Page 1

Operator's Manual

GAS/OIL

RATIO

50:1

Original Operating Instructions

Viper® 212cc

4-Cycle Engine

For more information email

info@ardisam.com

Product #: 13350

P/N: 13595

ECN: 10842

REV6: 06/22/15

© 2015 ARDISAM, INC.

ALL RIGHTS RESERVED

Page 2

Operator's Manual

DECAL

Viper® 212cc 4-Cycle Engine

INTRODUCTION

Congratulations on your investment in quality. Thank you for purchasing a Viper Engine. We have worked to ensure that your

engine meets the highest standards for usability and durability. With proper care, your engine will provide many years of service.

Please read this entire manual before installation and use. Viper reserves the right to change, alter or improve the

product and this document at any time without prior notice.

CONTENTS

Introduction/Contents/Federal Emissions Information/Registration and Service/Ownership Records ...................................................... 2

Warnings and Safety Precautions ...........................................................................................................................................................................................3

Engine Safety Precautions .....................................................................................................................................................................................................4-5

Service .............................................................................................................................................................................................................................................. 5

Hazard Symbols and Meanings/Control and Operating Symbols/Safety Decals/Specications ................................................................ 6-7

Features ...........................................................................................................................................................................................................................................7

Operation ..................................................................................................................................................................................................................................8-11

Maintenance and Storage ................................................................................................................................................................................................ 12-16

Troubleshooting and Repair/Troubleshooting Guide ...........................................................................................................................................16-17

Illustrated Parts Breakdown.............................................................................................................................................................................................18-19

Warranty ........................................................................................................................................................................................................................................20

FEDERAL EMISSION INFORMATION

Viper warrants to the retail purchaser, that this small, o-road engine was designed, built and equipped to conform at the time

of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA) and those of the State of California

(CARB).

REGISTRATION AND SERVICE

Record the engine model number and serial number in the space

provided for easy reference when ordering parts or requesting

technical support. Excluding emissions-related warranty items, the

warranty is valid only if the completed registration is received by

Ardisam within 30 days of purchase. (SEE WARRANTY SECTION FOR

MORE INFORMATION.) You can register your warranty online by

visiting www.ardisam.com, or by mailing it to: Ardisam, Inc., 1160

8th Avenue, Cumberland, WI 54829. If you prefer phone, call our

customer service department at (800) 345-6007 Mondays through

Fridays from 8 a.m. to 5 p.m. CST.

OWNERSHIP RECORDS

Owner’s Name:

Owner’s Address:

City: State/Province: Zip Code/Postal Code:

Engine Model Number: Engine Serial Number:

Date of Purchase:

Notes:

SERIAL

NUMBER

This manual may contain information for several models. Read and keep this manual for future reference. This manual contains important

information on SAFETY, ASSEMBLY, OPERATION, AND MAINTENANCE. The owner must be certain that all the product information is included

with the unit. This information includes the MANUAL, the REPLACEMENT PARTS and the WARRANTIES. This information must be included to

make sure state laws and other laws are followed. This manual should remain with the engine even if it is resold.

2

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 3

Operator’s Manual

Viper® 212cc 4-Cycle Engine

WARNINGS AND SAFETY PRECAUTIONS

Owner’s Responsibility

Accurate assembly and safe and eective use of the machine is

the owner’s responsibility.

• Read and follow all safety instructions.

• Carefully follow all assembly instructions.

• Maintain the machine according to directions and

schedule included in this Viper® operator’s manual.

• Ensure that anyone who uses the machine is familiar

with all controls and safety precautions.

Special Messages

Your manual contains special messages to bring attention to

potential safety concerns, machine damage as well as helpful

operating and servicing information. Please read all the

information carefully to avoid injury and machine damage.

NOTE: General information is given throughout the

manual that may help the operator in the

operation or service of the machine.

THIS SYMBOL POINTS OUT IMPORTANT

SAFETY INSTRUCTIONS WHICH IF NOT

FOLLOWED COULD ENDANGER YOUR

PERSONAL SAFETY. READ AND FOLLOW ALL

INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO OPERATE THIS EQUIPMENT.

Before Operating Equipment:

Please read this section carefully. Read entire operating and

maintenance instructions for this product. Failure to follow

instructions could result in serious injury or death. Operate

the machine according to the safety instructions outlined

here and inserted throughout the text. Anyone who uses this

machine must read the instructions and be familiar with the

controls.

WARNING

WARNING INDICATES A HAZARD WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS

INJURY AND/OR PROPERTY DAMAGE.

CAUTION

CAUTION INDICATES YOUR EQUIPMENT CAN BE

DAMAGED IF THE SAFETY INSTRUCTIONS THAT

FOLLOW THIS SIGNAL WORD ARE NOT OBEYED.

IMPORTANT

INDICATES HELPFUL INFORMATION FOR PROPER

ASSEMBLY, OPERATION, OR MAINTENANCE OF

YOUR EQUIPMENT.

WARNING

CALIFORNIA PROPOSITION 65 WARNING

ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS,

OR OTHER REPRODUCTIVE HARM.

WARNING

YOU MUST READ, UNDERSTAND AND

COMPLY WITH ALL SAFETY AND OPERATING

INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO SETUP AND OPERATE YOUR

MACHINE.

FAILURE TO COMPLY WITH ALL SAFETY AND

OPERATING INSTRUCTIONS CAN RESULT IN LOSS

OF MACHINE CONTROL, SERIOUS PERSONAL

INJURY TO YOU AND/OR BYSTANDERS, AND RISK

OF EQUIPMENT AND PROPERTY DAMAGE. THE

TRIANGLE IN THE TEXT SIGNIFIES IMPORTANT

CAUTIONS OR WARNINGS WHICH MUST BE

FOLLOWED.

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

3

Page 4

WARNING

ENGINES GIVE OFF CARBON MONOXIDE, AN

ODORLESS, COLORLESS, POISONOUS GAS.

CARBON MONOXIDE MAY BE PRESENT EVEN IF

YOU DO NOT SMELL OR SEE ANY ENGINE EXHAUST.

BREATHING CARBON MONOXIDE CAN CAUSE

NAUSEA, FAINTING OR DEATH, IN ADDITION TO

DROWSINESS, DIZZINESS AND CONFUSION.

IF YOU EXPERIENCE ANY OF THESE SYMPTOMS,

SEEK FRESH AIR AND MEDICAL ATTENTION

IMMEDIATELY.

START AND RUN ENGINE OUTDOORS. DO NOT

START OR RUN ENGINE IN ENCLOSED AREA, EVEN

IF DOORS OR WINDOWS ARE OPEN.

HOT GASES ARE A NORMAL BYPRODUCT OF A

FUNCTIONING CATALYTIC CONVERTER. FOLLOW

ALL SAFETY INSTRUCTIONS TO PREVENT BURNS

AND FIRES.

DO NOT ALTER/MODIFY ENGINE:

NEVER ALTER OR MODIFY THE ENGINE FROM

THE FACTORY. SERIOUS INJURY OR DEATH MAY

OCCUR IF ENGINE IS MODIFIED OR ALTERED.

WHEN WORKING ON OR REPLACING PARTS FOR

THE ENGINE OR PRODUCT, YOU MUST ALWAYS

DISCONNECT SPARK PLUG WIRE FROM THE SPARK

PLUG AND KEEP IT AWAY FROM THE SPARK PLUG.

Operator's Manual

Viper® 212cc 4-Cycle Engine

ENGINE SAFETY PRECAUTIONS

Preventing Carbon Monoxide Poisoning

• Never try to ventilate engine exhaust indoors. Carbon

monoxide can reach dangerous levels very quickly.

• Never run engine outdoors where exhaust fumes

may be pulled into a building.

• Never run engine outdoors in a poorly ventilated area

where the exhaust fumes may be trapped and not

easily taken away. (Examples include: in a large hole

or areas where hills surround your working area.)

• Never run engine in an enclosed or partially enclosed

area. (Examples include: buildings that are enclosed

on one or more sides, under tents, car ports or

basements.)

• Always run the engine with the exhaust and muer

pointed in the direction away from the operator.

• Never point the exhaust muer towards anyone.

People should always be many feet away from the

operation of the engine and its attachments.

• Do not change the engine governor settings or overspeed the engine.

• Stay away from rotating parts. Place protective covers

over rotating parts.

• Do not use engine around dry brush, cloth rags, or

other ammable materials.

• Always keep materials and debris clear of muer

guard and other hot engine parts.

• Never operate the engine without the muer guard

in place.

• Always make sure the exhaust pipe is free of foreign

objects.

• The engine exhaust becomes very hot during

operation. Keep engine at least three feet away from

buildings and other equipment during operation.

• Wear appropriate clothing such as a long-sleeved

shirt or jacket. Also wear long trousers or slacks. Do

not wear shorts. Never wear sandals, sneakers, or

open shoes, and never operate the machine with

bare feet.

• Do not wear loose clothing or jewelry. They can get

caught in moving parts. Always keep hands, feet, hair

and loose clothing away from any moving parts on

engine and machine.

4

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 5

Operator’s Manual

Viper® 212cc 4-Cycle Engine

Gasoline Fires and Handling Fuel Safely

Use extra care in handling gasoline and other fuels. They are

ammable and vapors are explosive.

• When storing extra fuel be sure that it is in an

appropriate container and away from any re

hazards. Prevent re and explosion caused by static

electric discharge. Use only nonmetal, portable fuel

containers approved by the Underwriter’s Laboratory

(U.L.) or the American Society for Testing & Materials

(ASTM).

• Always ll fuel tank outside in a well ventilated area.

Never ll your fuel tank with fuel indoors. (Examples

include: basement, garage, barn, shed, house, porch,

etc.) Never ll tank near appliances with pilot lights,

heaters, or other ignition sources. If the fuel has to

be drained, this should be done outdoors and with

the proper equipment. Do not pour fuel from fuel

tank. The drained fuel should be stored in a container

specically designed for fuel storage or it should be

disposed of carefully.

• Never remove the fuel cap or add fuel with the

engine running. Stop engine and allow to cool before

removing the fuel cap/and or relling the engine.

• Do not smoke near or while handling engine fuel.

• Never drain fuel from engine in an enclosed area.

• During storage, tightly screw down fuel cap.

• Never pour fuel from engine fuel tank.

• Never siphon fuel by mouth to drain fuel tank.

• Always have an adult ll the fuel tank and never allow

children to ll the engine.

• Never allow an adult or anyone under the inuence

of drugs or alcohol to ll engine.

• When storing gasoline or equipment with fuel in the

tank, store away from furnaces, stoves, water heaters

or other appliances that have a pilot light or other

ignition source because they can ignite gasoline

vapors.

Burns and Fires

• The muer, muer guard and other parts of the

engine become extremely hot during the operation

of the engine. These parts remain extremely hot after

the engine has stopped.

Prevention of Burns and Fires

• Never remove the muer guard from the engine.

• Never touch the muer guard because it is extremely

hot and will cause severe burns.

• Never touch parts of the engine that become hot

after operation.

• Always keep materials and debris away from muer

guard and other hot parts of the engine to avoid res.

• This engine is designed to operate using a catalytic

converter which contributes to the engine’s

compliance with the EPA

SERVICE

• Always stop the engine whenever you leave the

equipment, before cleaning, repairing or inspecting

the unit. Engine should be turned o and cool, spark

plug wire must be removed from spark plug before

any repairs or adjustments are attempted. Never

make adjustments or repairs with the engine (motor)

running. Disconnect the spark plug wire, and keep

the wire away from the plug to prevent accidental

starting.

• Always wear eye protection when you make

adjustments or repairs.

• Keep all nuts and bolts tight and keep equipment in

good condition. Never tamper with safety devices.

Check their proper operation regularly.

• When servicing or repairing the engine, do not tip the

engine over or up unless specically instructed to do

so in this manual. Service and repair procedures can

be done with the engine in an upright position. Some

procedures will be easier if the engine is lifted on a

raised platform or working surface.

• To reduce re hazard, keep engine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage. Allow engine to cool before storing.

• Stop and inspect the equipment if you strike an

object. Repair, if necessary, before restarting.

• Clean and replace safety and instruction decals as

necessary.

• To guard against engine over-heating, always have

engine debris lter mounted and clean.

• Inspect engine before storage. When not in use,

disconnect spark plug lead and store indoors in a dry

place locked or otherwise inaccessible to children.

• Use only original equipment parts from Viper,

including all nuts and bolts.

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

5

Page 6

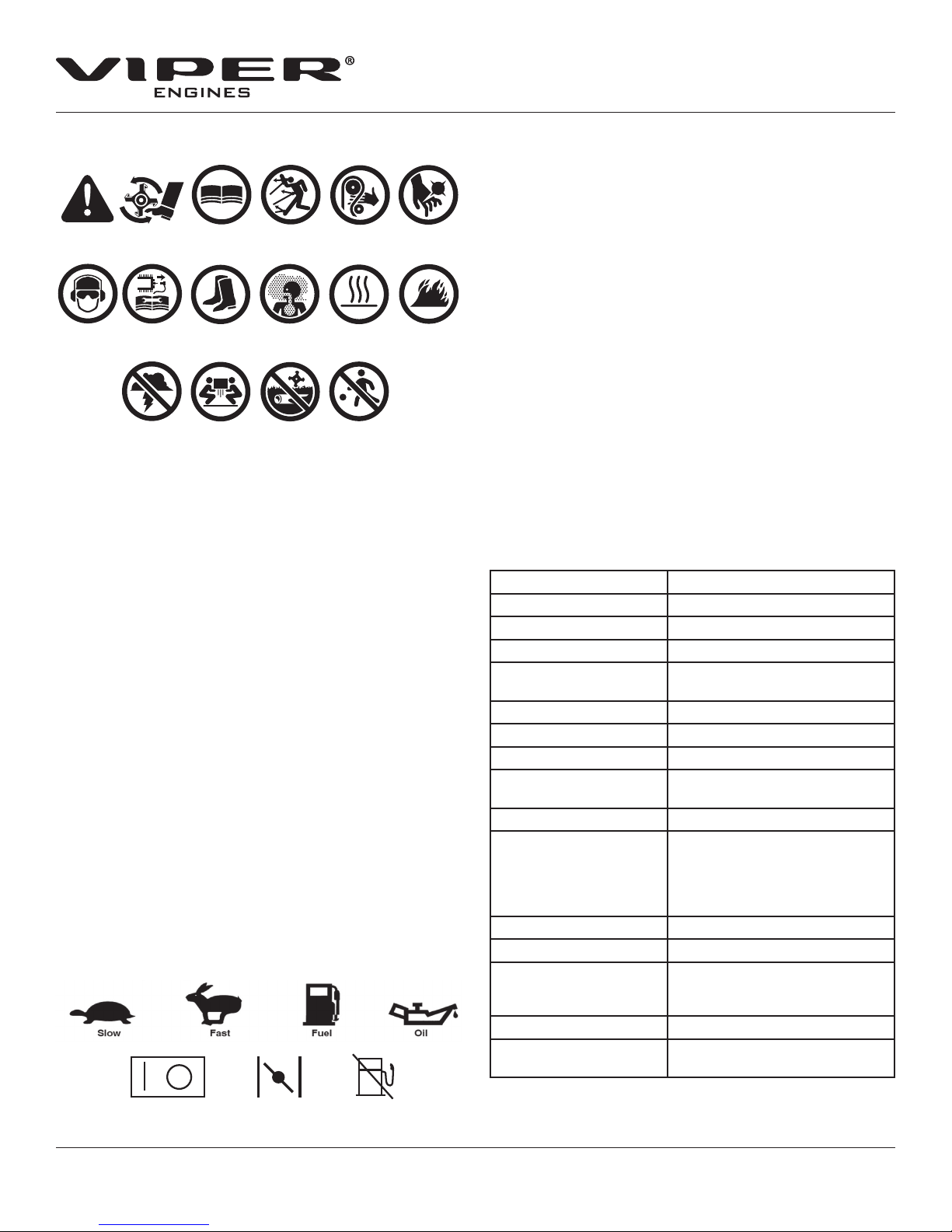

HAZARD SYMBOLS AND MEANINGS

A B

G

C

H

M

I J

N

D

O

E

K L

P

A: Warning!

B: Avoid Injury From Rotating Tines.

C: Read Owner’s Manual Before Operating Machine.

D: Remove Objects that Could Be Thrown By This

Machine.

E: Dangerous Moving Parts.

F: Be Aware of Moving and Rotating Parts.

G: Wear Ear and Eye Protection At All Times.

H: Do Not Service or Adjust Moving Parts Unless Engine is

Stopped and Spark Plug Wire is Disconnected.

I: Dress Appropriately And Wear Sturdy Footwear.

J: Toxic Fumes —Do Not Operate in Unventilated Areas.

K: Hot Surfaces.

L: Fire Hazards.

M. Do Not Use In Thunderstorms--For severe weather, stop

operation of this machine and seek shelter.

N. Team Lift--For your safety, always have at least two

people when lifting this machine.

O. Do Not Till Above Underground Utility Lines And Pipes.

P. Do Not Operate When Children Or Others Are Around.

F

CONTROL AND OPERATING SYMBOLS

Pictured below are control and operating symbols on the unit

or in this manual. Before you operate your unit, learn and

understand the purpose for each symbol.

Operator's Manual

Viper® 212cc 4-Cycle Engine

SAFETY DECALS

This engine has been designed and manufactured to provide

you with the safety and reliability you would expect from an

industry leader in outdoor power equipment manufacturing.

Although reading this manual and the safety instructions it

contains will provide you with the necessary basic knowledge

to operated this equipment safely and eectively, we have

placed several safety labels on the engine to remind you of this

important information while you are operating the unit.

These safety labels are illustrated on page 7, and are shown

here to help familiarize you with the location and content

of the safety messages you will see as you perform normal

operations. Please, review these decals now, and if you have

any questions regarding their meaning or how to comply

with these instructions, reread the complete safety instruction

text in this manual. For additional questions contact Ardisam

customer service.

SPECIFICATIONS

Displacement / Cycle 212 cc / 4-Cycle

Ignition Type Electronic ignition

Cooling System Forced air cooling

Idling Carburetor Adjust 1600 +/- 160 RPM

Valve Clearance Cold engine-Intake: 0.15 +/- 0.02

mm; Exhaust: 0.20 +/- 0.02 mm

Maximum Torque 8.85 ft-lb @ 2500 RPM

Bore and Stroke 70 x 55 mm

Spark Plug Type F6TC, NGK BP6ES

Fuel Type Unleaded gasoline (low/no ethanol

blends recommended)

Fuel Tank Capacity 0.95 gallon (3.6 liters or 121.7 oz)

Drive Shaft Type Horizontal, 3/4” straight, (3/16”)

keyed shaft with ball bearings.

Direction: counterclockwise (facing

shaft); Length: 2-1/4”; Central

thread: 5/16”-24

Start Type Recoil

Maximum RPM 3600 RPM

Oil Capacity and Type ~0.63 qt / 20.2 oz (0.6 liters); SAE

10W30 (in freezing weather use

5W30)

Dry Weight 37.5 lb (17 kg)

Overall Dimensions 15.4” x 12.6” x 13.6” (390mm x

320mm x 345mm)

On/O Fuel Shuto

Choke

6

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 7

Operator’s Manual

Viper® 212cc 4-Cycle Engine

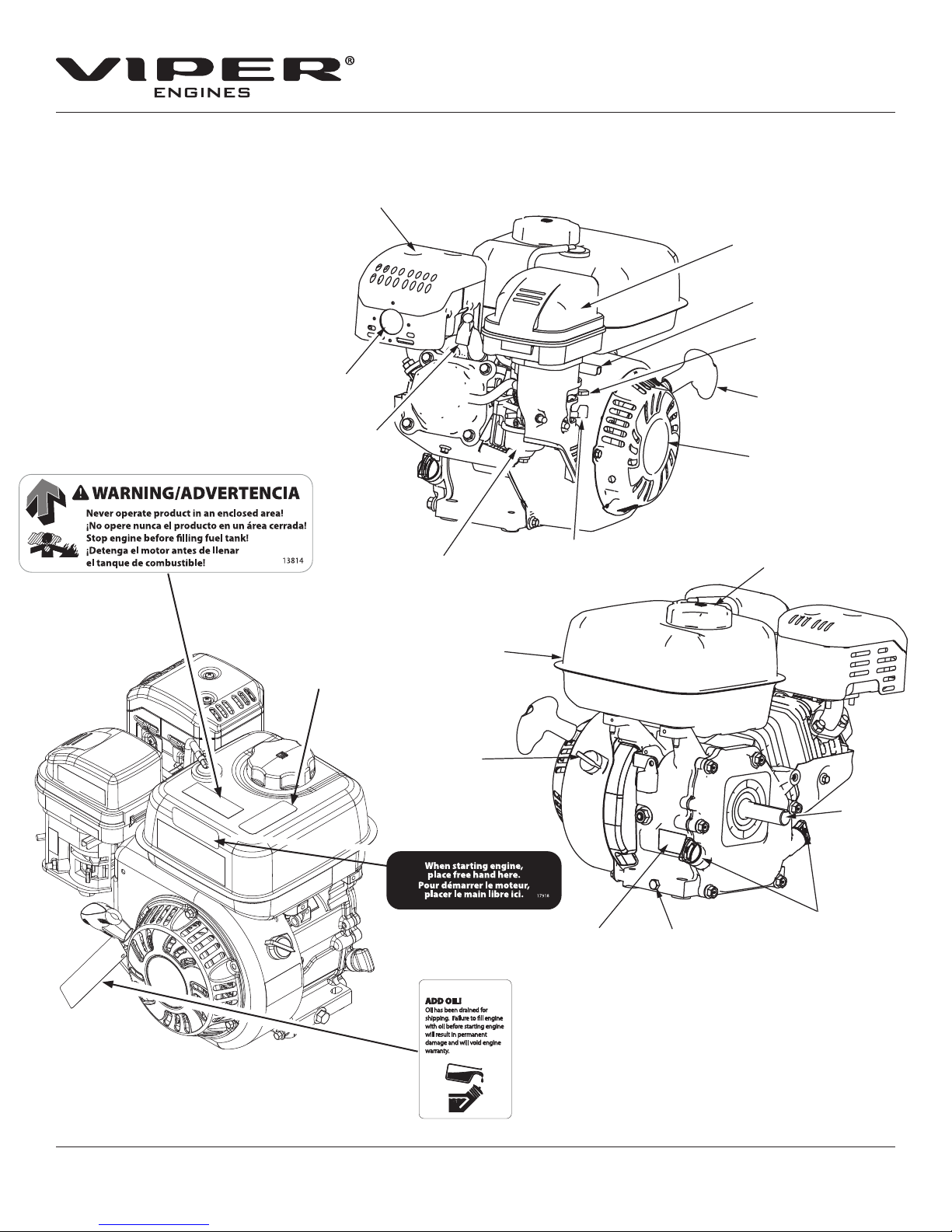

FEATURES

This is a 4-cycle air cooled engine. The 212cc engine utilizes a horizontal shaft and an oil slinger lubricated system.

MUFFLER

AIR CLEANER

THROTTLE CONTROL

CHOKE CONTROL

EXHAUST

OUTLET

PULL HANDLE

Part No. 13814

WARNING LABEL

SPARK

PLUG

Part No. 14072

DECAL- Read Owner’s

Manual

CARBURETOR &

FUEL BOWL

FUEL TANK

ON/OFF SWITCH

Part No. 17918

DECAL-PLACE FREE

HAND HERE

FUEL

SHUT OFF

SWITCH

STARTER RECOIL

FUEL CAP

PTO

SHAFT

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

ENGINE SERIAL

NUMBER DECAL

Part No. LBL6105OIL

CAUTION LABEL

OIL FILL PORTS

OIL DRAIN PLUG

7

Page 8

WARNING

DO NOT ATTEMPT TO START ENGINE IN THE

FOLLOWING WAYS:

• DO NOT USE STARTING FLUID.

• DO NOT SPRAY FLAMMABLE LIQUIDS OR VAPORS

INTO AIR CLEANER, CARBURETOR OR SPARK

PLUG CHAMBER.

• DO NOT REMOVE SPARK PLUG AND PULL ON

STARTER ROPE. FLAMMABLE FUEL CAN SPRAY

OUT AND IGNITE FROM A SPARK FROM SPARK

PLUG.

DO NOT REFUEL WHILE SMOKING, NEAR OPEN

FLAME, OR OTHER POTENTIAL HAZARDS.

FUEL IS HIGHLY FLAMMABLE AND MUST BE HANDLED

WITH CARE. NEVER FILL THE TANK WHEN THE ENGINE

IS HOT OR RUNNING. ALWAYS MOVE OUTDOORS TO

FILL TANK.

ALWAYS PERFORM A PREOPERATION INSPECTION

BEFORE EACH OPERATION AND CORRECT ANY

PROBLEM.

IMPROPER MAINTENANCE OF THIS ENGINE,

OR FAILURE TO CORRECT A PROBLEM BEFORE

OPERATION, CAN CAUSE A MALFUNCTION.

SERIOUS INJURY OR DEATH CAN OCCUR IF THIS

WARNING IS NOT COMPLIED WITH.

Operator's Manual

Viper® 212cc 4-Cycle Engine

9. Check the equipment powered by this engine. Review

the operator’s manual provide with the equipment

powered by this engine for any safety and warning

precautions and/or procedures that should be followed

before starting this engine.

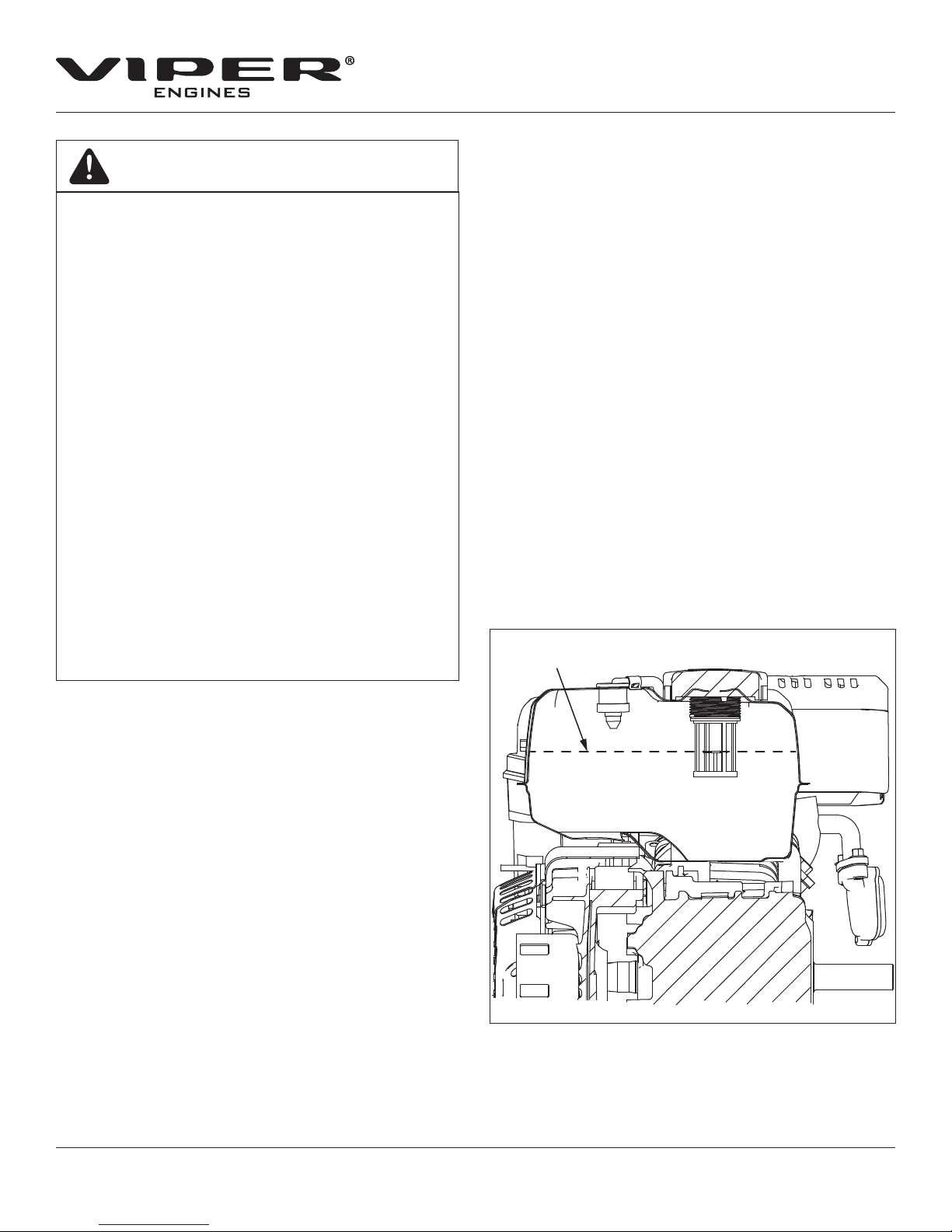

Checking And Filling The Fuel Tank

Be sure the engine is located on a level surface before

checking or relling fuel. Use unleaded regular, unleaded

premium automotive fuels only. Low/no ethanol blends

recommended. Fuel may contain up to 10% ethanol. DO NOT

mix oil with fuel.

NOTE: If using ethanol blends, it is recommended you

also use an ethanol fuel treatement to protect against

corrosion.

1. Make sure engine is cool and not running while lling.

2. Remove fuel cap.

3. Fill tank to fuel level limit (3.6L). SEE FIGURE 1

Note: Do not overll.

3. Replace cap and remove any spilled fuel before

operating.

MAXIMUM FUEL

FILL LEVEL

OPERATION

Pre-Operation Inspection

1. Check that engine is lled with the proper amount and

type of oil. For the most appropriate type of oil to use,

see “Choosing Oil Type” chart on page 9.

2. Check that the engine has the appropriate amount of

fuel.

3. Examine underneath and around engine for signs of oil

or fuel leaks.

4. Inspect fuel hoses and connections for tightness and fuel

seepage.

5. Look for signs of engine damage.

6. Check that all guards and shields are in place, and all

screws, nuts and bolts are tightened.

7. Eliminate excessive debris around muer and recoil

starter.

8. Be sure air lter and cylinder ns are clean and free of

debris.

FIGURE 1

8

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 9

Operator’s Manual

Viper® 212cc 4-Cycle Engine

WARNING

ENGINE IS SHIPPED FROM FACTORY WITHOUT OIL.

YOU MUST ADD ENGINE OIL BEFORE STARTING

ENGINE.

ENGINE OIL IS HAZARDOUS TO YOUR HEALTH.

DISPOSE OF OIL APPROPRIATELY. USE A SAFE

DISPOSAL/RECYCLING CENTER.

• ALWAYS PERFORM A PREOPERATION

INSPECTION BEFORE EACH OPERATION AND

CORRECT ANY PROBLEM.

• IMPROPER MAINTENANCE OF THIS ENGINE,

OR FAILURE TO CORRECT A PROBLEM BEFORE

OPERATION, CAN CAUSE A MALFUNCTION.

• SERIOUS INJURY OR DEATH CAN OCCUR IF THIS

WARNING IS NOT COMPLIED WITH.

Choosing Oil Type

Checking and Adding Oil

Be sure the engine is located on a level surface before

checking or relling oil.

1. Clean around oil ll area and drain plug. SEE FIGURE 2

2. Unscrew dipstick and wipe clean with cloth.

SEE FIGURE 2

3. Reinsert and tighten dipstick.

4. Unscrew and check dipstick. If no oil shows on the

dipstick, rell to the top thread of the oil ll oil.

5. Change oil if contaminated.

NOTE: Viper engine oil may be put in through the oil

dipstick hole or through the oil ll plug opening. If

an oil plug is present, loosen screw and ll oil until

oil level is even with top thread in plug hole.

SAE

30

10W-30

5W-30

-20 0 20 40 60 80 100 °F

-30 -20 -10 0 10 20 30 40 °C

Environment Temperature

OIL FILL PORT

& DIPSTICK

OIL DRAIN PLUG

FIGURE 2

UPPER OIL LEVEL

LOWER OIL LEVEL

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

9

Page 10

Operator's Manual

FULL CHOKE

Viper® 212cc 4-Cycle Engine

WARNING

CARBON MONOXIDE GAS IS TOXIC. MOVE

THE ENGINE TO A WELLVENTILATED AREA

OUTDOORS, TO PREVENT CARBON MONOXIDE

POISONING. INHALATION CAN CAUSE

UNCONSCIOUSNESS AND DEATH.

NEVER LEAVE ENGINE RUNNING WHILE

UNATTENDED.

MOVE ENGINE TO A WELLVENTILATED AREA,

ALWAYS OUTDOORS, TO PREVENT CARBON

MONOXIDE POISONING.

MOVE TO AN AREA AWAY FROM FLAMES OR

SPARKS, TO AVOID IGNITION OF VAPORS IF

PRESENT.

STARTING AND STOPPING THE ENGINE

Note: Operating engine on a steep angle will cause the

engine to lose lubrication and seize.

Review “safety and warning precautions” and “pre-operation

inspection” sections before starting engine.

Engine Start

1. Move the fuel valve lever to the ON position.

SEE FIGURE 5

2. Remove all debris from air cleaner holes and cooling ns

to ensure proper air ow.

3. Move throttle lever 1/2 way between the FULL and LOW

THROTTLE positions. (This is not necessary on models with

throttle xed at full throttle position.)

SEE FIGURES 3 AND 4

4. Move the choke lever:

• If the engine is cold or the ambient temperature is

low, move choke lever to the FULL CHOKE position.

SEE FIGURE 5

• If the engine is warm or the ambient temperature is

high, move choke lever to the HALF CHOKE position

or RUN position. SEE FIGURES 6 AND 7

CAUTION

DO NOT STOP ENGINE BY MOVING CHOKE

CONTROL TO CHOKE. BACKFIRE, ENGINE

DAMAGE, OR FIRE MAY OCCUR.

LOW THROTTLE POSITION

IS ALL THE WAY TO THE RIGHT

FIGURE 4

POSITION

FUEL LEVER

FIGURE 5

HALF CHOKE

POSITION

FIGURE 6

ON POSITION

FULL THROTTLE POSITION

IS ALL THE WAY TO THE LEFT

THROTTLE

LEVER

FIGURE 3

10

OPEN

CHOKE

(RUN)

POSITION

FIGURE 7

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 11

7. Turn the On/O switch to the ON position.

SEE FIGURE 8

8. Grasp starter handle and pull out slowly, until resistance

is felt. Without letting it retract, pull rope with a rapid

stroke. DO NOT pull out the rope all of the way. Let it

return to its original position very slowly. Repeat this step

until engine starts.

9. After engine begins operating, move choke lever to

HALF CHOKE position. SEE FIGURE 6

10. Run engine for 30 to 45 seconds at HALF CHOKE

position until engine warms up.

11. Once engine is warmed up, slowly move the choke lever

to the RUN position. SEE FIGURE 7

12. Move throttle lever to desired speed. (This is not necessary

on models with throttle xed at full throttle position.)

SEE FIGURE 3

To Stop the Engine:

1. Move the throttle lever to the LOW THROTTLE position

and allow the engine to run at low speeds for 1-2

minutes. (This is not necessary on models with throttle

xed at full throttle position.) SEE FIGURE 4

2. Turn the On/O switch to the OFF position.

SEE FIGURE 9

3. Move the fuel lever to the OFF position. SEE FIGURE 10

4. Pull the starter handle slowly and return the handle to its

original position when resistance is felt. This operation

will prevent outside moisture from entering the

combustion chamber.

Stopping the Engine with the Fuel Lever:

Move the fuel lever to the OFF position and wait until the

engine stops. Avoid letting fuel remain in the carburetor over

long periods, or the passages of the carburetor may become

clogged with impurities and malfunction may result.

Operator’s Manual

Viper® 212cc 4-Cycle Engine

FIGURE 8

FIGURE 9

FUEL LEVER

OFF POSITION

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

FIGURE 10

11

Page 12

MAINTENANCE AND STORAGE

Please read the maintenance schedule, found in the

accompanying combined exhaust and evaporative emissions

control warranty statement, and observe these recommended

care operating intervals to extend the life of your engine.

Good maintenance is essential for safe, economical, and

trouble-free operation. It will also help reduce air pollution.

To help you properly care for your engine, the following

pages include a routine inspection procedures and simple

maintenance procedures using basic hand tools. Other service

tasks that are more dicult, or require special tools, are best

handled by professionals and are normally performed by a

technician or other qualied mechanic.

Maintenance, replacement or repair of the emissions

control devices and systems may be performed by any

non-road engine repair establishment or individuals.

However, items must be serviced by an authorized dealer

to obtain "no charge" emissions control warranty service.

ENGINE MAINTENANCE

For daily maintenance checks, review “pre-operation

inspection” section.

LUBRICATION

Choose 4-cycle engine oil that meets or surpasses the latest

API service classication. For temperatures higher than 32º F,

use SAE 30 or SAE 10W-30 motor oil. Use SAE 5W-30 or SAE

10W if temperatures are below 32º F. DO NOT USE SAE 10W

40 MOTOR OIL.

See page 9 to reference Choosing Oil Type chart.

Operator's Manual

Viper® 212cc 4-Cycle Engine

WARNING

IMPROPER MAINTENANCE, OR FAILURE TO CORRECT

A PROBLEM BEFORE OPERATION CAN CAUSE A

MALFUNCTION. ALWAYS FOLLOW THE INSPECTION

AND MAINTENANCE RECOMMENDATIONS AND

SCHEDULES IN THIS OPERATOR’S MANUAL.

CHECK ENGINE REGULARLY FOR LOOSE NUTS AND

BOLTS. KEEP THESE ITEMS TIGHTENED.

TEMPERATURE OF MUFFLER AND NEARBY AREAS MAY

EXCEED 150° F 65° C. AVOID THESE AREAS.

PREVENT ACCIDENTAL STARTING:

• ENGINE MUST BE TURNED OFF AND COOL.

• SPARK PLUG WIRE MUST BE REMOVED FROM

SPARK PLUG BEFORE CHECKING AND ADJUSTING

ENGINE OR EQUIPMENT.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN

SERIOUS INJURY OR DEATH.

4. Fill with appropriate oil to FULL or top line of dipstick;

otherwise to top thread of oil ll hole. SEE FIGURE 12

NOTE: Oil capacity is 0.63 qt / 20.2 oz. See above, under

lubrication, for correct engine oil grade.

5. Reinsert dipstick or oil ll cap and tighten.

Oil Maintenance

After the rst 20 hours, or after the rst month, of operating

a new Viper® Engine the oil should be replaced, and every 50

hours of operating time thereafter. The oil should be changed

every 25 hours if used under severe conditions, such as in

high temperatures or under heavy loads, otherwise changed

weekly. Check oil periodically; do not overll.

Changing Oil

Be sure the engine is not operating and is located on a level

surface before checking or relling oil. Engine should be

warm for easy removal of oil.

1. Detach spark plug cap/wire and move away from spark

plug. SEE FIGURE 11

2. Remove oil drain plug and empty oil into suitable oil

container. Dispose of oil properly. SEE FIGURE 12

3. Reinstall drain plug. Remove dipstick (if applicable) or oil

ll cap. SEE FIGURE 12

12

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

CAUTION

ENGINE IS SHIPPED FROM FACTORY WITHOUT

OIL. YOU MUST ADD ENGINE OIL BEFORE

STARTING ENGINE.

RUNNING ENGINE WITH A LOW OIL LEVEL WILL

CAUSE DAMAGE TO YOUR ENGINE. THIS TYPE OF

DAMAGE IS NOT COVERED UNDER WARRANTY.

WARNING

NEVER RUN YOUR ENGINE IN A POORLY VENTILATED

AREA. THE EXHAUST FROM ENGINE MAY CONTAIN

POISONOUS CARBON MONOXIDE. BREATHING IT

WOULD CAUSE SHOCK, UNCONSCIOUSNESS, AND

EVEN DEATH.

Page 13

SPARK PLUG

WIRE/CAP

Operator’s Manual

Viper® 212cc 4-Cycle Engine

FIGURE 11

OIL FILL PORT

& DIPSTICK

OIL DRAIN PLUG

UPPER OIL LEVEL

LOWER OIL LEVEL

FIGURE 12

WARNING

ENGINE OIL IS HAZARDOUS TO YOUR HEALTH.

DISPOSE OF OIL APPROPRIATELY. USE A SAFE

DISPOSAL/RECYCLING CENTER.

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

13

Page 14

CAUTION

NEVER RUN ENGINE WITHOUT AIR FILTER

PROPERLY INSTALLED. ADDED WEAR AND

ENGINE FAILURE MAY OCCUR IF AIR FILTER IS NOT

INSTALLED ON ENGINE.

AIR FILTER

Refer to maintenance schedule for suggestions on when to

service your air lter. Clean lter daily in extremely dusty

conditions.

Remove/Install Air Filter as follows:

SEE FIGURE 13

1. Remove air cleaner cover.

2. Remove the air lter element.

3. Replace with clean or new air lter element.

4. Replace air lter cover.

Wash Air Filter as follows:

1. Wash in warm water with mild soap until dirt and debris

are removed. Press lter when washing, do not twist.

2. Rinse in warm water until soap and dirt are removed.

3. Dry lter by wrapping in a clean cloth and pressing lter

until it is dry.

4. Oil lter thoroughly with common household lubricating

oil.

5. Attach the lter and air lter cover to the engine.

Operator's Manual

Viper® 212cc 4-Cycle Engine

SPARK PLUG

The recommended spark plug is a F6TC (NGK BP6ES).

!

Check and Change Spark Plug as follows:

1. Check spark plug every 50 operating hours.

2. Disconnect the spark plug cap, and clean any debris from

around the spark plug area. SEE FIGURE 11 on previous

page.

3. Remove spark plug and replace if any of the following

occur; pitted electrodes, burned electrodes, cracked

porcelain, or deposits around electrodes.

4. After analysis, seat spark plug and tighten with spark

plug wrench to compress the sealing washer. SEE

FIGURE 11 on previous page.

• Reinstall original spark plug, tighten additional 1/2

turn.

• Installing new spark plug, adjust spark plug gap to

0.030” (0.7-0.8 mm) and tighten additional 1/8 – 1/4

turn.

NOTE: Loose spark plug may overheat and damage

engine. Over tightened spark plug may damage

threads in the cylinder head.

Spark Plug Maintenance

Spark plug should be removed, cleaned and gap adjusted

after approximately fty hours of operating time.

NOTE: A sand blaster should not be used to clean spark

plugs. Microscopic particles remaining in the plug

may score the engine cylinder during operation.

Use solvent and a wire brush to clean the plug and

compressed air to blow out completely.

AIR FILTER COVER

AIR FILTER ELEMENT

AIR FILTER BASE

14

FIGURE 13

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 15

Operator’s Manual

Viper® 212cc 4-Cycle Engine

WARNING

FUEL IS HIGHLY FLAMMABLE AND MUST BE

HANDLED WITH CARE. NEVER FILL OR DRAIN

THE FUEL TANK WHEN THE ENGINE IS HOT OR

RUNNING. ALWAYS MOVE OUTDOORS TO FILL

OR DRAIN FUEL FROM THE TANK. SERIOUS

INJURY OR DEATH CAN OCCUR.

DO NOT REMOVE FUEL WHILE SMOKING, NEAR

OPEN FLAME, OR OTHER POTENTIAL HAZARDS.

FUEL IS TOXIC. DO NOT SIPHON FUEL BY MOUTH.

DO NOT STORE ENGINE INSIDE A BUILDING WITH

FUEL IN THE TANK. POTENTIAL SPARKS MAY BE

PRESENT CAUSING IGNITION OF FUEL AND FUEL

VAPORS.

FAILURE TO FOLLOW SAFETY INSTRUCTIONS

CAN CAUSE SERIOUS INJURY OR DEATH.

CARBURETOR

• Never tamper with the factory setting of the

carburetor.

• Contact your service provider or Ardisam if

adjustment is needed.

FUEL FILTER

Clean Or Replace Fuel Filter as follows:

1. Disconnect spark plug wire from spark plug. Remove

spark plug and protect spark plug hole from debris.

2. Drain fuel from tank before attempting to clean/replace

lter.

3. Remove two nuts holding muer to the engine and

remove muer.

4. Remove single tank bolt from fuel tank assembly.

5. Remove two nuts from underside of tank.

6. Gently lift tank o of the engine and disconnect the fuel

line hose clamp. SEE FIGURES 14 and 15.

7. Remove fuel tank lter by using proper size socket to

turn lter counter clockwise. SEE FIGURE 16

8. Filter may be washed with kerosene or similar solvent.

9. If lter is extremely dirty or torn replace with new lter.

10. Reassemble and ll with clean fresh gasoline. Check for

leaks prior to starting engine.

FUEL LINE HOSE CLAMP

FIGURE 14

FUEL

LINE

FIGURE 15

FUEL FILTER

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

FIGURE 16

15

Page 16

WARNING

DO NOT REMOVE FUEL WHILE SMOKING, NEAR

OPEN FLAME, OR OTHER POTENTIAL HAZARDS.

FUEL IS TOXIC. DO NOT SIPHON FUEL BY MOUTH.

DO NOT STORE ENGINE INSIDE A BUILDING WITH

FUEL IN THE TANK. POTENTIAL SPARKS MAY BE

PRESENT CAUSING IGNITION OF FUEL AND FUEL

VAPORS.

CHECK ENGINE OFTEN FOR LOOSE NUTS AND

BOLTS. KEEP THESE ITEMS TIGHTENED.

FAILURE TO FOLLOW SAFETY INSTRUCTIONS

CAN CAUSE SERIOUS INJURY OR DEATH.

TRANSPORTING ENGINE

1. Shut fuel supply o by moving the fuel lever to the OFF

position. Failure to turn fuel o may cause raw fuel to

enter the crank case contaminating the engine oil and

providing insucient lubrication. SEVERE ENGINE

DAMAGE MAY RESULT. SEE FIGURES 17 AND 18

2. Never transport engine inside an enclosed space or

vehicle. Fuel or fuel vapors may ignite causing serious

injury or death.

3. If fuel is present in the fuel tank remove fuel or transport

with an open vehicle in an upright position.

4. If an enclosed vehicle must be used, remove fuel into an

approved red fuel container. DO NOT siphon by mouth.

5. Run engine or drain to use up the fuel in the carburetor

and fuel tank. Always run engine in a well ventilated

area.

6. Wipe away any spilled fuel from engine. Allow to dry.

Operator's Manual

Viper® 212cc 4-Cycle Engine

a. Move fuel lever to the OFF position and start

engine. Run until engine runs itself out of any

residual fuel left in fuel cup and fuel lines. (It is

normal for the engine to run two to three minutes

before the fuel is completely out of system.)

3. Store engine in its upright position.

4. Remove all debris from engine.

TROUBLESHOOTING AND REPAIR

At Ardisam, we build quality and durability into the design

of our products; but no amount of careful design by us, and

careful maintenance by you, can guarantee a repair-free life

for your Viper® Engine. Most repairs will be minor, and easily

xed by following the suggestions in the troubleshooting

guide in this section.

This section will help you pinpoint the causes of common

problems and identify remedies.

For more complicated repairs, you may want to rely on your

retailer, an authorized service center or Ardisam. Ardisam will

make the necessary repairs if a service center is not available.

A parts breakdown is located toward the end of this manual.

We will always be glad to answer any questions you have, or

help you nd suitable assistance. To order parts or inquire

about warranty, call or e-mail us using the contact information

found in this section.

FULL CHOKE

POSITION

STEPS FOR LONGTERM STORAGE

1. Mix an appropriate amount of fuel stabilizer, such as

STA-BIL®, to fresh gasoline, in the ratio recommended on

the stabilizer packaging. Run the engine for ve minutes

to distribute the stabilizer mixture throughout the fuel

system. This will prevent gum, varnish and corrosion

build up in your fuel system during long-term storage for

up to 12 months.

NOTE: It is recommended that fuel tank is drained and

new fuel stabilizer is added every four months. Starting

engine once a month to help preserve engine is also

recommended.

2. Run engine for 10-15 minutes to ensure that the stabilizer

reaches the carburetor.

16

FUEL LEVER

FIGURE 17

FUEL LEVER

OFF POSITION

FIGURE 18

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

ON POSITION

Page 17

Operator’s Manual

Viper® 212cc 4-Cycle Engine

Ordering Replacement Parts

Parts can be obtained from the store where the unit was

purchased or direct from the factory. To order parts call 1-800-

345-6007. For other general questions, you can email us at:

Info@Ardisam.com.

Please include the following information with your order:

1) Part numbers

2) Part description

3) Quantity

4) Model number and serial number

SPARE PARTS

Only use approved Viper® spares. Refer to the Illustrated Parts

Breakdown and parts list.

WARNING

IMPROPER MAINTENANCE, OR FAILURE TO

CORRECT A PROBLEM BEFORE OPERATION

CAN CAUSE A MALFUNCTION. ALWAYS

FOLLOW THE INSPECTION AND MAINTENANCE

RECOMMENDATIONS AND SCHEDULES INCLUDED

WITH THIS OPERATOR’S MANUAL.

CHECK ENGINE REGULARLY FOR LOOSE NUTS

AND BOLTS. KEEP THESE ITEMS TIGHTENED.

TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150° F 65° C. AVOID THESE AREAS.

PREVENT ACCIDENTAL STARTING:

• ENGINE MUST BE TURNED OFF AND COOL.

• SPARK PLUG WIRE MUST BE REMOVED

FROM SPARK PLUG BEFORE CHECKING AND

ADJUSTING ENGINE OR EQUIPMENT.

FAILURE TO FOLLOW THESE WARNINGS CAN

RESULT IN SERIOUS INJURY OR DEATH.

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE REMEDY/ACTION

Engine will not start 1. Power switch o 1. Flip switch to ON position

2. Fuel valve o 2. Check fuel valve is on

3. Spark plug wire disconnected 3. Connect spark plug wire to spark plug

4. Out of fuel 4. Refuel

Engine runs rough, oods during

operation

5. Spark plug wet, faulty or improperly

gapped

6. Stale Fuel 6. Drain old fuel and replace with fresh fuel.

1. Dirty air lter 1. Clean or replace air lter

5. Clean, replace or gap spark plug

Use fuel stabilizer as a future preventative

measure.

Engine is hard to start 1. Stale fuel 1. Drain old fuel and replace with fresh.

Engine misses or lacks power 1. Clogged fuel tank or fuel lter 1. Remove and clean

Engine runs, then quits 1. Fuel vapor hose not venting 1. Replace fuel vapor hose

Contact Ardisam customer service if above remedies fail.

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

2. Choke partially engaged 2. Turn o choke

3. Carburetor out of adjustment 3. Call factory

Use fuel stabilizer at end of season

2. Spark plug wire loose 2. Make sure spark wire is securely attached

to spark plug

3. Dirty carburetor 3. Clean carburetor, use fuel stabilizer, and

fresh fuel

2. Clogged air lter 2. Clean or replace

3. Improper carburetor adjustment 3. Call factory

4. Spark plug dirty, improper gap, or

wrong type

4. Replace spark plug and adjust gap to

0.030”

17

Page 18

ILLUSTRATED PARTS BREAKDOWN Viper 212cc Engine

15,16

Operator's Manual

Viper® 212cc 4-Cycle Engine

15

13

19

5,19

17

12

5

11

5

21

5

2

5,18

14

6

4

9

18

9,10

8

18

5,9,18

7

3

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 19

ILLUSTRATED PARTS BREAKDOWN Viper 212cc Engine

Operator’s Manual

Viper® 212cc 4-Cycle Engine

KEY PART # DESCRIPTION QT Y.

1 13831 KIT THROTTLE ASSEMBLY 1

2 67201 CYLINDER HEAD COVER KIT 1

3 67178 RECOIL STARTER ASSEMBLY 1

4 67069 ENGINE STOP SWITCH ASSEMBLY 1

5 67183 CARBURETOR GASKET KIT 1

6 67195 IGNITION MECHANISM KIT 1

7 13829 IGNITION COIL REPL. KIT 1

8 13830 BLOWER HOUSING KIT 1

9 67177 AIR CLEANER ASSEMBLY 1

10 67173 AIR CLEANER FILTER 1

KEY PART # DESCRIPTION QT Y.

11 67031 OIL PLUG KIT 1

12 67038 DIPSTICK 1

13 67012 SPARK PLUG 1

14 67198 FUEL LINE KIT AND CONNECTOR FILTER 1

15 13566 FUEL TANK ASSEMBLY KIT 1

16 13607 FUEL TANK COVER KIT 1

17 13608 FUEL VAPOR HOSE KIT 1

18 13606 CARBURETOR ASSEMBLY 1

19 13609 MUFFLER COMPLETE KIT 1

NOT SHOWN PARTS

14926 KIT ALTITUDE 3000 TO 6000 FT

14927 KIT ALTITUDE 6000 TO 8000 FT

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

19

Page 20

Operator’s Manual

Viper® 212cc 4-Cycle Engine

Warranty Terms and Conditions

ARDISAM LIMITED 5 YEAR VIPER ENGINE WARRANTY

FOR ENGINES GREATER THAN 79CC’S MANUFACTURED AFTER 10/1/2014

Ardisam, Inc. (Ardisam) warrants this engine under a ve-year limited warranty to be free from defects in the material or

workmanship or both for a period not exceeding sixty consecutive months from the date of original purchase by the rst retail

consumer or rst commercial end user. “Consumer use,” means personal recreational use by a retail consumer. “Commercial use,“

or “commercial application,“ means all other uses, including use for commercial, income producing or rental purposes. Once

a product has experienced commercial use, it shall thereafter be considered as a commercial use product for the purpose of

this warranty. This warranty applies to the original owner that provides a proof of purchase. This warranty is not transferable.

The warranty period begins on the date of purchase by the rst retail consumer or commercial end user, and continues for the

sixty month consecutive period thereafter. Any unit used in a commercial application is covered for a period of 90 days after

purchase by the rst commercial end user. For the warranty to be valid, the product must be registered online within 30 days

of purchase, or the warranty card must be lled out and received by Ardisam within 30 days of purchase. Ardisam shall not be

obligated for transportation charges that result from repair or replacement under the terms of this warranty. Transportation

charges are the sole responsibility of the purchaser.

This warranty excludes parts that are worn or damaged due to normal wear such as spark plugs, recoil ropes, fuel lters, and

bearings. Routine maintenance items such as lter elements, O-rings, seals, lubricants, and tune-ups are also excluded. Natural

fading or peeling from normal deterioration due to weather elements, sea water, and chemicals is also excluded. Non catalytic

muers will be warrantied for one year. For all catalytic muers refer to the emissions control warranty contained in the retail

package.

This limited warranty applies to defects in the material or workmanship of the engine only. This warranty does not apply to

the product to which the engine is mounted. This warranty policy applies only to engines which have not been subjected to

misuse including but not limited to operating engine with insucient, contaminated, or incorrect grade of oil, using gasoline

with ethanol greater than 10%, contaminated gasoline, dirt ingestion due to improper air lter maintenance or improper

installation, improper tension of belts creating excessive force on crankshaft, excessive vibration causing loose hardware,

unbalanced items attached to the crankshaft, uses other than those indicated in the product manual, alteration, accident, use

of unauthorized parts, failure to perform periodic maintenance as specied in engine manual, normal wear and tear, use of

unauthorized parts or repairs performed at unauthorized service centers. Parts applied to the external engine like clutches,

pulleys, belt engagement items are subject to the warranty of the product to which the engine is mounted. Failure resulting

from obstructing airow to the engine such as dirt, grass, rodent nests that cause overheating is excluded. All parts specied in

the “Emissions Control Warranty” contained in the retail package will follow the terms of that agreement and are not included as

part of this warranty. There is no other express warranty. Implied warranties, including those of merchantability and tness for

a particular purpose, are limited to one year from purchase, or to the extent permitted by law. All other implied warranties are

excluded. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted by law. Ardisam

does not assume, and does not authorize any other person to assume for Ardisam, any liability in connection with the sale

of Ardisam products. To be at “No Charge,” warranty work must be sent directly to and performed by Ardisam or an Ardisam

Authorized Warranty Service Facility. To obtain warranty service and/or replacement instructions, contact the Ardisam Customer

Service Department at 800-345-6007. If you choose to ship your product to Ardisam for warranty repair, you must rst have

prior approval from Ardisam by calling the Ardisam Customer Service Department for a return material authorization number

(RMA#). Under these circumstances, all items must be shipped prepaid. Ardisam will, in its discretion, at no charge, repair or

replace any defective part to which this warranty applies. Ardisam retains the right to change models, specications and price

without notice. Ardisam shall not be obligated to ship any repair or replacement product to any location outside of the United

States of America or Canada. Some states and countries do not allow the limitations on how long an implied warranty lasts, or

the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you. This warranty

gives you specic legal rights, and you may also have other rights which vary from state to state and country to country.

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

20

Page 21

NOTES

Operator's Manual

Viper® 212cc 4-Cycle Engine

21

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

Page 22

NOTES

Operator’s Manual

Viper® 212cc 4-Cycle Engine

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

22

Page 23

NOTES

Operator’s Manual

Viper® 212cc 4-Cycle Engine

For additional information email info@ardisam.com or call 800-345-6007 M-F 8-5

23

Page 24

All weights, specications and features are approximate and are subject to change without notice. Due to continuous product

improvements, product images may not be exact. Items used for props not included. Some assembly may be required.

Check for parts online at www.ardisam.com or call 800-345-6007 M-F 8-5

Viper Engines®, Division of Ardisam, Inc.

1160 8th Avenue, PO Box 666

Cumberland, WI 54829

800-345-6007 | Fax 715-822-2223

E-mail: info@ardisam.com

Loading...

Loading...