Viper Fang 24T, Fang 26T, Fang 28T Owner's Manual

CONGRATULATIONS on your purchase of a

Viper product, and welcome to the V.I.P. family.

We appreciate your business and will do everything in our power to keep you happy with your

purchase for many years to come.

As part of the V.I.P. family, you are entitled to the

best protection by one of the most comprehensive

warranties in the industry.

Thank-you for purchasing Viper products!

Tom VanderBie, CEO

TABLE OF CONTENTS

SAFETY PRECAUTIONS 3

MACHINE COMPONENTS 4

MACHINE SET UP

5

MACHINE INSTALLATION 5-6

MACHINE OPERATION 6

TANK DRAINING 7

BATTERY CHARGING 7-8

PREVENTATIVE MAINTENANCE 8-9

MACHINE STORAGE 9

BASIC TROUBLESHOOTING 10

PARTS BREAKDOWNS AND LISTS 11-27

WIRING DIAGRAM 28

2

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

constructed for use in an indoor environment and

is not intended for any other use. Use only with

recommended accessories.

All operators shall read, understand and exercise

the following safety precautions:

1) DO NOT OPERATE MACHINE:

x Unless trained and authorized.

x Unless you have read and understand

the operators manual.

x In flammable or explosive areas.

x If not in proper operating condition.

x In outdoor areas.

2) BEFORE OPERATING MACHINE:

x Make sure all safety devices are in

place and operate properly.

3) WHEN USING MACHINE:

x Go slow on inclines and slippery

surfaces.

x Follow all safety guidelines.

x Be very careful when using the

machine in reverse.

x Report and fix any damage to machine

prior to operating it.

4) BEFORE LEAVING OR SERVICING

MACHINE:

x Stop machine on level ground.

x Turn machine off.

5) WHEN SERVICING MACHINE:

x Read operators manual thoroughly

prior to operating or servicing this

machine.

x Use manufacturer supplied or

approved replacement parts.

x Secure machine with wheel blocks

prior to jacking the machine up.

x Use approved jack or hoist to safely

elevate the machine.

WHEN SERVICING MACHINE: (con’t)

x Disconnect batteries prior to working

on machine.

x Wear gloves when handling batteries

or battery cables.

x

Avoid any contact with battery acid.

x A

void moving parts. Do not wear

loose fitting clothing while servicing

machine.

: Batteries emit hydrogen gas.

Explosion or fire can result from hydrogen gas.

Keep sparks and open flames away! Keep battery

compartment open when charging.

: Flammable materials can cause an

explosion or fire. Do not use flammable materials

in tanks.

: Flammable materials or reactive

metals can cause explosion or fire. Do not pick up.

3

MACHINE COMPONENTS

1. Main power ON/OFF switch

2. Vacuum ON/OFF switch

3. Battery level meter

4. Brush ON/OFF switch

5. Brush pressure meter

6. Solution ON/OFF switch

7. Brush pressure UP/DOWN switch

8. Solution control knob

9. Speed control knob

10. Circuit breakers

11. Recovery tank drain hose

12. Squeegee adjustment nut & shaft

13. Squeegee assembly

14. Scrub head actuator

15. Solution tank level sight tube

16. Console adjustment levers

17. Rear solution fill

18. Reverse switch

19. Squeegee lift lever

20.

Co

ntrol housing

21. Operating triggers

22. Solution tank

23. Rear casters

24. Transport wheels

25. Scrub head

26. Scrub head skirt

27. Skirt housing latch

28. Protective rollers

29. Front solution fill

30. Recovery tank

31. Recovery tank lid

7

10

11

13

19

12

9

8

6 5 4 3 2 1

18

17

16

15

14

20 21

22

26

27

31

23

24

25

28

29

30

4

MACHINE SET UP & INSTALLATION

UNCRATING MACHINE

Be sure and check packing carton for any damage.

Immediately report any damage to carrier. Check

contents of package to ensure that the following

items are included: Machine, batteries (x2),

squeegee assembly, battery charger, and pad

driver.

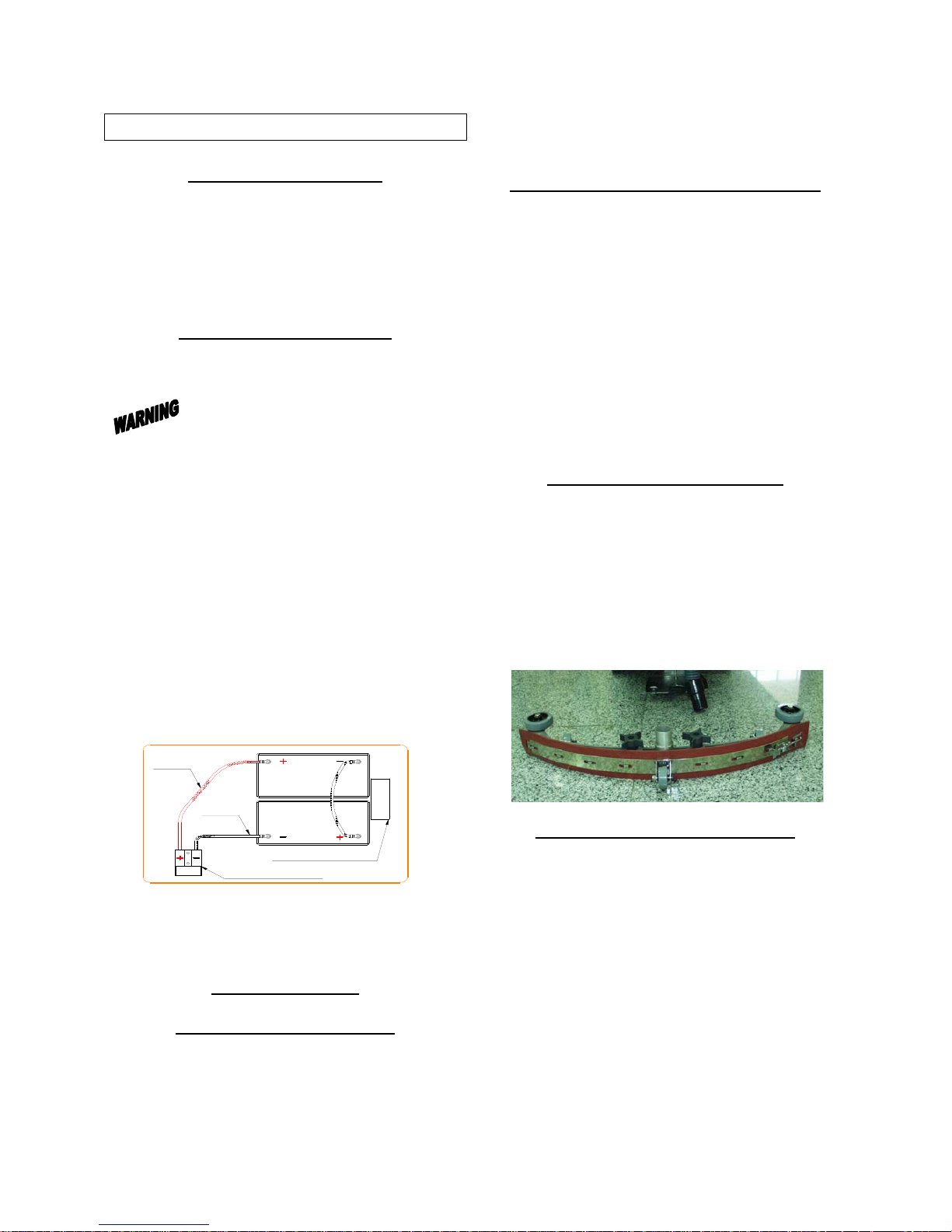

BATTERY CONNECTIONS

The batteries are and charger are shipped

separately and will need to be installed and

connected as shown in the diagram below.

: Batteries emit hydrogen gas.

Explosion or fire can result from hydrogen gas.

Keep sparks and open flames away! Keep battery

compartment open when charging.

1. Be sure power switch is in the “off” position.

2. Open recovery tank to gain access to battery

compartment.

3. Carefully place the two batteries into the

compartment as shown in figure below. Place

the battery brace at the rear of the two

batteries. DO NOT DROP BATTERIES

INTO COMPARTMENT!

4. Connect battery cables to posts in numbered

order as shown in drawing below. (RED to

POSITIVE and BLACK to NEGATIVE)

BATTERY BRACE

CHARGER PLUG

BLACK

RED

5. Apply a coat or protective spray on the cable

connections to prevent battery corrosion.

MACHINE SET UP

PRE-OPERATION CHECKS

1. Sweep or dust mop the surface to be cleaned.

2. Check battery meter to make sure batteries are

fully charged. (see BATTERY CHARGING)

3. Check that squeegee is properly installed.

4. Check that brush / pad is properly installed.

INSTALLING PAD DRIVER OR BRUSH

1. Ensure that the machine is turned off

2. Raise the brush head assembly off the floor by

pushing on the brush lift button on the control

console.

3. Open the swing away skirts to gain access to

the brush head assembly.

4. If using a pad driver, first attach the

appropriate pad to the pad driver surface.

5. Mount the pad driver or brush to the drive

motor hub by lining up the three studs with the

three holes in the drive motor hub. Once in

the holes, rotate the driver toward the spring

clip to lock driver into place.

MOUNTING THE SQUEEGEE

1. Pull back on the squeegee lift lever to raise the

squeegee bracket up.

2. Loosen the two knobs on the squeegee and

slide the squeegee into the slots at the rear of

the squeegee bracket. (the wheels on the

squeegee point to the back)

3. Tighten the knobs securely.

4. Secure the vacuum hose on the pick-up tube of

the squeegee.

FILLING THE SOLUTION TANK

1. The Fang 24T / 26T / 28T can be filled in two

different locations:

a. Front fill area for use with a hose or a

bucket.

b. Rear fill area for use with a hose only.

2. Determine which fill area you would like to

use to fill the machine with water.

3. Fill solution tank with up to 17 gallons of

water. (water temperature should not exceed

140° F) The clear tube in the back left of the

machine has gallon markers to help determine

the water level in the solution tank

5

: If you are filling the solution tank with a

bucket, make sure the bucket is clean. This will

prevent debris from clogging the lines or solenoid.

: Do not put any flammable materials

into solution tank. This can cause an explosion or

a fire. Only use recommended cleaning chemicals.

Contact your janitorial supply distributor for

recommendations on proper chemicals.

MACHINE OPERATION

: Do not operate machine unless you

have read and understand this manual.

1. Set control housing to a comfortable operating

height by squeezing together the two thumb

levers directly underneath the housing. (see

machine components, item #16)

2. Lower squeegee assembly to the floor by

releasing the lift lever from its locked position.

(see machine components, item #19)

3. Lower the brush head assembly to the floor by

pushing on the brush lift button on the control

console. (see machine components, item #7)

4. Turn main power to “on” position. (see

machine components, item #1)

5. Turn vacuum motor switch to “on” position.

(see machine components, item #2)

6. Turn the brush motor switch to “on” position.

(see machine components, item #4)

a. Brushes will not spin until the

operating triggers are pulled.

7. Turn the solution switch to “on” position. (see

machine components, item #6)

a. Solution will not begin to flow until

the operating triggers are pulled.

8. To begin scrubbing, pull on one or both of the

red operating triggers. (see machine

components, item #21) When these triggers

are pulled, the brush will begin to spin, the

solution will begin to flow, and the machine

will propel itself.

9. This machine is self-propelled. The speed can

be controlled by a dial located on the right

side of the control housing. (see machine

components, item #9)

10. This machine has reverse. In order to activate

reverse, there is a toggle switch located on the

left side of the control housing. (see machine

components, item #18) The toggle switch

must be pulled backwards and the red

operating triggers must be pressed to activate

reverse motion.

: Do not keep the machine in the same

position with the pad / brush spinning, or you

could cause damage to the floor.

11. Adjust amount of solution flow by turning the

solution control knob. Turn to the right for

more solution, or turn left for less solution.

(see machine components, item #8)

WHILE OPERATING MACHINE

1. Occasionally look through the clear recovery

tank lid to see if there is any foam build-up. If

excessive foam is found, add defoamer to the

recovery tank.

: Foam must not enter the float shut-off

screen, or damage can occur to the vacuum motor.

Foam will not activate the machines float shut-off

device.

2. Occasionally view the clear tube at the back

left of the machine to check the amount of

cleaning solution that is left in the machine.

3. Occasionally check the battery level meter.

(see machine components, item #3) When

meter is in the red, recharge the batteries.

: When battery meter is in the red, do

not continue to operate the machine. Battery

damage may result.

4. If the squeegee assembly leaves streaks on the

floor, raise the squeegee off the floor and wipe

the blades down with a damp cloth.

: Do not use your fingers to wipe or

remove debris from the blades, as injury may

occur.

5. When the solution tank runs empty, turn off

the brush switch, solution switch and raise the

brush head. Keep the squeegee down and

continue to vacuum until all the dirty water is

picked up. (see TANK DRAINING section to

learn how to drain recovery and solution tanks)

6

: The brush motors are circuit breaker

protected to protect them from damage. If a

breaker trips, it can’t be reset immediately. You

must first determine what caused the breaker to

trip, and allow the motor to cool down before you

can reset the breaker. The breakers are located on

the back panel of the control housing.

TANK DRAINING

1. Turn the power off on the machine

2. With the squeegee and brush head in their

“up” position, transport machine to approved

area for draining tank(s).

DRAINING THE RECOVERY (DIRTY) TANK

: Anytime scrubbing is completed, or when

refilling solution tank, the recovery tank should be

drained and cleaned.

: If the recovery tank is not drained

when the solution tank has been refilled, foam or

water may enter the float shut-off mechanism and

cause damage to the vacuum motor.

1. Remove the drain hose from the holder, and

place the drain hose over the floor drain.

Twist off the drain hose plug to begin the

draining process. In order to completely empty

the recovery tank, hinge open the recovery

tank and let it rest on the support stand.

2. Clean the recovery tank after every use. Use a

fresh water hose to rinse out the recovery tank.

Be careful not to spray water into the float

shut-off mechanism.

: If you are storing the machine for any

period of time, always leave the clear recovery

tank lid off the tank so the tank can dry

completely and smell fresh.

3. Replace the drain hose plug tightly as soon as

you are done draining the tank.

DRAINING THE SOLUTION (CLEAN) TANK

: Anytime scrubbing operation is completed,

the solution tank should be drained and cleaned.

1. Pull down on the clear tube (back left of the

machine) to remove it from the hose barb.

This will allow the solution to flow freely into

a bucket or floor drain.

2. Rinse the solution tank with clean water after

every use. This will help prevent chemical

buildup and clogging of the solution lines.

3. With clean water in solution tank, turn

machine power on, solution switch “on” and

pull the operating triggers. This will allow the

clean water to flush through and clean the

solution plumbing.

4. Once tank is rinsed, flushed and drained,

reconnect the clear tube to the hose barb. Be

sure the tube is pushed all the way up on the

hose barb.

BATTERY CHARGING

: Use only approved chargers with the

following specifications:

x Automatic shut off circuit

x Deep cycle charging

x Output current of 10 – 20 amps

x Output voltage of 24 volts

: For the best machine performance, keep

batteries charged at all times. Do not let them sit

in a discharged condition.

: Batteries are dangerous! Batteries emit

hydrogen gas and an explosion or fire can result.

Keep sparks and fire away from batteries at all

times. When charging the machine, make sure the

battery compartment is left open.

1. Place charger and machine in a well ventilated

area.

2. Turn machine off.

3. Open recovery tank up, exposing battery

compartment

4. Check fluid level in each battery cell. Do not

charge batteries unless fluid is slightly

covering the battery plates. Do not overfill the

batteries. Overfilling may cause the batteries

7

to overflow during charging due to expansion.

Replace the caps prior to charging.

5. Plug approved charger into grounded wall

outlet before plugging the charger into the

machine.

6. Plug charger into red charger receptacle

located in the front left of the battery

7. compartment.

8. Flip up the recovery tank “kick stand” and

gently lay the recovery tank down until it rests

on the stand.

9. The charger will automatically begin to

charger the batteries, and it will automatically

shut down once the batteries are fully charged.

10. Upon completion of charging, first unplug the

charger from the wall outlet, and then

disconnect the charger from the machine.

11. Check the battery level after charging is

complete. If fluid level is low, add distilled

water to bring the fluid level up to the bottom

of the sight tubes. Replace the caps and wipe

the batteries down with a towel.

PREVENTATIVE MAINTENANCE

: Before performing any maintenance on

the machine, be sure that the power is turned off,

or the batteries are disconnected!

: Repairs are to be completed by

Authorized Service Centers only. Any repairs

completed by unauthorized persons will void the

warranty.

DAILY MAINTENANCE

1. Remove pad driver / brush and clean with

approved cleaner.

2. Drain recovery and solution tanks completely

and rinse out with clean water. Visually check

the recovery tank for debris and clean out as

necessary.

3. Raise squeegee assembly off floor and wipe it

down with a damp towel. Be sure to store the

squeegee in the up position.

4. Remove the float shut-off assembly and rinse

it out with clean water.

5. Clean machine with an approved cleaner and a

damp towel.

6. Recharge batteries.

WEEKLY MAINTENANCE

1. Check fluid level in batteries.

2. Check batteries for loose or corroded cables.

3. Keep battery tops clean from corrosion.

MONTHLY MAINTENANCE

1. Check machine for leaks and loose fasteners.

2. Lubricate all grease points and pivot points

with silicon spray and approved grease.

3. Place machine over a floor drain. Flush

solution system by pouring 3 gallons of hot

water and approved alkaline detergent into the

solution tank and running machine (with

solution control on) for 45 seconds. Turn

machine off and let it sit overnight. Then next

day, drain the remaining solution and rinse the

solution tank out with clean water.

VACUUM MOTOR MAINTENANCE

8

1. Contact your local Viper Distributor for any

motor maintenance.

2. Vacuum motor should have the brushes

checked every 250 hours. Brushes should be

replaced when they are worn to a length of

10mm or less.

BATTERY MAINTENANCE

: For the best machine performance, keep

batteries charged at all times. Do not let them sit

in a discharged condition.

: Batteries are dangerous! Batteries emit

hydrogen gas and an explosion or fire can result.

Keep sparks and fire away from batteries at all

times.

: Whenever servicing batteries, be sure

to wear protective gloves. Avoid contact with

battery acid at all times!

1. Always follow the battery charging directions

as outlined in the BATTERY CHARGING

section of this manual.

2. Keep battery tops and terminals free from

corrosion. A strong solution of baking soda

and water is the best way to keep the batteries

corrosion free. DO NOT ALLOW THE

BAKING SODA / WATER SOLUTION TO

ENTER THE BATTERY CELLS.

3. Use a wire brush with the baking soda solution

to properly clean the battery posts and

connections.

4. Check battery connections for wear and loose

terminals. Replace if necessary.

MACHINE STORAGE

1. Always store the machine indoors.

2. Always store the machine in a dry area.

3. Always store the machine in its upright

position.

4. Always store the machine with the pad driver /

brush raised off the floor.

5. Always store the machine with the squeegee

assembly raised off the floor.

6. If storing in an area which may reach freezing

temperatures, be sure to drain all fluids from

the machine prior to storage. Any damage

caused by freezing temperatures will not be

covered by the warranty.

7. Drain the recovery tank and remove the clear

on the top of the recovery tank so that it can

“breathe” during storage.

8. Drain the solution tank of all fluid.

9

Loading...

Loading...