Vintage 551170 User Manual

1969-70 MUSTANG

w/o FACTORY AIR GEN IV

551170

18

865 G

O

L

L

S

T

.

-

S

A

N

AN

T

ONIO

, TX

. -

7826

6

ph

.2

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 1 OF 26

1

0

-65

4

-7

171

- f

a

x

21

0-65

4-3

1

13

1969-70 MUSTANG w/o AC GEN IV

Table of Contents

PAGES

1.

COVER

2.

TABLE OF CONTENTS

3.

PACKING LIST/ PARTS DISCLAIMER

4.

INFORMATION PAGE

5.

WIRING NOTICE

6.

ENGINE COMPARTMENT / PASSENGER COMPARTMENT

FIGURES 1 & 2

7.

DEFROST DUCT / FRESH AIR CAP & DRIVER AND PASSENGER SIDE

LOUVER INSTALLATION

FIGURES 3 & 4, 4a

8.

EVAPORATOR INSTALLATION

FIGURES 5,5a & 6

9.

FIREWALL COVER INSTALLATION

FIGURES 7 & 7a

10.

CENTER LOUVER INSTALLATION

FIGURES 8 & 8a

11.

DRAIN HOSE INSTALLATION & LUBRICATING O-RINGS, STANDARD HOSE KIT

& MODIFIED A/C HOSE KIT

FIGURES 9 & 10

12.

HEATER HOSE & HEATER CONTROL VALVE INSTALLATION

FIGURE 11

13.

A/C & HEATER HOSE ROUTING

FIGURE 12

14.

FINAL STEPS & GLOVE BOX INSTALLATION

FIGURES 13 & 13a

15.

DUCT HOSE ROUTING

FIGURE 14

16.

EVAPORATOR HARD LINE AND BRACKET INSTALLATION

FIGURE 15

17.

WIRING DIAGRAM

18.

GEN IV WIRING CONNECTION INSTRUCTIONS

19.

OPERATION OF CONTROLS.

20.

TROUBLE SHOOTING

21.

TROUBLE SHOOTING CONT.

22.

DRIVER SIDE LOUVER TEMPLATE

23.

PASSENGER SIDE LOUVER TEMPLATE

24.

CENTER LOUVER TEMPLATE

25.

FIREWALL COVER HOLE TEMPLATE

26.

EVAPORATOR KIT PACKING LIST

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 2 OF 26

2

1969-70 MUSTANG w/o AC GEN IV

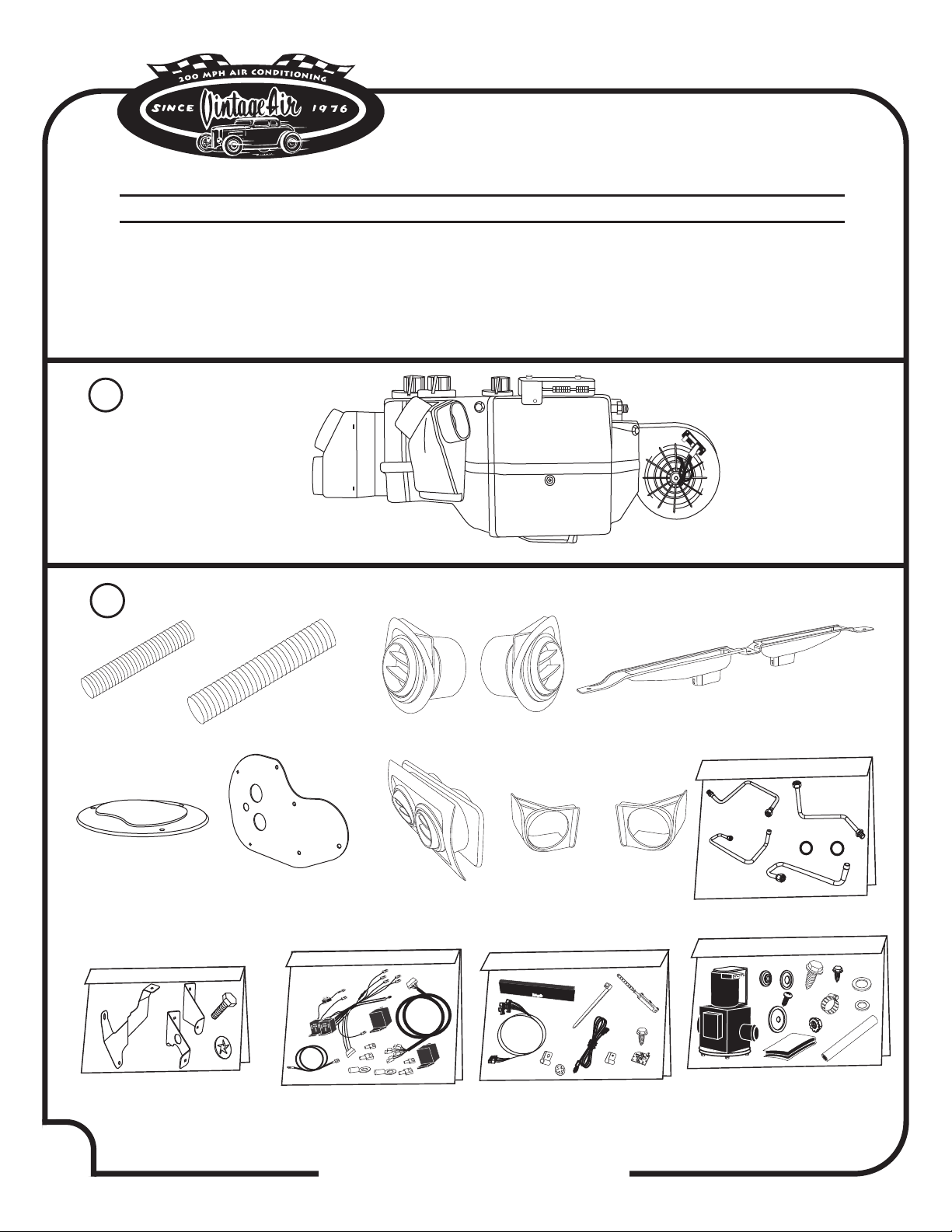

EVAPORATOR KIT

EVAPORATOR KIT PACKING LIST

No. QTY. PART No. DESCRIPTION

1.

2.

** BEFORE BEGINNING INSTALLATION OPEN ALL PACKAGES AND CHECK CONTENTS OF SHIPMENT.

PLEASE REPORT ANY SHORTAGES DIRECT LY TO VINTAGE AIR WITHIN 15 DAYS. AFTER 15 DAYS,

VINTAGE AIR WILL NOT BE RESPONSIBLE FOR MISSING OR DAMAGED ITEMS .

1

1

763069

781069

69-70 MUSTANG EVAP. SUB CASE

1969-70 MUSTANG w/o AC ACC. KIT

551170

1

69-70 MUSTANG

EVAP. SUB CASE

763069

2

F

D

AS

H

A

FLR

N

C

O

L

D

D

E

F

H

O

T

ACCESSORY KIT

3

781069

NOTE: IMAGES MAY NOT DEPICT ACTUAL PARTS AND QUANTITIES.

REFER TO PACKING LIST FOR ACTUAL PARTS AND QUANTITIES

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 3 OF 26

1969-70 MUSTANG w/o AC GEN IV

1969-70 MUSTANG

w/o FACTORY AIR

IMPORTANT NOTICE-PLEASE READ

FOR MAXIMUM SYSTEM PERFORMANCE VINTAGE AIR RECOMMENDS THE FOLLOWING:

THIS KIT DOES NOT CONTAIN HEATER HOSE. YOU MUST PURCHASE 8 FEET OF 5/8” DIA.

HEATER HOSE FROM VINTAGE AIR(31800-VUD) OR FROM YOU LOCAL PARTS RETAILER

SAFETY SWITCHES:

YOUR VINTAGE AIR SYSTEM IS EQUIPPED WITH A BINARY PRESSURE SAFETY SWITCH. A BINARY SWITCH

(11078-VUS) DISENGAGES THE COMPRESSOR CLUTCH IN CASE OF EXTREME LOW PRESSURE CONDITION

(REFRIGERANT LOSS) OR EXCESSIVELY HIGH HEAD PRESSURE (406 PSI), TO PREVENT COMPRESSOR DAMAGE

OR HOSE RUPTURE. A TRINARY SWITCH (11076-VUS) COMBINES HI/LO PRESSURE PROTECTION WITH AN

ELECTRIC FAN OPERATION SIGNAL AT 254 PSI., AND MAY BE SUBSTITUTED FOR USE WITH ELECTRIC

CONDENSER FANS. COMPRESSOR SAFETY SWITCHES ARE EXTREMELY IMPORTANT SINCE AN A/C SYSTEM

RELIES ON REFRIGERANT TO CARRY LUBRICATION THROUGH THE SYSTEM.

SERVICE INFO:

ATTENTION: SYSTEM COMPONENTS: THE COMPRESSOR, EVAPORATOR, CONDENSER & DRIER ARE CAPPED.

CAPS MAY BE UNDER PRESSURE WITH DRY NITROGEN; BE CAREFUL REMOVING CAPS. DO NOT REMOVE CAPS

PRIOR TO INSTALLATION. REMOVING CAPS PRIOR TO INSTALLATION WILL CAUSE COMPONENTS TO COLLECT

MOISTURE AND LEAD TO PREMATURE FAILURE AND REDUCED PERFORMANCE.

EVACUATE THE SYSTEM FOR 35-45 MINUTES WITH SYSTEM COMPONENTS (DRIER, COMPRESSOR, EVAPORATOR

AND CONDENSER) AT A TEMPERATURE OF AT LEAST 85° F. ON A COOL DAY THE COMPONENTS CAN BE HEATED

WITH A HEAT GUN OR BY RUNNING THE ENGINE WITH THE HEATER ON BEFORE EVACUATING. LEAK CHECK

AND CHARGE TO SPECIFICATIONS.

VINTAGE AIR SYSTEMS ARE DESIGNED TO OPERATE WITH R134a or R-12

REFRIGERANT ONLY ! USE OF ANY OTHER REFRIGERANTS RISKS A DANGER OF FIRE

AND COULD DAMAGE EITHER YOUR AIR CONDITIONING SYSTEM OR YOUR VEHICLE.

USE OF ANY OTHER REFRIGERANTS WILL VOID ALL WARRANTIES OF

THE AIR CONDITIONING SYSTEM AND COMPONE NTS. USE OF THE PROPER

TYPE AND AMOUNT OF REFRIGERANT IS CRITICAL TO PROPER SYSTEM

OPERATION. VINTAGE AIR RECOMMENDS OUR SYSTEMS BE CHARGED BY

WEIGHT WITH A QUALITY CHARGING STATION OR SCALE.

REFRIGERANT CAPACITIES FOR VINTAGE AIR SYSTEMS

(FOR OTHER SYSTEMS, CONSULT MANUFACTURER GUIDELINES)

134a SYSTEM

CHARGE WITH 1.8 lbs.

(1lbs. 12ozs) OF REFRIGERANT

R-12 SYSTEM

CHARGE WITH 2.0 lbs. OF REFRIGERANT

LUBRICANT CAPACITIES:

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 4 OF 26

NEW COMPRESSOR - NO ADDITIONAL OIL NEEDED

USED COMPRESSOR - CONSULT VINTAGE AIR

4

1969-70 MUSTANG w/o AC GEN IV

IMPORTANT WIRING NOTICE-PLEASE READ

IMPORTANT WIRING NOTICE-PLEASE READ

SOME VEHICLES MAY HAVE HAD SOME OR ALL OF THEIR RADIO INTERFERENCE CAPACITORS

REMOVED. THERE SHOULD BE A CAPACITOR FOUND AT EACH OF THE FOLLOWING LOCATIONS:

1. ON THE POSITIVE TERMINAL OF THE IGNITION COIL

2. IF THERE IS A GENERATOR, ON THE ARMATURE TERMINAL OF THE GENERATOR

3. IF THERE IS A GENERATOR, ON THE BATTERY TERMINAL OF THE VOLTAGE REGULATOR

MOST ALTERNATORS HAVE A CAPACITOR INSTALLED INTERNALLY TO ELIMINATE WHAT IS CALLED

'WHINING' AS THE ENGINE IS REVVED. IF WHINING IS HEARD IN THE RADIO, OR JUST TO BE EXTRA

CAUTIOUS, A RADIO INTERFERENCE CAPACITOR CAN BE ADDED TO THE BATTERY TERMINAL OF

THE ALTERNATOR.

IT IS ALSO IMPORTANT THAT THE BATTERY LEAD IS IN GOOD SHAPE AND THAT THE GROUND

LEADS ARE NOT COMPROMISED. THERE SHOULD BE A HEAVY GROUND FROM THE BATTERY TO

THE ENGINE BLOCK, AND ADDITIONAL GROUNDS TO THE BODY AND TO THE CHASSIS.

IF THESE PRECAUTIONS ARE NOT OBSERVED, IT IS POSSIBLE FOR VOLTAGE SPIKES TO BE PRESENT

ON THE BATTERY LEADS. THESE SPIKES COME FROM IGNITION SYSTEMS, CHARGING SYSTEMS,

AND FROM TURNING SOME OF THE VEHICLE'S OTHER SYSTEMS ON AND OFF. MODERN

COMPUTER OPERATED EQUIPMENT CAN BE SENSITIVE TO VOLTAGE SPIKES ON THEIR POWER

LEADS, WHICH CAN CAUSE UNEXPECTED RESETS, STRANGE BEHAVIOR, AND MAY ALSO CAUSE

PERMANENT DAMAGE.

VINTAGE AIR STRIVES TO HARDEN THEIR PRODUCTS AGAINST THESE TYPES OF ELECTRICAL NOISE,

BUT THERE IS A POINT WHERE A VEHICLE'S ELECTRICAL SYSTEM CAN BE DEGRADED SO MUCH

THAT NOTHING CAN HELP.

RADIO INTERFERENCE CAPACITORS SHOULD BE AVAILABLE AT MOST AUTO & TRUCK PARTS

SUPPLIERS. THEY TYPICALLY ARE CYLINDRICAL IN SHAPE, A LITTLE OVER AN INCH LONG, A LITTLE

OVER A HALF INCH IN DIAMETER, THEY HAVE A SINGLE LEAD COMING FROM ONE END OF THE

CYLINDER WITH A TERMINAL ON THE END OF THE WIRE, AND THEY WILL HAVE A MOUNTING CLIP

WHICH IS SCREWED INTO A GOOD GROUND ON THE VEHICLE. THE SPECIFIC VALUE OF THE

CAPACITANCE IS NOT TOO SIGNIFICANT, IN COMPARISON TO IGNITION CAPACITORS THAT ARE

MATCHED WITH THE COIL TO REDUCE PITTING OF THE POINTS.

CARE MUST BE TAKEN WHEN INSTALLING THE COMPRESSOR LEAD, NOT TO SHORT

IT TO GROUND. THE COMPRESSOR LEAD MUST NOT BE CONNECTED TO A CONDENSER

FAN OR ANY OTHER AUXILIARY DEVICE. SHORTING TO GROUND OR CONNECTING

TO A CONDENSER FAN OR ANY OTHER AUXILIARY DEVICE WILL CAUSE SEVERE DAMAGE

TO THE ECU.

5

WHEN INSTALLING GROUND LEADS ON EN IV SYSTEMS, THE BLOWER CONTROL GROUND

AND ECU GROUND MUST BE CONNECTED DIRECTLY TO THE NEGATIVE BATTERY POST.

THE HEATER CONTROL VALVE IS A NORMALLY OPEN VALVE. IT MUST BE CONNECTED TO

THE ECU TO BLOCK WATER FLOW IN AC MODE.

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 5 OF 26

G

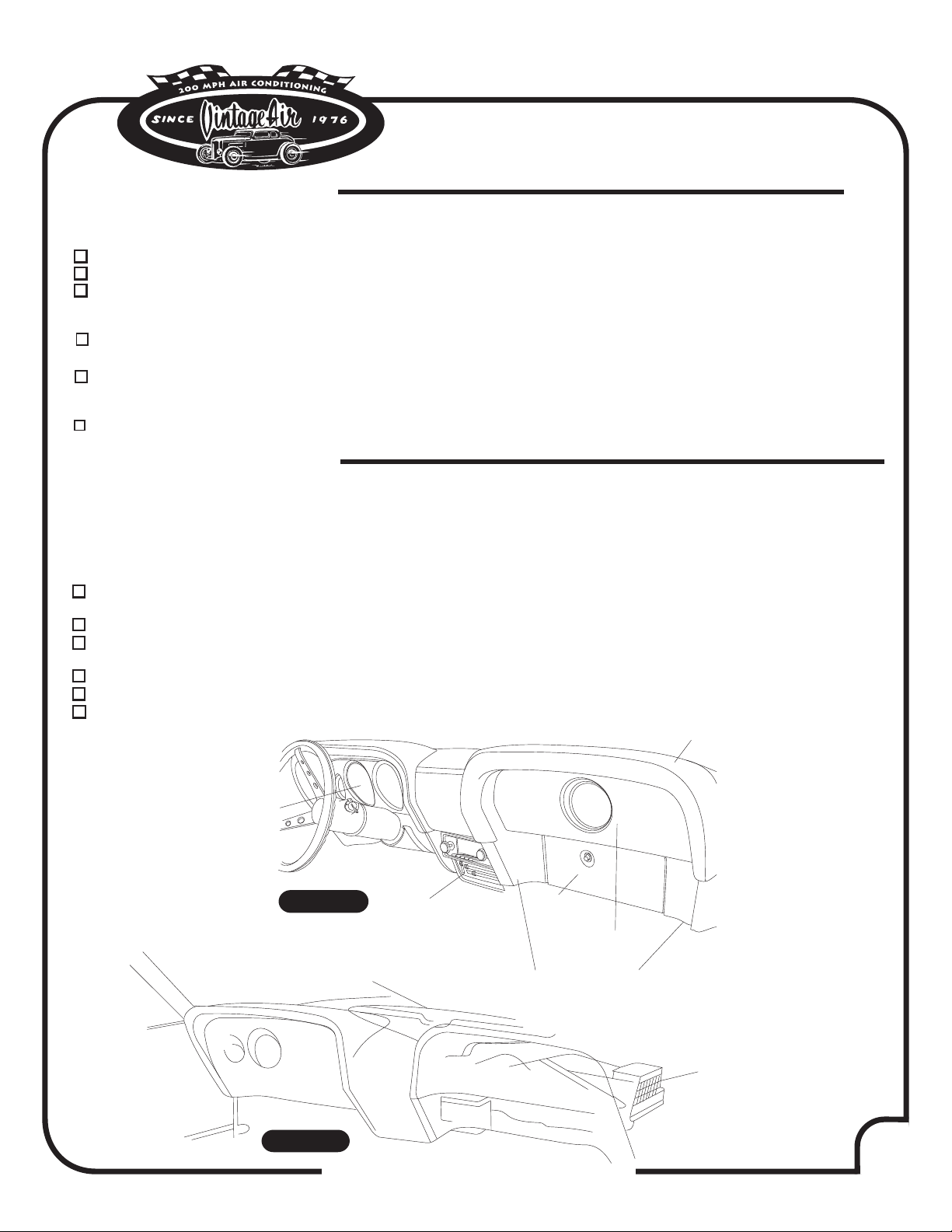

1969-70 MUSTANG w/o AC GEN IV

BEFORE STARTING THE INSTALLATION, CHECK THE FUNCTION

OF THE VEHICLE (HORN, LIGHTS,ETC.) FOR PROPER OPERATIONS.

STUDY THE INSTRUCTIONS, ILLUSTRATIONS, & DIAGRAMS.

ENGINE COMPARTMENT

REMOVE THE FOLLOWING:

BATTERY (RETAIN).

DRAIN RADIATOR

HEATER HOSES(DISCARD).

CONDENSER ASSEMBLY & INSTALLATION

REFER TO SEPARATE INSTRUCTIONS INCLUDED WITH

THE CONDENSER KIT TO INSTALL THE CONDENSER.

BINARY SWITCH INSTALLATION ( REFER TO CONDENSER INSTRUCTIONS)

COMPRESSOR & BRACKETS

REFER TO SEPARATE INSTRUCTIONS INCLUDED WITH THE

BRACKET KIT TO INSTALL THE COMPRESSOR BRACKET.

PASSENGER COMPARTMENT

NOTE: REMOVAL OF DASHBOARD REQUIRED TO INSTALL THE EVAPORATOR. VINTAGE AIR

RECOMMENDS THAT YOU UTILIZE THE FACTORY SERVICE MANUAL WHEN YOU DISASSEMBLE

AND REASSEMBLE THE DASHBOARD.

REMOVE THE FOLLOWING:

REMOVE DASH PAD, INSTRUMENT PANEL, PASSENGER SIDE PANEL AND LOWER PASSENGER SIDE

DASHBOARD (RETAIN SCREWS) SEE FIGURE 1.

GLOVE BOX (RETAIN) SEE FIGURE 1.

HEATER ASSEMBLY AND ALL RELATED DUCTING (DISCARD), RETAIN SCREWS.

SEE FIGURE 2.

CONTROL PANEL ASSEMBLY (RETAIN CONTROL PANEL) SEE FIGURE 1.

REFER TO CONTROL PANEL CONVERSION KIT INSTRUCTIONS FOR INSTALLATION OF CONTROLS.

REMOVE OEM DEFROST DUCT ASM SEE FIGURE 2.

DASH PAD

INSTRUMENT

PANEL

FIGURE 1

DEFROST DUCT

ASM

CONTROL

PANEL

GLOVE

BOX

PASSENGER SIDE

PANEL

LOWER PASSENGER

SIDE DASHBOARD

FIGURE 2

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 6 OF 26

HEATER

ASSEMBLY

6

1969-70 MUSTANG w/o AC GEN IV

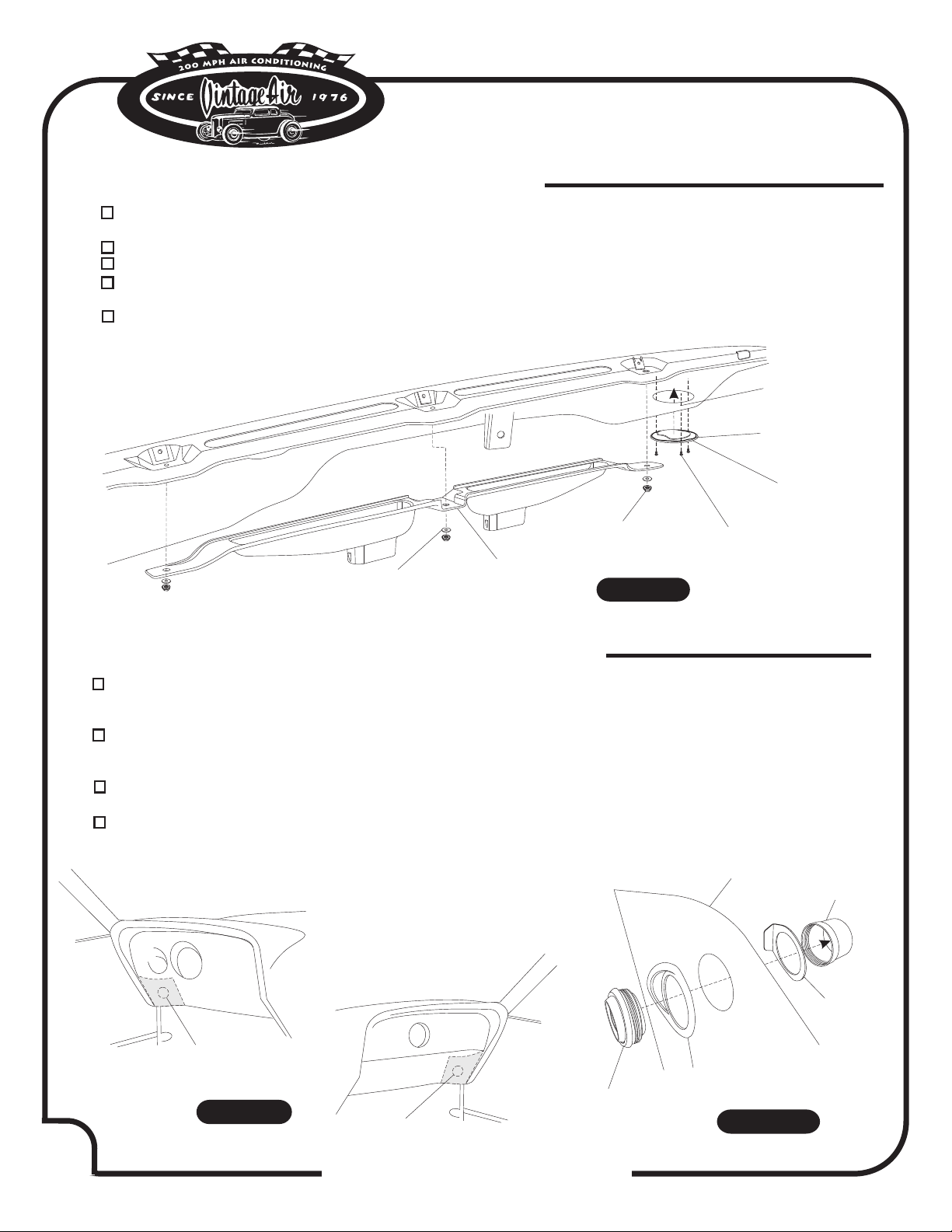

DEFROST DUCT/ FRESH AIR CAP INSTALLATION

INSTALL DEFROST DUCT UNDER DASH AS SHOWN IN FIGURE 3 BELOW. SECURE USING OEM NUTS

w/ (3) 3/16 SAE FLAT WASHERS.

HOLD FRESH AIR CAP UNDER DASH AND MARK THE (3) MOUNTING HOLES.

DRILL (3) 1/8” MOUNTING HOLES UNDER DASH.

PPLY A 1/4” BEAD OF SILICONE AROUND THE BACK SIDE OF THE FRESH AIR CAP AS SHOWN IN

A

FIGURE 3, BELOW.

SECURE FRESH AIR CAP TO FRESH AIR HOLE USING (3) #10 X 1/2 SHEET METAL SCREWS AS SHOWN

IN FIGURE 3 BELOW.

(3) 3/16

SAE FLAT

WASHERS

DEFROST

DUCT

605169

(3) OEM

STAR NUTS

FIGURE 3

(3) 10 X 1/2

SHEET METAL

SCREW

DRILL

HOLES

SILICONE

FRESH AIR

605174

DRIVER AND PASSENGER SIDE LOUVER INSTALLATION

CUT OUT TEMPLATE PROVIDED ON PAGE 22. PLACE THE DRIVER SIDE TEMPLATE ON THE DASH BY

ALIGNING THE LEFT SIDE OF THE TEMPLATE AGAINST THE EDGE OF THE DASH, THEN ALIGN THE

BOTTOM OF THE TEMPLATE TO BOTTOM OF DASH AS SHOWN IN FIGURE 4.

CUT OUT TEMPLATE PROVIDED ON PAGE 23. PLACE THE PASSENGER SIDE TEMPLATE ON THE DASH

BY ALIGNING THE RIGHT SIDE OF THE TEMPLATE AGAINST THE EDGE OF THE DASH, THEN ALIGN

THE BOTTOM OF THE TEMPLATE TO BOTTOM OF DASH AS SHOWN IN FIGURE 4.

ONCE TEMPLATE IS ALIGNED CORRECTLY, USE A CENTER PUNCH TO MARK THE HOLE ON THE

DASH. REMOVE TEMPLATE. USE A 2 3/4 HOLE SAW TO CUT HOLE IN DASH, SEE FIGURE 4 BELOW.

INSTALL LOUVERS IN DASH AS SHOWN IN FIGURE 4a BELOW.

CAP

7

DRIVER SIDE

TEMPLATE

DRILL 2 3/4

HOLE

FIGURE 4

PASSENGER SIDE

TEMPLATE

LOUVER

DRILL 2 3/4

HOLE

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 7 OF 26

490535

DASH

LOUVER BEZEL

605181

FIGURE 4a

2 1/2 HOSE

ADAPTER

LOUVER BRKT

642075

1969-70 MUSTANG w/o AC GEN IV

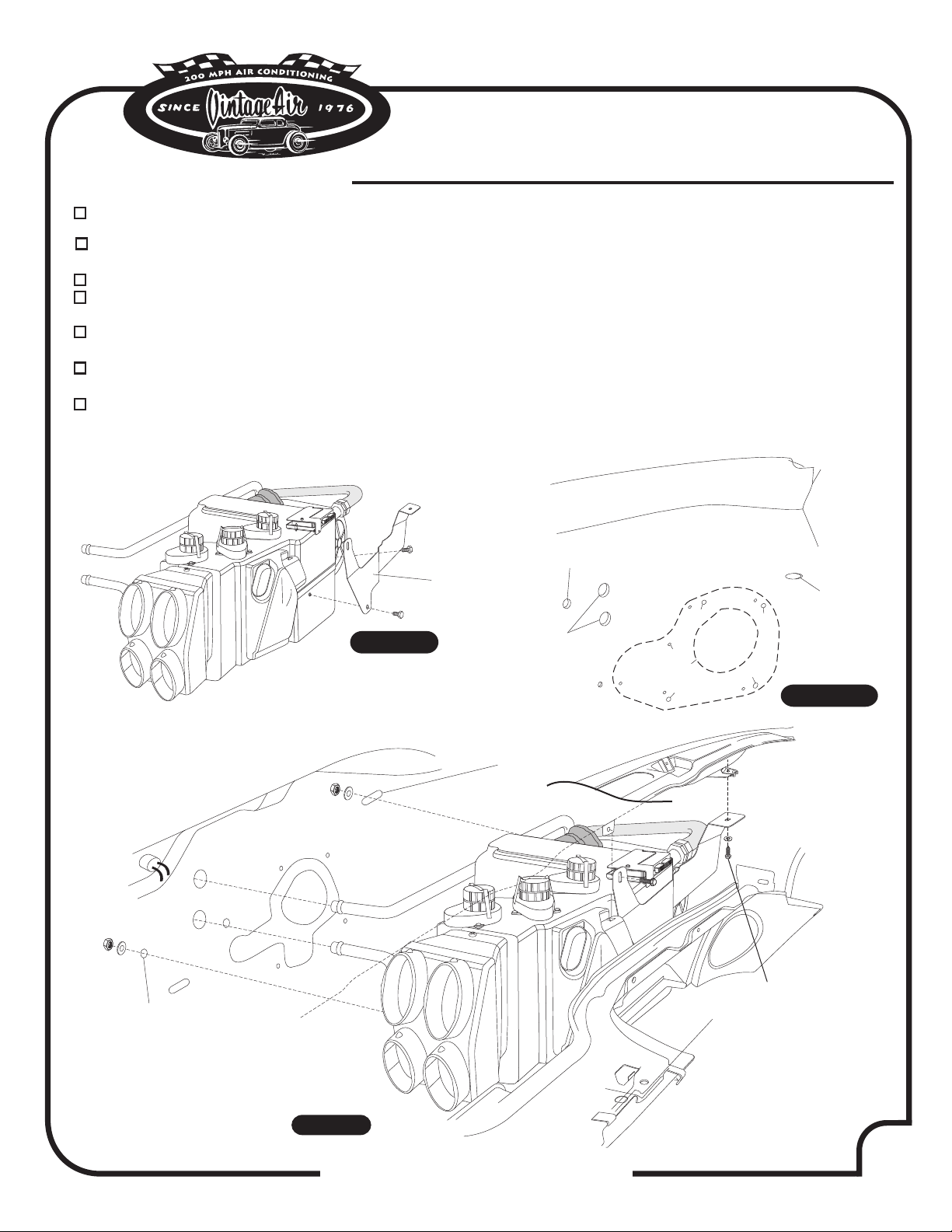

EVAPORATOR INSTALLATION

USE TEMPLATE PROVIDED ON PAGE 25. ALIGN TEMPLATE WITH OEM BLOWER MOTOR MOUNTING

HOLES & DRILL (6) 3/16 HOLES IN FIREWALL FROM INSIDE UNDER DASH, SEE FIGURE 5a.

ON A WORK BENCH, INSTALL EVAPORATOR REAR BRACKET AND HARDLINES WITH PROPERLY LUBRICATED O-RINGS.

(SEE FIGURE 10, PAGE 11, AND FIGURE 15, PAGE 16.)

REMOVE 2 OEM HEATER PLUGS IN FIREWALL, SEE FIGURE 7 PAGE 9.

INSTALL FRONT MOUNTING BRACKET ON EVAPORATOR USING (2) 1/4-20 X 1/2 HEX BOLTS AND TIGHTEN AS

SHOWN IN FIGURE 5 BELOW.

LIFT EVAPORATOR UNIT UP UNDER THE DASHBOARD SEE FIGURE 6. SECURE LOOSELY TO THE FIREWALL FROM THE

ENGINE COMPARTMENT SIDE USING (2) 1/4-20 NUT AND WASHER, SEE FIGURE 6 BELOW.

USING (2) #14 X 3/4 SHEET METAL SCREW w/ 1/4 FLAT WASHER SECURE THE FRONT EVAPORATOR MOUNTING

BRACKET TO THE INNER COWL. SEE FIGURE 6 BELOW.

VERIFY THAT EVAPORATOR UNIT IS LEVEL AND SQUARE TO THE DASH, THEN TIGHTEN ALL MOUNTING BOLTS.

(NOTE: TIGHTEN THE BOLT ON FIREWALL FIRST, THEN THE FRONT MOUNTING BRACKET SCREWS.)

DRIVER SIDE EVAP

MOUNTING HOLE

EVAP

FIGURE 5

DRIVER SIDE EVAP

MOUNTING HOLE

T

271

OEM HEATER

LINE HOLES

FRONT

BRK

641

PASSENGER SIDE EVAP

MOUNTING HOLE

1969-7

0 MUST

FIREWALL COVE

HOLE TEMPL

ANG w/o AC

ATE

NMENT HOLES

(4) ALIG

BLOWER MOTOR

G

MOUNTIN

HOLE

(6) 3/16

HOLES

R

OEM HEATER

HOLE

BLOWER

MOTOR

SIDE OF CAR

MOUNTING

THIS SIDE IN

HOLE

(2) #

SHE

PASSENGER SIDE EVAP

MOUNTING HOLE

BLOWER

MOTOR

MOUNTING

HOLE

BLOWER

MOTOR

MOUNTING

HOLE

FIGURE 5a

3/4

14 X

AL

ETMET

SCREW

/4

w/ 1

ASHER

T W

FLA

FIGURE 6

901271 REV A 2/11/08, 69-70 MUSTANG w/o AC GEN IV EVAP INSTR PG 8 OF 26

8

Loading...

Loading...