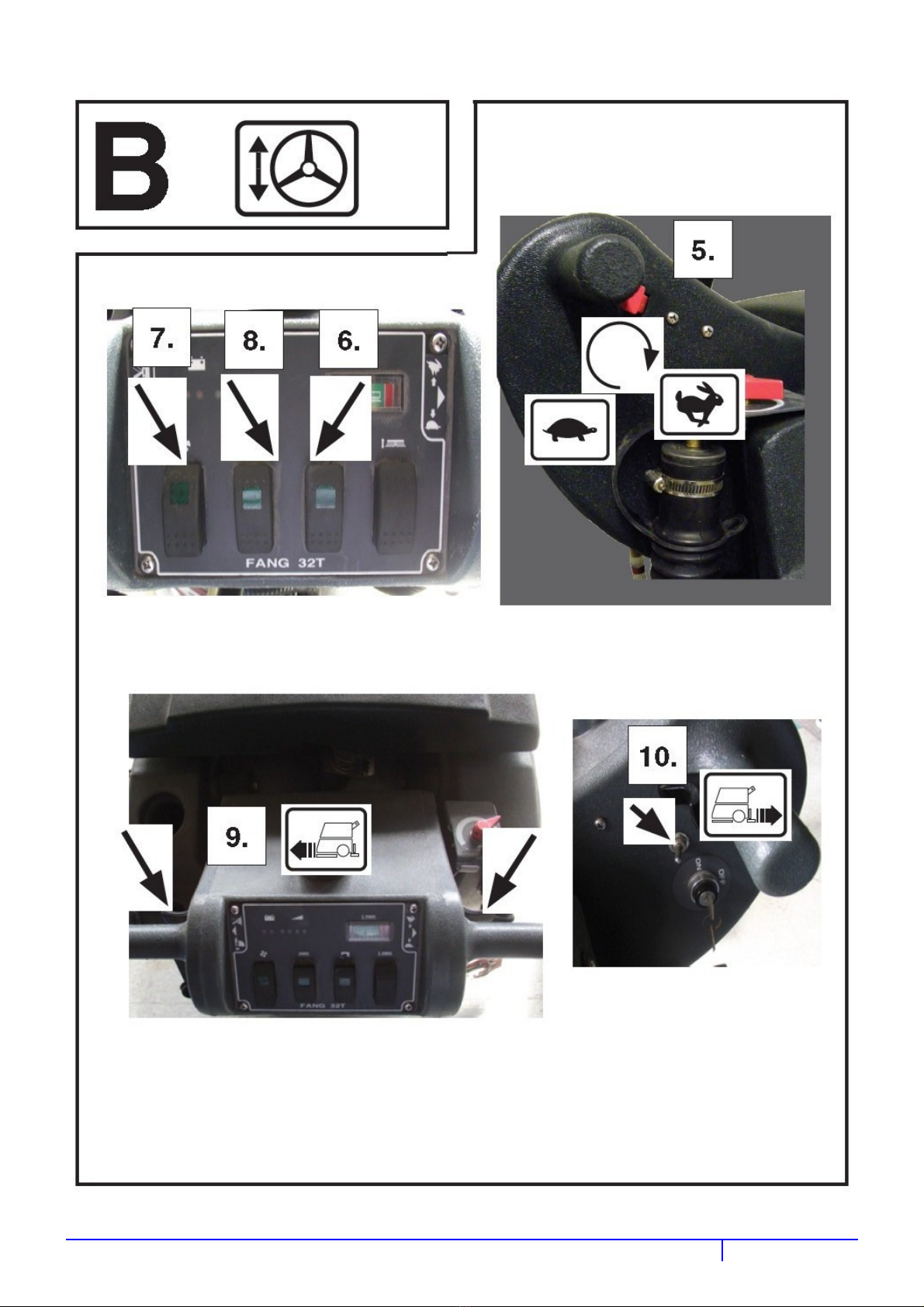

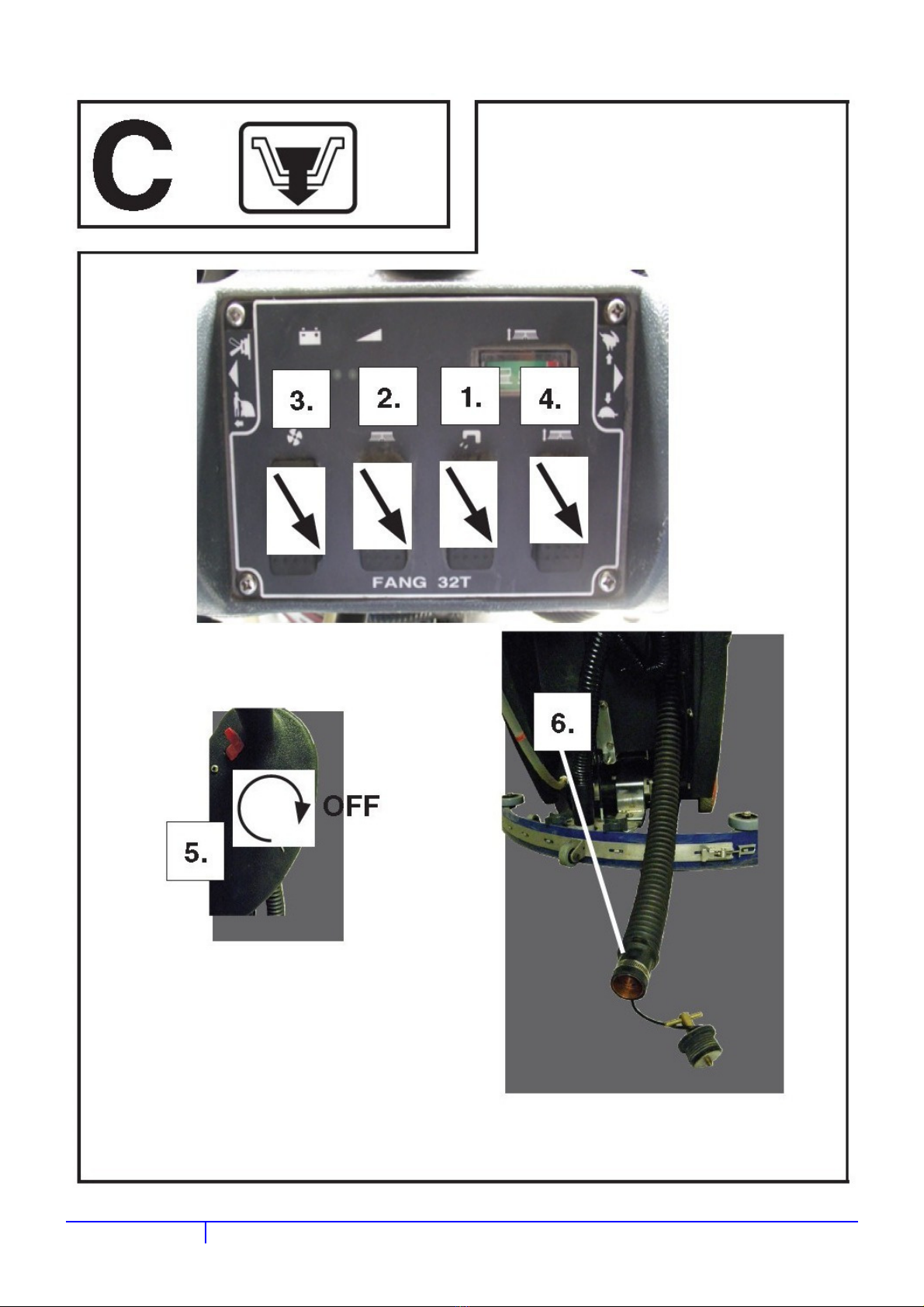

1. Vacuum ON/OFF switch

2. Brush ON/OFF switch

3. Battery level meter

4. Hour meter

5. Solution ON/OFF switch

6. Brush pressure meter

7. Brush pressure UP/DOWN switch

8. Solution control knob

9. Speed control knob

10. Recovery tank drain hose

11. Circuit breakers

12. Squeegee assembly

13. Squeegee adjustment nut & shaft

14. Squeegee lift lever

15. Rear casters

16. Console adjustment levers

17. Solution tank level sight tube

18. Rear solution fill

19. Key switch

20. Reverse switch

21.Front cover

22. Scrub head

23. Protective rollers

24. Scrub head door

25. Transport wheels

26. Solution tank

27. Operating triggers

28. Control housing

29. Recovery tank lid

26. Solution filter assembly

31. Recovery tank

32. Squeegee vacuum hose

13

Page 16

ENGLISH

BETRİEBSANLEİTUNG

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according to the

ma-chine specific use:

Brush

Pad driver

For further information concerning the optional accessories, contact an authorised retailer.

TECHNICAL DATA

Model

Machine height

Solution/clean water tank capacity

Recovery water tank capacity

Rear wheel diameter

Vacuum system motor power

Drive system motor power

Drive speed (variable)

Gradeability

Sound pressure level at workstation

Standard batteries

Vacuum system circuit capacity

Cleaning width

Squeegee width

Machine maximum length

mm

l

l

mm

W

W

km/h

%

dB(A)

Ah @ 20 h

mm H2O

mm

mm

mm

FANG 32T-EU

(1 brush/pad-holder, with drive system)

1090

115

106

297

650

370

0 - 4.5

2

70

6-6V/305AmP.hR

1,860

800

1020

1690

Machine width without squeegee

Brush diameter

Weight without batteries and with empty tanks

Gross W

Brush motor power

Brush speed

eight

Battery compartment size (length x width x

height)

Charger output voltage

mm

mm

kg

kg

W

rpm

mm

V

1050

2*406

200

286

740

200

580*500*370

36

14

Page 17

USER MANUAL

ENGLISH

BATTERY CAPACITY LIGHTS

(16AWG GRN)

8

(16AWG WHT)

5

(14AWG RED)

13

(14AWG BLK)

01

(14AWG BLK)

16

(14AWG RED)

15

(16AWG BLU)

18

(16AWG BLU)

17

(16AWG WHT)

1

(12AWG RED)

12

(16AWG BLU)

0

(12AWG RED)

10

(12AWG RED)

10

12

(12AWG RED)

(14AWG RED)

14

(14AWG RED)

20

6V BATTERY

_

6V BATTERY

_

6V BATTERY

+

+

+

_

HOUR

METER

1

CIRCUIT BREAKER

VACUUM

SOLENOID

6V BATTERY

_

6V BATTERY

_

6V BATTERY

+

0

-

+

22

KEY

SWITCH

(16AWG WHT)

12A

BRUSH

SOLENOID

12

AMMETER

0

0

21

23

0

20

VACCUM MOTOR

CIRCUIT BREAKER

+

+

_

19

35A

(4AWG RED)

(4AWG BLK)

0

VACUUM

SWITCH

TRIGGER SWITCH

5

(16AWG WHT)

3

DRIVING MOTOR

SPEED

CONTROLLER

3

22

7

0

35A

LEFT BRUSH

CIRCUIT BREAKER

(16AWG BLU)

(16AWG BLU)

(16AWG WHT)

19

(14AWG RED)

+

0

21

5

RITHT BRUSH CIRCUIT BREAKER

(16AWG BLU)

0

(16AWG BLU)

0

(16AWG BLU)

0

11

BRUSH

SWITCH

5

B+ B- M2

12 11

(12AWG RED)

11

(4AWG RED)

_+_

(4AWG BLK)

0

0

7

6

6

19

M1

35A

11 (12AWG RED)

5

B+

0

B -

9 (14AWG RED)

1 (16AWG WHT)

+

10 (12AWG RED)

10 (12AWG RED)

14 (14AWG RED)

0 (16AWG BLU)

_

01 (14AWG BLK)

02 (16AWG GRN)

03 (12AWG BLK)

03 (12AWG BLK)

04 (14AWG BLK)

0 (16AWG BLU)

PCB

00

8

6

SOLUTION

SWITCH

F

R

DIRECTION

SWITCH

4.7K

2W

5

5

0

ACTUATOR

8 (16AWG GRN) 2 (16AWG GRN)

17 (16AWG BLU)

12 (12AWG RED)

12 (12AWG RED)

20 (14AWG RED)

15 (14AWG RED)

5 (16AWG WHT)

0 (16AWG BLU)

13 (14AWG RED)

17

UP

18

DOWN

SOLUTION SOLENOID

18 (16AWG BLU)

ACTUATOR MOTOR

03 (12AWG BLK)

LEFT BRUSH MOTOR

03 (12AWG BLK)

RIGHT BRUSH MOTOR

04 (14AWG BLK)

VACUUM MOTOR

16 (14AWG BLK)

DRIVE MOTOR

3

0

9

MAIN

SOLENOID

15

Page 18

ENGLISH

BETRİEBSANLEİTUNG

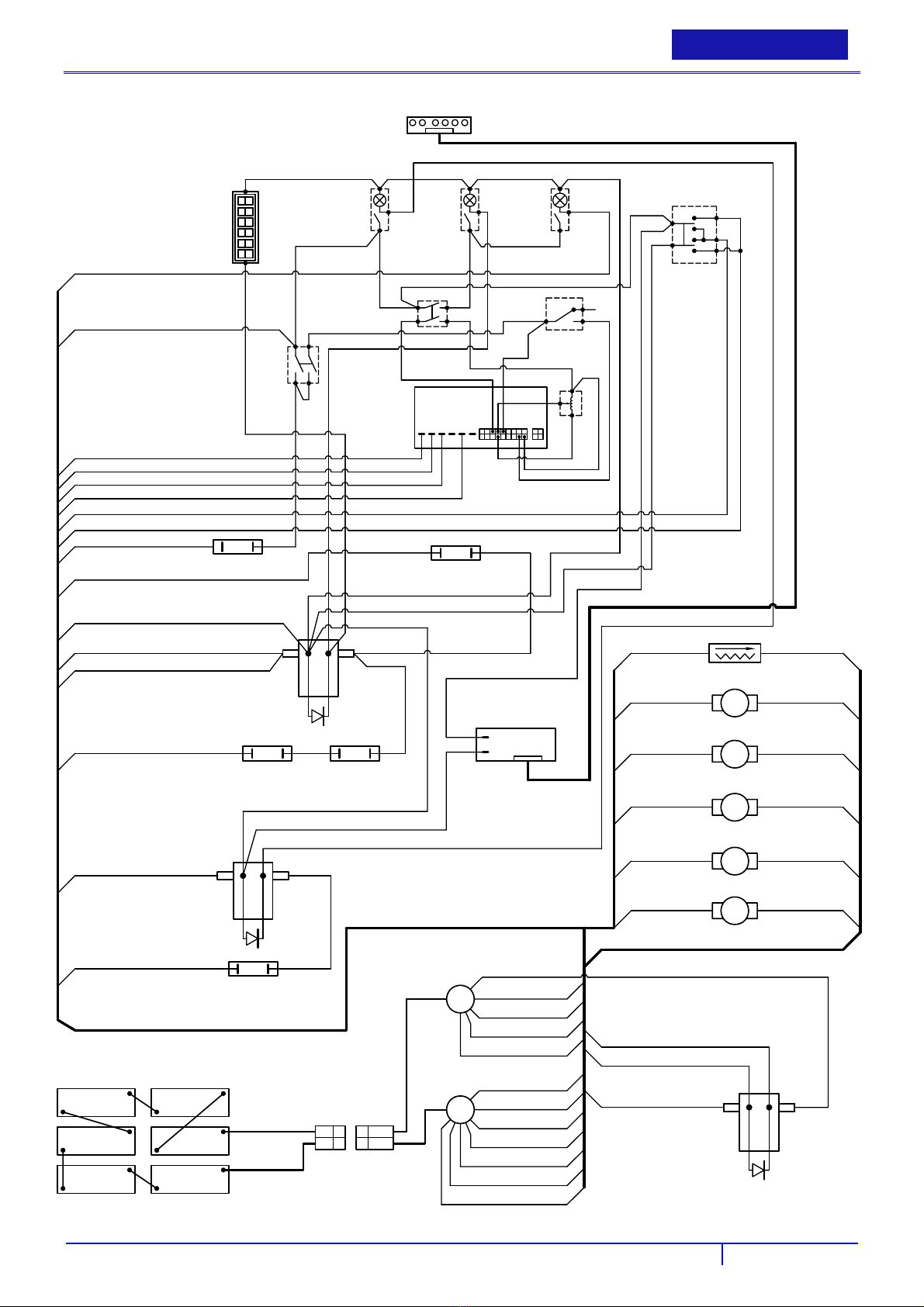

WIRING DIAGRAM (FANG32T-EU )

WIRING DIAGRAM(FANG32T-EU)

Colour codes

BLK Black

BLU Blue

GRU Green

RED Red

WHT White

1 BATTERY CAPACITY LIGHTS insert translation

2 HOUR METER

3 VACUUM SWITCH

4 BRUSH SWITCH

5 SOLUTION SWITCH

6 AMMETER

7 ACTUATOR

8 TRIGGER SWITCH

9

10 DIRECTION SWITCH

11

12 KEY SWITCH

13 CIRCUIT BREAKER

14 BRUSH SOLENOID

15 PCB

16 SOLUTION SOLENOID

DRIVING MOTOR SPEED

RIGHT BRUSH CIRCUIT

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

İnsert translation

İnsert translation

17 ACTUATOR MOTOR

18 LEFT BRUSH MOTOR

19 VACUUM MOTOR

20 DRIVE MOTOR

21 VACUUM SOLENOID

22 VACUUM CIRCUIT BREAKER

23 MAIN SOLENIOD

24 RIGHT BRUSH MOTOR

5

2

6

1

ATTERY

B

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

insert translation

nsert translation

i

Page 19

USER MANUAL

ENGLISH

OPERATION

BEFORE STARTING THE MACHINE

WARNING!

On some points of the machine there are some adhesive plates indicating:

DANGER

WARNING

CAUTION

CONSULTATION

While reading this Manual, the operator must pay careful attention to the symbols shown on the plates. Do not cover these

plates for any reason and immediately replace them if damaged.

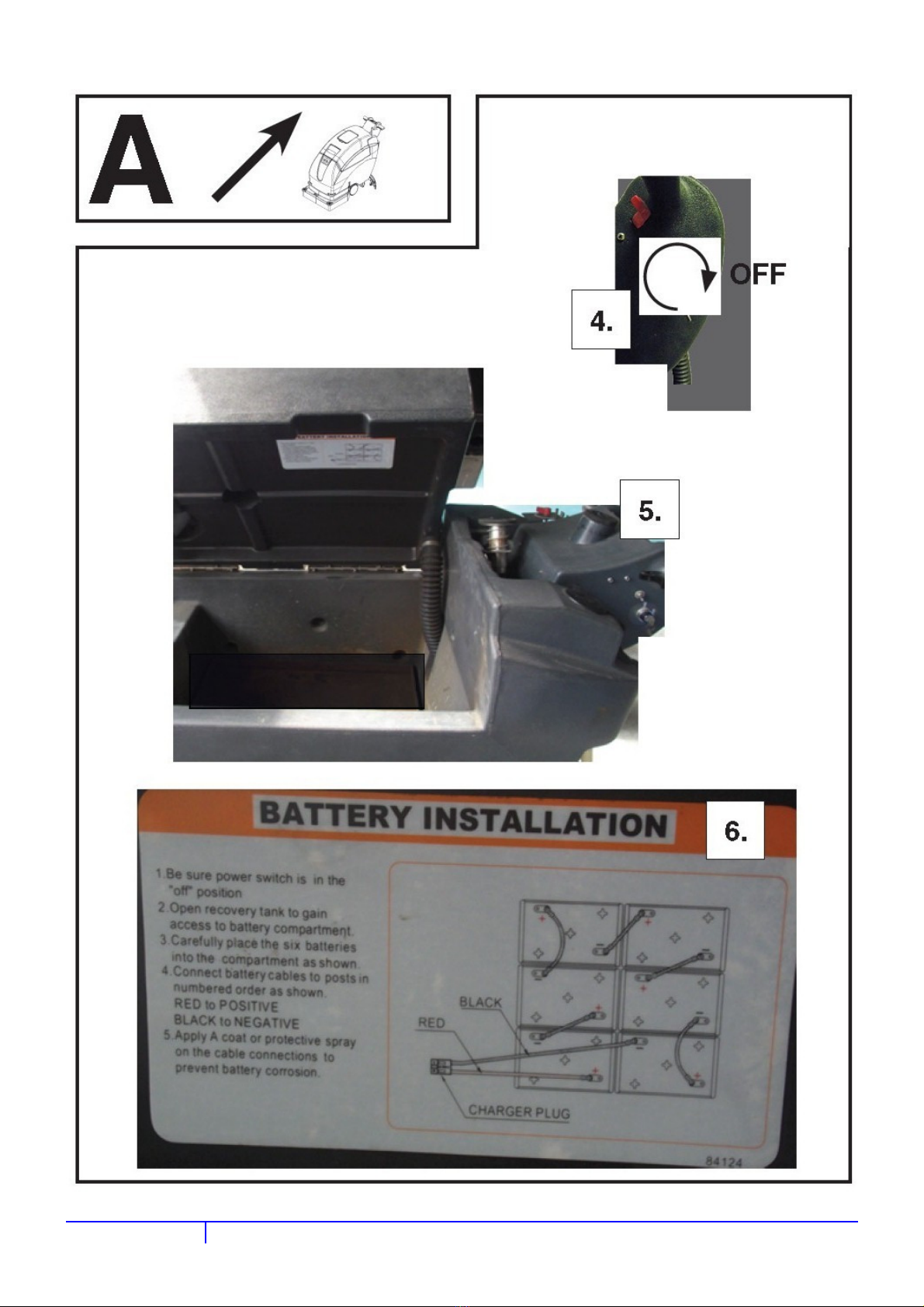

BATTERY INSTALLATION

WARNING!

The electric components of the machine can be seriously damaged if the batteries are either improperly

installed or connected. The batteries must be installed by qualified personnel only.

Set the function electronic board and the battery charger (optional) according to the type of batteries used

(WET or GEL).

Check the batteries for damage before installation.

Disconnect the battery connector and the battery charger plug.

Handle the batteries with great care.

Install the battery terminal protection caps supplied with the machine.

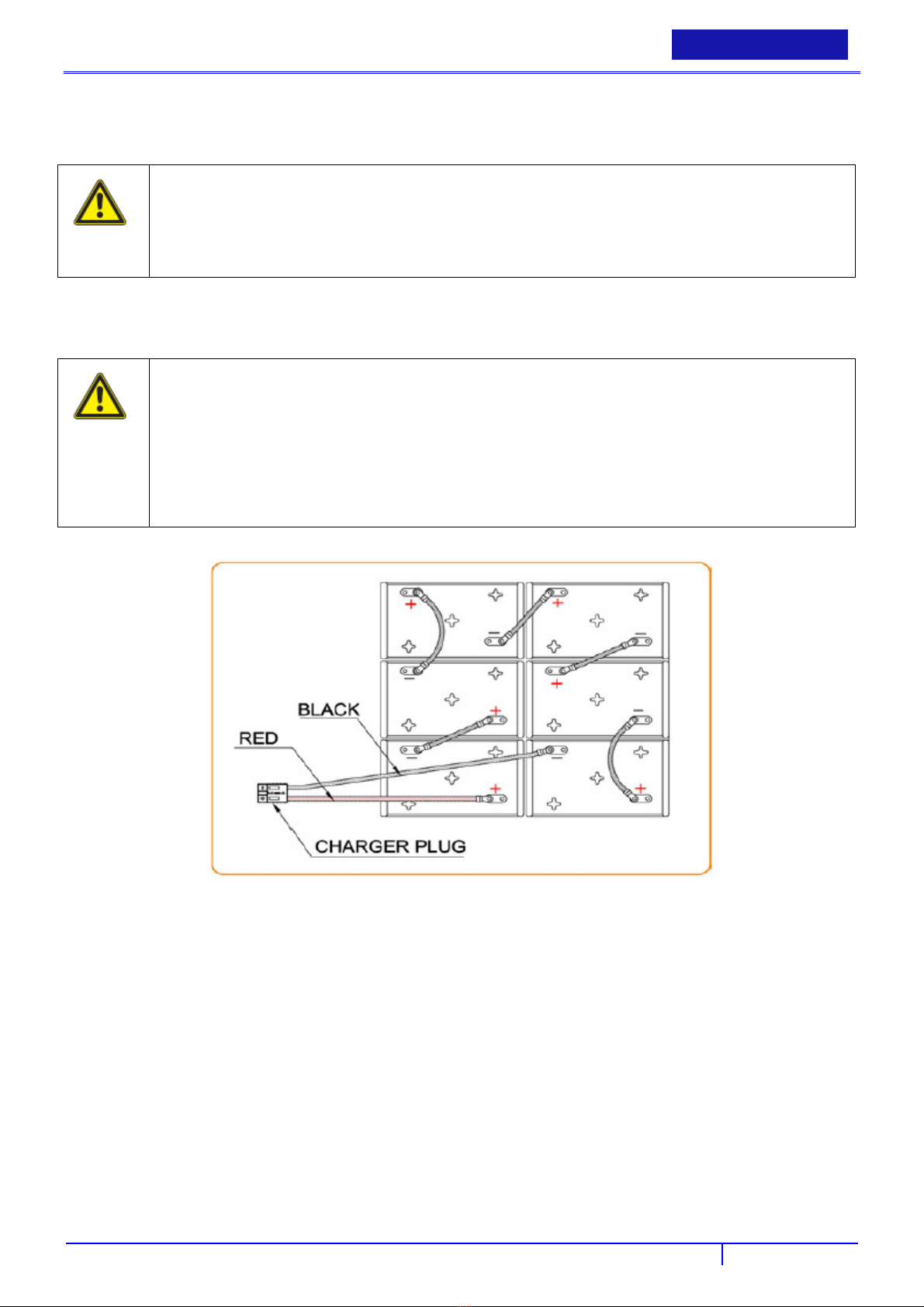

The machine requires two 12 V batteries, connected according to the below diagram:

There are no batteries on the machine from factory, but customers can purchase batteries ( WET or GEL).

Buy appropriate batteries (see Technical Data paragraph).

For battery choice and installation, apply to qualified battery dealers.

Set the machine and the battery charger according to the type of batteries installed (WET or GEL) as shown in the

following para-grap

a) When batteries (WET or GEL) are already installed and ready to be used

Check that the batteries are connected to the machine with the charger plug.

Insert the ignition key (19) and turn it to “on”.

If the green warning light (3) turns on, the batteries are ready to be used.

If the yellow or red warning light (3) turns on, the batteri es must be charged (see the procedure in Maintenance

chapter).

b) When batteries (WET) are installed on the machine, but without electrolyte

Open the cover (29) and check that the recovery water tank (31) is empty, otherwise empty it with the drain hose (10).

17

Page 20

ENGLISH

Carefully lift the tank (31).

WARNING!

Pay attention when using sulphuric acid, as it is corrosive. If it comes in contact with skin or eyes, rinse

thoroughly with water and consult a physician.

Batteries have to be filled in a well-ventilated area. Wear protective gloves.

Fill up the battery cells with sulphuric acid for batteries (density 1.27 to 1.29 kg at 25°C) in accordance with the

instructions shown in the Battery Manual. The correct quantity of sulphuric acid is shown in the Battery Manual.

To avoid damaging the floor, dry with a cloth both acid and water on the top of the batteries after charging.

Let the batteries rest and fill in with sulphuric acid in accordance with the instructions shown in the Battery Manual.

Charge the batteries (see the procedure in Maintenance chapter).

BETRİEBSANLEİTUNG

BATTERY CHARGER SETTING

The charger default setting is common position for AGM,Gel,SLA,VRLA from factory

If needed use WET position only for lead batteries. Please contact dealer.

PRE-OPERATION CHECKS

Sweep the outside of the machine.

Make sure the voltage of machine conforms to local voltage.

Check that squeegee is properly installed.

Check that brush / pad is properly installed.

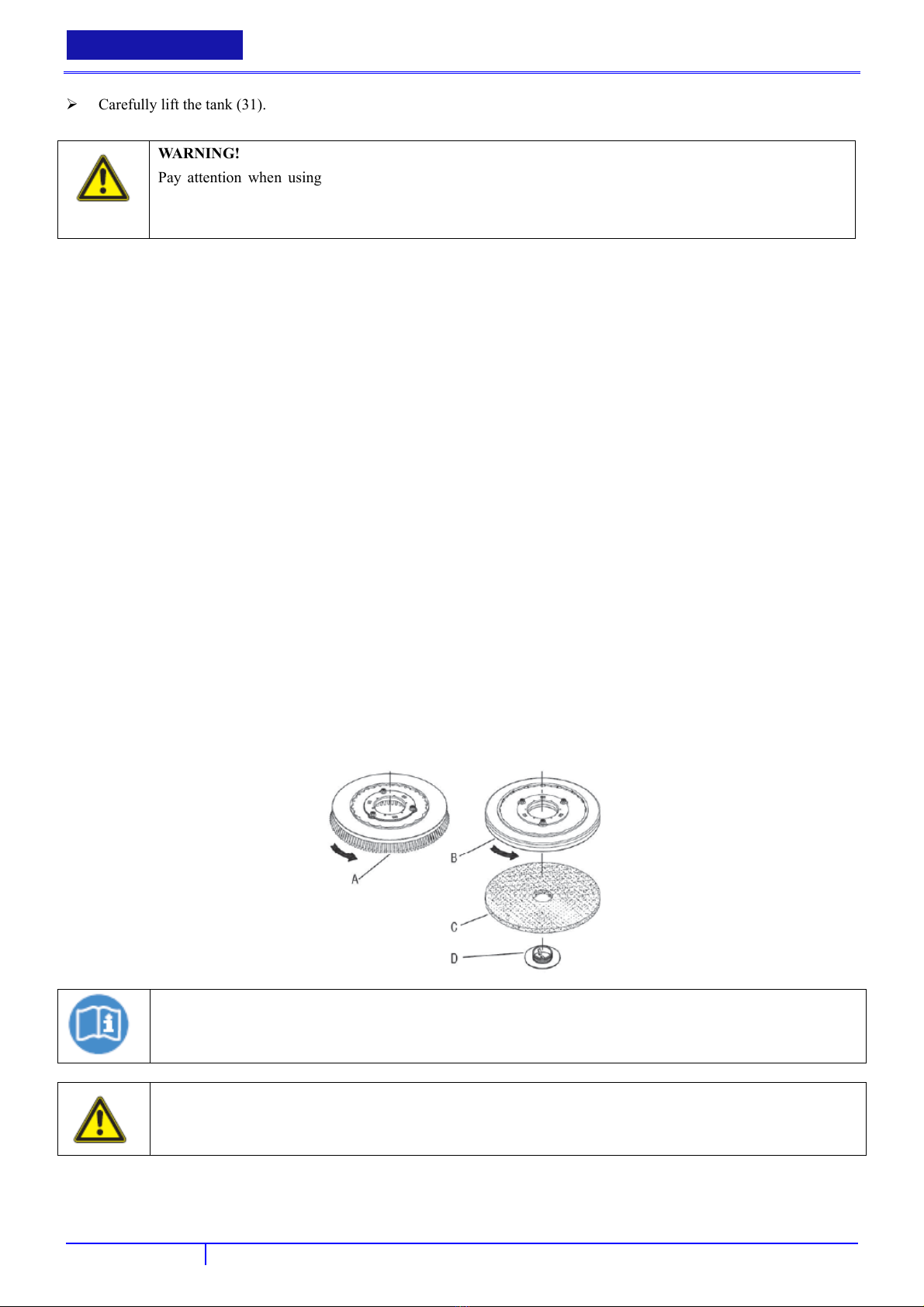

INSTALLING PAD DRIVER OR BRUSH

Ensure that the machine is turned off.

Lower brush head assembly to the floor by stepping on the foot pedal and pushing pedal forward.

Tilt the machine backward to access the drive motor hub.

NOTE

Remove the squeegee assembly prior to tilting the machine backwards. It makes the process faster and easier.

WARNING!

Do not keep the machine tilted back for a long time. This could cause battery acid to leak from the batteries.

If using a pad driver, first attach the appropriate pad to the pad driver surface.

Mount the pad driver or brush to the drive motor hub by lining up the three studs with the three holes in the drive motor

hub. Once in the holes, rotate the driver toward the spring clip to lock driver into place.

18

Page 21

USER MANUAL

ENGLISH

MOUNTING THE SQUEEGEE

Pull back on the squeegee lift lever to raise the squeegee bracket up.

Loosen the two knobs on the squeegee and slide the squeegee into the slots at the rear of the squeegee bracket. (the

wheels on the squeegee point to the back)

Tighten the knobs securely.

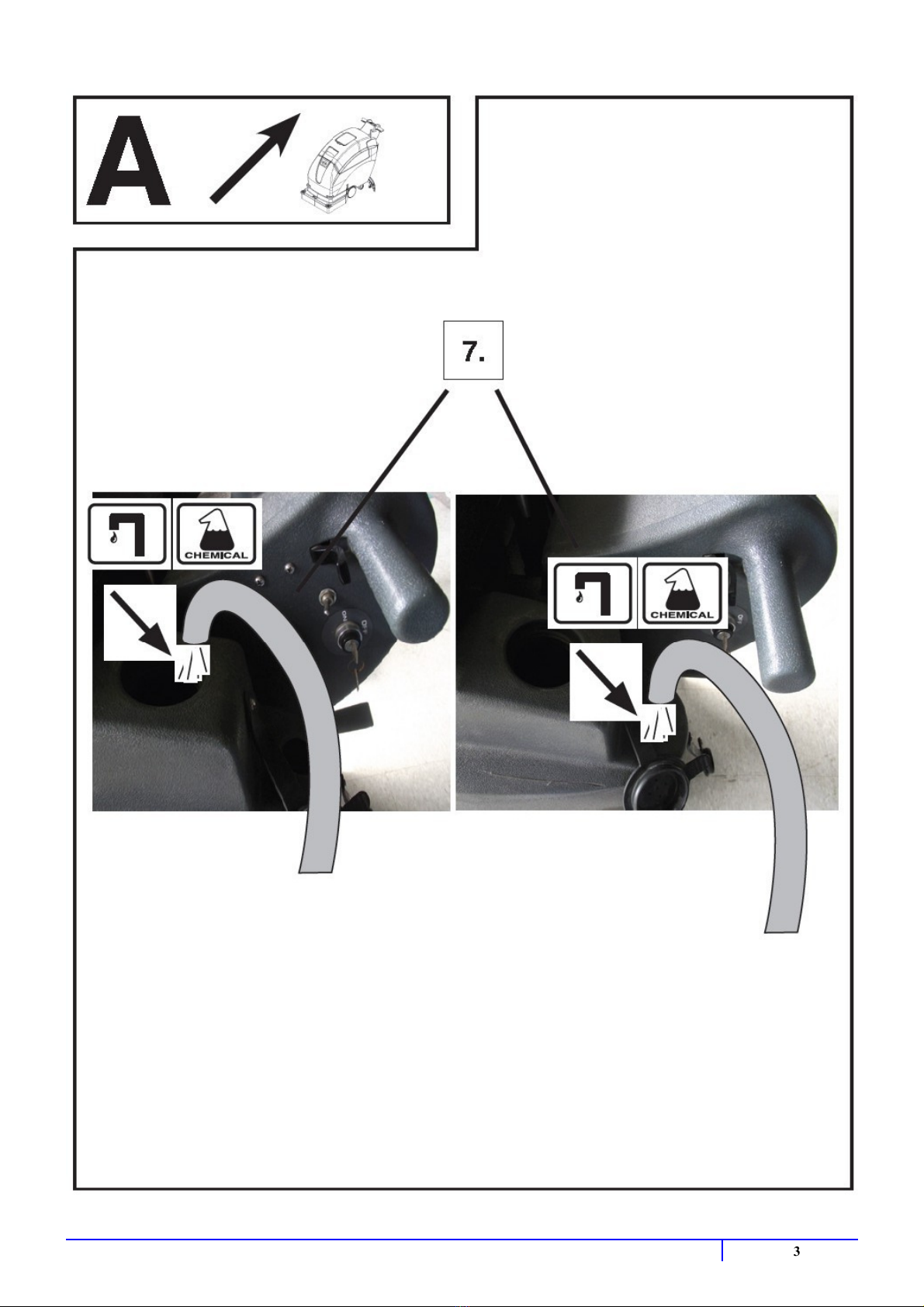

FILLING THE SOLUTION TANK

The Fang 32T-EU can be filled in two different locations:

a. Front fill area for use with a hose or a bucket.

b. Rear fill area for use with a hose only.

Determine which fill area you would like to use to fill the machine with water.

Fill solution tank with up to 52 liters of water. (water temperature should not exceed 40° C). The clear tube in the back

left of the machine has gallon markers to help determine the water level in the solution tank.

NOTE

If you are filling the solution tank with a bucket, make sure the bucket is clean. This will prevent debris from

clogging the lines or solenoid.

WARNING!

Do not put any flammable materials into solution tank. This can cause an explosion or a fire. Only use

recommended cleaning chemicals. Contact your janitorial supply distributor for recommendations on proper

chemicals.

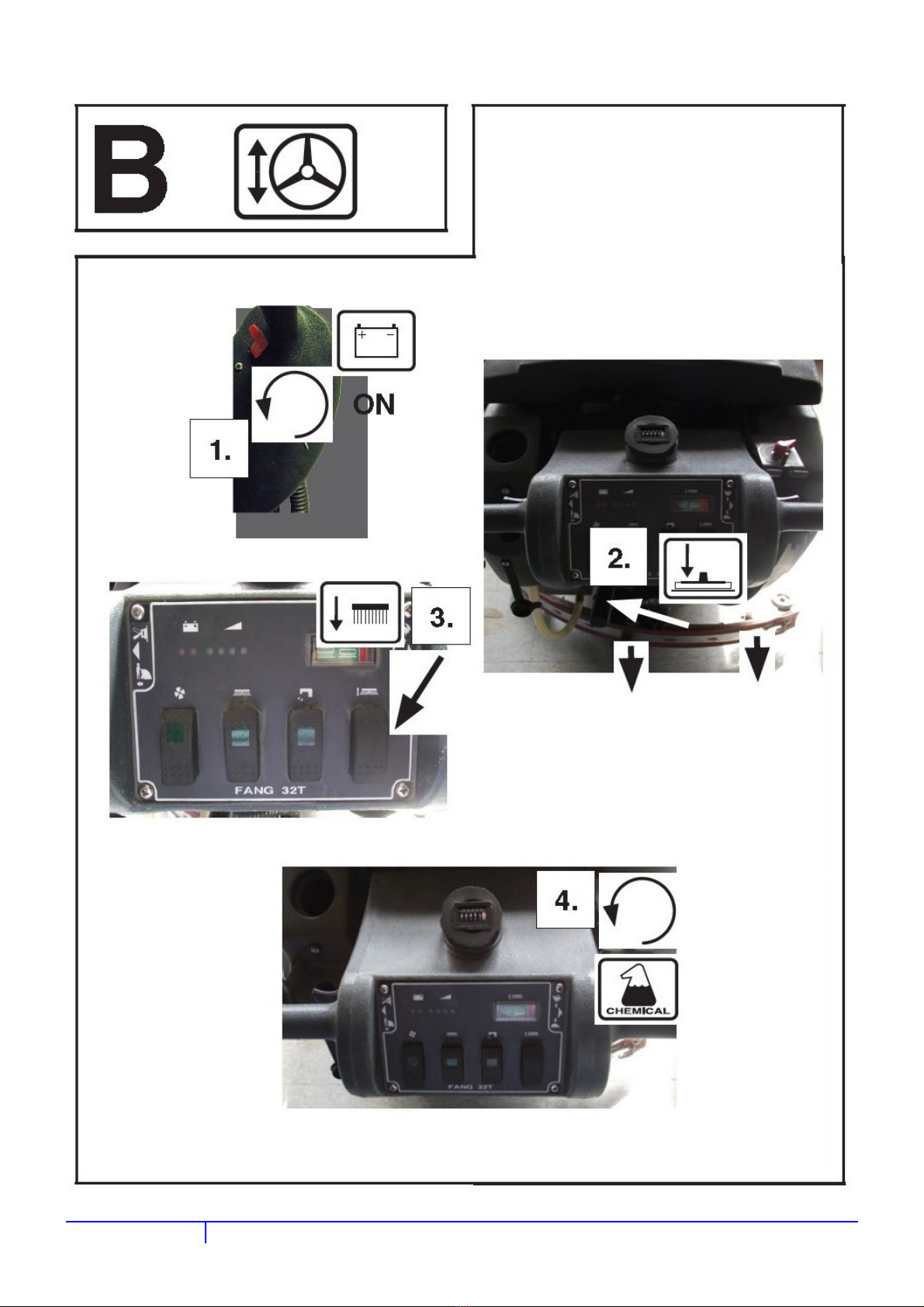

MACHINE START AND STOP

WA

RNING!

Do not operate machine unless you have read and understand this manual.

Set control housing to a comfortable operating height by squeezing together the two thumb levers (16) directly

underneath the housing.

Lower squeegee assembly to the floor by releasing the lift lever (14) from its locked position.

Lower brush head assembly to the foor by turn brush pressure switch(7)to ON position.

Turn vacuun motor switch (1) to “ ON” position.

Turn brush motor switch (2) to “ON” position.

Turn the solution switch (5) to “ON” position.

a. Solution will not begin to flow until the operating triggers are pulled.

The Fang 32T-EU is self-propelled. The speed can be controlled by a knob (9) located on the right side of the control

housing.

The Fang 32T-EU has reverse. In order to activate reverse,there is a toggle switch (20) located on the left side of the

control housing.

To begin scrubbing, pull on one or both of the red operating triggers (27). When these triggers are pulled, the brush will

begin to spin and the solution will begin to flow.FANG32T-EU:will propel itself.FANG32T-EU:Begin scrubbing by

moving the machine forward.

WARNING!

Do not keep the machine in the same position with the pad / brush spinning, or you could cause damage to the

floor.

Adjust amount of solution flow by turning the solution control knob (8). Turn to the right for more solution, or turn left

for less solution.

19

Page 22

ENGLISH

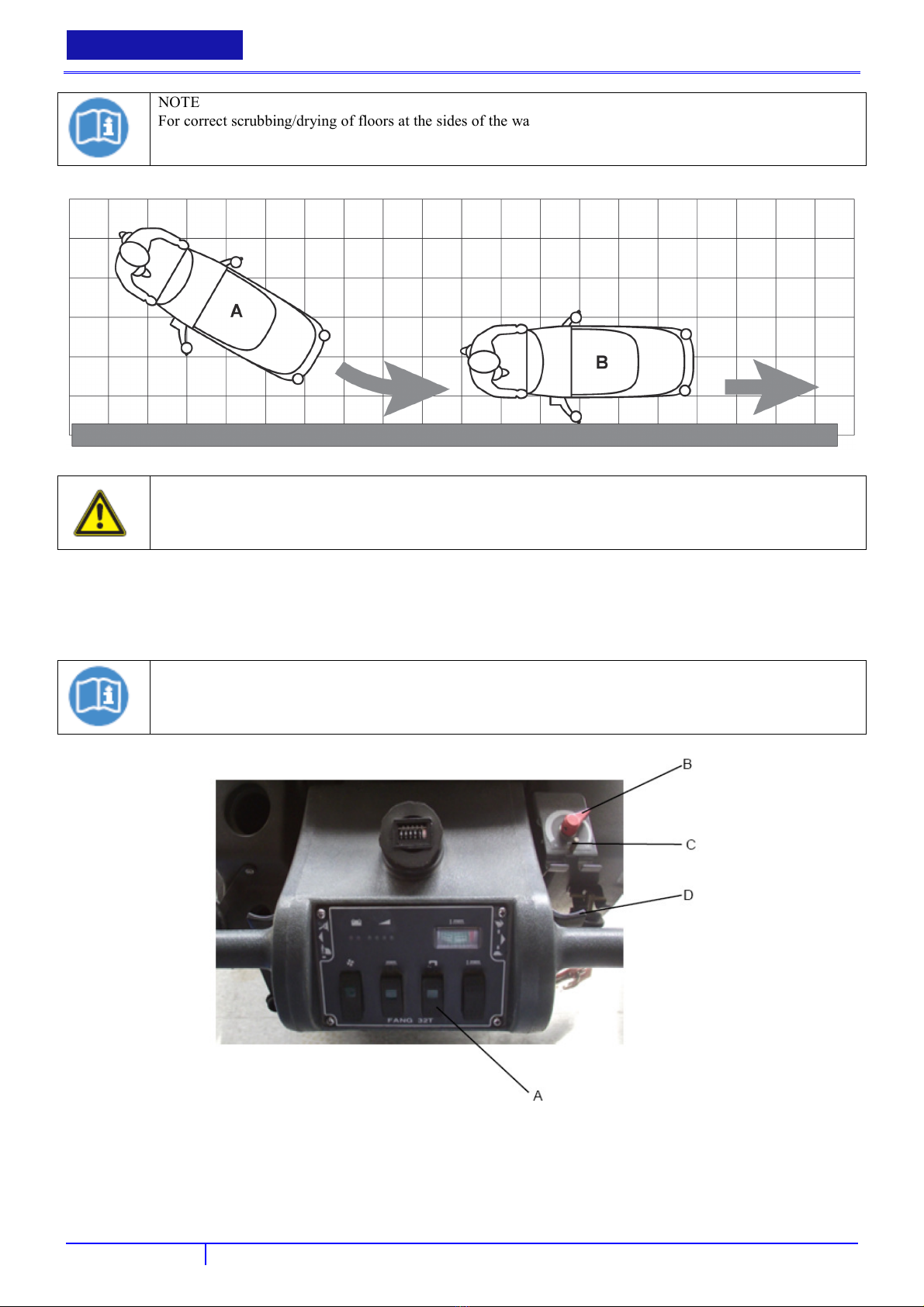

NOTE

For correct scrubbing/drying of floors at the sides of the walls, Viper suggests to go near the walls with the right

side of the machine as shown.

BETRİEBSANLEİTUNG

CAUTION!

To avoid any damage to the floor surface, turn off the brush/pad-holder when the machine stops in one place,

especially when the extra pressure function is on.

SOLUTION FLOW ADJUSTMENT

Turn the solution switch (A) to “ON” position.

Adjust amount of solution flow by turning the solution control knob (B), turn left (counter-clockwise) for more solution,

or Turn right (clockwise) for less solution. The pin (C) is limit position of the solution control knob (B).

NOTE

Even if turn on the solution switch (A) ,the solution will not begin to flow until the operating triggers (D) are

pulled.

BATTERY DISCHARGE DURING OPERATION

Until the green warning light (3) stays on, the batteries allow the machine to work normally.

When the green warning light (3) turns off, and the yellow warning light (3) turns on, it is advisable to charge the batteries,

because the residual autonomy will last for a few minutes (depending on battery characteristics and work to be performed).

20

Page 23

USER MANUAL

When the red warning light (3) turns on, the autonomy is over. After a few seconds, the brush/pad-holder is automatically

tuned off, while the vacuum system and the drive system stay on, to finish drying the floor and drive the machine to the

appointed recharging area.

CAUTION!

Do not use the machine with discharged batteries, to avoid damaging the batteries and reducing the battery life.

ENGLISH

WHILE OPERATING MACHINE

Occasionally look through the clear recovery tank lid to see if there is any foam build-up. If excessive foam is found, add

defoamer to the recovery tank.

WARNING!

Foam must not enter the float shut-off screen, or damage can occur to the vacuum motor. Foam will not activate

the machines float shut-off device.

Occasionally view the clear tube at the back left of the machine to check the amount of cleaning solution that is left in the

machine.

Occasionally check the battery level meter (3). When meter is in the red, recharge the batteries.

WARNING!

When battery meter is in the red, do not continue to operate the machine. Battery damage may result.

If the squeegee assembly leaves streaks on the floor, raise the squeegee off the floor and wipe the blades down with a

damp cloth.

WARNING!

Do not use your fingers to wipe or remove debris from the blades, as injury may occur.

When the solution tank runs empty, turn off the brush switch, solution switch and raise the brush head. Keep the squeegee

down and continue to vacuum until all the dirty water is picked up. (see TANK DRAINING section to learn how to drain

recovery and solution tanks)

NOTE

The brush motor is circuit breaker protected to protect it from damage. If this breaker trips, it can’t be reset

immediately.

You must first determine what caused the circuit breaker to trip, and allow the motor to cool down before you

can reset the circuit breaker.

TANK DRAINING

Turn the power off on the machine.

With the squeegee and brush head in their “up” position, transport machine to approved area for draining tank(s).

DRAINING THE RECOVERY (DIRTY) TANK

NOTE

Any time scrubbing is completed, or when refilling solution tank, the recovery tank should be drained and

cleaned.

WARNING!

If the recovery tank is not drained when the solution tank has been refilled, foam or water may enter the float

shut-off mechanism and cause damage to the vacuum motor.

Remove the drain hose from the holder, and place the drain hose over the floor drain. Twist off the drain hose plug to

begin the draining process. In order to completely empty the recovery tank, hinge opens the recovery tank and let it rest

on the support stand.

Clean the recovery tank after every use. Use a fresh water hose to rinse out the recovery tank. Be careful not to spray

21

Page 24

ENGLISH

BETRİEBSANLEİTUNG

water into the float shut-off mechanism.

NOTE

If you are storing the machine for any period of time, always leave the clear recovery tank lid off the tank so the

tank can dry completely and smell fresh.

Replace the drain hose plug tightly as soon as you are done draining the tank.

DRAINING THE SOLUTION (CLEAN) TANK

NOTE

Any time scrubbing operation is completed, the solution tank should be drained and cleaned.

Pull down on the clear tube (back left of the machine) to remove it from the hose barb. This will allow the solution to

flow freely into a bucket or floor drain.

Rinse the solution tank with clean water after every use. This will help prevent chemical buildup and clogging of the

solution lines.

With clean water in solution tank, turn machine power on, solution switch “on” and pull the operating triggers. This will

allow the clean water to flush through and clean the solution plumbing.

Once tank is rinsed, flushed and drained, reconnect the clear tube to the hose barb. Be sure the tube is pushed all the way

up on the hose barb.

BATTERY CHARGING

NOTE

For the best machine performance, keep batteries charged at all times. Do not let them sit in a discharged

condition.

NOTE

If the machine has an optional battery charger installed, the machine cannot operate if the charger is not on

board. In case of battery charger malfunction, contact an authorised Service Center.

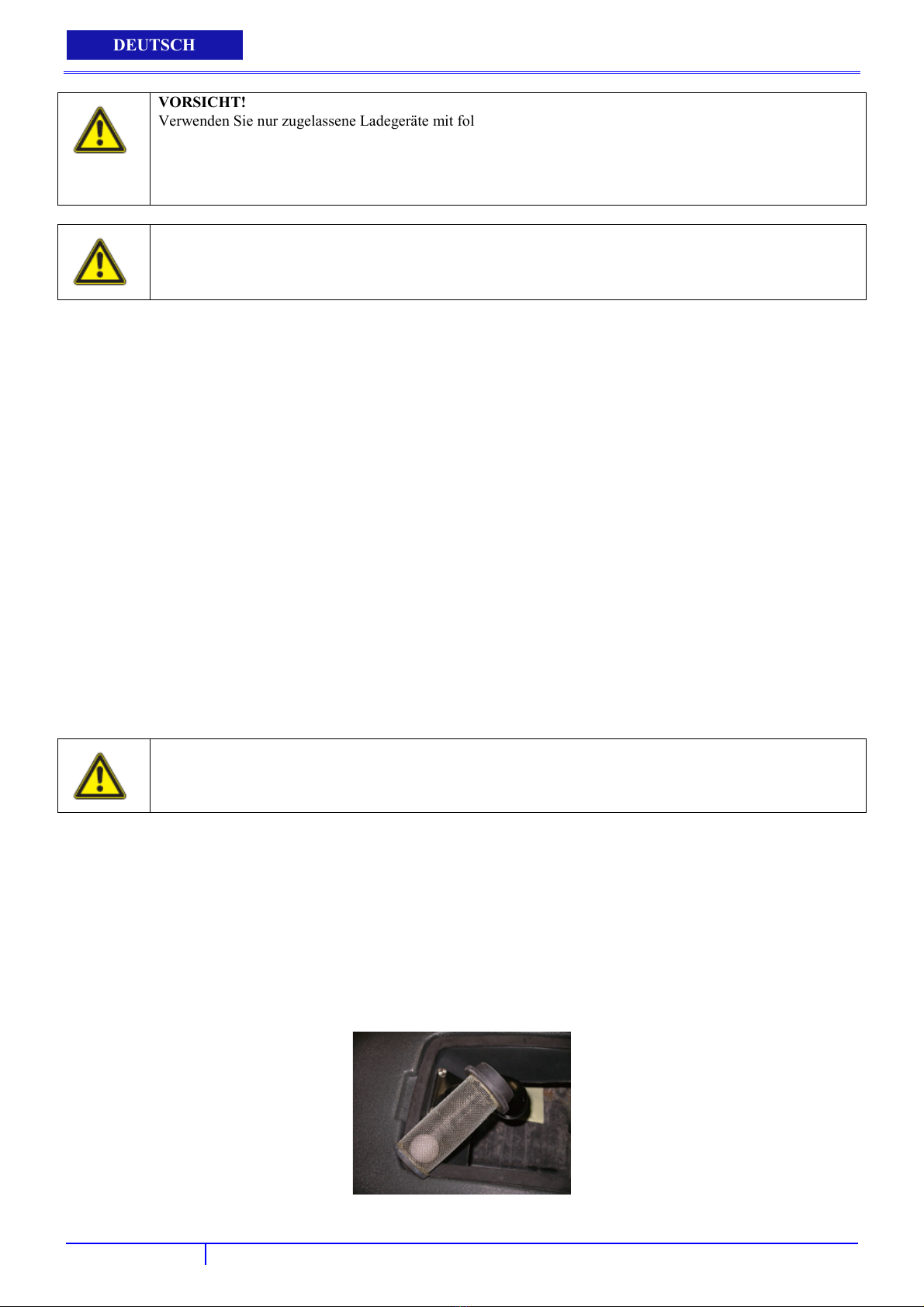

CAUTION!

Use only approved chargers with the following specifications:

Automatic shut off circuit

Deep cycle charging

Output current of 25-35 Amps

Output voltage of 36 Volts

CAUTION!

Batteries are dangerous! Batteries emit hydrogen gas and an explosion or fire can result. Keep sparks and fire

away from batteries at all times. When charging the machine, make sure the battery compartment is left open.

Place charge and machine in a well ventilated area.

Turn machine off.

Open recovery tank up, exposing battery compartment .

Check fluid level in each battery cell. Do not charge batteries unless fluid is slightly covering the battery plates. Do not

overfill the batters. Overfilling may cause the batteries to overflow during charging due to expansion. Replace the caps

prior to charging.

Plug approved charger into grounded wall out let before plugging the charger into the machine.

Plug charger into red charger receptacle located in the front left of the battery compartment.

Flip up the recovery tank “Kick stand” and gently lay the recovery tank down until it rests on the stand.

The battery charger will automatically begin to charge the batteries, and it will automatically shut down once the batteries

are fully charged.

Upon completion of charging, first unplug the charger from the wall outlet, and then disconnect the charger from the

machine.

Check the battery level after charging is complete. If fluid level is low, add distilled water to bring the fluid level up to the

bottom of the sight tubes. Replace the caps and wipe the batteries down with a towel.

2

2

Page 25

USER MANUAL

ENGLISH

MAINTENANCE

To keep the machine performing well for many years, please follow the following maintenance procedures.

CAUTION!

Always confirm that the machine is switched off and the battery cable is disconnected prior to performing any

mainte-nance or repairs

DAILY MAINTENANCE

Remove pad driver / brush and clean with approved cleaner.

Drain recovery and solution tanks completely and rinse out with clean water. Visually check the recovery tank for debris

and clean out as necessary.

Raise squeegee assembly off floor and wipe it down with a damp towel. Be sure to store the squeegee in the up position.

Remove the float shut-off assembly and rinse it out with clean water.

Clean machine with an approved cleaner and a damp towel. Don’t spray water to clean the outside of machine to avoid

damage to motor and wiring.

Recharge batteries.

WEEKLY MAINTENANCE

Check fluid level in batteries.

Check batteries for loose or corroded cables.

Keep battery tops clean from corrosion.

MONTHLY MAINTENANCE

Check machine for leaks and loose fasteners.

Lubricate all grease points and pivot points with silicon spray and approved grease.

Place machine over a floor drain. Flush solution system by pouring 10 liters of hot water and approved alkaline detergent

into the solution tank and running machine (with solution control on) for 45 seconds. Turn machine off and let it sit

overnight. Then next day, drain the remaining solution and rinse the solution tank out with clean water.

VACUUM SYSTEM MOTOR FILTER CLEANING

Drive the machine on a level floor.

Turn the ignition key (19) to “OFF”.

Open the recovery water tank.

If necessary, drain the water from the tank in order to make the filter visible.

Check that the pre-filter is clean. If necessary clean it with water and compressed air, then install it.

Perform steps 1, 2 and 3 in the reverse order.

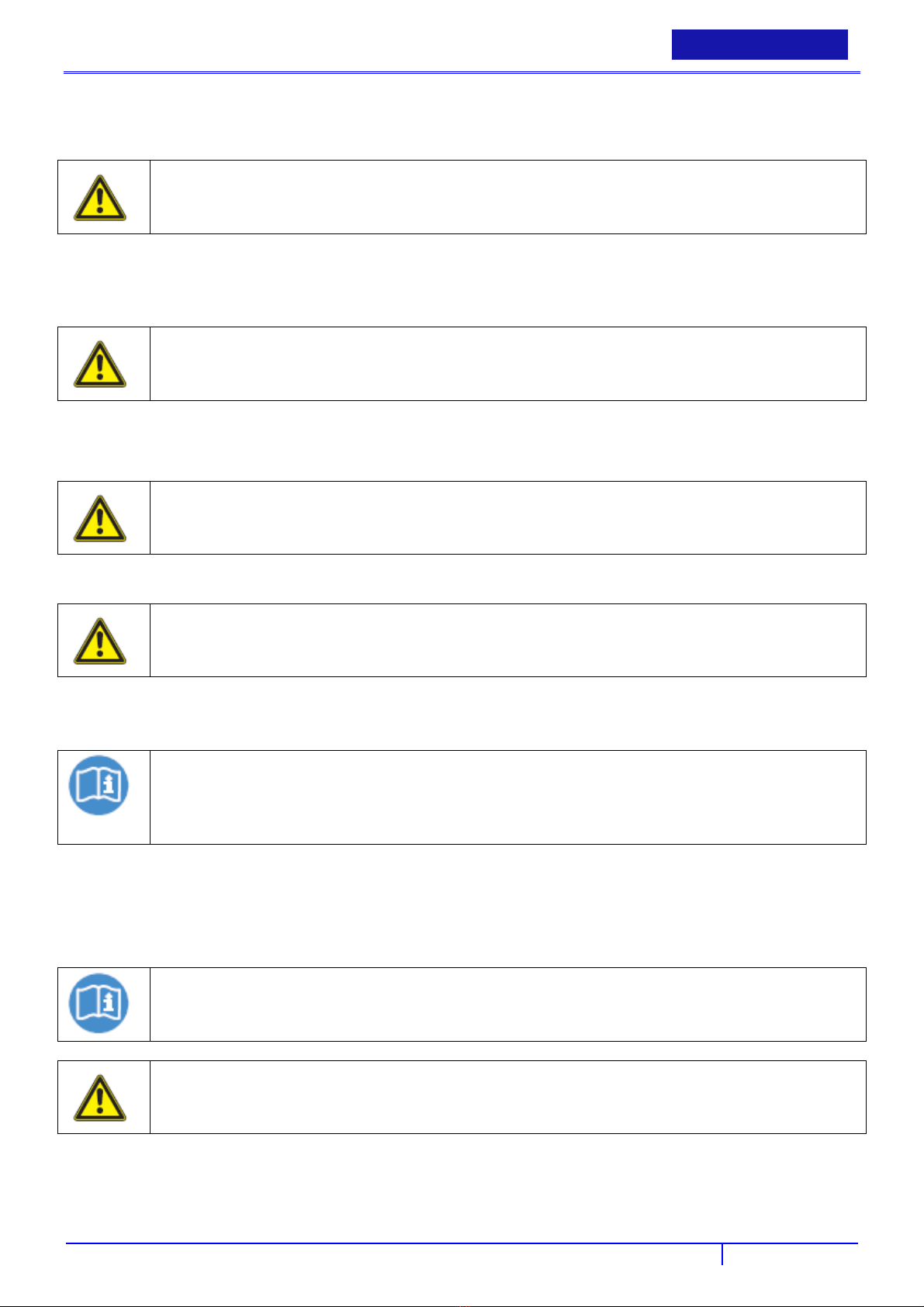

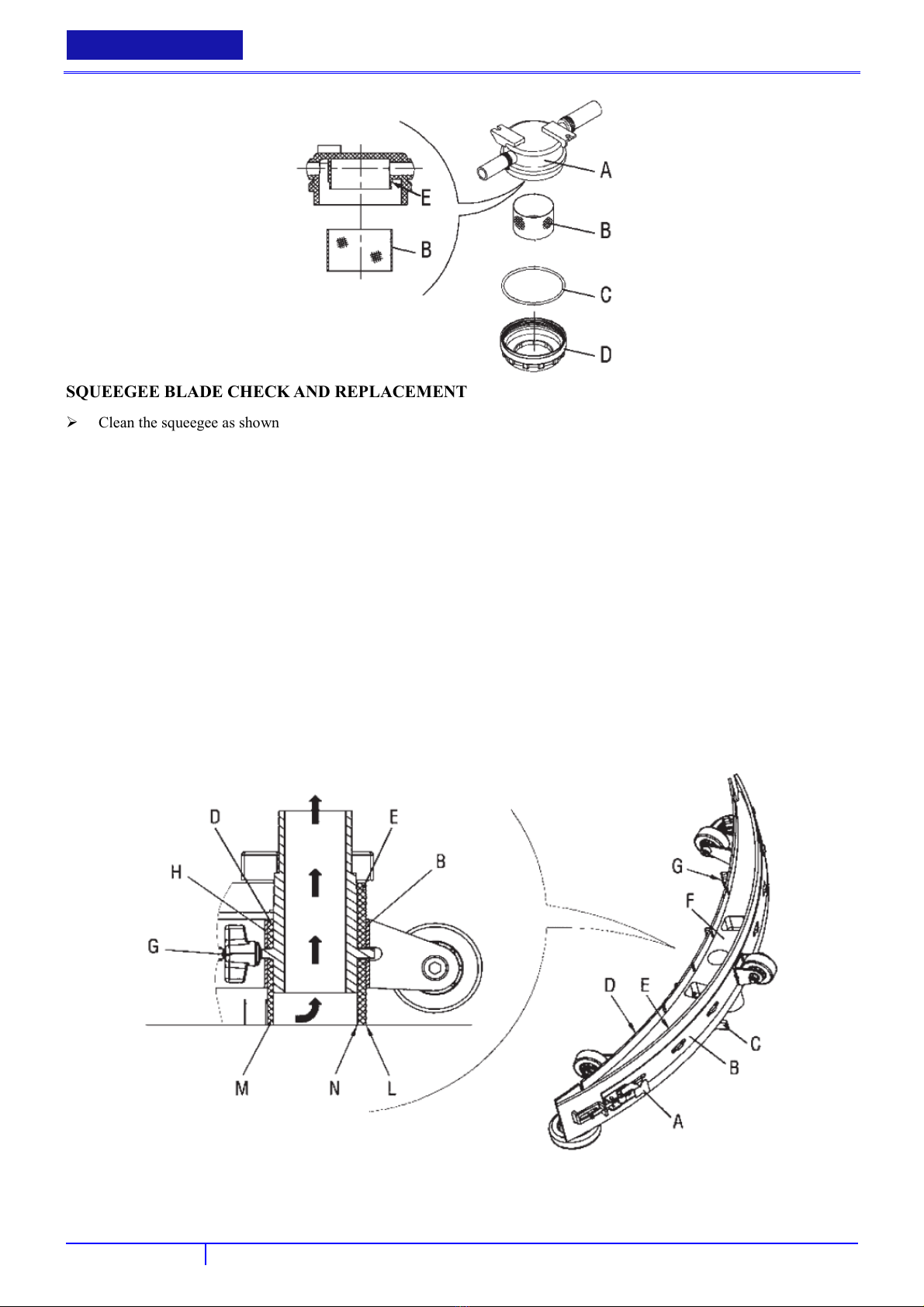

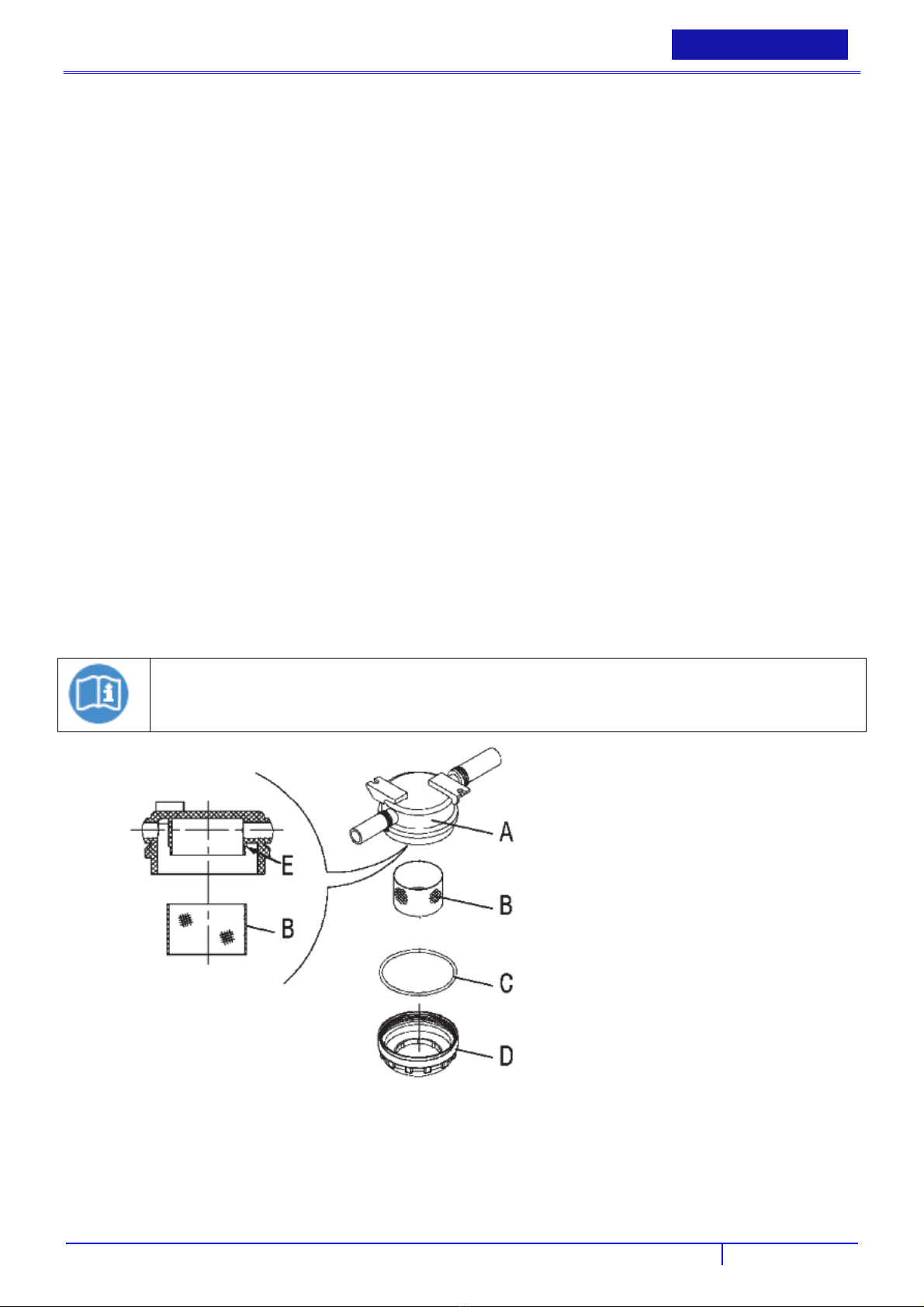

SOLUTION/CLEAN WATER FILTER CLEANING

Drive the machine on a level floor.

Turn the ignition key (19) to “OFF”.

Remove the transparent cover (D) (the water filter position is under the machine), then remove the filter strainer (B).

Clean and install them on the support (A).

NOTE

The filter strainer (B) must be correctly positioned on the housing (E) of the support (A).

23

Page 26

ENGLISH

BETRİEBSANLEİTUNG

SQUEEGEE BLADE CHECK AND REPLACEMENT

Clean the squeegee as shown in the previous paragraph.

Check that the edge (M) of the front blade (D) and the edge (L) of the rear blade (E) lay down on the same level, along

their length; otherwise adjust their height according to the following procedure:

− Disengage the retainers (A) to adjust the rear blade (E); then engage the retainers.

− Loosen the handwheels (G) and adjust the front blade (D); then tighten the handwheels.

Check the front blade (D) and rear blade (E) for integrity, cuts and tears; if necessary replace them as shown below.

Check that the front corner (N) of the rear blade is not worn; otherwise, overturn the blade to replace the worn corner with

an integral one. If the other corners are worn too, replace the blade according to the following procedure:

− Disengage the retainers (A) and remove the retaining strip (B), then replace/overturn the rear blade (E). Install the

blade in the reverse order of removal.

− Unscrew the handwheels (G) and remove the retaining strip (H), then replace the front blade (D). Install the blade in

the reverse order of removal.

After the blade replacement (or overturning), adjust the height as shown in the previous step.

Connect the vacuum hose (32) to the squeegee.

Install the squeegee (12) and screw down the handwheels (13).

If necessary, adjust the squeegee adjusting handweel(13).

BRUSH/PAD CLEANING

24

Page 27

USER MANUAL

ENGLISH

CAUTION!

Risk of cuts.

It is advisable to wear protective gloves when cleaning the brush/pad because there may be sharp debris.

Remove the brush/pad from the machine, as shown in Use chapter.

Clean and wash the brush/pad with water and detergent.

Check that the brush/pad is integral and not excessively worn; otherwise replace it.

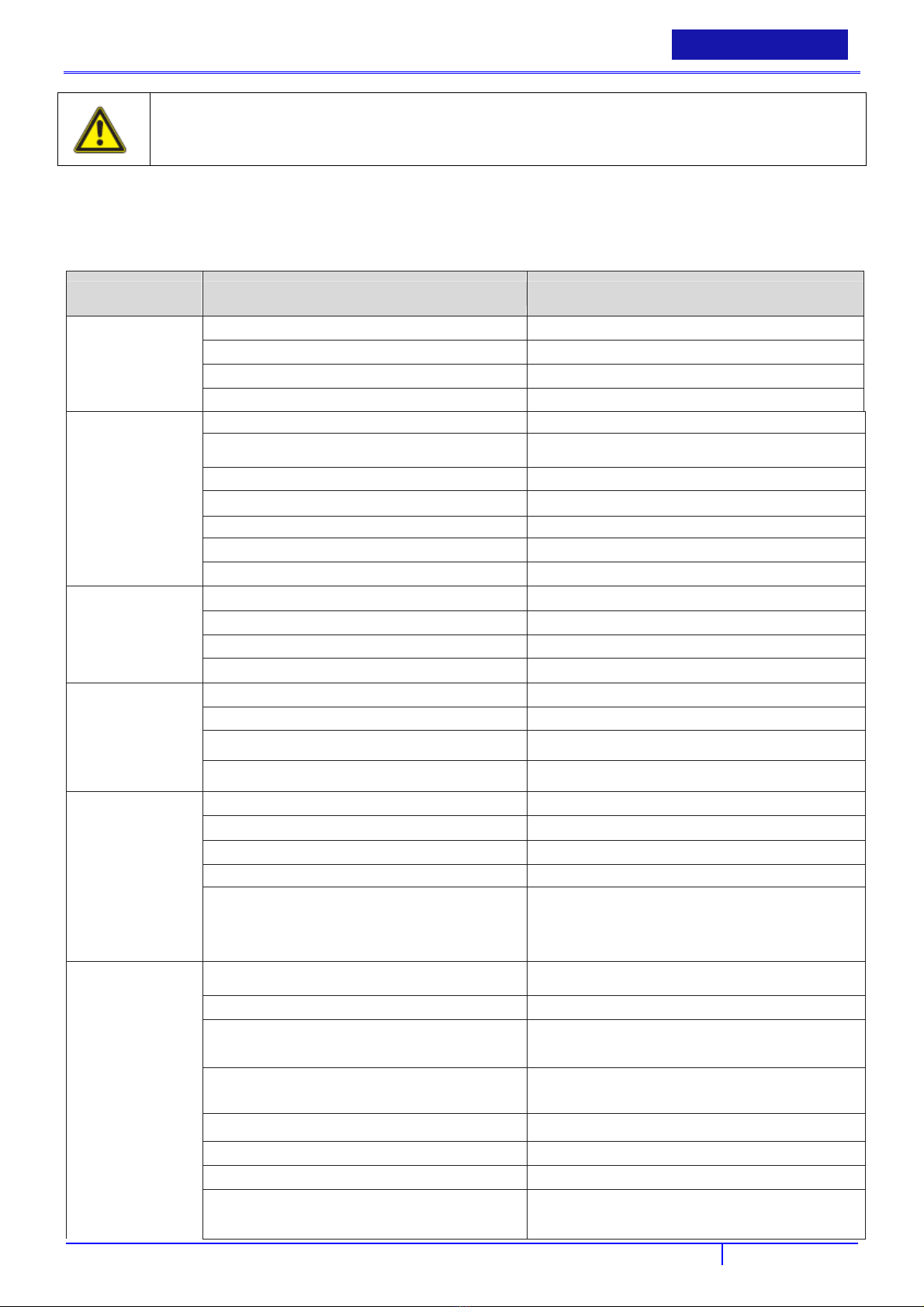

TROBLESHOOTING

PROBLEM CAUSE SOLUTION

No power Bad batteries Replace batteries

Batteries need to be charged Charge batteries (see Battery Charging)

Loose battery cable Tighten loose cable(s)

Batteries not connected properly Follow battery installation instructions

Brush motor does

not run

Vacuum motor does

not run

Short run time Batteries need to be charged Charge batteries (see Battery Charging)

Bad brush switch Contact Viper Distributor

Brush circuit breaker has tripped Check brush motor for obstructions and reset breaker

Rectifier has burned out Contact Viper Distributor

Bad wiring Contact Viper Distributor

Bad brush motor Contact Viper Distributor

Carbon brushes worn out Contact Viper Distributor

Bad solenoid Contact Viper Distributor

Bad vacuum switch Contact Viper Distributor

Bad wiring Contact Viper Distributor

Bad vacuum motor Contact Viper Distributor

Carbon brushes worn out Contact Viper Distributor

Batteries need maintenance See Battery Maintenance in this manual

Bad cell in battery(s) Replace batteries

Bad charger Replace charger

Little or no solution

flow

Poor water pick up Squeegee clogged Clean debris off squeegee with damp towel

Bad solution switch Contact Viper Distributor

Clogged solution solenoid Contact Viper Distributor

Clogged solution filter Remove filter and clean

Solution line obstructed Remove solution line and clean

Solution flow adjustment knob in need of adjustment Increase flow by twisting solution adjustment knob to

the right. Decrease flow by twisting solution adjustment

knob

Squeegee blades worn Install new squeegee blades

Squeegee not mounted correctly Confirm that the squeegee assembly is securely fastened

to the machine and not loose fitting.

Vacuum hoses have a hole or are loose Check hose connections and make sure they are firm.

Replace hose if damaged.

Vacuum hose may be clogged Check hose for debris and remove any clog.

Drain hose stopper is loose Tighten drain plug.

Batteries need to be charged Charge batteries (see Battery Charging)

Vacuum motor is loose Tighten vac motor mounting screws. Do not over tighten

or damage will occur.

25

Page 28

ENGLISH

PROBLEM CAUSE SOLUTION

BETRİEBSANLEİTUNG

Recovery tank lid is loose Confirm the clear recovery tank lid is securely in place.

Recovery tank inlet hole is clogged Drain recovery tank and tilt tank on side. Check the inlet

hole for debris and remove debris.

Recovery tank is full Drain recovery tank.

Float shut off is clogged Remove float shut off from inside recovery tank and

remove any debris.

STORAGE

CAUTION!

If you are storing the machine in an area which can freeze, be sure both tanks and the solution plumbing are

empty of all water and dry!

Store the appliance in a dry place, protected from frost.

The machine storage temperature must be between 0°C and +40°C.

Always store the machine indoors.

Always take off the pad driver / brush

Always store the machine with the squeegee assembly raised off the floor.

If storing in an area which may reach freezing temperatures, be sure to drain all fluids from the machine prior to storage.

Any dam-age caused by freezing temperatures will not be covered by the warranty.

Drain the recovery tank and remove the clear on the top of the recovery tank so that it can “breathe” during storage.

Drain the solution tank of all fluid.

RECYCLING THE CLEANER

Make the old cleaner unusable immediately:

Remove batteries

Do not discard of electrical appliances with household waste.

As specified in European Directive 2002/96/EC on old electrical and electronic appliances, used electrical goods

must be collected separately and recycled ecologically. Contact your local authorities or your nearest dealer for

further information.

26

Page 29

BETRİEBSANLEİTUNG

DEUTSCH

INHALTSVERZEİCHNİS

EINLEITUNG ............................................................................................................................................................................. 28

ZWECK UND INHALT DES HANDBUCHS……………………………………………………………………………28

ZIEL………………………………………………………………………………………………………………………28

WIE DIESES HANDBUCH AUFBEWAHRT WIRD……………………………………………………………………28

KONFORMITÄTSERKLÄRUNG……………………………………………………………………………………28

KENNZEICHNUNGSDATEN……………………………………………………………………………………………28

ANDERE REFERENZ-HANDBÜCHER…………………………………………………………………………………28

ERSATZTEILE UND WARTUNG……………………………………………………………… ………………28

ÄNDERUNGEN UND VERBESSERUNGEN……………………………………………………………………………29

VORGESEHENER VERWENDUNGSZWECK…………………………………………………………………………29

KONVENTIONEN………………………………………………………………………………………………………29

ENTPACKEN/LIEFERUNG ..................................................................................................................................................... 29

SICHERHEIT ............................................................................................................................................................................. 29

SYMBOLE ZUR KENNZEICHNUNG VON ANWEISUNGEN………………………………………………………30

ALLGEMEINE ANLEITUNG……………………………………………………………………………………………30

MASCHINENBESCHREIBUNG .............................................................................................................................................. 34

MASCHINENAUFBAU…………………………………………………………………………………………………34

ZUBEHÖR/OPTIONEN…………………………………………………………………………………………………35

SCHALTPLAN (FANG32T-EU)…………………………………………………………………………………………37

BETRIEB ..................................................................................................................................................................................... 38

VOR DEM STARTEN DER MASCHINE………………………………………………………………………………38

WÄHEND DES MASCHINENBETRIEBS………………………………………………………………………………42

WARTUNG ................................................................................................................................................................................. 44

TÄGLICHE INSTANDHALTUNG………………………………………………………………………………………44

WÖCHENTLICHE INSTANDHALTUNG………………………………………………………………………………45

MONATLICHE INSTANDHALTUNG…………………………………………………………………………………45

REINIGUNG DES MOTORFILTERS DES VAKUUMSYSTEMS………………………………………………………45

LÖSUNGS-/FRISCHWASSER-FILTERREINIGUNG…………………………………………………………………45

ÜBERPRÜFUNG UND AUSTAUSCH DES GUMMIABZIEHERWISCHERS………………………………………45

BÜRSTEN-/PAD-REINIGUNG…………………………………………………………………………………………46

PROBLEMBEHEBUNG ............................................................................................................................................................ 46

LAGERUNG ................................................................................................................................................................................ 47

RECYCLING DER REINIGUNGSMASCHINE ..................................................................................................................... 48

27

Page 30

DEUTSCH

BETRİEBSANLEİTUNG

EINLEITUNG

HINWEIS

Die Zahlen in Klammern beziehen sich auf die Komponenten im Kapitel Maschinenbeschreibung.

ZWECK UND INHALT DES HANDBUCHS

Dieses Handbuch möchte dem Bediener alle nötigen Informationen zum ordnungsgemäßen, sicheren und autonomen Gebrauch

der Maschine bieten. Es enthält Informationen zu technischen Daten, Sicherheit, Betrieb, Lagerung, Wartung, Ersatzteilen und

Entsorgung. Bevor die Maschine eingesetzt wird, müssen Bediener und qualifizierte Techniker dieses Handbuch sorgfältig

durchlesen. Wenden Sie sich in Zweifelsfragen bezüglich der Interpretation der Anleitung oder weiterführenden Informationen

an Viper.

ZIEL

Dieses Handbuch ist für Bediener vorgesehen sowie für Techniker , die Wartungsarbeiten an der Maschine durchführen

dürfen.

Bediener dürfen Verfahren, die qualifizierten Technikern vorbehalten sind, nicht ausführen. Viper übernimmt für Schäden

aufgrund der Nichtbeachtung dieses Verbots keine Verantwortung.

WIE DIESES HANDBUCH AUFBEWAHRT WIRD

Diese Betriebsanleitung muss in einem angemessen Behälter, geschützt vor Flüssigkeiten und anderen Substanzen, die sie

beschädigen könnten, in der Nähe der Maschine aufbewahrt werden.

KONFORMITÄTSERKLÄRUNG

Die dieser Maschine beigelegte Konformitätserklärung bestätigt die Konformität der Maschine mit den geltenden Gesetzen.

HINWEIS

Zwei Kopien der Original-Konformitätserklärung sind den Maschinenunterlagen beigefügt.

Die CE-Erklärung ist in der Kurzanleitung enthalten.

KENNZEICHNUNGSDATEN

Modell- und Seriennummer der Maschine befinden sich auf dem Typenschild.

Diese Informationen sind für die Ersatzteilbestellung nützlich. Verwenden Sie die folgende Tabelle, um die

Kennzeichnungsdaten der Maschine festzuhalten.

MASCHINEN-Modell ...............................................................................

MASCHINEN-Seriennummer ...................................................................

ANDERE REFERENZ-HANDBÜCHER

-

Wartungshandbuch (kann vom Viper-Kundencenter bezogen werden)

-

Ersatzteilliste (siehe www.vipercleaning.eu)

ERSATZTEILE UND WARTUNG

lle notwendigen Betriebs-, Wartungs- und Reparaturverfahren müssen von qualifiziertem Personal oder dem

A

Viper-Kundencenter durchgeführt werden. Nur Original-Ersatzteile und -Zubehör dürfen verwendet werden. Wenden Sie sich

für die Wartung oder Ersatzteil- sowie Zubehörbestellung an Viper und geben Sie die Modell- und Seriennummer der

Maschine an.

8

2

Page 31

USER MANUAL

DEUTSCH

ÄNDERUNGEN UND VERBESSERUNGEN

Viper verbessert seine Produkte kontinuierlich und behält sich das Recht vor, nach eigenem Ermessen Änderungen und

Verbesserungen vorzunehmen, ohne dazu verpflichtet zu sein, diese Vorteile an früher verkaufte Maschinen anzubringen.

Jede Änderung und/oder Beifügung von Zubehör muss von Viper zugelassen und durchgeführt werden.

VORGESEHENER VERWENDUNGSZWECK

Alle automatischen Reinigungsmaschinen sind ausschließlich für die Feuchtreinigung wasserresistenter Bodenbeläge in

Gebäude-Innenbereichen bestimmt. Automatische Reinigungsmaschinen können für verlegte Teppiche und zur

Teppichreinigung nicht verwendet werden.

Dieses Gerät ist für den kommerziellen Gebrauch geeignet, zum Beispiel in Hotels, Schulen, Krankenhäusern, Fabriken,

Geschäften, Büros und Vermietungsunternehmen.

Eine andere Verwendung wird als unsachgemäße Verwendung angesehen. Der Hersteller übernimmt für jeglichen Schaden aus

solch einer Verwendung keinerlei Haftung. Die Risiken aus einer solchen Verwendung liegen ausschließlich beim Benutzer.

Die ordnungsgemäße Verwendung schließt ebenfalls die sachgemäße Bedienung, Wartung, Reparatur ein, wie sie vom

Hersteller spezifiziert wird.

Vom Benutzer selbst durchgeführte Änderungen an der automatischen Maschine schließen die Haftung des Herstellers für

daraus resultierende Schäden aus.

Bödenbelege müssen vor Gebrauch der Maschine auf Angemessenheit für diese Reinigungsmethode überprüft werden.

Beachten sie die Flächenpressung im Fall von punktelastischen Böden wie z. B. in Sporthallen!

Der Hersteller übernimmt keine Verantwortung für Schäden an der Maschine oder an zu reinigenden Bodenbelägen, die aus der

falschen Verwendung von Bürsten und Reinigungsmitteln entstehen.

KONVENTIONEN

Vorwärts, rückwärts, vor, hinter, links, rechts und nach oben beziehen sich auf die Position des Bedieners, d. h. die

Arbeitsposition.

ENTPACKEN/LIEFERUNG

Folgen Sie zum Entpacken der Maschine genau der Anleitung auf der Verpackung.

Überprüfen Sie bei Lieferung der Maschine, ob Verpackung sowie Maschine während des Transports nicht beschädigt wurden.

Bewahren Sie die Verpackung im Falle sichtbarer Schäden auf, damit sie vom Lieferanten überprüft werden kann.

den Lieferanten sofort an, um Schadensansprüche anzumelden.

Überprüfen Sie den Packungsinhalt, um sicherzustellen, dass folgende Teile vorhanden sind:

-

Maschine

-

Gummischieber-Baugruppe

-

Bürstenantrieb (und Padtriebteller)

Rufen Sie

SICHERHEIT

Folgende Symbole weisen auf potenziell gefährliche Situationen hin. Diese Informationen immer sorgfältig durchlesen und alle

notwendigen Sicherheitsvorkehrungen zum Schutz von Personen und Eigentum treffen.

Die Kooperation des Bedieners ist für die Vermeidung von Verletzungen unerlässlich. Kein Unfallvermeidungsprogramm kann

ohne die vollkommene Kooperation der für den Maschinenbetrieb verantwortlichen Person wirken.

Die meisten Unfälle in Fabriken, die während des Arbeitens und Umhergehens entstehen, werden durch das Nicht-Beachten der

29

Page 32

DEUTSCH

einfachsten Regeln bezüglich der Rücksichtnahme verursacht.

Ein vorsichtiger und rücksichtsvoller Bediener stellt die beste Garantie gegen Unfälle dar und ist für ein erfolgreiches

Präventionsprogramm unerlässlich.

BETRİEBSANLEİTUNG

SYMBOLE ZUR KENNZEICHNUNG VON ANWEISUNGEN

GEFAHR!

Eine Gefahr, die unmittelbar zu ernsten und irreversiblen Verletzungen oder sogar zum Tod führen kann.

WARNUNG!

Eine Gefahr, die zu ernsten Verletzungen oder sogar zum Tod führen kann.

VORSICHT!

Eine Gefahr, die zu minderschweren Verletzungen und Schäden führen kann.

HINWEIS

Hinweis auf eine Anmerkung im Zusammenhang mit wichtigen und nützlichen Funktionen.

ALLGEMEINE ANLEITUNG

Spezifische Warnungen und Vorsichtsmaßnahmen, die über potenzielle Gefährdungen von Personen und der Maschine

informieren, werden untenstehend angeführt.

Die Maschine darf

-

nur von Personen verwendet werden, die über den korrekte Verwendung instruiert und ausdrücklich mit dem Betrieb

beauftragt wurden

-

nur unter Aufsicht betrieben werden

-

nicht von Kindern verwendet werden.

Der Arbeitsplatz befindet sich hinter der Reinigungsmaschine.

Unsichere Arbeitstechniken dürfen nicht angewandt werden.

Führen Sie die Reinigungsmaschine immer mit beiden Händen am Griff.

Steht die Reinigungsmaschine, die Bürsteneinheit sofort ausschalten, um Schäden am Bodenbelag zu vermeiden.

In folgenden Situationen wird die Maschine ausgeschaltet und der Batteriestecker gezogen:

-

vor der Reinigung und Wartung

-

vor dem Austausch von Komponenten

-

bevor an der Maschine Veränderungen vorgenommen werden

Die Verwendung der Reinigungsmaschine unterliegt den aktuellen nationalen Bestimmungen. Neben den Betriebshinweisen

und verbindlichen, im Einsatzland geltenden Bestimmungen zur Unfallverhütung müssen die anerkannten Regeln in Sachen

Sicherheit und fachgerechtem Arbeiten beachtet werden.

TRANSPORT

Wird die Reinigungsmaschine in Aufzügen transportiert, müssen aktuelle Sicherheitsbestimmungen, insbesondere im Hinblick

auf die Lastenkapazität, beachtet werden.

30

Page 33

USER MANUAL

DEUTSCH

BETRIEB

Um den unbefugten Gebrauch der Maschine zu verhindern, muss die Stromversorgung ausgeschaltet oder gesperrt werden,

indem beispielsweise der Schlüssel des Netzschalters abgezogen wird.

Treffen Sie alle notwendigen Vorsichtsmaßnahmen, damit sich Haare, Schmuck oder lose Kleidung nicht in den beweglichen

Maschinenteilen verfangen.

Schließen Sie vor dem Gebrauch der Maschine alle Türen und/oder Abdeckungen.

Die Betriebstemperatur der Maschine muss zwischen 0 °C und +40 °C liegen.

Die Luftfeuchtigkeit muss zwischen 30 % und 95 % liegen.

Die Maschine darf nicht als Transportmittel verwendet werden.

Verwenden Sie im Brandfall einen Pulver- und keinen Wasser-Feuerlöscher.

Manipulieren Sie nicht die Schutzvorkehrungen der Maschine und beachten Sie gewissenhaft die einfache Wartungsanleitung.

Kein Gegenstand darf durch die Öffnungen dringen. Bei verstopften Öffnungen darf die Maschine nicht verwendet werden.

Halten Sie die Öffnungen immer frei von Staub, Haaren und anderen, den Luftstrom reduzierenden Fremdkörpern.

Die auf der Maschine angebrachten Schilder dürfen nicht entfernt oder modifiziert werden.

Wenn die Maschine in Übereinstimmung mit der Anleitung verwendet wird, geht von den Vibrationen keine Gefahr aus. Das

Vibrationsniveau der Maschine liegt unter 2,5 ms² (98/37/EEC-EN 1033/1995).

Die Hand-/Armvibrationsniveaus liegen deutlich unter 2,5 m/s² (gemessen nach ISO 5349), dem Grenzwert für einen

kontinuierlichen Arbeitszeitraum von 8 Stunden.

Die Maschine darf auf Verkehrswegen und öffentlichen Straßen nicht verwendet werden.

Viper-Maschinen können zusammen mit Standard-Reinigungsmitteln, die keine Viper-Maschinenteile beschädigen (keine

Lösungsmittel oder andere aggressive Flüssigkeiten), verwendet werden. Viper wird für keine Schadenfälle im Hinblick auf

die Verwendung aggressiver Reinigungsmittel in Viper-Maschinen aufkommen. Wenn Sie ein spezielles Reinigungsmittel

benötigen, wenden Sie sich bitte an Ihren Viper-Händler.

Passen Sie beim Transport der Maschine auf, wenn die Temperatur unter dem Gefrierpunkt liegt. Das Wasser im Tank oder in

den Schläuchen könnte gefrieren und die Maschine ernsthaft beschädigen.

WARTUNG

Um den ordnungsgemäßen und sicheren Betrieb der Maschine zu gewährleisten, muss die regelmäßige Wartung, wie im

jeweiligen Kapitel dieses Handbuchs gezeigt, von autorisiertem Personal oder vom Viper-Kundencenter durchgeführt werden.

Vor der Durchführung von Wartungs- oder Reparaturarbeiten müssen alle Anweisungen sorgfältig durchgelesen werden.

Arbeiten Sie nicht unter der aufgebockten Maschine ohne die Anbringung von Sicherheitsständern.

Die Maschine darf nicht direkt bzw. unter Verwendung von Hochdruck-Wasserdüsen oder mit korrosiven Substanzen gereinigt

werden.

GARANTIE

Bezüglich der Garantie gelten die allgemeinen Geschäftsbedingungen.

Nicht genehmigte Modifizierungen der Maschine, die Verwendung falscher Bürsten und Reinigungsmittel sowie die

Verwendung der Maschine für einen anderen als den vorgesehenen Verwendungszweck entbindet den Hersteller von jeglicher

Haftung für daraus resultierende Schäden.

31

Page 34

DEUTSCH

BETRİEBSANLEİTUNG

PRÜFUNGEN UND ZULASSUNGEN

Elektrische Prüfungen müssen in Übereinstimmung mit den Bestimmungen der Sicherheitsvorschriften (BGV A3) und der

DIN VDE 0701 Teil 1 und Teil 3 durchgeführt werden. In Übereinstimmung mit der DIN VDE 0702 müssen diese Prüfungen

in regelmäßigen Abständen und nach Reparaturen oder Modifikationen durchgeführt werden.

ELEKTRISCHE KOMPONENTEN

GEFAHR

Batterien.

Explosionsgefahr.

Das Aufladen von Batterien erzeugt hochexplosiven Wasserstoff. Belassen Sie die Tankbaugruppe

während des Aufladens der Batterien offen und führen Sie diesen Vorgang in gut belüfteten Bereichen

und fern von offenen Flammen durch.

Lassen Sie die an die Stromversorgung angeschlossene Maschine zur Verringerung der Brand-,

Stromschlag- und Verletzungsgefahr nicht unbeaufsichtigt.

Trennen Sie vor jeglichen Wartungsarbeiten das Batterieladekabel von der Stromversorgung.

Nicht rauchen, während die Batterien aufgeladen werden.

Die Verwendung von nicht originalen Ersatzteilen, Zubehörteilen, Batterien und Ladegeräten kann die

Sicherheit der Maschine beeinträchtigen. Verwenden Sie nur Ersatzteile und Zubehörteile von Viper

sowie Batterien, die VIPER empfohlen hat.

Wenn Sie nicht genehmigte und nicht empfohlene Batterien und Ladegeräte verwenden, kommt VIPER

nicht für dadurch entstehende Kosten von Schäden (Gewährleistung) auf.

VORSICHT

Batterieladegerät.

Stromschlag durch defekte Netzanschlussleitung oder defektes Ladekabel.

Das Berühren einer defekten Netzanschlussleitung oder eines defekten Ladekabels kann zu ernsten und sogar

tödlichen Verletzungen führen.

Halten Sie die Batterie fern von Funken, Flammen und glühenden Materialien. Während des normalen

Betriebs werden explosive Gase freigesetzt.

Stellen Sie vor der Verwendung des Batterieladegeräts sicher, dass die auf dem Seriennummernschild der

Maschine abgebrachten Frequenz- und Spannungswerte der elektrischen Netzspannung entsprechen.

Beschädigen Sie nicht die Netzstromleitung (z. B. durch Überfahren, Zerren oder Quetschen).

Überprüfen Sie in regelmäßigen Abständen, ob die Stromleitung beschädigt ist oder Anzeichen von

Verschleiß aufweist.

Lassen Sie die defekte Netzanschlussleitung von Ihrem Viper-Kundendienstrepräsentanten oder einem

qualifizierten Elektriker vor der nächsten Verwendung der Maschine austauschen.

Die Maschine darf nicht am Batterieladekabel gezogen oder getragen werden und das Batterieladekabel

darf keinesfalls als Griff genutzt werden.

Schließen Sie eine Tür nicht über dem Batterieladekabel und ziehen Sie das Batterieladekabel nicht um

scharfe Kanten oder Ecken.

Halten Sie das Batterieladekabel fern von heißen Oberflächen.

Die Batterien dürfen bei beschädigtem Batterieladekabel oder Stecker nicht aufgeladen werden.

Funktioniert die Maschine nicht ordungsgemäß, wurde sie beschädigt, im Freien stehen gelassen oder in

Wasser fallen gelassen, muss sie zum Kundendienstcenter überstellt werden.

TREPPEN UND STEIGUNGEN

VORSICHT

Kipp- und Rutschgefahr auf Treppen und Steigungen.

Wenn Treppen und Steigungen behandelt werden, besteht die Gefahr von Personen- und Sachschäden.

Behandeln Sie keine Treppen.

Verwenden Sie die Maschine nur auf ebenen Flächen mit einer maximalen Steigung von 2 %.

BODENBELÄGE

VORSICHT

Schäden an empfindlichen Bodenbelägen.

Besonders empfindliche Bodenbeläge können durch die Reinigung beschädigt werden.

Bevor Sie die Reinigungsmaschine verwenden, überprüfen Sie bitte, ob sich die Bodenbeläge für dieses

Reinigungstechnik eignen.

Beachten Sie die Flächenpressung auf punktelastischen Böden, z. b. in Sporthallen!

Verwenden Sie nur von Viper zugelassene Reinigungsmittel.

GESUNDHEITSSCHÄDLICHE STOFFE

32

Page 35

WARNUNG

Gesundheitsschädliche Stoffe in Bodenbelägen.

Bodenbeläge können gesundheitsschädlige Stoffe enthalten, die während der Reinigung herausgelöst werden.

Reinigen Sie keine Bodenbeläge, aus denen sich gesundheitsschädliche Stäube oder Flüssigkeiten herauslösen

können.

EXPLOSIONSGEFAHR

WARNUNG

Brennbare und explosive Stoffe.

Explosionsgefahr in explosionsfähiger Atmosphäre oder Bereichen, in denen brennbare und explosive Stoffe

gelagert werden.

Betreiben Sie die Maschine nicht in der Nähe von gefährlichen, brennbaren und/oder explosiven Pulvern,

Flüssigkeiten und Dämpfen.

ERSATZTEILE UND ZUBEHÖR

VORSICHT

Nicht originale Komponenten und ungeeignete Reinigungsmittel.

Die Verwendung von nicht originalen Teilen und ungeeigneten Reinigungsmitteln kann die Sicherheit der

Maschine beeinträchtigen und zu Schäden führen.

Verwenden Sie Ersatzteile und Zubehör von Viper.

Verwenden Sie nur Zubehör und Reinigungsmittel, die mit der Maschine geliefert wurden und solche,

die in der Betriebsanleitung ausgewiesen sind.

USER MANUAL

DEUTSCH

33

Page 36

DEUTSCH

BETRİEBSANLEİTUNG

MASCHINENBESCHREIBUNG

MASCHINENAUFBAU

1.Vakuumnetzschalter (AN/AUS)

2.Bürstennetzschalter (AN/AUS)

3.Batterieanzeige

4.Betriebsstundenzähler

5.Lösungsnetzschalter (AN/AUS)

6.Bürstendruckanzeige

7.Bürstendruckschalter (AUF/AB)

8.Lösungsregelknopf

9.Geschwindigkeitsregelknopf

10.Schmutzwassertank-Ablaufschlauch

11.Leistungsschalter

12.Gummiabzieherbaugruppe

13.Gummiabzieher-Einstellmutter- und -Welle

14.Gummiabzieher-Hubhebel

15.Hintere Rollen

16.Konsolen-Einstellhebel

17.Lösungstank-Füllstandsichtrohr

18.Hintere Lösungs-Befülleinheit

19.Hauptschalter

20.Rückwärts-Schalter

21.Vordere Abdeckung

22.Schrubberkopf

23.Schutzrollen

24.Schrubberkopfklappe

25.Transporträder

26.Lösungsräder

27.Betriebsauslöser

28.Steuergehäuse

29.Schmutzwassertankdeckel

30.Lösungsfilterbaugruppe

31.Schmutzwassertank

32.Gummiabzieher-Vakuumschlauch

34

Page 37

USER MANUAL

DEUTSCH

ZUBEHÖR/OPTIONEN

Neben den Standardkomponenten kann die Maschine mit folgenden maschinenspezifischen Zubehörteilen/Optionen

ausgestattet werden:

● Bürste

● Padtriebteller

Wenden Sie sich für weiter Informationen über optionales Zubehör an einen autorisierten Händler.

TECHNISCHE DATEN

Modell FANG 32T-EU

Bürsten-/Pad-Halter, mit Antriebssystem)

Maschinenhöhe

Lösungs-/Wassertankkapazität

Schmutzwassertankkapazität

Hinterraddurchmesser

Vakuumsystem-Motorleistung

Antriebssystem-Motorleistung

Antriebsgeschwindigkeit (variabel)

Steigfähigkeit

Schalldruckpegel am Arbeitsplatz

Standardbatterien

Vakuumsystem-Stromkreiskapazität

Reinigungsbreite

Gummiabzieherbreite

Maximallänge der Maschine

Maschinenbreite ohne Gummiabzieher

Bürstendurchmesser

Gewicht ohne Batterien und bei leeren Tanks

Gesamtgewicht

Bürstenmotorleistung

Bürstengeschwindigkeit

Batteriefachgröße (Länge x Breite x Höhe)

mm 1090

l 115

l 106

mm 297

W 650

W 370

km/h 0 – 4.5

% 2

dB(A) 70

Ah @ 20 h 6-6V/305AmP.hR

mm H2O 1,860

mm 800

mm 1020

mm 1690

mm 1050

mm 2*406

kg 200

kg 286

W 740

rpm 200

mm 580*500*370

35

Page 38

DEUTSCH

BETRİEBSANLEİTUNG

BATTERY CAPACITY LIGHTS

(16AWG GRN)

8

(16AWG WHT)

5

(14AWG RED)

13

(14AWG BLK)

01

(14AWG BLK)

16

(14AWG RED)

15

(16AWG BLU)

18

(16AWG BLU)

17

(16AWG WHT)

1

(12AWG RED)

12

(16AWG BLU)

0

(12AWG RED)

10

(12AWG RED)

10

12

(12AWG RED)

(14AWG RED)

14

(14AWG RED)

20

6V BATTERY

_

6V BATTERY

_

6V BATTERY

+

+

+

_

HOUR

METER

1

CIRCUIT BREAKER

VACUUM

SOLENOID

6V BATTERY

_

6V BATTERY

_

6V BATTERY

+

0

-

+

22

KEY

SWITCH

(16AWG WHT)

12A

BRUSH

SOLENOID

12

AMMETER

0

0

21

23

0

20

VACCUM MOTOR

CIRCUIT BREAKER

+

+

_

19

35A

(4AWG RED)

(4AWG BLK)

0

VACUUM

SWITCH

TRIGGER SWITCH

5

(16AWG WHT)

3

DRIVING MOTOR

SPEED

CONTROLLER

3

0

0

0

22

7

0

35A

LEFT BRUSH

CIRCUIT BREAKER

(16AWG BLU)

(16AWG BLU)

(16AWG WHT)

19

(14AWG RED)

+

0

21

5

BRUSH

SWITCH

5

B+ B- M2

12 11

RITHT BRUSH CIRCUIT BREAKER

(16AWG BLU)

(16AWG BLU)

(16AWG BLU)

11

(12AWG RED)

11

(4AWG RED)

_+_

(4AWG BLK)

0

0

7

6

6

19

M1

35A

11 (12AWG RED)

5

B+

0

B -

9 (14AWG RED)

1 (16AWG WHT)

+

10 (12AWG RED)

10 (12AWG RED)

14 (14AWG RED)

0 (16AWG BLU)

_

01 (14AWG BLK)

02 (16AWG GRN)

03 (12AWG BLK)

03 (12AWG BLK)

04 (14AWG BLK)

0 (16AWG BLU)

PCB

00

8

6

SOLUTION

SWITCH

F

R

DIRECTION

SWITCH

4.7K

2W

5

5

0

ACTUATOR

8 (16AWG GRN) 2 (16AWG GRN)

17 (16AWG BLU)

12 (12AWG RED)

12 (12AWG RED)

20 (14AWG RED)

15 (14AWG RED)

5 (16AWG WHT)

0 (16AWG BLU)

13 (14AWG RED)

17

UP

18

DOWN

SOLUTION SOLENOID

18 (16AWG BLU)

ACTUATOR MOTOR

03 (12AWG BLK)

LEFT BRUSH MOTOR

03 (12AWG BLK)

RIGHT BRUSH MOTOR

04 (14AWG BLK)

VACUUM MOTOR

16 (14AWG BLK)

DRIVE MOTOR

3

0

9

MAIN

SOLENOID

36

Page 39

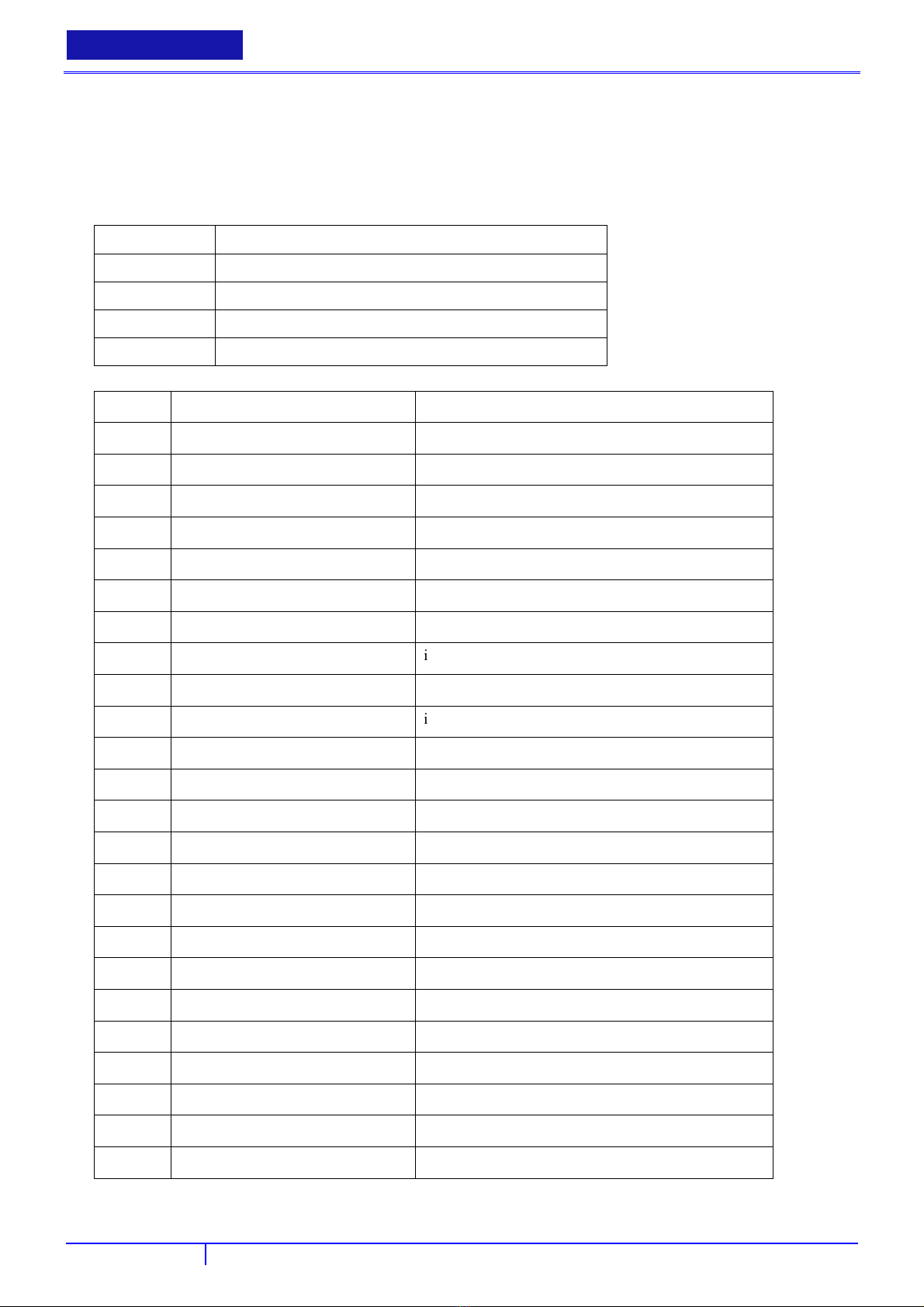

SCHALTPLAN (FANG32T-EU)

SCHALTPLAN (FANG32T-EU)

Farbcodes

BLK SCHWARZ

BLU BLAU

GRU GRÜN

RED ROT

WHT WEISS

1 BATTERY CAPACITY LIGHTS BATTERIEKAPAZITÄTSLEUCHTEN

2 HOUR METER BETRIEBSSTUNDENZÄHLER

3 VACUUM SWITCH VAKUUMSCHALTER

4 BRUSH SWITCH BÜRSTENSCHALTER

USER MANUAL

DEUTSCH

5 SOLUTION SWITCH LÖSUNGSSCHALTER

6 AMMETER AMPEREMETER

7 ACTUATOR STELLGLIED

8 TRIGGER SWITCH AUSLÖSERSCHALTER

9 DRIVING MOTOR SPEED CONTROLLER

10 DIRECTION SWITCH RICHTUNGSSCHALTER

11 RIGHT BRUSH CIRCUIT BREAKER RECHTE BÜRSTE LEISTUNGSSCHALTER

12 KEY SWITCH HAUPTSCHALTER

13 CIRCUIT BREAKER LEISTUNGSSCHALTER

14 BRUSH SOLENOID BÜRSTENMAGNETVENTIL

15 PCB PCB

16 SOLUTION SOLENOID LÖSUNGSMAGNETVENTIL

17 ACTUATOR MOTOR STELLGLIEDMOTOR

18 LEFT BRUSH MOTOR LINKER BÜRSTENMOTOR

19 VACUUM MOTOR VAKUUMMOTOR

ANTRIEBSMOTOR-GESCHWINDIGKEITSREGLER

20 DRIVE MOTOR ANTRIEBSMOTOR

21 VACUUM SOLENOID VAKUUMMAGNETVENTIL

22 VACUUM CIRCUIT BREAKER VAKUUMLEISTUNGSSCHALTER

23 MAIN SOLENIOD HAUPTMAGNETVENTIL

24 RIGHT BRUSH MOTOR RECHTER BÜRSTENMOTOR

25 BATTERY BATTERIE

37

Page 40

DEUTSCH

BETRİEBSANLEİTUNG

BETRIEB

VOR DEM STARTEN DER MASCHINE

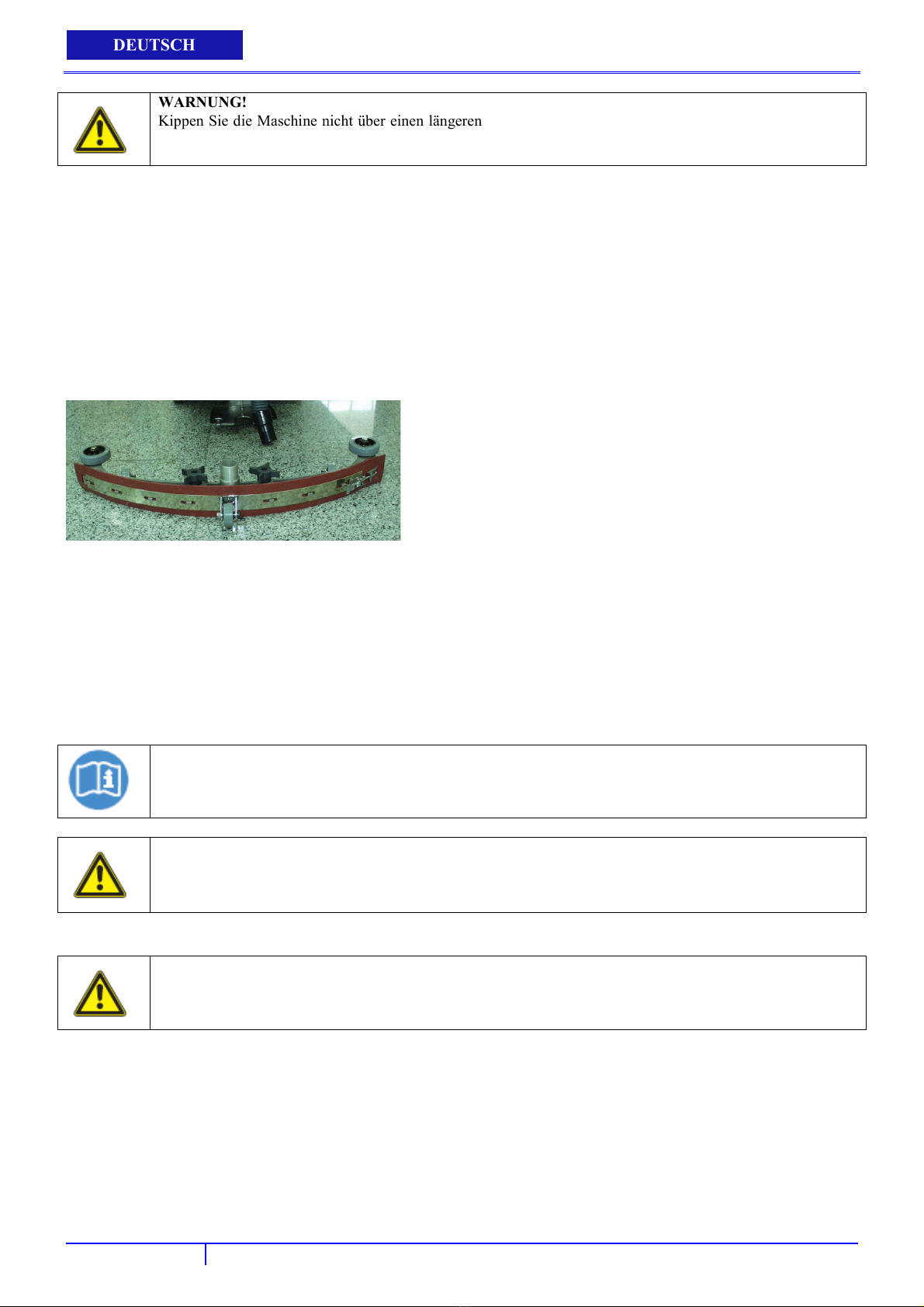

WARNUNG!

An manchen Stellen der Maschine sind einige Aufkleber angebracht, die Folgendes anzeigen:

GEFAHR

WARNUNG

VORSICHT

RÜCKSPRACHE

Während des Lesens dieses Handbuchs muss der Bediener den Symbolen auf diesen Aufklebern sorgfältige Beachtung schenken.

Diese Aufkleber dürfen keinesfalls bedeckt werden und müssen bei Beschädigung umgehend ausgetauscht werden.

EINSETZEN DER BATTERIE

WARNUNG!

Die elektrischen Komponenten der Maschine können ernsthaft beschädigt werden, wenn die Batterien

entweder nicht richtig eingesetzt oder nicht richtig angeschlossen werden.

Die Batterien dürfen nur von qualifizierten Personen eingesetzt werden.

Stellen Sie die Funktionsplatine und das Batterieladegerät (optional) auf den verwendeten Batterietyp ein

(NASS oder GEL).

Überprüfen Sie die Batterien vor dem Einsetzen auf Beschädigungen.

Trennen Sie den Batteriestecker und den Stecker des Batterieladegerätes ab.