Page 1

BILD1400Owner’sManual

Page 2

B I L D W I N E C A B I N E T S

T A B L E O F C O N T E N T S

I. Important Notes……………..……………………………………. 3

II. Delivery and Inspection …………………………………………. 4

III. Assembly Instructions……………………………………………. 5

IV. Placement of Your Wine Cabinet………………………………. 13

V. Cabinet Set-Up Instructions……………………………………. 14

VI. Cooling Unit Operating Instructions… ………………………... 16

VII. Bottle Storage Tips…………………………………...…………. 23

VIII. Maintenance Instructions……………………………………….. 24

IX. Troubleshooting Guide…………………………………………. 25

X. Limited Warranty…………………………………………………. 28

XI. Contact Information……………………………………………… 29

DON’T FORGET TO REGISTER YOUR WARRANTY AT:

www.lecache.com/register-lc

To register, you’ll need your 7-digit serial number, which you can find on

the white label that is located on the left side of the cooling unit.

-2-

Page 3

B I L D W I N E C A B I N E T S

I. I M P O R T A N T N O T E S

WHEN TAKING DELIVERY OF YOUR WINE CABINET, FOLLOW THE INSPECTION

PROCEDURES DESCRIBED IN CHAPTER III.

YOU MAY PLUG IN THE COOLING UNIT AT TIME OF DELIVERY TO TEST THAT IT

WORKS. ONCE TESTED, WE RECOMMEND SWITCHNG “OFF” THE COOLING

UNIT AND WAITING FOR 24 HOURS BEFORE NORMAL OPERATION.

THE COOLING UNIT S HOULD BE PLUGGED INTO AN O UTLET CONNECTED TO A

15-AMP CIRCUIT

IF THE WALL OUTLET IS D IRECTLY BEHIND THE WINE CABINET, USE AN EXTENSION

CORD (GROUNDED; 14 GAUGE OR THICKER) AND COIL THE EXCESS AT THE

TOP OF THE CABINET S O THAT YOU WON’T NEED TO MOVE THE WINE CABINET

IN THE EVENT THAT THE COOLING UNIT NEEDS TO BE REPLACED.

WE RECOMMEND PLUGGING THE COOLING UNIT INTO A SURGE PROTECTOR

(MINIMUM OF 15-AMPS) TO PROTECT THE ELECTRICAL COMPONENTS FROM

POWER SURGES OR SPIKES.

THE COOLING UNIT SHOULD BE “OFF” WHEN LOADING LARGE QUANTITIES OF

BOTTLES. IF THE COOLING UNIT RUNS WHILE THE DOORS ARE OPEN, IT WILL

CAUSE EXCESS CONDENSATION, LEAKING AND A REDUCTION IN COOLING

POWER

P L E A S E N O T E!

UNTIL YOU’VE LOADED BOTTLES INTO YOUR WINE CABINET, BE CAREFUL WHEN

OPENING THE DOOR. WHEN THE DOORS ARE OPENED, THE CABINET MAY TIP

FORWARD IF THE CABINET IS EMPTY.

-3-

Page 4

B I L D W I N E C A B I N E T S

II. D E L I V E R Y A N D I N S P E C T I O N

The BILD line is a ready to assemble unit that is shipped with three boxes for the

cabinet and a separate box for the cooling unit. Alternatively, the unit can also be

sold as an assembled unit, shipped on a pallet. The boxes are strapped to the pallet

and shipped by LTL carrier with curbside delivery.

In the event of freight damage, it is critically important that you follow each and

every one of the following procedures in the sequence described below.

1. INSPECT THE PACKAGING BEFORE UNPACKING THE BOXES

The boxes should arrive lying flat on a pallet and be strapped together or if

assembled, upright on a pallet.

The packaging shouldn’t have any tears, holes, marks or other damage.

2. IF YOU FIND DAMAGE TO THE BOXES:

a. Describe the damage on the bill of lading. Be detailed and descriptive.

b. Call Le Cache at 1.877.532.2243 before the delivery men leave

c. Save a copy of all freight documents, including the bill of lading with your

comment, making sure that everything is legible on your copy

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A DENIED INSURANCE

CLAIM AND/OR BILLING(S) FOR REPAIRS OR RETURNED MERCHANDISE.

-4-

Page 5

B I L D W I N E C A B I N E T S

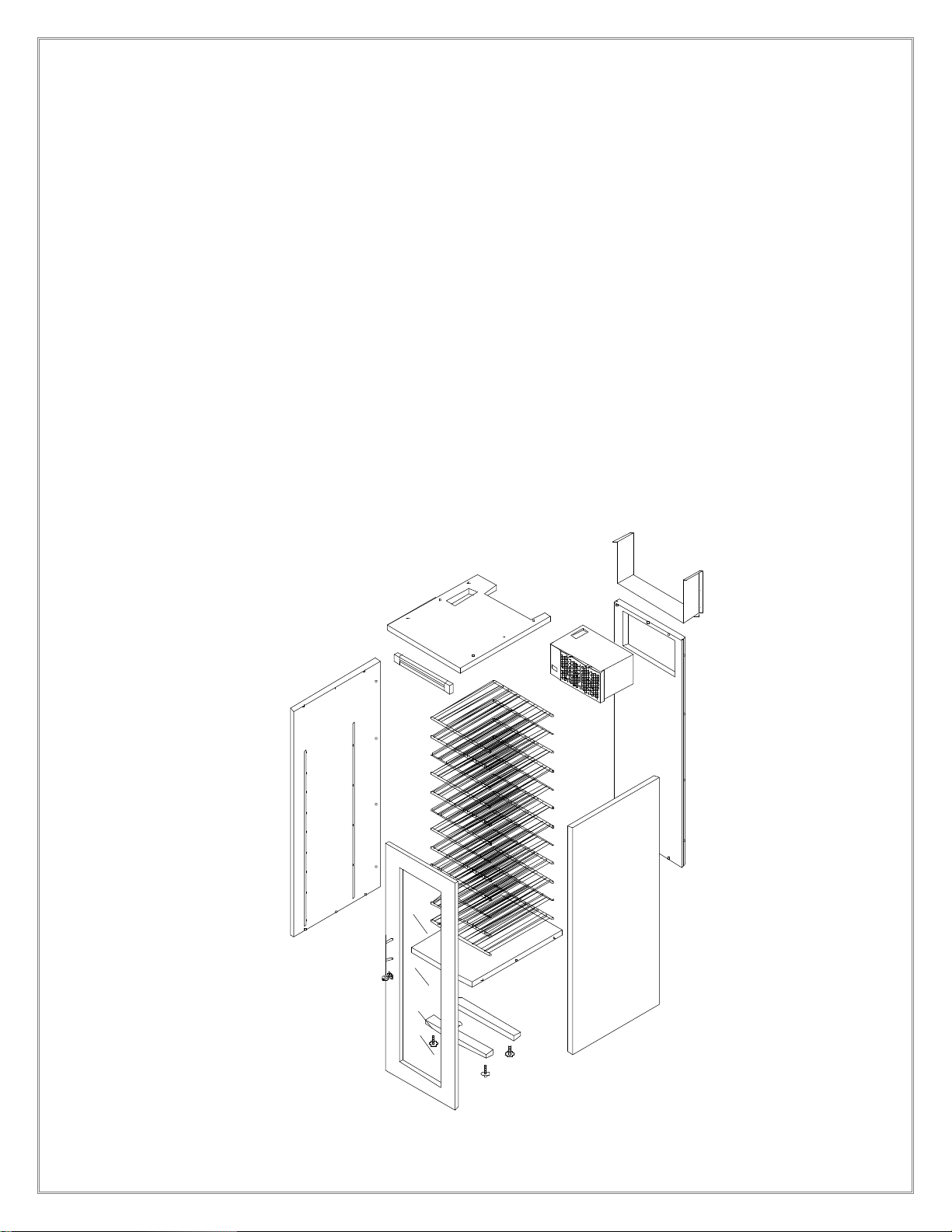

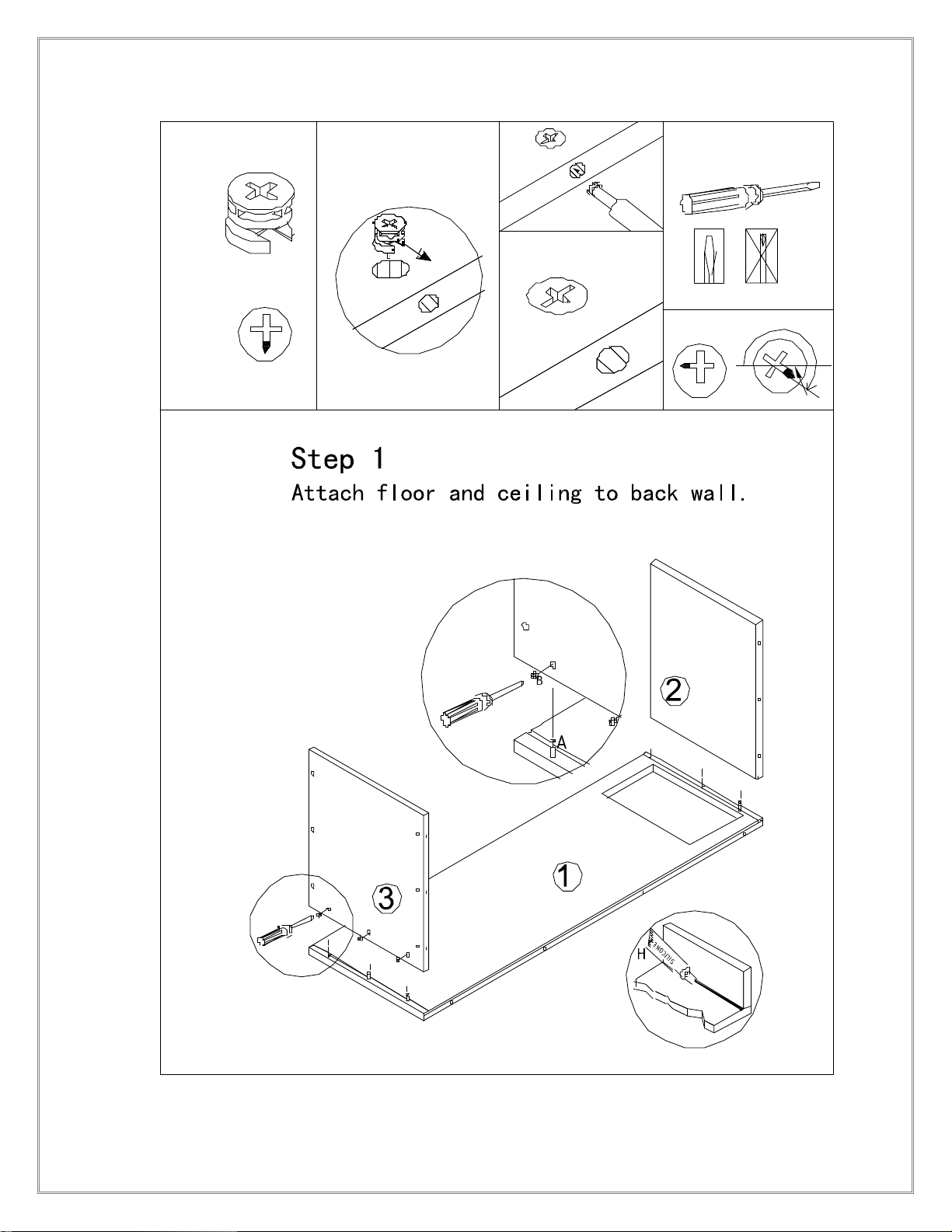

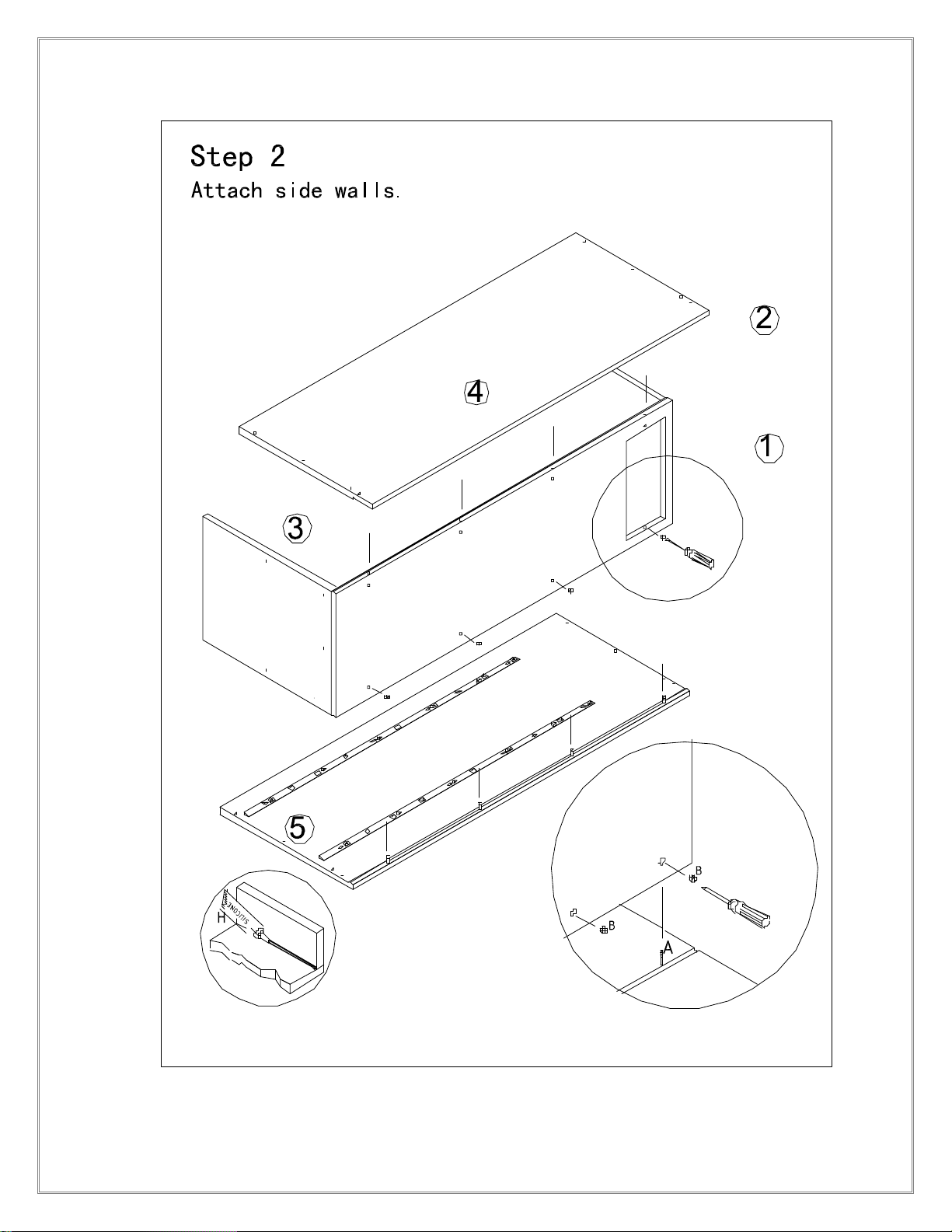

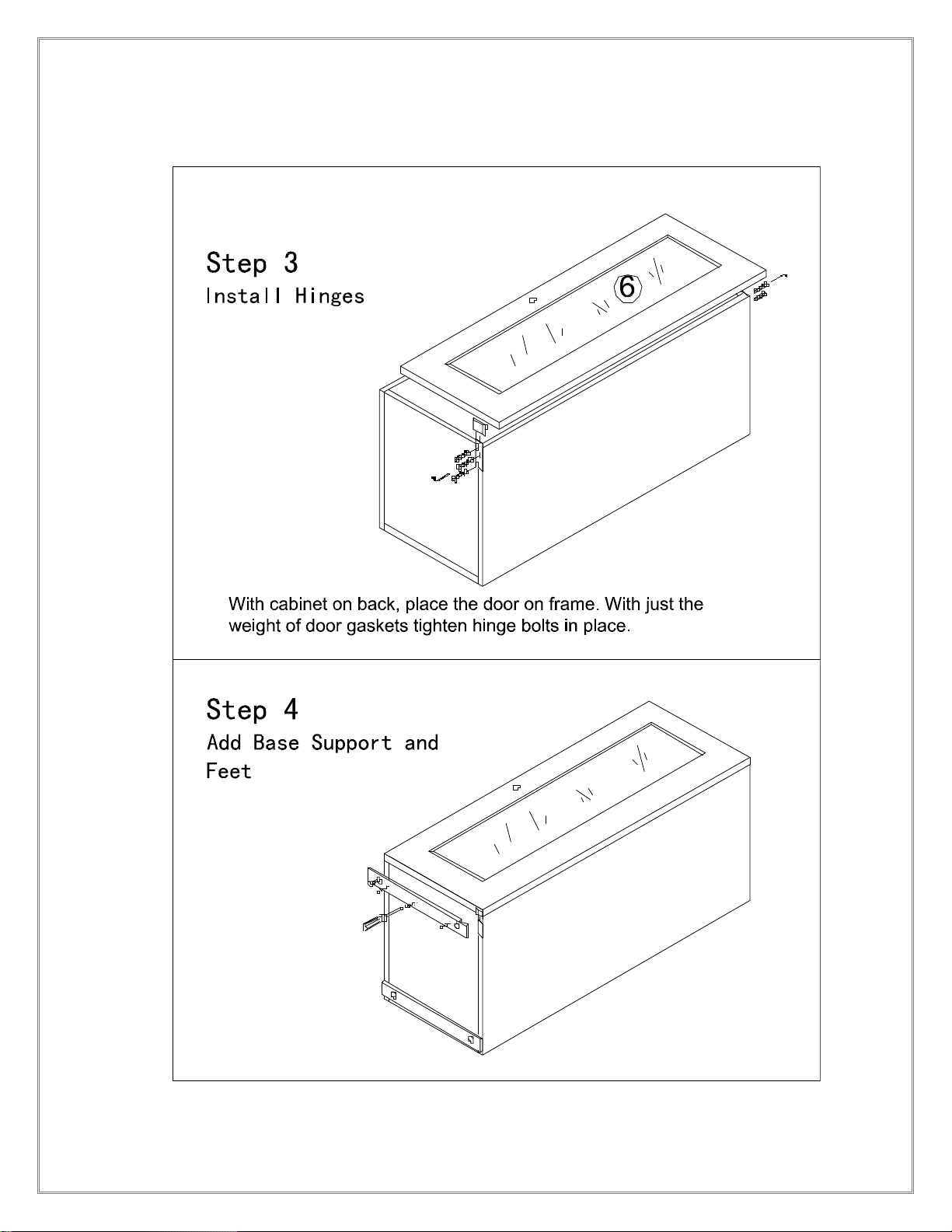

III. A S S E M B L Y I N S T R U C T I O N S

The following diagrams provide a step-by-step procedure to assemble the cooling

unit. When undertaking this process the following tips should be employed:

- A set of basic hand tools – flat and Philips screwdriver – will be helpful

- A second helper will be important when moving the panels, as they are quite

heavy

- A large clean, padded area for laying out the pieces and raising assembled

pieces

- Make sure the unit can be moved into its final location from the assembly area

- Ensure the doors seal well before moving on to next steps as this is a critical

point

- The metal racks should not be forced into place as they will break – use a

screwdriver to open the brackets if the fit is too tight.

BILD 1400 Assembly

-5-

Page 6

B I L D W I N E C A B I N E T S

-6-

Page 7

B I L D W I N E C A B I N E T S

-7-

Page 8

B I L D W I N E C A B I N E T S

-8-

Page 9

B I L D W I N E C A B I N E T S

-9-

Page 10

B I L D W I N E C A B I N E T S

-10-

Page 11

B I L D W I N E C A B I N E T S

Saddle:

Centercoolingunitsaddleonbackwallopening.Usinglong

screwdriver,attachtowallandceiling.

TopVent:

Slideincoolingunituntilclipscanbeboltedintofirsttwoholesin

ceiling.Makesurethetopholeincoolingunitalignswithceiling

opening.

RearVent:

Saddleis

optionalfor

thisconfiguration.

Slideincoolingunit

untilitrestsonback

nd

wall.Use2

rowof

ceilingholesto

mountclips.Make

surecoolingunit

blowshotairoutthe

rear.Placecabinet4

inchesfromwall.

Applybutylcaulk

aroundallthe

exteriorseamswhere

thecoolingunit

contactsthesaddle

andcabinet.

-11-

Page 12

B I L D W I N E C A B I N E T S

TopVent:NoMinimumclearance

RearVent:Fourinchminimumclearance

-12-

Page 13

B I L D W I N E C A B I N E T S

IV. P L A C E M E N T O F Y O U R W I N E C A B I N E T

VENTILATION REQUIREMENTS

The hot air generated by the cooling unit is ventilated through the top of our upright

wine cabinets (ie not credenzas.) Consequently, upright wine cabinets must have

sufficient clearance above the cabinets for hot air to dissipate, or else the hot air must

be channeled away from the cooling unit. If the hot air cannot be dissipated or

channeled, the cooling unit will recycle its own hot air, and therefore it will be unable to

maintain cold temperatures inside the wine cabinet and/or will run all the time.

These units are top vented and require 18 inches of clearance above the wine cabinet

If there is not enough clearance above, the BILD 1400 offers the options to have the unit

rear vented.

The sides always need to be open – ie alcoves, closets or other built-in installations will

not work without an active duct system with an inline fan.

The cabinet and cooling unit can be placed flat against the wall when top vented.

FLOOR SURFACE

Because of the significant weight of your wine cabinet, it is important that it be placed

on a hard surface, otherwise the cabinet may become skewed if the doors settle

unevenly over time. If you will be placing your BILD 1400 cabinet on thick carpeting,

consider placing a carpet board underneath the wine cabinet. You can purchase a

carpet board from Le Cache, or you can have your local hardware store cut a 3/4 inch

plywood board to fit under the four feet of the cabinet.

POWER REQUIREMENT

The cooling unit plugs into a standard wall outlet. The components of the cooling unit

draw 3 amps, and the electric outlet on the side of the cooling unit also is rated for 3

amps. The cord extends 6 ½ feet from the back of the cabinet. If an extension cord is

used, it should be 14-gauge wire or thicker, grounded, and as short as possible. We

recommend using a surge protector rated at 15 amps or more.

WEIGHT LOAD FACTOR

After loading your wine cabinet with wine bottles, it will be extremely heavy. When

selecting a location for your cabinet, make sure that the floor underneath is strong

enough to support the weight of the cabinet.

Approximate Weight (lbs)

Bild Series

Empty

Cabinet

Bottles

Total –

Full Cabinet

1400 240 500 740

-13-

Page 14

B I L D W I N E C A B I N E T S

V. C A B I N E T S E T – U P I N S T R U C T I O N S

OPENING THE DOORS

While empty the cabinet is prone to tipping due to the weight of the door when

opened. Make sure the entire cabinet is supported when opening the door.

MOVING THE CABINET

Once the cabinet is fully assembled it is OK to tip the wine cabinet forward,

backwards or on its side in order to get it through a doorway. However, you should

NEVER PUSH, PULL OR LIFT the cabinet by its doors.

If you need to remove the door(s) to get the cabinet through a doorway, simply

remove the top hinge at the top corner(s) of the cabinet (three screws) and lift the

door straight up until it slides out of the bottom hinge. When setting the door down

on the floor, be careful to avoid damaging the hinge pin on the bottom of the door.

To reinstall the doors, follow these instructions in reverse.

LEVELING INSTRUCTIONS

The first step in setting up your wine cabinet is to make sure that it is level, with all the

leveling feet squarely on the floor and with the doors properly sealed against the

cabinet. The wine cabinet can be leveled by turning the leveling feet underneath

the cabinet. You can extend the feet of the cabinet by turning the feet CLOCKWISE

(assuming you are looking down from the top of the cabinet.)

Begin with corner feet touching the floor and center feet (if any) raised.

If the cabinet is resting on plush carpet, place a carpet board under the

cabinet so that all the leveling feet will remain on the same plane over time.

Side to Side – Place a level on the top of the cabinet (not the door) parallel to

the door. Raise or lower either side of the cabinet by rotating the feet by hand.

On larger cabinets with six leveling feet, use the four corner feet only for

leveling purposes. After leveling, lower the center leveling feet to the floor.

Front to Back – place a level on top of the cabinet (not the door)

perpendicular to the door, and follow the same procedure.

If cabinet is level, the lock should work freely without force. Also, the door(s)

should be even (within 1/4 inch) with the top edge of the cabinet.

Additionally, there should be no gaps between the rubber gasket on the door,

and the face of the cabinet.

-14-

Page 15

B I L D W I N E C A B I N E T S

DOOR ALIGNMENT INSTRUCTIONS

After leveling the cabinet, the doors must be aligned so that they are even with

each other, square with the cabinet and create an airtight seal inside the cabinet.

Air leaks caused by improper door alignment will compromise the environment inside

the cabinet, and may create condensation which, left untreated , will cau se warpi ng

of the door. Follow the instructions below to properly align your door(s).

If your cabinet has only one door, the plane of the top of the door should be

parallel to the plane of the cabinet. If the non-hinge (i.e. left) corner of the

door is higher than the cabinet, go to the BACK RIGHT CORNER of the cabinet

and turn the leveling foot once CLOCKWISE, which will raise the right/back of

the cabinet and lower corner of the front door. If the non-hinge corner is lower

than the cabinet, go to the BACK LEFT CORNER of the cabinet and turn the

leveling foot once CLOCKWISE, which will raise the left/back of the cabinet so

that it is even with the corner of the front door. After adjusting the feet, open

and shut the door, and check again to see if the door is aligned.

If the top corner of a door is sticking out more than 1/8 inch, you have "top

torque". If the bottom corner of a door is sticking out more than 1/8 inch, you

have "bottom torque". To fix torque, if your cabinet has six leveling feet, start by

raising the two center leveling feet so that those feet aren’t touching the floor.

For top torque, go to the BACK CORNER LEVELING FOOT on the OPPOSITE SIDE

of the torqued door and turn CLOCKWISE. For bottom torque, go to the BACK

CORNER LEVELING FOOT on the SAME SIDE as the torqued door and turn

CLOCKWISE. When the torque has been fixed (tolerances up to 1/8 inch are

acceptable), lower the center leveling feet until they touch the floor.

IF YOU ARE PLACING YOUR WINE CABINET ON CARPET: Much of the weight of

an EMPTY wine cabinet resides in the doors. If your wine cabinet is tilting

forward when first placed on the carpet or a carpet board, DO NOT overcompensate by extending the front leveling feet. Instead, load some bottles

into the back of the wine cabinet until the weight is more evenly distributed,

and adjust the leveling feet so that the wine cabinet is level front-to-back. The

cabinet no longer should be leaning forward at this point.

-15-

Page 16

B I L D W I N E C A B I N E T S

VI. C O O L I N G U N I T O P E R A T I N G I N S T R U C T I O N S

COOLING UNIT SELECTION

We offer a choice of several cooling units with your BILD wine cabinet, which should

be selected based on the size of the cabinet, the temperature in the ambient

environment and the desired temperature inside the wine cabinet, as follows:

Ambient Temperature Recommended Cooling Unit

Less than 85°F CellarPro 1800QTL

Between 85°F & 95°F CellarPro 1800QT

AIR FILTER

All wine cabinets include an air filter that magnetically attaches to the rear of the

cooling unit. To replace the filter, remove the filter frame from the rear of the cooling

unit and replace the air filter when it becomes dirty. The frequency can be anywhere

from 3 to 9 months depending on the conditions in your location.

When replacing the filter, the blue fibers should face the cooling unit, and the white

fibers should face away from the cooling unit. Replacement filters may be

purchased at www.lecache.com.

CELLARPRO COOLING UNIT

Factory Settings

The settings on your CellarPro cooling unit have been preset and optimized by the

factory, and it is not necessary to change these settings initially.

If you find that you want to change one or more of the settings, we strongly

recommend that you allow the cooling unit to operate for 14 days before making

any changes.

-16-

Page 17

B I L D W I N E C A B I N E T S

CELLARPRO COOLING UNIT (continued)

Temperature

Proper temperatures are maintained by transferring heat from inside wine cellars and

exhausting the heat through the top (top-vent) or rear (rear-vent) of the cooling

units.

CellarPro cooling units are designed to turn on when the temperature inside the

cellar exceeds the Minimum Set Point plus the Temperature Differential, and turn off

when the temperature inside the cellar drops below the Minimum Set Point. For

example, if the Minimum Set Point is 58°F and the Temperature Differential is 4°F, the

cooling unit will turn on when the temperature inside the cellar rises above 62°F, and

turn off when the temperature falls below 58°F.

A number of variables, including the temperatures of the ambient environment, the

insulation of the cellar and the thermal mass inside the cellar, will affect the speed

with which the temperature inside the cellar rises during the cooling unit’s “off” cycle.

CellarPro cooling units are designed to maintain optimal temperatures for storage

and aging of wine. Most wine collectors store their wine in the range of 55 - 60°F. If

the cooling unit runs too much, you should raise the Minimum Set Point to reduce the

cycle “on” time. It is normal for the cooling unit to run up to 75 percent of the time in

order to maintain proper conditions inside the cellar.

Humidity

CellarPro cooling units are designed to maintain appropriate levels of humidity,

ranging from 50 to 70 percent, inside your wine cellar. Relative humidity conditions

depend on several factors, including:

o Ambient humidity: The higher the ambient humidity, the higher the

humidity will be inside the cellar

o Fon Setting: By increasing the Fon setting, humidity can be increased inside

the cellar. The recommended range for the Fon setting is 2-6.

In order to increase or decrease humidity inside the cellar, the Fon setting can be

changed as described in the “Advanced Settings” section below.

-17-

Page 18

B I L D W I N E C A B I N E T S

Basic Operation

Digital Display

Power On/Off Button

Up and Down Buttons

The temperature displayed on the control

indicates the real-time air temperature as

measured by Probe 1 (P1) located behind

the front grill of the cooling unit

Press “Power On/Off” to turn the unit on and

off

When the “Compressor On” indicator light is

on, the Compressor is running. When the

“Fan On” indicator light is on, the Fan is

running

To view the “High Temp” recorded by the

cooling unit, press the “Up” button once.

Set Button

To view the “Low Temp” recorded by the

cooling unit, press the “Down” button once

To reset the “High Temp” or “Low Temp”,

press the “Set” button for three seconds

while “Hi” or “Lo” is displayed. “RST” will blink

three times to indicate confirmation.

The cooling unit is factory preset with a

-18-

Page 19

B I L D W I N E C A B I N E T S

Minimum Set Point of 58°F and a

Temperature Differential of 4°F. This means

that the cooling unit will turn on when the

display rises above 62°F (58°F + 4°F), and turn

off when the display falls below 58°F.

To view the Minimum Set Point, press the

“Set” button for one second.

To change the Minimum Set Point:

Energy Saver Button

1. Press the “Set” button for three

seconds until “°F” blinks

2. Press the “Up” or “Down” button

3. Press the “Set” button to confirm

The “Set” temperature will blink three times to

indicate confirmation.

The recommended Minimum Set Point range

is 53 - 60°F. To change the Temperature

Differential, see “Advanced Operation” later

in this chapter.

To activate and deactivate the “Energy

Saver” mode, press the “Energy Saver”

button

The “Energy Saver” indicator light will turn on

when the cooling unit is in “Energy Saver”

mode

In “Energy Saver” mode, the Minimum Set

Point increases 4°F and the Temperature

Differential is unchanged

Quick Chill Button

To activate the “Quick Chill” mode, press the

“Up” / “Quick Chill” button for three seconds.

To deactivate “Quick Chill”, press “Quick

Chill” button for three seconds again

The “Quick Chill” indicator light will turn on

when the unit is in “Quick Chill” mode.

In the “Quick Chill” mode, the unit will run

continuously for 6 hours (or until the intake

temperature registers 50°F). This mode is

useful after loading “warm” bottles in a cellar

-19-

Page 20

B I L D W I N E C A B I N E T S

Advanced Operation

CellarPro cooling systems can be programmed with advanced settings to achieve

more control over conditions inside the cellar. Conditions like humidity, the

Temperature Differential, and alarm settings all can be modified for custom

applications. To access the advanced settings, do the following:

Press the “Set” button and the “Down” button together at the same time, and

hold for three seconds. Then, use the “Up” or “Down” button to scroll to the

following screen:

HUMIDITY: The factory preset for this setting is “3”.

If the humidity inside the cellar is too low, press the

“Set” button, then use the “Up” button until the

desired setting is reached. The recommended range

for this setting is 2-6.

TEMPERATURE DIFFERENTIAL: The factory preset for this

setting is “4”.

This setting determines the Temperature Differential

and therefore the temperature at which the cooling

unit will cycle on. The recommended range for this

setting is 4 or 5.

HIGH TEMPERATURE ALARM: The factory preset for this

setting is “70”.

This setting designates the High temperature inside

the cellar at which the alarm is triggered. We

recommend leaving this setting at the factory preset.

LOW TEMPERATURE ALARM: The factory preset for this

setting is “45”.

This setting designates the Low temperature inside

the cellar at which the alarm is triggered. We

recommend leaving this setting at the factory preset.

ENERGY SAVINGS MODE DIFFERENTIAL: The factory

preset for this setting is “4”.

This setting increases or decreases the Temperature

Differential for the Energy Savings Mode. The

recommended range for this setting is 2-4.

-20-

Page 21

B I L D W I N E C A B I N E T S

Alarms

Alarm

Indicators*

Alarm Code What it means What to do

The control panel has an audible buzzer and an alarm indicator light

(Row 4) that turns on when an alarm is triggered. In addition, the

control panel will flash the following codes when an alarm is triggered:

P1, P3

HA

HA2

LA2

Probe Failure Call CellarPro at 877.726.8496

The temperature

inside the cel l ar is too

warm (>70°F for more

than 1 hour)

The condenser

temperature is too

high (above 140°F for

2 hours)

The temperature at

the condenser coils

(outside the cabinet)

has dropped below

the alarm

temperature setting

Check seals;

Check if door was left open;

Lower the ambient temperatures

Check for appropriate installation, ventilation,

ambient conditions and cooling capacity

Clean the condenser coils and/or replace the

air filter;

Check for obstructions to the intake and/or

exhaust vents;

Check that the condenser fan is operating

Lower the alarm temperature setting as

follows:

1. Depress the “Set” and “Down” button for

three seconds until the controller displays a

parameter (eg “HY”), then release

2. Depress the “Set” and “Down” button

again for seven seconds until the “PR2”

flashes on the display, followed quickly by

a parameter (eg “HY”), then release

3. Using the “Down” button, scroll until the

display reads “AL2”

4. Depress the “Set” button

5. Use the “Down” button to lower the alarm

temperature setting to 45

6. Depress the “Set” button again

7. After three seconds, the display will return

to the normal screen

* Please note: the temperature alarms (HA, HA2, LA and LA2) are disabled during the

first 23 hours of operation after the cooling unit is plugged in and/or turned on.

-21-

Page 22

Optional

Protection

Mechanism

B I L D W I N E C A B I N E T S

Optional Protection Mechanism

CellarPro cooling systems can be programmed to turn off

the compressor and condenser fan in the event of an

HA2 alarm, as described below. If you’d like to turn on

this protection mechanism, please call us toll-free at

877.726.8496

P3 > 140°F for more

than 2 hours

The condenser probe is

measuring

temperatures that are

too hot

The compressor and condenser

fan will turn off until the

condenser temperature falls

below 120°F

-22-

Page 23

B I L D W I N E C A B I N E T S

VII . B O T T L E S T O R A G E T I P S

To achieve the best results with your BILD wine cabinet, follow the recommendations

below when loading and storing bottles:

Start storing bottles in the center of the cabinet, and enlarge the "circle" as you

add bottles to the cabinet. This will minimize temperature fluctuations by

creating a thermal mass of bottles in the center of the cabinet, and will reduce

the number of cooling cycles required by the cooling system.

Once the cabinet is loaded, turn on the cooling unit. The settings on the

CellarPro cooling unit have been preset and optimized by the factory, and we

recommend that you wait two weeks before changing any of the settings.

Create an "airflow path" by keeping the top 3-

4 cells directly below the cold-air discharge

empty of bottles (see picture at right). The

cold air discharge is located on the left side

underneath the cooling system. By keeping

these cells free of bottles, the cold air

produced by the cooling unit will be able to

circulate freely inside the cabinet, resulting in

less stratification and more efficient operation.

Some of our wine racks are designed to hold

bottles “double-deep.” Generally, both bottles

should be loaded with the cork facing the

door. Most collectors load the same wines together in a slot, so that they know

which wines are in the back.

Some wine bott les (e.g . German Riesli ngs) are extra-long and won’t fit double-

deep in our racks. When storing long bottles, they should be loaded with

shorter bottles so that the door can close properly.

Most large-format bottles should fit inside our wine cabinet racks. However,

some bottles are too big and will need to be stored in the bulk storage area at

the bottom of the racks.

Temperature fluctuations inside the wine cabinet vary the LEAST in the bottom

two-thirds of the cabinet, and temperatures in the back of the cabinet

fluctuate less than in front of the cabinet. Therefore, it is advisable to store the

most expensive wine bottles in the back / bottom two-thirds of the wine

cabinet.

-23-

Page 24

B I L D W I N E C A B I N E T S

VIII. M A I N T E N A N C E I N S T R U C T I O N S

EXTERIOR SURFACE

The cabinet walls and doors are made with a tough PVC laminate which will

withstand cleaning with mild soapy water. A furniture polish periodically appli ed will

maintain the sheen of the finish.

DOOR INSTRUCTIONS

We recommend keeping the doors locked when the cabinet is not in use. By

keeping the doors locked, you will ensure that you have a tight seal between the

cabinet doors and the cabinet itself, and will help prevent the possibility of the door

becoming warped over time.

AIR FILTER

All BILD 1400 wine cabinets sold with a CellarPro unit include an air filter that

magnetically attaches to the rear of the cooling unit. To replace the filter, remove

the filter frame from the top of the wine cabinet (see the image at right), and

replace the filter when it becomes dirty (anywhere from 3 to 9 months depending on

the conditions in your location.

When replacing the filter, the blue fibers should face the cooling unit, and the white

fibers should face away from the cooling unit.

Replacement filters may be purchased at www.lecache.com.

-24-

Page 25

B I L D W I N E C A B I N E T S

IX. T R O U B L E S H O O T I N G G U I D E

My wine cabinet is leaning forward.

When the wine cabinet is empty, the door(s) of the wine cabinet represent a

disproportionate share of the wine cabinet weight. Thus, when an empty wine

cabinet is first placed on carpet, it may lean forward even though the wine cabinet

is placed on a carpet board.

DO NOT over-compensate by extending the front leveling feet. Instead, load some

bottles into the back of the wine cabinet until the weight is more evenly distributed.

The cabinet should no longer be leaning forward at this point. Additional

adjustments may be required to level the wine cabinet front to back as the cabinet

board compresses the carpet underneath over time.

The cabinet is assembled and in place but the door(s) are not aligned and/or the

corner(s) are torqued out.

1. Make sure the cabinet is level and the doors are properly aligned (refer to

Chapter V).

2. Check to see that the hinges aren't bent or loose. The hinge pins (attached to the

top and bottom of each door) should be perfectly upright, and the hinge plates

(attached to the top and the bottom of the wine cabinet) should be attached

tightly to the cabinet and perfectly parallel to the floor.

3. Check to see if the door(s) are bowed using a long straight-edged object (e.g. a

yardstick).

I’ve had the cabinet for some time, and the cabinet door(s) are no longer sealing

properly against the cabinet.

You can check the door seals by placing a flashlight inside the cabinet and aiming it

at the door. Then, close the door. If there are any gaps and the light shines through,

the door is not sealing properly.

Another way to check the seals is by closing each door on a dollar bill around the

perimeter of each door. It should be difficult to slide the bill along the edge of the

door without pulling out the bill.

If the door(s) aren’t sealing properly against the cabinet, do the following:

1. Make sure the cabinet is level and the doors are aligned (refer to Chapter V)

-25-

Page 26

B I L D W I N E C A B I N E T S

2. If there is a kink in the rubber gasket on the door, use a hair dryer for several

minutes and stretch the gasket into the proper shape. Then, close the doors for

several hours to allow the gasket to regain its proper shape.

3. If necessary, it is Ok to stuff the gasket with cloth or paper, and/or add another

wood strip inside the gasket, to push out the gasket so that it seals against the

door.

The cooling unit runs constantly.

The cooling unit is designed to turn on when the air temperature in the cellar rises

ABOVE the Minimum Set Point + Temperature Differential, and turn off when the air

temperature falls below the Minimum Set Point. For example, if the Minimum Set Point

is 58°F and the Temperature Differential is 4°F, the cooling unit will turn on above 62°F

and turn off below 58°F.

When bottles are first loaded in the wine cabinet, the cooling unit will run

continuously (even up to a week) until the temperature inside the cellar falls below

the Minimum Set Point.

The cooling unit will cool 25°F below the ambient temperature in the space outside

the condenser coils. In other words, when the ambient temperature in the space

outside the condenser coils is 85°F, the cooling unit can't cool below 60°F inside the

cellar.

Hot weather conditions, insufficient ventilation and/or dirty condenser coils can all

cause the cooling unit to run continuously. To reduce cycle times,

1. Clean the condenser coils

2. Check the ambient temperature in the space outside the condenser coils while

the cooling unit is running, making sure that the difference between this

temperature and the Minimum Set Point is no more than 25°F.

3. Increase the supply of cool air to the space outside the condenser coils, using a

fan or an exhaust system to remove heat from the space.

4. Raise the Minimum Set Point on the cooling unit

5. Make sure that the “Quick Chill” and “Energy Saver” features are not enabled

-26-

Page 27

B I L D W I N E C A B I N E T S

The cooling unit is dripping inside the cabinet and/or the cabinet is having problems

with condensation.

The cooling unit does not generate water. If the cooling unit is dripping, or the

cabinet is having excess condensation, it is because the cooling unit is running too

much and/or the cabinet does not have an airtight seal from the ambient

environment.

To eliminate dripping and condensation, do the following:

1. Raise the Minimum Set Point of the cooling unit to 58 degrees.

2. Make sure the cellar has good seals, especially at the door(s), and repair any

leaks immediately.

3. Keep the first 3-4 rows clear in the column directly below the cold-air discharge

(front column only). This will stop the cold air from "splashing" against the center

post. See Chapter VII for more information.

4. If your wine cabinet is less than half full, build the thermal mass to reduce the

cycle time of the cooling unit. If you don't have enough wine, use soda cans,

water bottles, etc.

5. If the lock on the outside is sweating then wrap the lock tab with electrical tape.

6. If condensation is coming into contact with the cabinet’s surfaces, wipe it away

frequently to prevent damage to the structure of the cabinet, such as warping of

the doors and mold.

-27-

Page 28

B I L D W I N E C A B I N E T S

X. L I M I T E D W A R R A N T Y

FIVE YEAR COOLING UNIT LIMITED WARRANTY

For f ive y ears from the d ate o f orig ina l del ivery , yo ur BILD warranty covers all parts and labor to repair or

replace any components that prove to be defective in materials or workmanship in the cooling unit.

Under the terms of this warranty, we will repair or replace the original cooling unit with a new or

refurbished cooling unit and, once replaced, the original cooling unit must be returned to us. The

cooling unit is self-enclosed and is located inside the wine cabinet and is mounted to the top of the

cabinet.

ONE YEAR LIMITED WARRANTY

For one year from the date of original delivery, your BILD warranty covers all parts and labor to repair or

replace any part of the product which proves to be defective in materials or workmanship.

TERMS APPLICABLE TO EACH WARRANTY

All service provided by Le Cache under the abov e warranty must be performed by a designated

repair center, unless otherwise specified by Le Cache. Purchas er is responsible for removing and

reinstalling the cooling unit from the wine cabinet, and for shipping to and from Le Cache or to and

from a designated repair facility.

The limited warranty applies only to wine cabinets purchased from the factory or an authorized dealer.

For wine cabinets delivered to Hawaii and locations outside the United States, the District of Columbia

or Canada, the limited warranty appli es only to the cooling unit, but it does not apply to the wine

cabinet. The limited warranty does not cover any parts or labor to correct any defect caused by

negligence, commercial use, accident, or improper use, maintenance, installation, service or repair.

The limited warranty also does not cover any parts or labor to correct any damage caused by severe

temperature variations, direct sunlight, extremely dry conditions or great humidity changes.

THE REMEDIES DESCRIBED ABOVE FOR EACH WARRANTY ARE THE ONLY ONES, WHICH LE CACHE WILL

PROVIDE, EITHER UNDER THESE WARRANTIES OR UNDER ANY WARRANTY ARISING BY OPERATION OF

LAW. LE CACHE WILL NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES

ARISING FROM THE BREACH OF THESE WARRANTIES OR ANY OTHER WARRANTIES, WHETHER EXPRESS,

IMPLIED OR STATUTORY.

Some states do not allow the exclusion or limitation of i ncidental or consequential damages , so the

above limitation or exclusion may not apply to you. Thi s warranty giv es you speci fic legal ri ghts and

you may also have other legal rights, which vary from state to state.

To receive parts and/or service and the name of a Le Cache designated repair facility nearest you,

contact your Le Cache dealer. You may also contact Le Cache Premium Wine Cabinets directly by

calling our toll-free number at 1.877.532.2243.

-28-

Page 29

B I L D W I N E C A B I N E T S

XI. C O N T A C T I N F O R M A T I O N

Le Cache Premium Wine Cabinets

531 Mercantile Drive

Cotati, CA 94931

Toll Free: 1.877.532.2243

Direct: 1.707.794.8000

Email: info@lecache.com

www.lecache.com

# # # #

© The New Yorker Collection 2003 Christopher Weyant from cartoonbank.com. All

Rights Reserved.

-29-

Loading...

Loading...