Vinyl Express Qe60 User Manual

Vinyl

Express Qe60

USER’S MANUAL

MANUAL NO. VEXQe06-UM-151

CUTTING PLOTTER

Signwarehouse.com

i

Contents

1. INTRODUCTION

1.1 Checking the Accessories ..............................................................................................1-2

1.2 Parts Names and Functions ...........................................................................................1-3

Front View ......................................................................................................................... 1-3

Rear View..........................................................................................................................1-3

Control Panel..................................................................................................................... 1-4

1.3 Assembling the Stand .....................................................................................................1-5

Stand Construction............................................................................................................1-5

Stand Assembly Instructions.............................................................................................1-5

1.4 Attaching the Basket .......................................................................................................1-7

Basket Construction .......................................................................................................... 1-7

Basket Attachment Instructions.........................................................................................1-7

2. SETTING UP THE CUTTER PLOTTER

2.1 Connecting to Your Computer .......................................................................................2-2

2.2 Turning on the Power ......................................................................................................2-3

2.3 Loading the Medium ........................................................................................................2-4

Loading a Roll Medium...................................................................................................... 2-4

Loading Sheet Media.........................................................................................................2-7

Aligning the Push Rollers .................................................................................................. 2-8

2.4 Adjusting and Mounting the Cutter Pen ......................................................................2-10

Types and Features of Cutter Blades.............................................................................. 2-10

Cutter-Pen Construction..................................................................................................2-11

Replacing the Cutter Blade..............................................................................................2-11

Adjusting the Blade Length..............................................................................................2-12

Mounting the Cutter Pen..................................................................................................2-12

3. BASIC SETTINGS AND OPERATIONS

3.1 Setting the Format of Data to be Received ...................................................................3-2

Setting the Command Mode.............................................................................................. 3-2

Setting the STEP SIZE......................................................................................................3-3

Setting the ORIGIN POINT................................................................................................3-3

3.2 Setting the Interface Conditions ....................................................................................3-4

3.3 Setting the Cutter-Pen Conditions .................................................................................3-5

Selecting Cutter-Pen-Condition Setting Areas .................................................................. 3-6

Storing Cutter-Pen-Condition Setting Areas...................................................................... 3-6

Setting TOOL (cutter blade or pen)...................................................................................3-7

Setting OFFSET................................................................................................................3-7

Setting FORCE.................................................................................................................. 3-8

Setting SPEED..................................................................................................................3-8

Setting QUALITY...............................................................................................................3-9

3.4 Displaying the Effective Cutting Area ...........................................................................3-9

3.5 Moving the Pen ................................................................................................................3-9

3.6 Setting the Initial Cutting Position ...............................................................................3-10

3.7 Stop Function ................................................................................................................3-11

3.8 Moving the Pen Carriage in +100 mm Steps ...............................................................3-12

3.9 Test Cutting ....................................................................................................................3-12

ii

4. FUNCTION SETTINGS AND OPERATIONS

4.1 PAUSE Menu List ............................................................................................................4-2

4.2 Reading the Auto Registration Marks (Option) ............................................................4-3

4.3 Setting the FEED function ..............................................................................................4-4

4.4 Setting AUTO PRE-FEED ................................................................................................4-5

4.5 Setting TANGENTIAL Mode ............................................................................................4-6

4.6 Auto-Registration-Mark-Reading Settings (Option) .....................................................4-8

Setting the Registration-Mark Mode................................................................................4-10

4.7 Clearing the Buffer Memory .........................................................................................4-21

4.8 Aligning the Coordinate Axes ......................................................................................4-22

4.9 Distance Adjustment .....................................................................................................4-24

4.10 Setting the PAGE LENGTH ...........................................................................................4-26

4.11 Setting the Cutting/Plotting Area .................................................................................4-27

4.12 Expanding the Cutting/Plotting Area ...........................................................................4-28

4.13 Rotating the Coordinate Axes ......................................................................................4-29

4.14 Mirroring .........................................................................................................................4-30

4.15 Cutting/Plotting Using the Buffer Memory ..................................................................4-31

4.16 Sorting Settings .............................................................................................................4-33

4.17 Interface Settings ..........................................................................................................4-34

4.18 Setting the Format of Data to be Received .................................................................4-35

Setting the Command Mode............................................................................................4-35

Setting the STEP SIZE....................................................................................................4-36

Setting the ORIGIN POINT..............................................................................................4-36

4.19 Blade Wear Detection ....................................................................................................4-37

Checking the Wear Rate .................................................................................................4-37

Setting Wear-Rate Groups..............................................................................................4-38

Setting Wear-Rate Factors..............................................................................................4-39

Clearing the Total Distance (Wear Rate).........................................................................4-39

4.20 Raising and Lowering the Pen .....................................................................................4-41

4.21 TEST Mode .....................................................................................................................4-42

Condition-List Printing .....................................................................................................4-42

Dump Mode.....................................................................................................................4-43

Cutting Force Test Cutting...............................................................................................4-44

4.22 Setting the PEN UP SPEED ..........................................................................................4-46

4.23 Setting the OFFSET FORCE .........................................................................................4-47

4.24 Setting the OFFSET ANGLE .........................................................................................4-48

4.25 Setting the STEP PASS .................................................................................................4-49

4.26 Setting the Initial Down Force ......................................................................................4-50

4.27 Setting the LENGTH UNIT .............................................................................................4-51

5. Setting and Using the Special Functions

5.1 Description of Special Functions A ...............................................................................5-2

Enabling/Disabling the “:” and “;” Commands (when the COMMAND setting is GP-GL)..5-2

Moving the Pen While Raised or Lowered in Response to the “W” Command (when the

COMMAND setting is GP-GL)........................................................................................... 5-2

Model ID Response (when the COMMAND setting is HP-GL)..........................................5-2

SETTING PRIORITY.........................................................................................................5-2

Blade-Tip Initial Position Setting........................................................................................5-2

Enabling/Disabling PEN UP MOVE...................................................................................5-3

Enabling/Disabling the Media Sensors..............................................................................5-3

iii

Enabling/Disabling the Home Sensors..............................................................................5-3

Setting the PARALLEL I/F Mode.......................................................................................5-3

Circle-Command Resolution Setting (when the COMMAND setting is HP-GL)................5-3

Enabling/Disabling Blade Wear Detection......................................................................... 5-3

5.2 Setting Special Functions A ...........................................................................................5-4

5.3 Description of Special Functions B ...............................................................................5-4

Display Language Setting (MENU LANGUAGE SELECTION).........................................5-4

5.4 Setting Special Functions B ...........................................................................................5-5

6. TROUBLESHOOTING

6.1 The Cutting Plotter Does Not Operate When Turned On .............................................6-2

6.2 The Cutting Plotter Does Not Operate Correctly ..........................................................6-2

6.3 The Cutting Results Are Unsatisfactory ........................................................................6-3

6.4 An Error Message Was Displayed .................................................................................6-4

APPENDIX

Appendix A Main Specifications .........................................................................................................A-2

Appendix B Options and Supplies ......................................................................................................A-3

Appendix C External Dimensions .......................................................................................................A-4

Appendix D Menu Tree .........................................................................................................................A-5

INDEX

iv

1

1

INTRODUCTION

1.1 Checking the Accessories

......................................................1-2

1.2 Parts Names and Functions

...................................................1-3

1.3 Assembling the Stand

...............................................................1-5

1.4 Attaching the Basket

.................................................................1-7

1 – 2

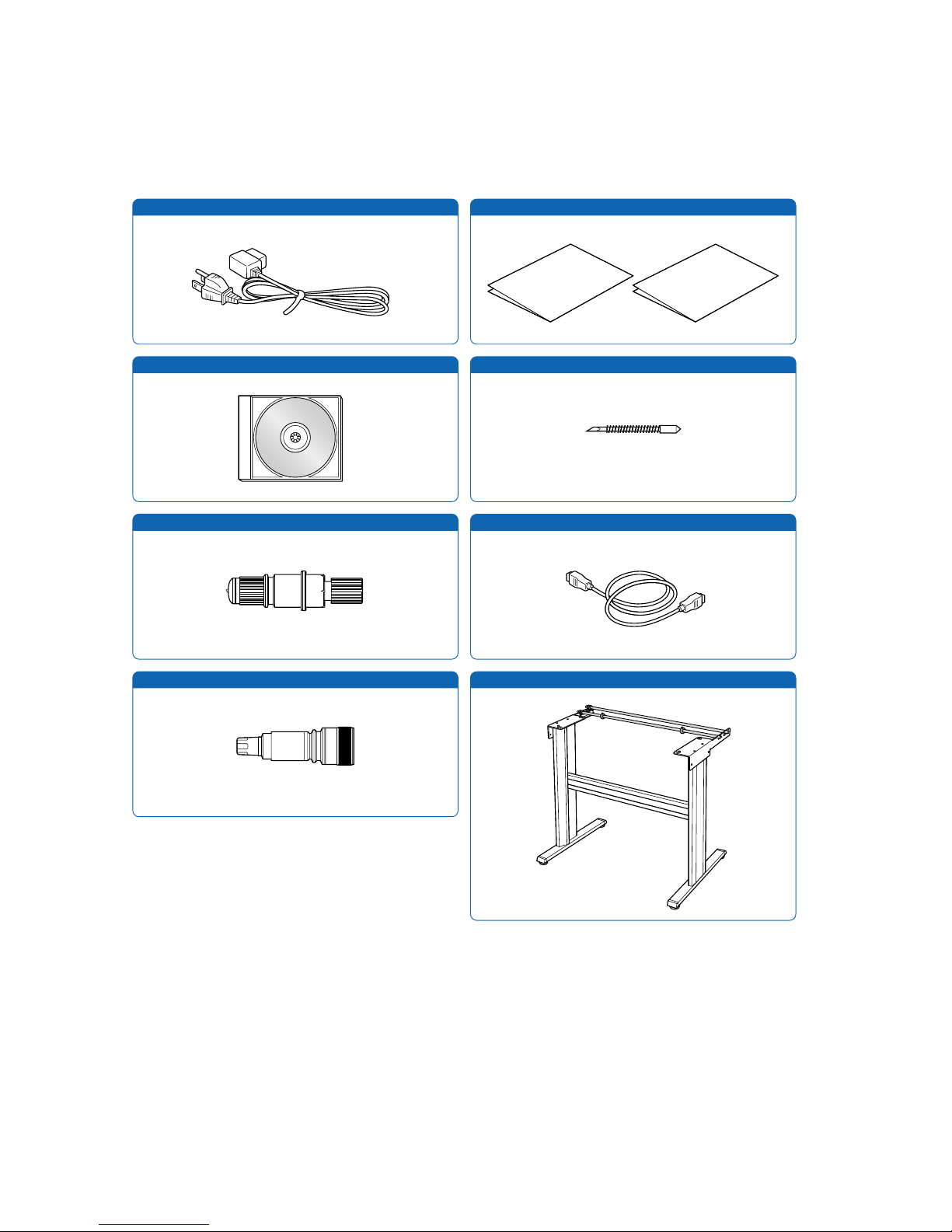

1.1 Checking the Accessories

Check to confirm that all of the standard accessories listed below are present. If any item is missing,

please contact your sales representative or nearest Signwarehouse vendor promptly.

AC power cord Quick Start Manual, Usage Precautions

User Guide CD-ROM

Stand

Cutter blade (CB09UA)

Water-based fiber-tip pen

1 1 each

1

1

1

1

Cutter plunger

1

USB cable

1

1 – 3

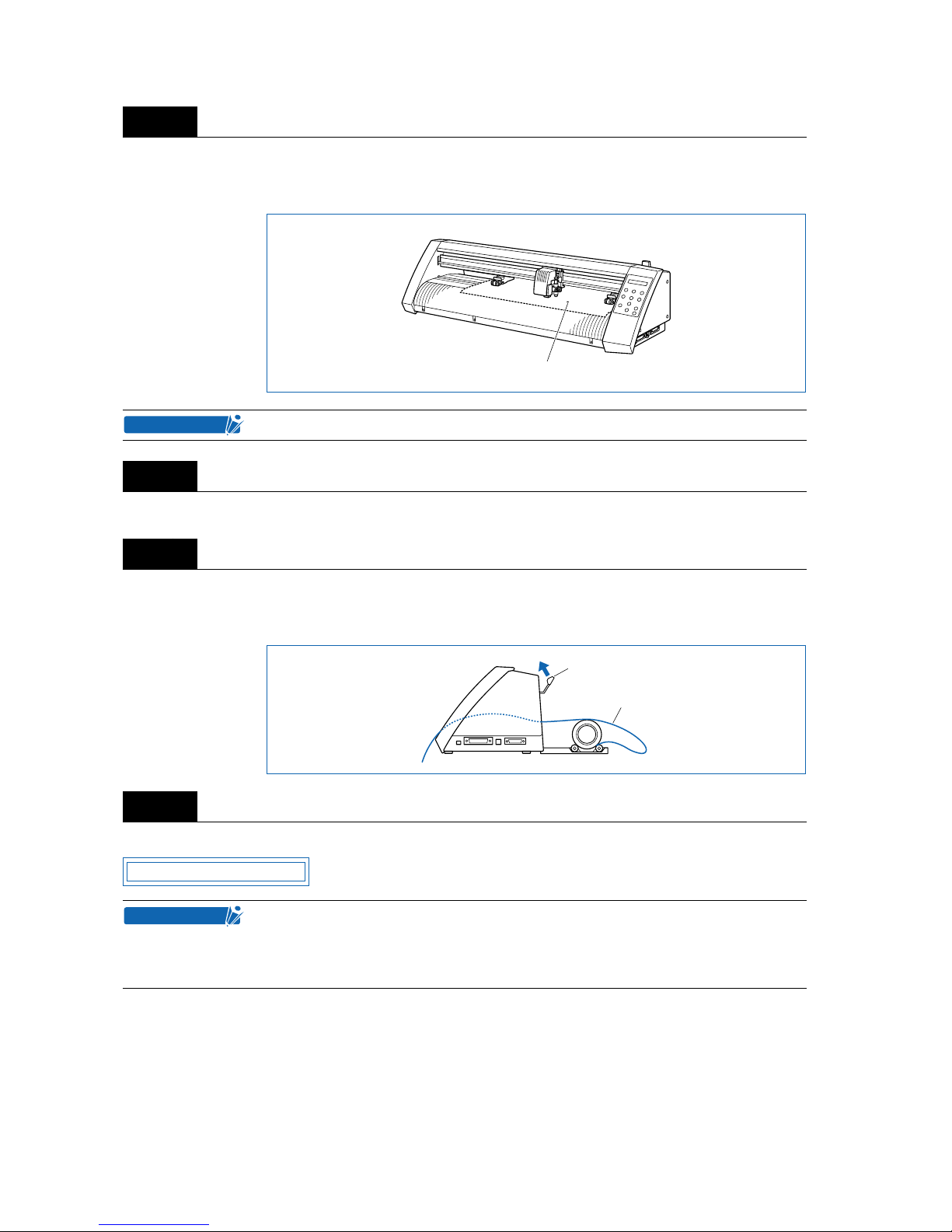

1.2 Parts Names and Functions

■

Front View

Cutting mat

: Cutting or plotting is performed on this mat.

Grit roller

: Feeds the medium backward or forward

Push rollers

: Pushes the medium against the grit rollers

Pen carriage

: Moves the cutter pen to the left and right

Pen holder

: Holds the cutter pen and moves it up and down

Media set lever

: Raises or lowers the push rollers during loading of a medium

Control panel

: Used to operate the cutting plotter and set functions

Parallel (Centronics) interface connector : Used to connect a Centronics-compatible parallel interface cable

USB interface connector

: Used to connect a USB cable

Serial (RS-232C) interface connector

: Used to connect an RS-232C serial interface cable

■

Rear View

AC power inlet

: Connects the power cord to the cutting plotter

Power switch

: Turns the power supply to the cutting plotter on or off

Cutting mat

Grit roller

Pen carriage

Push rollers

Media set leverPen holder

USB interface

connector

Serial (RS-232C)

interface connector

Control panel

Parallel (Centronics)

interface connector

AC power inlet

Power switch

1 – 4

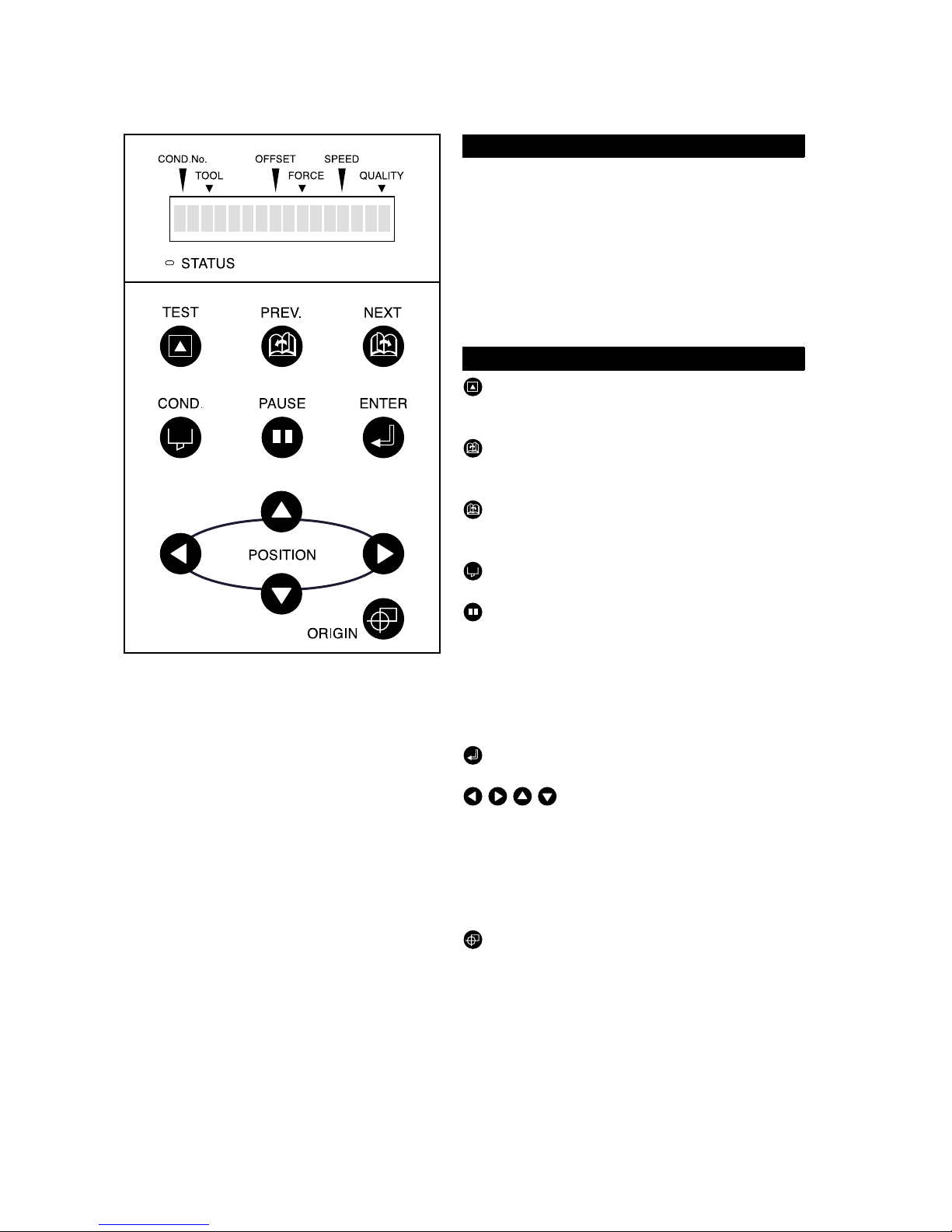

■

Control Panel

STATUS: Illuminates while the power to the cut-

ting plotter is turned on, and goes out

when the cutting plotter is in PAUSE

status. This lamp flashes when data is

being received from an interface,

regardless of whether or not the cutting

plotter is in PAUSE status.

TEST: Press this function key to conduct a cut-

ting test and check the cutting conditions.

PREV.: Press this function key to view the pre vi-

ous display on the LCD when in PAUSE

status.

NEXT: Press this function key to view the next

display on the LCD when in PAUSE status.

COND.: Press this function key to view the cut-

ter-pen condition settings.

PAUSE: Press this function key once in READY

status to switch to PAUSE status in

order to change the various settings.

Press it again to cancel the PAUSE status. Pressing this key while cutting or

plotting is in progress stops the cutting

or plotting.

ENTER: Pressing this function key registers the

cutting or plotting conditions set.

POSITION:

These keys are used to mov e the cursor

or change the settings on the LCD display on the function setting screens.

Press these keys when in PAUSE status

to move the pen carriage or the

medium.

ORIGIN: Press this function key to set the origin

point. The pen position is set as the origin point when this key is pressed.

Indicator Lamp

Panel Keys

1 – 5

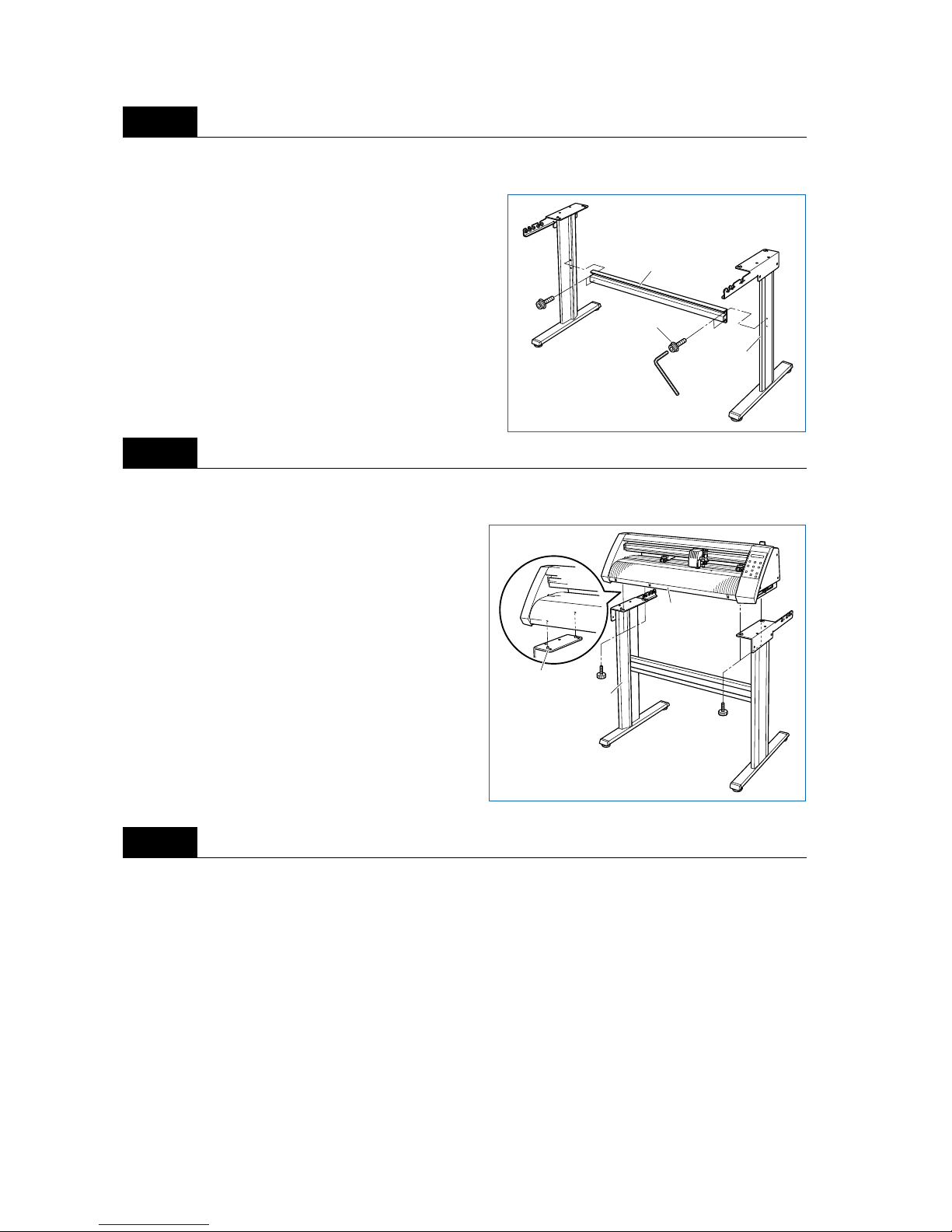

1.3 Assembling the Stand

■ Stand Construction

The stand is made up of the following parts.

■ Stand Assembly Instructions

Fasten the stand feet (L/R) to the stand side bars (L/R) with the hexagonal socket bolts (M5), using the

Allen wrench.

Fasten the stand tops (L/R) to the stand side bars (L/R) with the hexagonal socket bolts (M5), using the

Allen wrench.

Step

1

Step

2

Stand feet (L/R)

Hexagonal socket bolt

(M5) x 12

Coin screw x 4

Allen wrench (M5)

Center barStand side bars (L/R)

Hexagonal

socket bolt (M5)

Stand side bar

Stand foot

Front

* There are three

bolt holes, but

the center one

is not used.

Hexagonal

socket bolt (M5)

Stand side bar

Stand top

1 – 6

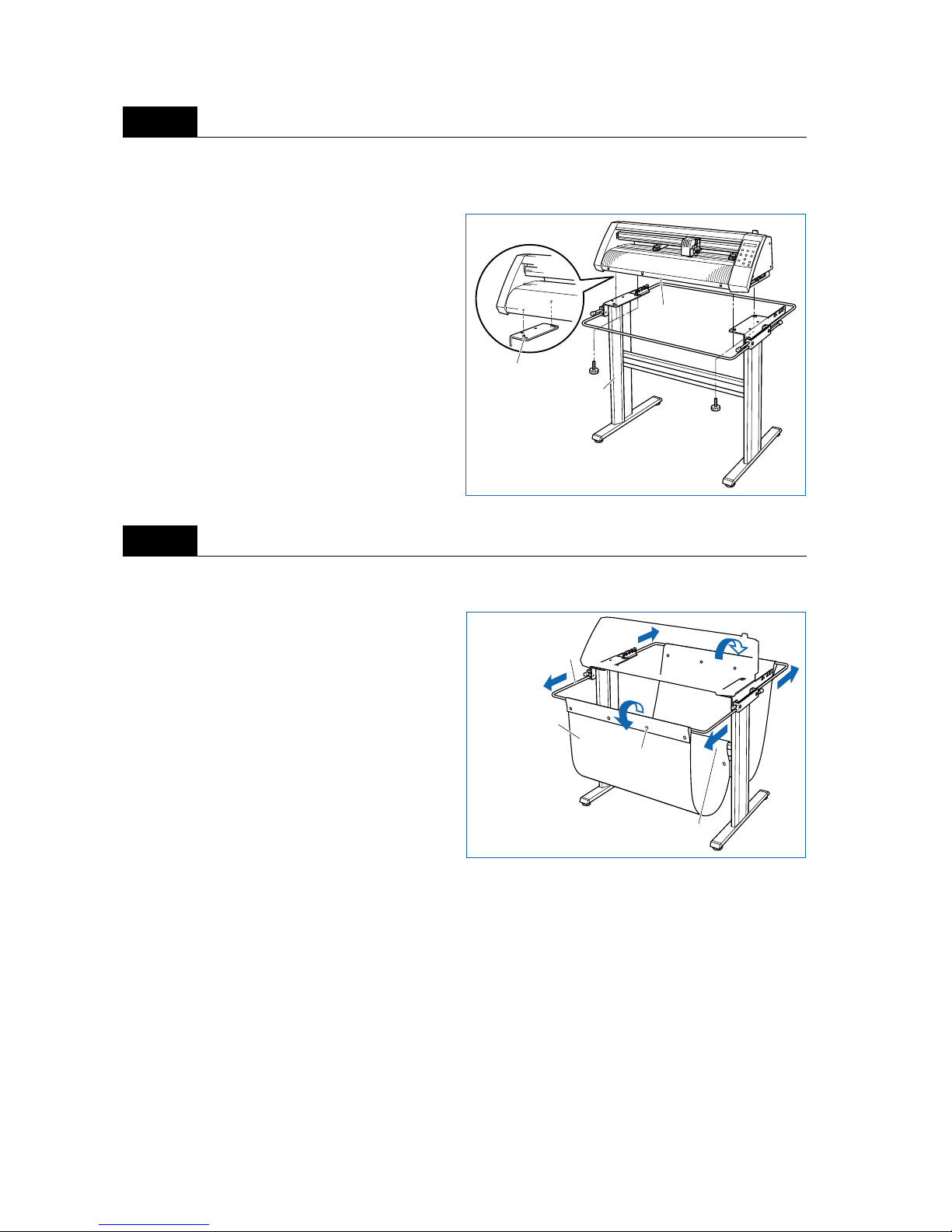

Loosely fasten the stand side bars (L/R) to the center bar with the hexagonal socket bolts (M5), using the

Allen wrench.

Mount the Vinyl Express cutting plotter on the stand by inserting the positioning pins on the stand into the

positioning holes on the underside of the cutting plotter. Fasten using the four coin screws.

Tighten the hexagonal socket bolts loosely fastened in step 3.

Step

3

Step

4

Step

5

Hexagonal

socket bolt (M5)

Center bar

Stand side bar

Coin screws

Stand

cutting plotter

Positioning pins

1 – 7

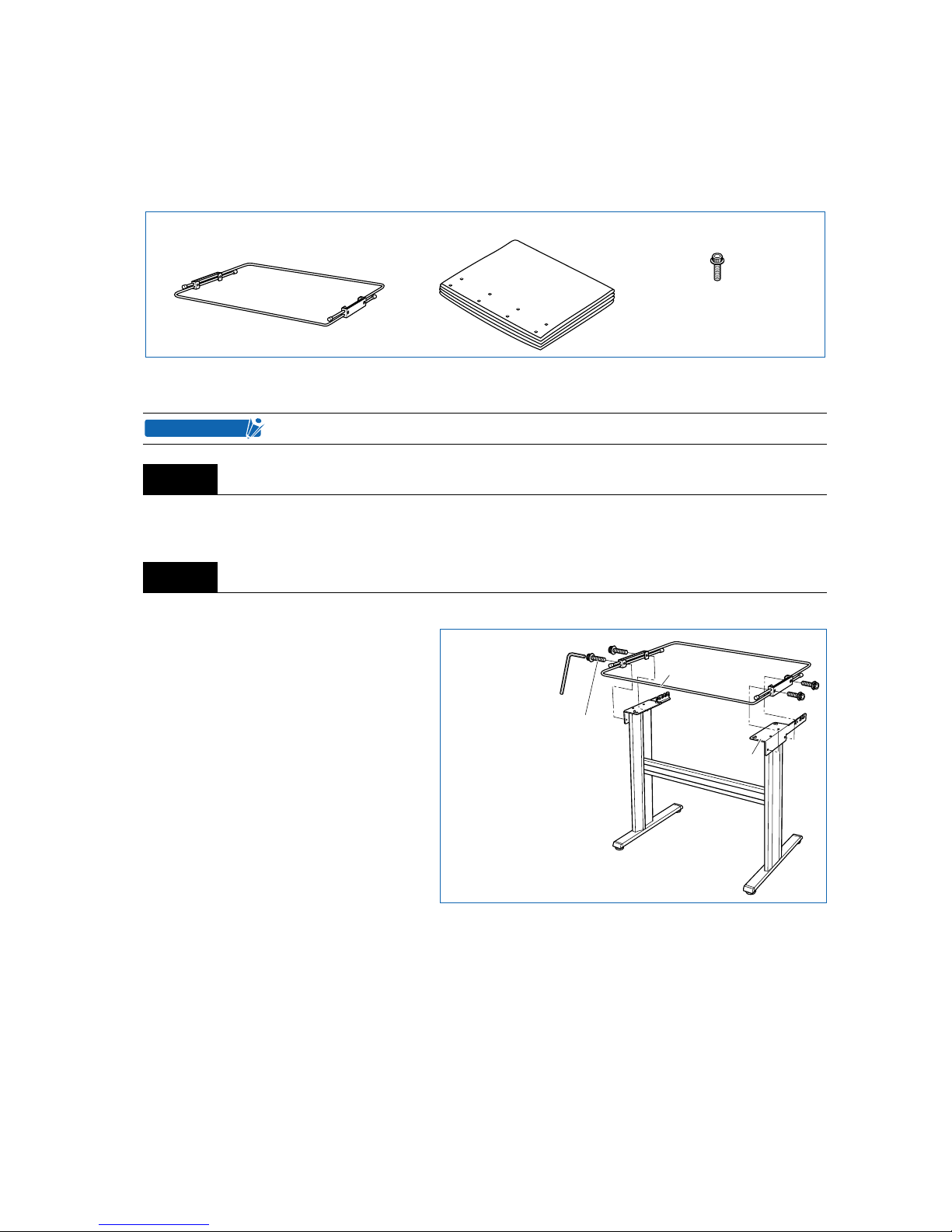

1.4 Attaching the Basket (Optional)

■ Basket Construction

The basket is made up of the following parts.

■ Basket Attachment Instructions

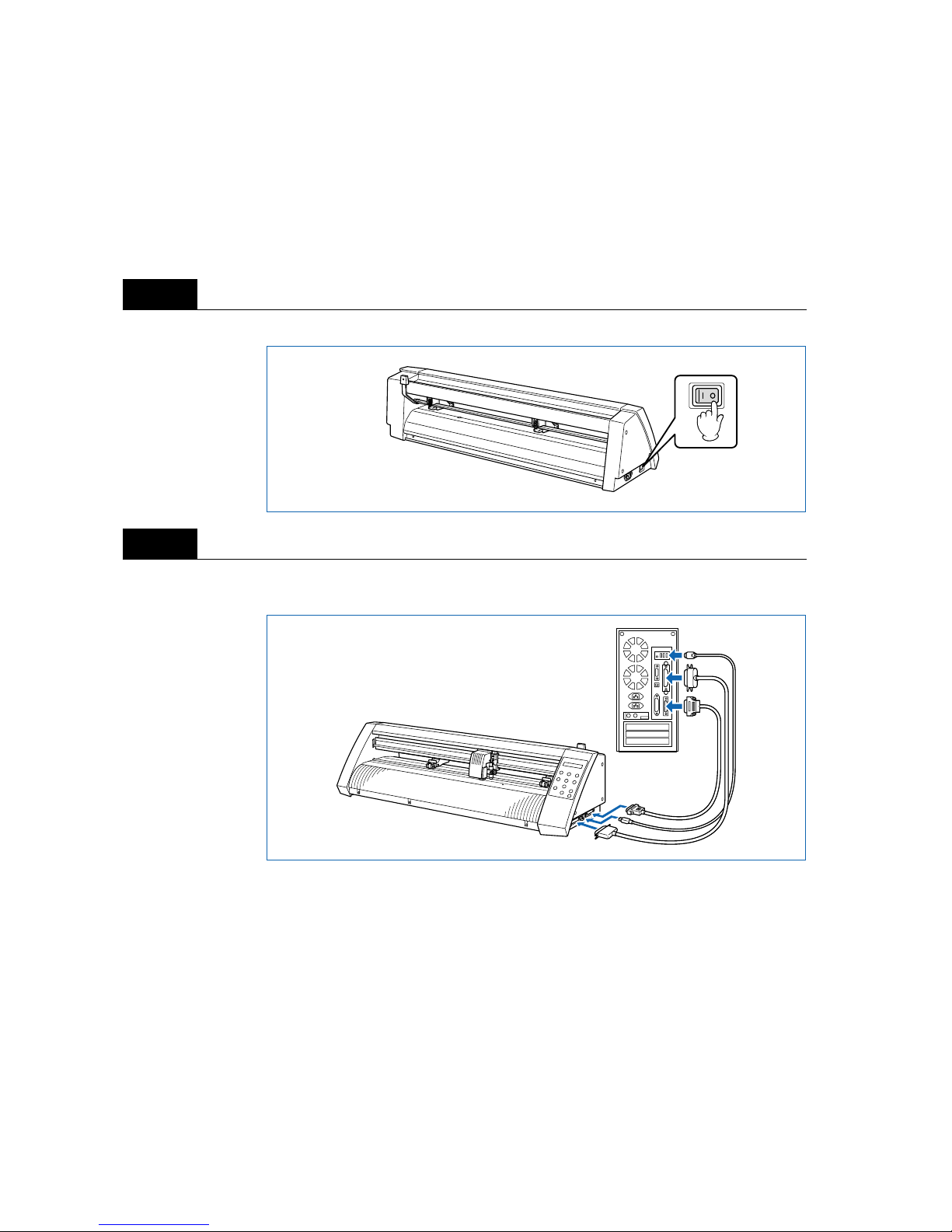

Detach the four coin screws or he xagonal soc k et bolts (M6), and separate the cutting plotter from the stand

(see “1.3 Assembling the Stand”).

Attach the sheet support pipe to the stand tops, and fasten using the hexagonal socket bolts.

At least two people are required for assembly of the basket.

Step

1

Step

2

Sheet support pipe Sheet Hexagonal socket bolts (M6) x 4

CHECKPOINT

Sheet support pipe

Stand top

Hexagonal socket bolts (M6)

1 – 8

Mount the Vinyl Express cutting plotter on the stand by inserting the positioning pins on the stand into the

positioning holes on the underside of the cutting plotter. Fasten using the four coin screws or hexagonal

socket bolts (M6).

Pull out the sheet support pipe and attach the sheet. Divide the sheet over the center bar, and then fasten

the sheet to the sheet support pipe using the press-studs.

Step

3

Step

4

Coin screws

Stand

cutting plotter

Positioning pins

Sheet

Press-studs

Sheet support pipe

Divide over

the center bar

2

2

SETTING UP THE CUTTER PLOTTER

2.1 Connecting to Your Computer................................................2-2

2.2 Turning on the Power................................................................2-3

2.3 Loading the Medium..................................................................2-4

2.4 Adjusting and Mounting the Cutter Pen...........................2-10

2 – 2

2.1 Connecting to Your Computer

The cutting plotter can be connected to a computer via the parallel (Centronics-compatible) port, serial

(RS-232C) port, or USB por t. Select which port to use according to the requirements of your application

software and/or which of your computer’s interface ports are available for use.

Use a Centronics-compatible parallel cable, serial cable, or USB cable in accordance with the connection

method chosen. Obtain a Signwarehouse approved interface cable that is compatible with the interface

ports (the interface cables are available separately).

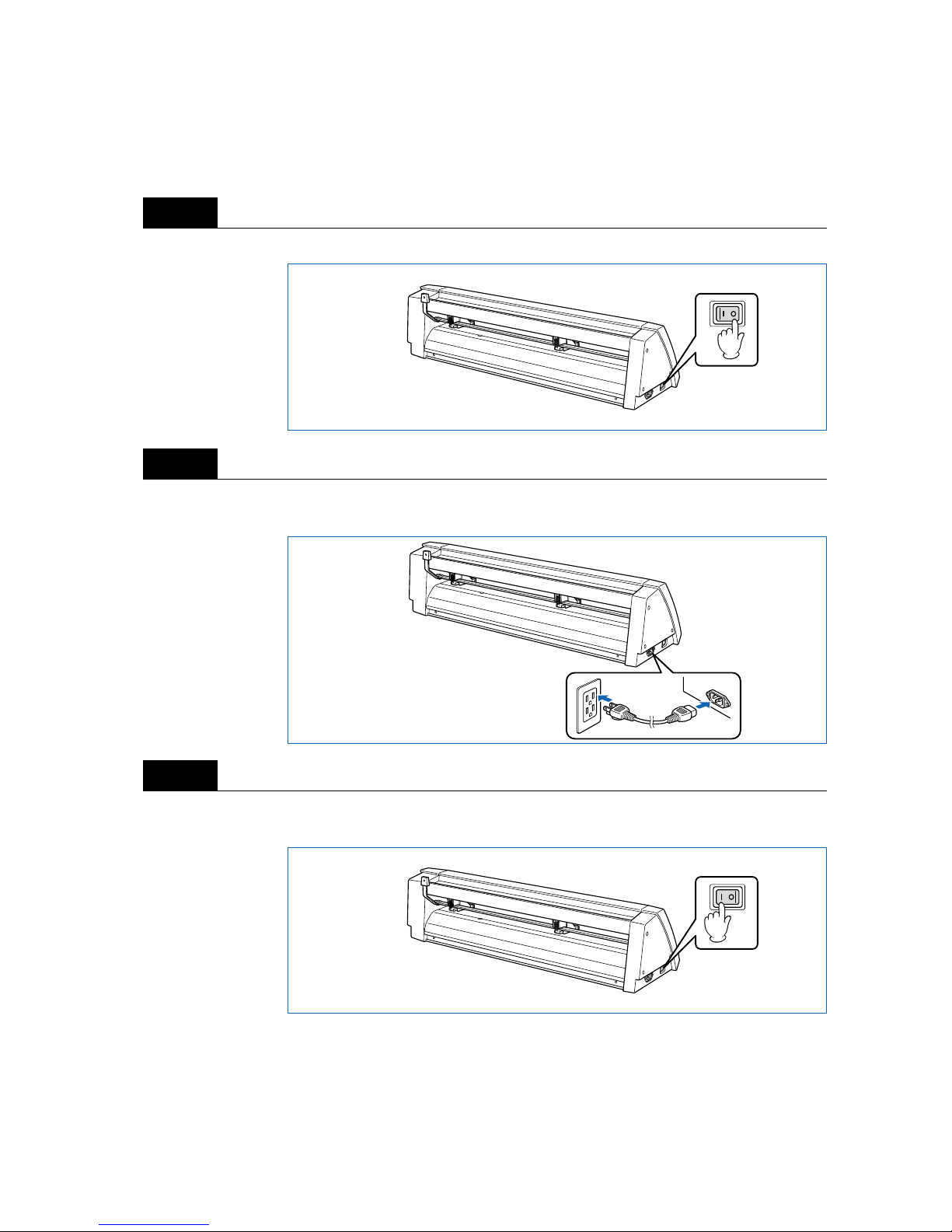

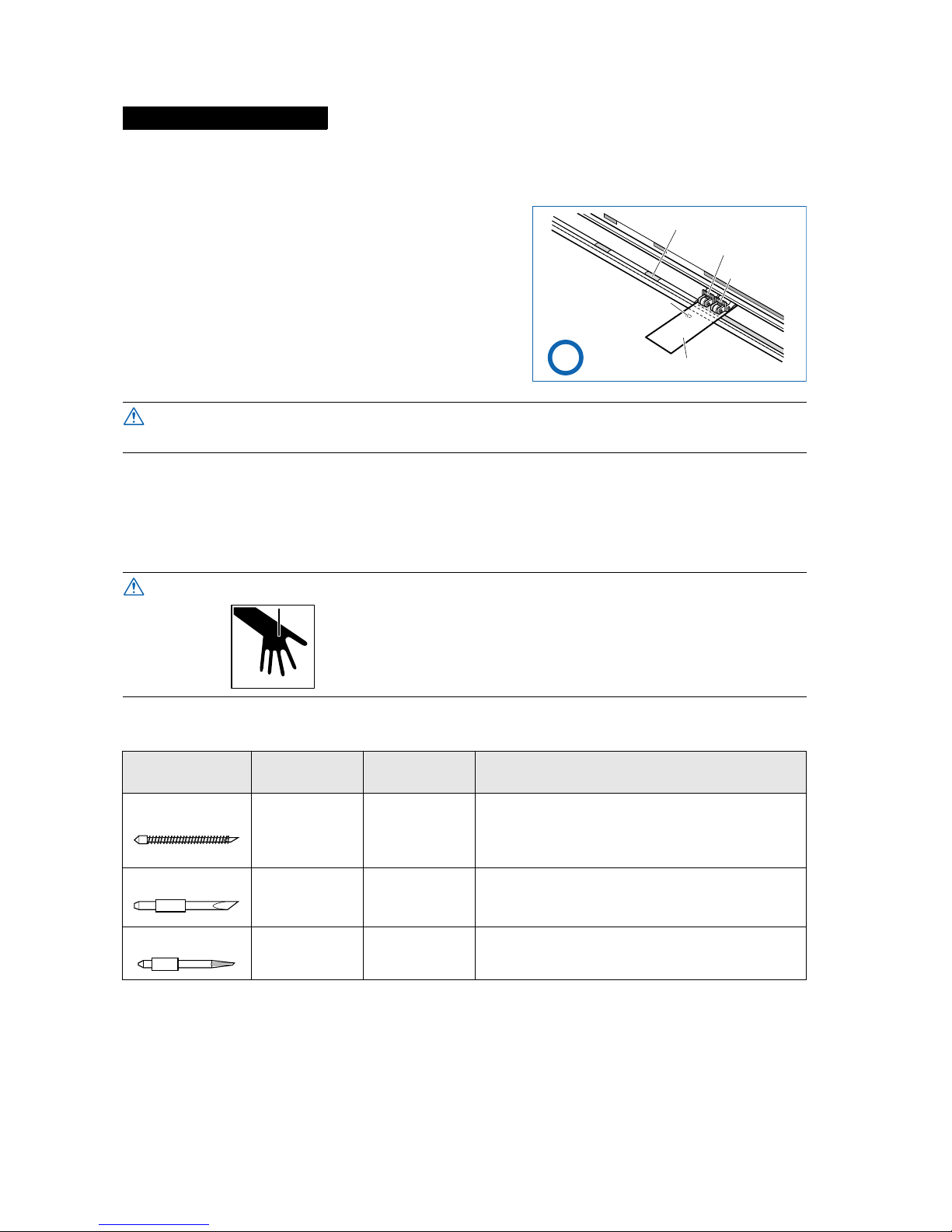

Check to confirm that the Power switch is turned off (the “O” side is down).

Connect the cable between the cutting plotter and the computer. Make sure the connectors at the cutting

plotter and computer ends are correctly oriented.

Step

1

Step

2

2 – 3

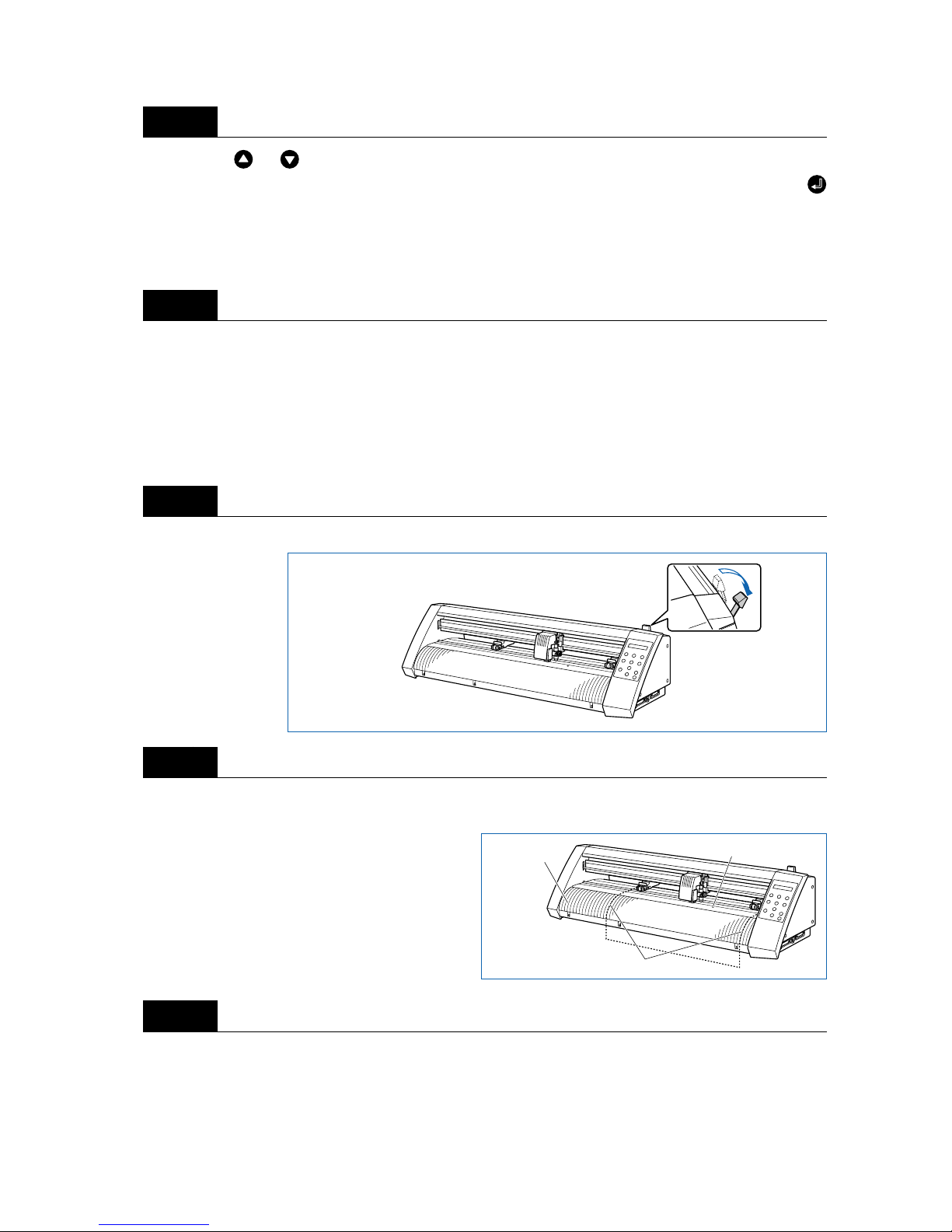

2.2 Turning on the Power

Connect the cutting plotter to the AC electrical socket using the power cord provided, and turn on the

power.

Check to confirm that the Power switch is turned off (the “O” side is down).

Connect the cutting-plotter AC power inlet to a correctly rated electrical socket using the power cord provided.

Turn on the cutting plotter by pressing the “|” side of the Power switch. The STATUS lamp on the control

panel will light up.

Step

1

Step

2

Step

3

2 – 4

If no medium has been loaded, the message below appears on the display, prompting the loading of a

medium.

If a medium has already been loaded, the current media setting is displayed as shown below.

Select the media mode to suit the medium used. F or instructions on loading media and selecting the media

mode, see “2.3 Loading the Medium.”

2.3 Loading the Medium

Load the medium, aligning it with the right-hand grit roller when viewed from the front so that it registers

with the media sensor. Then, adjust the push-roller position to match the width of the medium. The cutting

plotter can use media in roll or sheet form. Load the desired medium type by following the appropriate

instructions.

■ Loading a Roll Medium

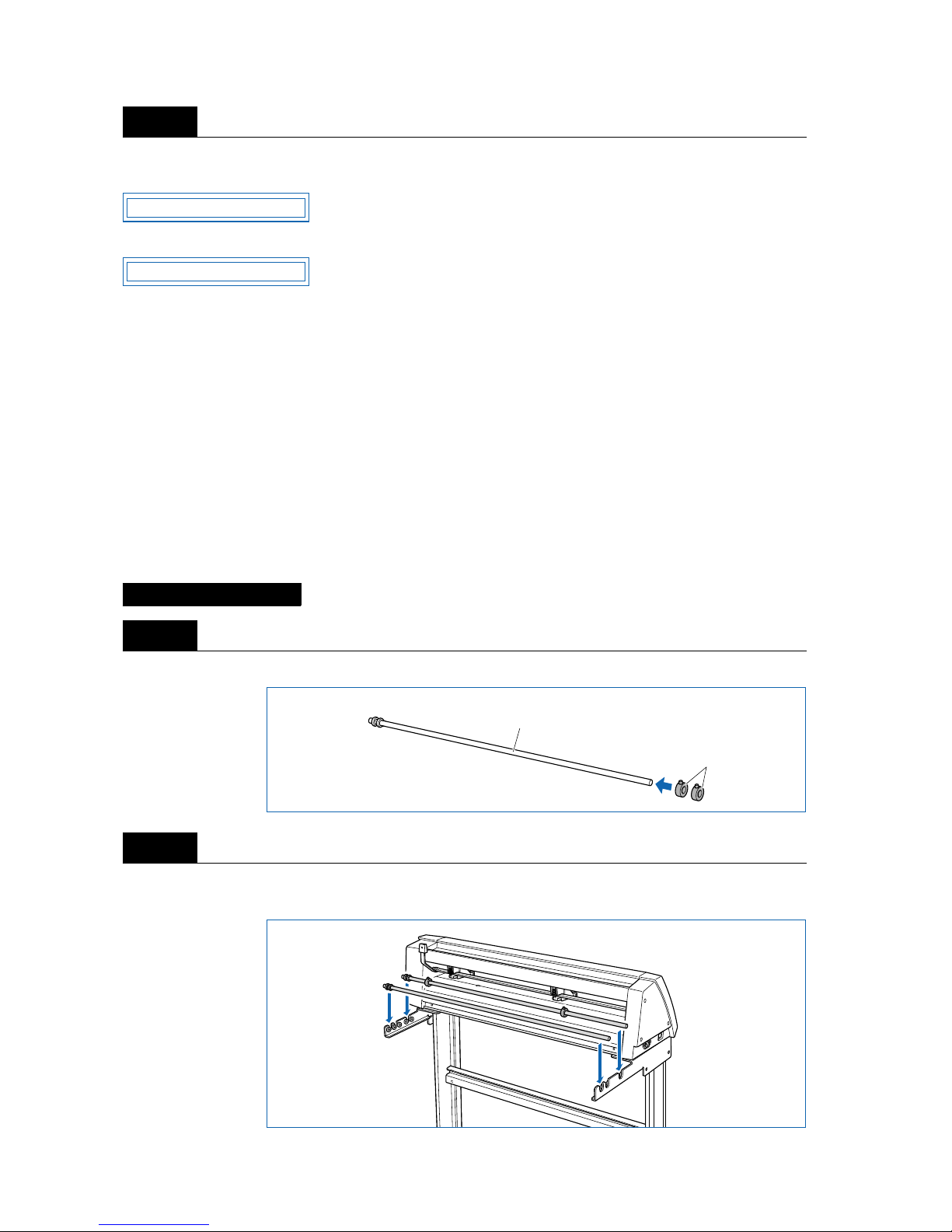

Load the roll medium onto the stand stock rollers.

Fit the stoppers to one of the stock rollers (loosen the screws on the stoppers first).

Position the stock roller with the stoppers towards the front, and place the other stock roller toward the rear

to suit the roll-medium size.

Step

4

Placing on the Stand

Step

1

Step

2

LOAD MEDIA!!

ROLL2 PRESS ENTR

Stoppers

Stock roller

2 – 5

Place the roll medium on the stock rollers, and clamp it between the stoppers. Once the position is fixed,

tighten the screws on the stoppers.

Lower the media set lever to raise the push rollers.

Place the roll medium on the stand stock rollers, and then pass the leading edge of the medium from the

back of the cutting plotter so it emerges from the front, while making sure to remove any slack in the

medium conveyance path.

Step

3

Loading the Roll Medium

Step

1

Step

2

2 – 6

Pull the leading edge out of the front of the cutting plotter so that it completely covers the media sensor. If

the leading edge has been pulled out too far , turn the roll to adjust the length of the medium that is protruding.

Adjust the position of the left- and right-hand push rollers to suit the width of the roll medium.

After ensuring that there is no slack in the medium’s conveyance path, raise the media set lever to lower

the push rollers and provide slack in the medium for a length corresponding to the length of the medium to

be used.

Raising the media set lever displays a menu for selection of the media mode. Select the media mode.

Step

3

Load the medium so that it passes over the media sensor.

Step

4

Step

5

Step

6

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller or the left-hand push roller is not positioned over

the grit roller. Check to confirm that they are positioned correctly.

Media sensor

CHECKPOINT

Raise media set lever to

clamp medium

Provide slack

ROLL2 PRESS ENTR

CHECKPOINT

2 – 7

Pressing the or key displays “ROLL1 PRESS ENTR”, “ROLL2 PRESS ENTR”, and “SHEET

PRESS ENTR”. Select “ROLL2 PRESS ENTR” or “ROLL1 PRESS ENTR” and then press the

(ENTER) key to confirm. When “ROLL2 PRESS ENTR” is selected, only the medium width is detected.

Select this mode to begin cutting at a point beyond the leading edge. When “ROLL1 PRESS ENTR” is

selected, the leading edge and width of the medium are detected. Select this mode to begin cutting from

the leading edge.

After the medium size has been detected, the pen carriage returns to the origin point and the cutting plotter

awaits cutting data. If the INTERFACE conditions or COMMAND mode have not yet been set, they should

be set. If they have already been set, adjust the cutter pen. Once the cutter pen has been adjusted, the

cutting plotter is ready to perform cutting, so cutting data can be sent from the application software on the

computer.

■ Loading Sheet Media

Lower the media set lever to raise the push rollers.

With the Vinyl Express, position the edges of the medium flush against the guide lines engraved on the

front guide.

Adjust the position of the left- and right-hand push rollers to suit the medium width.

Step

7

Step

8

Step

1

Step

2

Step

3

Guide lines

Media sensor

Flush

2 – 8

Raising the media set lever displays a menu for selecting the media mode. Select the media mode.

Pressing the or key displays “ROLL1 PRESS ENTR”, “ROLL2 PRESS ENTR”, and “SHEET

PRESS ENTR”. Select “SHEET PRESS ENTR” and then press the (ENTER) key to confirm the

selection. When “SHEET PRESS ENTR” is selected, the front and rear edges are detected.

After the medium size has been detected, the pen carriage returns to the origin point and the cutting plotter

awaits cutting data. If the INTERFACE conditions or COMMAND mode have not yet been set, they should

be set. If they have already been set, adjust the cutter pen. Once the cutter pen has been adjusted, the

cutting plotter is ready to perform cutting, so cutting data can be sent from the application software on the

computer.

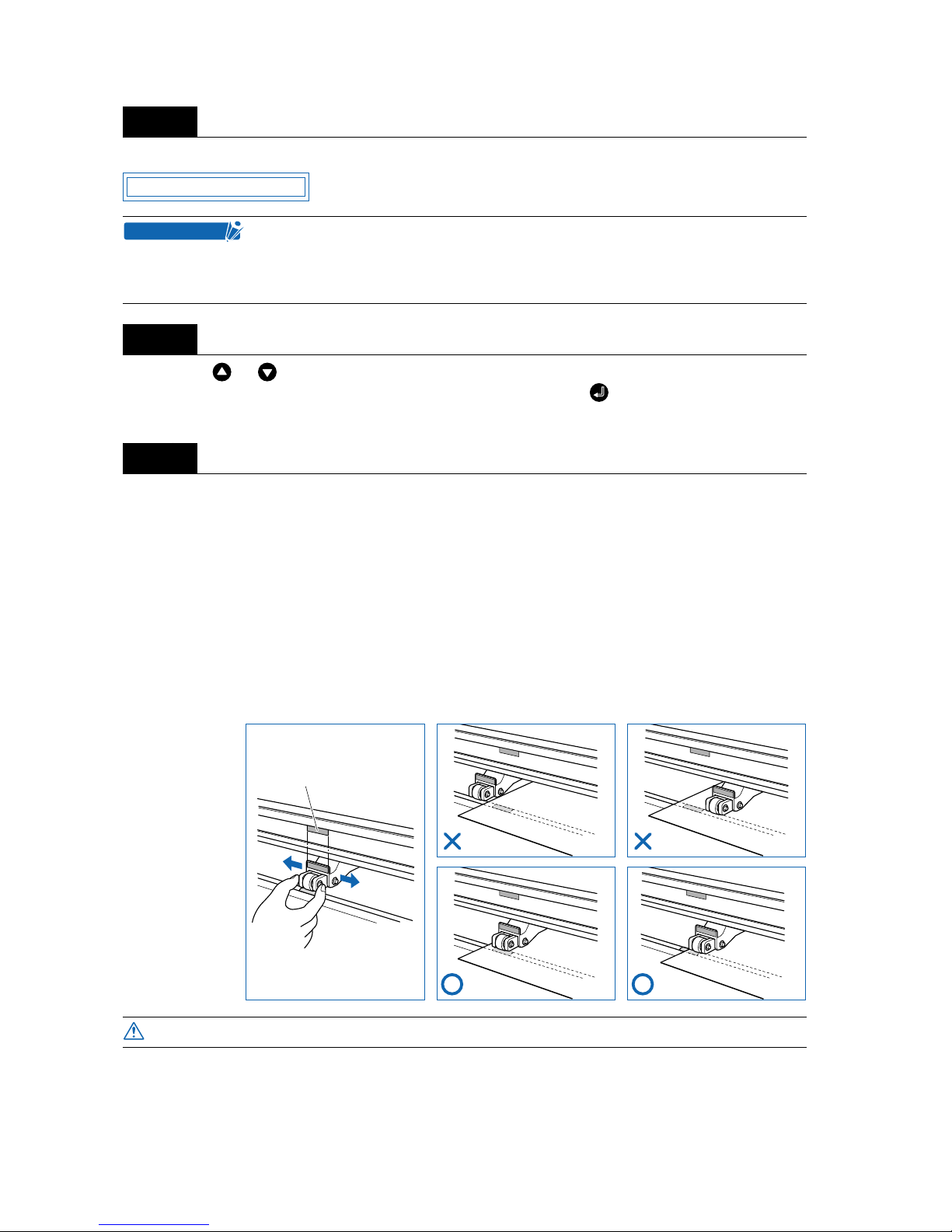

■ Aligning the Push Rollers

Adjust the position of the left- and right-hand push rollers to suit the medium width. Position the push rollers at either edge of the medium so that they are above the grit rollers. Adjust the push rollers so that they

are positioned above both the medium and the grit rollers. Positioning the push rollers within the pushroller alignment marks ensures that they are above the grit rollers.

Step

4

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller, or the left-hand push rollers are not positioned

over the grit roller. Check to confirm that they are positioned correctly.

Step

5

Step

6

To move the push rollers, the media set lever must be in the lowered position.

SHEET PRESS ENTR

CHECKPOINT

Push-roller alignment mark

NG NG

OK OK

CAUTION

2 – 9

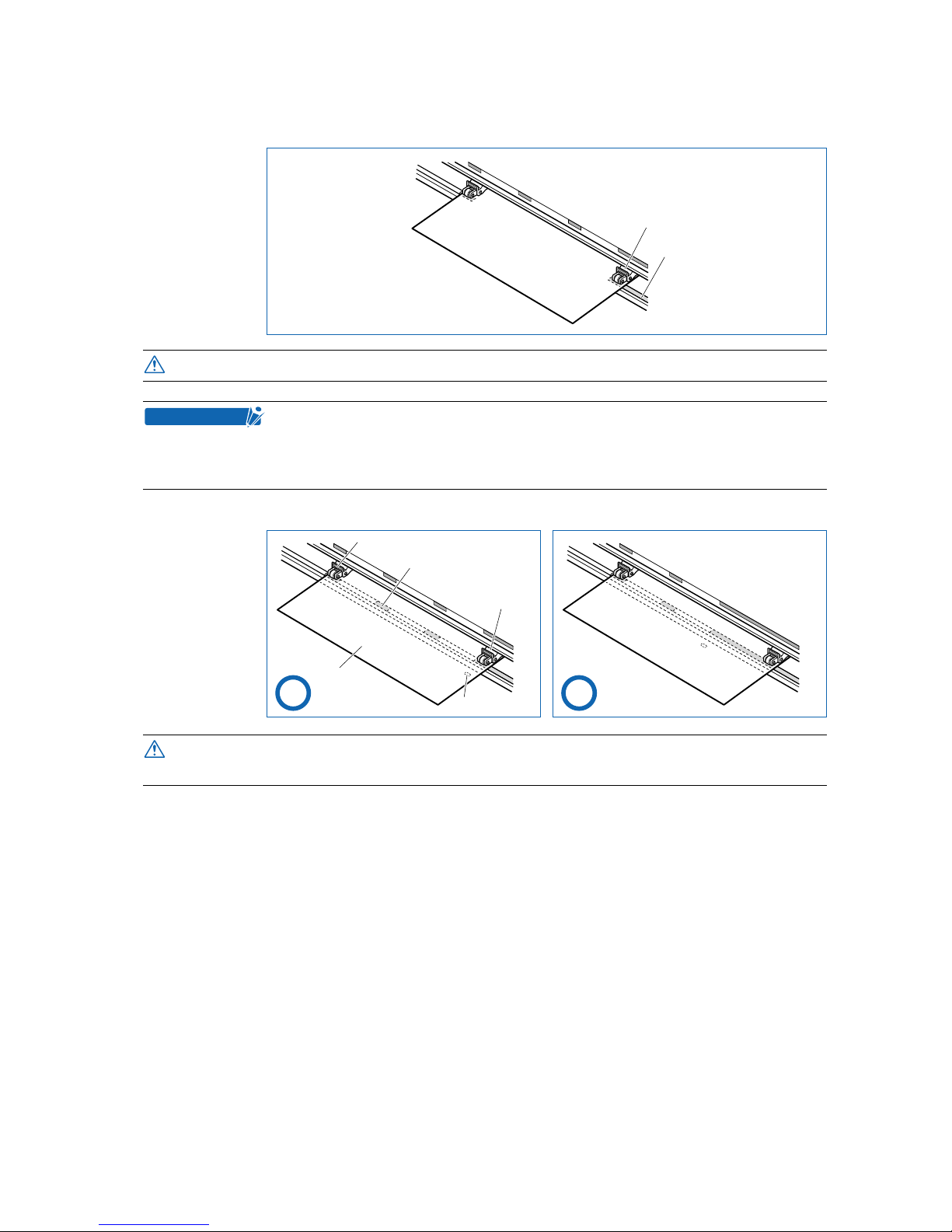

The push roller on the right-hand edge when viewed from the front must always be moved over the righthand wide grit roller.

Position the push rollers over the grit rollers to grip each edge of the medium.

To move the push rollers, the media set lever must be in the lowered position.

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller, or the left-hand push roller is not positioned

over the grit roller. Check to confirm that they are positioned correctly.

• The push roller (1) must be positioned over the right-hand wide grit roller.

• The medium must always be positioned over the media sensor.

Right-hand push roller

Right-hand grit roller

CAUTION

CHECKPOINT

Media sensor

Push roller (1)

Push roller (2)

Grit roller

Medium

OK OK

CAUTION

2 – 10

Position all of the rollers over the r ight-hand wide grit roller. Position the medium with the left-hand edge

aligned with the left-hand edge of the grit roller, and position the push rollers over both edges. The minimum width of the medium that can be set is 50 mm for the Vinyl Express.

2.4 Adjusting and Mounting the Cutter Pen

Individual cutter blades have a var iety of features. Select the optimal cutter blade to suit the medium to be

cut.

■ Types and Features of Cutter Blades

For Minimum-Size Media

• The medium must be at least 125 mm in length.

• The medium must always be positioned over the media sensor.

To avoid cutting your fingers, always handle the cutter blade with caution.

Part No. and

profile

Blade diameter

and offset

Compatible

plunger

Use and features

CB 09UA ø0.9 mm

0.45

PHP32-CB09N The standard blade for cutting color adhesive-backed

media. Suitable for cutting media up to 0.25 mm in

thickness.

Max. cutting distance: Approx. 4,000 m

CB 15U ø1.5 mm

0.75

PHP32-CB15N Capable of cutting thicker media than possible with the

CB09UA blade. Suitable for cutting media 0.25 mm to

0.5 mm in thickness.

CB 15UB ø1.5 mm

0.15

PHP32-CB15N Suitable for detailed cutting (e.g., letters less than 10

mm in size) of media up to 0.25 mm in thickness.

Medium

Push roller (2)

Grit roller

Media sensor

Push roller (1)

OK

CAUTION

CAUTION

2 – 11

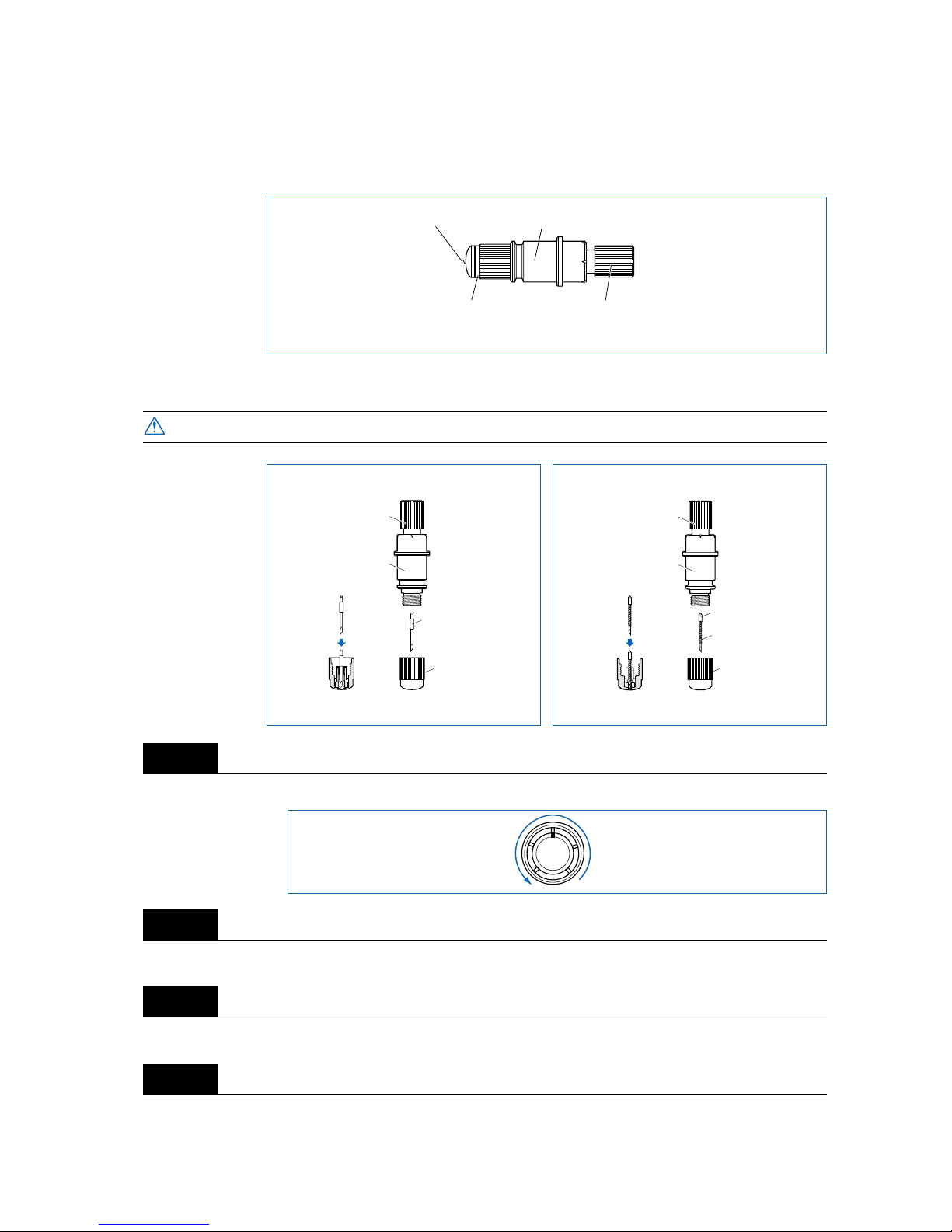

■ Cutter-Pen Construction

The cutting plotter cuts using a cutter blade mounted in a cutter-pen plunger. There are two different cutterpen plungers to suit the diameter of the cutter blade to be mounted (the 0.9-mm cutter-pen plunger is provided as standard equipment). Be sure to mount the cutter blade in the corresponding cutter-pen plunger.

■ Replacing the Cutter Blade

Turn the blade-length adjustment knob to retract the blade into the plunger.

Turn the plunger cap in the counter-clockwise direction to remove it from the plunger.

Remove the blade from inside the plunger cap.

Insert the new blade into the hole provided in the plunger cap.

To prevent cutting your fingers, always handle the cutter blade with caution.

Step

1

Step

2

Step

3

Step

4

Cutter blade

Plunger cap

Plunger

Blade-length adjustment knob

(Blue: For 0.9-mm-diameter blades)

(Red: For 1.5-mm-diameter blades)

CAUTION

1.5-mm-diameter cutter pen

Plunger-cap

cross-section

Plunger cap

1.5-mm-dia. blades

Blade-length

adjustment knob (red)

Plunger

Spring

Plunger cap

Plunger-cap

cross-section

0.9-mm-dia. blades

0.9-mm-diameter cutter pen

Blade-length

adjustment knob (blue)

Plunger

2 – 12

With the blade inserted into the plunger cap, screw on the plunger from above.

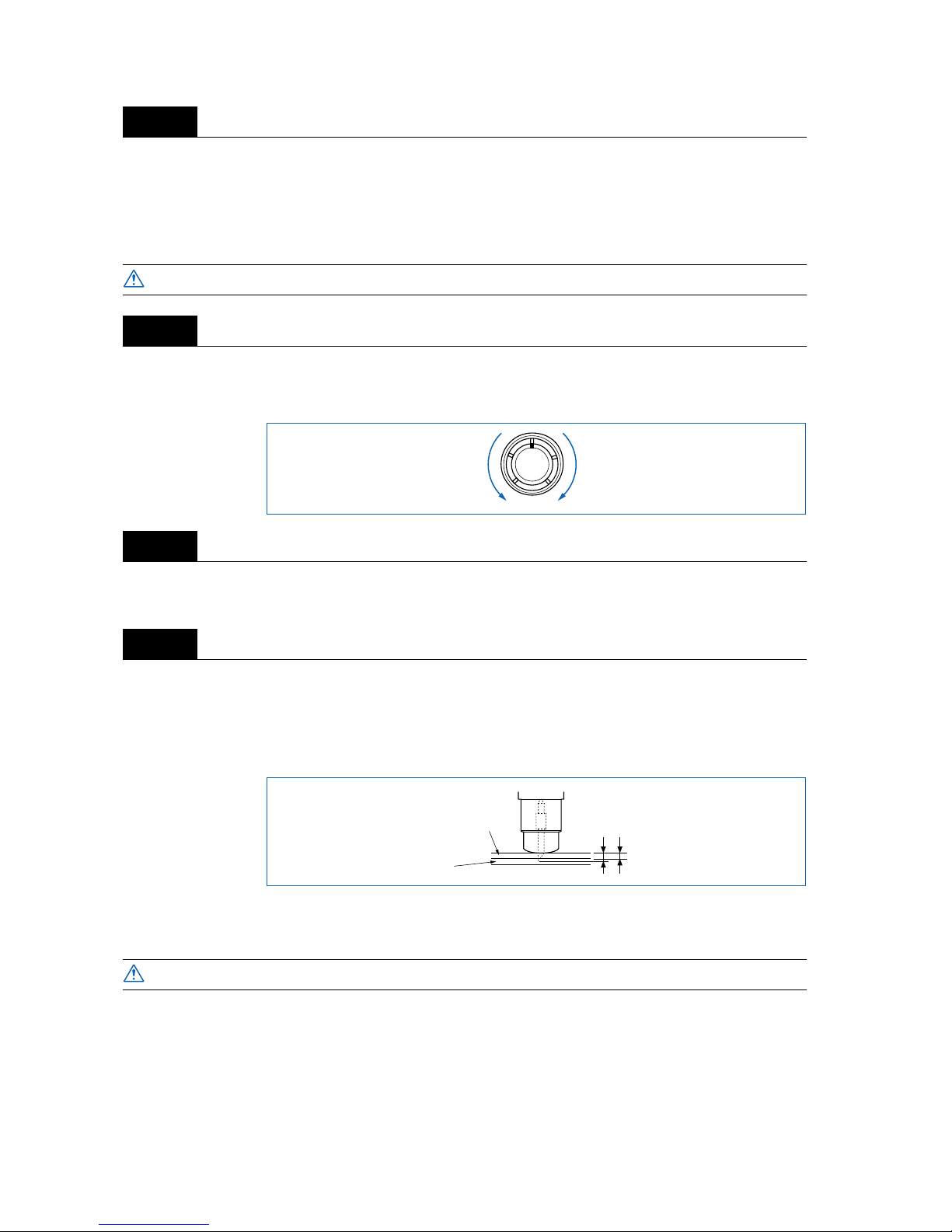

■ Adjusting the Blade Length

If the blade is extended too far in relation to the thickness of the medium being cut, it will damage the cutting mat. Be sure to adjust the blade length correctly.

Adjust the blade length by turning the blade-length adjustment knob. Turn the knob in direction “A” to

extend the blade, or in direction “B” to retract the blade. When the knob is turned by one scale unit, the

blade moves approximately 0.1 mm. One full turn of the knob moves the blade approximately 0.5 mm.

First align the blade tip with the tip of the cutter pen, and then extend the blade from that position to suit the

thickness of the media to be cut.

Assuming that the medium thickness is “t,” as shown in the figure below, the blade length “rrrr” should be

equal to or slightly greater than “t.” Make sure “rrrr” is never greater than the combined thickness of the

medium and its backing sheet. If it is not possib le to accurately determine the medium thickness , adjust the

blade length by gradually increasing it until only traces of the b lade appear on the bac king sheet after a cutting test is conducted.

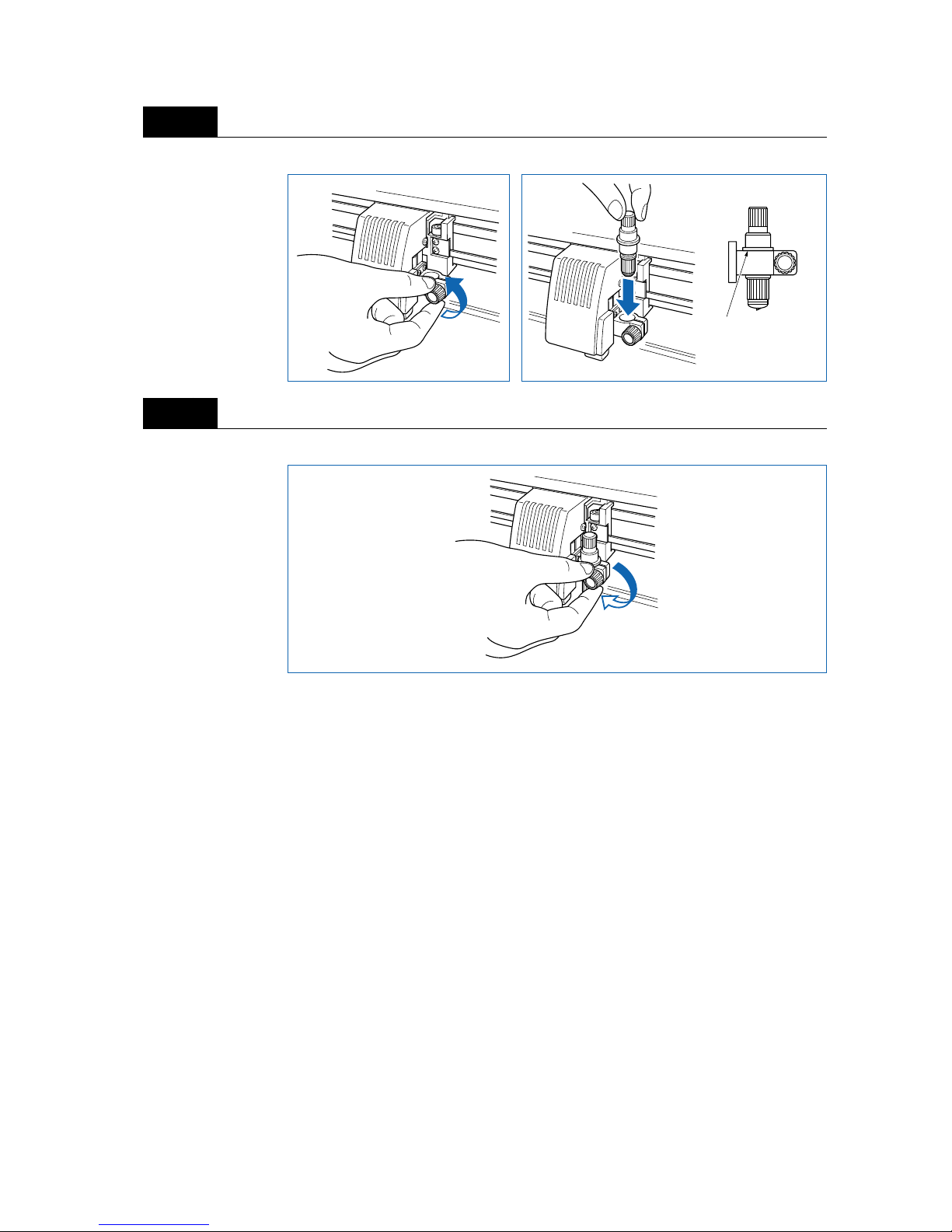

■ Mounting the Cutter Pen

After the blade length has been adjusted, mount the cutter pen in the cutting plotter.

Step

5

To prevent cutting your fingers, always handle the cutter blade with caution.

Step

1

Step

2

Step

3

To prevent cutting your fingers, always handle the cutter blade with caution.

CAUTION

AB

t

Medium

Backing sheet

R

CAUTION

2 – 13

Loosen the pen-holder screw and then mount the cutter pen.

Once the cutter pen is properly positioned, tighten the pen-holder screw.

Step

1

Step

2

Press the plunger in

firmly so that it

contacts this surface

of the pen holder.

2 – 14

3

3

BASIC SETTINGS AND OPERATIONS

3.1 Setting the Format of Data to be Received .......................3-2

3.2 Setting the Interface Conditions...........................................3-4

3.3 Setting the Cutter-Pen Conditions.......................................3-5

3.4 Displaying the Effective Cutting Area.................................3-9

3.5 Moving the Pen............................................................................3-9

3.6 Setting the Initial Cutting Position (Origin Point) ...........3-10

3.7 Stop Function ............................................................................3-11

3.8 Moving the Pen Carriage in +100 mm Steps...................3-12

3.9 Test Cutting ................................................................................3-12

3 – 2

3.1 Setting the Format of Data to be Received

Before data is sent from the computer , the f ormat (command mode) of the data sent by the application software must be checked. The cutting plotter accepts two data formats (command modes): GP-GL (Gr aphtec)

and HP-GL commands. Set the command mode to suit the application used.

■ Setting the Command Mode

Check to confirm that the cutting plotter is in READY mode (displaying the current pen settings).

Press the (PAUSE) key to switch to PAUSE mode, and then press the (NEXT) or (PREV.) key

until the menu shown below is displayed.

Press the (ENTER) key to display the menu shown below.

Press the or key to select “GP-GL” or “HP-GL,” and then press the (ENTER) key to confirm.

To cancel the selection, press the (NEXT) or (PREV.) key.

If “GP-GL” is selected, set the STEP SIZE. If “HP-GL” is selected, set the ORIGIN POINT. If a different

command from that set previously is selected, the PAUSE mode is automatically cancelled once the STEP

SIZE (GP-GL) or ORIGIN POINT (HP-GL) is set.

Step

1

Step

2

Step

3

Step

4

Step

5

1 PEN 23 30 2

COMMAND

COMMAND HP-GL

Loading...

Loading...