Vinyl Express Qe6000 Setup Manual

This Setup Manual describes the procedures required for

setup. For operation procedures and details on how to make

the settings, and for any other points that are not clear,

please refer to the "Vinyl Express Qe6000 User's Manual"

PDF files that are included in the CD provided with the

Qe6000 Cutting plotter.

•

Windows is either a registered trademark or trademark of Microsoft

Corporation in the United States and/or other countries.

•

The names of products and brands mentioned herein are the

registered trademarks or trademarks of their respective companies.

Check to confirm that all of the items shown below are present.

If any item is missing, promptly contact the store where you

purchased your printer or your nearest Signwarehouse dealer.

Checking the Contents of the Package

Connect the plotter to PC with one of the following cables.

•

RS-232C (Serial port)

•

USB cable

Select the cable according to the specification of the application

software or the availability of the communication port on your PC.

Prepare the connection cable

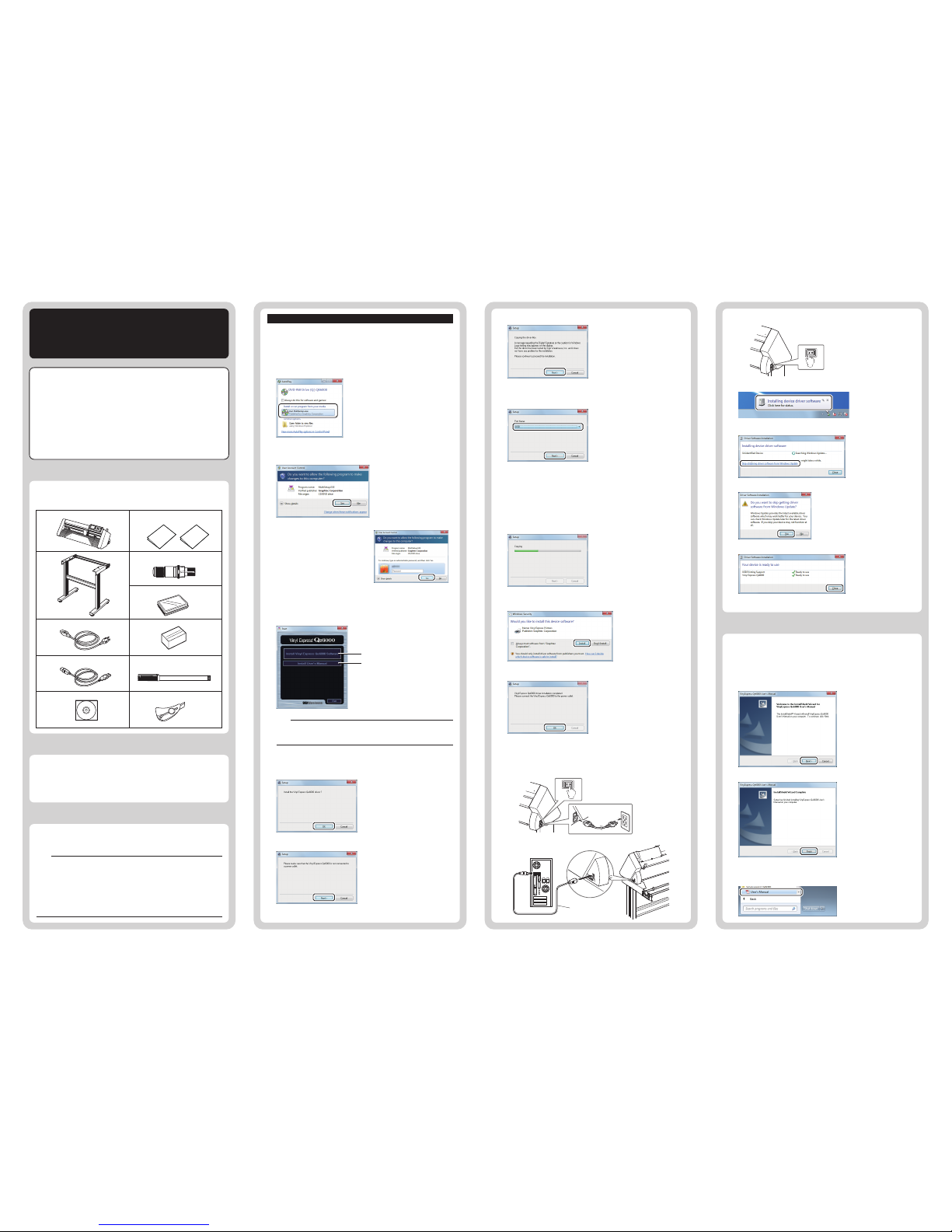

Install the software housed in the attached CD-ROM into the PC that

is used. This section explains how to install the software when using a

Windows 7 (32 bit) operating environment.

Upon installation, be sure to log on Windows using an account with

administrator privileges on your computer. If you have logged on using a

standard user account, an [User Account Control] screen asking you to

enter the administrator account password may appear.

•Supported OS

This software supports the following OS environments:

Windows 8 (32bit/64bit), Windows 7 (32 bit/64 bit), Windows Vista (32

bit/64 bit), Windows XP SP3 (32bit/64bit).

* For the latest OS, please access our web site.

Vinyl Express Qe6000

SETUP MANUAL

Power cable – 1 pc

CD – 1 pc

Cutter holder (PHP33-CB09N-HS) – 1 pc

Water-based fiber pen adapter (PHP31-FIBER)

– 1 set

Media Cutter – 1 pc

Plotter – 1 pc

USB cable – 1 pc

SETUP MANUAL,

TO ENSURE SAFE AND CORRECT USE

– 1 of each

Cutter blade (CB09UB-1) – 1 pc

Water-based fiber pen (KF700-BK)

– 1 pc

* Plunger/Height adjustment tool.

Stand– 1 pc

Installing the Software

Note

Do not connect the accompanying USB cable yet. Doing so may

prevent the [Driver software] from being installed properly. Refer to the

procedures in this User's Manual when connecting the USB cable.

Note

Install Qe6000 Software

After starting up Windows, insert the [USER GUIDE & SOFTWARE

CD] provided with the Qe6000 into your computer's CD drive. The

below screen will appear before the Start Menu launches. Continue

with installation in accordance with the following procedures.

(1) The Windows [AutoPlay] screen will appear. Select [Run Multi

Setup.exe] from the Windows [AutoPlay] screen.

(2) The [User Account Control] will appear.

Click [Yes] if you have logged on using an administrator account.

Supplement

If you have logged on using a

standard user account, an [User

Account Control] screen asking you

to enter the administrator account

password may appear. Enter the

password, and then click [Yes].

Supplement (When selecting the COM1)

To select "COM1" in "Port Name", do the installation according to

the message.

After the installation is completed, connect the RS-232C cable.

(For more information about connecting the RS-232C cable, see

"1.4 Connecting to the Computer" on page 1-9 in Qe6000 User's

Manual.)

(3) The [Start] will appear. "Use this menu to install the software you

require to use the Qe6000. First-time users should proceed with

installation by clicking on [Install Vinyl Express Qe6000 Software]."

Proceed with installation according to your operating environment.

(4) Click on [Install Vinyl Express Qe6000 Software] button in the

[Start] screen to display the following screen.

When it does, click on [OK].

* If the [AutoPlay] screen does not

appear, open [Explorer] and select

the CD drive containing the

software to be installed.

Open the CD and double-click on

[MultiSetup.exe].

A. Install Vinyl Express Qe6000

Software: Install the [Vinyl Express

Qe6000 Driver].

B. Install User's Manual: Installs the

Vinyl Express Qe6000 User's Manual.

A

B

(6) Click on [Next] again.

(7) A window for selecting the [Port Name] to be used appears.

Select [USB].

Clicking on [Next] will begin the driver software installation process

(8) The following window appears. Please wait for a few minutes.

(9) The [Windows Security] screen will appear momentarily.

Click on [Install] to install the [Plotter Driver].

(2) When this screen appears, click on [Finish].

(10) Click on [OK] to reboot your computer.

After rebooting your computer, follow the below procedures to

connect the USB cable.

(11) Ensure that the Plotter's power is turned off ("O" position).

Connect the power cable.

Available Port Names

USB : Selected when a USB cable

is used for connection.

COM1 : Selected when an RS-232C

(serial) cable is used for

connection.

FILE : Selected to save outputted

data (plot data) to a file.

(13) Turn on the Qe6000 unit.

(14) Click on this message.

(15) Click on [Skip obtaining driver software from Windows Update].

(16) Click on [Yes] again.

(17) Click on [Close].

This concludes the installation of the driver software.

Follow the below procedures to install the Qe6000 User's Manual

(PDF format). Adobe Reader must be installed on your computer in

order to read the manual.

(1) Click on [Install User's Manual] button in the [Start] screen to

display the following screen.

Click on [Next] to install the User's Manual.

This concludes the installation of the [User's Manual].

The newly-installed [User's Manual] will be registered under your

Windows Start Menu.

(12) Connect the USB cable.

Connect to your computer.

Connect to the Plotter.

Install User's Manual

(5) When it does, click on [Next].

621640310

Load the media according to the instructions given for each type. Use

the grit roller on the right side of the media (looking from the front) as

a guide when setting it in the media sensor. Afterwards, adjust the

push roller so that it's lined up with the side of the media.

Loading Media (Paper or Marking Film)

Position the left and right push rollers to correspond with the width of

the media. Adjust the push rollers so that they are positioned above

both the media and the grit rollers. Position the push rollers within the

grit roller position guides ensures that they are above the grit rollers.

After setting the Tool/Speed/Force/Acceleration, make test cutting,

and repeat until optimal condition is achieved.

(1) Load the media for test cutting in the plotter.

(2)

Press the [COND/TEST] key in the default screen.

The Qe6000 can take media width

of 55 mm or more.

Aligning the Push Rollers

When removing the tool, turn it counterclockwise to remove the tool.

(2) Set the roll media on top of the stock shaft, and then insert the roll

media into the stopper. Once it's set, tighten the stopper's screws.

(3) Push the tip of the roll media forward from the back of the Qe6000.

Make sure to pull it so that there is no slackening across the roll

media's route.

Simple mode/Normal mode

You can use the [SIMPLE] key on the default screen to switch between

Simple mode and Normal mode.

Qe6000 will be reset once when you switch. In Simple mode you can

change easy settings from the menu screen. In Normal mode, you will be

able to change more detailed settings. Simple mode and Normal mode are

independent from one another. The settings of the mode you're currently in

will take precedence.

(4) Press the media lock to engage it, and then pull the leading edge

out of the front of the plotter, making sure that it completely covers

the media sensor.

(5) Position the media and the push rollers to correspond with the

width of the media. The push rollers push down on either side of

the media. Use the grit roller position guide to make sure the push

rollers are set on top of the grit rollers.

(6) Pull the media taut to make sure that there is no slack in the

conveyance path, and then raise the media set lever to lower the

push rollers.

(7)

Release the media stopper lock (Pull the sides and slide it forward.)

(8)

When the set lever is up (and the media is held down by the push

rollers) and the media stopper is unlocked, pull out the roll media

and give it slack.

Caution

To avoid bodily injury, always handle the cutter blade with caution.

Preparation of Tool

(1) Loosen the tool holder screw.

(2) While pushing up the tool holder, push until its flange completely

touches the upper part of the holder.

(3) Make sure that the tool bracket is engaged on the tool's flange,

and then tighten the screw.

Attaching a Tool

Removing the tool

(1) Lower the media set lever to raise the push rollers.

Loading Roll Media

(1) Lower the media set lever to raise the push rollers.

(2)

Make sure that the sheet media completely covers the media sensor.

(3) Set the Tool conditions (Tool, Speed, Force, Acceleration).

(4) Make test cutting for three pieces while Tool conditions are being

set.

(6) Press the POSITION ( ) key the tool carriage to the location

you wish to perform the test cutting.

(7) Press the [1] key (FORCE).

3 cutting test patterns are cut, with current FORCE in the center,

and 1 each of FORCE increased and decreased for 1.

(3) Position the media and the push rollers to correspond with the

width of the media.

(4) Pull the media taut to make sure that there is no slack in the

conveyance path, and then raise the media set lever to lower the

push rollers. Set the sheet media so that the paper's edges line up

with the guideline on the front side.

Loading Sheet Media

To make 3 cuts with set value and ±1 of set value

Check if the offset value is set correctly by following.

Media stopper

This stops the stock shaft

from spinning when setting in

media. It is also utilized when

pulling roll media straight out.

Supplement

When actually cutting, please

release the lock from the

media stopper (while pulling to

the exterior, slide it forward).

When Feeding Long-axis Media

(at exceeds 2 meters)

Position the push rollers at least 15

mm inside the edges of the media.

Supplement

Dirt from the floor may stick to

the media when giving it slack,

so please be careful.

Setting the Tool

conditions

For more

information about

the various cutting

conditions, see

"Qe6000 User's

Manual".

To move the push rollers, the media set lever must be in the lowered position.

Caution

Set the media type into the Plotter depending on the preset media.

(1)

If you have already loaded the media, the MEDIA TYPE menu

appears. Select the media type to suit the loaded media.

Set the media type into the Plotter

(2)

After the media is detected, the plotter is ready to receive data for

cutting or plotting. This status is called "READY status" of the

default screen. When setting is finished, the tool carriage's location

will become the initial point.

Release the media stopper.

Caution

Caution

Tool adjustment and test cutting

Do not touch the

Tool edge when

power is turned on

or during operation.

(8) Press the [ENTER] key after completion.

It will return to CUT TEST menu screen.

(9) Press the [2] key (CUTTER OFFSET). (Normal mode only)

3 cutting test patterns are cut, with current CUTTER OFFSET in

the center, and 1 each of CUTTER OFFSET increased and

decreased for 1.

(10) Press the [ENTER] key after completion.

It will return to CUT TEST menu screen.

(11) Check if the cut test is appropriate. Confirm the cutting test

results, and adjust to optimal setting. Repeat cutting test and

adjustment until optimal cut is achieved.

How to check offset

Cutter plunger

Cutter blade

(CB09UA)

Insert the

cutter blade

Right

Extend the blade Extract the blade

Too short

Guide of the cutter blade length

Adjusting

the blade-tip

length

Media with backing sheet

Too long

When Feeding Long-axis Media

(at least 2 meters)

Position the push rollers at least 5

mm inside the edges of the media.

Release the

media lock

Media stopper

Give it slack

Give it slack

Media sensors

Media set lever

Line up

Menu screen (Normal mode) Menu screen (Simple mode)

Roll media

Sheet media

CONTINUE

Plot starting with the edge of media

Plot starting with the preset position

Set a sheet media

When similar media is reset

[1]

ROLL-1 FRONT EDGE

[2] ROLL-2 CURRENT

[3] SHEET

[4] CONTINUE

CONDITION screen

(Normal mode)

CONDITION screen

(Simple mode)

CONDITION screen

(Normal mode)

CONDITION screen

(Simple mode)

Ex.) TOOLS CONDITION

Settings screen (Normal mode)

Ex.) TOOLS CONDITION

Settings screen (Simple mode)

CUT TEST screen

(Normal mode)

CUT TEST screen

(Simple mode)

Not enough

adjustment.

Increase the

offset value.

Optimal offset

value.

Too much

adjustment.

Decrease the

offset value.

Cut Order

–1Setting values+1

Flange

Bracket to hold tool

Tool holder

Top

Bracket to

hold tool

Tool holder

Bracket to hold tool

Tool holder

Bracket to

hold tool

Flange

Media sensor

Push roller

Media set

lever

Media set

lever

Media stopper

Slide the

media lock

Media sensors

Push roller

Media sensor

Media

Grit roller

Grit roller position guide

Push roller

Push roller

15 mm

Media

15 mm

5 mm 5 mm

Media

Push roller

Push roller

Grit roller

position guide

Grit roller

(It isn't on the grit roller) (It isn't on the grit roller)

Push roller

Grit roller

Media

Media sensor

(5) Press the POSITION ( ) key (CUT TEST).

CUT TEST screen is displayed.

621640310

Loading...

Loading...