Vintage Cellars 1800 User Manual

Control the Elements

Owner’s Manual

Fine Furniture for Fine Wines

C O N G R A T U L A T I O N S !

Thank you for purchasing a new CellarPro cooling system.

Please take a minute to read through this Owner’s Manual before you unpack, install and

turn on your Cooling Unit.

If you have any questions about your new cooling unit, it is likely that you will find the

answers in this Owner’s Manual. We also have more information on our website,

including the latest version of the Owner’s Manual, at www.cellarpro.com/customer-

service .

If you still have questions, please don’t hesitate to contact your dealer or CellarPro

directly. We can be reached during normal business hours at 1.877.726.8496. You also

may contact us anytime via email at info@cellarpro.com.

Contact Information:

CellarPro Cooling Systems

531 Mercantile Drive

Cotati, CA 94931

877.726.8496

Email: info@cellarpro.com

Website: www.CellarProCoolingSystems.com

Serial Number*: ____________________

*We recommend that you take a minute to fill-in your CellarPro serial number above. The

serial number has seven-digits and can be found on the printed label on the left side of

your cooling unit.

Don’t forget to register your cooling unit warranty at www.cellarpro.com/register

1

Table of Contents

I. Prior to Installation 4

II. Overview 5

III. Installation Instructions – Wine Cellars 8

IV. Replacement Instructions – Wine Cabinets 14

V. Operating Instructions 17

VI. Troubleshooting 25

VII. Limited Warranty 28

3

I. Prior to Installation

Test the unit before installing it.

1. Remove the unit from the box. SAVE THE BOX AND PACKING MATERIALS.

2. Remove any materials that have been packed inside the exhaust cavity

3. Plug in the power cord. The cooling system is programmed with a 3-Minute

Delay at Startup to protect its internal components

4. Let the unit run on a hard, flat surface for no more than 10 minutes.

5. Make sure that all fans in the cooling unit are spinning.

6. Check that the cooling unit is discharging cold air from the bottom (it should

be approximately 10°F colder than the temperature on the digital display)

7. Turn the unit “off”, install the unit, and wait 24 hours before operating your

CellarPro cooling unit. This will protect the unit from internal damage that

could arise if the unit was shipped, stored or tilted on its side.

Make sure that the exhaust panel is installed in the correct position – it should

cover either the TOP or the REAR exhaust vent:

o TOP VENT CONFIGURATION: If

the hot air will be discharged

through the TOP of the cellar,

install the exhaust panel on the

BACK of the cooling unit (as

shown in the Picture A). In this

configuration, the cavity on TOP

of the cooling unit is OPEN.

Picture A

Top Vent Configuration

o REAR VENT CONFIGURATION: If

the hot air will be discharged through the

REAR of the cellar, use the exhaust panel to

seal the TOP of the cooling unit (as shown in

the Picture B). In this configuration, the

cavity at the REAR of the CellarPro is OPEN.

Picture B

Rear Vent Configuration

4

II. Overview

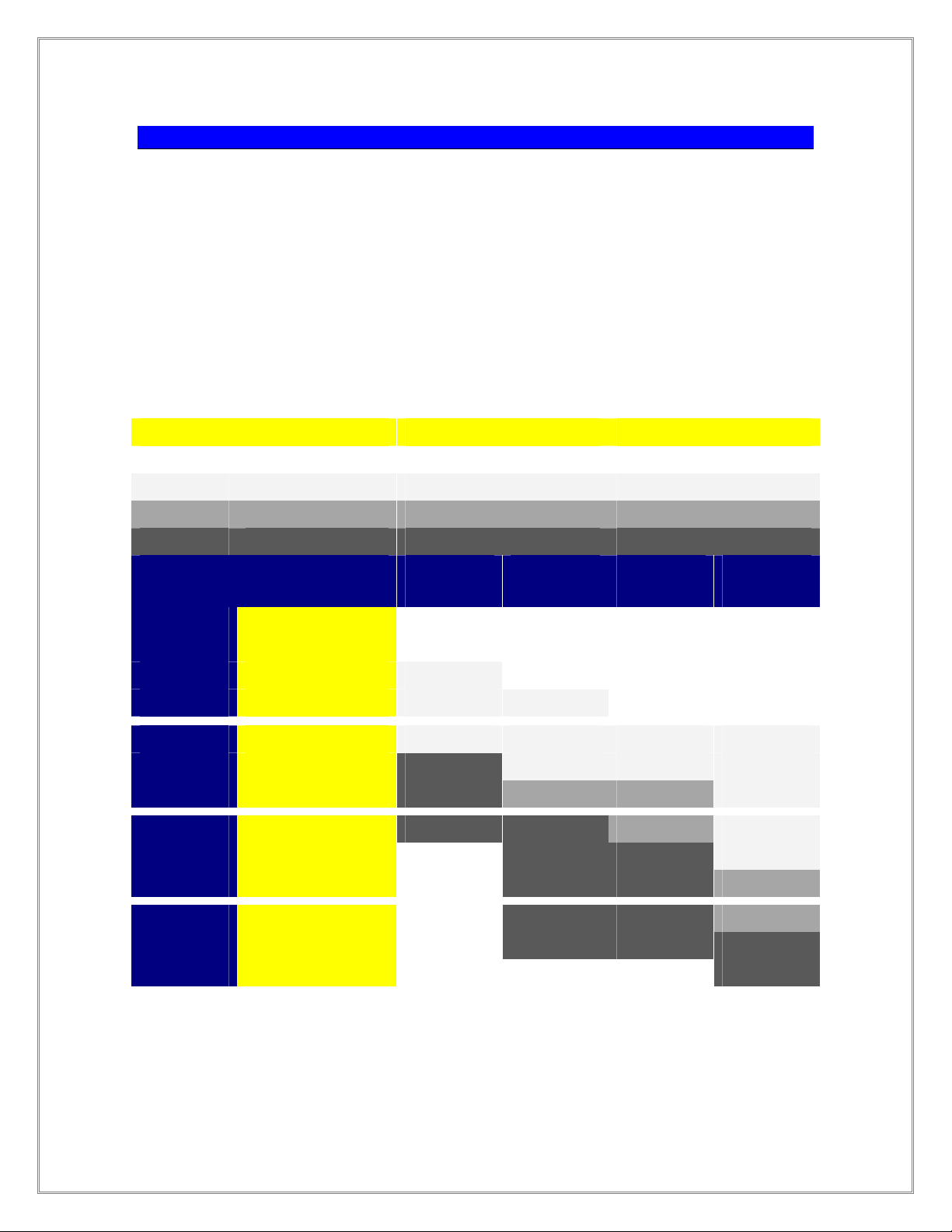

CellarPro Cooling Capacity*

Estimated thermal loads for various size cellars, with various insulations, various

ambient temperatures and various cellar temperatures, are shown in the table below.

To figure out whether a CellarPro unit will work in your space, make sure that the

cooling unit’s BTUH for a given cellar temperature (at the top of the table) is equal or

greater than the thermal load shown in the body of the table. The non-bold,

unshaded numbers are within the capacity of all units. The unbold, lightly shaded

numbers are within all units except the 1800QTL. The bold numbers are beyond the

capacity of the 1800QTL and 1800QT. The italicized numbers are appropriate only

for the 1800XTS / XTSx. “X” indicates conditions beyond the capacity of all units.

Cellar Temp

BTUH 1800QTL

BTUH 1800QT

BTUH 1800XT

BTUH 1800XTS / XTSx

Cellar Insulation –

Walls, ceiling & floor*:

Cellar Size Ambient Temp

75 Degrees

100 Cu Ft. 85 Degrees

95 Degrees

75 Degrees

200 Cu Ft. 85 Degrees

95 Degrees

75 Degrees

300 Cu Ft. 85 Degrees

55 Degrees 60 Degrees

1065 1154

1380 1479

1456 1558

1886 2031

R-12

R-19

R-12

R-19

1068 979 940 862

1180 1046 1038 920

1291 1114 1136 980

1380 1253 1214 1103

1538 1349 1353 1187

1699 1446 1495 1272

1700 1542 1496 1357

X 1562 1672 1463

95 Degrees

75 Degrees

400 Cu Ft. 85 Degrees

X 1909 2003 1558

X 1744 1690 1535

X 1879 1888 1654

95 Degrees X X X 1773

*Please note: Glass panels, windows and doors have much lower insulation (at most

R-3) and therefore heat loads will increase dramatically when glass is used in cellars.

5

Size & Electrical Specifications

Model

1800 QTL/QT/XT/XTS 18 x 16.5 x

1800 XTSx 18.1 x 22 x

Dimensions

W” x D” x H”

10.5

10.6

Weight

(lbs)

Operating

Amps

Required

Circuit

60 3 15-Amp

Dedicated

70 3 15-Amp

Dedicated

Ambient Environment

CellarPro cooling units are designed to operate in ambient temperatures between

45°F and 95°F. Except for the 1800XTSx cooling unit, all cooling units are designed

for internal use only, and are not designed for exposure to the exterior.

CellarPro cooling units are not designed to generate heat inside the cellar, so if

temperatures inside the cellar drop below proper wine storage temperatures, the

cooling unit cannot increase the temperature inside the cellar.

Proper temperatures are maintained by transferring heat from inside wine cellars

and exhausting heat through the top (top-vent) or rear (rear-vent) of the cooling units.

Insulation

CellarPro cooling units are designed to be installed inside wine cellars that have

proper insulation, moisture barriers and an airtight seal from the environment

outside the cellar.

Interior walls and floor

should have a minimum of

R-11 insulation, and a

vapor barrier on the warm

side of the insulation. The

ceiling should have a

minimum of R-19 insulation

and a vapor barrier on the

warm side of the insulation.

Doors also should be

insulated and tightly sealed

with weather stripping

around the perimeter of the

door. Surface-mounted

fixtures are recommended

over recessed lighting,

which can allow air to leak

6

into the cellar. Please note: The R-values above are the MINIMUM recommended

amounts of insulation. It is advisable to use as much insulation as possible inside

your walls, ceiling and floor.

It is critical that all walls, joints, doors and windows, electrical outlets and/or

switches, pipes, vents and light fixtures be sealed to prevent air and moisture from

entering the cellar. If there is a leak in the cellar, the cooling unit will build up excess

condensation that eventually may damage the internal components and shorten the

life of the cooling unit, and may cause water to leak from the cooling unit.

We offer a Wine Cellar Modification for cooling

units that will be installed in wine cellars (as

opposed to wine cabinets.) The Wine Cellar

Modification provides a fitting and condensate

tube at the back of the cooling unit to relieve

excess moisture that may condense inside the

cooling unit. For installations in warm

environments and/or cellars without airtight

seals, we strongly recommend this

modification. However, the modification does

not replace the requirement for a cellar to have proper insulation, moisture barriers

and airtight seals from the environment outside the cellar.

If your cooling unit has the wine cellar modification, please make sure that the tube

has a condensate trap that is slightly filled with water, as follows:

As shown above, the drain line should drop, then rise (but stay below the height of

the fitting), and then drop again into a drain or bucket. Then, fill the trap with water.

The condensate trap will allow any excess moisture inside the cooling unit to

overcome the static pressure and flow out of the drain line. Please note: If you do

not use a trap, you will see little – if any – condensation, for the same reason that

water stays inside a straw when one end is sealed.

7

III. Installation Instructions – Wine Cellars

CellarPro cooling units are designed to be installed THROUGH THE WALL. A hole

should be cut 1/4 inch larger than the dimensions (W x H) of the cooling unit.

Horizontal 2 x 4 inch braces should be installed between the studs below and above

the cooling unit. If the studs in the wall must be cut to accommodate the width of the

cooling unit, vertical braces also should be installed on either side of the cooling unit.

CellarPro cooling units must always be mounted in the upright position and located

as close to the ceiling as possible inside the cellar. As warm air rises to the top of the

cellar, the cooling unit pulls the warm air through the evaporator coils and removes

the heat from the warm air. Once cooled, the cold air is discharged from the bottom

of the cooling unit and circulates downward through the cellar.

The rear of the cooling unit should be slightly lower than the front of the cooling unit

(ie the cooling unit should be tilted backwards slightly), so that excess condensation

won’t drip through the evaporator fan cavity. The rear of the cooling unit should be

supported by the wall through which it is installed, and should be flush with the wall.

Assuming 4 1/2 inch interior wall thickness, the front 12 inches will be inside the

cellar.

The rear of the cooling unit must be installed in a space that is at least as large as

the wine cellar unless the rear intake and exhaust are ducted. The rear of the

cooling unit requires a minimum clearance of 8 inches in an open (ie non-enclosed,

non-recessed) environment.

The front of the cooling unit requires a minimum of 3 inches of clearance inside the

cellar, and the bottom of the cooling unit requires clearance of 8 inches below the

cold air discharge.

The front of the cooling unit can be mounted using optional mounting clips (available

for purchase from CellarPro), as follows:

8

Alternatively, the front of the cooling unit can be supported by a shelf and a diagonal

brace. The shelf can be up to 13.25” inches wide, and should be positioned on the

right side of the cooling unit so that it doesn’t restrict the exhaust vent below the

cooling unit, as follows:

9

Loading...

Loading...