Vintage Cellars AH8500 User Manual

C O N G R A T U L A T I O N S !

Thank you for purchasing a new CellarPro cooling system.

Please take a minute to read through this Owner’s Manual before you

unpack, install and turn on your Cooling Unit.

Also please look through the boxes you receive with your Air Handler

shipment to make sure you have received the correct components you

ordered and that they are all functioning before the installation.

Box 1 – Cooling unit and Accessories

Box 2 – Duct Plates and Optional Humidifier

If you have any questions about your new cooling unit, it is likely that you will find

the answers in this Owner’s Manual. We also have more information

on our website, including the latest version of the Owner’s

Manual, at www.cellarpro.com/customerservice .

If you still have questions, please don’t hesitate to contact your dealer or

CellarPro directly. We can be reached during normal business hours at

707.794.8000. You also may contact us anytime via email at info@cellarpro.com.

Contact Information:

CellarPro Cooling Systems

531 Mercantile Drive

Cotati, CA 94931

707.794.8000

Email: info@cellarprocoolingsystems.com

Website: www.cellarprocoolingsystems.com

Table of Contents

I. Specifications, Cut Sheets, and Cellar Construction 4

II. Installation Instructions 9

III. Operating Instructions 24

IV. Troubleshooting 33

V. Limited Warranty 39

VI. Support and Data Service Sheet (Split Configuration) 40

3

V

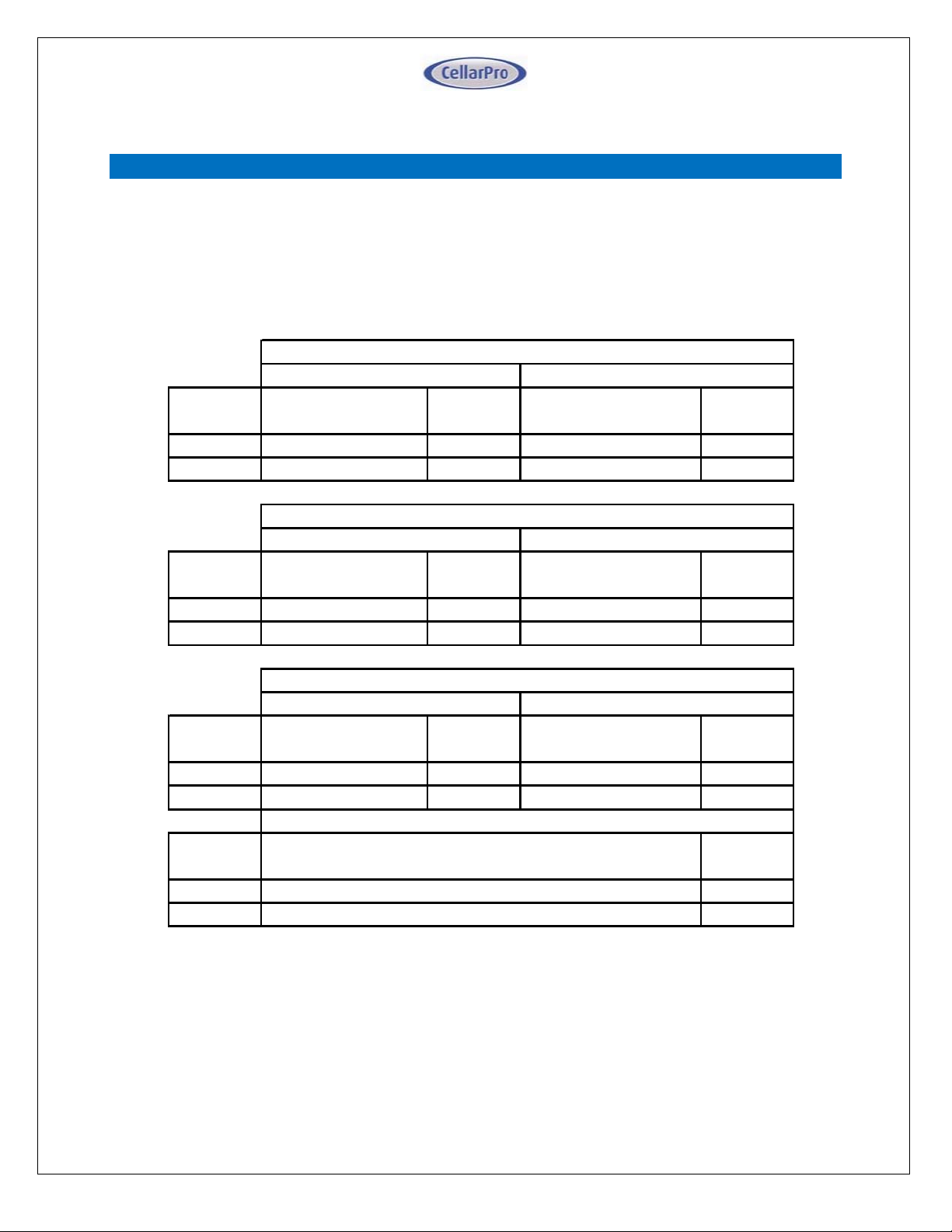

I. Specifications, Cut Sheets and Cellar Construction

The following tables will provide information on the dimensions of the unit and how best

to mount or locate the various models available.

Specifications

Horizontal Self Contained

No Humdifier With Humidifier

Dimensions

Model

WxDxH (inches)

AH6500 18.6 x 37.1 x 19.3 161 33.0 x 37.1 x 18.5 181

AH8500 18.6 x 37.1 x 19.3 170 33.0 x 37.1 x 18.5 190

No Humdifier With Humidifier

Dimensions

Model

WxDxH (inches)

AH6500 18.6 x 18.6 x 37.8 161 33.0 x 18.6 x 37.8 181

AH8500 18.6 x 18.6 x 37.8 170 33.0 x 18.6 x 37.8 190

Weight

(lbs)

Dimensions WxDxH

(inches)

ertical Self Contained

Weight

(lbs)

Dimensions WxDxH

(inches)

Weight

(lbs)

Weight

(lbs)

Split System Evaporator Module

No Humdifier With Humidifier

Model

Dimensions

WxDxH (inches)

Weight

(lbs)

Dimensions WxDxH

(inches)

Weight

(lbs)

AH6500S 18.6 x 18.6 x 19.3 60 33.0 x 18.6 x 19.3 80

AH8500S 18.6 x 18.6 x 19.3 60 33.0 x 18.6 x 19.3 80

Split System Condenser Module

Weight

Model

Dimensions WxDxH (inches)

(lbs)

AH6500S 18.6 x 18.6 x 19.3 111

AH8500S 18.6 x 18.6 x 19.3 120

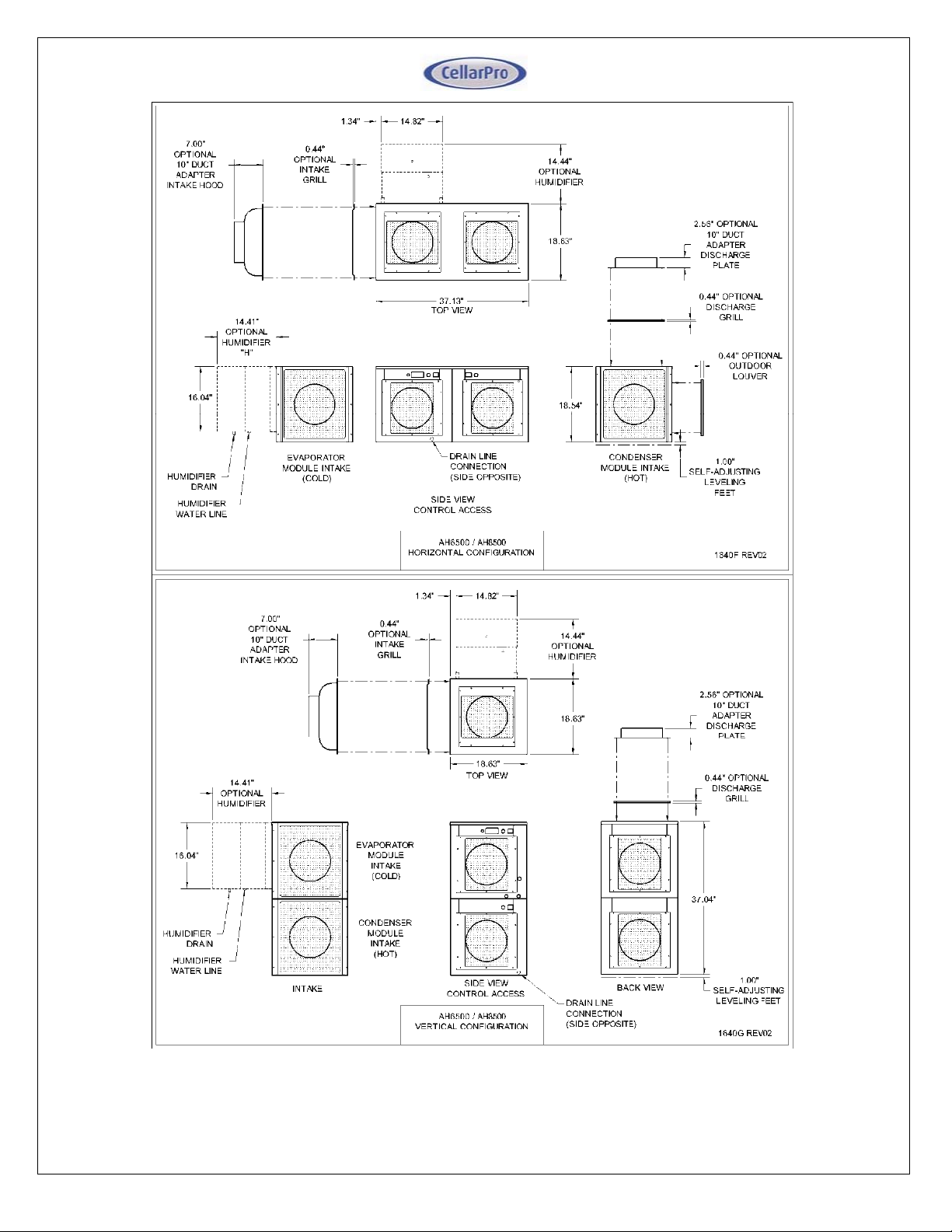

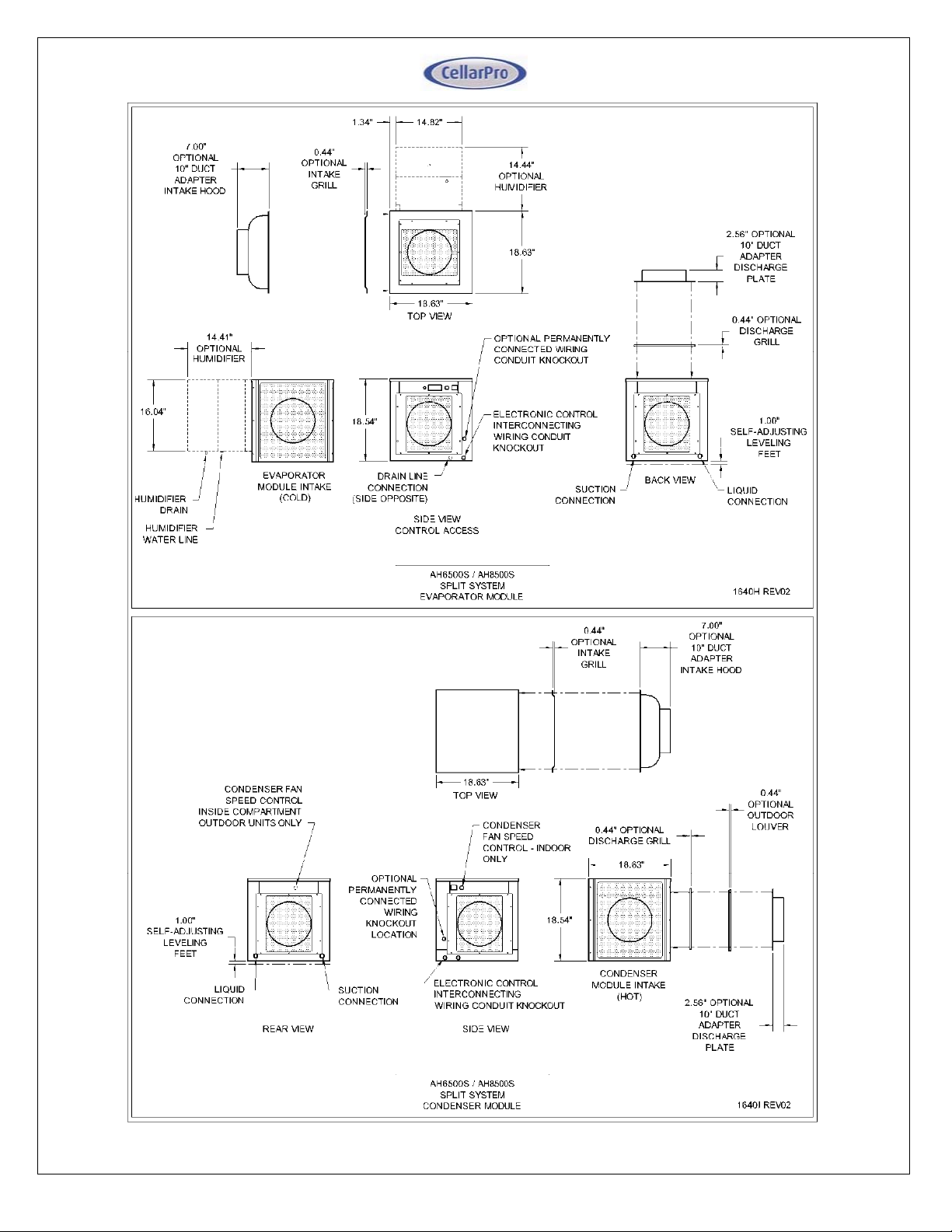

Cut Sheets

Note dimensions for mounting bolts and space required for installation.

4

5

6

Cellar Construction

Insulation

CellarPro cooling units are designed to be installed inside wine cellars that have pro per

insulation, moisture barriers and an airtight seal from the environment outside the

cellar. Interior walls and floor

should have a minimum of R11 insulation, and a vapor

barrier on the warm side of

the insulation. The ceiling

should have a minimum of

R-19 insulation and a vapor

barrier on the warm side of

the insulation. Doors also

should be insulated and

tightly sealed with weatherstripping around the

perimeter of the door.

Surface-mounted fixtures are

recommended over

recessed lighting, which can

allow air to leak into the

cellar.

It is important that all walljoints, doors and windows, electrical outlets and/or switches, pipes, vents and light

fixtures be sealed to prevent air and moisture from entering the cellar. If there is a leak in

the cellar, the cooling unit will build up excess condensation.

The condensate drain line and optional humidifier drain line must be connected to a

suitable drain.

Fan Speeds

Your evaporator module fan speed setting will depend on the amount of ducting and

thermal load on the wine cellar, and the r esulting airflow and BTUH that is required

to cool and maintain your wine cellar at the desired temperature. Your condensing

module fan speed setting will depend on the condenser air intake temperature and the

amount of ducting, allowing for sufficient airflow to reject the heat absorbed by the cooling

system.

Ventilation

Adequate ventilation is critically important for the proper operation of your

CellarPro cooling unit, particularly on the condenser (hot) side of the cooling unit.

7

Condenser Air Exhaust/Intake.

Condensing units create significant hot air which

must be exhausted into an appropriately-sized space in order for the heat to

dissipate. If the space is constrained and/or too small, the heat will not dissipate.

In this event, the cooling unit will be forced to re-circulate its hot air exhaust and/or

the static pressure will back up the cooling unit. If this happens, th e cooling unit’s

ability to create cold air inside the cellar will be compromised. In addition, the

cooling unit must be installed so that, after its installation, the condenser coils are

accessible for periodic cleaning.

Evaporator Air Exhaust/Intake.

When the warm air from the cellar passes across

the evaporator coils, heat is removed from the air, and the resulting cold air is

exhausted into the cellar. On non-ducted installations, a minim um clea rance of 12” is

required from all air intake and discharge locations to maintain proper airflow. Cold

air exhaust must be located at the highest point inside wine cellars, the cold air

exhaust eventually will drop to the bottom of the cellar. To ensure proper airflow and

reduce temperature stratification inside the cellar, the space in front of the cold air

discharge should be clear of any obstructions, including wine bottles, wine racks, etc.

Evaporator/Condensor Ducting.

CellarPro Air Handlers exhaust and return (hot

and cold side) can be ducted up to 50 equivalent feet (100' total equivalent feet

exhaust and return) with 10” diameter ducting. With our units we offer duct adaptors

and ducting that attach to either the evaporator or condenser module.

8

II. Installation Instructions

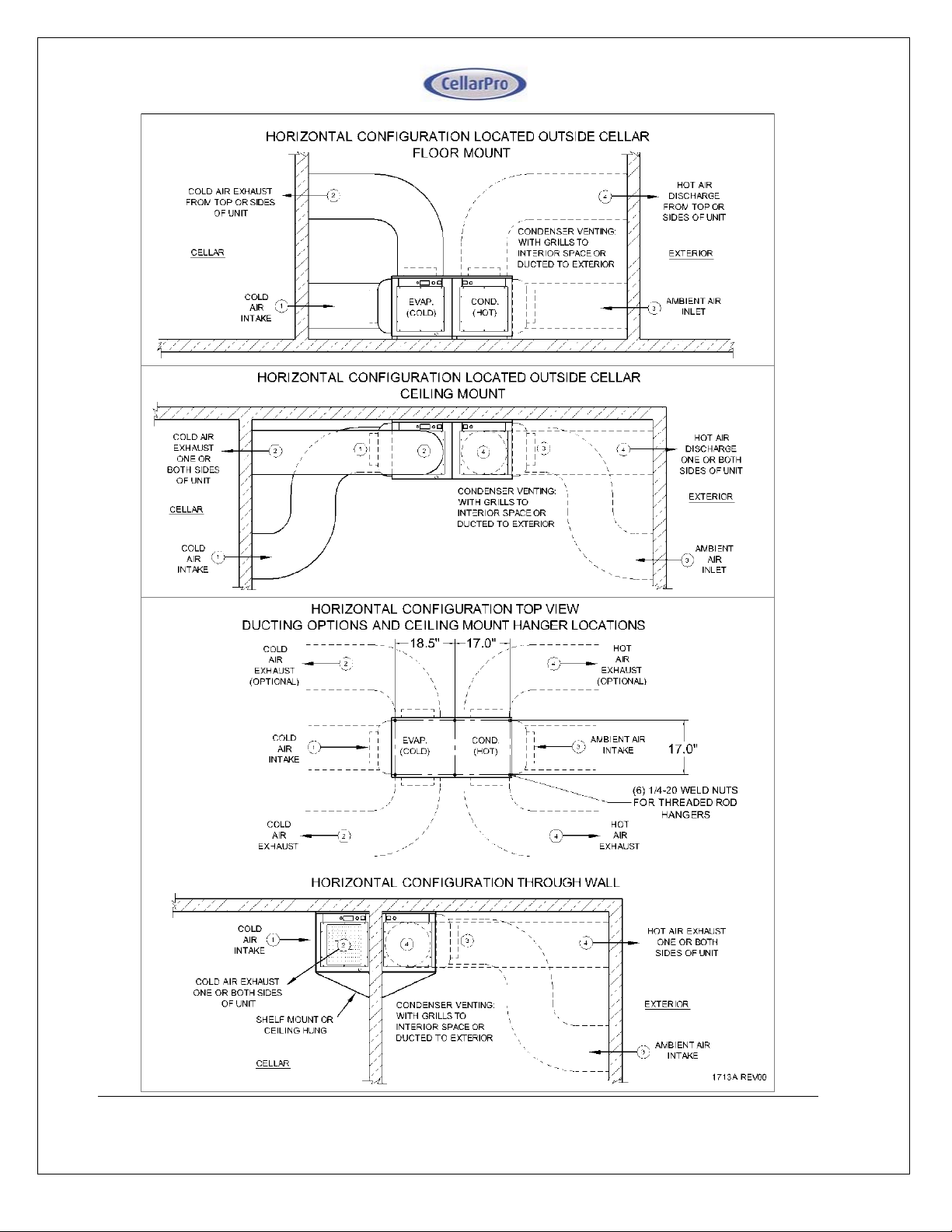

Configuration Options

The Air Handler comes in three basic configurations:

Horizontal configuration - which can be installed inside or outside the cellar.

Additionally it can be installed through the wall with a portion of the unit in the cellar

and outside the cellar.

Vertical configuration – this is the ‘stacked’ option which is a space saving approach.

Split configuration – with the evaporator in the cellar (ductless) or outside (ducted)

and with the condenser either inside or outside the house or building.

Horizontal Configuration.

Through wall: The unit is installed through the cellar wall with the evaporator module

inside the cellar, and the condenser module outside. The unit requires a mounting shelf,

sized to fit the width and depth of the unit and strong enough to support the weight of the

unit. The unit is secured to the mounting shelf using (4) 1/4-20 bolts secured to captive

nuts located in the bottom corners of the unit (note: the provided leveling feet must be

removed). The condenser can be provided with grills to vent the air, or duct adapters to

duct the intake, discharge, or both. The condenser module can also pass through the

cellar wall to an outdoor exposure by installing optional outdoor louvers to the intake and

discharge air panel openings.

Remote ducted: The unit is mounted remote to the cellar, and the evaporator module

intake and discharge air are ducted to the cellar. The condenser can be provided with

grills to vent the air, or duct adapters to duct the intake, discharge, or both. The

condenser module can also pass through an exterior wall to an outdoor exposure by

installing optional outdoor louvers to the intake and discharge air panel openings. The

unit may be floor mounted on the leveling feet provided, or flush to the floor with the

leveling feel removed. The unit may be ceiling hung using six 1/4-20 threaded rods (field

provided), attaching to captive nuts provided in the top corners and middle edges of the

unit.

Inside cellar: The unit can be mounted inside the cellar, provided that the condenser

intake and discharge are ducted to a suitably ventilated area outside the cellar.

9

10

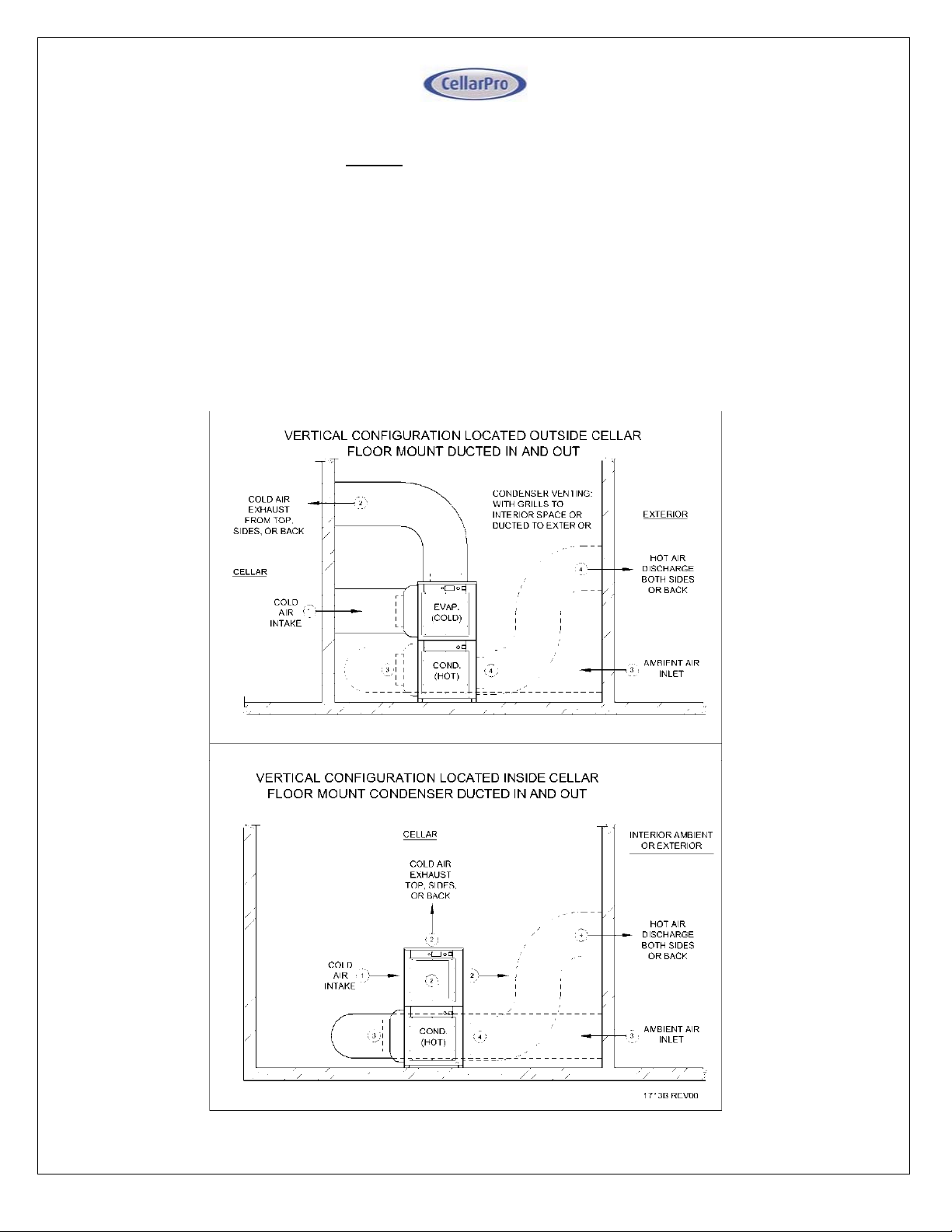

Vertical Configuration.

Through wall: Vertical units cannot be mounted in a through wall configuration.

Remote ducted: Vertical units can be mounted remotely with the evaporator intake and

discharge air are ducted to the cellar. The condenser can be configured with grills to

vent the air provided that the location is suitably ventilated, or with duct adapters for

ducting the intake, discharge, or both to a suitably ventilated area. The unit may be

floor mounted on the provided leveling feet, or flush to the floor with the leveling feel

removed. The unit cannot be ceiling hung, and cannot be installed outdoors.

Inside cellar: Vertical units can be located inside the cellar, with the condenser intake

and discharge ducted to a suitably ventilated area outside the cellar.

11

Split Configuration.

Models in the Split Configuration can be mounted as follows, with interconnecting wiring

and refrigerant piping field provided by an experienced Refrigeration contractor:

Remote ducted: The unit is mounted remote to the cellar, and the evaporator module

intake and discharge air are ducted to the cellar. The condenser can be provided with

grills to vent the air, or duct adapters to duct the intake, discharge, or both. The

condenser module can also be located outdoors by installing optional outdoor louvers to

the intake and discharge air panel openings. The separate modules may be floor

mounted on leveling feet, or flush to the floor with the leveling feel removed. Each

module may be ceiling hung using four 1/4-20 threaded rods per module (field

provided), attaching to captive nuts provided in the top corners of the module.

Inside cellar: The evaporator module can be mounted inside the cellar as follows:

The module may be floor or shelf-mounted, or flush to the floor or shelf with the

leveling-feet removed. If shelf mounted, the evaporator module requires a

mounting shelf designed to support the weight of the module, and secured by

four 1/4-20 bolts secured to weld nuts located in the bottom corners.

The module may be ceiling hung using f our 1/4-20 threaded rods (field provided),

attaching to captive nuts provided in the top corners of the module.

Condensing Units - Indoor

Condensing units can be installed remotely from the cellar in an area protected

from direct exposure to moisture and sunlight.

The area must have adequate ventilation to maintain a temperature of 110°F or

less.

If the area does not have adequate ventilation, a vent fan should be added to

supply fresh air to the space.

On units that are not ducted, a minimum of 12" of open air space is required in

front of the intake and discharge air panels.

Condensing Units - Outdoor

Both the Horizontal and Split configurations can be installed with the Condenser

module located outdoors, with optional outdoor louvers installed in the air intake

and discharge positions.

The unit is designed to operate in temperatures ranging from 0°F to 110°F.

Please note: Our compressor heater (ordered separately) is required for

temperatures below 40° F.

A minimum of 12" of open air space is required in front of the intake and

discharge air panels.

Knockouts are provided in the unit housing for field connection of conduit. The

conduit must be liquid tight and approved for outdoor use. Conduit fittings shall

be in accordance with UL 514B.

12

Loading...

Loading...