Page 1

Scrubber User Manual

AS430C

VF90031-US

Rev.01

VI PE R NORTH AM E R I C A

[866] 418-4737

[866] 41-VIPER

Page 2

................. .. 13-26.....................................................

.......................................................................................... .. 27

USER MANUAL

1

TABLE OF CONTENTS

INTRODUCTION ......................................................................... ......................................................................... 2

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPARE PARTS AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . 2

CHANGES AND IMPROVEMENTS . . . . . . . . . . . . . . . . . . . . 2

MACHINE APPLICATION . . . . . . . . . . . . . . . . . . . . . . .2

UNPACKING/TRANSPORT

.............................

2

SAFETY GUIDES

.................................

2

TECHNICAL DATA

.................................

3

MACHINE DESCRIPTION ...............................................................................................................................

4

MACHINE EXPLODED VIEW

.............................

4

CONTROL PANEL

.................................

5

GUIDE FOR USE ................................................................................................................................................

5

BEFORE MACHINE START-UP

..........................

5

BRUSH / PAD-HOLDER INSTALLING AND REMOVAL

.................

5

SQUEEGEE ADJUSTMENT

............................

5

REGULATING WATER FLOW

...........................

6

MACHINE START AND STOP

...........................

6

MACHINE OPERATION

.............................

7

TANK EMPTYING

................................

7

AFTER EACH USE

...............................

8

USING FOR THE FIRST TIME

...........................

8

MAINTENANCE AND CARE ...........................................................................................................................

8

SCHEDULED MAINTENANCE TABLE

.......................

9

SQUEEGEE CLEANING

.............................

9

SQUEEGEE BLADE CHECK AND REPLACEMENT

.................

9

BRUSH/ PAD CLEANING

.............................

10

WATER TANK AND FLOAT FILTER MESH CLEANING

................

10

SOLUTION FILTER CLEANING

.........................

11

TROUBLESHOOTING . .............................................................................................................................. .. 12

PART BREAKDOWNS AND LISTS .......................

WIRING DIAGRAM ..................................

Page 3

USER MANUAL

2

INTRODUCTION

NOTE

Numbers shown in parenthesis correspond with the numbers in the machine exploded

view.

CONTENTS

This manual is intended to provide the operator with the necessary information to use this machine

properly and safely. The information includes technical data, safety, operation, storage, maintenance

and disposal of the machine. All operators and technicians should study this manual carefully before

prior to operating or servicing the machine. Please contact your local Viper distributor with any

questions.

PURPOSE

The intention of this manual is to educate the operator and service provider on the proper use

and maintenance of this machine.

SPARE PARTS AND MAINTENANCE

All necessary operation, maintenance, and repair procedures must be performed by an authorized

Viper service provider.

Only authorized spare parts and accessories should be used.

If service, parts or accessories are needed, please contact your local Viper distributor.

CHANGES AND IMPROVEMENTS

VIPER makes continuous improvements on its products. VIPER reserves the right to change and

improve the machines. All changes / improvements should be performed by and authorized Viper

service provider.

MACHINE APPLICATION

This scrubber is used in commercial and industrial environments and is suitable for the cleaning of

smooth hard floor surfaces. It must be used by qualified operators and in a safe environment. This

machine is not to be used outdoors, on carpets, and on coarse floors.

UNPACKING/TRANSPORT

Please follow carefully the instructions on the package when unpacking.

Upon delivery, please inspect the packing and the machine to ensure no damage has been done

during transport. If there is any visible damage, please contact the distributor you purchased the

machine from.

----

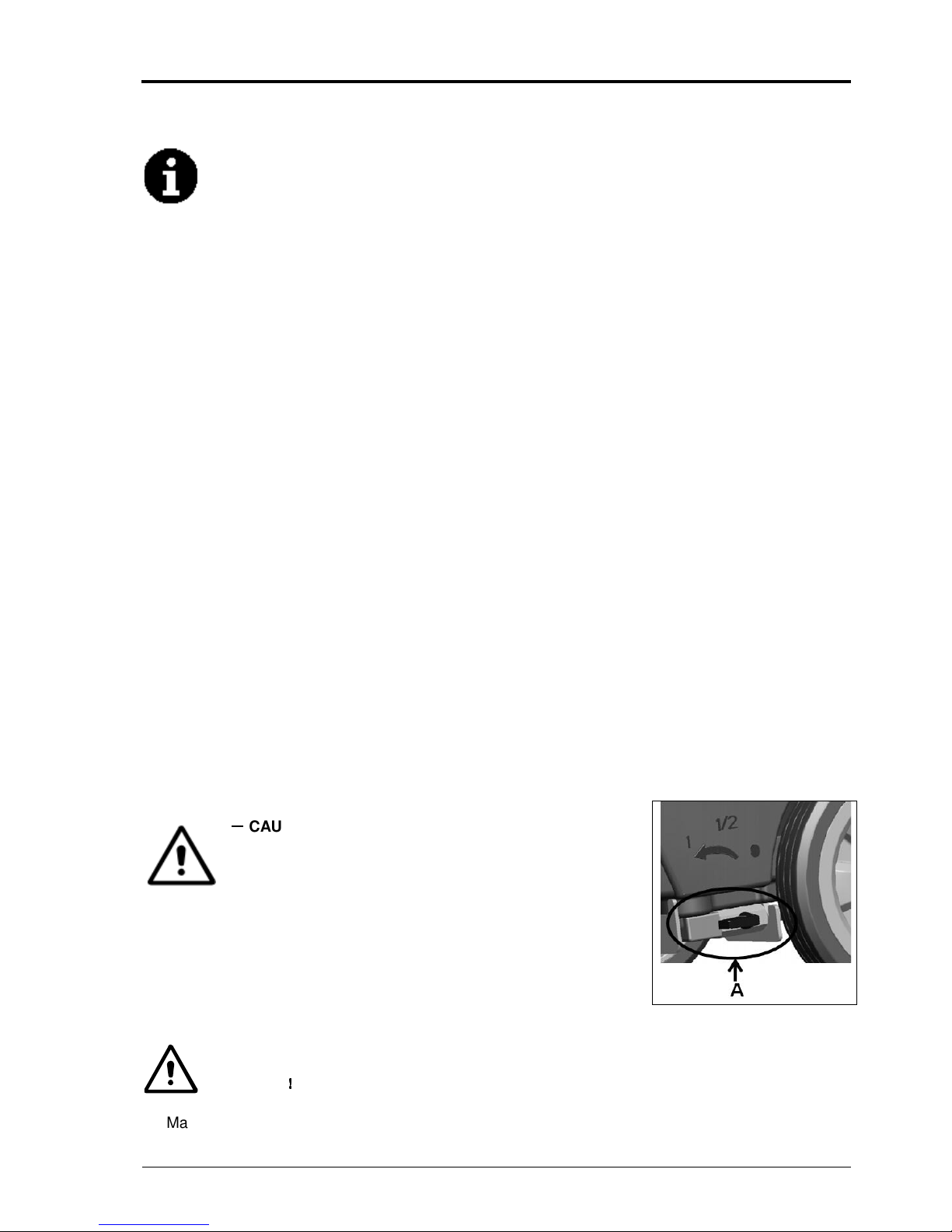

CAUTION

When unpacking and unloading, or during

transportation, please take care to avoid hitting the

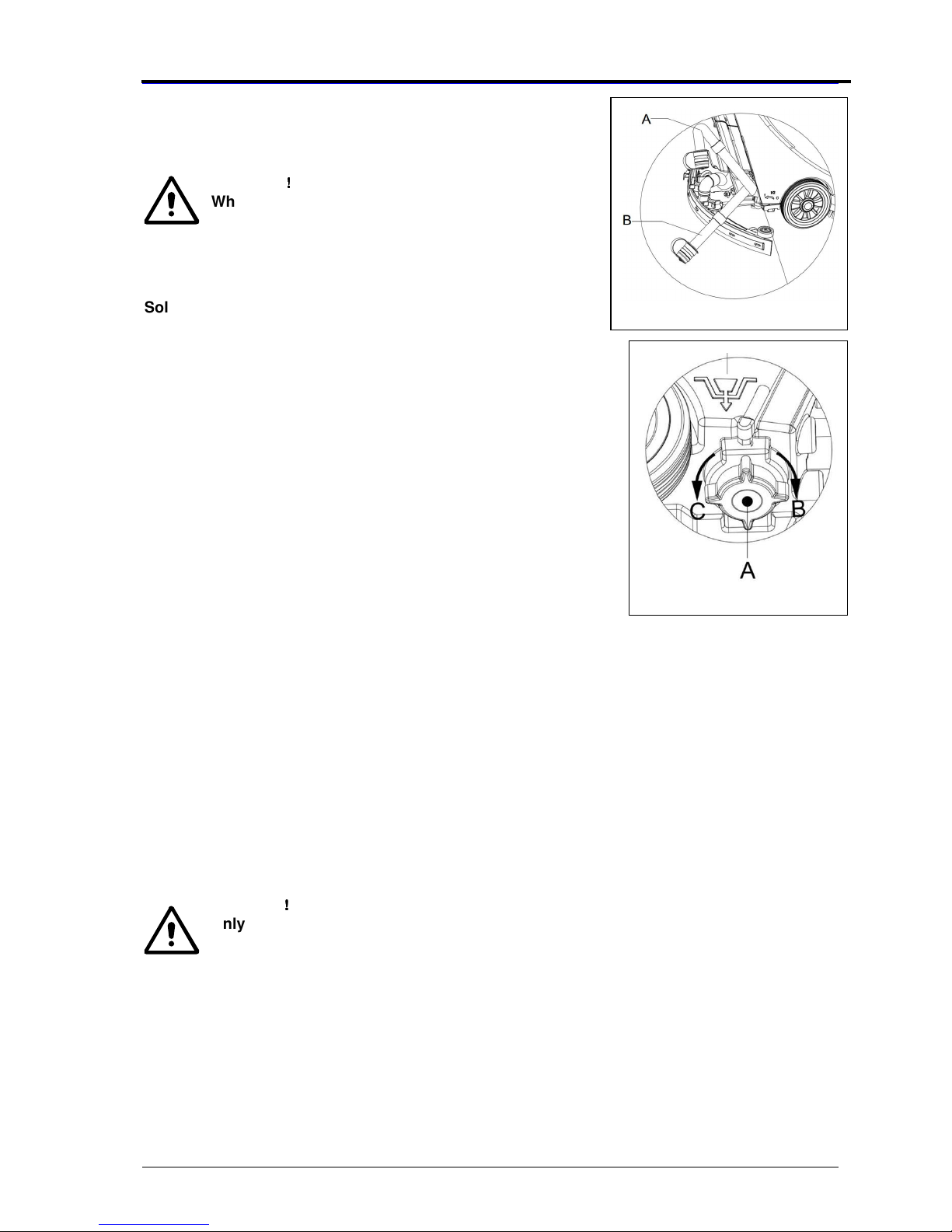

solution valve. Part A in the figure on the right.

Check if the machine is equipped with the following items:

Scrubber User Manual

SAFETY GUIDES

The following are special warnings and notices on potential damages (personnel and machine):

WARNING

!!!!

-

Machine may only be operated under the guidance of this manual. Only accessories approved by

VIPER should be used.

Page 4

USER MANUAL

3

-

This machine must be only used by trained & authorized personnel. Children or untrained persons

must not use this machine.

-

When working near electrical parts, please do not wear any jewelry. Please take all precautionary

measures to avoid hair, jewelry, and loose fitting clothing from being caught by any moving parts of

the machine.

-

Prior to scrubbing, it is best to pre-sweep the area to be cleaned. Do not wash the machine directly

with water. Do not let the machine come in touch with corrosive liquids.

-

The temperature for storage and for working environment of the machine must be between 0 - 400C.

-

The humidity of air must be between 30% - 105%.

-

Please do not use the machine on a slope with a gradient of more than 2%.

-

In case of fire, please use dry powder fire extinguishers. Do not use liquid fire extinguishers.

-

Particular attention should be paid when the machine is transported below 00 C. The water tank and

the water in the hoses may freeze and cause serious damages to the machine.

-

Use brush or pad driver supplied with the machine and those specified in the owners manual. Using

other brushes or pads could reduce safety.

-

In case of machine malfunction, please make sure that it is not caused by lack of maintenance. If it is

caused by other conditions, contact your local Viper authorized service center. If it is confirmed that

spare parts must be replaced, please secure the genuine parts from your local Viper distributor.

-

In order to ensure safe and proper operation of the machine, it is advised that your Viper authorized

service provider perform the scheduled maintenance according to the maintenance schedules

outlined in this manual.

-

This machine must be properly disposed of in accordance with local laws and regulations (please

refer to machine disposal section).

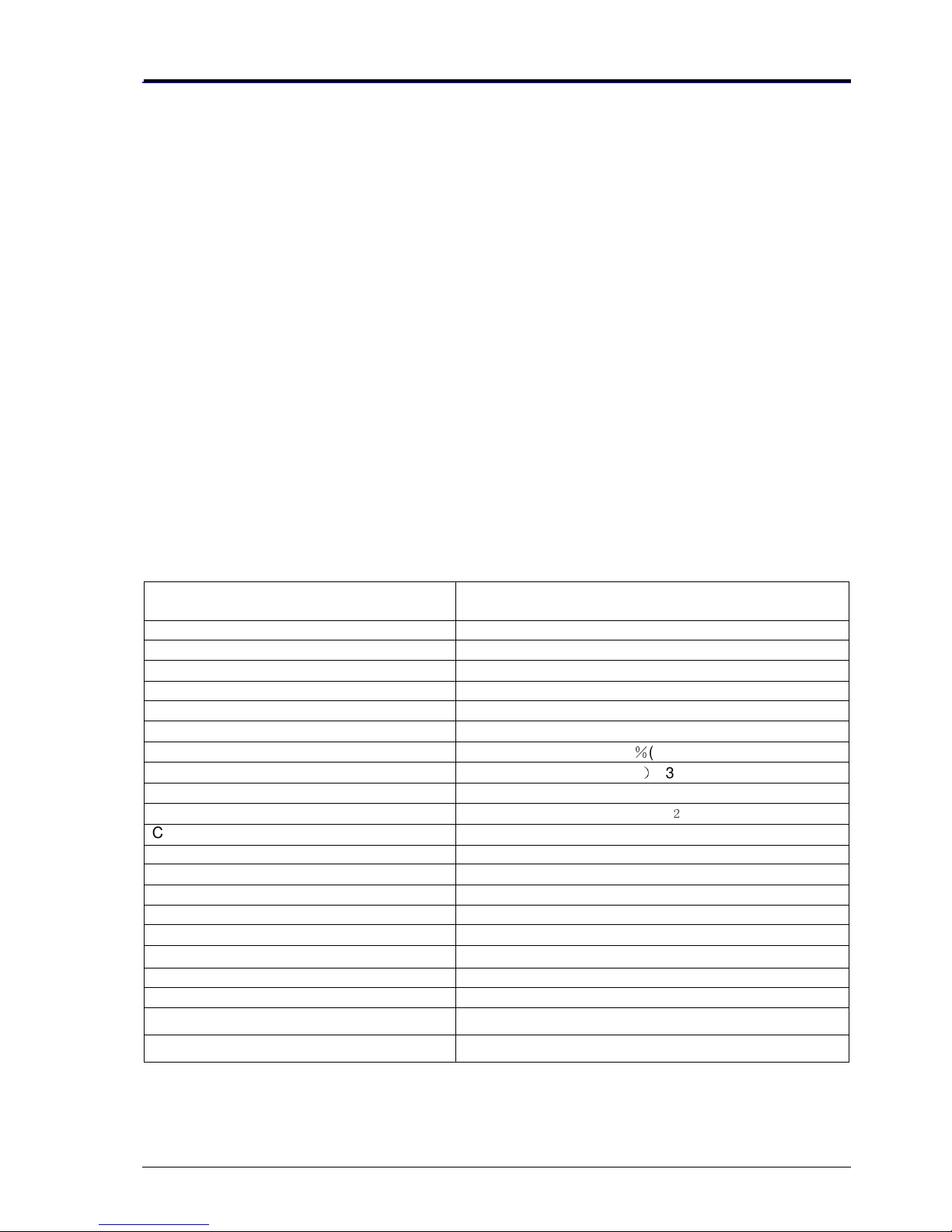

TECHNICAL DATA

Model AS430C

Machine Height 980mm

Solution tank capacity 50 litre

Recovery tank capacity 50 litre

Diameter of transport wheel 200mm

Diameter of guide wheel 63.5mm

Power of vacuum system motor 400w

Maximum gradient when working

2

%

(Max)

Sound pressure level at workstation

72dB(A

)

±3dB(A)

Cable length 20m

Vacuum system circuit capacity

1200 mm H

2

O

Cleaning width

430mm

Squeegee width

730mm

machine maximum length

1060mm

Machine width without squeegee

480mm

Brush diameter

430mm

Weight with empty tanks

70kg

Gross weight of the machine ready for use

120kg

Brush motor power

750W

Brush speed

150rpm

Brush /pad-holder Maximum pressure

32kg (Max)

Packing size (Lx W x H)

1200 x 610 x 1170mm

Page 5

USER MANUAL

4

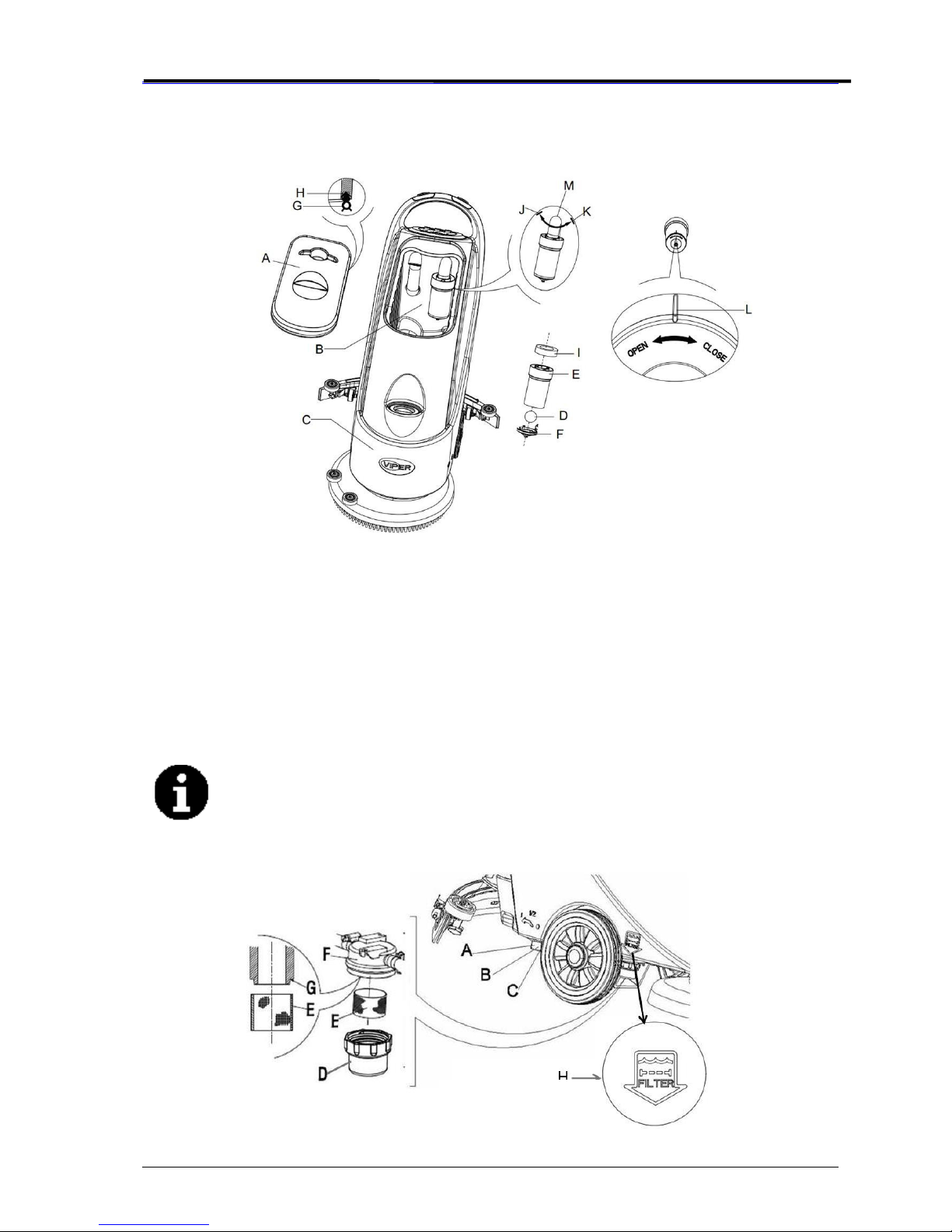

MACHINE DESCRIPTION

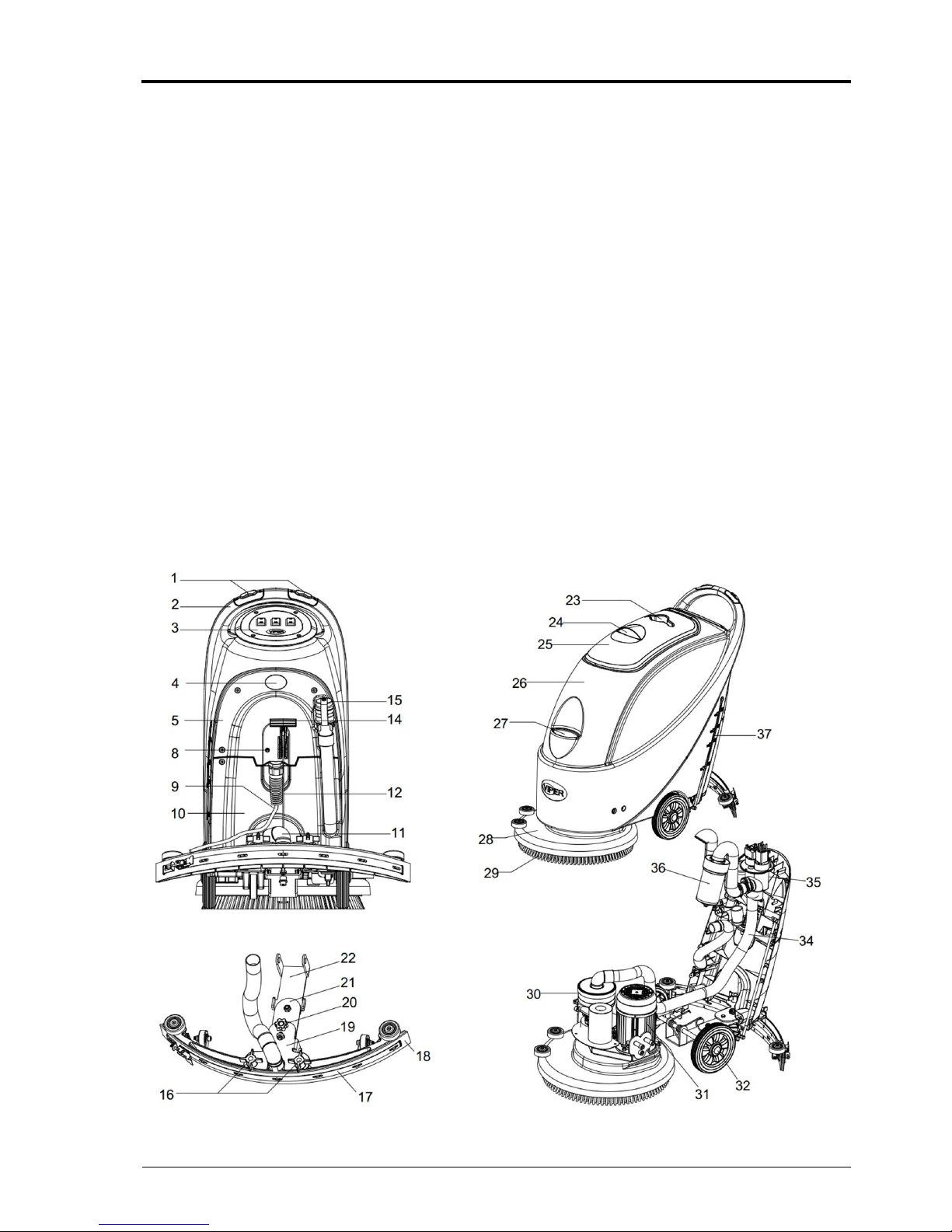

MACHINE EXPLODED VIEW

1. Safety switch button 20. Squeegee adjusting knob

2. Handle 21. Squeegee rear support frame

3. Control panel 22. Squeegee front support frame

4. Serial number plate/Technical data 23. Cup holder

5. Control cover 24. Recovery tank cover handle

6.

N/A 25. Recovery tank lid

7.

N/A 26. Recovery tank

8. Reset switch 27. Solution fill

9.

Power cable 28. Brush deck

10.

Battery cover 29. Brush / pad-holder

11. Drain hose 30. Vacuum motor

12. Squeegee lift cable 31. Brush motor

13. N/A 32. 8” wheel

14. Squeegee lift handle 33. N/A

15. Drain cap 34. Vacuum tube

16. Squeegee knob 35. Electric box

17. Squeegee clip 36. Float filter

18. Squeegee blade 37. Water level site tube

19. Squeegee bracket

Figure 1

Page 6

USER MANUAL

5

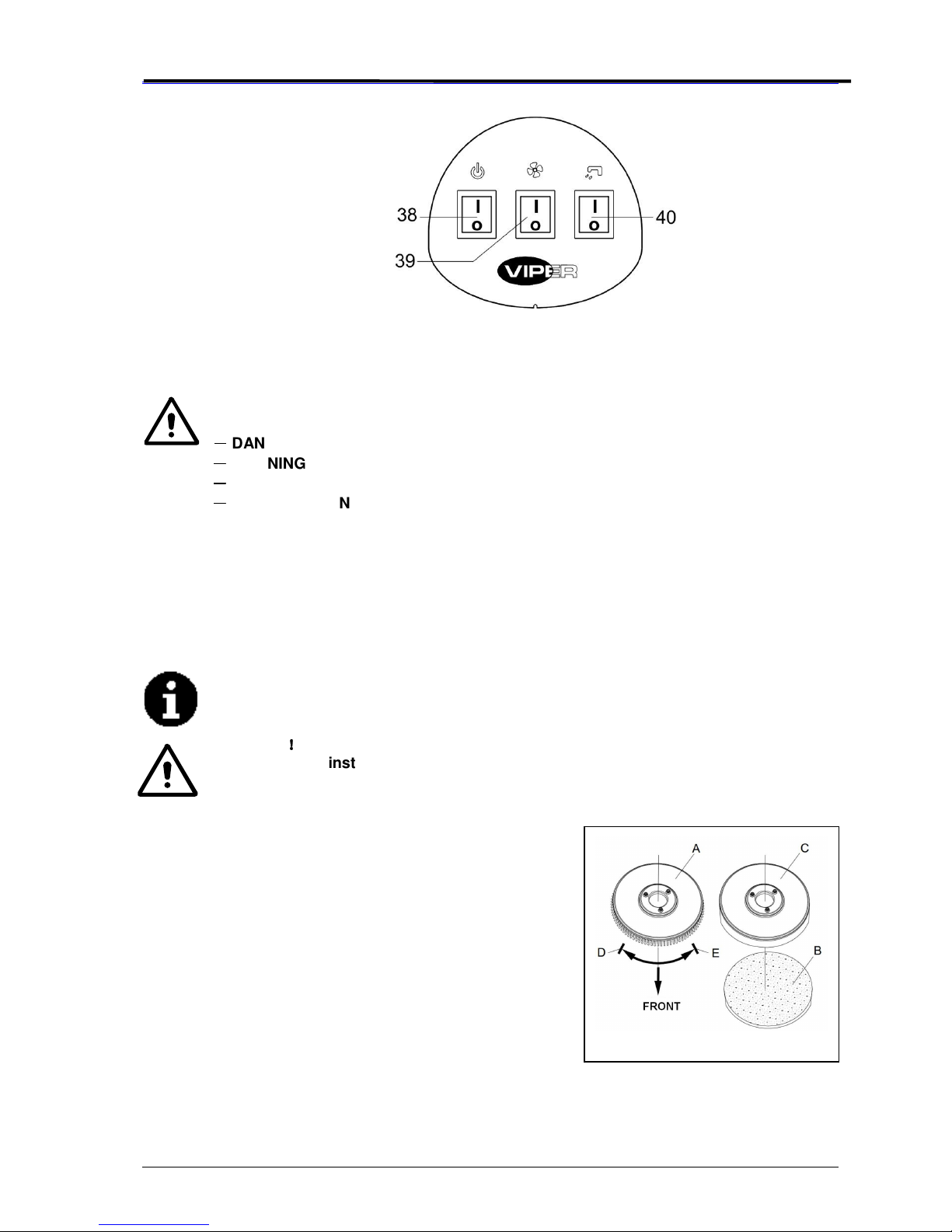

CONTROL PANEL (Figure2)

38. Power switch

39. Vacuum switch

40. Solution switch

Figure 2

GUIDE FOR USE

WARNING

On certain parts of the machine are pasted some indicative signs:

----

DANGER

----

WARNING

----

CAUTION

----

CONSULTATION

When reading this manual, the operator must pay particular attention to the symbols on these labels.

Under no circumstances shall these labels be covered. If they are damaged, please replace them

immediately.

BEFORE MACHINE START-UP

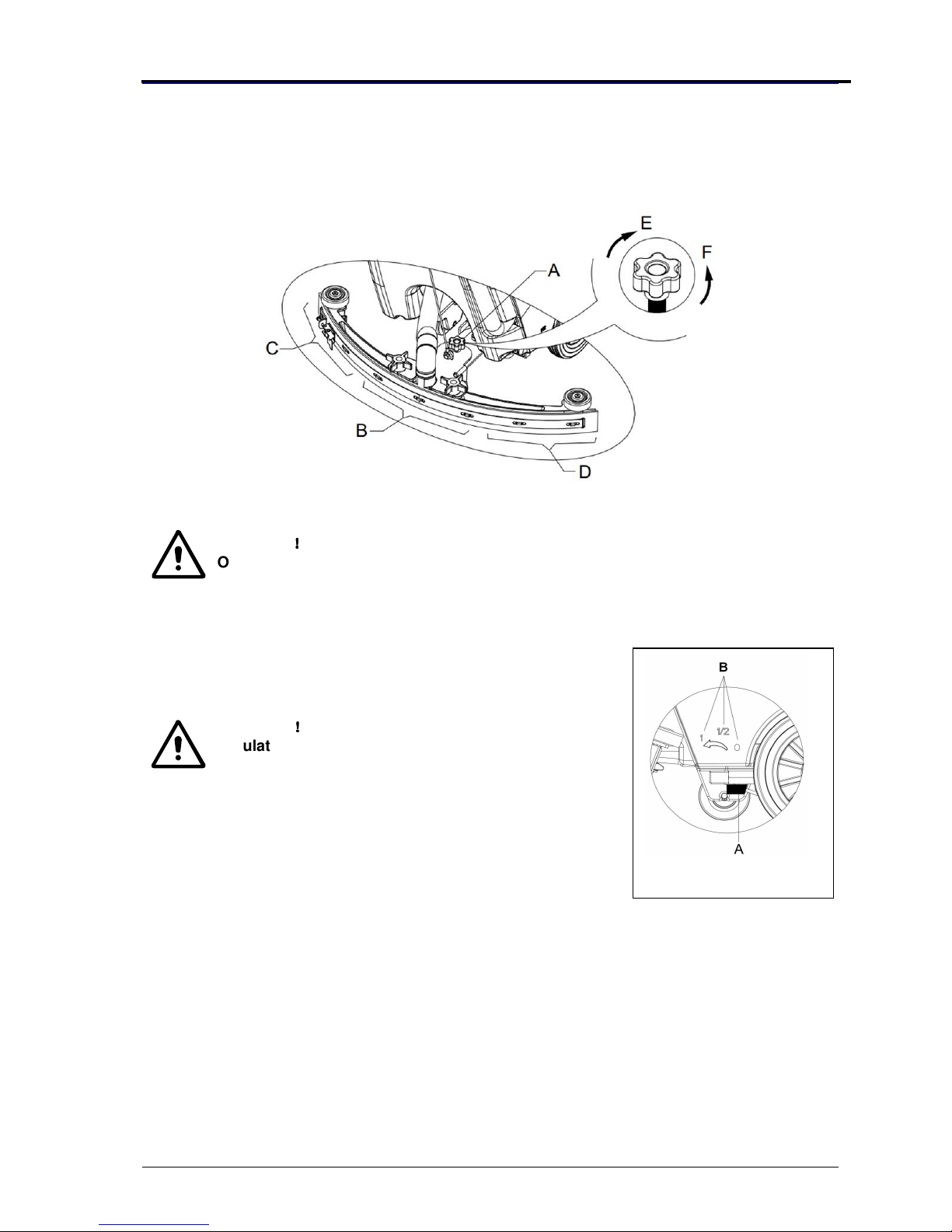

BRUSH / PAD-HOLDER INSTALLING AND REMOVAL

NOTE

According to the type of floor to be cleaned, the machine may be installed with brush

(Figure 3, A), or a pad-holder (Figure 3, B and C).

CAUTION

!!!!

When manually installing or removing the brush/pad-holder, first ensure that all the

switches are in the “off” position and lift the squeegee off the floor. Only after which

can the brush or pad-holder be worked on. Always wear protective gloves.

1. (Only applicable to AS430C ): make sure the power cable

(9) disconnecting the power supply and the switch (38) is

at the disconnecting (Off) condition.

2. Press down the handle (2) to lift the tank body (26).

1. Put the brush (A) or the pad-holder (B – C) under the case.

2. Use the handle (2) to lower the tank body (26) to come into

contact with the brush or pad-holder.

3. Manually attach by following the arrow head (D) to install

the brush/pad-holder (as shown in Figure 3).

6. Remove by turning the brush/pad-holder in the opposite

direction and it can be taken off. (Figure 3)

SQUEEGEE ADJUSTING

7. Install the squeegee and tighten the knobs. Then connect

the vacuum hose to the squeegee assembly.

.

8. Adjust the squeegee through the adjusting handle (A) of the squeegee (Figure 4).

1) If the mid-section of the rear squeegee bracket, section B, has a gap with the floor or the

downward pressure is relatively light, adjust the handle in an anti-clockwise direction until the

Figure 3

Page 7

USER MANUAL

6

whole length of the rear squeegee strip touches well with the floor. The front squeegee strip

should lightly touch the floor.

2) If the two ends of the rear squeegee strip, sections C and D, have a gap with the floor or the

downward pressure is relatively light, adjust the handle in a clockwise direction until the whole

length of the rear squeegee strip touches well with the floor. The front squeegee strip should

Lightly touch the floor.

Figure 4

Solution tank filling

CAUTION

!!!!

Only low foam, nonflammable detergents may be used. These detergents must be

suitable for the use of scrubbers.

9. Open the water inlet cover (27) and add water to solution tank. Do not overfill the tank. When

preparing the cleaning solutions, please follow the dilution rates supplied by the chemical

manufacturer Water temperature must not exceed 400 C.

REGULATING WATER FLOW

WARNING

!!!!

Regulating the ball valve handle (A, Figure 5) must be

done under the condition when the power switch (38)

is in the “Off” position.

10. The volume

of the water flow may be adjusted through the ball

valve handle (A, Figure 5) according to the amount of water

required for your scrubbing application.

MACHINE START AND STOP

Starting the machine

1. Complete the preparatory steps as outlined above.

2. Press the power switch (38) to the “I” position.

3. Use the squeegee handle (38) to lower the squeegee.

4. Press the Vacuum switch (39) to the “I” position.

5. Press the solution switch (40) to the “I” position. (Work simultaneously with the safety switch (1)

to control the solenoid valve.)

6. Squeeze the on / off switch (1) and push to move the machine. When switches are squeezed, the

brush (29) will to rotate, and the solution will flow.

Figure 5

Page 8

USER MANUAL

7

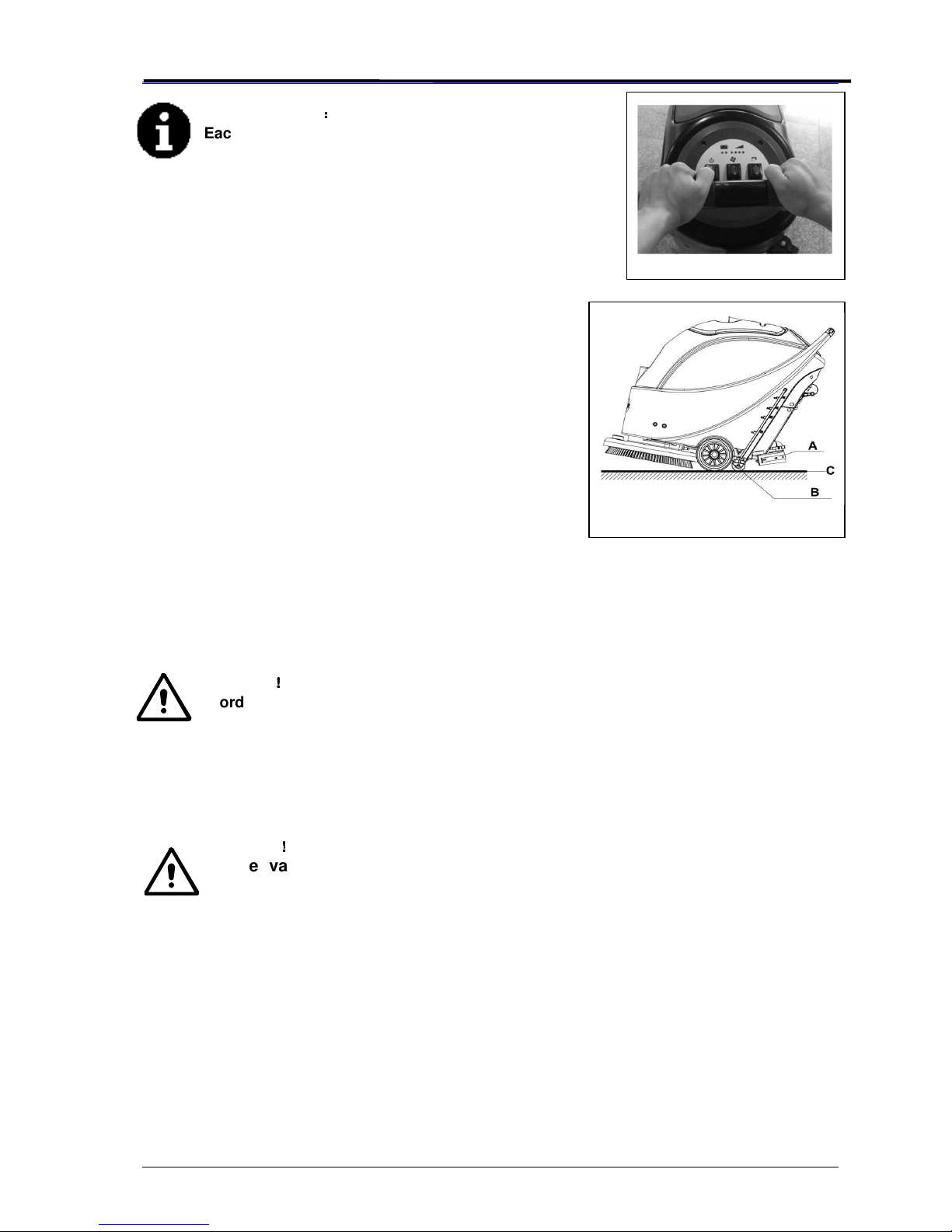

CONSULTATION

::::

Each safety switch is capable of controlling

independently the operation of the brush. In use, it

facilitates the control of the operation of the machine.

Operators are encouraged to find the most comfortable

position their hands.

Turning off the machine

7. When you have finished using the machine, first remove the

brush/pad-holder (refer to the steps mentioned above)

8. Release the safety switch (1) to turn off the brush/padholder and solenoid valve.

9. Press the Vacuum switch (39) to the “Off” position, and the

Vacuum will delay for 5 seconds before stopping work.

10. Press the solution control switch (40) to the “Off” position

to completely turn off the solution flow.

11. Press the power switch (38) to the “Off” position. And

disconnecting the power cable (9) from the power supply.

12. Use the squeegee lift handle (14) to lift the squeegee.

13. Grasp the handle (2) and gently tilt the machine backward

until the guide wheel (B) touches the floor. See Figure7.

MACHINE OPERATION

1. Start the machine according to the description above.

2. Hold the on / off switch (1) (Figure 6), push to move the machine, and start the scrubbing.

3. If necessary, turn off the machine, and adjust the squeegee. (Refer to the steps for squeegee

adjustment)

4. If necessary, turn off the machine, and adjust the solution flow with the ball valve handle. (Refer

to the steps for adjusting solution flow.

CAUTION

!!!!

In order to avoid damaging the floor, when the machine stays in one place without

moving, remove hands from switches & turn off the main power switch (38).

TANK EMPTYING

When recovery tank is full, a float shut-off device (36) will block the inlet connecting to the vacuum

motor. Through a sudden increase of noise from the vacuum motor, it can be considered that the

recovery tank is full and requires immediate draining.

CAUTION

!!!!

If the vacuum motor is suddenly turned off (due to sudden movement

resulting in an activation of the float), and if a resumption of operation is

needed, please perform the following steps: press the power switch (38 and

39) to turn off the power and the vacuum motor, and open the recovery tank

cover (25) to check if the float has returned to the water surface. Close the

recovery tank cover (25), and press the power switch (38 and 39) to turn on

the main power and the vacuum motor.

Recovery tank emptying

1. Turn off the machine.

2. Raise the squeegee assembly (14).

3. Move the machine to a dedicated draining location.

4. Grasp the handle (2) and tilt the machine backward until the guide wheel touches the floor.

5. Remove the drain hose from the clip, bend the top end of draining hose (A, Figure 8), and then

remove the drain hose cap. Lower the hose to a low level or on the ground to drain the water.

Alternatively, place drain hose to a low position or on the ground to make the water outlet face

Figure 7

Page 9

USER MANUAL

8

downward (B, Figure 8), and then twist open the drain cap to

drain the wastewater in the tank. After draining is completed,

rinse the inside of recovery tank with clean water

CAUTION

!!!!

When draining the wastewater, the drain hose must

be folded or lowered to a lower position (Figure 8 A

or B), and the cap removed for wastewater to drain.

Do not allow the opening of the drain hose to face

upward, as it could get wastewater on the operator..

Solution tank emptying

6. Complete Steps 1 to 4.

7. As shown in Figure 9, turn open the lid of Solution tank (A) counter

clockwise (direction C), to drain Solution tank completely. Use

clean water to rinse the inside of Solution tank. When work is

completed, replace the solution tank lid (A) by twisting in a

clockwise in direction (B).

AFTER EACH USE

When work is done and before leaving the machine, completes the

following steps:

1. Remove the brush / pad holder.

2. Drain solution tank & rinse with clean water.

3. Drain recovery tank & rinse with clean water.

4. Complete the daily maintenance procedures. (see maintenance

section)

5. Remove and rinse squeegee assembly with damp towel.

6. Keep recovery tank lid unsealed from tank to allow fresh air to

circulate freely

USING FOR THE FIRST TIME

After the first 9 hours of use, please check components to ensure all connections (electrical &

mechanical) are tight & check for any damage that may have occurred during operation. Check for

water leakage.

MAINTENANCE AND CARE

The service life and the maximum operation safety of the machine are assured by proper and timely

maintenance and care.

The following table is a routine maintenance guide for the machine. The time intervals of

maintenance are determined to a large extent by the working conditions of the machine. These time

intervals should be formulated by the person responsible for the maintenance.

WARNING

!!!!

Only after the main power is disconnected should these procedures be performed.

Prior to proceeding with any of the maintenance procedures, please study carefully

the related safety sections.

All maintenance should be done by qualified personnel or authorized Viper service centers.

This manual only relates the simplest and the most common maintenance procedures.

For any maintenance procedures other than those stated in this table of planned maintenance,

please contact your local Viper distributor.

Figure 9

Figure 8

Page 10

USER MANUAL

9

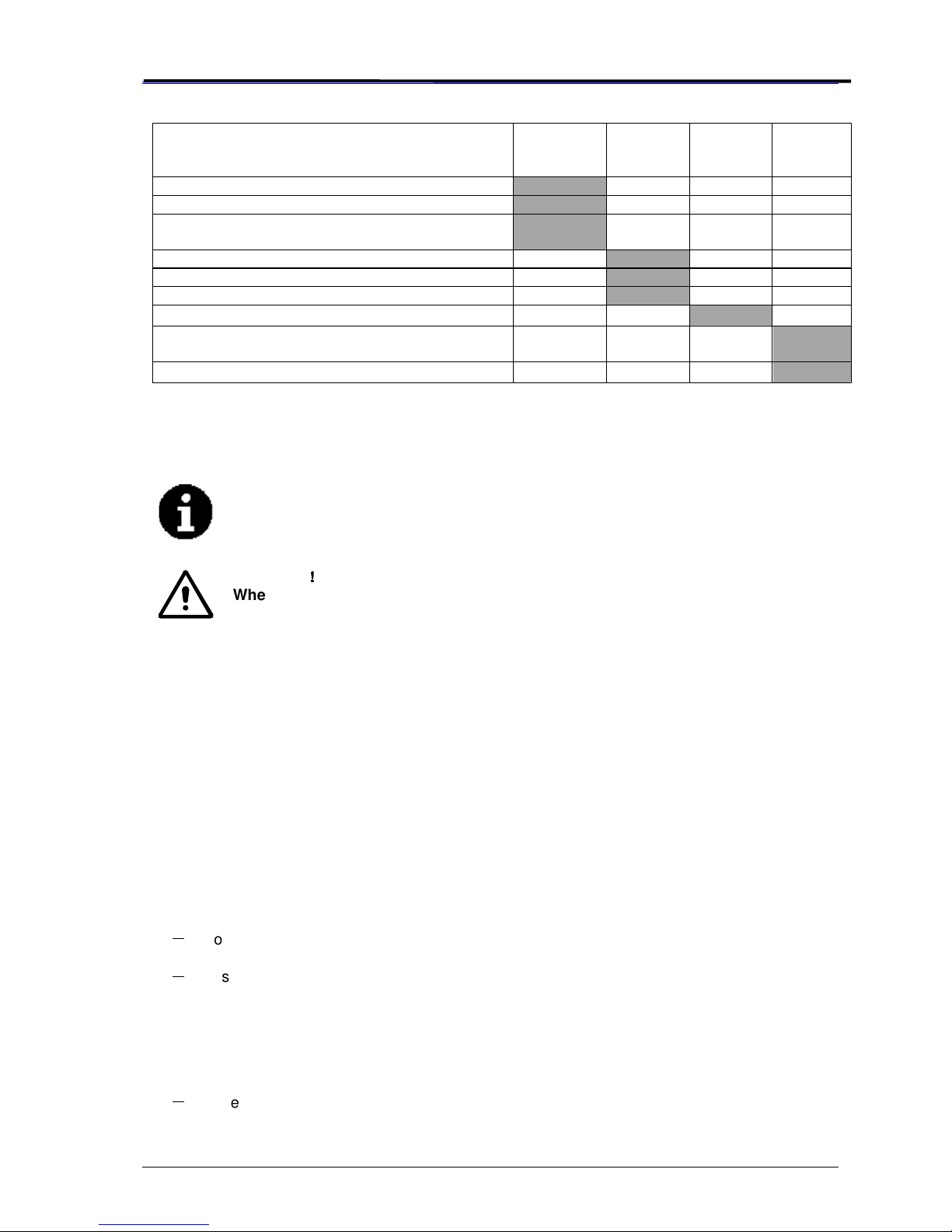

SCHEDULED MAINTENANCE TABLE

Procedure

Daily,

Machine

after use

Weekly Every

6 months

Annually

Clean squeegee

Clean brush/pad

-holder

Clean water tank and float filter, inspect

tank gaskets

Inspect and change the squeegee blades

Clean solution filter

Clean vacuum motor filter

Inspect tightness of nuts and bolts

(1)

Inspect or change motor carbon brush of

brush motor

(2)

Inspect or change carbon brush of Vacuum motor

(2)

(1) It should be done 9 hours after the machine starts working.

(2) These maintenance procedures must be done by an authorized VIPER Service Center.

SQUEEGEE CLEANING

NOTE

In order to maintain the optimal squeegee performance, the squeegee must be

kept clean, and the squeegee blades must remain in good condition.

CAUTION

!!!!

When cleaning the squeegee, it is recommended to put on protective gloves as

the squeegee may contain sharp debris

.

1. Move the machine to a flat and smooth surface.

2. Press the power switch (38) to the “O” position to turn off the machine.

3. Unscrew the squeegee knobs (16); remove the vacuum hose from the squeegee assembly &

remove squeegee.

4. Use the squeegee lift handle (14) to lift the squeegee mount bracket.

5. Using a damp towel, clean the squeegee (Figure 10). Clean in particular the groove (A, Figure

10) and the dirt and fragments on the vacuum tube. Check if the front squeegee blade (C) and

the rear squeegee blade (D) are intact, and if there are broken edges and cracks. Replace them

if necessary (refer to the steps in the following section).

6. Re-install the squeegee in the reverse order of the above

SQUEEGEE BLADE CHECK AND REPLACEMENT

1. Following the methods related in the previous section clean the squeegee (Figure 10)

2. Check the edge (E, Figure 10) of the front squeegee blade and the edge (F) of the rear squeegee

blade (D). On the whole length, they should be level. Otherwise, adjust their heights through the

following procedure.

-

Loosen the clip (G) to let the rear squeegee blade (D) separate from the bracket (M) for the

adjustment of the position of the squeegee. After the adjustment, lock the clip once again.

-

Loosen the screw on the handle (I) to adjust the front squeegee blade (C); tighten the handle

screw after adjustment.

3 Check if the front squeegee blade (C) and the rear squeegee blade (D) is intact and if there are

broken edges and cracks. If damage is found, change them according in the following way. If the

front edge of the rear squeegee blade (J) has worn, it can be flipped upside down and re-installed

(the top edge is required to be intact). If the top edge is also worn, change it by following the

procedure below:

-

Loosen the clip (G) to let the pressure blade separate from the bracket (M), take off the clip

bar (K), and then change or turn the rear squeegee blade (D) upside down. Re-install the rear

squeegee blade in the reverse order of taking it off.

Page 11

USER MANUAL

10

- Loosen the handle screw (I) and take off the front clip bar (L), and then change the front

squeegee (C).

Re-install the front squeegee blade in the reverse order of taking it off.

After changing the squeegee blade, adjust the level of the front and rear squeegee blades in

the procedures as described above.

4. Connect the Vacuum hose (11) to the squeegee.

5. Install the squeegee and tighten the knobs.

6. If necessary, adjust the squeegee by turning the adjustment knob (20) (refer to the procedures

for adjusting the balance of the squeegee).

Figure 10

BRUSH/ PAD CLEANING

CAUTION

!!!!

When cleaning t h e b rush/pad-driver, w earing protecti v e g loves is

Recommended as the brush / pad may contain sharp debris.

1. Remove the brush/pad-driver.

2. With the use of water and detergents, clean the brush/pad driver.

3. Check the brush for wear & if necessary, replace the brush.

4. Check the pad driver for wear & if necessary, replace the pad driver.

WATER TANK AND FLOAT FILTER MESH CLEANING

1. Move the machine to a dedicated draining area.

2. Press the power switch (38) to the position “O” to turn off the machine.

3. Open recovery tank lid (A, Figure 11), and remove the float device (36) from inside the tank.

4. Use

clean water to rinse the recovery tank lid (A), the tank (B and C), and the float filter support

frame (E). Drain all the water from the water tank.

5. If necessary, following the symbols “Open” and “Close” as shown in Figure 11, open the bottom

lid (F) of the float filter and clean the float (D), float filter support frame (E), and the filter sponge

(I). After cleaning, re-attach the float onto the support frame (E), and then align the mark groove

(L) of the bottom lid (F) of the float filter with the mark groove (L) of the float filter support frame

(E). Turn the bottom lid (F) of the float filter tight, and re-attach the filter sponge (I) onto the

support frame (E), and then onto the vacuum tube (M).

6. Inspect the seal / gasket (G) of the recovery tank lid.

NOTE

The seal / gasket (G) of the recovery tank allows the tank to create a vacuum. It

must be completely sealed to be able to effectively suck the wastewater from the

floor.

If necessary, If necessary, the recovery tank seal / gasket (G) may be taken out from the groove

(H) and changed. When installing the new seal / gasket as shown in Figure 11 below, install the

Page 12

USER MANUAL

11

connector to the middle section of the rear part.

7. Check if the receiving surface of the sealing strip (G) is intact and seals adequately.

8. Close recovery tank lid (A).

Figure 11

SOLUTION FILTER CLEANING

1. Drain all the water from Solution tank as previously outlined.

2. Move the machine to a flat and smooth surface.

3. Press the power switch (38) to the “O” position to turn off the machine.

4. Turn off the draining ball valve (A, Figure 12) (located at the bottom of the machine, behind the

wheels). Position B ball valve open, and position C ball valve closed.

5. Remove the transparent cap (D), and then take off the filter (E), and install them onto the filter

box (F) after cleaning.

NOTE

The filter (E) must be accurately installed onto the position of the housing (G).

6. Open the draining ball valve (A).

Figure 12

Filter Mesh Mark

Page 13

USER MANUAL

12

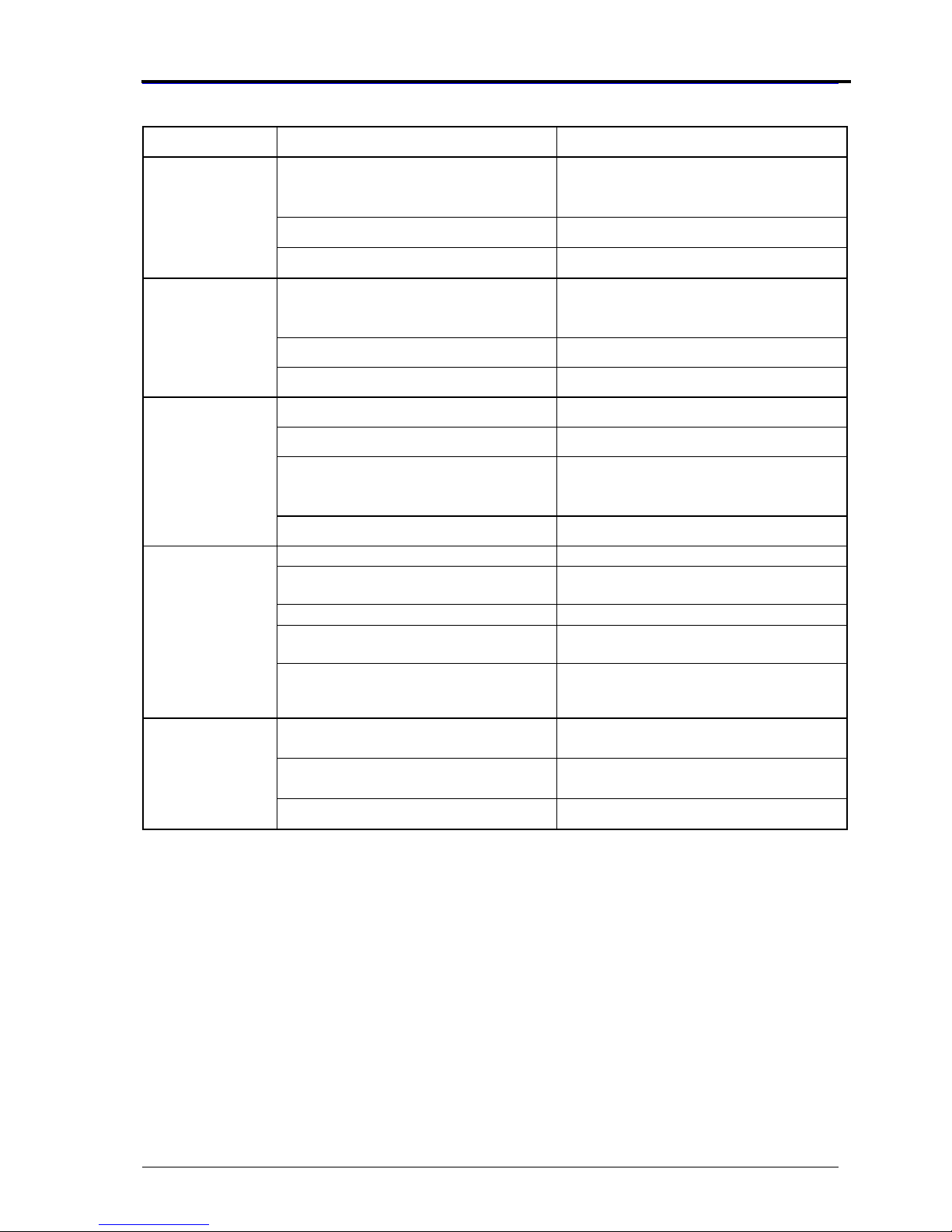

TROUBLESHOOTING

Breakdown Probable Causes Remedies

Machine not

working

The wiring not connected correctly or

bad wiring

Check the wiring or contact Viper

Distributor

Bad brush motor Contact Viper Distributor

Carbon brush worn out Contact Viper Distributor

Vacuum motor

not working

The wiring not connected correctly or

bad wiring

Check the wiring or contact Viper

Distributor

Bad vacuum motor Contact Viper Distributor

Carbon brushes worn out Contact Viper Distributor

Little or no

solution flow

Bad ball valve Contact Viper Distributor

Bad solution valve Contact Viper Distributor

Ball valve position in need of

adjustment

When ball valve is in horizontal position,

the amount of solution flow is maximum

Filter dirty. Clean the filter

Inadequate

Vacuum

Wastewater tank is full. Drain the water tank

Vacuum tube for waste and squeegee

not properly connected

Connect the Vacuum tube for waste and

the squeegee

Float filter blocked or inlet blocked Clean the float filter, check the float ball

Squeegee dirty or squeegee blade

worn and damaged

Clean and check the squeegee

Recovery tank lid not properly turned

on, or the sealing strip of the water

tank damaged

Refit on the lid properly, or change the

water tank sealing strip

Squeegee

leaving marks

Debris like fragments under the

squeegee blade

Remove the fragments

Squeegee blade already worn,

cracked, brittle.

Change the squeegee blade

Balance of squeegee not adjusted Adjust the balance

Page 14

TANK SYSTEM

AS430C PART LIST

Page 15

Page 16

Item Part No. Description Qty

TANK SYSTEM

AS430C PART LIST

37 VF13604 GROOVED METAL GASKET 1

38 VF90235 SCEREW TM4x10 1

39 VF90508 SUCTION HOSE 2

40 VF90231 GASKET 1

41 VF90214 SEAL PLATE COVER 2

42 VF90217 SEAL PLATE 2

43 VA80758 SCREW 4

44 VF90529 SUCTION TUBE CONNECTER 1

45 VF90528 DRAIN HOSE CONNECTOR 1

46 VF90512 SUCTION TUBE GASKET 2

47 VF90509 SEALING KNOB 2

48 VA20304 CLAMP 4

49 VF90534 FLOAT KIT 1

50 VF90530 CAGE,FLOAT COMPLETE 1

51 VF90526 FLOAT BRACKET 1

52 VF85124 FLOATE 1

53 VF90527 FLOATE BRACKET COVER 1

54 VF90218 CONTROL SEAL GASKET 1

55 VF90401 DRAIN HOSE CONNECTER 1

56 VF90443 DRAIN HOSE-38 1

57 VF83150 HOLDER,"U"HOSE 1

58 VF90701

17"COUNTER WEIGHT BLOCK 1

59 VF13534 WASHER 4

60 VF13519 WASHER,LOCK,Ø8 4

61 VF14067 SCREW M8*25 4

62 GT13054 SCEREW TM5x12 4

63 VF90814 BATTERY COVERY 1

64 VF90720 VACUUM MOTOR CONNECTION LINE 1

65 VF90730 SOLENOID VALVE CONNECTION LINE 1

66 VF90721 BRUSH MOTOR CONNECTION LINE 1

15

Page 17

AS430C PART LIST

CONTROL SYSTEM AND ELECTRICAL SYSTEM

Page 18

Item Part No. Description Qty

1 VF90203 SAFETY SWITCH KNOB 2

2 VF90286 SCREW KA3.5x12 4

3 VF90201 SAFETY SWITCH COVER LEFT 1

4 VV68303 SCREW KA3.5x15 4

5 VF90288 WASHER Φ3.6XΦ8X0.5 4

6 VF90210 SWITCH FIX FRAME 2

7 VV60153

SWITCH RL2

(P)

3

8 VF90009 DECAL CONTROL PANEL 1

9 VF90235 SCREW TM4x10 6

10 VF90204 17" SWITCH COVER 1

11 VF90706 24VDC REGULATOR BOARD 1

12 VA14584 SCREW PB3.0x8 4

13 VF90285 SWITCH SEAL STRIP 1

14 VF90216 SWITCH SEAL BUSHING 2

15 VF90202 SPRING 4

16 VF90252 SWITCH 2

17 VF90212 SAFETY SWITCH COVER RIGHT 1

18 VF90219 GASKET 2

19 VA13469 SCREW PB3x12 4

20 VF90213 SWITCH SEAL RING 2

21 GT13091 SCREW,PB3.5x9.5mm 2

22 VF89042-3 RELAY 1

23 GT13025 SCREW,M3X12 2

24 VF90725-1 RUNNING CAPACITOR 1

25 VF90815 COVER CONTROL HOUSING 1

26 GT13054 SCREW TM5x12 4

27 N/A 17" SERIAL NUMBER LABEL 1

28 GV70034 CLAMP DRAIN HOSE 1

29 VF14538 SCREW ST3.5x16 2

30 VF90027 BACK COVER PANEL 1

31 VF90129 SCREW M5x20 1

32 VF90113 HANDLE LIFT 1

33 VF14514 NUT LOCK M5 5

17

AS430C PART LIST

CONTROL SYSTEM AND ELECTRICAL SYSTEM

Page 19

Item Part No. Description Qty

AS430C PART LIST

CONTROL SYSTEM AND ELECTRICAL SYSTEM

34 VF90128 SCREW M5 2

35 VF90114 CABLE SQUEEGEE LIFT 1

36 VF89076 CIRCUIT BREAKER CAP 2

37 80407A SCREW M5X25 2

38 VF90116 HAND BRACKET 1

39 VF90704

24V RELAY 1

40 VV13652 NUT LOCK M3 2

41 VV13653 WASHER Ø3.4xØ10x1.0mm 4

42 VF90232 ELECTRIC SUPPORT 1

43 VF90725-2 START CAPACITOR 1

44 VF90259 HAND FIX PANEL 1

45 VF99010C CIRCUIT BREAKER 1

46 VF90517 CABLE FIX BRACKET 1

47 VF73705 CABLE SLEEVE 1

48 VF90745 POWER CORD 1

49 VV67105 CONNECTOR 1

50 VF90703-US CABLE (20M) 1

51 VF422997 HANGING BOARD 1

52 VV13667 SCEREW TM4x8 1

53 VF13604 GROOVED METAL GASKET 1

54 VF90019 BRUSH CIRCUIT LABEL 1

55 VF90747 CIRCUIT BREAKER 1

56 VF90020 VACUUM CIRCUIT LABEL 1

18

Page 20

AS430C PART LIST

WHEELS AND SOLUTION SYSTEM

Page 21

Page 22

BRUSH SYSTEM

AS430C PART LIST

Page 23

Item Part No. Description Qty

1 VF90729 BRUSH MOTOR KIT 1

2 VF90284 SOLENOID VALVE KIT 1

3 VF90418 SOLENOID VALVE BRACKET 1

4 VV13650A SCREW M4x10 4

5 VV20274 WASHER 2

6 VF90460 CONNECT PLATE C 1

7 VF90461 BRASS SPACER B 2

8 VF90421 SPACER 4

9 VF14555 SCREW,SHOULDER M12x50 4

10 VF14238 SCREW, M12x30 2

11 VF14530 SCREW,SHOULDER M6×40 2

12 VF85134 SPACER 2

13 VF85107 BUMPER ROLLER 2

14 VV13604 SCREW,SHOULDER M8x20 4

15 VF90406 17" BRUSH DECK 1

16 VF14506 NUT LOCK M6 2

17 GT13067 SCREW,SHOULDER M8x25 2

18 VF90465 DRIVEN PULLEY KIT 1

19 VF90424 NUT M20 2

20 VF90422 SPACER 1

21 ZD45425 BEARING 6204 LU 2

22 VF90423 CLAMP SLEEVE 1

23 VV13650A SCREW M4x10 2

24 VV20291 WASHER,LOCK,Ø4 2

25 VF90437 BRUSH SPRING CLIP 1

26 VF90463 DRIVEN PULLEY 1

27 VF90425 DRIVEN PULLEY SHAFT 1

28 VF90415 VIBRATION GASKET 1

29 VF13534 WASHER φ8.4x φ18x 2 1

30 VV20298 WASHER,LOCK,Ø8 1

31 VF90462 BELT 1

BRUSH SYSTEM

22

AS430C PART LIST

Page 24

Item Part No. Description Qty

BRUSH SYSTEM

AS430C PART LIST

32 VF13503 NUT LOCK M8 9

33 VF14057A NUT LOCK M12 3

34 VF90459 SLIDING CONNECT PLATE 1

35 VF90455 FRAME 1

36 VF13538 WASHER φ12xφ24x2 1

37 VF13541

WASHER,LOCK

¢

12

3

38 VV20298 WASHER,LOCK,Ø8 4

39 VA13491 SCREW, M8x25 3

40 VF90445 TENSION WHEEL KIT 1

41 VF14516 NUT LOCK M8 1

42 VF13535 WASHER

¢8x¢

20x2 1

43 VF999821A BEARING 6002 2

44 VF90426 TENSION WHEEL 1

45 VF80209 SPACER 1

46 VF80214 SPACER 1

47 GT13066 SCREW,SHOULDER M8x55 1

48 VF90427 ROD, TENSION WHEEL 1

49 VF80232 SPRING 1

50 VF80235 SPACER 1

51 VF14255 SCREW, M12x65 1

52 VF14236 SCREW, M8x40 1

53 VF13534 WASHER φ8.4x φ18x 2 2

54 VF90439 BUSHING TENSION WHEEL 2

55 VF90438 SCREW,SHOULDER M8x30 1

56 VF90411 17"BRUSH 1

57 VF90453 17" PAD 1

23

Page 25

SQUEEGEE SYSTEM

AS430C PART LIST

Page 26

Item Part No. Description Qty

1 VF14547 SCREW LOCK M10 1

2 VF85104 HAND WHEEL 1

3 VF13534 WASHER φ8.4x φ18x 2 1

4 VF14503 NUT M8 3

5 VF90133 SPACER 1

6 VF90110 BACK-SQUEEGEE-SUPPORT 1

7 VF14516 NUT LOCK M8 2

8 VF14506 NUT M6 3

9 VF13533 WASHER FLAT Ø6 1

10 VF90111 FRONT-SQUEEGEE-SUPPORT 1

11 VF85336 WASHER NYLON 2

12 VF90130 SCREW SHOULDER 1

13 VF81210 KNOB 2

14 VF84228 SCREW SHOULDER M8 2

15 VF82112 SPACER 1

16 VF14233 SCREW 1

17 VF90109 SQUEEGEE-SUPPORT 1

18 VF90134 17" SQUEEGEE KIT 1

19 VF90136 SQUEEGEE ROLL WHEEL KIT 2

20 VV20203 NUT LOCK 2

21 VF81219 2" WHEEL 2

22 VF81222 BOLT SHOULDER 5/16" 2

23 VF90102

17" STRAP

,

SQUEEGEE FRONT

1

24 VF90137 BUMPER ROLLER KIT 2

25 VF14530 SCREW M6×40 2

26 VF85107 BUMPER ROLLER 2

27 VF85134 SPACER 2

VF90103 17" BLADE FRONT (NR) 1

VF90146 17" BLADE FRONT (PU) 1

VF90104 17" BLADE REAR (NR) 1

VF90147 17" BLADE REAR (PU) 1

30 VF85420 WING NUT M8×30 2

SQUEEGEE SYSTEM

25

AS430C PART LIST

28

29

Page 27

Item Part No. Description Qty

SQUEEGEE SYSTEM

AS430C PART LIST

31 VF90101 SQUEEGEE 17" 1

32 VF90127 SQUEEGEE SCREW 2

33 VF90138

17" STRAP

,

SQUEEGEE BACK KIT

1

34 VF14305 SCREW M5×60 1

35 VF90121 HOOK 1

36 VF81208A RIVET Ø4×5 2

37 VF81218A LATCH HOOD 1

38 GT13022 NUT LOCK M5 1

39 VF90105

17" STRAP,SQUEEGEE BACK

1

26

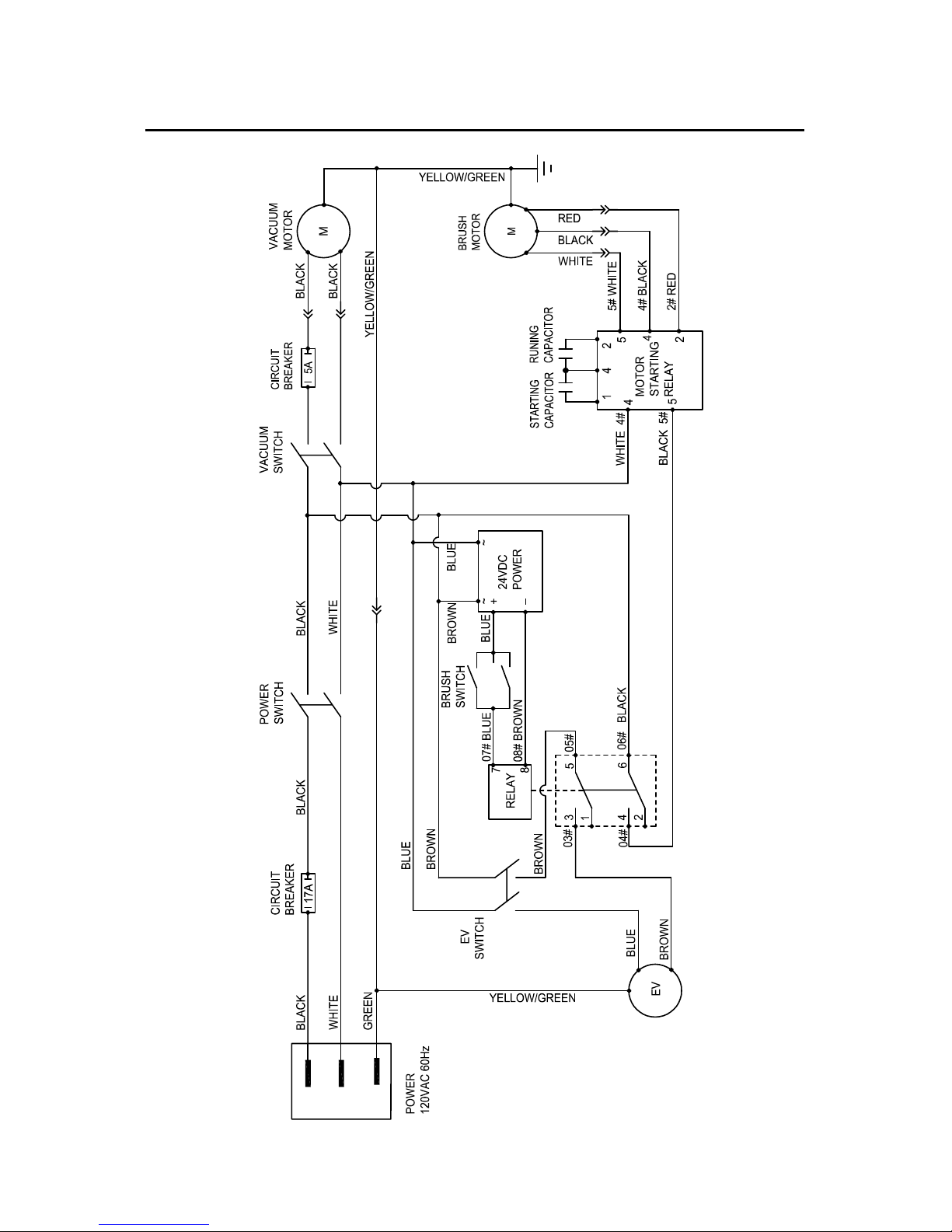

Page 28

WIRING DIAGRAM

AS430C PART LIST

27

Page 29

Company information:

www.usviper.com

Loading...

Loading...