Page 1

AS530R

USER MANUAL

Model: 50000417

VR28016

Rev.01

2016.10.24

Nilfisk Inc.

9435 Winnetka Avenue North

Minneapolis, MN 55445

www.usviper.com

Page 2

TABLE OF CONTENTS

ENGLISH

USER MANUAL…………………………………………………………………….

1-21

FRANÇAIS

MANUEL UTILISATEUR…………………………………………………………

22-42

ESPAÑ OL

INSTRUCCIONES DE USO……………………………………………………..

43-63

Page 3

USER MANUAL ENGLISH

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................ 1

MANUAL CONTENT AND PURPOSE ....................................................................................................................................... 1

HOW TO KEEP THIS MANUAL ................................................................................................................................................ 1

DECLARATION OF CONFORMITY ............................................................................................................................................ 1

ACCESSORIES AND MAINTENANCE ........................................................................................................................................ 1

CHANGES AND IMPROVEMENTS ........................................................................................................................................... 1

SCOPE OF APPLICATION ......................................................................................................................................................... 1

MACHINE IDENTIFICATION DATA .......................................................................................................................................... 1

TRANSPORT AND UNPACKING ............................................................................................................................................... 1

SAFETY ............................................................................................................................................................ 2

SYMBOLS THAT APPEAR ON THEINSTRUCTION FOR USE MANUAL ...................................................................................... 2

GENERAL SAFETY INSTRUCTION ............................................................................................................................................ 2

MACHINE DESCRIPTION................................................................................................................ 4

MACHINE STRUCTURE ........................................................................................................................................................... 4

CONTROL PANEL .................................................................................................................................................................... 5

LED SCREEN DISPLAY INFORMATION ..................................................................................................................................... 5

DISPLAY WINDOW OF CHARGER INDICATON LIGHT ............................................................................................................. 5

TECHNICAL PARAMETERS ...................................................................................................................................................... 6

CIRCUIT DIAGRAM ................................................................................................................................................................. 7

OPERATING GUIDE ....................................................................................................................... 9

INSTALLING AND SETTING OF NEW MACHINE BATTERY ....................................................................................................... 9

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL/ AGM) ........................................................................ 9

EMERGENCY BRAKING ......................................................................................................................................................... 10

BRUSH/PAD INSTALLATION AND UNINSTALLATION ............................................................................................................ 10

ADJUSTING THE BALANCE OF SQUEEGEE ............................................................................................................................ 11

SOLUTION TANK FILLING ..................................................................................................................................................... 11

MACHINE START AND STOP ................................................................................................................................................. 12

MACHINE OPERATION (SCRUBBING AND DRYING) ............................................................................................................. 13

TANK EMPTYING .................................................................................................................................................................. 14

AFTER USING THE MACHINE ................................................................................................................................................ 14

MACHINE LONG INACTIVITY ................................................................................................................................................ 14

USING FOR THE FIRST TIME ................................................................................................................................................. 15

MAINTENANCE ........................................................................................................................... 15

SCHEDULED MAINTENANCE TABLE ..................................................................................................................................... 15

BATTERY CHARGING ............................................................................................................................................................ 15

BRUSH/PAD CLEANING ........................................................................................................................................................ 16

SOLUTION FILTER CLEANING ............................................................................................................................................... 17

SQUEEGEE CLEANING .......................................................................................................................................................... 17

SQUEEGEE BLADE CHECK AND REPLACEMENT .................................................................................................................... 17

TANK AND VACUUM GRID WITH FLOAT CLEANING, AND COVER GASKET CHECK .............................................................. 18

FUSE CHECK/REPLACEMENT ................................................................................................................................................ 19

ACCESSORIES/OPTIONS ....................................................................................................................................................... 19

TROUBLE SHOOTING .................................................................................................................. 19

SCRAPPING ................................................................................................................................ 21

Page 4

USER MANUAL ENGLISH

1

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL CONTENT AND PURPOSE

The purpose of this Instruction for Use Manual is to provide the operator with necessary information to use the

machine properly and safely. It contains information about technical data, safety, operation, storage, maintenance,

spare parts and how to scrap it.

Before performing any procedure on the machine, no matter the operators and qualified technicians must read this

Manual carefully. Contact our company’s service center for any query about this manual or for any further information

is needed.

The operators must not perform procedures that should be done by qualified technicians. Our company will not be

answerable for damages coming from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Manual must be kept near the machine, inside an adequate case, away from liquids and other substances that can

cause any damage to it.

DECLARATION OF CONFORMITY

Declaration of Conformity is supplied with the machine and certifies machine conformity with the law in force.

NOTE

The copies of the original declaration of conformity are provided together with the machine

documentation.

ACCESSORIES AND MAINTENANCE

All the necessary operation, maintenance and repair procedures must be performed by qualified personnel, or by our

company appointed service center. ONLY authorized spare parts and accessories should be used.

Contact our company customer service for any service or purchase of accessories or spare parts if necessary.

CHANGES AND IMPROVEMENTS

We committed to continuous improvement of the products, the company reserves the right to the machine changes

and improvements without informing in additional.

SCOPE OF APPLICATION

The scrubber applies to commercial and industrial use. It is suitable for cleaning smooth and solid floors, operating by a

qualified personnel in safety circumstance. It is not suitable for outdoor use, carpet or rough floor cleaning.

MACHINE IDENTIFICATION DATA

The machine serial number and model name are marked on the serial label.

This information is useful. Use the following table to write down the machine identification data when requiring spare

parts for the machine.

MACHINE MODEL....................................................................................

MACHINE SERIAL NUMBER......................................................................

TRANSPORT AND UNPACKING

When the carrier delivers the machine, make sure the packaging and machine are both whole and undamaged. If any

damaged, make the carrier know the damage and before accepting the goods, reserve the right in compensation of the

damage.

Follow the instructions on packing strictly when unpacking the machine.

Check the package to ensure following items are included:

Page 5

USER MANUAL ENGLISH

2

1. Technical documentations including user manual, and on-board charger manual if on-board charger is equipped.

2. Charger cable if on-board charger is equipped.

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all

necessary precautions to safeguard people and property.

SYMBOLS THAT APPEAR ON THEINSTRUCTION FOR USE MANUAL

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions.

Pay attention to the paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

It indicates the necessity to refer to the Instruction for Use manual before performing any procedure.

GENERAL SAFETY INSTRUCTION

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

This machine must be operated by trained and authorized personnel according to guidance of the manual.

Before performing any cleaning, maintenance, repair or replacement procedure, read all the instructions

carefully, ensure to turn the machine OFF and disconnect the battery connector.

Do not operate the machine near toxic, dangerous, flammable and/or explosive powders, liquids or vapour.

This machine is not suitable for collecting dangerous powders.

Do not wear jewels when working near electrical components.

Do not work under the lifted machine without supporting it with safety stands.

When using lead (WET) batteries, they may emit inflammable gas under normal use, must keep sparks,

flames, smoking materials and radiating, illuminating and burning items away from the batteries.

When charging lead (WET) batteries, they may emit hydrogen gas which may cause explosive. Must ensure

the charging environment is well ventilated and away from naked flames.

WARNING!

Check the machine carefully before each use. Ensure that all the components have been well assembled

before use. Or it may causes damages to people and properties.

Page 6

USER MANUAL ENGLISH

3

Before using the battery charger, ensure that the values of frequency and voltage indicated on the machine

serial number label match those of mains.

Never move the machine by pulling the battery charger cable. Do not let the cable through a closed door, or

winding on sharp edges or corners. Do not run the machine on the battery charger cable. Keep the battery

charger cable away from heated surfaces.

Do not charge the batteries if the battery charger cable or the plug are damaged.

To reduce the risk of fire, electric shock, or injury, make sure machine is off before leaving.

Use or store the machine indoors in dry conditions, it is not allowed for outdoor use.

The machine both storage and working temperature must be between 0 °C and +40 °C, the humidity of air

must be between 30% - 95%.

Do not use the machine on slopes with a gradient exceeding as specification show.

When using and handling floor cleaning detergents, follow the instructions on the labels of the detergent

bottles and wear suitable gloves and protections.

Use brushes and pads supplied with the machine or defined in the manual. Using other brushes or pads

could reduce safety.

In case of machine malfunctions, ensure that these are not due to lack of maintenance. If necessary, request

assistance from the authorized personnel or from an authorized Service Center.

Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine

moving parts.

Do not use the machine in particularly dusty areas.

Do not wash the machine with direct or pressured water jets, or with corrosive substances.

Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

Do not lean liquid containers on the machine, use the relevant can holder.

To avoid damaging the floor, do not allow the brush/pad to operate while the machine is stationary.

In case of fire, use a dry powder fire extinguisher. Do not use liquid fire extinguishers.

Do not remove or modify the machine stickers.

Do not tamper with the machine safety guards and follow the ordinary maintenance instructions

scrupulously.

Pay attention during machine transportation when temperature is below freezing point. The water in the

recovery tank and in the hoses could freeze and cause seriously damage to the machine.

If spare parts need be replaced, order ORIGINAL spare parts from an Authorized Dealers or Retailers.

Return the machine to the Service Center if it doesn’t work as usual or it is in condition such as damaged,

placed outdoors, dropped into water.

To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of

this Manual, must be performed by the authorized personnel or an authorized Service Center.

The machine must be properly disposed of, because the presence of toxic-harmful materials (batteries, etc.),

which are subject to standards that require disposal in special centers (see Scrapping chapter).

This machine as a cleaning tool only, not for any other purpose use.

Always keep the openings free from dust, hairs and any other foreign material which could reduce the

airflow. Do not use the machine if the openings are clogged.

Use the machine only where a proper lighting is provided.

This machine is not intended for use by persons with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the

machine by a person responsible for their safety.

Close attention is necessary when used near children.

Children should be supervised to ensure that they do not play with the machine.

While using this machine, take care not to cause damage to people or objects.

Page 7

USER MANUAL ENGLISH

4

MACHINE DESCRIPTION

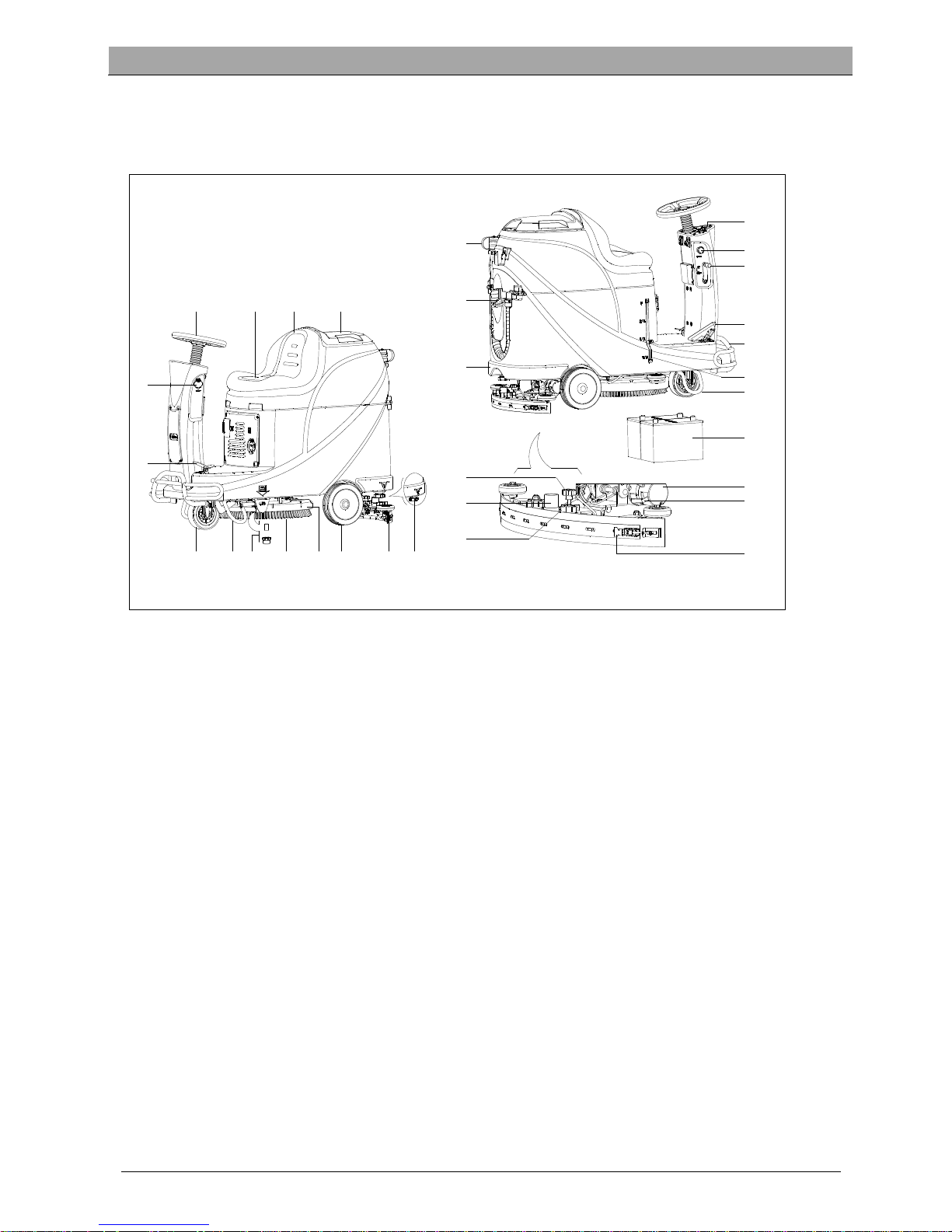

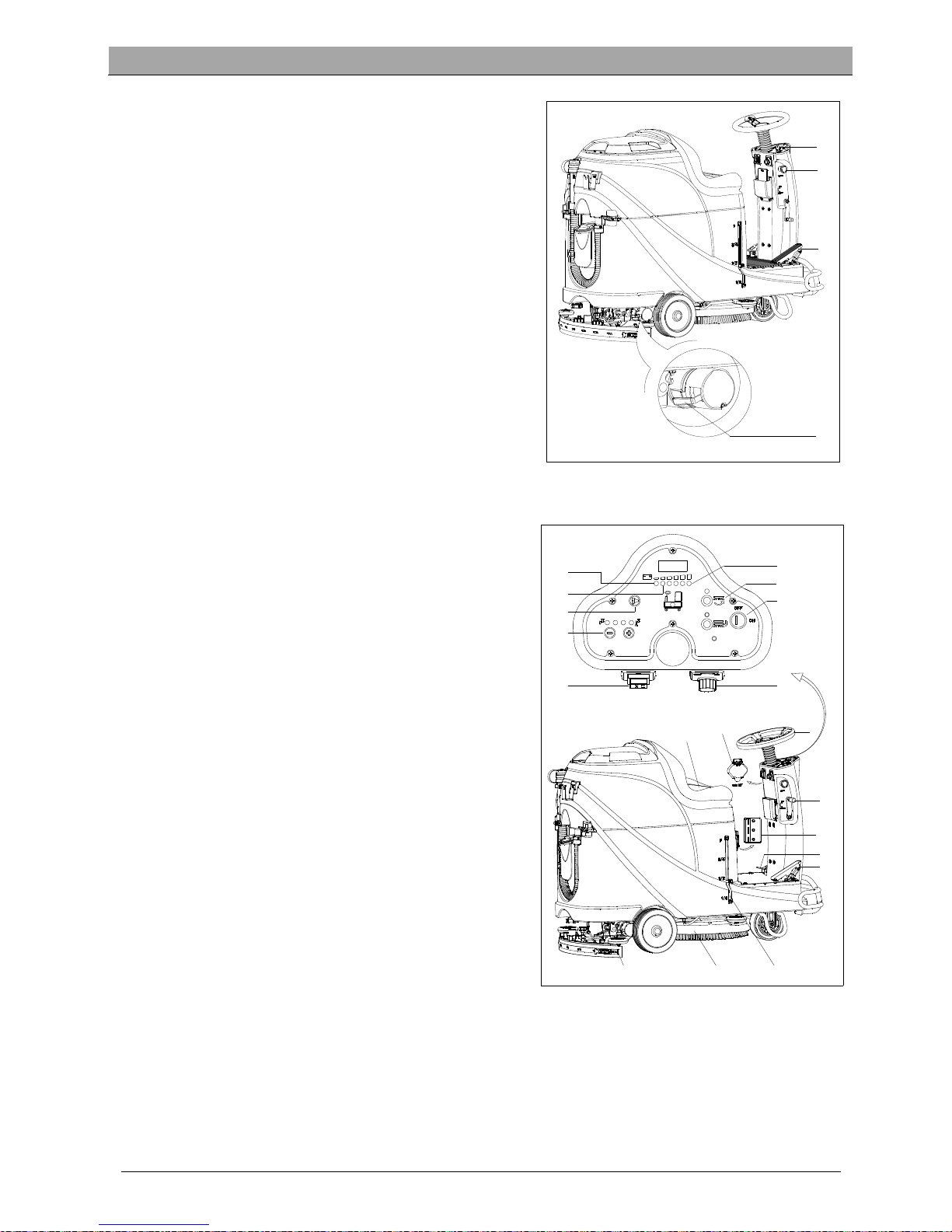

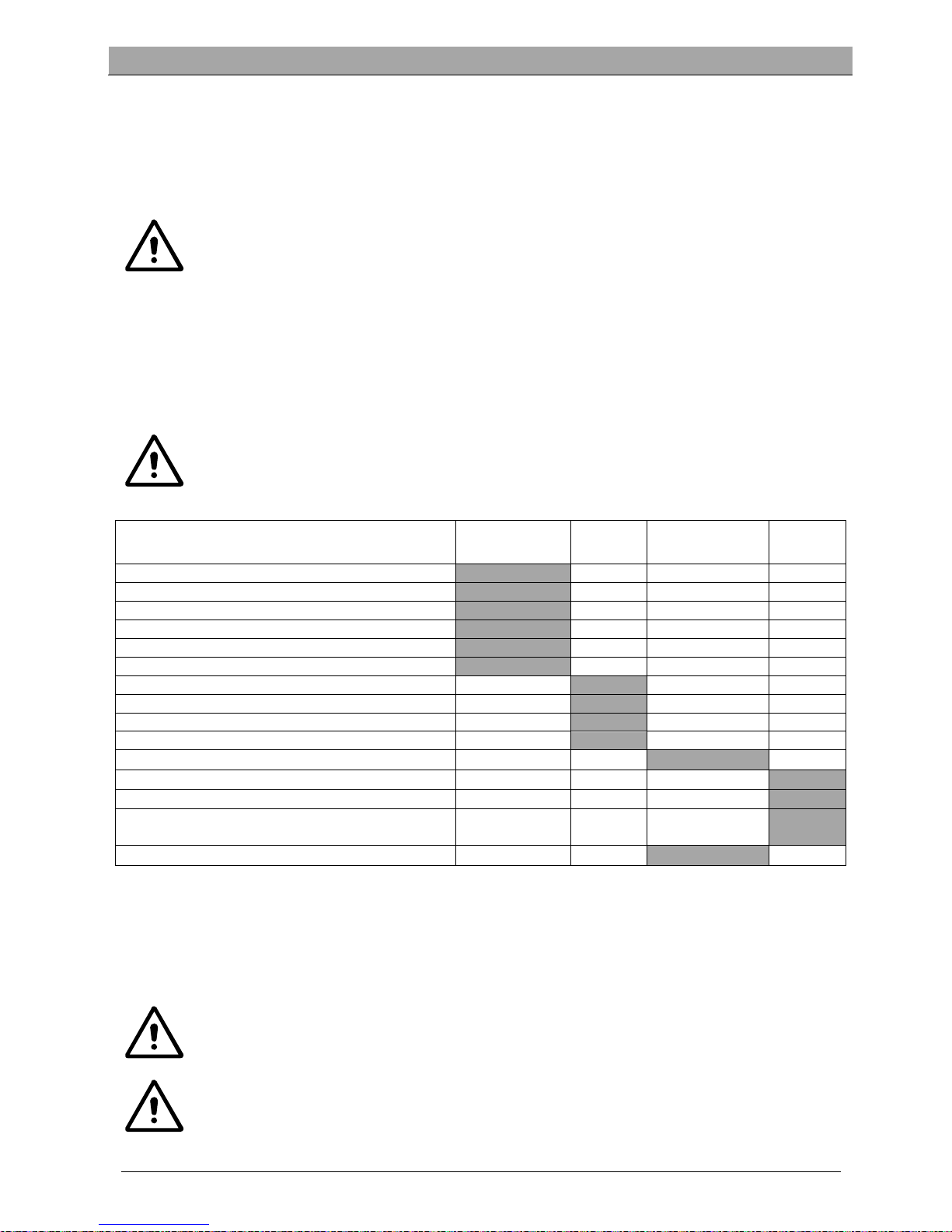

MACHINE STRUCTURE (as shown in Figure 1)

1. Steering wheel

2. Seat cushion

3. Recovery tank

4. Recovery tank cover

5. USB charging port

6. Pedal

7. Front wheel

8. Left support bracket

9. Solution Filter

10. Brush

11. Brush deck

12. Rear wheel

13. Squeegee assembly

14. Solution outlet cover

15. Sewage drain hose

16. Water inlet cover

17. Solution tank

18. Squeegee adjustment knob

19. Vacuum hose

20. Squeegee knob

21. Control panel

22. Emergency switch

23. Squeegee lifting/lowering lever

24. Accelerate pedal

25. Front bumper

26. Solution level indicator

27. Right support bracket

28. Battery

29. Drive motor

30. Brake block bracket

31. Squeegee hasp

1

2 3 4

5

6

7

8

9 10 11 12

13 14

15

16

17

18

19

21

22

23

24

25

26

27

28

29

30

31

20

Figure 1

Page 8

USER MANUAL ENGLISH

5

MACHINE DESCRIPTION

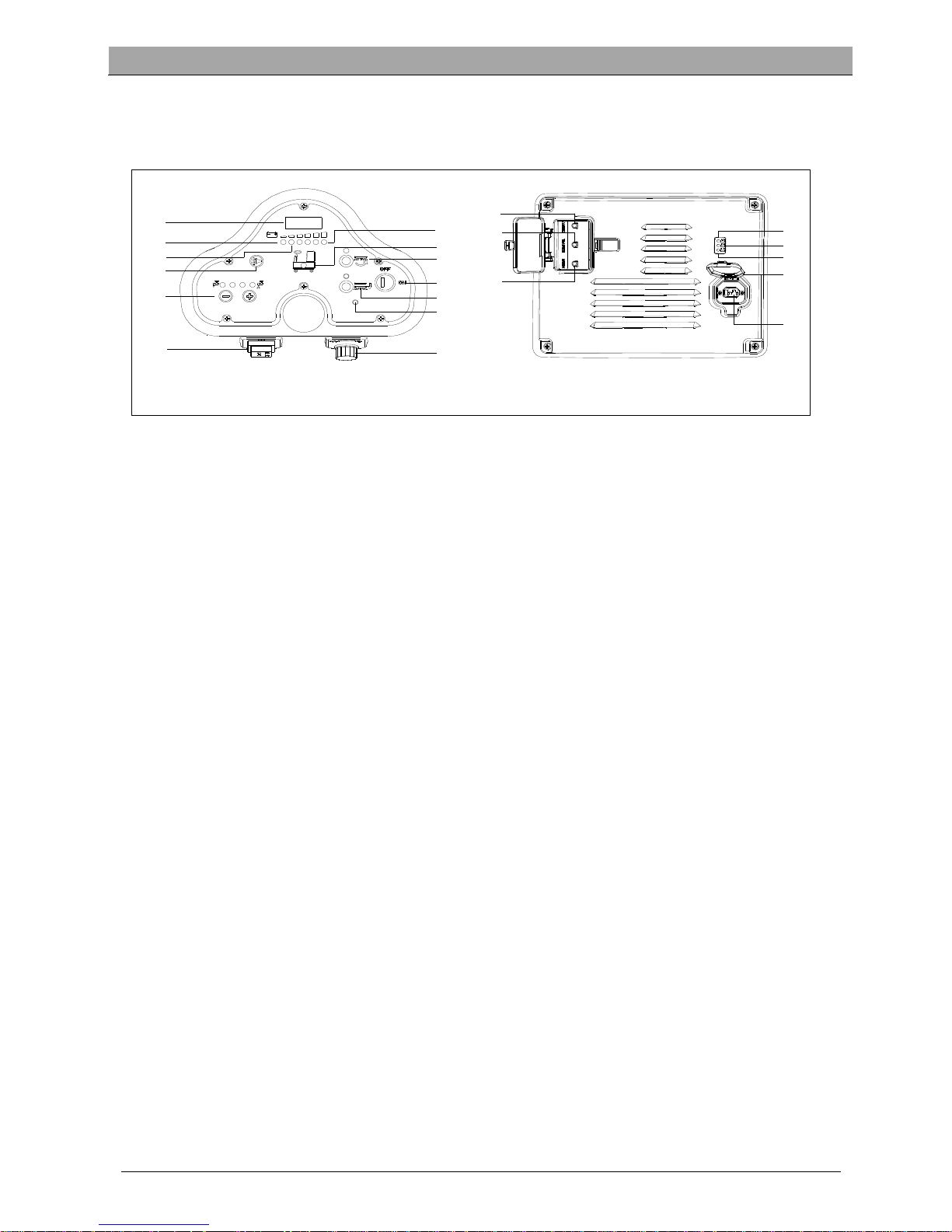

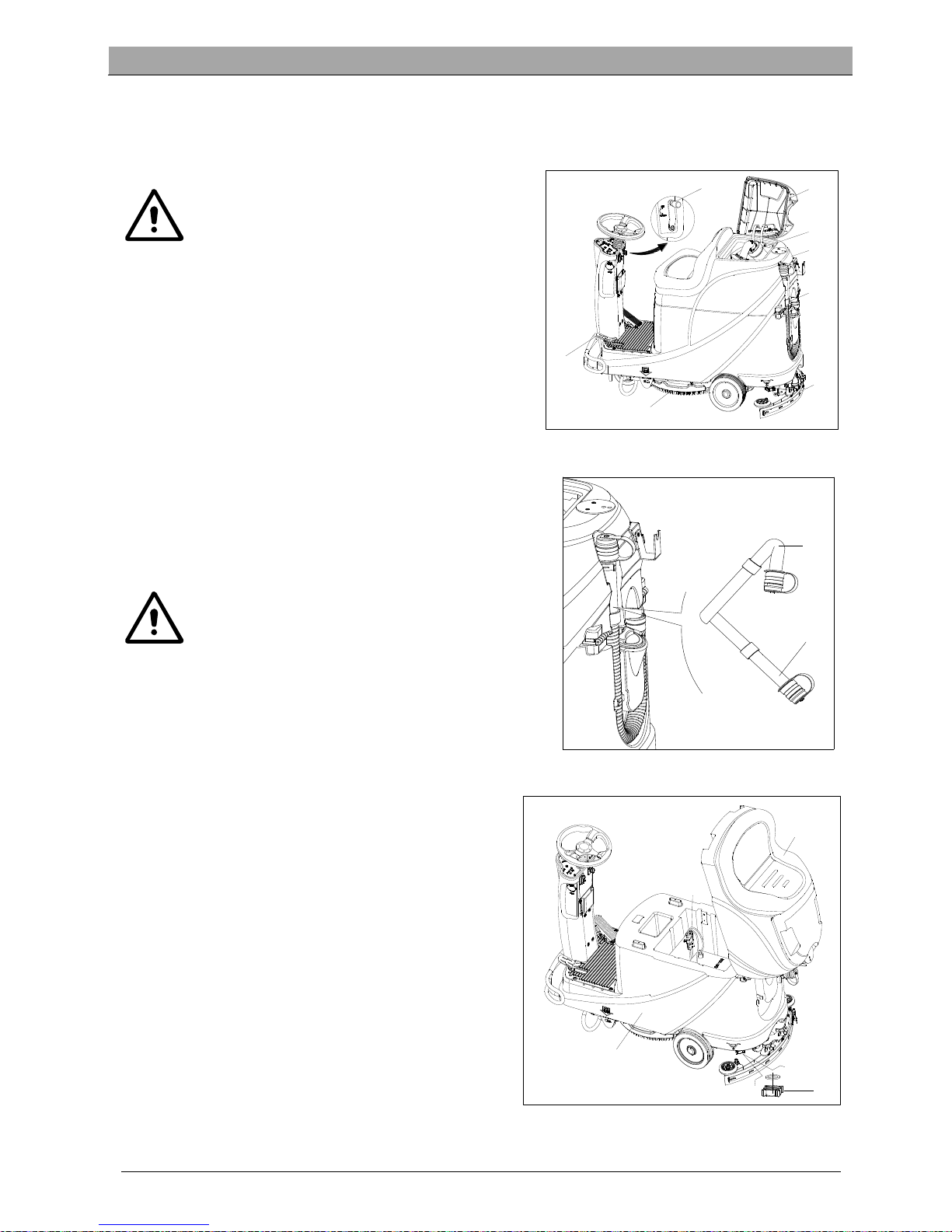

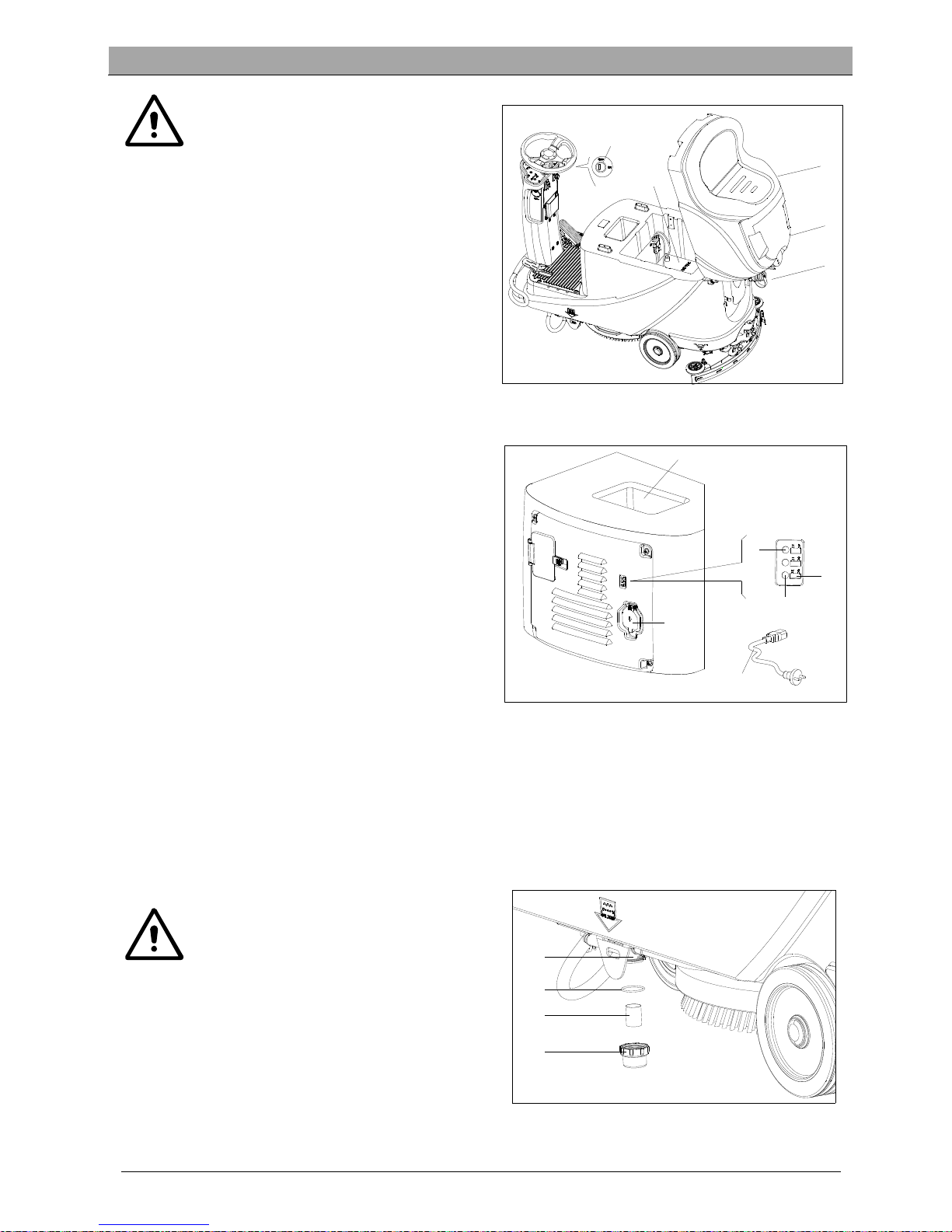

CONTROL PANEL (as shown in Figure 2)

31. LED screen

32. Discharged battery warning light (Red)

33. Battery semi-discharged indicator (Yellow)

34. Horn button

35. Solution volume adjusting button

36. Forward-Backward switch

37. Battery fully charged indicator (Green)

38. Solution tank empty indicator

39. Brush button

40. Key switch

41. Brush unload button

42. Drive motor trouble light

43. Speed adjusting knob

44. Vacuum motor overload protector

45. Drive motor overload protector

46. Brush motor overload protector

47. Battery charge indicator (Red)

48. Battery semi-charged indicator (Yellow)

49. Battery fully charged indicator (Green)

50. Charger plug cover

51. Charger plug

LED SCREEN DISPLAY INFORMATION

STOP– Machine cannot move, brush stops working but vacuum motor can work

(00012.3) – Total working hours of machine are 12.3hours

L0-(18) – Battery voltage lower than 18V

U-(25.5) – Battery voltage is 25.5V

ERR-01 – Squeegee is not lifted when machine turns backward

DISPLAY WINDOW OF CHARGER INDICATON LIGHT (as shown in Figure 2)

1. At the beginning of charging, the Yellow LED (48) twinkles, the red LED (47) and green LED (49) turn on for a second,

on the red LED turns off, and then the green LED twinkles a few times before the red LED on charger is normally. It

is the first stage of charging.

2. After charging for some time, the red LED (47) on charger turns off, the yellow LED (48) turns on, this is the second

stage of charging.

3. When charging is completed, the yellow LED (48) turns off, the green LED (49) turns on to indicate that the battery

is fully charged.

NOTE

In the process of charging, if the yellow light (48) is on, it may be caused by: Battery and charger doesn’t

match, battery is not connected well, or output is short-circuited.

The red light of charger flashing may be caused by the charger internal short circuit.

42

31

32

35

36

38

39

40

41

43

37

33

44

45

47

48

34

50

46

49

51

Figure 2

Page 9

25

USER MANUAL ENGLISH

6

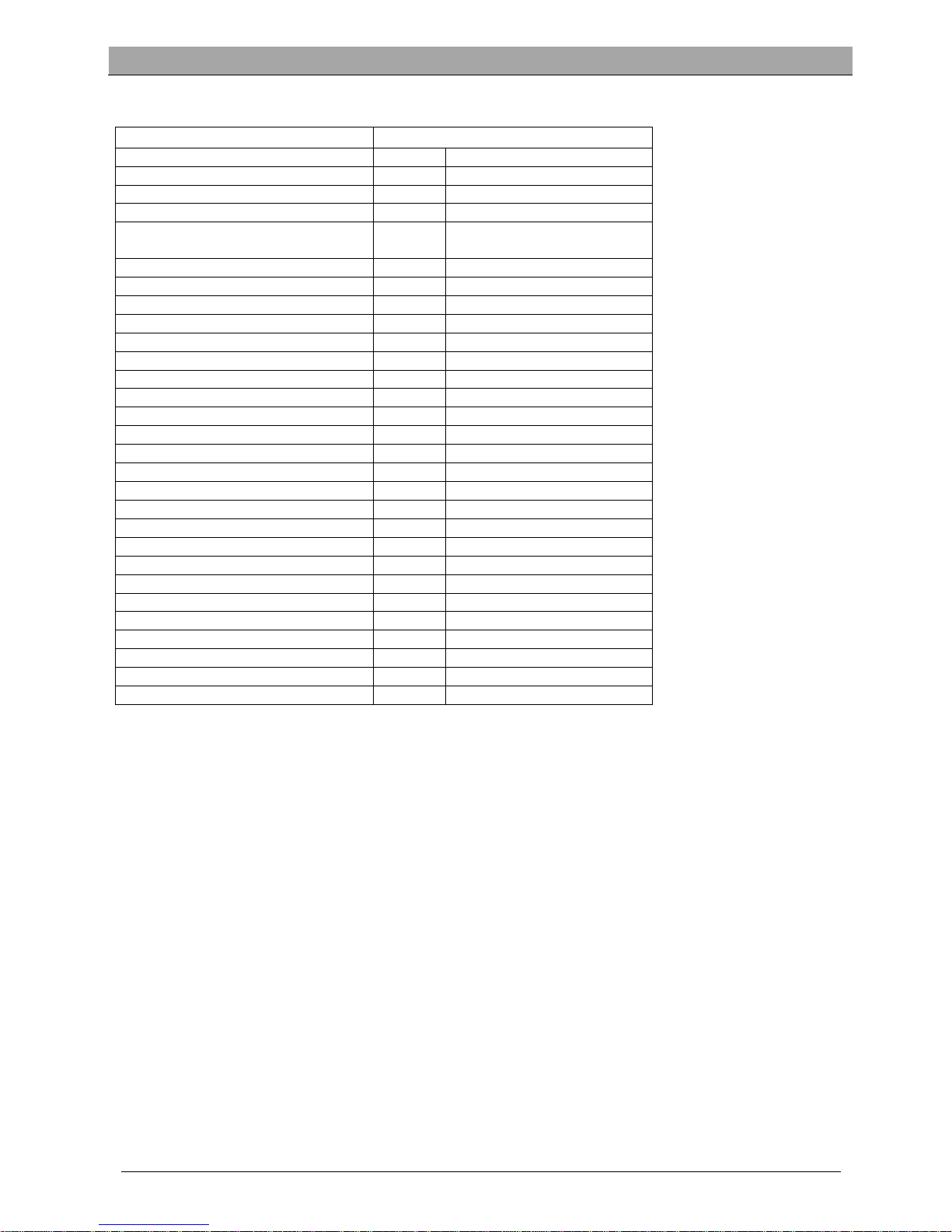

TECHNICAL PARAMETERS

MODEL AS530R

Packing dimensions (Lx W x H) mm 1470*730*1310

Machine height mm 1120

Machine length mm 1360

Machine width (without squeegee) mm 580

Machine weight with empty tanks

(without batteries)

Kg 140

Gross vehicle weight (GVW) Kg 270

Shipping weight Kg 245

Solution tank capacity Liter 72

Recovery tank capacity Liter 73

Vacuum motor power Watt 400

Vacuum capacity mm H₂O 1223

Climbing capacity (Max) % 10

Front wheel diameter mm φ175

Rear wheel diameter mm φ230

Sound level dB(A) 69

Solution/water Flow L/min 0.84-2.0

Working width mm 530

Squeegee width mm 730

Brush/pad diameter mm 530

Brush motor power Watt 450

Brush speed Rpm 160

Brush/pad pressure (Max) Kg

Drive motor power Watt 300W

Working speed Km/h 5.5km/h

Voltage V 24V

Battery Ah 2x100AH (20 hours)

Battery charger V/A 24V 10A

Battery compartment size (L x W x H) mm 350*380*300

USB charger specification V/A 5V, 0.8A

Page 10

USER MANUAL ENGLISH

7

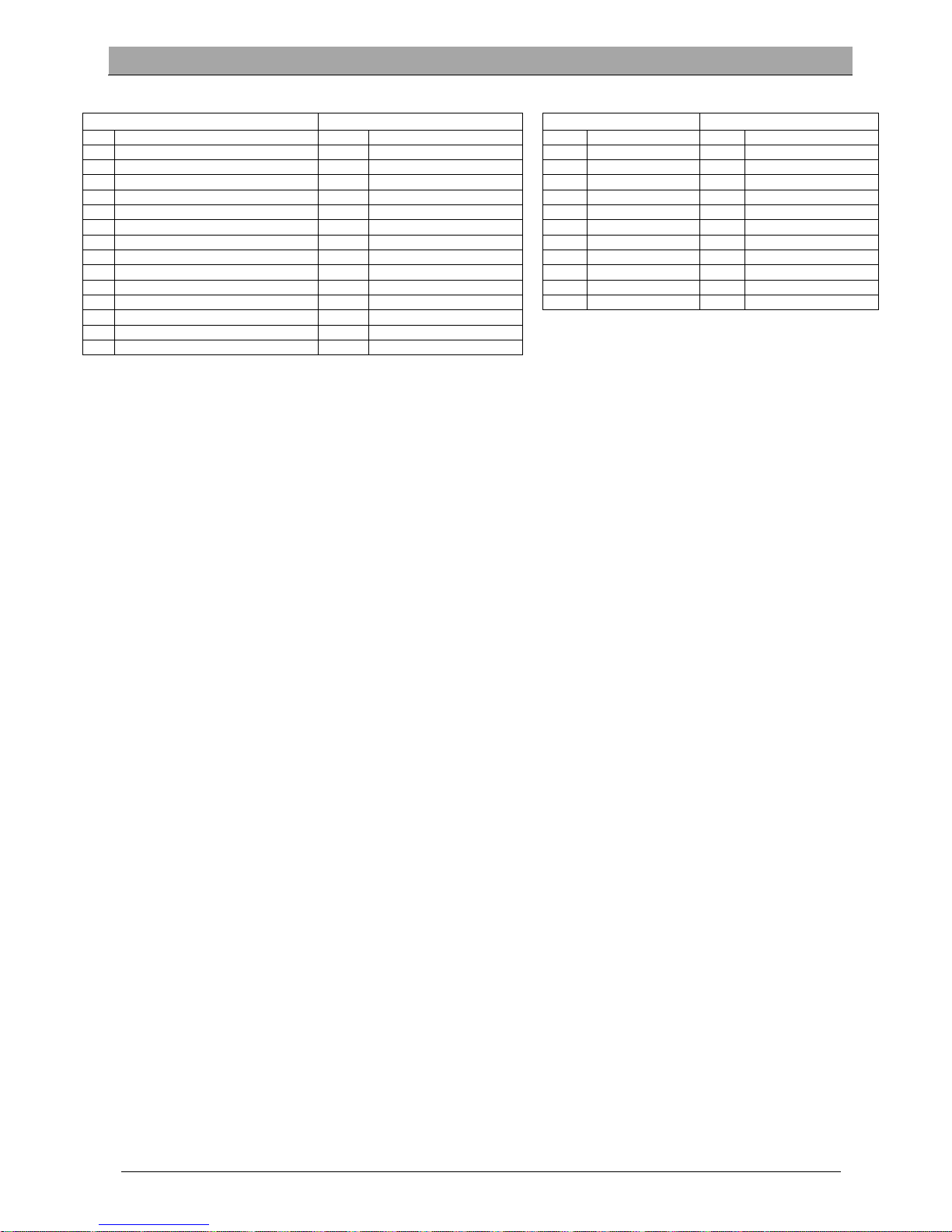

CIRCUIT DIAGRAM

C

U

RTIS 1212

M1

M1

B+

B-

2

4

3

1

J1

J2

SPK

BU2

BN2

6

2

7

384

9

5

10

1

EB1

5

1

6

2

7

3

8

4

1

2

J3

SW

1

AC

DC

+

_

NC

F

2

30A

R

L1

R

L2

YV

R

L3

SQ

+

_

7

6

5

4

3

2

1

14

13

12

11

10

2

1

8

9

M

EB2

VR

KA

J4

J5

M

M

F3

30A

F4

30A

BAT

24V

F1

5

A

F5 20A

W

H

1

WH1

WH1

RD2

RD2

RD2

RD3

RD1

BK1 BK3 BK2 BK3

RD4

RD/BK

RD/BK

RD/BK

RD3

RD4

BK5

BK5

YEYE YERD4

BN/BK

BU/BK

BN2

BK5

BK5

BK

5

OR

W

H2

BN1

BN1

BN1

YE

WH2

GN/BK

OR

SW7

RD4

SW6-A

YE

YE

PU

BK5

BK4

BU/BK

RD4

BN2

OR

GN

PU

GY

BN

1

BK4

SW2

M2

M1

M3

BK5

BK5

SW

3

SW

4

SW

6-

B

RL3

RL2

RL1

OR

GY

CH

RD4

100K

3

SW

5

BU

1

RD4

EB3

BK5

RD4

BK5

1

+

PU

WI

R

E ROD

RD1

RD2

RD3

BK1

BK2

RED/6AWG

RED/10AWG

RED/18AWG

BLACK/6AWG

BLACK/10AWG

RD/BK RED/BLACK / 20AWG

BN1 BROWN/14AWG

BN2 BROWN/20AWG

BK4 BLACK/14AWG

BK5

BLAC

K/18

AWG

BK3

BLAC

K/12

AWG

SW2

SW3

SW1

M1

M2

M3

BR

USH MOTOR

VACUUM MOTOR

DRIVE MOTOR

CLEAN WATER LEVEL SWITCH

VACUUM MOTOR SWITCH

KEY SWITCH

COMPONENTS

VR SPEED POTENTIOMETER

F

OO

T THROTTLE

SQ

EMERGENCY-STOP SWITCH

SW4

SW5 OPT

ION

AL MODE SWITCH

OPTIONAL REVERSE SWITCH SW6-B

OPT

ION

AL REVERSE SWITCH SW6-A

SPK 12VDC BUZZER

KA BR

A

KE

SW7

SEAT

S

WITCH

BA

T

C

H

EB1

EB3

F1

F2

F3

RL1

RL2

24V BAT

T

ERIES

BATTERY CHARGER

CONTROL PANEL BOARD

BRUSH MOTOR CIRCUIT BREAKER

VACUUM MOTOR CIRCUIT BREAKER

BRUSH MOEOR ELECTROM SWITCH

DRIVE ELECTRONIC BOARD

VACUUM MOEOR ELECTROM SWITCH

DRIVE SYSTEM CIRCUIT BREAKER F4

YV WATER ELECTROVALVE

CONTROL PANEL BOARD FUSE

COMPONENTS

R

L

3

DRIVE SYSTEM ELECTROM SWITCH

EB2

U

SB CHARGING ELECTRONIC BOARD

BR

U

SH RELEASE FUSE

F5

WI

R

E ROD

GN GREEN/20AWG

GN/BK

GREEN/BLACK /20AWG

BN/BK BROWN/BLACK / 20AWG

BU/BK BLUE/BLACK / 20AWG

PU PURPLE/20AWG

OR ORANGE/20AWG

YE YELLOW/20AWG

WH1

WHITE/12AWG

WH

2

WHITE/20AWG

BU1 BLUE/18AWG

GY

GR

AY/20

AWG

R

D

4 RED/20AWG

BU2

BLUE/20AWG

Page 11

USER MANUAL ENGLISH

8

COMPONENTS COMPONENTS WIRE ROD WIRE ROD

BAT 24V BATTERIES M1 BRUSH MOTOR RD1 RED/6AWG BN/BK BROWN/BLACK / 20AWG

CH BATTERY CHARGER M2 VACUUM MOTOR RD2 RED/10AWG BU1 BLUE/18AWG

EB1 CONTROL PANEL BOARD M3 DRIVE MOTOR RD3 RED/18AWG BU2 BLUE/20AWG

EB2 USB CHARGING ELECTRONIC BOARD SW1 EMERGENCY-STOP SWITCH RD4 RED/20AWG BU/BK BLUE/BLACK/20 AWG

EB3 DRIVE ELECTRONIC BOARD SW2 KEY SWITCH RD/BK RED/BLACK/20AWG GN GREEN/20AWG

RL1 BRUSH MOEOR ELECTROM SWITCH SW3 CLEAN WATER LEVEL SWITCH BK1 BLACK/6AWG GN/BK GREEN/BLACK / 20AWG

RL2 VACUUM MOEOR ELECTROM SWITCH SW4 VACUUM MOTOR SWITCH BK2 BLACK/10AWG GY GRAY/20AWG

RL3 DRIVE SYSTEM ELECTROM SWITCH SW5 OPTIONAL MODE SWITCH BK3 BLACK/12AWG PU PURPLE/20AWG

YV WATER ELECTROVALVE SW6-A OPTIONAL REVERSE SWITCH BK4 BLACK/14AWG OR ORANGE/20AWG

F1 CONTROL PANEL BOARD FUSE SW6-B OPTIONAL REVERSE SWITCH BK5 BLACK/18AWG YE YELLOW/20AWG

F2 BRUSH MOTOR CIRCUIT BREAKER SW7 SEAT SWITCH BN1 BROWN/14AWG WH1 WHITE/12 AWG

F3 VACUUM MOTOR CIRCUIT BREAKER SQ FOOT THROTTLE BN2 BROWN/20AWG WH2 WHITE/20AWG

F4 DRIVE SYSTEM CIRCUIT BREAKER SPK 12VDC BUZZER

F5 BRUSH RELEASE FUSE VR SPEED POTENTIOMETER

KA BRAKE

Page 12

USER MANUAL ENGLISH

9

Figure 3

OPERATING GUIDE

WARNING!

Pay high attention to these symbols in this manual:

– DANGER!

– WARING!

– CAUTION!

– CONSULTATION

Never cover these symbols on the machine for any reason, replace it immediately if any damage.

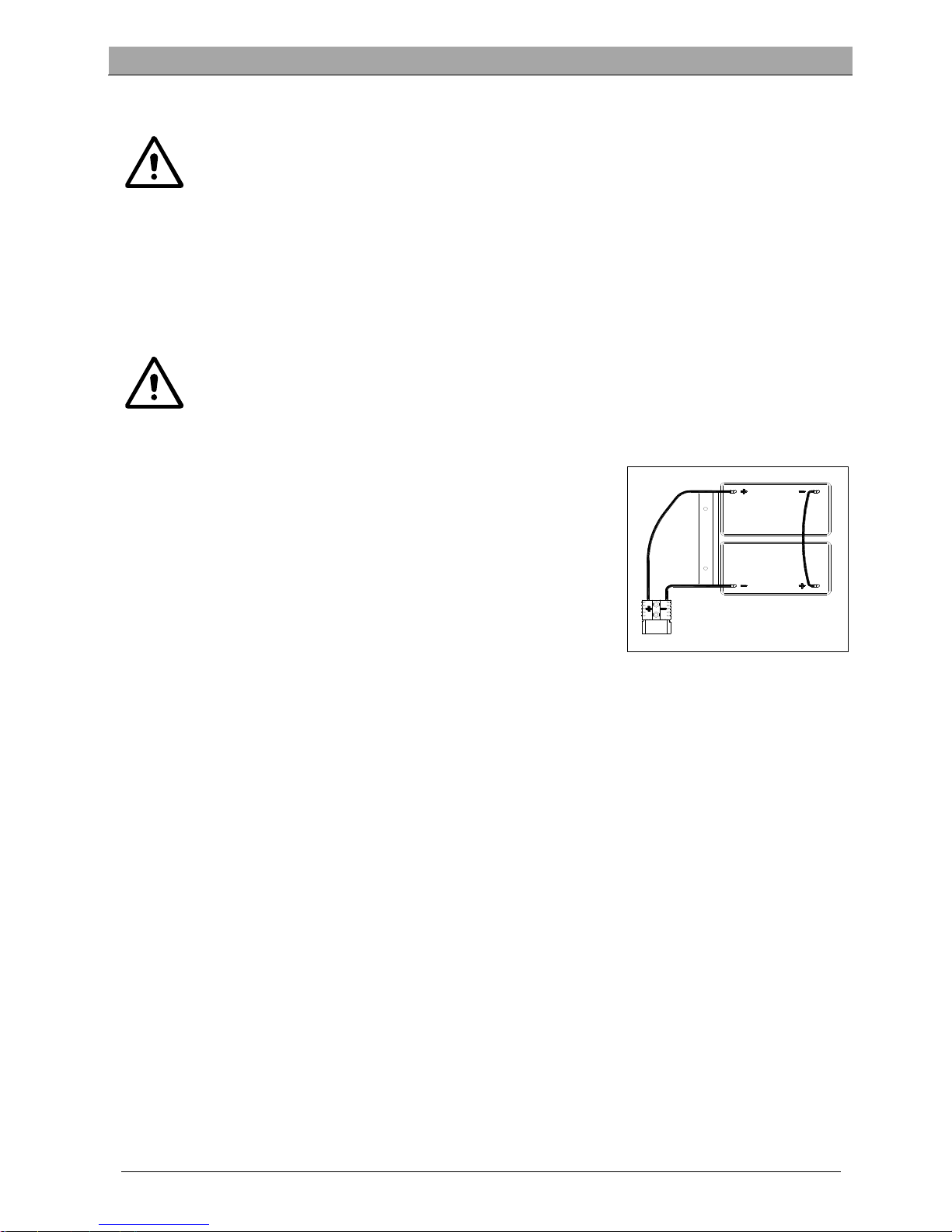

INSTALLING AND SETTING OF NEW MACHINE BATTERY

WARNING!

The electric components of the machine can be seriously damaged if the batteries are either improperly

installed or connected.

The batteries must be installed by qualified personnel. Set the battery charger (optional) and machine PCBA

according to the battery type (WET or GEL/AGM).

Check the batteries whether it is damaged before installation.

Disconnect the battery connector and the battery charger plug.

Handle the batteries with great care.

NOTE

The machine requires two 12V batteries, connecting according

to Figure 3.

The machine can be operated in one of following battery modes:

A) WET or GEL/AGM batteries are already installed and ready to

be used

1. Check the batteries and connect the battery connector to the machine.

2. Insert the key switch (40) and turn to “on”. If the green light (48) turns on, batteries are full charged for use; If the

yellow or red light (47 or 48) turns it on, the batteries must be charged.

B) Without Batteries

1. If your machine isn’t equipped with batteries, buy appropriate batteries *See the Technical Data Paragraph+. For

battery choice and installation, turn to qualified battery Retailers.

2. When batteries are ready, set the machine and the battery charger according to the type of installed batteries,

then follow the procedures shown in the next paragraph.

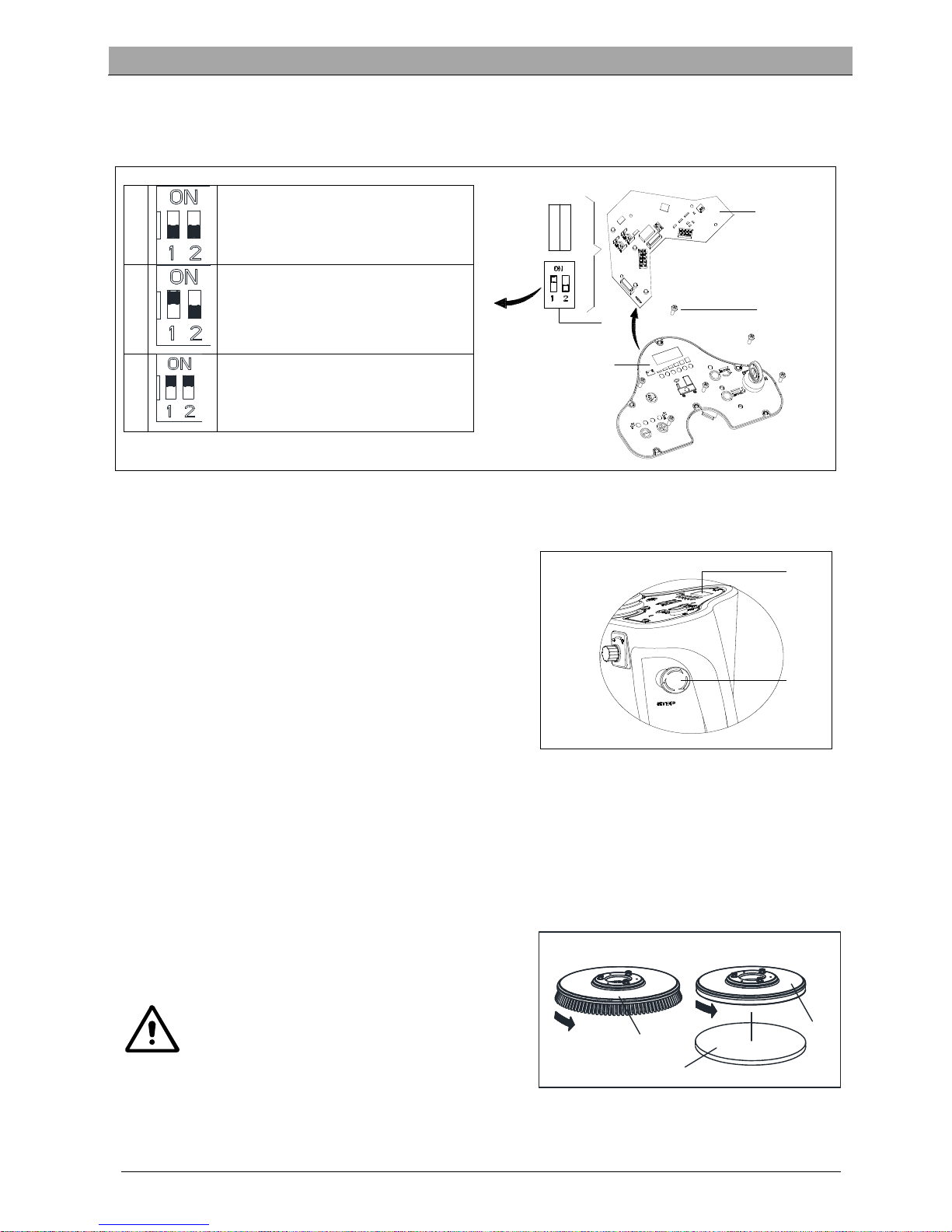

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL/ AGM)

Set the electronic circuit board of the machine and battery charger according to battery types (WET or GEL/AGM)

following steps below:

NOTE

When install new batteries, follow Figure 4 to set DIP switch, or batteries may be damaged by wrong

setting.

Machine setting

1. Insert key switch (40) and turn to “ON”, pay attention to below during the first seconds of machine start:

If the green light (37) flash, machine is set up to use GEL/AGM batteries.

If the yellow light (33) flash, machine is set up to use Discover EV AGM batteries.

If the red light (32) flash, machine is set up to use WET batteries.

2. Follow below steps to change the machine settings.

3. The factory setting of the machine is to use Discover EV AGM batteries. If the setting corresponds to selected

batteries, go to step 6 directly, or follow the next step.

Page 13

USER MANUAL ENGLISH

10

A

B

Figure 5

A

C

B

Figure 6

4. Unscrew the screw (B, Figure 4) on control panel, then turn over the PCBA (A) on the panel to find DIP switch (D),

follow Figure 4 for DIP settings.

5. Perform steps in reserve order of disassembly to fix control panel and lock the screw after setting is done.

1

WET BATTERIES

(NOTE: Turn pin1 and pin2 of DIP switch

to “OFF”)

2

DISCOVER EV AGM BATTERIES

(NOTE: Turn pin 1 of DIP switch to “ON”,

pin2 to “OFF”)

3

GENERAL GEL/AFM BATTERIES

(NOTE: Turn pin1 and pin2 of DIP switch

to “ON”)

Battery Installation

6. Open the recovery tank cover (4) and check the recovery tank (3) is empty, otherwise, empty it with the drain hose

(15).

7. Close the recovery tank cover (4).

8. Overturn the recovery tank (3) carefully.

9. The machine is supplied with cables suitable to install 2X12V

batteries. Carefully put the batteries into the compartment,

then install them correctly.

10. Route and install the battery cable as shown in (Figure 3),

then carefully tighten the nut on each battery terminal.

11. Place the protection cap on each terminal, then connect the

battery connector.

12. Carefully lower the recovery tank (3).

Charging the Batteries

13. Charging the batteries. [Refer to MAINTENANCE chapters].

EMERGENCY BRAKING

If there is any emergency during machine operating, press the emergency switch (A, Figure 5), then all functions of

machine will stop, there is no display on control panel (B, Figure 5)

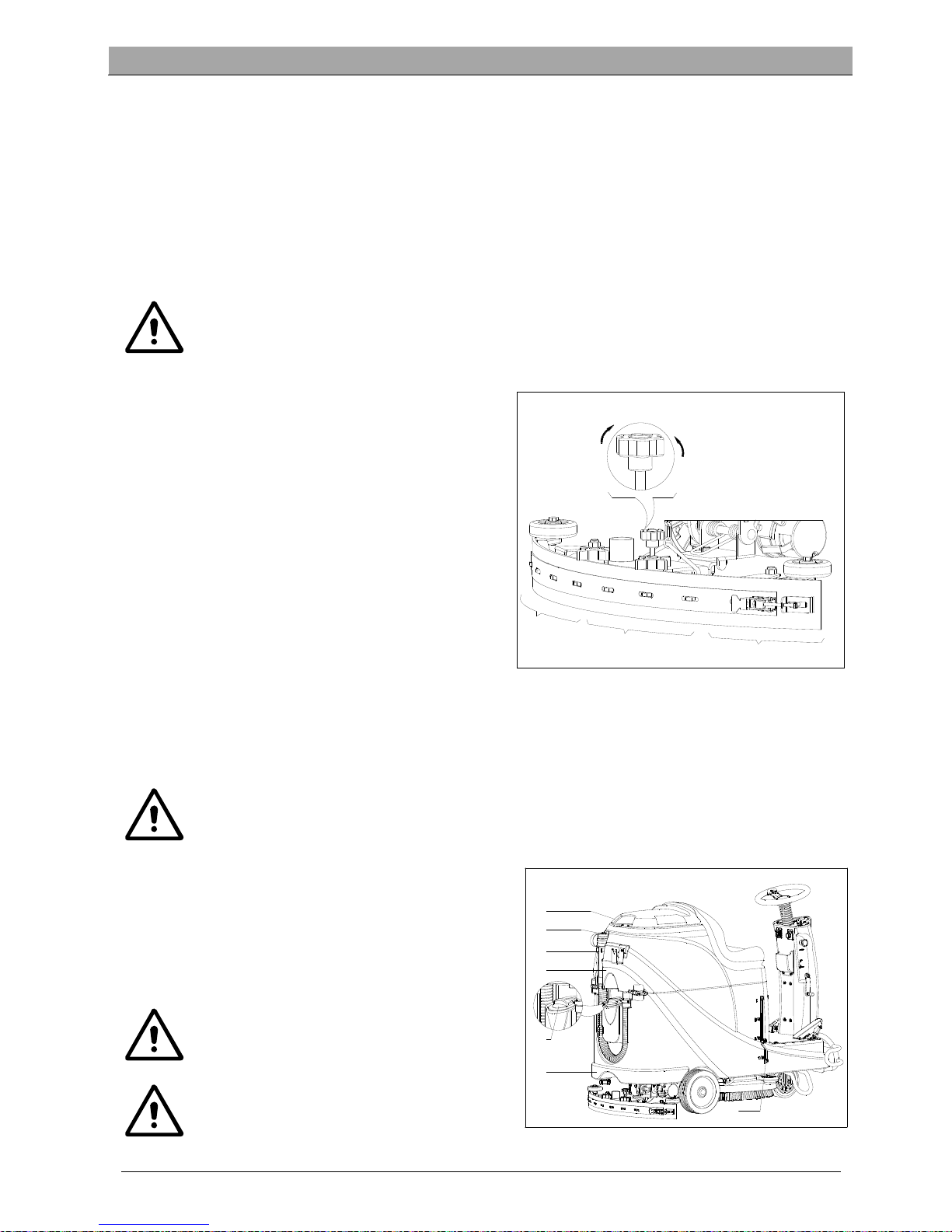

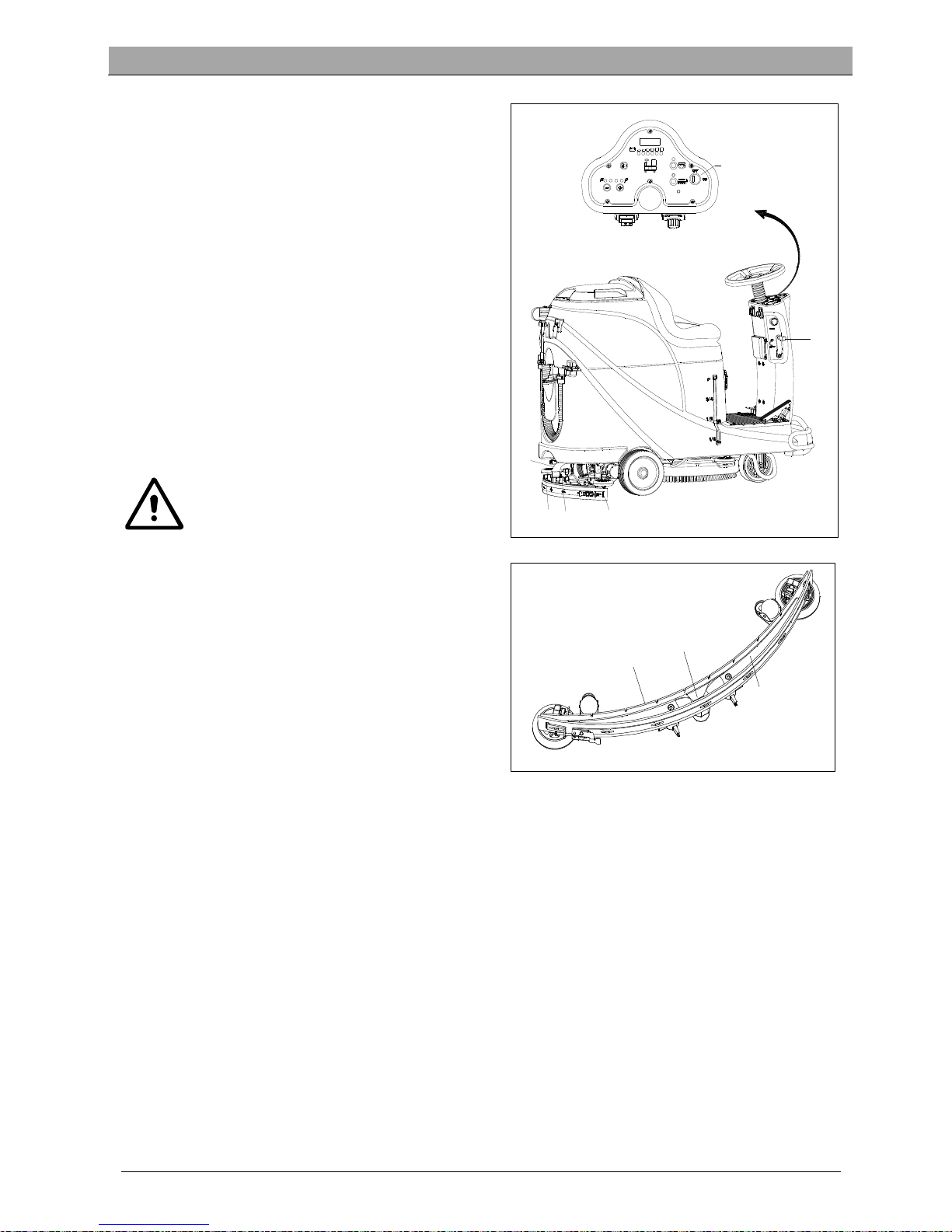

BRUSH/PAD INSTALLATION AND UNINSTALLATION

NOTE

Install suitable brush (A, Figure 6) or Pad (B and

C, Figure 6) according to the type of floor to be

cleaned.

CAUTION

Before installation or uninstallation of brush or

pad, make sure all the switches on machine are

in off position and lifting up the squeegee from

the floor. The operator must be equipped with

suitable personnel protection devices such as

gloves to reduce the risk of accidents. Proceed as

following:

OTHE

R

GEL/A

GM

DIS-EV

WET

D

A

B

C

Figure 4

Page 14

USER MANUAL ENGLISH

11

E

F

C

B

D

A

Figure 7

1. Insert key switch (40) and turn to “ON”.

2. Press the pedal (6) forward by foot to lift brush assembly (11) from the floor.

3. Rotate speed adjusting knob (42) in counterclockwise until to the end.

4. Place the brush (A, Figure 5) or pad (B, Figure 5) center align with brush deck.

5. Press the pedal (6) backward by foot to lower down brush assembly (11). Sit on the seat, press the brush button (39)

and depress the pedal (23) slightly, the brush/pad can be assembled automatically. Repeat these steps until

brush/pad is installed.

6. If step5 install the brush/pad but not successfully, please manually take the brush/pad down.

7. Depress the pedal (6) forward by foot to lift the brush assembly (11) from floor, press brush remove button (41) to

uninstall it automatically.

CAUTION!

Rotate the speed adjusting knob (42) to the minimum speed before depressing accelerate pedal (6) to

avoid the machine running too quickly when it is started. Make sure the brush/pad is installed correctly

before machine operating.

ADJUSTING THE BALANCE OF SQUEEGEE

1. Install the squeegee (13) and fasten the squeegee knob

(20), then connect the vacuum hose (19) to the squeegee.

2. Adjust the squeegee by squeegee adjusting handle (A,

Figure 7).

a) If there is gap between the ground and middle section

of rear squeegee blade (B), adjust the knob (A) in

counterclockwise direction (F) until all section of rear

squeegee blade good contact with ground, the front

blade touch the ground slightly.

b) If there is gap between the ground and both end

section of rear blade(C and D), adjust the knob (A) in

clockwise direction (E) until all section of rear blade

good contact with the ground, the front blade touch

the ground slightly.

SOLUTION TANK FILLING

1. Open the water inlet cover (E, Figure 8).

2. Filling water or solution suitable for work performance through the water inlet with filter. The solution

temperature must not exceed +104F (+40°C).

3. Don’t overfill the tank, refer to water level indicator (G) for the water volume.

WARNING!

Use only low-foam and non-flammable detergents intended for automatic scrubber applications.

Drive motor inspection

1. Turn the key switch (A, Figure 9) to “ON”

2. Depress the accelerate pedal (C) slightly then loosen it to

check if the machine can be steered forward and stopped.

3. To ensure the security, confirm if the machine can be

stopped immediately by pressing the emergency button (B).

Rotate the emergency button to reset it.

CAUTION

Climbing capacity of the machine must not

exceed 10%.

CAUTION

The brake of drive motor is unstuck when the

motor works normally, it locks when the motor

stops working.

F

E

D

C

B

A

G

Figure 8

Page 15

USER MANUAL ENGLISH

12

B

C

D

A

Figure 9

A

C

E

D

B

F

G

H

I

L

M

N

O

P

Q

R

ST

U

Figure 10

Brake unstuck -the brake handle(D, Figure 9) locates above

Brake locked –the brake handle locates lower

In some special cases, such as machine packing/unpacking,

machine fault etc., need to move the machine without drive

motor working, please manually set the brake to unstuck

status to move it.

To avoid any security risk, ensure to set the brake back to

locked status after machine movement.

MACHINE START AND STOP

Starting the machine

1. Prepare the machine as shown in previous paragraph.

2. Sit on the seat (L, Figure 10), insert the key switch (A) and turn

it to “ON”. If the green light (C) is on, the batteries are fully

charged for use. If the yellow light (E) or red light (D) is on,

batteries must be charged before operation. [Refer to

MENTAINENCE chapters for batteries charging]

3. Lower the squeegee assembly to the floor.

NOTE

Make sure the squeegee assembly is lifted before

the machine steer backward, or the Machine will

be stopped and LED screen show “Error”

information.

4. Lower the brush assembly to the floor.

NOTE

Make sure to turn off brush button before brush

assembly is lifted, and lift the brush assembly

before machine steers forward/backward.

5. Press brush button (B)

6. Depress the accelerate pedal (R), operate the machine

forward or backward by steering wheel (N) together with

forward-backward switch (H), you can adjust speed by speed

adjusting knob (I).

7. Adjust solution flow by solution adjusting button (G) base on

cleaning requirement.

8. You can charge your phone or pad through USB charging

port (M) when the key switch (A) is turned to “ON”.

9. Press the horn button (F) to warn people when necessary.

10. If necessary, press the emergency button for machine

emergency stop.

NOTE

The brush motor, vacuum motor, drive motor and

control circuit are protected by overload protector (P).When the overload protector trip, do not

reset it immediately without finding out the root

cause, and make sure the motor is cooling-off

before reset.

Stopping the machine

11. Loosen the accelerate pedal (R, Figure 10), the machine stops running.

12. Press brush button (B) to stop brush motor.

13. Lift brush assembly (T) by depressing the pedal (Q).

14. Lift squeegee assembly (U) by squeegee lifting/lowering lever (O), and a few seconds later the vacuum system will

be closed.

Page 16

USER MANUAL ENGLISH

13

A

D

B

C

Figure 12

15. Turn the key switch to “OFF”

16. Ensure the machine is stopped.

MACHINE OPERATION (SCRUBBING AND DRYING)

1. Start the machine according to procedures in previous paragraphs.

2. Start cleaning by following procedures in section of “Starting the machine”.

3. If necessary, stop the machine to adjust squeegee according to section “Adjusting the balance of squeegee”.

CAUTION!

To avoid any damage to the floor surface, turn off the brush/pad-holder when the machine stop in one

place.

NOTE

For correct scrubbing/drying of floors at the sides of walls, we suggest to go near the walls with right

side (Bumper wheel side) of the machine as shown in below Figure 11.

Battery charging during the work

When there is green light (A, Figure 12) on, the batteries have

enough power for the machine to work normally; when all the

green lights off, the yellow light (C, Figure 12) is on, the power

of batteries are too low, please charge the batteries; when the

red light (B, Figure 12) flashes, the batteries has run out, the

vacuum motor and brush motor will be turned off

automatically a few seconds delay, please drive the machine

for batteries charging immediately.

CAUTION!

To avoid damaging the batteries and

shortening their working life, do not use the

machine once the batteries are flat.

Figure 11

Page 17

USER MANUAL ENGLISH

14

A

B

C

D

E

F

G

H

Figure 13

A

B

Figure 14

A

D

C

B

Figure 15

TANK EMPTYING

An automatic float shut-off system (B, Figure 13) blocks the vacuum system when the recovery water tank (C) is full. The

vacuum system deactivation is signaled by a sudden increase in the vacuum system motor noise frequency, also the

floor has not dried.

CAUTION!

If the vacuum system turns off accidentally, (For

example, when the float is activated because of a

sudden machine movement), to resume the

operation: turnoff the vacuum system by pressing

the switch (D, Figure 12), then open the cover (A,

Figure 11) and check that the float inside the grid

(B) has gone down to the water level. Then close

the cover (A) and turn on the vacuum system by

pressing the switch (D, Figure 12).

When the recovery water tank (C, Figure 13) is full, empty it

according to the following procedure.

Recovery water tank emptying

1. Stop the machine.

2. Lift the brush/pad deck (H, Figure 12) by pressing the pedal (G).

3. Lift the squeegee with the lever (H).

4. Drive the machine to the appointed disposal area.

5. Empty the recovery tank with the drain hose (D). Then rinse the

tank with clean water.

CAUTION!

When draining the wastewater, the drain hose

must be folded (A, Figure 14) and put to a low

position (B, Figure 14) before opening the drain

hose cover. Do not make the outlet of the drain

hose upward to drain the water vertically in order

to avoid wastewater spilling onto the operator.

Solution/clean water tank emptying

6. Perform steps 1 to 4 in chapter “Recovery water tank emptying”.

7. Empty the solution tank through the outlet cover (A, Figure

15). And then, rinse the tank with clean water.

AFTER USING THE MACHINE

After working, before leaving the machine:

1. Remove the brushes/pad-holder.

2. Empty the tanks (B and C, Figure 15) as shown in previous

paragraph.

3. Perform the daily maintenance procedures (see the

Maintenance chapter).

4. Store the machine in a clean and dry place, with the

brushes / pad-holders and the squeegee lifted or removed.

MACHINE LONG INACTIVITY

If the machine is not going to be used for more than 30 days,

proceed as follows:

1. Perform the procedures shown in “AFTER USING THE

MACHINE” paragraph.

2. Disconnect the battery connector (D, Figure 15).

Page 18

USER MANUAL ENGLISH

15

USING FOR THE FIRST TIME

After nine hours using of the machine for the first time, please check if any damage or abnormal situation, check

whether the fasteners or fittings is loose.

MAINTENANCE

WARNING!

Maintenance procedures must be performed after the machine is turned off and the battery charger

cable is disconnected. In addition, carefully read the safety chapters in the manual.

All scheduled or extraordinary maintenance procedures must be performed by qualified personnel or an authorized

Service Center. This guide only describes the general and common maintenance procedures.

For other maintenance procedures that are in below maintenance schedule table, please refer to the Service Manual

that can be consulted at any Service Center.

SCHEDULED MAINTENANCE TABLE

CAUTION!

The procedure marked with (1) must be performed when the machine is used after 9 hours for the first

time.

The procedure marked with (2) must be done by Service Center that qualified by our company.

Procedure Daily, after

each use

Weekly semiannually Yearly

Battery charging

Squeegee cleaning

Brush/Pad-holder cleaning

Tank cleaning

Tank sealing strip inspection

Float ball filter cleaning

Squeegee blade check and replacement

Cleaning water filter cleaning

Suction filter cleaning

WET battery fluid level check

Screw and nut tightness inspection

(1)

Brush/Pad-holder carbon brush check or replacement

(2)

Suction motor carbon brush check or replacement

(2)

Drive system motor carbon brush check or

replacement (only for machine with traction)

(2)

Add lubricating oil for rotating parts

(1)

BATTERY CHARGING

NOTE

Please charge the batteries when the yellow LED (32) or red LED (33) is on, or at the end of each working

cycle.

CAUTION

Always keep the battery in a full charged state can extend its lifetime.

CAUTION

Please charge the battery as soon as possible if the battery level is low. Otherwise, the lifespan of

battery can be reduced. It is better to check the battery at least once a week.

Page 19

USER MANUAL ENGLISH

16

CAUTION!

To be especial careful when battery is

charging, because there may be leaked

acid in the process of charging.

Battery acid is corrosive, if it accidentally

comes into contact with the skin or eyes,

rinse immediately with plenty of clean

water and go to see a doctor.

The preparation steps to charge the

batteries

1. Open the recovery tank cover (B, Figure 16) to check if

the recovery tank (C) is empty, or empty the recovery

tank through the drain hose (A).

2. Drive the machine to designated charging area.

3. Turn the key switch to “OFF”.

4. This step only for WET batteries:

Clean the battery surface if necessary.

Check the battery electrolyte level of the

batteries (D), if necessary, open the cover to full

fill electrolyte, and then recover it.

Keep the cover opened during charging.

5. Select one of below charging mode base on the

selected charger type.

Use on-board charger for battery charging

6. Connect the battery charger cable (A, Figure 17) to the

electric mains (G), and then all machine functions

except charging are cut off automatically.

The normally on red LED (B) states that the machine is

in process of charging.

7. The batteries are fully charged when the green LED (C)

becomes on.

8. Disconnect battery charge cable from electric mains after charging is completed, and then store the battery charger

cable in the storage box (D).

NOTE

For further information about on-board charger (E, Figure 17), please refer to relevant manual from

service center.

BRUSH/PAD CLEANING

CAUTION!

It is recommended to wear gloves when

cleaning the brush/pad-holder, since it may

contain sharp fragments.

1. Take the brush/pad-holder off base on procedures in

previous sections.

2. Clean the brush/pad-holder using water and detergent.

3. Check the integrity and abrasion conditions of the bristle

on the brush, if necessary, replace the brush.

4. Check the abrasion condition of the polishing pad, if

necessary, replace it.

D

A

B

C

E

Figure 16

B

A

C

D

Figure 18

Figure 17

E

C

G

A

B

D

Page 20

USER MANUAL ENGLISH

17

B

C

A

Figure 20

SOLUTION FILTER CLEANING

1. Drive the machine to the flat ground.

2. Make sure the machine is off.

3. Empty the solution tank (optional step).

4. Take down the solution filter cover (A, Figure 18) to

clean the filter screen (B), and them fix them back to the

filter support (D).

NOTE

The filter screen (B) must be correctly

positioned to the housing of filter support

(D).

SQUEEGEE CLEANING

NOTE

The squeegee must be clean and its blades

must be in good conditions in order to get

good drying.

CAUTION

It is advisable to wear protective gloves

when cleaning the squeegee because there

may be sharp debris.

1. Drive the machine on a level floor.

2. Turn the key switch (A, Figure 19) to “OFF”.

3. Lower the squeegee (B) with the lever (C).

4. Loosen the knobs (D) and remove the squeegee.

5. Disconnect the vacuum hose (E) from the squeegee.

6. Clean the steel or aluminum squeegee, especially the

compartments (A, Figure 20) and the holes (B). Check

the integrity, cuts and tears of the front blade (B) and

rear blade (C), if necessary, replace them according to

procedures in the following paragraph.

7. Assemble the squeegee in the reverse order of

disassembly.

SQUEEGEE BLADE CHECK AND REPLACEMENT

1. Clean the steel or the aluminum squeegee, as shown in the previous paragraph.

2. Check that the edges (E, Figure 21) of the front blade (C) and the edges (F) of the rear blade (D) lay down on the

same level, along their length; if necessary adjust their height according to the following procedure:

Remove the tie rod (G), disengage the fasteners (M) and adjust the rear blade (D), then engage the fasteners (M)

and install the tie rod (G).

Loosen the knobs (I) and adjust the front blade (C), then tighten the knobs.

3. Check the front blade (C) and rear blade (D) for wear, cuts and tears; if necessary replace them according to the

following procedure. Check that the front corner (J) of the rear blade (D) is not worn; if necessary overturn the

blade to replace the worn corner with an integral one. If the other corners are worn too, replace the blade

according to the following procedure:

Remove the tie rod (G), disengage the fastener (M) and remove the retaining strip (K), then replace/overturn the

rear blade (D). Assemble the blade in the reverse order of disassembly.

Unscrew the knobs (I) and remove the retaining strip (L), then replace front blade (C). Assemble the blade in the

reserve order of disassembly. After the blade replacement (or overturning), adjust the height as shown in the

previous step.

4. Connect the vacuum hose (A, Figure 22) to the squeegee.

5. Install the squeegee (B) and screw down the knobs (C).

6. If necessary, adjust the squeegee balance adjusting knob (D).

A

B

C

D

E

D

Figure 19

Page 21

USER MANUAL ENGLISH

18

TANK AND VACUUM GRID WITH FLOAT CLEANING, AND COVER GASKET CHECK

1. Drive the machine on a level floor.

2. Ensure that the machine is off and the ignition key (40)

has been removed.

3. Turn the recovery tank lid (A, Figure 23) 90 degree

position where it can be took off from the tank, and then

take down the float ball filter (P) from the tank.

4. Clean the recovery tank lid (A), recovery tank (B), clean

water tank (C) and the float ball filter support frame (E).

Empty the recovery tank with the drain hose (15).

5. If necessary, follow the symbols “OPEN” and “CLOSE” as

shown in Figure 23 to open the bottom cover (F) of float

ball filter and then clean the float ball (D), filter support

frame (E) and filter sponge (I). After cleaning, fix the float

ball (D) into the filter support frame (E) and then align

the mark groove (L) of the bottom cap (F) of the float ball

filter with the mark groove (L) of the float filter support

frame (E). Screw the bottom cap of the float ball filter

tight, and fix the filter sponge (I) onto the float filter

support frame (E). Finally, connect it to the sewage

suction hose (M).

6. Inspect the integrity of the tank sealing strip.

NOTE

Tank sealing strip (G) makes to produce the vacuum inside the tank when suction motor works. The

tank must be sealed can effectively absorb the water from the ground to recovery tank.

7. Check whether the contact surface of sealing strip (G) is integrity and sealing is sufficient. If necessary, take the

sealing strip of the tank out of the groove (H) and replace it. Assembly the new sealing strip as shown in Figure 23,

the joint should be back in the middle area.

8. Close the recovery tank lid (A).

Figure 22

A

C

D

C

B

I

E

D

F

L

P

M

A

B

C

H

G

Figure 23

B

A

M

D

J

I

C

A

G

M

I

I

K

D

F

C

L

E

Figure 21

Page 22

USER MANUAL ENGLISH

19

A

B

C

D

E

F

G

Figure 24

FUSE CHECK/REPLACEMENT

1. Turn the key switch (D, Figure 24) to “OFF”.

2. Disconnect the battery connect cable.

3. Unscrew the screws (C) on the control panel and then turn over

the PCBA to find the fuse (A and B).

4. Check/replace the fuses:

A) F1 is the low-power circuit fuse (5A)

B) F3 is brush dismount fuse (20A)

5. After check/replacement is done, re-assemble in the reserve

order of dismount.

6. Check or reset the motor overload protector.

E) F5 is vacuum motor overload protector (30A)

F) F4 is drive motor overload protector (30A)

G) F2 is brush motor overload protector (30A)

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped

with the following accessories/options, according to the machine

specific use.

For further information concerning the above mentioned optional

accessories, contact an authorized retailer.

Accessories/Options

See “Parts List” section

1. GEL/AGM batteries

2. Pads of different materials

TROUBLE SHOOTING

Trouble Probable causes Remedy

The motors do not work; no warning

light turns on (C9)

The battery connector is disconnected Connect the battery connector

The batteries are completely discharged Charge the batteries

The machine do not work, red battery

capacity warning light turns on (C8)

The batteries level is too low Charge the batteries

The machine do not go-forward /

backward

The control circuit board fault Replace the control circuit board

The drive motor controller fault

Refer to “DRIVE MOTOR ERROR

INDICATOR INFORMATION”

The operator not on the seat Sit on the seat

Squeegee is not lifted during machine

goes backward

Lift the squeegee

The brush motor does not work

The control circuit board fault Replace the control circuit board

Brush motor overload

Use soft bristle brush that is

suitable for cleaning, and reset the

brush motor overload protector

Brush motor contactor fault Contact after-sales service

Brush motor carbon brush wearing Contact after-sales service

Obstacles prevent the brush rotating Clean the brush

The drive motor does not work

Drive motor trouble light turns on

Refer to “DRIVE MOTOR ERROR

INDICATOR INFORMATION”

Drive motor overload

Reset drive motor overload

protector and check drive

motor/circuit

The vacuum motor does not work

Vacuum motor overload

Reset vacuum motor overload

protector and check vacuum motor

Relay of vacuum motor fault Contact after-sales service

Page 23

USER MANUAL ENGLISH

20

Control board fault Replace the control board

Insufficient suction, the floor cannot be

dried

Recovery tank is full Empty the recovery tank

Drain hose and squeegee poor

connection

Connect the drain hose and

squeegee correctly

Float ball filter block

Clean the float ball filter and check

the float ball position status

Squeegee is dirty or wearing Check and clean the squeegee

The recovery tank cover is not closed

properly, or the gasket is damaged, or

the Bend tube is clogged

Close the cover correctly, or re-

place the gasket or clean the Bend

tube.

The Recovery tank is dirty Clean the recovery tank

Insufficient solution supply to brush

plate

The solution filter is dirty Clean the filter

The solution tank empty indicator is on Fill the solution tank

The solution tank is too dirty Clean the solution tank

Squeegee leaves scratch on the floor

There are debris under the squeegee

blade

Remove the debris

Squeegee blade wear, crack, aged Replace the squeegee blades

The squeegee balance is not adjusted Adjust the squeegee balance

Drive motor brake failure The brake is locked Set the brake unstuck

DRIVE MOTOR ERROR INDICATOR INFORMATION

LED CODES FAULT POSSIBLE CAUSE

1.1

¤¤

THERMAL FAULT

1. Temperature >80°C or < -10°C.

2. Excessive load on vehicle.

3. Operation in extreme environments.

4. Electromagnetic brake not releasing.

1.2

¤¤¤

THROTTLE FAULT

1. Throttle input wire open or shorted.

2. Throttle pot defective.

3. Wrong throttle type selected.

1.3

¤¤¤¤

SPEED POT FAULT

1. Speed limit pot wire(s) broken or shorted.

2. Broken speed limit pot.

1.4

¤¤¤¤¤

UNDERVOLTAGE FAULT

1. Battery voltage <17 volts.

2. Bad connection at battery or controller.

1.5

¤¤¤¤¤¤

OVERVOLTAGE FAULT

1. Battery voltage >31 volts.

2. Vehicle operating with charger attached.

3. Intermittent battery connection.

2.1

¤¤¤

MAIN OFF FAULT

1. Main contactor driver failed open.

2.3

¤¤¤¤¤ MAIN FAULT ❊

1. Main contactor welded or stuck open.

2. Main contactor driver fault.

2.4

¤¤¤¤¤¤

MAIN ON FAULT

1. Main contactor driver failed closed.

3.1

¤¤¤¤ WIRING FAULT ❊

1. Misadjusted throttle.

2. Broken throttle pot or throttle mechanism.

3.2

¤¤¤¤¤

BRAKE ON FAULT

1. Electromagnetic brake driver shorted.

2. Electromagnetic brake coil open.

3.3

¤¤¤¤¤¤ PRECHARGE FAULT ❊

1. Brake driver shorted.

2. Precharge circuit damaged.

3. MOSFET failure.

3.4

¤¤¤¤¤¤¤

BRAKE OFF FAULT

1. Electromagnetic brake driver open.

2. Electromagnetic brake coil shorted.

3.5

¤¤¤¤¤¤¤¤

HPD FAULT

1. Improper sequence of throttle and KSI, push,

or inhibit inputs.

2. Misadjusted throttle pot.

4.1

¤¤¤¤¤ CURRENT SENSE FAULT ❊

1. Short in motor or in motor wiring.

2. Controller failure.

4.2

¤¤¤¤¤¤ HARDWARE FAILSAFE ❊

1. Motor voltage does not correspond to throttle

request.

2. Short in motor or in motor wiring.

3. Controller failure.

Page 24

USER MANUAL ENGLISH

21

4.3

¤¤¤¤¤¤¤ EEPROM CHECKSUM FAULT †

1. EEPROM failure or fault.

4.5

¤¤¤¤¤¤¤¤¤ BATTERY DISCONNECT FAULT ❊

1. Battery not connected.

2. Poor connection to battery terminals.

❊= Must cycle keys witch to clear.

† = Must use programmer to clear, as follows: select Program menu, alter data value of any parameter, cycle keys

witch.

NOTE

The machine which is equipped with on-board charger will not be operated when the on-board charger

malfunction, please contact our qualitied maintenance center for help.

SCRAPPING

Scrap the machine by the qualified waste treatment institution.

Before the machine is scrapped, please take away and segregate below subassembly that relevant laws and regulations

request must be disposed in appropriate way.

– Battery

– Brush/Pad-holder

– Plastic hose and plastic parts

– Electrical and electronic components (*)

(*) Please contact our service center to destroy any of electrical and electronic components.

Page 25

MANUEL UTILISATEUR FRANÇAIS

TABLE DES MATIÈRES

INTRODUCTION .......................................................................................................................... 22

CONTENU DU MANUEL ET BUT ........................................................................................................................................... 22

COMMENT GARDER CE MANUEL ........................................................................................................................................ 22

DÉCLARATION DE CONFORMITÉ .......................................................................................................................................... 22

ACCESSOIRES ET ENTRETIEN ................................................................................................................................................ 22

CHANGEMENT ET AMÉLIORATION ...................................................................................................................................... 22

CHAMP D'APPLICATION ....................................................................................................................................................... 22

DONNÉES D'IDENTIFICATION DE LA MACHINE .................................................................................................................... 22

TRANSPORT ET DÉBALLAGE ................................................................................................................................................. 22

SÉCURITÉ ................................................................................................................................... 23

SYMBOLES QUI APPARAISSENT SUR LE MANUEL D'UTILISATION ........................................................................................ 23

CONSIGNES GÉNÉRALES DE SÉCURITÉ ................................................................................................................................. 23

DESCRIPTION DE LA MACHINE .................................................................................................... 25

STRUCTURE DE LA MACHINE ............................................................................................................................................... 25

PANNEAU DE COMMANDE .................................................................................................................................................. 26

INFORMATIONS D'AFFICHAGE ÉCRAN LED .......................................................................................................................... 26

FENÊTRE D'AFFICHAGE DU VOYANT DU CHARGEUR ........................................................................................................... 26

PARAMÈTRES TECHNIQUES ................................................................................................................................................. 27

SCHÉMA DU CIRCUIT ........................................................................................................................................................... 28

GUIDE D'UTILISATION ................................................................................................................. 30

INSTALLATION ET CONFIGURATION D'UNE NOUVELLE BATTERIE ....................................................................................... 30

INSTALLATION DES BATTERIES ET RÉGLAGE DU TYPE DE BATTERIE (AVEC ENTRETIEN OU GEL/AGM) .............................. 30

FREINAGE D'URGENCE ......................................................................................................................................................... 31

INSTALLATION ET DÉSINSTALLATION DE LA BROSSE / DU COUSSINET ............................................................................... 31

AJUSTEMENT DE L’ÉQUILIBRE DE L' EMBOUCHURE ............................................................................................................ 32

REMPLISSAGE DU RÉSERVOIR DE LA SOLUTION .................................................................................................................. 32

DÉMARRAGE ET ARRÊT DE LA MACHINE ............................................................................................................................. 33

FONCTIONNEMENT DE LA MACHINE (BROSSAGE ET SÉCHAGE) ......................................................................................... 34

VIDANGE DU RÉSERVOIR ..................................................................................................................................................... 35

APRÈS UTILISATION DE LA MACHINE ................................................................................................................................... 35

LONGUE INACTIVITÉ DE LA MACHINE ................................................................................................................................. 35

UTILISATION POUR LA PREMIÈRE FOIS ................................................................................................................................ 36

ENTRETIEN ................................................................................................................................. 36

CALENDRIER D'ENTRETIEN PROGRAMME ........................................................................................................................... 36

CHARGEMENT DE BATTERIE ................................................................................................................................................ 36

NETTOYAGE DE LA BROSSE/DU DISQUE .............................................................................................................................. 37

NETTOYAGE DU FILTRE DE SOLUTION ................................................................................................................................. 38

NETTOYAGE DE L‘EMBOUCHURE ......................................................................................................................................... 38

VÉRIFICATION ET REMPLACEMENT DE LA LAMELLE DE L’EMBOUCHURE ........................................................................... 38

NETTOYAGE DU RÉSERVOIR ET DE LA GRILLE D'ASPIRATION AVEC LE FLOTTEUR, VÉRIFICATION DU JOINT DE COUVERCLE ...... 39

VÉRIFICATION / REMPLACEMENT DU FUSIBLE .................................................................................................................... 40

ACCESSOIRES/OPTIONS ....................................................................................................................................................... 40

DÉPANNAGE .............................................................................................................................. 40

RECYCLAGE ................................................................................................................................ 42

Page 26

MANUEL UTILISATEUR FRANÇAIS

22

INTRODUCTION

REMARQUE

Les chiffres entre parenthèses renvoient aux éléments présentés dans le chapitre Description de la

Machine.

CONTENU DU MANUEL ET BUT

Le but de ce Mode d'Emploi est de fournir à l'opérateur des informations nécessaires afin d'utiliser correctement la

machine et en toute sécurité. Il contient des informations sur des données techniques, la sécurité, l'exploitation, le

stockage, la maintenance, les pièces de rechange et comment mettre au rebut.

Avant d'effectuer toute opération sur la machine, peu importe les opérateurs et les techniciens qualifiés doivent lire

attentivement ce manuel. Contacter le centre d'entretien de notre société pour toute question concernant ce manuel

ou pour toute information complémentaire qui est nécessaire.

Les opérateurs ne doivent pas effectuer de procédures qui devraient être faites par des techniciens qualifiés. Notre

société ne sera pas responsable des dommages provenant du non-respect de cette interdiction.

COMMENT GARDER CE MANUEL

Le manuel doit être conservé près de la machine, dans une enveloppe spéciale, loin de liquides et d'autres substances

qui peuvent causer des dommages à celle-ci.

DÉCLARATION DE CONFORMITÉ

La déclaration de conformité est fournie avec la machine et en atteste la conformité aux lois en vigueur.

REMARQUE

Les copies de la déclaration originale de conformité sont fournies avec la documentation de la machine.

ACCESSOIRES ET ENTRETIEN

Toutes les opérations d'entretien et de réparation doivent être effectuées par un personnel qualifié ou par un service de

maintenance agréé. SEULS les pièces détachées et les accessoires autorisés doivent être utilisés.

Contacter notre service après-vente pour tout service ou achat d'accessoires ou pièces détachées si nécessaire.

CHANGEMENT ET AMÉLIORATION

Nous nous sommes engagés à une amélioration continue de nos produits. Notre, société se réserve le droit de modifier

et d'améliorer la machine sans vous en informer.

CHAMP D'APPLICATION

L'autolaveuse est à usage commercial et industriel. Elle est adaptée pour le nettoyage de sols lisses et durs. Pour plus de

sécurité, elle doit être utilisée par un personnel qualifié. Elle ne convient pas pour une utilisation en extérieur ou pour le

nettoyage de la moquette ou des sols rugueux.

DONNÉES D'IDENTIFICATION DE LA MACHINE

Le numéro de série et le nom du modèle de la machine sont indiqués sur l'étiquette.

Ces informations sont importantes. Utiliser le tableau suivant pour noter les données d'identification de la machine,

nécessaires lors de la commande de pièces de rechange.

MODÈLE DE LA MACHINE.........................................................................

NUMÉRO DE SÉRIE DE LA MACHINE.........................................................

TRANSPORT ET DÉBALLAGE

À la livraison s'assurer que l'emballage et la machine sont intacts et en bon état. En cas de dommage, porter à la

connaissance du transporteur les dommages et avant d'accepter les marchandises, effectuer des réserves.

Suivre attentivement les instructions sur l'emballage, lors du déballage de la machine.

Page 27

MANUEL UTILISATEUR FRANÇAIS

23

Vérifier l'emballage pour assurer que les éléments suivants sont inclus:

1. Documentations techniques, y compris manuel utilisateur et manuel du chargeur à bord s'il est équipé du chargeur

à bord.

2. Câble du chargeur, s'il est équipé du chargeur à bord.

SÉCURITÉ

Les symboles suivants indiquent les situations potentiellement dangereuses. Toujours lire attentivement ces

informations et prendre toutes les précautions nécessaires pour protéger les personnes et les biens.

SYMBOLES QUI APPARAISSENT SUR LE MANUEL D'UTILISATION

DANGER!

Cela indique une situation dangereuse avec risque de mort pour l'opérateur.

ATTENTION!

Cela indique un risque potentiel de blessure pour les personnes.

ATTENTION!

Cela indique un avertissement ou une remarque concernant des fonctions clés ou utiles.

Prêter attention aux paragraphes marqués par ce symbole.

REMARQUE

Cela indique une remarque sur des fonctions clés ou utiles.

CONSULTATION

Cela indique la nécessité de se référer aux instructions d'utilisation avant toute manipulation.

CONSIGNES GÉNÉRALES DE SÉCURITÉ

Les avertissements et les mises en garde spécifiques, pour informer des dommages potentiels aux personnes et à la

machine, sont indiqués ci-dessous.

DANGER!

Cette machine doit être utilisée par un personnel qualifié selon les conseils du manuel.

Avant d'effectuer toute opération de nettoyage, d'entretien, de réparation ou de remplacement, lire

attentivement toutes les instructions, s'assurer d'éteindre la machine et de débrancher le connecteur de la

batterie.

Ne pas faire fonctionner la machine à proximité de poudres, liquides ou vapeurs toxiques, dangereux,

inflammables et/ou explosifs. Cette machine ne convient pas pour la collecte des poudres dangereuses.

Ne pas porter de bijoux, lorsque vous travaillez à proximité de composants électriques.

Ne pas travailler sous la machine soulevée, sans la maintenir avec des sangles de sécurité.

Lors de l'utilisation de batteries au plomb (AVEC ENTRETIEN), elles peuvent émettre des gaz inflammables en

utilisation normale, vous devez éloigner les étincelles, les flammes, les substances fumigènes et les éléments

rayonnants, éclairants et brûlants des batteries.

Quand vous chargez les batteries au plomb (AVEC ENTRETIEN), elles peuvent émettre de l'hydrogène gazeux

ce qui peut provoquer des explosions. Assurez-vous que le local de charge soit bien aéré et éloigné des

flammes nues.

ATTENTION!

Page 28

MANUEL UTILISATEUR FRANÇAIS

24

Inspecter attentivement la machine avant chaque utilisation. Veiller à ce que tous les composants aient été

bien assemblés avant l'utilisation. À défaut cela peut causer des dommages aux personnes et aux biens.

Avant d'utiliser le chargeur de batterie, veiller à ce que les valeurs de fréquence et de tension indiquées sur

l'étiquette du numéro de série de la machine correspondent à celles du secteur.

Ne jamais déplacer la machine en tirant sur le câble du chargeur de batterie. Ne pas faire passer le câble sous

une porte fermée. Ne pas faire fonctionner la machine avec le câble du chargeur de batterie. Éloigner le

câble du chargeur de batterie des surfaces chauffées.

Ne pas charger les batteries si le câble de chargeur de batterie ou la fiche sont endommagés.

Pour réduire le risque d'incendie, de choc électrique ou de blessure, s'assurer que la machine est éteinte

avant de partir.

Utiliser ou stocker la machine en intérieur dans des conditions sèches, il est interdit de l'utiliser en extérieur.

La température de stockage et celle de travail doivent être comprise entre 0 ° C et +40 ° C, l'humidité de l'air

doit être comprise entre 30% et 95%.

Ne pas utiliser la machine sur des pentes avec une inclinaison dépassant ce qui est défini dans le cahier des

charges.

Lors de l'utilisation et de la manipulation de détergents de nettoyage de sols, suivre les instructions sur les

étiquettes des bouteilles de détergent et porter des gants et des protections appropriées.

Utiliser des brosses et des disques fournis avec la machine ou définis dans le manuel. L'utilisation d'autres

brosses ou de disques pourrait nuire à la sécurité.

En cas de dysfonctionnements de la machine, vérifier l'entretien de la machine. Si nécessaire, demander

l'assistance du personnel autorisé ou d'un centre de maintenance agréé.

Prendre toutes les précautions nécessaires pour empêcher les cheveux, les bijoux et les vêtements amples

d'être retenus par des pièces en mouvement de la machine.

Ne pas utiliser la machine dans des endroits particulièrement poussiéreux.

Ne pas laver la machine avec des jets d'eau directs ou sous pression, ou avec des substances corrosives.

Ne pas heurter des étagères ou des échafaudages, en particulier là où un risque de chute d'objets existe.

Ne pas incliner de récipients de liquide sur la machine, utiliser le porte gobelet.

Pour éviter d'endommager le sol, ne pas laisser la brosse/le disque fonctionner alors que la machine est à

l'arrêt.

En cas d'incendie, utiliser un extincteur à poudre. Ne pas utiliser les extincteurs liquides.

Ne pas enlever ou modifier les autocollants de la machine.

Suivre scrupuleusement les instructions d'entretien journalier.

Faire attention lors du transport de la machine, lorsque la température est basse. L'eau, dans le réservoir de

récupération et dans les tuyaux, pourrait geler et causer de sérieux dommages à la machine.

Si les pièces détachées doivent être remplacées, commander les pièces détachées D'ORIGINE auprès de

détaillants agréés.

Retourner la machine au centre d'entretien, si elle ne fonctionne pas comme d'habitude ou si elle est

endommagée.

Pour assurer un fonctionnement adéquat et sécurisé de la machine, l'entretien prévu indiqué dans le

chapitre de ce manuel, doit être effectué par le personnel autorisé ou un centre d'entretien autorisé.

La machine doit être correctement recyclée, en raison de la présence de matières toxiques (batteries, etc.),

qui sont soumises à des normes qui exigent l'élimination dans des centres spéciaux (voir le chapitre

Recyclage).

Cette machine est un outil de nettoyage, et ne doit pas être utilisée pour toute autre d'utilisation.

Toujours garder les ouvertures exemptes de poussière, de poils et de tout autre corps étranger qui pourrait

réduire le flux d'air. Ne pas utiliser la machine si les ouvertures sont bouchées.

Utiliser uniquement la machine lorsqu'un éclairage adéquat est fourni.

Cette machine n'est pas conçue pour être utilisée par des personnes physiquement ou intellectuellement

déficientes ou sans expérience ni connaissances, à moins qu'elles ne soient sous surveillance ou bien qu'elles

n’aient été informées quant à l'utilisation de l'appareil de manière sécurisée, par une personne responsable

de leur sécurité.

Une attention particulière est nécessaire lorsqu'elle est utilisée à proximité des enfants.

Les enfants doivent rester sous surveillance afin de s'assurer qu'ils ne jouent pas avec la machine.

Tout en utilisant cette machine, prendre soin de ne pas causer de dommages aux personnes ou aux objets se

trouvant aux alentours.

Page 29

MANUEL UTILISATEUR FRANÇAIS

25

DESCRIPTION DE LA MACHINE

STRUCTURE DE LA MACHINE (comme représenté sur la Figure 1)

1. Volant

2. Siège

3. Réservoir de récupération

4. Couvercle du réservoir de récupération

5. Port USB de charge

6. Pédale

7. Roue avant

8. Protection gauche

9. Filtre de solution

10. Brosse

11. Carter de brosse

12. Roue arrière

13. Ensemble de raclette

14. Bouchon de vidange de solution

15. Tuyau de vidange des égouts

16. Bouchon pour remplissage

17. Réservoir de solution

18. Molette de réglage de la raclette

19. Embout d’aspiration

20. Visserie pour la raclette

21. Panneau de contrôle