Vintage Cellars Monterey 12-bottle User Manual

MONTEREY /

SONOMA

Operating Instructions Manual

Auto Defrost Refrigerators

!

2!

Table of Contents

Setting Up Your Unit 3

Unpacking, installing faucets, installing the regulator, and connecting wine bottles.

Getting to Know Your WineKeeper™ 5

Temperature zones, lights, cords, hoses, knobs, and switches.

Operating Your Unit 6

Changing bottles and gas cylinders.

Cleaning Your Unit 7

Troubleshooting 8

Finding a nitrogen leak, frost build-up, or making temperature adjustments.

FAQs 10

Technical Information 13

System diagram and wiring diagram.

531 Mercantile Drive

Cotati, CA 94931

1.855.511.5113

info@winekeeper.com

www.winekeeper.com

!

3!

Unpacking

While unpacking your unit, please check to make sure that all parts are included and undamaged. Please

call WineKeeper at 855.511.5113 if there are any problems. YOU MUST REPORT damage immediately

and missing parts within 7 days of receiving your unit.

These parts are included with your unit:

• Appropriate number of faucets for your unit

• Regulator (for use with refillable nitrogen or argon cylinder)

• Cleaning kit

• Instructions

Setting Up Your Unit

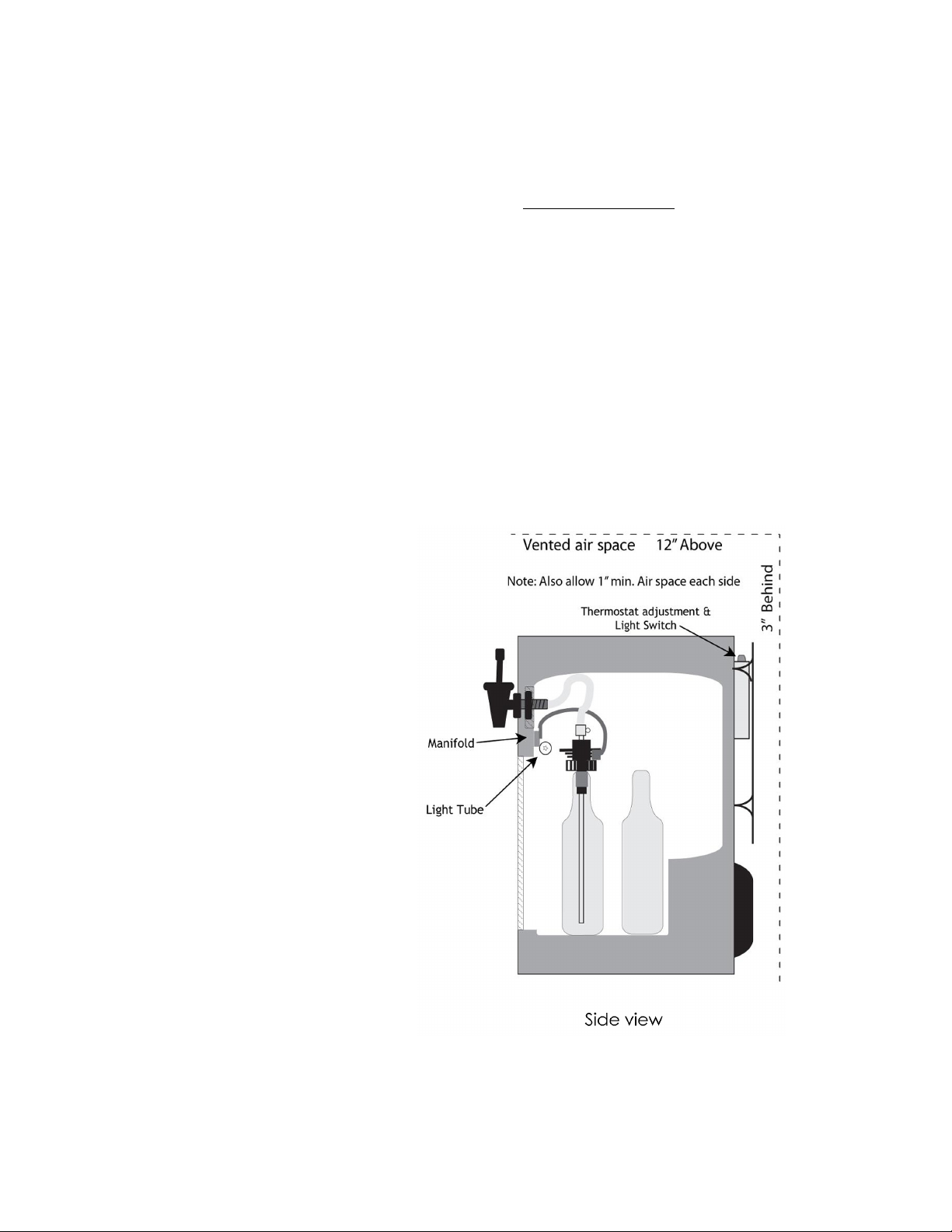

Your WineKeeper wine dispensing unit must be installed on a flat, level surface with vented space of at

least 3" behind, 1" on the sides, and 12" above the unit for proper ventilation. Once your unit is properly

located, attach the faucets. Taking care to align the threads properly, place the faucet on the thru-wall and

tighten the wing nut.

You may now plug the units’ power cord

into 110 volt grounded electrical outlets.

Be sure to plug in all electrical cords:

• 4-bottle units = 1 plug

• 8-bottle units = 2 plugs

• 12-bottle units = 3 plugs

An 8 foot gas supply line is included with

your unit. The supply line includes a

quick connect fitting that connects to the

regulator supplied with your unit.

USING A REGULATOR OTHER

THAN THE ONE SUPPLIED WILL

VOID THE WARRANTY. Your

nitrogen/argon cylinder can be placed

anywhere convenient—vertical or

horizontal.

DO NOT TAMPER WITH OR

REMOVE THE QUICK-

DISCONNECT TO COUPLE YOUR GAS SUPPLY

LINE AND REGULATOR, THIS WILL ALSO VOID THE WARRANTY.

!

4!

Hand tighten the supplied regulator to your nitrogen/argon cylinder, do not use a wrench. Do not

connect the gas line to the regulator at this time. Open the gas cylinder valve (turn the valve counter-

clockwise to open.) The gas pressure from the cylinder will seal the regulator in place. The gauge on the

regulator should read approx. 1800 lbs. for an aluminum cylinder, and 2200 lbs. for a steel cylinder, when

full.

You must now bleed the air from the system. With all the pinch clamps open, attach the gas supply line

quick connect fitting to the regulator fitting. Be sure the small metal lever on the gas supply line fitting is

in the down position. When the gas begins to flow through the lines and out the stopper assemblies, move

down the unit closing off all the pinch clamps. You are now ready to connect wine bottles.

How to Attach Wine Bottles to Your Machine

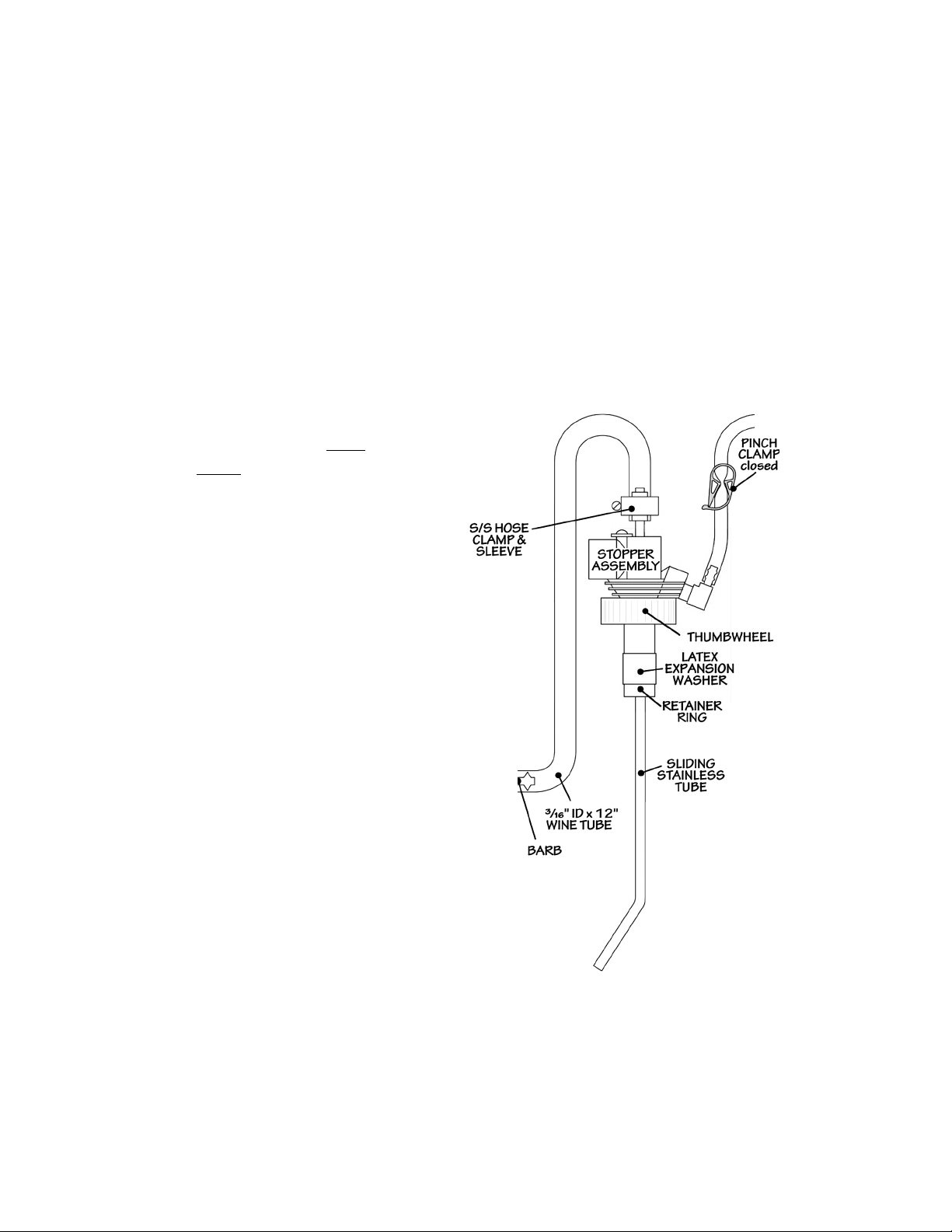

1. Place the stopper assembly into the

wine bottle. (Attach FULL wine bottles

ONLY.)

2. While holding the stopper so that the

latex seal is just at the lip of the bottle

opening, open the pinch clamp for 2

seconds. This will displace the air from

the bottleneck.

3. Close off the pinch clamp, and insert

the stopper all the way into the bottle.

4. Hold the stopper assembly with one

hand and tighten the knurled

thumbwheel clockwise with the other

hand until gently snug. Turn the

thumbwheel 1⁄4 to 1⁄2 of a turn further.

DO NOT OVER-TIGHTEN THE

THUMBWHEEL. If the thumbwheel

“pops” while turning, you have over-

tightened it. The best seal is obtained

with a dry bottleneck and latex seal.

OVER-TIGHTENING will damage

the stopper.

5. Adjust the sliding stainless steel tube for proper bottle depth. The tube may be placed all the way

to the bottom for white wines, and slightly raised off the bottom for red wines with sediment.

Loading...

Loading...