Vinyl Express Q60, Q100, Q75, Q160, Q130 User Manual

CUTTING PLOTTER

Vinyl

Express Q60/75/100/130/160

user manual

MANUAL NO. VEXQ06-UM-152

Signwarehouse.com

ii

Table of Contents

TO ENSURE SAFE AND CORRECT USE .............................................................................................vii

Conventions Used in This Manual.........................................................................................................vii

Description of Safety Symbols ..............................................................................................................vii

PREFACE ..................................................................................................................................................xii

Notes on this Manual .............................................................................................................................xii

Registered Trademarks ..........................................................................................................................xii

Copyright ...............................................................................................................................................xii

Special Precautions on Handling Blades ..................................................................................................xiii

Cutting Blades.......................................................................................................................................xiii

Cutter Pens ............................................................................................................................................xiii

After Turning on the Plotter......................................................................................................................xiii

Notes on the Stand ....................................................................................................................................xiv

Machine Caution Label.............................................................................................................................xiv

Daily Maintenance and Storage ................................................................................................................ xiv

Daily Maintenance ................................................................................................................................xiv

Storing the Plotter ................................................................................................................................. xiv

Chapter 1: Out of the Box

1.1 Checking the Contents ....................................................................................................................1-2

1.2 Nomenclature .................................................................................................................................1-3

Front View ...................................................................................................................................1-3

Rear View .....................................................................................................................................1-4

1.3 Assembling the plotter ....................................................................................................................1-5

Vinyl Express Q60/75/100/130/160 (stand provided) .................................................................1-5

Assembling the Stand ................................................................................................................ 1-5

Mounting the stock rollers ...........................................................................................................1-8

1.4 Attaching the Vinyl Express Basket (Option) ................................................................................1-9

1.5 Attaching a Cutter Pen ..................................................................................................................1-10

Attaching a Pen to the Two-Pen Holder (Option) ......................................................................1-11

Attaching a Plotting Pen to the Pen Station ...............................................................................1-12

1.6 Replacing the Cross-Cutter Unit ..................................................................................................1-13

Chapter 2: Cutter Blades and Cutter Pens

2.1 Blade Application and Features ......................................................................................................2-2

2.2 Cutter Pen Nomenclature ...............................................................................................................2-3

2.3 Replacing the Cutter Blade .............................................................................................................2-4

Structure of Cutter Pen .................................................................................................................2-4

Replacing the Cutter Blade ..........................................................................................................2-4

2.4 Adjusting the Blade Length ............................................................................................................2-5

Chapter 3: Preparing to Cut

3.1 Control Panel ..................................................................................................................................3-2

Indicator Lamps ...........................................................................................................................3-2

Function Keys ..............................................................................................................................3-2

Position Keys ...............................................................................................................................3-2

Menu Keys ...................................................................................................................................3-3

3.2 Selecting a Function Menu .............................................................................................................3-4

When the Vinyl Express is in MENU mode ................................................................................3-4

When the power is turned on without any media loaded .............................................................3-5

3.3 Connecting to your Computer ........................................................................................................3-6

3.4 Turning on the Power .....................................................................................................................3-7

3.5 Loading Media ................................................................................................................................3-9

Loading Roll Media (Rear Loading) ............................................................................................3-9

Loading Roll Media (Front Loading) .........................................................................................3-10

Loading Sheet Media .................................................................................................................3-11

3.6 Aligning the Pinch Rollers ...........................................................................................................3-13

Standby Position .........................................................................................................................3-13

When Feeding Long-axis Media (at least 2 meters) ..................................................................3-14

When the Media Width is 100 to 160 mm .................................................................................3-14

When the Media Width is 160 to 540 mm .................................................................................3-14

When the Media Width Exceeds 540 mm ..................................................................................3-15

Changing the Hold-down Force .................................................................................................3-15

Switching between the Strong and Weak settings ................................................................... 3-15

Hold-down Force Assignments................................................................................................ 3-16

3.7 Selecting the Media Type .............................................................................................................3-17

Chapter 4: Pen Setting Conditions

4.1 Pen Conditions ................................................................................................................................4-2

Precautions to observe when cutting high-intensity reflective film........................................... 4-3

How to improve weedability...................................................................................................... 4-3

4.2 Selecting Cutter-Pen Condition Setting Areas ...............................................................................4-4

Selection method........................................................................................................................ 4-4

4.3 Setting the Cutter-pen Conditions ..................................................................................................4-5

To Change the FORCE ................................................................................................................4-5

Setting Procedure ....................................................................................................................... 4-5

To Change the SPEED .................................................................................................................4-5

Setting Procedure ....................................................................................................................... 4-6

To Change the QUALITY ...........................................................................................................4-6

Setting Procedure ....................................................................................................................... 4-6

To Change the OFFSET ...............................................................................................................4-7

Setting Procedure ....................................................................................................................... 4-7

4.4 Running Cutting Tests ....................................................................................................................4-8

Test Cutting Procedure ............................................................................................................. 4-8

4.5 Adjusting the Blade Length ..........................................................................................................4-10

Test Cutting Procedure ............................................................................................................ 4-10

iii

Chapter 5: BASIC FUNCTIONS AND OPERATIONS

5.1 Using the HOLD Function .............................................................................................................5-2

Setting Procedure ....................................................................................................................... 5-2

5.2 Withdrawing the Pen Carriage .......................................................................................................5-3

Setting Procedure ....................................................................................................................... 5-3

5.3 Moving the Pen Carriage to the Origin Point .................................................................................5-3

Setting Procedure ....................................................................................................................... 5-3

5.4 Using the PRE FEED Function ......................................................................................................5-4

Setting Procedure ....................................................................................................................... 5-4

5.5 Moving the Origin Point .................................................................................................................5-5

Setting Procedure ....................................................................................................................... 5-5

When the origin is moved after the coordinate axes were rotated ...............................................5-5

When the coordinate axes are rotated after moving the origin point ...........................................5-6

5.6 Using the COPY Function ..............................................................................................................5-7

Setting Procedure ....................................................................................................................... 5-7

iv

5.7 Pen Up/Down ..............................................................................................................................5-10

Setting Procedure ..................................................................................................................... 5-10

5.8 Using the CROSS-CUT Function ................................................................................................5-11

Cutting position........................................................................................................................ 5-11

Cutting width ........................................................................................................................... 5-11

Guidelines for replacing the cross-cutting unit........................................................................ 5-11

Auto Cross-cutting .....................................................................................................................5-11

Manual Cross-cutting .................................................................................................................5-12

Setting Procedure ..................................................................................................................... 5-12

5.9 Using the MOVE STEP Function ...............................................................................................5-13

Setting Procedure ..................................................................................................................... 5-13

5.10 Upon detection of no medium during roll media cutting .............................................................5-14

Setting Operation ..................................................................................................................... 5-14

Chapter 6: ADVANCED FUNCTIONS AND OPERATIONS

6.1 Changing the Initial Feed Speed ..................................................................................................... 6-2

Setting Procedure ....................................................................................................................... 6-2

6.2 Setting AUTO PRE FEED .............................................................................................................6-3

Making the setting at the INITIAL MENU screen .................................................................... 6-3

Making the setting at the FUNCTION 2 screen ........................................................................ 6-4

6.3 Setting the ORIGIN in HP-GL™ Mode ........................................................................................6-5

Setting Procedure ....................................................................................................................... 6-5

6.4 Setting the Cutting/Plotting Area ...................................................................................................6-6

Setting Procedure ....................................................................................................................... 6-6

6.5 Expanding the Cutting/Plotting Area .............................................................................................6-9

Setting Procedure ....................................................................................................................... 6-9

6.6 Setting the PAGE LENGTH ........................................................................................................6-11

Setting Operation ..................................................................................................................... 6-11

6.7 Rotating the Coordinate Axes ......................................................................................................6-13

6.8 Setting the Mirror Mode ...............................................................................................................6-14

Setting Procedure ..................................................................................................................... 6-14

6.9 Enlarging or Reducing an Image ..................................................................................................6-15

Setting Procedure ..................................................................................................................... 6-15

6.10 Data Sorting Settings ....................................................................................................................6-16

Setting Procedure ..................................................................................................................... 6-16

6.11 Auto Registration Mark Reading Function (Option) ....................................................................6-17

The registration mark pattern .....................................................................................................6-17

The reading area required for registration mark detection .........................................................6-18

The registration mark locations .................................................................................................. 6-18

The position of the origin point ..................................................................................................6-19

Media on which registration marks cannot be detected .............................................................6-20

If registration marks cannot be automatically recognized ......................................................... 6-20

6.12 Setting the Registration Mark Mode (Option) ..............................................................................6-21

Setting Procedure ..................................................................................................................... 6-21

2-point reading (2POINTS) ........................................................................................................6-22

3-point reading (3POINTS) ........................................................................................................6-23

4-point reading (4POINTS) ........................................................................................................6-25

6.13 Setting the Registration Mark Reading Area (Option) .................................................................6-27

Setting Procedure ..................................................................................................................... 6-27

6.14 Selecting the Registration MARK TYPE (Option) ......................................................................6-29

Setting Procedure ..................................................................................................................... 6-29

6.15 Specifying the Registration MARK SIZE (Option) .....................................................................6-30

Setting Procedure ..................................................................................................................... 6-30

6.16 Setting the DISTANCE ADJUSTMENT (Option) ......................................................................6-31

Setting Procedure ..................................................................................................................... 6-31

6.17 Setting the AXIS ORIGIN OFFSET (Option) .............................................................................6-33

Setting Procedure ..................................................................................................................... 6-33

6.18 Setting the PAPER-WEIGHT Function (Option) ........................................................................6-35

Setting Procedure ..................................................................................................................... 6-35

6.19 Setting the SENSOR ADJUSTMENT Function ..........................................................................6-37

Setting Operation ..................................................................................................................... 6-37

6.20 Setting the SENSOR OFFSET ADJUSTMENT (Method 1) (Option) ........................................6-39

Setting Procedure ..................................................................................................................... 6-39

6.21 Setting the AXIS OFFSET ADJUSTMENT (Method 2) (Option) ..............................................6-41

Setting Procedure ..................................................................................................................... 6-41

6.22 Selecting the Axis Alignment Method .........................................................................................6-43

Selecting the Axis Alignment Method..................................................................................... 6-43

6.23 Selecting the Axis Alignment Tool ..............................................................................................6-44

Selecting the Axis Alignment Tool.......................................................................................... 6-44

6.24 AXIS ALIGNMENT Settings ......................................................................................................6-45

Selecting an Axis Alignment Method ........................................................................................6-45

2-point method ......................................................................................................................... 6-45

3-point method ......................................................................................................................... 6-46

4-point method ......................................................................................................................... 6-48

6.25 Setting Tangential Emulation .......................................................................................................6-50

Selecting the tangential emulation mode ................................................................................. 6-50

Enabling/Disabling Tangential Emulation............................................................................... 6-51

Setting Overcut ........................................................................................................................ 6-52

6.26 Setting the PEN UP SPEED .........................................................................................................6-53

Setting Procedure ..................................................................................................................... 6-53

6.27 Adjusting the Blade OFFSET ANGLE ........................................................................................6-54

Setting Procedure ..................................................................................................................... 6-54

6.28 Setting the OFFSET FORCE ........................................................................................................6-55

Setting Procedure ..................................................................................................................... 6-55

6.29 Setting the STEP PASS ................................................................................................................6-56

Setting Procedure ..................................................................................................................... 6-56

6.30 Setting the INTIAL DOWN FORCE ...........................................................................................6-57

Setting Procedure ..................................................................................................................... 6-57

6.31 Setting the DISTANCE ADJUST Function .................................................................................6-58

Setting Procedure ..................................................................................................................... 6-58

Setting the Distance Adjust Parameter .................................................................................... 6-59

6.32 Selecting the Type of Perforated Line ..........................................................................................6-60

Setting Operation ..................................................................................................................... 6-60

v

Chapter 7: OPTIONS

7.1 Loupe (PHP61-LOUPE) .................................................................................................................7-2

Axis Alighment and plotting Area Adjustment ...........................................................................7-2

Attaching the Loupe .....................................................................................................................7-2

Using the Loupe ...........................................................................................................................7-3

7.2 Pouncing Tool ................................................................................................................................7-4

Attaching the Pouncing Tool .......................................................................................................7-4

Holder for auto registration mark sensor ........................................................................7-5

Setting Procedure ....................................................................................................................... 7-5

7.3 Pen Assignment (for 2-pen models only) .......................................................................................7-6

Setting Procedure ....................................................................................................................... 7-6

vi

7.4 Pen Offset (for 2-pen models only) ................................................................................................7-7

Setting Procedure ....................................................................................................................... 7-7

Chapter 8: BACK GROUND SETTINGS

8.1 Description of the Background Settings .........................................................................................8-2

8.2 Setting the Background Settings ....................................................................................................8-5

Setting Procedure ....................................................................................................................... 8-5

Chapter 9: TEST MODES AND TROUBLESHOOTING

9.1 Using the Condition List Mode ......................................................................................................9-2

Setting Procedure ....................................................................................................................... 9-2

9.2 Using the DATA DUMP mode ......................................................................................................9-3

Setting Procedure ....................................................................................................................... 9-3

9.3 The Plotter Does Not Operate When Turned On ...........................................................................9-4

9.4 The Plotter Does Not Operate Correctly ........................................................................................9-5

9.5 The Cutting Results Are Unsatisfactory .........................................................................................9-8

9.6 Error Messages in GP-GL Command Mode ................................................................................9-10

9.7 Error Messages in HP-GL Command Mode ................................................................................9-11

CAUSE .................................................................................................................................... 9-11

SOLUTION.............................................................................................................................. 9-11

Chapter 10: INTERFACES

10.1 RS-232C Interface ........................................................................................................................10-2

Factory Preset Settings............................................................................................................. 10-2

10.2 USB Interface Settings .................................................................................................................10-3

Supported Operating Systems.................................................................................................. 10-3

10.3 Interface Setting Menu .................................................................................................................10-4

Using the INITIAL MENU to set the functions ...................................................................... 10-4

Using the MENU MODE to set the functions ......................................................................... 10-4

10.4 Setting the STEP SIZE .................................................................................................................10-5

Setting Procedure ..................................................................................................................... 10-5

10.5 Setting the RS-232C Interface Transmission Conditions ............................................................. 10-6

Setting Procedure ..................................................................................................................... 10-6

10.6 COMMAND Settings ...................................................................................................................10-7

Setting Procedure ..................................................................................................................... 10-7

Chapter 11: Specifications

11.1 Main Specifications ......................................................................................................................11-2

11.2 Options .........................................................................................................................................11-3

11.3 Supplies ........................................................................................................................................11-3

11.4 Menu Tree ....................................................................................................................................11-4

11.5 External Dimensions ....................................................................................................................11-5

Vinyl Express Q60/75/100/130/160 ...........................................................................................11-5

vii

DANGER

WARNING

CAUTION

TO ENSURE SAFE AND CORRECT USE

• To ensure the safe and correct use of your plotter, read this manual thoroughly prior to use.

• After reading this manual, keep it in a handy location for quick reference as necessary.

• Do not allow small children to touch the plotter.

• The following describes important points for safe operation. Be sure to observe them strictly.

Conventions Used in This Manual

To ensure the safe and accurate use of the plotter as well as to prevent human injury and property damage, the safety

precautions provided in this manual are ranked in the three categories described below. Be sure to gain a full understanding of the difference between each of the categories before reading the Manual.

: This category provides information that, if ignored, is highly likely to cause fatal or serious

injury to the operator.

: This category provides information that, if ignored, is likely to cause fatal or serious injury

to the operator.

: This category provides information that, if ignored, could cause injury to the operator or

damage to the plotter.

Description of Safety Symbols

The symbol indicates information that requires careful attention (including warnings). The specific point

requiring attention is described by an illustration or text within or next to the symbol.

The symbol indicates an action that is prohibited. Such prohibited action is described by an illustration

or text within or next to the symbol.

The symbol indicates an action that must be performed. Such imperative action is described by an

illustration or text within or next to the symbol.

viii

Specified

rating

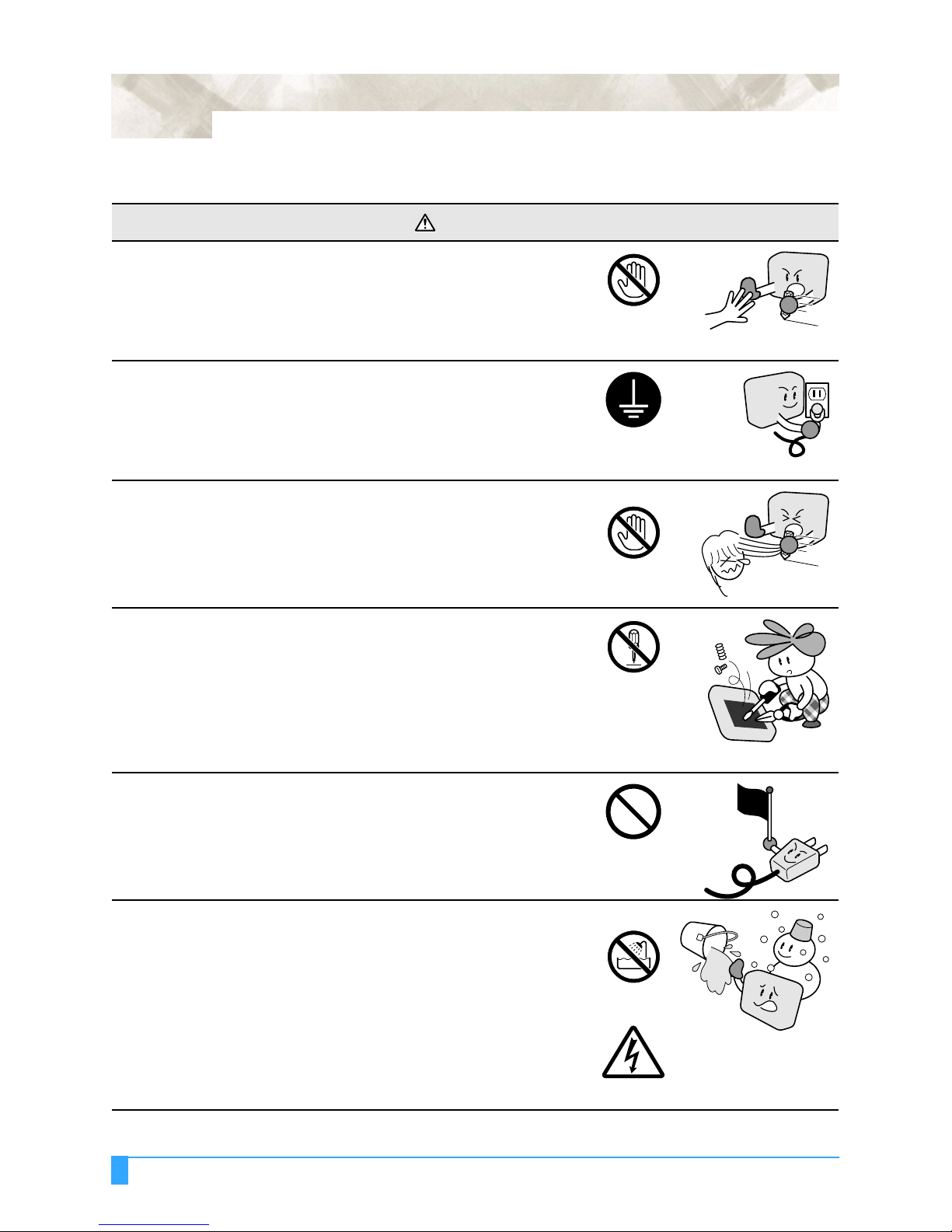

Safety Precautions

WARNING

Do not touch the rollers or moving parts such as the carriage

while cutting or plotting is in progress.

• Such action may result in injury.

Be sure to ground the earth terminal.

• If the plotter is not grounded, the operator could suffer an electric

shock in the event of current leakage.

Keep your hands, hair, etc., away from the rollers or moving

parts such as the carriage even if the plotter is stopped, as it

may suddenly start moving when data is received.

• Such action may result in injury.

Do not touch

Ground the plotter

Keep your distance

Do not disassemble, repair, or remodel the plotter.

• Such action may cause electric shock or a fire hazard due to current

leakage.

• Contact with the high-voltage parts within the plotter may cause electric shock.

• If the plotter requires repairs, contact your sales representative or

nearest Signwarehouse vendor.

Do not connect the plotter to a non-rated power supply.

• Use of a different supply voltage may result in electric shock or a fire

hazard due to current leakage.

Do not use the plotter in a location where it will be exposed to

water, rain, or snow.

• Such locations may cause electric shock or a fire hazard due to current leakage.

No disassembly

Prohibited

Avoid water

Beware of electric shock

Safety Precautions (Continued)

WARNING

If the plotter generates smoke, overheats, emits a strange

odor, or otherwise functions abnormally, do not continue

using it. Turn off the power and unplug the power cord from

the electrical socket.

• Use of the plotter in such a condition may result in a fire hazard or

electric shock.

• After confirming that smoke is no longer being emitted, contact your

sales representative or nearest Signwarehouse vendor for repairs.

• Never attempt to perform repairs yourself. Repair work by inexperienced personnel is extremely dangerous.

Do not allow dust or metal scraps to adhere to the power

plug.

• A dirty power plug may result in electric shock or a fire hazard due to

current leakage.

ix

Prohibited

Prohibited

Do not use the power cord if it is damaged.

• Use of a damaged cord may result in electric shock or a fire hazard

due to current leakage.

• Replace the power cord with a new one.

Be careful when handling the cutter blade.

• Touching the blade with your bare hand may cause injury.

• Do not touch the cutter blade while cutting is in progress.

Beware of electric shock

Unplug the power

cord from the socket

Do not touch

x

Safety Precautions (Continued)

CAUTION

Do not use or store the plotter in a location exposed to direct

sunlight or the direct draft of an air conditioner or heater.

• Such locations may impair the performance of the plotter.

Do not use the plotter in an excessively dusty or humid

location.

• Such locations may impair the performance of the plotter.

Do not place any receptacle containing water or other fluid on

top of the plotter.

• Fluid falling inside the plotter may cause electric shock or a fire hazard due to current leakage.

Prohibited

Prohibited

Avoid water

Beware of electric shock

Do not use the plotter in a location subject to excessive

mechanical vibration or electrical noise.

• Use in such locations may impair the performance of the plotter.

When disconnecting the power cord or interface cable, do not

pull on the cord/cable.

• Such action will damage the cord/cable, resulting in a fire hazard or

electric shock.

If water or foreign matter enters the plotter, discontinue use.

Turn off the power and unplug the power cord from the

electrical socket.

• Use of the plotter in such a condition may result in electric shock or a

fire hazard due to current leakage.

• Contact your sales representative or nearest Signwarehouse vendor

for repairs.

Prohibited

Prohibited

Unplug the power

cord from the socket

Safety Precautions (Continued)

CAUTION

Do not attempt to lubricate the cutting-plotter mechanisms.

• Such action may cause it to break down.

Do not clean the plotter using volatile solvents such as

thinner or benzene.

• Such action may impair its performance.

Provide sufficient space around the plotter so that it does not

strike any objects in its vicinity during cutting or plotting.

• Such contact may cause misalignment in cutting or plotting.

Prohibited

Prohibited

Do not touch

xi

T

h

i

n

n

e

r

e

n

e

z

n

e

B

When using indoor lighting such as fluorescent or other

electrical lamps, provide a distance of at least one meter

between the plotter and the light source.

• Close proximity of such a light source may cause the sensor to malfunction and prevent proper size detection of the media.

When using the cutter, take care not to extend the blade more

than necessary.

• An overly extended blade will damage the cutting mat and adversely

affect the cutting quality.

Move the pen carriage slowly when moving it manually in

order to load the medium or for other reasons.

• Moving it quickly may damage the plotter.

xii

PREFACE

Thank you for choosing a Signwarehouse Vinyl Express Series plotter. The Vinyl Express Series plotters employ a digital servo drive system to achieve high-speed and high-precision cutting. In addition to cutting marking film and othereop media, an Vinyl Express series plotter can also be used as a pen plotter. To ensure high cutting quality and

optimal productivity, be sure to read this User's Manual thoroughly prior to use.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, without the prior written permission of Signwarehouse.com.

(2) The product specifications and other information in this manual are subject to change without notice.

(3) While every effort has been made to provide complete and accurate information, please contact your sales repre-

sentative or nearest Signwarehouse vendor if you find any unclear or erroneous information or wish to make

other comments or suggestions.

(4) Notwithstanding the stipulations in the preceding paragraph, Signwarehouse.com assumes no liability for dam-

ages resulting from either the use of the information contained herein or the use of the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks or registered

trademarks of their respective companies.

Copyright

This User’s Manual is copyrighted by Signwarehouse.com.

xiii

Special Precautions on Handling Blades

Sharp cutter blades are used with this plotter. Handle the cutter blades and holders with care to prevent bodily injury.

Cutting Blades

Cutter blades are very sharp. While handling a cutter blade or cutter pen, be careful to avoid cutting your fingers or

other parts of your body.

Promptly return used blades to the cutter case provided. When the case is completely filled, discard the used blades

together with the case.

Cutter Pens

The tip consists of a sharp blade. Be sure not to extend it too far. Moreover, when you are not using the cutter pen,

make sure that the blade is fully retracted.

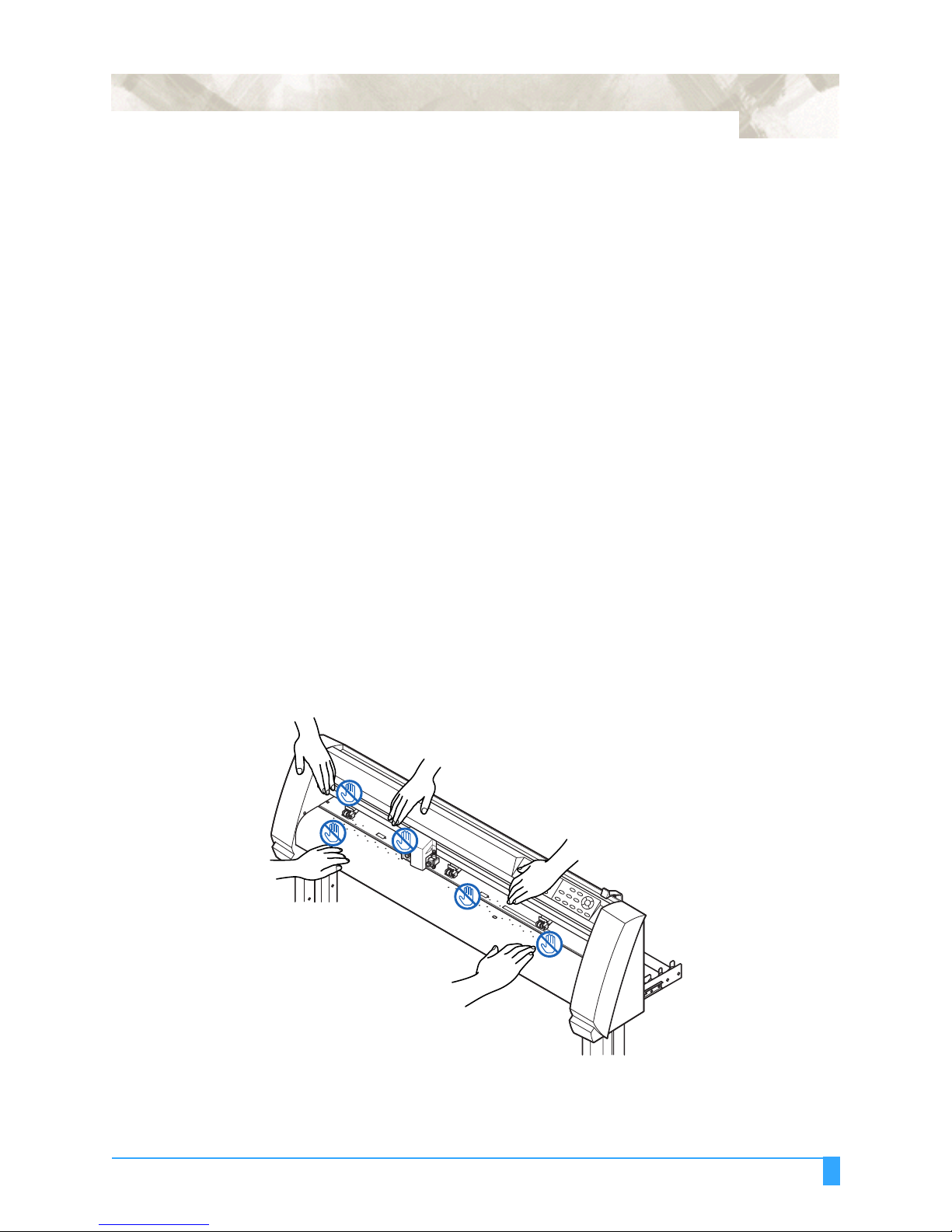

After Turning on the Plotter

During the course of turning on the plotter, be sure to observe the following precautions. The pen carriage and loaded

media may suddenly move during the cutting operation, immediately afterward and when setting the plotter's functions.

Keep hands, hair, clothing and other objects out of the vicinity of the pen carriage, grit rollers and loaded media. To prevent operator injury and poor cutting results, be careful not to allow hands, hair, clothing or other foreign objects to

become entangled with the pen carriage or loaded media while the plotter is operating.

.

xiv

Notes on the Stand

Be sure to use only the stand designed for the Vinyl Express Series with your Vinyl Express Series plotter. The use of

a different stand may cause a plotter malfunction or bodily injury.

Machine Caution Label

The machine's Caution Label is located on the top cover. Be sure to observe all the cautions on the label.

Daily Maintenance and Storage

Daily Maintenance

During the course of daily plotter operation, be sure to observe the following precautions:

(1) Never lubricate the mechanisms of the plotter.

(2) Clean the plotter's casing using a dry cloth that has been moistened in a neutral detergent diluted with water.

Never use thinner, benzene, alcohol, or similar solvents to clean the casings; they will damage the casing's finish.

(3) Clean the cutting mat using a dry cloth. In case of stubborn stains, use a cloth that has been moistened in alcohol

or in a neutral detergent diluted with water.

(4) Clean the plotter's paper sensors using a cloth moistened in a neutral detergent diluted with water. Never use thin-

ner, benzene, alcohol, or similar solvents to clean the sensors; cleaners such as these will damage the sensors.

Storing the Plotter

When your plotter is not in use, be sure to observe the following points:

(1) Remove the pen attached to the penholder

(2) Cover the plotter with a cloth to protect it from dust and dirt

(3) Do not store the plotter in direct sunlight or in high temperatures

Chapter 1: Out of the Box

This chapter describes plotter nomenclature and how to

install your plotter.

Topics in this chapter

1.1 Checking the Contents

1.2 Nomenclature

1.3 Assembling the plotter

1.4 Attaching the Vinyl Express Basket (Option)

1.5 Attaching a Cutter Pen

1.6 Replacing the Cross-Cutter Unit

1 - 2

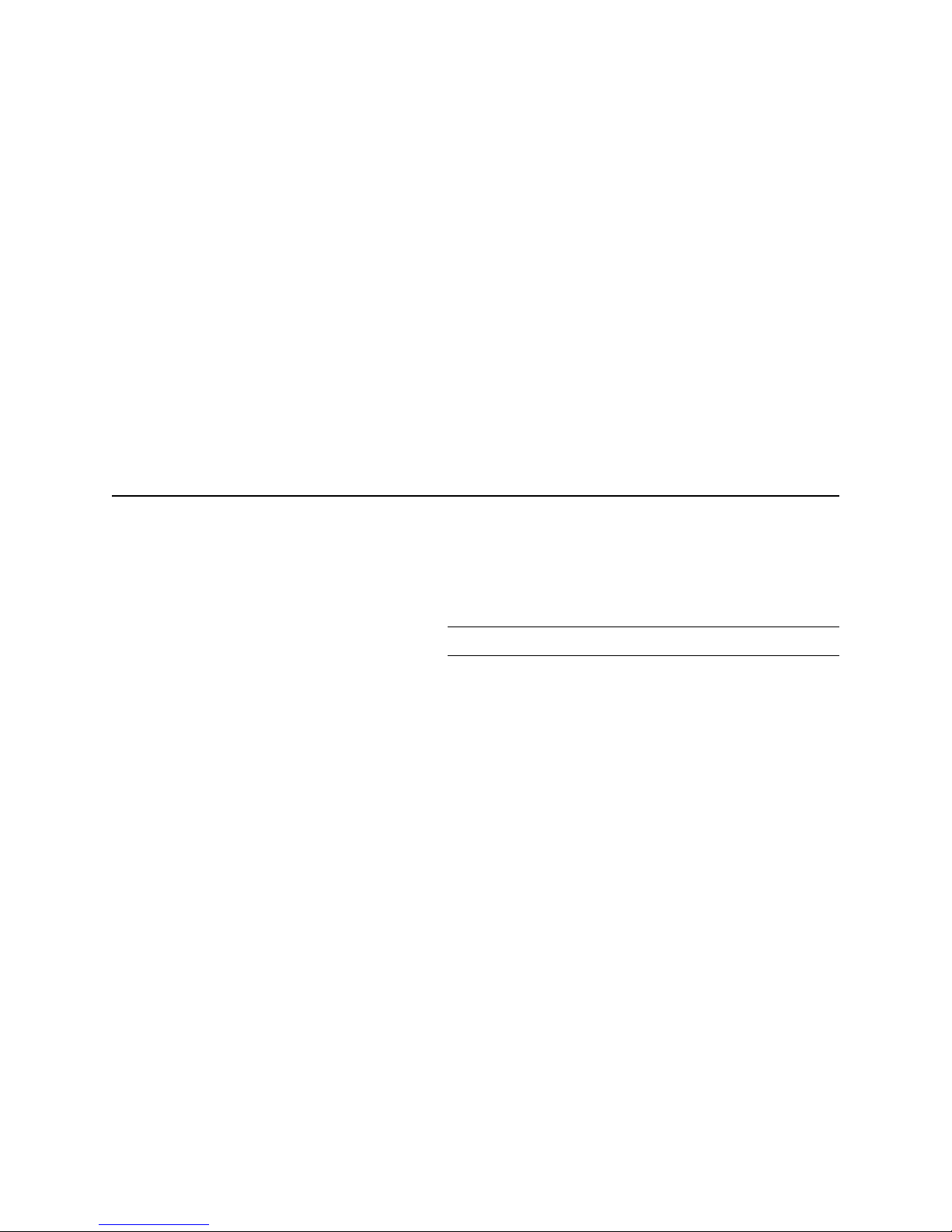

1.1 Checking the Contents

After unpacking your plotter, check that all of the standard accessories shown

below are present. If any accessory is missing, contact your sales representative

or the nearest Signwarehouse dealer.

AC power cord

1 1 each

USB cable (3-m length)

User Guide CD-ROM

1

Contains:

User's Manual (pdf)

Windows driver

Cutter holder

(PHP32-CB09N)

1

Cutter blades

1

Media bracket

1

Quick Start Manual, Usage Precautions

1 of each

Water-based fibertip pen

1

Stand

1

Base assembly x 2

Stand side bar x 2

Center bar x 1

Socket head cap screw x 20

Allen wrench x 1

Media stocker x 2

Stock roller x 2

M4 binding head screws x 8

Out of the Box: Checking the Contents

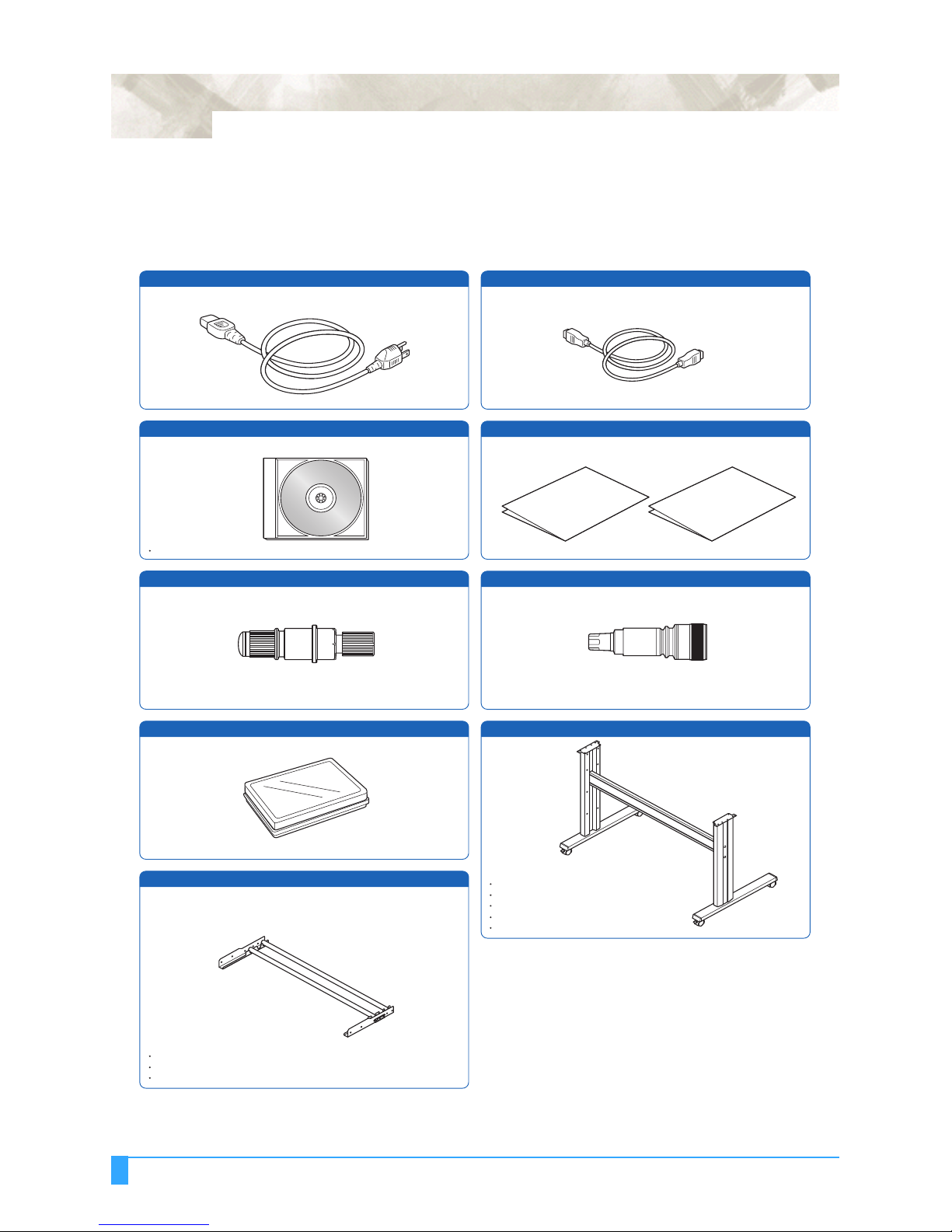

1.2 Nomenclature

Grit roller

Media sensor

Front View

Power switch

Grit roller position guide

Cutting mat

Cutting groove

1 - 3

Pinch roller

Cross-cutter unit

Pen carriage

Pen holder

Pinch rollers

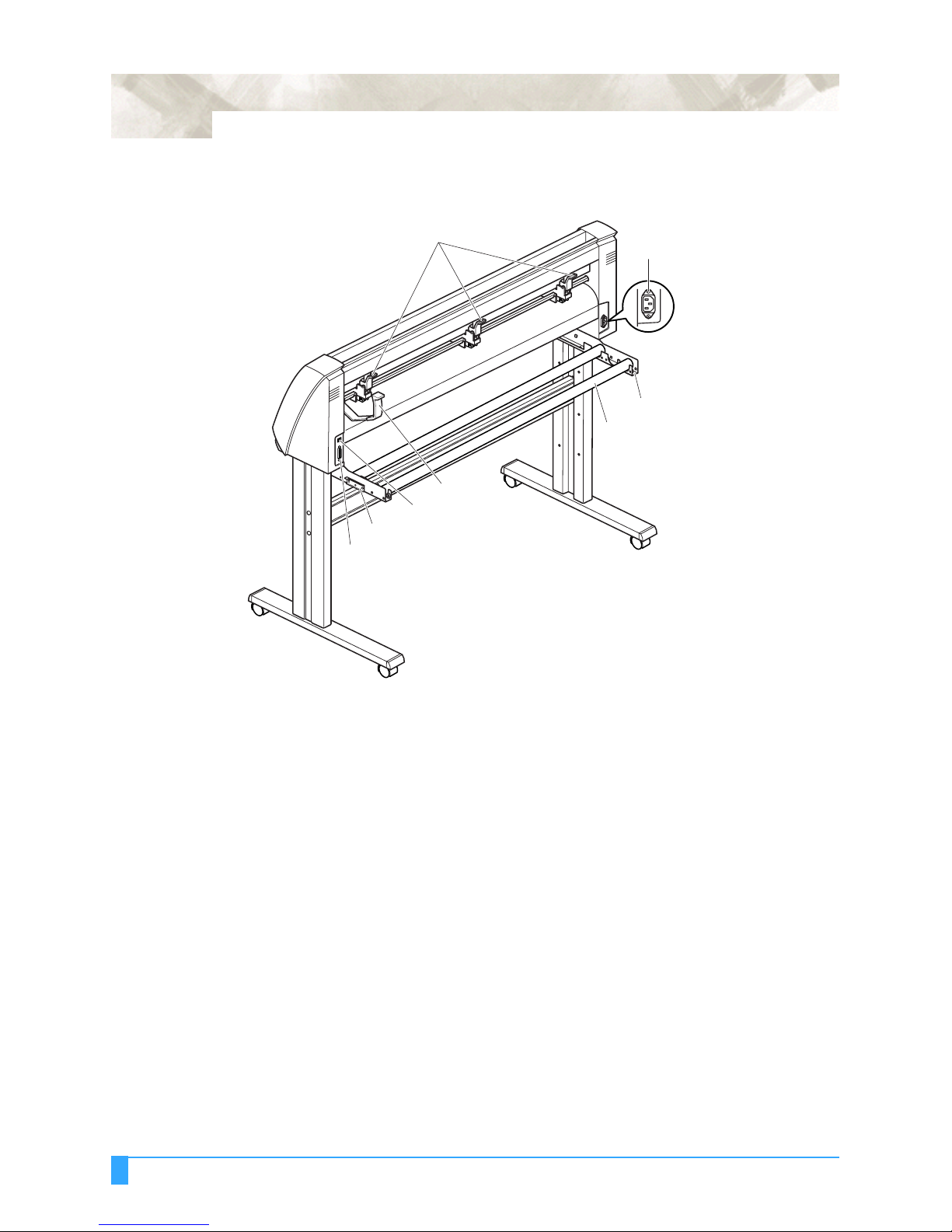

Control panel

Grit roller

Media sensor

Stand

Pen station

Power switch: ..............Used to turn the plotter on and off.

Control panel: ..............Used to access various plotter functions.

Pinch rollers: ...............Rollers that push the media against the grit rollers.

Grit rollers: ..................Metallic rollers with a file-like surface that feed the media

back and forth.

Media sensors: ............The front sensor is used to sense the leading edge of the

media. The rear sensor is used to sense the trailing edge

of the media.

Pen carriage: ...............Moves the cutter-pen or plotting pen across the media

during cutting or plotting.

Pen holder: ..................Holds the cutter-pen or plotting pen and moves it up or

down.

Pen station (installed on 2-pen models only: option):

The second pen is mounted here.

Stand: .........................Used to make the plotter more portable and to free up

counter space

Grit roller position guide:

Stickers on the front of the Y rail and the rear side of the

top cover that show the position of each grit roller. Use

these alignment marks as an aid in locating the pinch roll-

ers.

Cutting groove: ............Used when cross-cutting is performed.

Cross-cutter unit: .........Used to perform cross-cutting of media so that the cut

length can be removed from the roll.

Out of the Box: Nomenclature

1 - 4

Rear View

Pinch roller hold-down force switching lever

AC line inlet

Media stocker

Stock rollers

Media set lever

USB interface connector

Media lock

RS-232C interface connector

Media set lever: ...........Used to raise or lower the pinch rollers during the loading

or unloading of media.

Pinch roller hold-down force switching lever:

Used to switch between the two pinch roller forces (strong

and weak).

AC line inlet: ................Inlet where the power cord is connected.

Media stocker: .............Used to carry roll media and ensure its proper rotation.

Stock rollers: ...............A media roll is placed on these rollers.

Media lock: ..................Used to prevent the stock rollers from rotating when the

media roll has been placed on top of them. The media

lock ensures that the media is pulled straight out from the

roll.

USB interface connector:

Used to connect the plotter to the computer with a USB

interface cable.

Serial interface connector:

Used to connect the plotter to the computer with an RS-

232 serial interface cable.

Out of the Box: Nomenclature

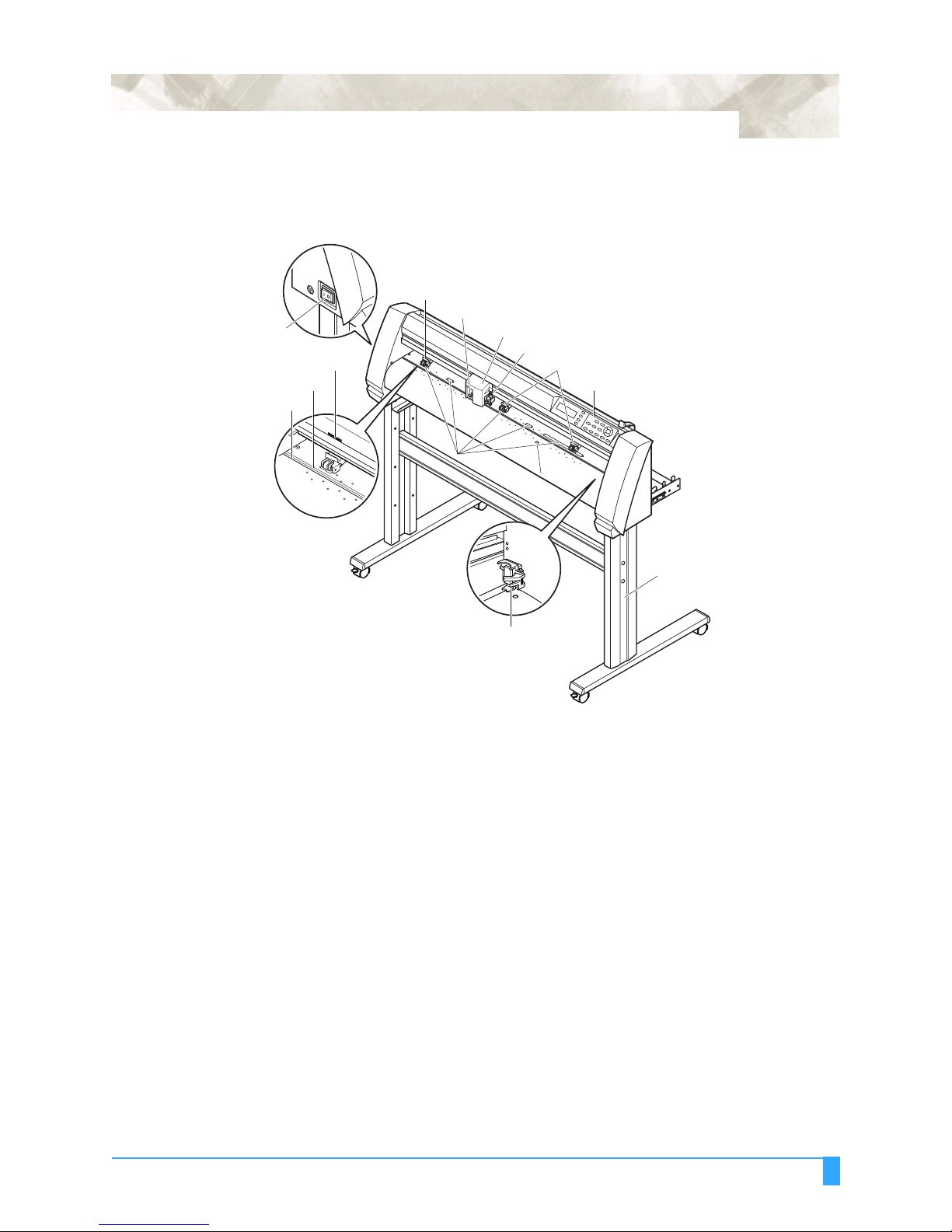

1.3 Assembling the plotter

Vinyl Express Q60/75/100/130/160 (stand provided)

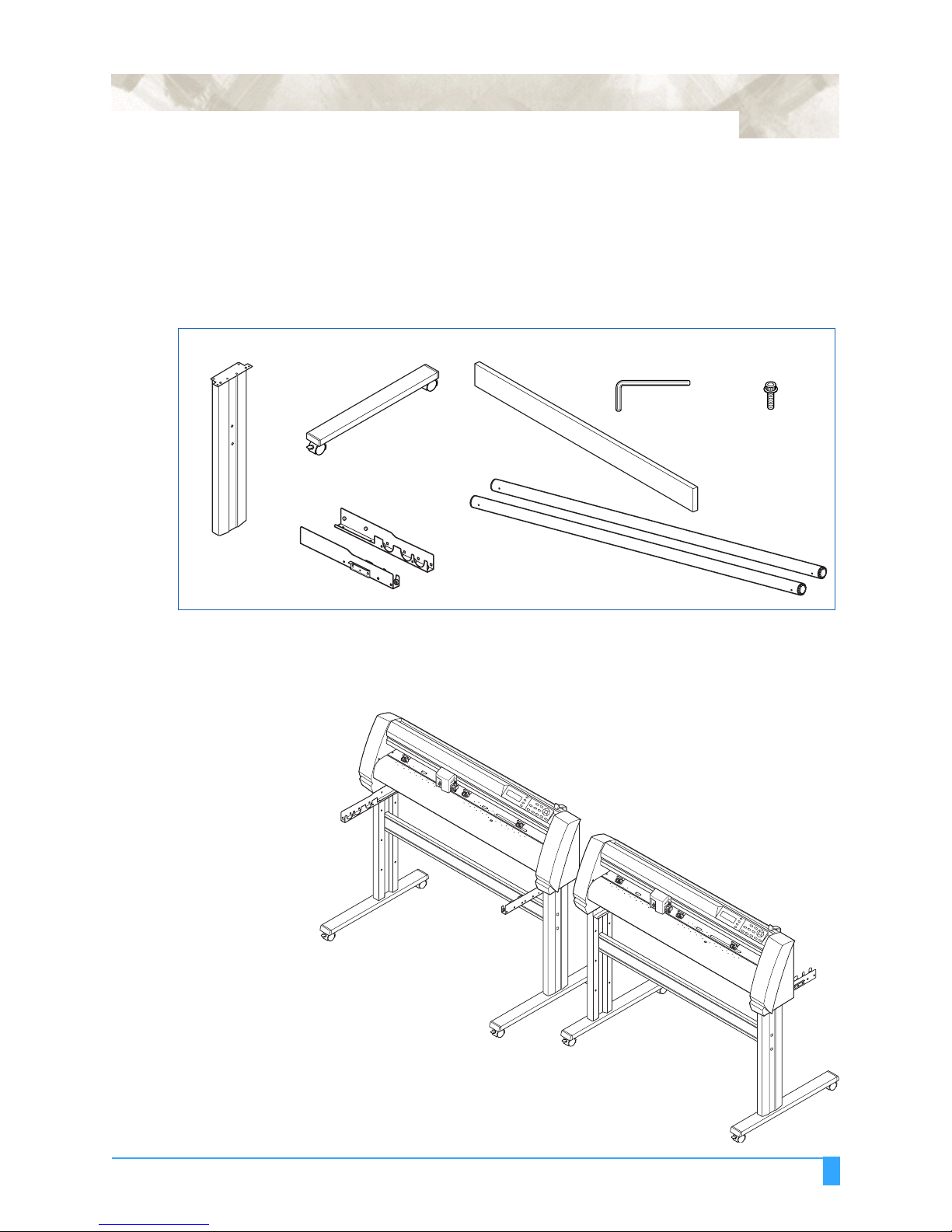

Assemble the stand, attach the media bracket to the stand, and then mount the

plotter on the stand.

The stand and the media bracket are made up of the following parts.

1 - 5

Base assembly x 2 Allen wrench

Media stocker x 2

Center bar x 1Stand side bar x 2 Socket head cap screw

Stock roller x 2

(for M5 screws) x 1

(M5) x 20

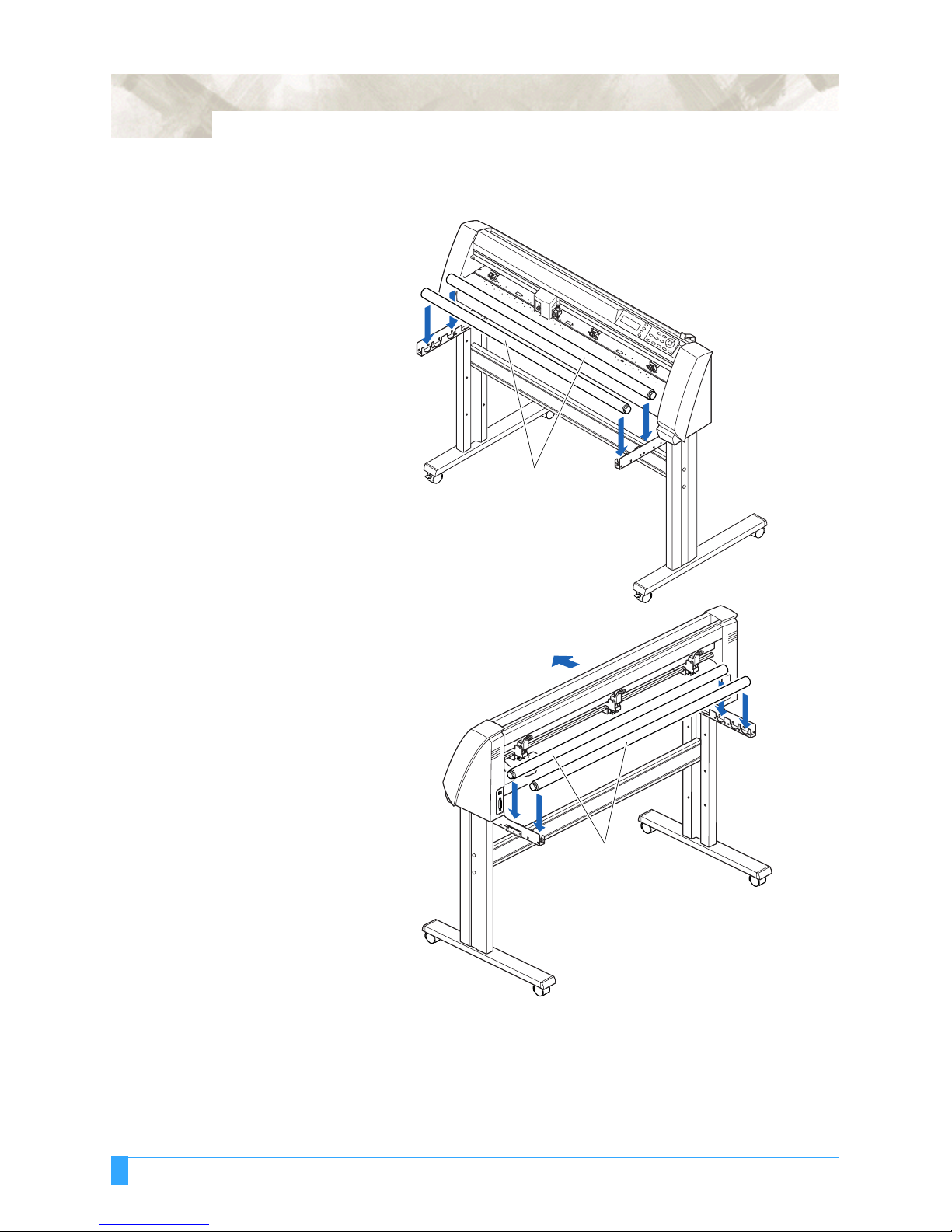

ASSEMBLING THE STAND

The mounting direction is different for the front loading and the rear loading

models.

<Front loading>

<Rear loading>

Out of the Box: Assembling the plotter

1 - 6

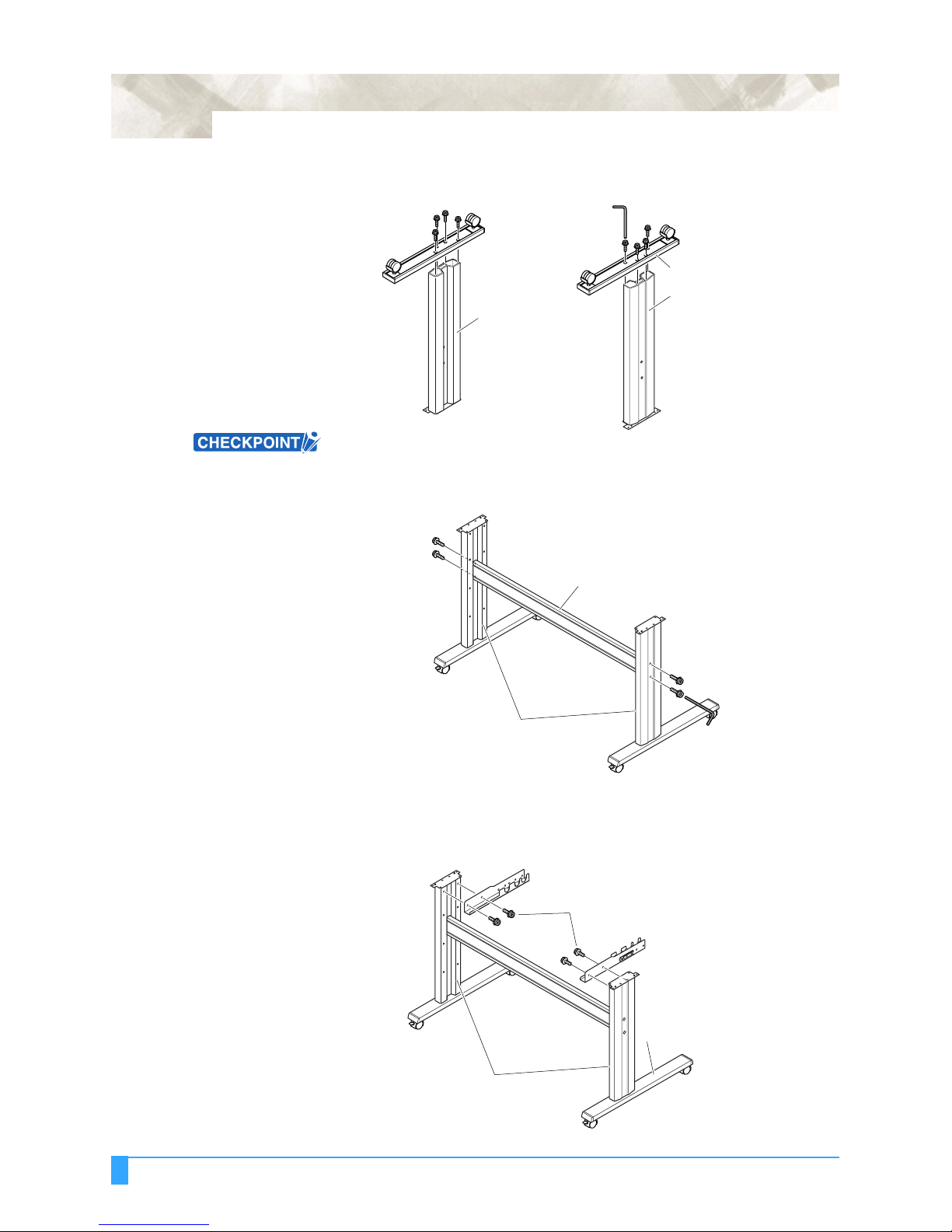

1 Assemble the left and right stand sides. Fasten a base assembly to each of the

stand side bars with four socket head cap screws, using the Allen wrench.

Socket head

cap screws

Base assembly

Stand side bar

Stand side bar

Assemble the stand so that the front and rear lengths of the base assembly are

the same for both the left and right stand sides.

2 Loosely fasten the center bar to the left and right stand sides with four socket

head cap screws (two on each side), using the Allen wrench.

Socket head

cap screws

Center bar

Socket head

cap screws

Stand sides

3 Attach a media stocker to each of the left and right stand sides with two socket

head cap screws, using the Allen wrench. Mount the media stockers so that

each one protrudes directly above the longer of the two base assembly

lengths.

Media stocker

Socket head cap screws

Media stocker

Out of the Box: Assembling the plotter

Base assembly

Stand sides

1 - 7

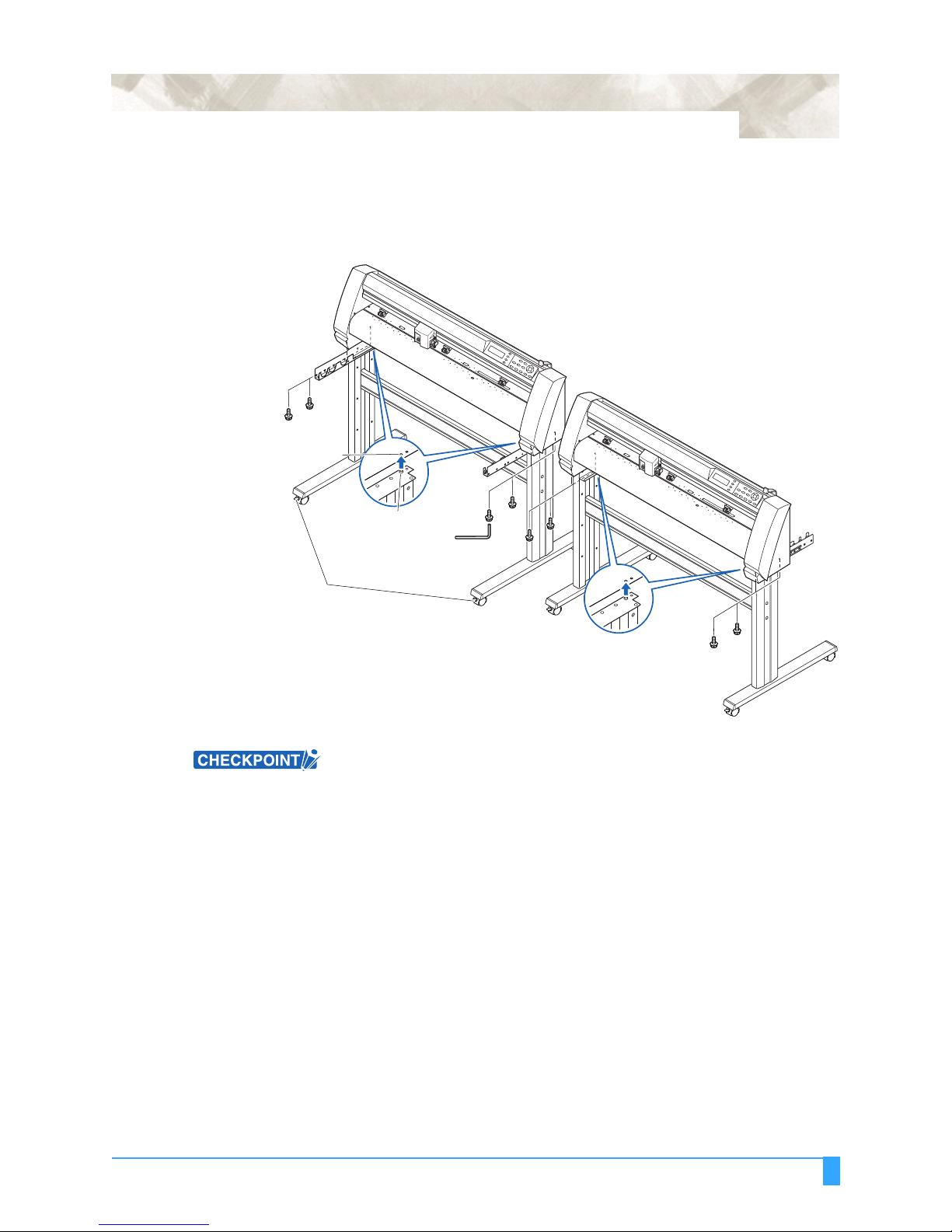

4 Mount the plotter on the stand by inserting the positioning pins on the stand

into the positioning holes on the underside of the plotter. Fasten with four

socket head cap screws (two on each side), using the Allen wrench.The cutting

plotter mounting direction is different for the front loading and the rear loading

models.

<Front loading>

Socket head

cap screws

Positioning pin hole

<Rear loading>

Socket head

Positioning pin

Caster stoppers

cap screws

5 Tighten the socket head cap screws loosely fastened in Step 2.

• Check that all of the screws used for fastening have been tightened. The media

may not be fed correctly if even one of the screws is loose.

• When installing the plotter, make sure that there are no objects in its vicinity.

Leave a clear space of at least 300 mm around the plotter.

Out of the Box: Assembling the plotter

1 - 8

Mounting the stock rollers

Insert the stock rollers into the slots on the media stocker.

<Front loading>

Stock rollers

<Rear loading>

Front

Stock rollers

Out of the Box: Assembling the plotter

1 - 9

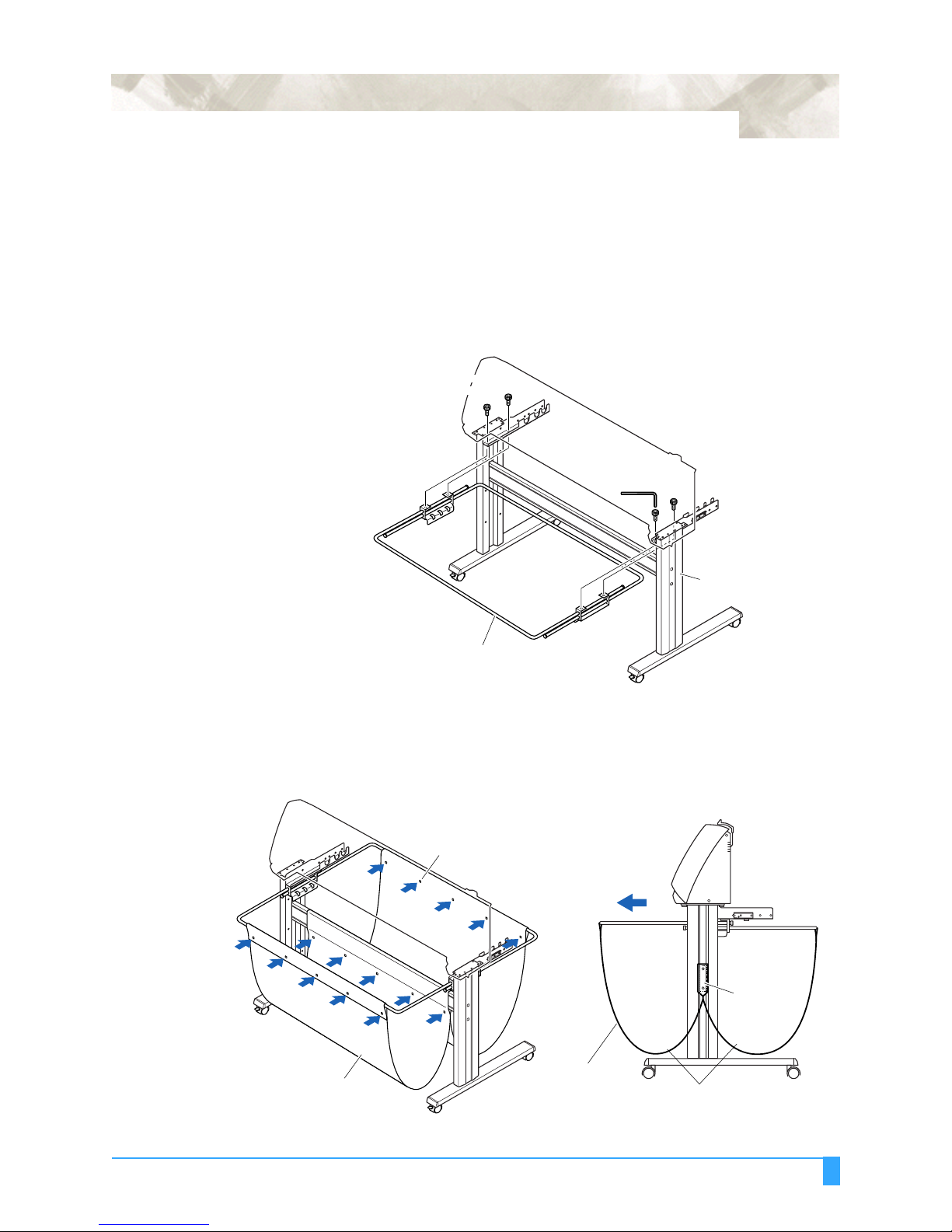

1.4 Attaching the Vinyl Express Basket (Option)

The Vinyl Express Basket box contains one basket holder assembly (one front

basket tube and one rear basket tube inserted into two tube brackets), one cloth

basket, and a screw/wrench set.

1 Attach one of the two tube brackets on the basket holder assembly to the left

side of the stand with two socket head cap screws, using the Allen wrench.

Repeat this step with the other side.

Socket head

cap screw

Socket head

cap screw

Stand

Basket holder assembly

2 Drape the middle section of the cloth basket over the stand's center bar, and

then snap the middle section of the cloth basket around the center bar. Snap

the front edge of the cloth basket around the front basket tube, and then snap

the rear edge of the cloth basket around the rear basket tube.

Side view

Holder snap

Front

Center bar

Cloth basket

Cloth basket

Separate into front and rear baskets,

with the center bar as the center point

Out of the Box: Attaching the Vinyl Express Basket (Option)

1 - 10

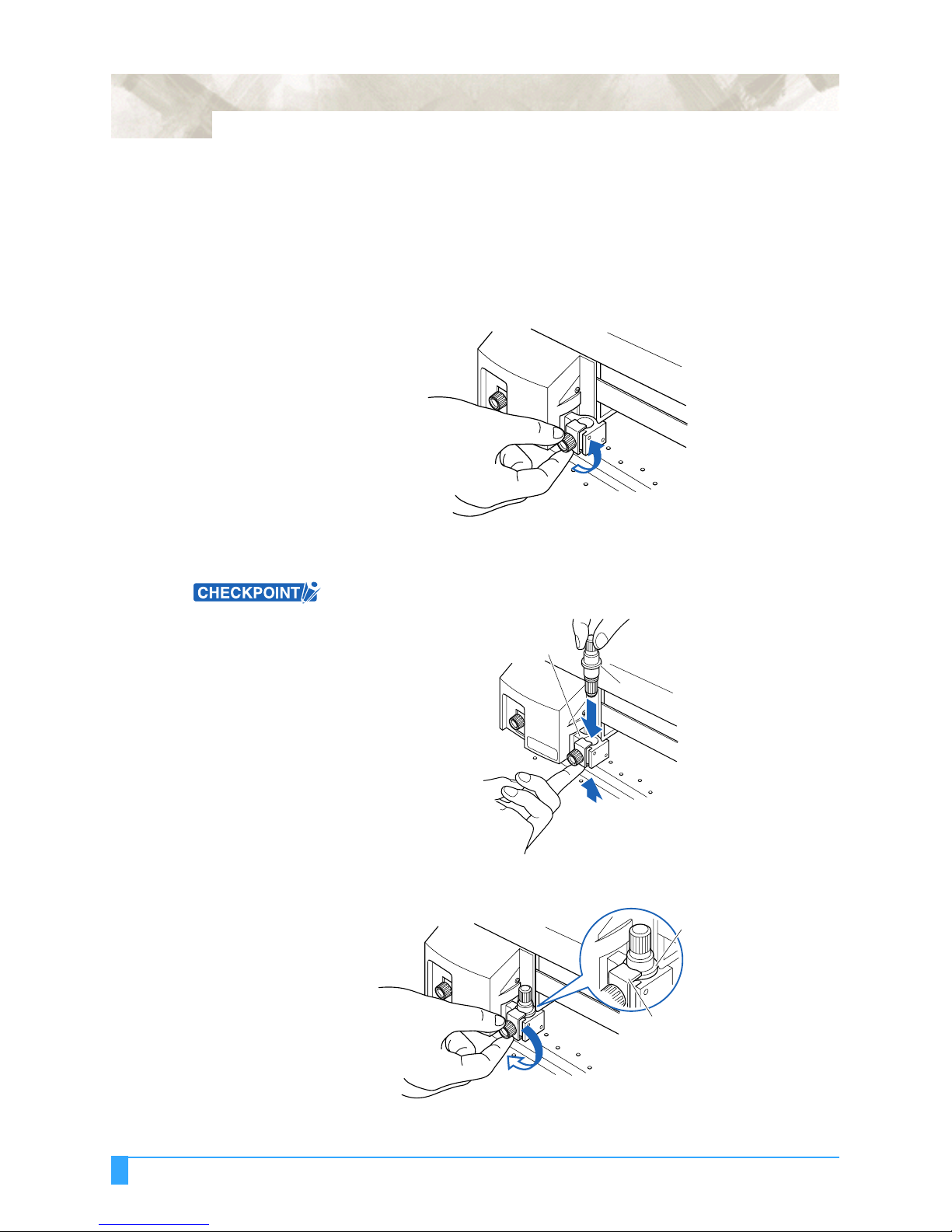

1.5 Attaching a Cutter Pen

When mounting the cutter pen in the pen holder, push the pen all the way into the

holder until its flange contacts the upper part of the holder and then tighten the

screw firmly. To prevent injury, avoid touching the pen immediately after the cutting

plotter is turned on or whenever the pen is moving.

1 Loosen the pen holder screw.

2 While pushing the pen holder in the upward direction, push the pen all the way

into the holder until its flange contacts the upper part of the holder.

When pushing the pen holder with your fingers, the blade tip may be

protruding. Take care not to cut your fingers.

Upper part of pen holder

Flange

3 Make sure that the pen bracket is engaged on the pen’s flange, and then

tighten the screw.

Flange

Bracket to hold pen

Out of the Box: Attaching a Cutter Pen

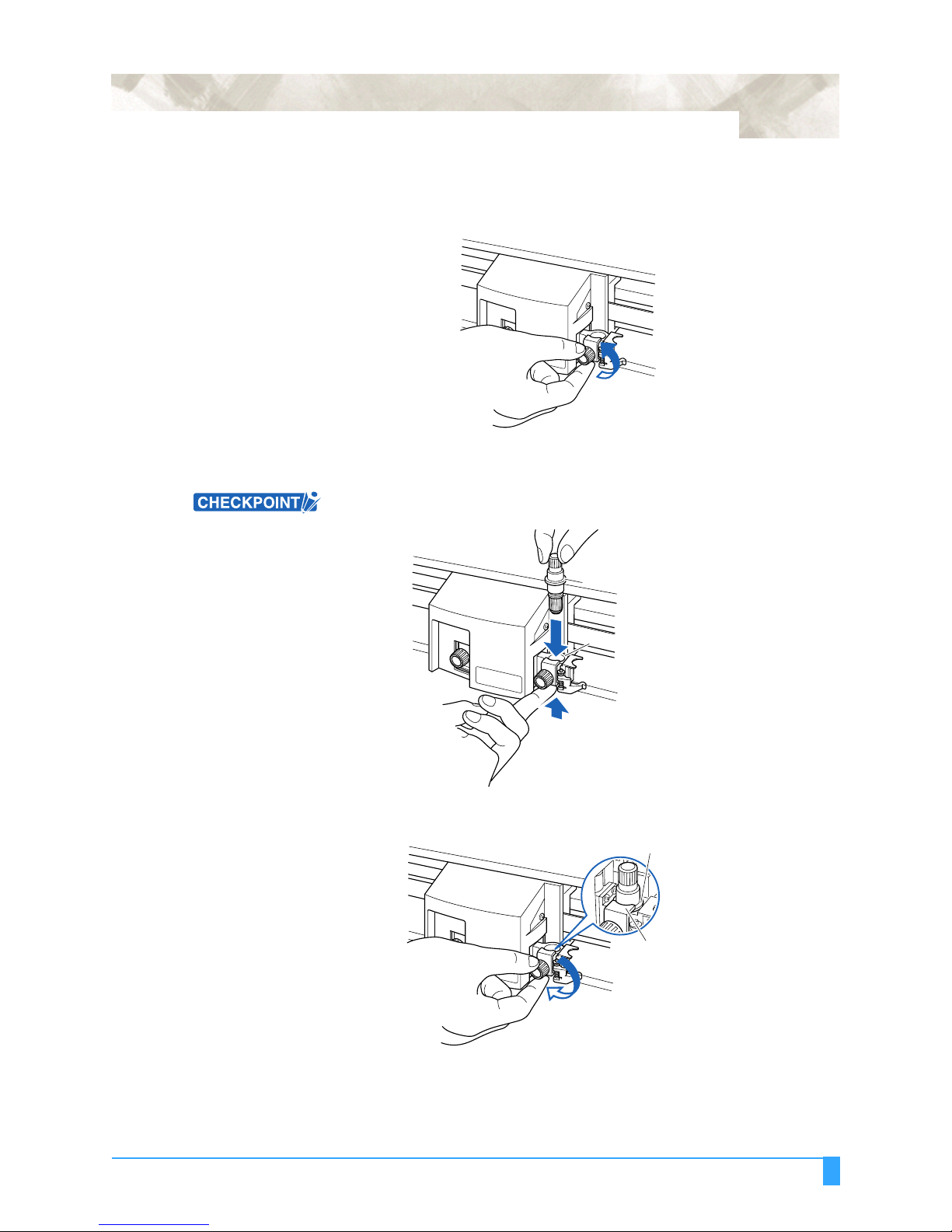

Attaching a Pen to the Two-Pen Holder (Option)

The two-pen holder is a factory-installed option, and cannot be retrofitted.

1 Loosen the pen holder screw.

2 While pushing the pen holder in the upward direction, push the pen all the way

into the holder until its flange contacts the upper part of the holder.

When you push the pen holder with your fingers, the blade tip may be

protruding. Take care not to cut your fingers.

1 - 11

Flange

Upper part of pen holder

3 Make sure that the pen bracket is engaged on the pen’s flange, and then

tighten the screw.

Flange

Bracket to hold pen

Out of the Box: Attaching a Cutter Pen

1 - 12

Attaching a Plotting Pen to the Pen Station

Follow the procedure below to replace the cross-cutter unit that is used to cut the

media after the plotting or cutting operation has been completed.

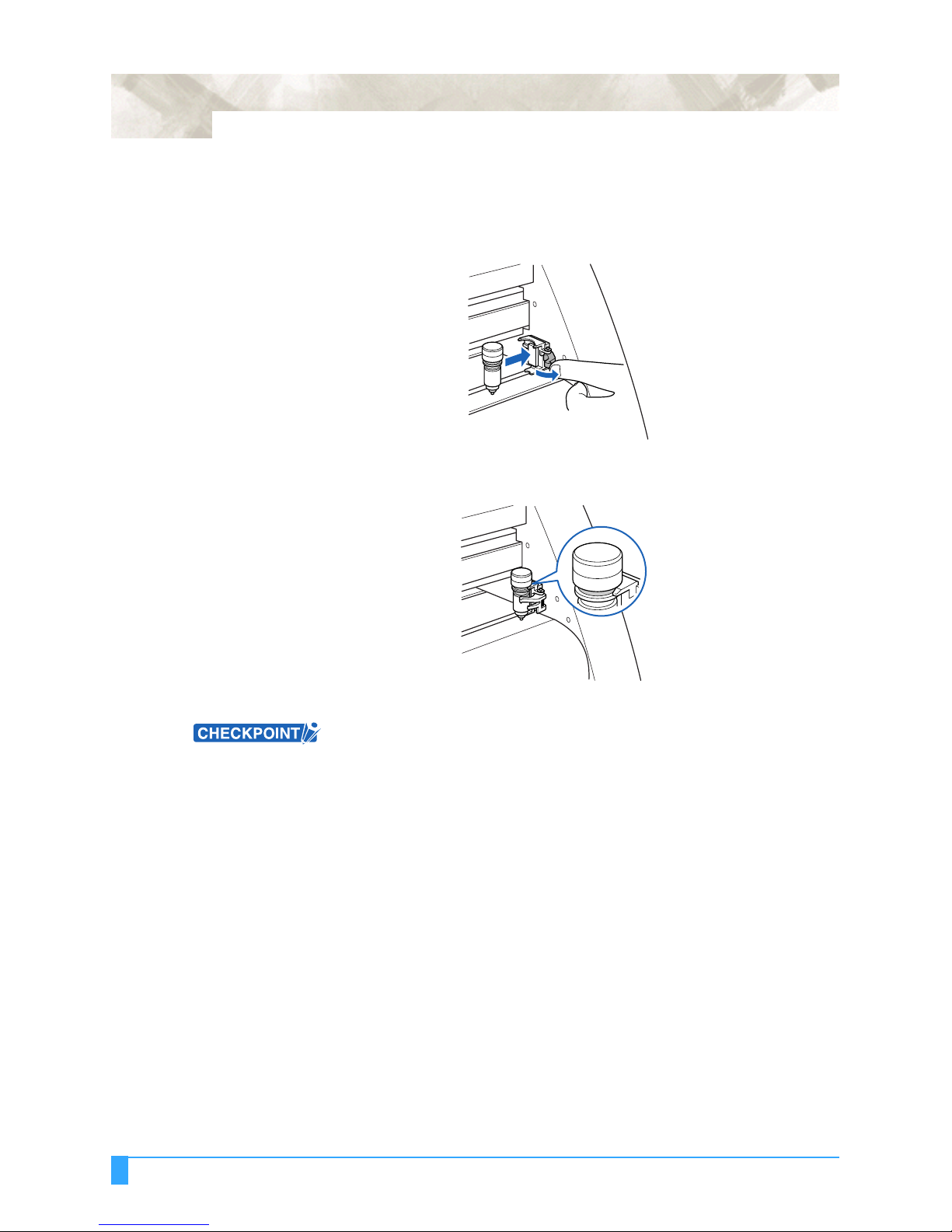

1 Open the pen-hold mechanism on the pen station, and then attach a pen.

2 Make sure that the bracket of the pen station is engaged in the upper groove of

the pen.

3 Close the pen-hold mechanism on the pen station to hold the pen in place.

• Do not leave a pen attached to the pen station for a long period of time, as the

pen tip will dry up and make it unusable.

• To store the pen, remove it from the pen station and replace its protective cap.

Out of the Box: Attaching a Cutter Pen

1.6 Replacing the Cross-Cutter Unit

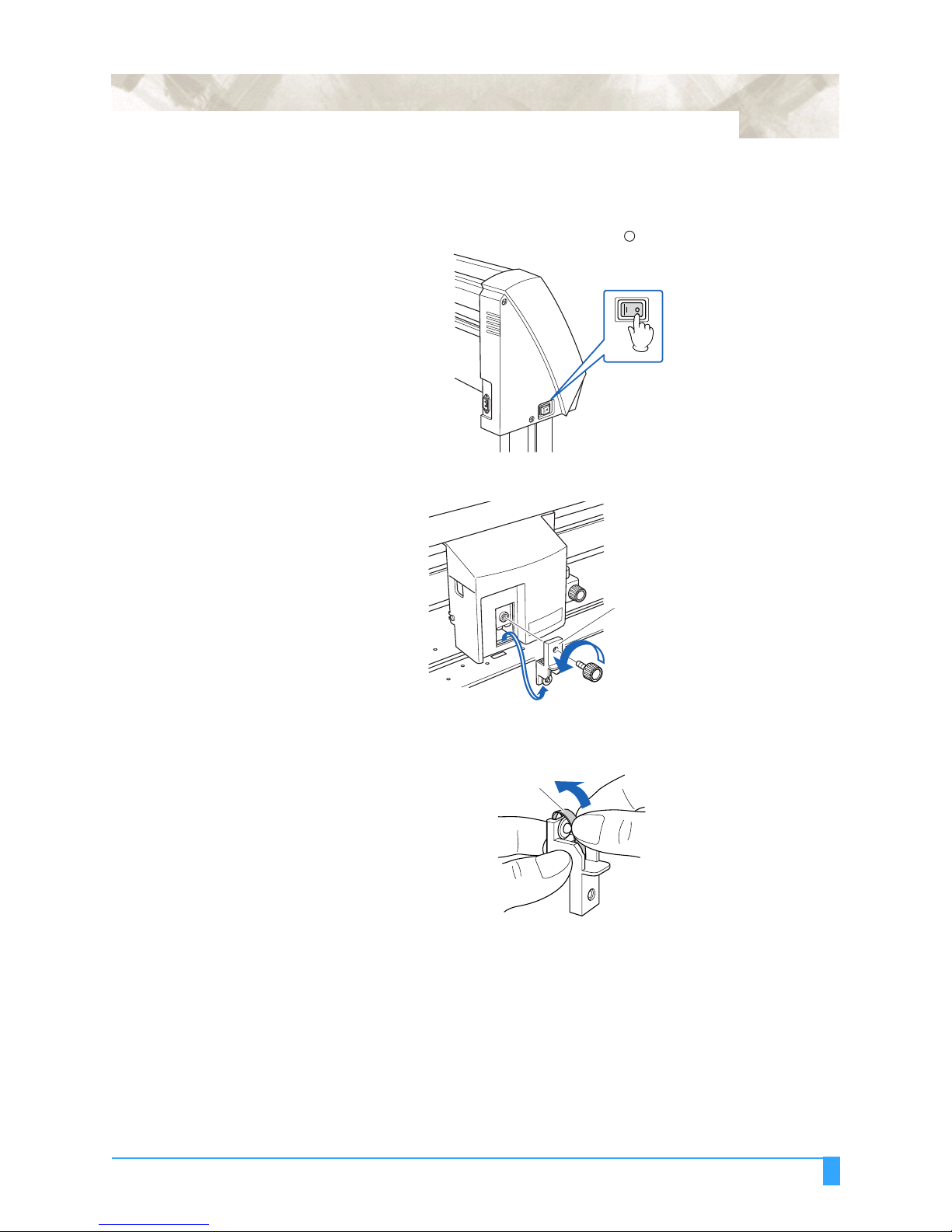

1 Check that the power switch is turned off (the " " side is pressed down).

2 Remove the screw holding the cross-cutter unit in place, and then remove the

cross-cutter unit.

1 - 13

Cross-cutter unit

3 Remove the protective cover from the replacement cross-cutter unit. Be sure

to remove the protective cover while holding the part of the unit shown in the

figure below.

Protective cover

Out of the Box: Replacing the Cross-Cutter Unit

1 - 14

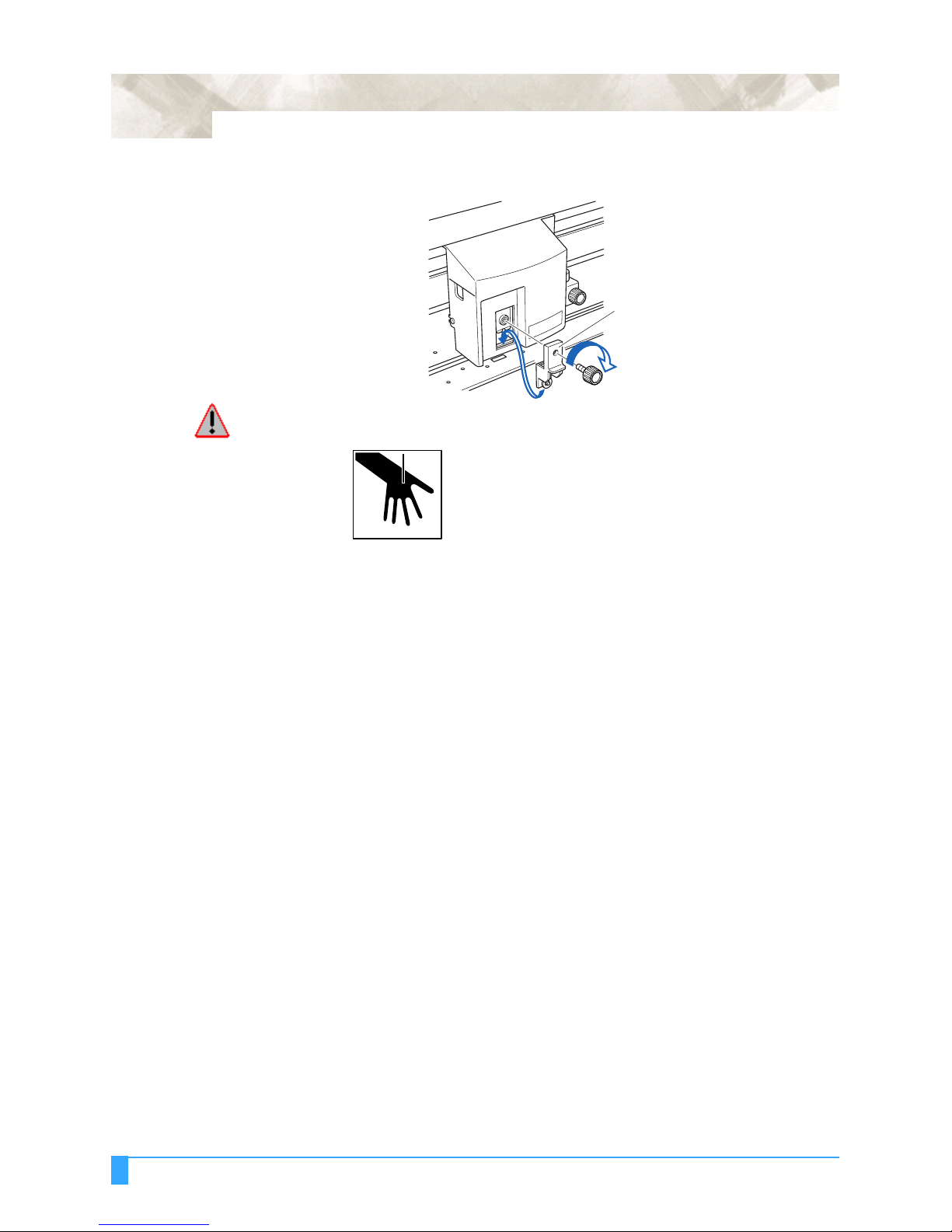

4 Attach the replacement cross-cutter unit, and tighten the screw to hold it in

place.

Cross-cutter unit

WARNING: The cross-cutter unit uses a very sharp blade. Take care not to cut your-

self on the blade.

Out of the Box: Replacing the Cross-Cutter Unit

Chapter 2: Cutter Blades

and Cutter Pens

This chapter describes the different cutter blades and cutter

pens.

Topics in this chapter

2.1 Blade Application and Features

2.2 Cutter Pen Nomenclature

2.3 Replacing the Cutter Blade

2.4 Adjusting the Blade Length

2 - 2

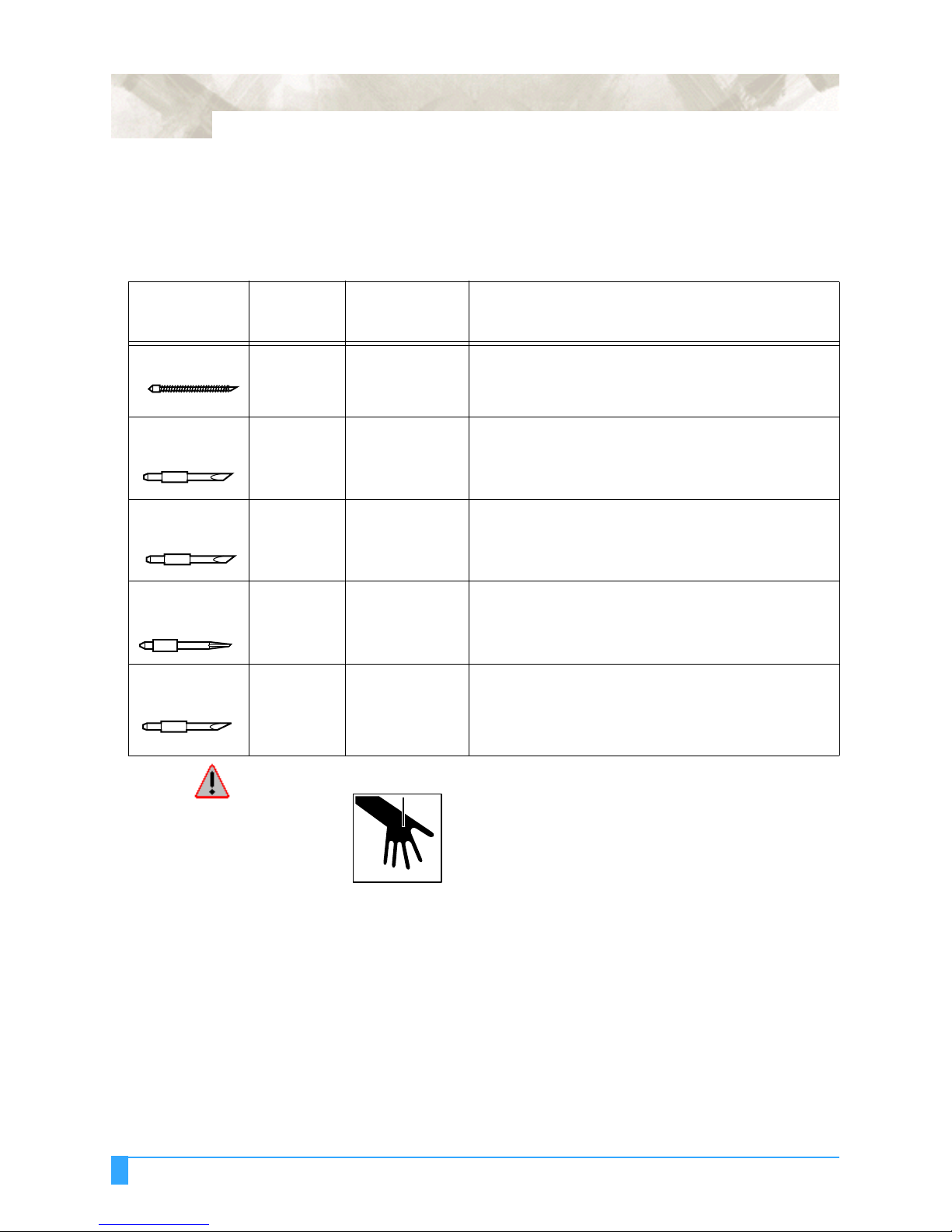

2.1 Blade Application and Features

Individual cutter blades have a variety of features. Select the optimal cutter blade

to suit the medium to be cut.

Blade part

no. and type Diameter

CB09UA 0.9 mm PHP32-CB09N Standard blade for cutting color adhesive media. Suit-

CB15U 1.5 mm PHP32-CB15N For cutting media which is too thick for the CB09UA

CB15UA 1.5 mm PHP32-CB15N For cutting high intensity reflective media.

CB15UB 1.5 mm PHP32-CB15N For cutting small characters on mono-vinyl chloride

CB15U-K30 1.5 mm PHP32-CB15N

Plunger part

no. Applications and features

able for cutting media up to 0.25 mm thick. Maximum cutting distance of approximately 4000 m.

blade to handle. Suitable for cutting media from 0.25 mm

to 0.5 mm thick.

media. Suitable for cutting small size characters that are

less than 10mm.

For cutting sandblast rubber. The sharply angled point

or

PHP32-CB15

provides a longer cutting edge. Suitable for cutting material from 0.05 mm to 1.5 mm thick.

WARNING: To avoid bodily injury, handle the cutter blade with care.

Cutter Blades and Cutter Pens: Blade Application and Features

Loading...

Loading...