Page 1

Operator's Manual

Viper Engine

159cc

MODELS INCLUDED:

60005072

31337

OM60005072

Rev. 09-27-10

© 2010 Ardisam, Inc.

All Rights Reserved.

Page 2

Operator's Manual

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

2

Page 3

Operator's Manual

Viper Engine, 159cc

WARRANTY

Ardisam, Inc., warrants its Viper Engines under a two-year limited warranty to be free from defects in materials and workmanship

for the service life of the product not to exceed twenty-four consecutive months from the date of purchase for consumer applications. As an Ardisam Viper small engine owner, you are responsible for executing proper maintenance listed in the operating

and maintenance instructions. The warranty period begins on the date of purchase by the rst retail consumer or commercial

end user, and continues for the period of time stated above.

This warranty applies only to products which have not been subjected to negligent use, misuse, alteration, accident, unauthorized parts, failure to use proper fuel and oil, or if repairs have been performed at non-authorized service centers. This warranty

supersedes all other warranties either expressed or implied and all other obligations or liabilities on our part. Ardisam, does

not assume, and does not authorize any other person to assume for us, any liability in connection with the sale of our products.

To be at "No Charge," however, warranty work must be sent directly to Ardisam, Inc. or one of our authorized service centers

and performed by them. To obtain warranty service and replacement instructions, contact our customer service department

at 800-345-6007 Monday through Friday from 8 a.m. to 5 p.m., or visit www.ardisam.com. Ardisam will, at no charge, repair or

replace at their discretion, any defective part which falls under the conditions stated above. Ardisam retains the right to change

models, specications and price without notice.

Viper Engines, A Division of Ardisam, Inc.

1160 Eighth Avenue; P.O. Box 666

Cumberland, Wisconsin 54829

800-345-6007 · Fax (715) 822-2223

E-mail: info@ardisam.com

REGISTRATION, SERVICE AND MAINTENANCE LOG

Record the model number and serial number in the space provided for easy reference. Fill out and mail the registration card located in the

parts packet or register online at www.ardisam.com.

OWNERSHIP RECORDS

Owner’s Name:

Owner’s Address:

City: State/Province: Zip Code/Postal Code:

Model Number: Serial Number:

Date of Purchase:

Notes:

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

3

Page 4

Operator's Manual

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engine, 159cc

Explanation of Emissions Control

Warranty Provisions

Viper Engines are designed, built and equipped to meet all EPA

requirements. It warrants that it is free from defects in material and

workmanship that could cause failure to the warranted part, and

that it is identical in all material respects to the engine described

in the manufacturer's application for certication. When a warrantable condition exists, Viper will repair your engine at no cost to you,

including parts and labor. The engine emissions label will indicate

certification information. If the purchaser is in need of a warrantable

repair and is not within 100 miles distance from an Ardisam authorized repair center, Ardisam will pay for shipping costs to and from an

authorized Ardisam repair center.

Listed below are the parts covered by the Emissions Control Systems

Warranty. Some parts listed below may require scheduled maintenance

and are warranted up to the rst scheduled replacement point for that

part. Coverage under this warranty includes only the parts listed below

(the emission and evaporation control systems) if so equipped:

• Air Filter Assembly (only to the first scheduled replacement point)

• Fuel Filter (only to the first scheduled replacement point)

• Carburetor

• Fuel Lines, Fuel Line Fittings and Clamps

• Fuel Metering Valve (if equipped)

• Evaporative System (if equipped)

- Canister (if equipped)

- Canister filter (if equipped)

- Vapor hose (if equipped)

- Orifice connector (if equipped)

-Fuel tank

-Fuel cap

-Primer bulb canister (if equipped)

• Spark Plugs

• Magneto Ignition System

• Muffler Assembly

LIMITATIONS

The Emission Control Systems Warranty shall not cover any of the

following:

a) Repair or replacement required because of misuse or neglect,

improper maintenance, repairs improperly performed or

replacements not conforming to Ardisam, Inc., specications

that adversely aect performance and/or durability, and

alterations or modications not recommended or approved in

writing by Ardisam, Inc.

b) Replacement of parts and other services and adjustments nec-

essary for required maintenance at or after the rst scheduled

replacement point;

c) Consequential damages such as loss of time, inconvenience,

loss of use of the engine or equipment, etc.

d) Diagnosis and inspection fees that do not result in eligible

warranty service being performed; and

e) Any add-on or modied part, or malfunction of authorized

parts due to the use of add-on or modied parts.

These items will be covered for a period of two years from the

date of the original purchase. Viper warrants that: the compo-

nents are designed, built and equipped so as to conform with all

applicable regulations adopted by the EPA; that they are free from

defects in material and workmanship that could cause failure to

the engine or other components; and that the components used

are identical in all material respects to the engine described in the

manufacturer's application for certification. The warranty period

begins on the date the engine is originally purchased.

MAINTENANCE AND REPAIR REQUIREMENTS

The owner is responsible for the proper use and maintenance

of the engine. Ardisam, Inc., recommends that all receipts and

records covering the performance of regular maintenance be

retained in case questions arise. If the engine is resold during the

warranty period, the maintenance records should be transferred

to each subsequent owner. Ardisam, Inc., reserves the right to

deny warranty coverage if the engine has not been properly

maintained; however, Ardisam, Inc., may not deny warranty repairs

solely because of the lack of repair maintenance or failure to keep

maintenance records.

Normal maintenance replacement or repair of emission control

devices and systems may be performed by any repair establishment

or individuals; however, warranty repairs must be performed by an

Ardisam-authorized service center. Any replacement parts or service

that is equivalent in performance and durability may be used in nonwarranty maintenance or repairs, and shall not reduce the warranty

obligations of the engine manufacturer.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as

required maintenance in the owner's manual supplied, is warranted

for the warranty period stated above. If any such part fails during the

period of warranty coverage, that part will be repaired or replaced at

no charge to the owner. Any such part repaired or replaced under

the warranty will be warranted for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection

in the owner's manual supplied is warranted for the warranty

period. Any such part repaired or replaced under warranty will

be warranted for the remaining warranty period.

• Any warranted part that is scheduled for replacement as required

maintenance in the owner's manual supplied is warranted for the

period of time prior to the first scheduled replacement point for

that part. If the part fails prior to the first scheduled replacement,

the part will be repaired or replaced at no charge to the owner. Any

such part repaired or replaced under warranty will be warranted for

the remainder of the period prior to the first scheduled replacement

point for the part.

• Add-on or modified parts that are not exempted by the Air

Resources Board may not be used. The use of any nonexempted

add-on or modified parts by the owner will be grounds for

disallowing a warranty claim. The manufacturer will not be liable

to warrant failures of warranted parts caused by the use of a

nonexempted add on or modified part.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

4

Page 5

Operator's Manual

Viper Engine, 159cc

INTRODUCTION

Thank You . . .

for purchasing a Viper Engine from Ardisam, Inc. We have worked to ensure that our product meets high standards for

usability and durability. With proper care, your engine will provide many years of excellent service. Please take the time

to read this manual carefully to learn how to correctly operate and maintain your Viper Engine. Due to continuous

efforts to perfect our products, certain procedures and specifications are subject to change without notice. Congratulations on your investment in quality.

Ardisam, Inc., warrants to the retail purchaser that this small, off-road engine was designed, built and equipped to conform at the

time of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA).

CONTENTS

Registration and Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Introduction/Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation Safety, Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

Starting your Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transporting/Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical and Consumer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts Diagrams & Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

18

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

5

Page 6

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

General Safety Precautions

Please read this section carefully. It is important to

operate the engine according to the safety instructions

and recommendations outlined here and throughout

the manual. Anyone who uses this engine must read

the instructions and be familiar with the controls.

Owner’s Responsibility:

It is the owner’s responsibility to accurately assemble

the engine for safe and effective use.

• Read and follow all safety instructions.

• Carefully follow all assembly instructions.

• Maintain the engine according to directions and

schedule included in this operator’s manual.

• Ensure that anyone who uses this engine is familiar

with all controls and safety precautions.

Signal Words

This is the safety alert symbol.

Operator's Manual

Viper Engine, 159cc

WARNING

INDICATES SERIOUS INJURY OR DEATH WILL

RESULT IF INSTRUCTIONS ARE NOT FOL

LOWED.

DANGER

INDICATES A STRONG POSSIBILITY THAT SE

RIOUS INJURY OR DEATH COULD RESULT IF

INSTRUCTIONS ARE NOT FOLLOWED.

CAUTION

INDICATES A POSSIBILITY THAT MINOR IN

JURY COULD RESULT IF INSTRUCTIONS ARE

NOT FOLLOWED.

The safety alert symbol accompanies a signal word. A

signal word alerts you to potential hazards that could

harm you or others. Each signal word is preceded by

the safety alert symbol and by one of the following

words: DANGER, WARNING, CAUTION or IMPOR-

TANT.

Each signal word will make you aware of what the

hazard is, what can happen, and what you can do to

prevent or decrease injury occurrence.

Keep this owner's manual handy so you can refer to

it at any time. This owner's manual is considered a

permanent part of the engine and should remain with

the engine if resold. The information and specifications

included in this publication were in effect at the time of

approval for printing.

READ THIS OWNER’S MANUAL CAREFULLY. Pay

special attention to these symbols and any instructions

that follow. If a problem should arise, or if you have

questions about your engine, consult your engine

dealer.

IMPORTANT NOTE: We do not necessarily know

what equipment this engine will power. For that

reason, you should carefully read and understand

the operating instructions for the equipment on

which your engine is placed.

IMPORTANT

INDICATES HELPFUL INFORMATION FOR

PROPER ASSEMBLY, OPERATION, OR

MAINTENANCE OF YOUR ENGINE.

WARNING

READ THE ENTIRE OPERATING

AND MAINTENANCE INSTRUC

TIONS AND THE INSTRUCTIONS

FOR THE EQUIPMENT THIS ENGINE

POWERS. FAILURE TO FOLLOW

ALL INSTRUCTIONS MAY RESULT IN ELECTRIC

SHOCK, FIRE AND/OR SERIOUS INJURY.

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS, OR OTHER REPRODUCTIVE HARM.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

6

Page 7

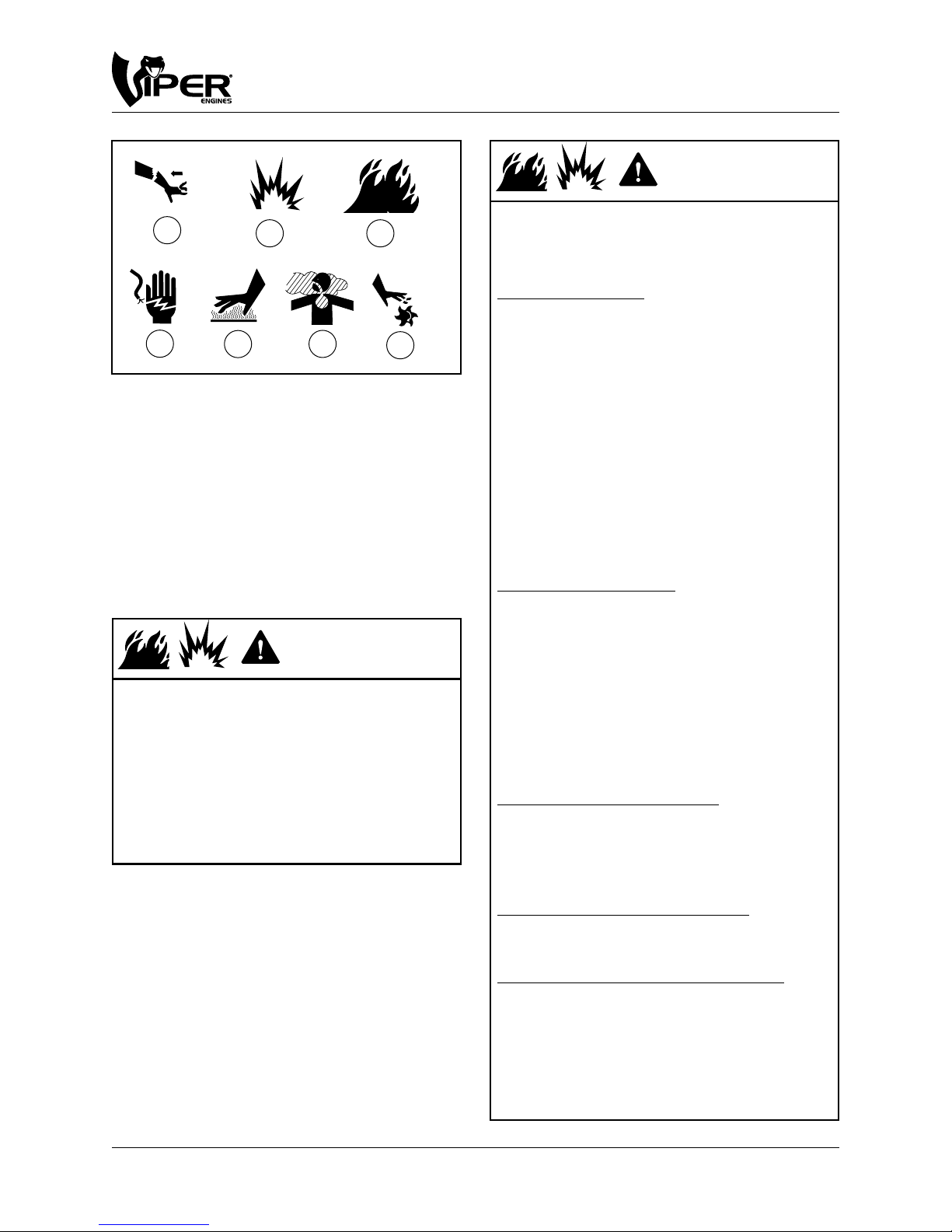

A

D

B

FE

C

G

Hazard Symbols and Meanings

A - Kickback

B - Explosions

C - Fire

D - Electric Shock

E - Hot Surface

F - Toxic Fumes

G - Moving Parts

WARNING

STARTING ENGINE CREATES SPARKING.

SPARKING CAN IGNITE NEARBY FLAMMABLE

GASES.

EXPLOSION AND FIRE COULD RESULT.

• IF THERE IS A NATURAL GAS LEAKAGE IN

AREA, DO NOT START ENGINE.

• DO NOT USE PRESSURIZED STARTING FLU

IDS BECAUSE VAPORS ARE FLAMMABLE.

Operator's Manual

Viper Engine, 159cc

WARNING

FUEL AND ITS VAPORS ARE FLAMMABLE AND

EXPLOSIVE. LOCATE THE MACHINE IN AREAS

AWAY FROM COMBUSTIBLE MATERIALS, COM

BUSTIBLE FUMES OR DUST.

WHEN ADDING FUEL

• TURN OFF ENGINE AND LET IT COOL AT LEAST

TWO MINUTES BEFORE REMOVING GAS CAP.

• FILL FUEL TANK OUTDOORS OR IN WELL

VENTILATED AREA.

• DO NOT OVERFILL FUEL TANK. FILL TANK TO

APPROXIMATELY 11/2 INCHES BELOW TOP

OF NECK TO ALLOW FOR FUEL EXPANSION.

• KEEP GASOLINE AWAY FROM SPARKS, OPEN

FLAMES, PILOT LIGHTS, HEAT, AND OTHER

IGNITION SOURCES.

• CHECK FUEL LINES, TANK, CAP, AND FIT

TINGS FREQUENTLY FOR CRACKS OR LEAKS.

REPLACE IF NECESSARY.

WHEN STARTING ENGINE

• MAKE SURE SPARK PLUG, MUFFLER, FUEL

CAP, AND AIR CLEANER ARE IN PLACE.

• DO NOT CRANK ENGINE WITH SPARK PLUG

REMOVED.

• IF FUEL SPILLS, WAIT UNTIL IT EVAPORATES

BEFORE STARTING ENGINE.

• IF ENGINE FLOODS, SET CHOKE TO OPEN/RUN

POSITION. PLACE THROTTLE IN FAST POSI

TION AND CRANK UNTIL ENGINE STARTS.

WHEN OPERATING EQUIPMENT

• DO NOT TIP ENGINE OR EQUIPMENT AT AN

GLE WHICH CAUSES GASOLINE TO SPILL.

• DO NOT CHOKE CARBURETOR TO STOP EN

GINE.

WHEN TRANSPORTING EQUIPMENT

• TRANSPORT WITH FUEL TANK EMPTY OR

WITH FUEL SHUTOFF VALVE OFF

WHEN STORING EQUIPMENT WITH FUEL

• STORE AWAY FROM FURNACES, STOVES, WA

TER HEATERS OR OTHER APPLIANCES THAT

HAVE A PILOT LIGHT OR OTHER IGNITION

SOURCE BECAUSE THEY CAN IGNITE GASO

LINE VAPORS.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

7

Page 8

Operator's Manual

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engine, 159cc

WARNING

THE RAPID RETRACTION OF THE STARTER

CORD CAN CAUSE BODILY INJURY. THE RE

TRACTION WILL PULL YOUR HAND AND ARM

TOWARD THE ENGINE FASTER THAN YOU CAN

LET GO.

• WHEN STARTING THE ENGINE, PULL CORD

SLOWLY UNTIL RESISTANCE IS FELT, THEN

PULL RAPIDLY.

• REMOVE ALL EXTERNAL EQUIPMENT/EN

GINE LOADS BEFORE STARTING ENGINE.

• DIRECTLY COUPLED EQUIPMENT COM

PONENTS SUCH AS, BUT NOT LIMITED TO,

BLADES, IMPELLERS, PULLEYS, SPROCKETS,

ETC., MUST BE SECURELY ATTACHED.

WARNING

UNINTENTIONAL SPARKING CAN RESULT IN

FIRE OR ELECTRIC SHOCK.

UNINTENTIONAL STARTUP CAN RESULT IN EN

TANGLEMENT, TRAUMATIC AMPUTATION, OR

LACERATION.

BEFORE PERFORMING ADJUSTMENTS OR RE

PAIRS

• DISCONNECT SPARK PLUG WIRE AND KEEP IT

AWAY FROM SPARK PLUG.

• DISCONNECT BATTERY AT NEGATIVE TERMI

NAL ONLY ENGINES WITH ELECTRIC START.

WHEN TESTING FOR SPARK

• USE APPROVED SPARK PLUG TESTER.

• DO NOT CHECK FOR SPARK WITH SPARK PLUG

REMOVED.

WARNING

ROTATING PARTS CAN CONTACT OR ENTAN

GLE HANDS, FEET, HAIR, CLOTHING, OR AC

CESSORIES.

TRAUMATIC AMPUTATION OR SEVERE LACER

ATION CAN RESULT.

• OPERATE EQUIPMENT WITH GUARDS IN

PLACE.

• KEEP HANDS AND FEET AWAY FROM ROTAT

ING PARTS.

• TIE UP LONG HAIR AND REMOVE JEWELRY.

• DO NOT WEAR LOOSEFITTING CLOTHING,

DANGLING DRAWSTRINGS OR ITEMS THAT

COULD BECOME CAUGHT.

WARNING

RUNNING ENGINES PRODUCE HEAT. ENGINE

PARTS, ESPECIALLY THE MUFFLER, BECOME

EXTREMELY HOT.

SEVERE THERMAL BURNS CAN OCCUR ON

CONTACT.

COMBUSTIBLE DEBRIS, SUCH AS LEAVES,

GRASS, BRUSH, ETC., CAN CATCH FIRE.

• ALLOW MUFFLER, ENGINE CYLINDER AND

FINS TO COOL BEFORE TOUCHING.

• REMOVE ACCUMULATED COMBUSTIBLES

FROM MUFFLER AREA AND CYLINDER

AREA.

WARNING

ENGINES GIVE OFF CARBON MONOXIDE, AN

ODORLESS, COLORLESS, POISONOUS GAS.

BROKEN BONES, FRACTURES, BRUISES OR

SPRAINS COULD RESULT.

• START AND RUN ENGINE OUTDOORS.

• DO NOT START OR RUN ENGINE IN ENCLOSED

AREA, EVEN IF DOORS OR WINDOWS ARE

OPEN.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

8

Page 9

ENGINE SAFETY

IMPORTANT SAFETY INFORMATION

Most accidents with engines can be prevented if you

follow all instructions in this manual and the information

supplied on the engine itself. Some of the most common hazards are discussed in the manual, along with

the best way to protect yourself and others.

Owner Responsibilities

• The engines are designed to give safe and depend

able service if operated according to instructions.

Read and understand this owner’s manual before

operating the engine. Failure to do so could result in

personal injury or equipment damage.

• Know how to stop the engine quickly and understand

the operation of all controls. Never permit anyone to

operate the engine without proper instructions.

• Do not allow children to operate the engine. Keep

children and pets away from the area of operation.

-

Operator's Manual

Viper Engine, 159cc

WARNING

DO NOT ATTEMPT TO START ENGINE IN THE

FOLLOWING WAYS:

• DO NOT USE STARTING FLUID.

• DO NOT SPRAY FLAMMABLE LIQUIDS OR

VAPORS INTO AIR FILTER, CARBURETOR OR

SPARK PLUG CHAMBER.

• DO NOT REMOVE SPARK PLUG AND PULL

ON STARTER ROPE. FLAMMABLE FUEL CAN

SPRAY OUT AND IGNITE FROM A SPARK

FROM SPARK PLUG.

• DO NOT REFUEL WHILE SMOKING, NEAR OPEN

FLAME, OR OTHER POTENTIAL HAZARDS.

FUEL IS HIGHLY FLAMMABLE AND MUST BE

HANDLED WITH CARE. NEVER FILL THE TANK

WHEN THE ENGINE IS HOT OR RUNNING. AL

WAYS MOVE OUTDOORS TO FILL THE TANK.

Refuel With Care

Gasoline is extremely flammable and gasoline vapors can

spark an explosion. Refuel outdoors in a well-ventilated

area, with the engine stopped. Never smoke near gasoline and keep other flames and sparks away. Always store

gasoline in an approved container. If any fuel is spilled,

make sure the area is dry before starting the engine.

Hot Exhaust

• The muffler gets very hot during operation and

remains hot after stopping the engine. Be careful not

to touch the muffler while it is hot. Let the engine

cool before storing it indoors.

• To prevent fire hazards and to provide adequate

ventilation, keep the engine at least three feet (one

meter) away from building walls and other equipment

during operation. Do not place flammable objects

close to the engine.

Carbon Monoxide Hazard

The engine exhaust contains poisonous carbon monoxide. Avoid inhalation of exhaust gas. Never run the

engine in a closed garage or confined area.

CAUTION

FOR THE SAFETY OF THE USER, AND TO MAXI

MIZE THE LIFE OF THE ENGINE, IT IS CRUCIAL

TO TAKE TIME TO CHECK THE CONDITION OF

THE ENGINE. PROBLEMS MUST BE CORRECT

ED BEFORE OPERATING.

AVOID INJURY! ENGINE OIL IS HAZARDOUS

TO YOUR HEALTH. DISPOSE OF OIL APPRO

PRIATELY. USE A SAFE DISPOSAL/RECYCLING

CENTER.

Other Equipment

ALWAYS review the instructions provided with the equipment powered by this engine for any additional safety

precautions that should be observed in conjunction

with engine start-up, shut-down, operation, or protective

apparel, that may be needed to operate the equipment.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

9

Page 10

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

ENGINE COMPONENTS

Operator's Manual

Viper Engine, 159cc

STARTER GRIP

FINGER GUARD

MUFFLER

SPARK PLUG

CARBURETOR

FUEL TANK CAP

FUEL TANK

AIR CLEANER

FUEL TANK CAP

STARTER GRIP

FUEL TANK

OIL FILLERCAP/

DIPSTICK

FINGER GUARD

AIR CLEANER

MUFFLER

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

10

Page 11

BEFORE STARTING

ENGINE OIL

ENGINE OIL RECOMMENDATIONS

Oil is a major factor affecting performance and service

life. Use 4-stroke automotive detergent oil.

SAE 10W-30 is recommended for general use. Other

viscosities shown in the chart may be used when the

average temperature in your area is within the recommended range.

SAE VISCOSITY GRADES

30

10W-30

5W-30

Operator's Manual

Viper Engine, 159cc

WARNING

CARBON MONOXIDE GAS IS TOXIC. INHALA

TION CAN CAUSE UNCONSCIOUSNESS AND

DEATH.

NEVER LEAVE ENGINE RUNNING WHILE UN

ATTENDED.

DO NOT ATTEMPT TO START ENGINE IN THE

FOLLOWING WAYS:

• DO NOT USE STARTING FLUID.

• DO NOT SPRAY FLAMMABLE LIQUIDS OR

VAPORS INTO AIR FILTER, CARBURETOR OR

SPARK PLUG CHAMBER.

• DO NOT REMOVE SPARK PLUG AND PULL

ON STARTER ROPE. FLAMMABLE FUEL CAN

SPRAY OUT AND IGNITE FROM A SPARK

FROM SPARK PLUG.

20 0 20 40 60 80 100

30 20 10 0 10 20 30 40

AMBIENT TEMPERATURES

The SAE oil viscosity and service classification are in the

API label on the oil container. We recommend that you

use API SERVICE Category SE or SF oil.

To check the oil

• Check the engine oil level with the engine stopped

and in a level position.

• Remove the oil filler cap/dipstick and wipe it clean.

• Insert the oil filler cap/dipstick into the oil filler neck as

shown, but do not screw it in; then remove it to check

the oil level.

• If the oil level is near or below the lower limit mark

on the dipstick, fill with the recommended oil to the

upper limit mark. Do not overfill.

• Reinstall the oil filler cap/dipstick.

NOTE:

o

F

o

C

CAUTION

THIS ENGINE IS SHIPPED FROM FACTORY

WITHOUT OIL. CHECK OIL LEVEL BEFORE

STARTING ENGINE. IF YOU START THE EN

GINE WITHOUT OIL, THE ENGINE WILL BE

DAMAGED BEYOND REPAIR AND WILL NOT

BE COVERED UNDER WARRANTY.

CAUTION

DO NOT OVERFILL. OVERFILLING WITH OIL

MAY CAUSE SMOKING, HARD STARTING,

SPARK PLUG FOULING, OR OIL SATURATION

OF AIR FILTER. USED OIL SHOULD BE SENT TO

SPECIAL RECYCLE BIN FOR DISPOSING.

Engine oil capacities

0.55L (0.146 US Gal, 0.119 Imp Gal)

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

OIL FILLER CAP/DIPSTICK

UPPER

LOWER

Figure 2: Checking the oil level

11

Page 12

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

FUEL

FUEL RECOMMENDATIONS

Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane.

• These engines are certified to operate on unleaded

gasoline. Unleaded gasoline produces fewer engine

and spark plug deposits and extends exhaust system

life.

• Never use stale or contaminated gasoline or an

oil/gasoline mixture. Avoid getting dirt or water in the

fuel tank.

• Occasionally, you may hear a light ‘‘spark knock’’ or

‘‘pinging’’ (metallic rapping noise) while operating

under heavy loads. This is no cause for concern.

• If spark knock or pinging occurs at a steady engine

speed, under a normal load, change gasoline brands.

If spark knock or pinging persists, see an authorized

servicing dealer.

Operator's Manual

Viper Engine, 159cc

WARNING

FUEL AND FUEL VAPORS ARE HIGHLY FLAM

MABLE AND MUST BE HANDLED WITH CARE.

NEVER FILL THE TANK WHEN THE ENGINE

IS HOT OR RUNNING. ALWAYS MOVE OUT

DOORS TO FILL THE TANK. DO NOT USE PRES

SURIZED STARTING FLUIDS.

WARNING

DO NOT REFUEL WHILE SMOKING, NEAR OPEN

FLAME, OR OTHER POTENTIAL HAZARDS.

FUEL IS HIGHLY FLAMMABLE AND MUST BE

HANDLED WITH CARE. NEVER FILL THE TANK

WHEN THE ENGINE IS HOT OR RUNNING. AL

WAYS MOVE OUTDOORS TO FILL THE TANK.

Fuel tank capacity

1P65FA : 1.2L (0.32 US Gal, 0.26 Imp Gal)

WARNING

IMPROPERLY MAINTAINING THIS ENGINE, OR

FAILING TO CORRECT A PROBLEM BEFORE OP

ERATION, COULD CAUSE A MALFUNCTION IN

WHICH YOU COULD BE SERIOUSLY INJURED.

ALWAYS PERFORM A PREOPERATION INSPEC

TION BEFORE EACH OPERATION, AND COR

RECT ANY PROBLEM.

CAUTION

TO PREVENT ACCIDENTAL STARTING:

AVOID INJURY! ENGINE MUST BE TURNED

OFF AND COOL AND SPARK PLUG WIRE MUST

BE REMOVED FROM SPARK PLUG BEFORE

CHECKING AND ADJUSTING ENGINE OR

EQUIPMENT.

AVOID INJURY! TEMPERATURE OF MUFFLER

AND NEARBY AREAS MAY EXCEED 150° F 65°

C. AVOID THESE AREAS.

AVOID INJURY! CHECK ENGINE OFTEN FOR

LOOSE NUTS AND BOLTS. KEEP THESE ITEMS

TIGHTENED.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

12

Page 13

STARTING ENGINE

Control Lever

• FOR STARTING A COLD ENGINE: Move the control

lever to the choke position.

• FOR RESTARTING A WARM ENGINE: Do not use the

choke when the engine is warm. Move the control

lever slightly past the idle position.

• FLYWHEEL BRAKE MODELS: Move the flywheel brake lever

(located on equipment) to release the flywheel brake.

Start Engine

• Grasp rope handle. Pull slowly until resistance is felt,

then pull rapidly to start engine and avoid kickback.

• If the choke was used to start the engine, move the

throttle to the FAST (or high) position as soon as the

engine warms up enough to run smoothly without

the use of the choke.

• FLYWHEEL BRAKE MODELS: Continue to hold the

flywheel brake lever (located on equipment). The

engine will stop if you release the flywheel brake lever.

• Position the control lever for the desired engine

speed. For best engine performance, it is recommended the engine be operated with the throttle in

the FAST (or high) position.

• If using primer pump carburetor, press primer one to

three times according to the direction of the arrow

when coldstart, then start it.

Operator's Manual

Viper Engine, 159cc

DANGER

DANGER: RAPID RETRACTION OF STARTER

CORD KICKBACK WILL PULL HAND AND

ARM TOWARD ENGINE FASTER THAN YOU

CAN LET GO.

ROTATING PARTS CAN CONTACT OR ENTAN

GLE HANDS, FEET, HAIR, CLOTHING, OR AC

CESSORIES.

RUNNING ENGINES PRODUCE HEAT. ENGINE

PARTS, ESPECIALLY MUFFLER, BECOME EX

TREMELY HOT.

SEVERE THERMAL BURNS CAN OCCUR ON

CONTACT.

CAUTION

CAREFULLY CHECK IF THERE IS ENOUGH OIL

BEFORE STARTING.

AIR PUMP

AIR CLEANER

STOP

Figure 2: Starting the engine

IDLE FAST CHOKE

Figure 3: Using the primer pump

STOPPING ENGINE

1. Move the control lever to the slow (IDLE) position.

2. Move the control lever to the STOP position.

3. FLYWHEEL BRAKE MODELS: Release the flywheel brake

lever (located on equipment) to stop the engine.

4. Turn the fuel valve to the OFF position if you do not

intend to restart the engine soon.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

13

Page 14

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

MAINTENANCE

WARNING

The Importance of Maintenance

Good maintenance is essential for safe, economical, and

trouble-free operation. It will also help reduce air pollution. To

help you properly care for your engine, the following pages include a maintenance schedule, routine inspection procedures,

and simple maintenance procedures using basic hand tools.

Other service tasks that are more difficult, or require special

tools, are best handled by professionals and are normally

performed by a technician or other qualified mechanic.

Maintenance, replacement or repair of the emissions control

devices and systems may be performed by any non-road

engine repair establishment or individuals. However, items

must be serviced by an authorized dealer to obtain "no

charge" emissions control service.

The maintenance schedule applies to normal operating

conditions. If you operate your engine under unusual

conditions, such as sustained high-load or high-temperature operation, or use in unusually wet or dusty conditions,

consult your servicing dealer for recommendations

applicable to your individual needs and use.

MAINTENANCE SCHEDULE

Regular service period Each use First month or

20 hours

Engine oil Check

Change

Air cleaner Check

Clean

Replace

Flywheel brake

pad

Spark plug Clean/

Spark arrester Clean

Idle speed Check/

Valve clearance Check/

Combustion

chamber

Fuel line Check Every two years (replace if necessary) (3)

Check

Check

adjust

adjust

Clean

•

• • (1)

•

IMPROPERLY MAINTAINING THIS ENGINE, OR

FAILURE TO CORRECT A PROBLEM BEFORE

OPERATION, CAN CAUSE A MALFUNCTION

IN wHICH YOU CAN BE SERIOUSLY HURT OR

kILLED. ALwAYS FOLLOw THE INSPECTION

AND MAINTENANCE RECOMMENDATIONS AND

SCHEDULES IN THIS OwNER’S MANUAL.

WARNING

FAILURE TO PROPERLY FOLLOW MAINTE

NANCE INSTRUCTIONS AND PRECAUTIONS

CAN CAUSE YOU TO BE SERIOUSLY HURT OR

KILLED. ALWAYS FOLLOW THE PROCEDURES

AND PRECAUTIONS IN THE OWNER’S MANUAL.

Every 3 months or

50 hours

• (2)

After every 100 hours (2)

Every 6 months or

100 hours

•

•

•

Operator's Manual

Viper Engine, 159cc

Every Year or

300 hours

•*

Replace

• (3)

• (3)

(1) Change engine oil every 25 hours when used under heavy load or in high ambient temperatures.

(2) Clean more often under dusty conditions or when airborne debris is present. Replace air cleaner parts, if very dirty.

(3) These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically

proficient. Refer to manual for service procedures.

* Replace paper element only.

Failure to follow this maintenance schedule could result in nonwarrantable failures.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

14

Page 15

Safety Precautions

Make sure the engine is off before you begin any

maintenance or repairs. This will eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust.

Be sure there is adequate ventilation whenever you

operate the engine.

• Burns from hot parts. Let the engine and exhaust

system cool before touching.

• Injury from moving parts. Do not run the engine

unless instructed to do so.

Read the instructions before you begin, and make sure

you have the tools and skills required.

To reduce the possibility of fire or explosion, be careful

when working around gasoline. Use only a nonflammable solvent, not gasoline, to clean parts. Keep cigarettes,

sparks and flames away from all fuel-related parts.

Remember that your servicing dealer knows your

engine best and is fully equipped to maintain and repair

it. To ensure the best quality and reliability, use only

new, genuine parts or their equivalents for repair and

replacement.

Operator's Manual

Viper Engine, 159cc

WARNING

GASOLINE IS HIGHLY FLAMMABLE AND EX

PLOSIVE. YOU CAN BE BURNED OR SERIOUS

LY INJURED WHEN HANDLING FUEL.

• STOP THE ENGINE AND KEEP HEAT, SPARKS,

AND FLAME AWAY.

• HANDLE FUEL ONLY OUTDOORS.

• WIPE UP SPILLS IMMEDIATELY.

CAUTION

USED OIL IS A HAZARDOUS WASTE PRODUCT.

DISPOSE OF USED OIL PROPERLY. DO NOT

DISCARD WITH HOUSEHOLD WASTE. WE SUG

GEST YOU TAKE USED OIL IN A SEALED CON

TAINER TO YOUR LOCAL RECYCLING CENTER

OR SERVICE STATION FOR RECLAMATION.

CHANGE ENGINE OIL

Drain the used oil while the engine is warm. Warm oil

drains quickly and completely.

1. Place a suitable container below the engine to catch

the used oil, and then remove the filler cap/dipstick,

the drain bolt and sealing washer.

2. Allow the used oil to drain completely, and then

reinstall the drain bolt and sealing washer, and tighten

it securely.

3. With the engine in a level position, fill to the upper

limit mark on the dipstick with the recommended oil.

4. Reinstall the oil filler cap/dipstick securely.

CAUTION

RUNNING THE ENGINE WITH A LOW OIL

LEVEL CAN CAUSE ENGINE DAMAGE.

OIL FILLER CAP/

DIPSTICK

SEALING

WASHER

DRAIN

BOLT

Figure 4: Changing the engine oil

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

15

Page 16

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

REFUELING

With the engine stopped, remove the fuel tank cap and

check the fuel level. Refill the tank if the fuel level is low.

Refuel in a well-ventilated area before starting the

engine. If the engine has been running, allow it to cool.

Refuel carefully to avoid spilling fuel. Do not fill above

the fuel strainer shoulder. After refueling, tighten the

fuel tank cap securely.

NOTE: Spilled fuel isn’t only a fire hazard, it causes

environmental damage. Wipe up spills immediately.

SPARK PLUG SERVICE

Recommended spark plugs: F7RTC or other equivalents.

NOTE: An incorrect spark plug can cause engine

damage.

1. Disconnect the spark plug cap and remove any dirt

from around the spark plug area.

2. Remove the spark plug with a spark plug wrench.

3. Inspect the spark plug.

Replace it if the electrodes

are worn, or if the insulator

is cracked or chipped.

4. Measure the spark plug

electrode gap with a

suitable gauge. The gap

should be 0.028 -0.031 in

(0.70 - 0.80 mm). Correct

the gap, if necessary, by

carefully bending the side

electrode.

5. Install the spark plug

carefully, by hand, to avoid

cross-threading.

6. After the spark plug seats, tighten with a spark plug

wrench to compress the water. If reinstalling the used

spark plug, tighten 1/8 - 1/4 turn after the spark plug

seats. If installing a new spark plug, tighten 1/2 turn

after the spark plug seats.

NOTE: A loose spark plug can overheat and damage the engine. Over tightening the spark plug

can damage the threads in the cylinder head.

7. Attach the spark plug cap.

Figure 4: Spark plug

Operator's Manual

Viper Engine, 159cc

WARNING

NEVER REFUEL THE ENGINE INSIDE A BUILD

ING WHERE GASOLINE FUMES MAY REACH

FLAMES OR SPARKS. KEEP GASOLINE AWAY

FROM APPLIANCE PILOT LIGHTS, BARBECUES,

ELECTRIC APPLIANCES, POWER TOOLS, ETC.

CAUTION

FUEL CAN DAMAGE PAINT AND PLASTIC. BE

CAREFUL NOT TO SPILL FUEL WHEN FILL

ING YOUR FUEL TANK. DAMAGE CAUSED BY

SPILLED FUEL IS NOT COVERED UNDER WAR

RANTY.

CAUTION

OPERATING THE ENGINE WITHOUT AN AIR

FILTER, OR WITH A DAMAGED AIR FILTER,

WILL ALLOW DIRT TO ENTER THE ENGINE,

CAUSING RAPID ENGINE WEAR. THIS TYPE OF

DAMAGE IS NOT COVERED BY THE DISTRIBU

TOR’S LIMITED WARRANTY.

CAUTION

A DIRTY AIR FILTER WILL RESTRICT AIR FLOW

TO THE CARBURETOR, REDUCING ENGINE

PERFORMANCE.

IF YOU OPERATE THE ENGINE IN VERY DUSTY

AREAS, CLEAN THE AIR FILTER MORE OF

TEN THAN SPECIFIED IN THE MAINTENANCE

SCHEDULE.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

16

Page 17

AIR CLEANER

Remove the air cleaner cover and inspect the filter.

Clean or replace dirty filter elements. Always replace

damaged filter elements. If equipped with an oil-bath air

cleaner, also check the oil level.

Inspection

1. Press the latch tabs on the air cleaner cover or remove

the cap nuts, and remove the cover. Check the filter

to be sure it is clean and in good condition.

2. Reinstall the filter and air cleaner cover.

Cleaning

1. Tap the filter several times on a hard surface to

remove dirt, or blow compressed air (not exceeding

30 psi [207kPa, 2.1kg/cm²]) through the filter from the

clean side that faces the engine. Never try to brush off

dirt. Brushing will force dirt into the fibers.

2. Tap the filter outer several times on a hard surface

to remove dirt. Clean. If the outer filter is very dirty,

replace it.

3. Wipe dirt from the air cleaner body and cover using a

moist rag. Be careful to prevent dirt from entering the

air duct that leads to the carburetor.

Operator's Manual

Viper Engine, 159cc

CAUTION

OPERATING THE ENGINE WITHOUT AN AIR

FILTER, OR WITH A DAMAGED AIR FILTER,

WILL ALLOW DIRT TO ENTER THE ENGINE,

CAUSING RAPID ENGINE WEAR. THIS TYPE OF

DAMAGE IS NOT COVERED BY THE DISTRIBU

TOR’S LIMITED WARRANTY.

FILTER

AIR CLEANER BODY

Figure 22: Cleaning the foam filter element

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

LATCH TABS

OUTER FILTER

AIR CLEANER

COVER

CAP NUT

FILTER

17

Page 18

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

STORAGE/ TRANSPORTING

STORING YOUR ENGINE

Storage Preparation

Proper storage preparation is essential for keeping your

engine trouble-free and looking good. The following

steps will help to keep rust and corrosion from impairing

your engine’s function and appearance, and will make

the engine easier to start after storage.

Operator's Manual

Viper Engine, 159cc

CAUTION

USING A GARDEN HOSE OR PRESSURE WASH

ING EQUIPMENT CAN FORCE WATER INTO THE

AIR CLEANER OR MUFFLER OPENING. WATER

IN THE AIR CLEANER WILL SOAK THE AIR FIL

TER, AND WATER THAT PASSES THROUGH

THE AIR FILTER OR MUFFLER CAN ENTER THE

CYLINDER, CAUSING DAMAGE.

Cleaning

If the engine has been running, allow it to cool for at

least half an hour before cleaning. Clean all exterior

surfaces, touch up any damaged paint, and coat other

areas that may rust with a light film of oil.

NOTE: Water contacting a hot engine can cause

damage. If the engine has been running, allow it

to cool for at least half an hour before washing.

Fuel

Gasoline will oxidize and deteriorate in storage. Old

gasoline will cause hard starting, and it leaves gum

deposits that clog the fuel system. If the gasoline in your

engine deteriorates during storage, you may need to

have the carburetor and other fuel system components

serviced or replaced.

The length of time that gasoline can be left in your

fuel tank and carburetor without causing functional

problems will vary with such factors as gasoline blend,

your storage temperatures, and whether the fuel tank

is partially or completely filled. The air in a partially

filled fuel tank promotes fuel deterioration. Very warm

storage/temperatures accelerate fuel deterioration. Fuel

deterioration problems may occur within a few months,

or even less if the gasoline was not fresh when you filled

the fuel tank.

NOTE: The distributor’s limited warranty does not

cover fuel system damage or engine performance

problems resulting from neglected storage

preparation.

You can extend fuel storage life by adding a fuel

stabilizer that is formulated for that purpose, or you can

avoid fuel deterioration problems by draining the fuel

tank and carburetor.

WARNING

FAILURE TO FOLLOw MAINTENANCE INFORMATION CAN CAUSE DEATH OR SERIOUS INjURY.

DO NOT REMOvE FUEL wHILE SMOkING,

NEAR OPEN FLAME, OR OTHER POTENTIAL HAzARDS.

AvOID INjURY! NEvER STORE ENGINE

wITH FUEL IN THE TANk INSIDE A BUILDING. POTENTIAL SPARkS MAY BE PRESENT CAUSING IGNITION OF FUEL AND

FUEL vAPORS.

ADDING A FUEL STABILIZER TO EXTEND FUEL

STORAGE LIFE

When adding a fuel stabilizer, fill the fuel tank with

fresh gasoline. If only partially filled, air in the tank will

promote fuel deterioration during storage. If you keep

a container of gasoline for refueling, be sure that it

contains only fresh gasoline.

1. Add fuel stabilizer following the manufacturer’s

instructions.

2. After adding a fuel stabilizer, run the engine outdoors

for 10 minutes to be sure that treated gasoline has

replaced the untreated gasoline in the carburetor.

3. Stop the engine, and move the fuel valve to the OFF

position.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

18

Page 19

DRAINING THE FUEL TANK AND CARBURETOR

1. Place an approved gasoline container below the

carburetor and use a funnel to avoid spilling fuel.

2. Remove the carburetor drain bolt and sealing washer,

and then move the fuel valve lever to the ON position.

3. After all the fuel has drained into the container,

reinstall the drain bolt and sealing washer. Tighten

them securely.

STORAGE PRECAUTIONS

1. Change the engine oil.

2. Remove the spark plugs.

3. Pour a tablespoon (1-2 teaspoons) of clean engine oil

into the cylinder.

4. Pull the starter rope several times to distribute the oil

in the cylinder.

5. Reinstall the spark plugs.

6. Pull the starter rope slowly until resistance is felt. This

will close the valves so moisture cannot enter the

engine cylinder. Return the starter rope gently.

If your engine will be stored with gasoline in the fuel

tank and carburetor, it is important to reduce the hazard

of gasoline vapor ignition. Select a well-ventilated storage area away from any appliance that operates with a

flame, such as a furnace, water heater, or clothes dryer.

Also avoid any area with a spark-producing electric

motor, or where power tools are operated.

If possible, avoid storage areas with high humidity,

because that promotes rust and corrosion.

Unless all fuel has been drained from the fuel tank, leave

the fuel valve lever in the OFF position to reduce the

possibility of fuel leakage.

Position the equipment so the engine is level. Tilting can

cause fuel or oil leakage.

7. With the engine and exhaust system cool, cover the

engine to keep out dust. A hot engine and exhaust

system can ignite or melt some materials. Do not use

sheet plastic as a dust cover. A nonporous cover will

trap moisture around the engine, promoting rust and

corrosion.

If equipped with a battery for an electric starter,

recharge the battery once a month while the engine is

in storage. This will help to extend the service life of the

battery.

Operator's Manual

Viper Engine, 159cc

CARBURETOR

FLOAT BOWL

SEALING WASHER

DRAIN BOLT

Figure 22: Draining the fuel tank and carburetor

REMOVAL FROM STORAGE

Check your engine as described in the "Operation"

section.

If the fuel was drained during storage preparation, fill

the tank with fresh gasoline. If you keep a container of

gasoline for refueling, be sure that it contains only fresh

gasoline. Gasoline oxidizes and deteriorates over time,

causing hard starting.

If the cylinders were coated with oil during storage

preparation, the engine may smoke briefly at startup.

This is normal.

TRANSPORTING

If the engine has been running, allow it to cool for at

least 15 minutes before loading the engine-powered

equipment on the transport vehicle. A hot engine and

exhaust system can burn you and can ignite some

materials.

Keep the engine level when transporting to reduce the

possibility of fuel leakage. Move the fuel valve lever to

the OFF position.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

19

Page 20

Operator's Manual

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engine, 159cc

TROUBLESHOOTING

Engine will not start Possible Cause Correction

1) Check control positions Choke OPEN Move lever to CLOSE unless

engine is warm.

Engine switch OFF Turn engine switch to ON.

2) Check fuel Out of fuel Refuel.

3) Remove and inspect spark

plugs

4) Take engine to authorized

servicing dealer, or refer to

manual

Bad fuel; engine started without

treating or draining gasoline, or

engine has been refueled with

bad gasoline

Spark plugs faulty, fouled or

improperly gapped

Spark plugs wet with fuel

(ooded engine)

Fuel lter clogged, carburetor

malfunction, ignition malfunction, valve stuck, etc.

Drain fuel tank and carburetor.

Refuel with fresh gasoline.

Gap, or replace spark plugs.

Dry and reinstall spark plugs.

Start engine with control lever in

FAST position.

Replace or repair faulty components as necessary.

Engine lacks power Possible Cause Correction

1) Check air lter Filter element(s) clogged Clean or replace lter element(s).

2) Check fuel Out of fuel Refuel.

Bad fuel; engine started without

treating or draining gasoline, or

engine has been refueled with

bad gasoline.

3) Take engine to authorized

servicing dealer, or refer to

manual

Engine operates erratically Possible Cause Correction

1) Check spark plug Spark plug is defective Install new, correctly gapped

2) Check air cleaner Air cleaner element is dirty Clean air cleaner element.

Fuel lter clogged, carburetor

malfunction, ignition malfunction, valve stuck, etc.

Spark plug gap is incorrect Set gap between electrodes at

Drain fuel tank and carburetor.

Refuel with fresh gasoline.

Replace or repair faulty components as necessary.

plug.

0.7 to 0.8 mm.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

20

Page 21

Operator's Manual

Viper Engine, 159cc

TECHNICAL & CONSUMER INFORMATION

Serial number

location

SERIAL NUMBER LOCATION

Record the engine serial number in the space below.

You will need this serial number when ordering parts,

and when making technical or warranty inquires.

Engine serial number: ______________________

MAINTENANCE

Follow the maintenance schedule. Remember that this

schedule is based on the assumption that your machine

will be used for its designed purpose. Sustained highload or high-temperature operation, or use in unusually

wet or dusty conditions, will require more frequent

service.

QUICK REFERENCE INFORMATION

Engine Oil Type SAE 10W-30, API SE

or SF, for general

use

Capacity .055L (0.146 US Gal.)

Spark plug Type F7RTC or other

equivalent

Gap 0.028-0.031 inches

(0.7-0.8 MM)

Carburetor Idle speed 1800 + 150 RPM

Maintenance

Each use Check engine oil;

check air lter

First 5 hours Change engine oil

Subsequent Refer to mainte-

nance schedule

ENGINE SPECIFICATIONS

Model 60005072/31337

Type Single cylinder, four-stroke,

Rated Power (kw/

3600rpm)

Max torque 8.8/2500

Fuel consumption

(g/kW•h)

forced air cooling, OHV

3.7

<395

ENGINE TUNEUP

ITEM SPECIFICATION

Spark plug gap 0.028-0.031 in.

(0.70-0.80 mm)

Valve clearance IN: 0.10+ 0.02 mm (cold)

Other specications No other adjustments

needed

Idle speed 1800+150

Bore x Stroke (mm)

Displacement (cc)

Compression ration

Lubricating mode Splash

Starting mode

Rotation Counter-clockwise (from

Valve clearance Input valve: 0.10+0.02 mm,

Spark plug

clearance

Igniting mode Transistorized magneto

Air cleaner Semi-dry, oil bath,

Dimension

(LxWxH)

Net weight (kg)

output valve: 0.15

65x48

159

8:1

Recoil start

P.T.O side)

+0.02 mm

0.7~0.8mm

ignition

foam lter

430x380x380

12

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

21

Page 22

Operator's Manual

Viper Engine, 159cc

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

SERVICE PARTS

11

Operator's Manual

Viper Engine, 159cc

1

4

6

5

12

7

10

2

10

8

STARTER

KEY # PART # DESCRIPTION QTY.

11 60005085 RECOIL HOUSING 1

12 60005084 RECOIL ASSEMBLY 1

3

9

CRANKCASE/CRANKCASE COVER

KEY # PART # DESCRIPTION QTY.

1 60005073 OIL SEAL, 25X38X7 1

2 60005083 OIL FILL TUBE ASSEMBLY 1

3 600050114 DRAIN BOLT WITH WASHER 1

4 60005074 BREATHER GASKET 1

5 60005076 BREATHER TUBE 1

6 60005075 ENGINE STOP SWITCH ASSEMBLY 1

7 60005077 OIL SEAL, 6X11X4 1

8 60005079 CRANK CASE COVER GASKET 1

9 60005078 OIL SEAL 1

10 60005080 PIN DOWEL 2

13

MUFFLER

KEY # PART # DESCRIPTION QTY.

13 600050115 KIT, MUFFLER WITH

COVER AND SHIELD

1

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

22

22

Page 23

1

2

CARBURETOR

KEY # PART # DESCRIPTION QTY.

1 600050116 KIT, CARBURETOR SEAL 1

2 60005091 CARBURETOR ASSEMBLY 1

6

Operator's Manual

Viper Engine, 159cc

3

AIR FILTER

KEY # PART # DESCRIPTION QTY.

3 600050117 KIT, AIR FILTERINCLUDES

INNER AND OUTER

4 600050118 KIT, COMPLETE AIR

CLEANER

1

1

4

5

7

FLYWHEEL

KEY # PART # DESCRIPTION QTY.

5 60005093 IGNITION COIL ASSEMBLY 1

6 600050119 KIT, FLYWHEEL FINS AND

RECOIL CONE WITH NUT

7 600050120 KIT, FLYWHEEL WITH NUT 1

1

11

12

13

14

10

9

8

CONTROL

KEY # PART # DESCRIPTION QTY.

8 600050103 THROTTLE ROD 1

9 600050104 THROTTLE RETURN SPRING 1

10 600050105 GOVERNOR ROD 1

FUEL TANK

KEY # PART # DESCRIPTION QTY.

11 600050121 FUEL CAP WITH GASKET 1

12 600050111 FUEL TANK 1

13 600050112 FUEL LINE 1

14 600050113 FUEL FILTER 1

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

23

Page 24

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engines, Division of Ardisam, Inc.

1160 8th Avenue, PO Box 666

Cumberland, WI 54829

800-345-6007 | Fax 715-822-2223

Email: info@ardisam.com

Loading...

Loading...