Vinotemp Wine-Mate WM-6500DS, Wine-Mate WM-12030DS, Wine-Mate WM-4500DS-LA, Wine-Mate WM-6500DS-LA, Wine-Mate WM-12030DS-LA Operation Care Installation Manual

...

wwwwww..vviinnootteemmpp..ccoomm

RReeaadd aanndd ssaavvee tthheessee iinnssttrruuccttiioonnss

Packaged Central-Ducted Cooling System

Operation Care Installation Manual

WM-4500DS WM-6500DS WM-8500DS WM-12030DS

WM-4500DS-LA WM-6500DS-LA WM-8500DS-LA WM-12030DS-LA

Vinotemp International Corp

732 S Racetrack Road, Henderson, NV 89015

Tel: (800) 777-VINO Email: info@vinotemp.com

- 1 -

Important Safety Information

- 2 -

Table of Contents

Cellar Construction.…………………………….……………..3

Features & Specifications…………………….….…………..4

Temperature & Humidity……….…………..………..……….6

Care Guide…………………………………………………….10

User’ Troubleshooting…….………………………………...11

Installer’s Instructions………….…..….……..…………….14

Service Instructions…………………………….……………18

Electrical Wirings..…………….…..….……..………………25

Customer Support……………………………………………27

Warranty……………………………………………………….28

- 3 -

Cellar Construction Guide

This is only a guide and shall be considered as the minimum requirements.

All interior walls, ceilings and floors shall have a vapor barrier and a minimum of

R13 insulation. All exterior walls and ceiling shall have a vapor barrier and a

minimum of R19 insulation. The vapor barrier shall be installed on the warm side

of insulation. All joints, door frames, electrical outlets or switches and any pipes

or vents that go through the cellar shall be sealed to prevent air and moisture

leaking into the cellar. Concrete, rock, and brick are not insulations or vapor

barriers. Doors shall be of a minimum size, insulated to at least R13 and tightly

sealed with high quality weather stripping. Be sure to seal the bottom of the door

and fill gap between the door’s frame and wall before installing the cap molding.

In order to maintain 55 °F in the wine cellar, the ambient temperature

surrounding the cellar shall not exceed the temperature of the cellar by more

than 25 °F. No cellar walls shall receive direct sun or strong wind.

Lighting shall be of low wattage, with a timer to insure lights are not left on when

the cellar is not occupied.

The cooling system will not be able to maintain the proper temperature if fresh

moisture-laden air is constantly being introduced to the cellar. Symptoms of this

condition are; cooling unit runs all the time with only a slight reduction in

temperature and/or water overflows from the cooling unit. Because of the

temperature difference between the inside and outside, very small cracks can

allow large amounts of outside air to enter into the cellar. Please be aware that

moisture can pass through solid concrete, paint and wood. Often a newly

constructed cellar contains fresh wood, paint, concrete and other building

materials. These materials contain large amounts of moisture. When placed into

operation in this type of environment, the system will work harder to remove this

extra moisture resulting in increased “run” time.

- 4 -

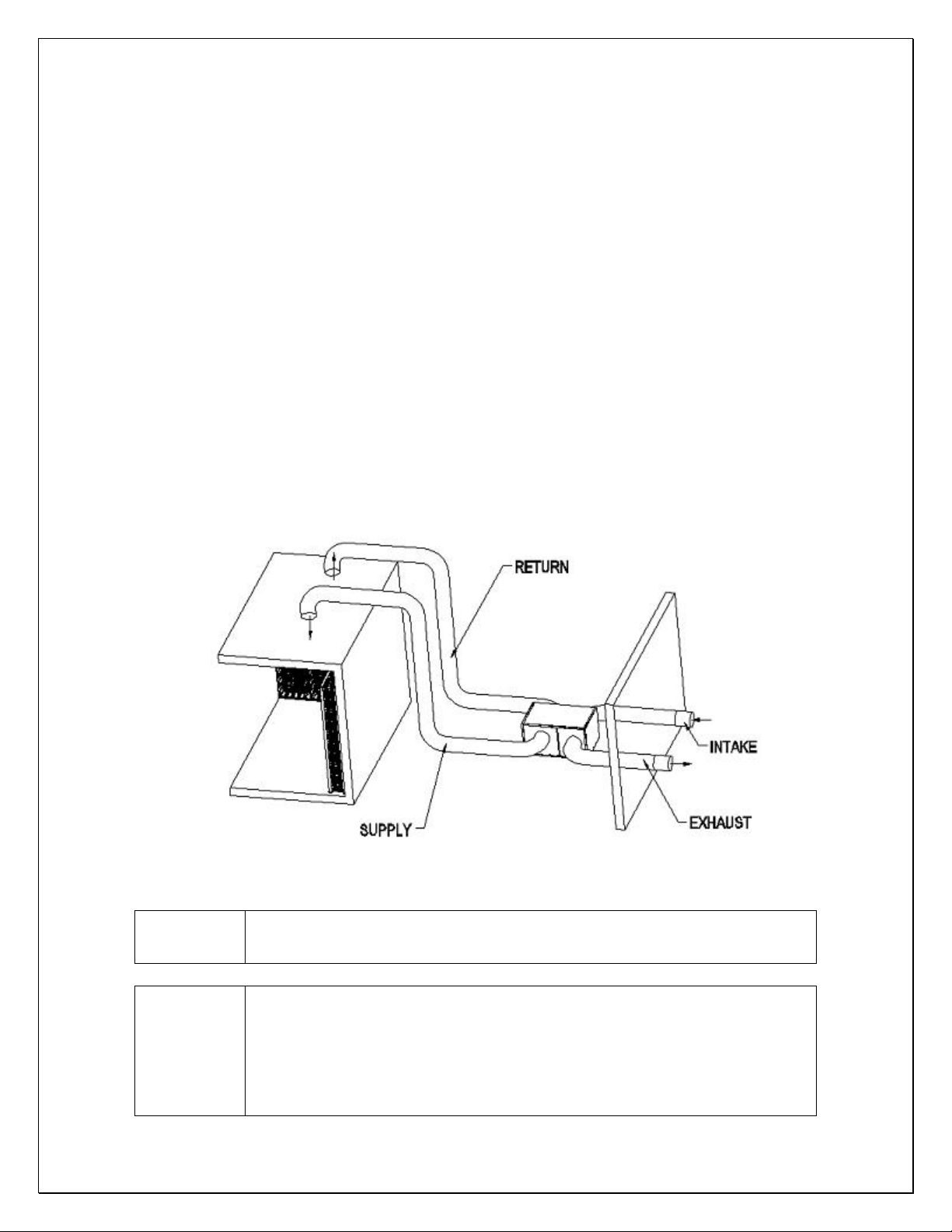

CAUTION

If the cooling unit operates below 50°F, a low ambient

condition kit will be required.

NOTE

The cooling capacity is determined using 55°F cellar

temperature, 75°F cellar ambient temperature, 90°F

condensing unit ambient temperature, R13 interior insulation

and R19 exterior insulations. Higher ambient temperatures or

lower insulations will cause reducing capacity and the cellar

temperature may not be maintained at 55°F.

Features and Specifications

• Wine-Mate packaged central-ducted cooling systems WM-4500~12030DS &

WM-4500~12030DS-LA are designed to provide a cold temperature between

50~65 °F with a humidity range within 50~70% RH for a properly insulated

wine cellar.

• These temperature and humidity ranges are optimized for long term storage

of wine like that in natural caves.

• It is self-contained ready for use and no additional refrigeration tubing is

required in the field.

• The cooling systems are designed to provide chilled air to a wine cellar

through insulated ducts to provide quieter operation and better installation

flexibility.

• The cooling systems can be installed up to 25 ft away from the cellar since

the back-curved impeller fans are so powerful to run a total duct length of 50

ft.

• The cooling systems can be installed both outdoors and indoors.

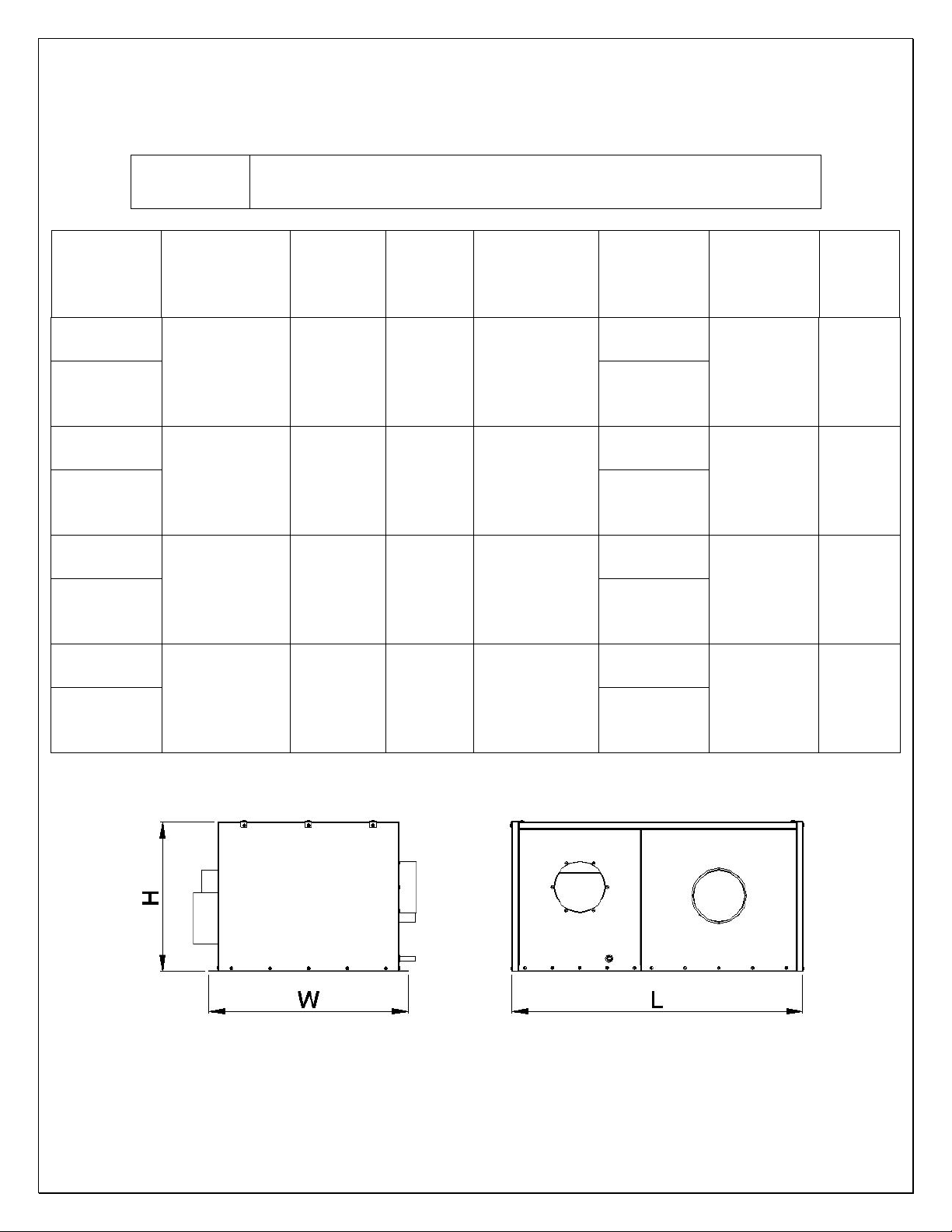

Fig. 1 DS Packaged Central-Ducted Cooling System

- 5 -

NOTE

“LA” refers the unit equipped with a low ambient kit.

Model No

Dimensions

L” x W” x H”

Capacity

(Btu/h)

Airflow

(CFM)

Cellar

Size

(cu ft)

Refrigerant

Electrical

Rating

Min

Circuit

Ampacity

Weight

(lb)

WM-

4500DS

45 x 34 x 23

4500

380

1000

R134a

115V-

60Hz-8A

20A

140

WM-

4500DS-

LA

115V-

60Hz-9A

WM-

6500DS

45 x 34 x 23

6500

490

1500

R134a

115V-

60Hz-14A

30A

170

WM-

6500DS-

LA

115V-

60Hz-15A

WM-

8500DS

45 x 34 x 25

8500

750

2000

R134a

115V-

60Hz-17A

30A

220

WM-

8500DS-

LA

115V-

60Hz-18A

WM-

12030DS

45 x 34 x 25

12000

810

3300

R134a

230V-

60Hz-10A

20A

260

WM-

12030DS-

LA

230V-

60Hz-11A

The specifications and dimensions are listed as follows:

Fig. 2 WM-4500~12030DS Dimensions

- 6 -

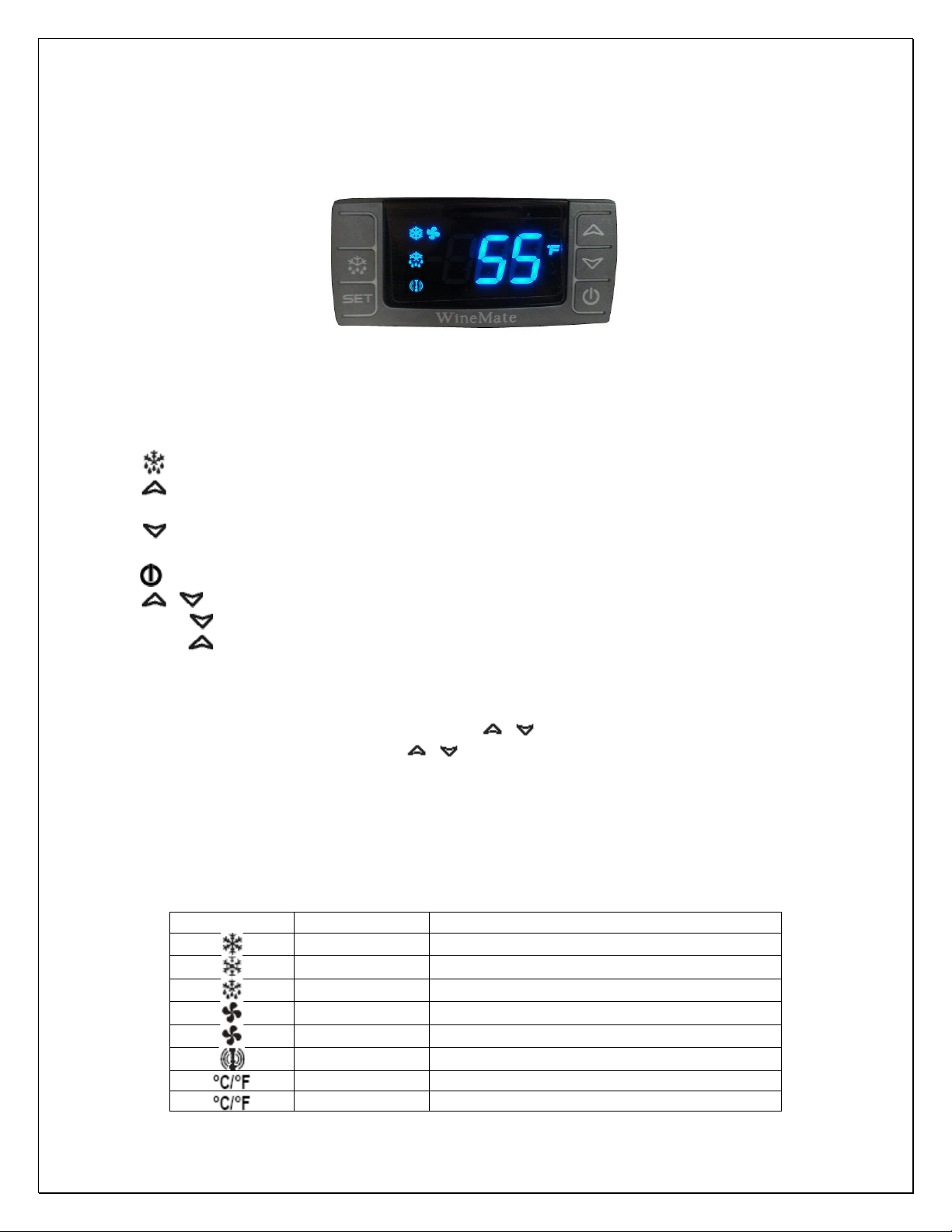

LED

MODE

FUNCTION

ON

Compressor enabled

Flashing

Anti-short cycle enabled

ON

Defrost enabled

ON

Fan enabled

Flashing

Fan delay after defrost enabled

ON

Alarm occurring

ON

Temperature measuring unit

Flashing

Programming mode

Temperature and Humidity

1. The controller

Fig. 3 TEMPERATURE CONTROLLER

1) Keys

SET: To display set-point; in programming mode it selects a parameter or

confirms an operation.

: To start a manual defrost.

: To see the maximum stored temperature; in programming mode it browses

the parameter codes or increases the displayed value.

: To see the minimum stored temperature; in programming mode it browses

the parameter codes or decreases the displayed value.

: To turn on/off the power to the unit.

+ : To lock/unlock the keypad.

SET+ : To enter in the programming mode.

SET+ : To return to the temperature display.

2) Lock and unlock the keys

To lock the keys, press up + down keys + until POF is displayed; to unlock

the keys, press up + down keys + until PON is displayed.

3) Display

During normal operating conditions, the display shows the value measured by

the air temperature probe. In case of active alarm, the temperature flashes

alternately to the code alarm. The LED functions are listed as follows.

- 7 -

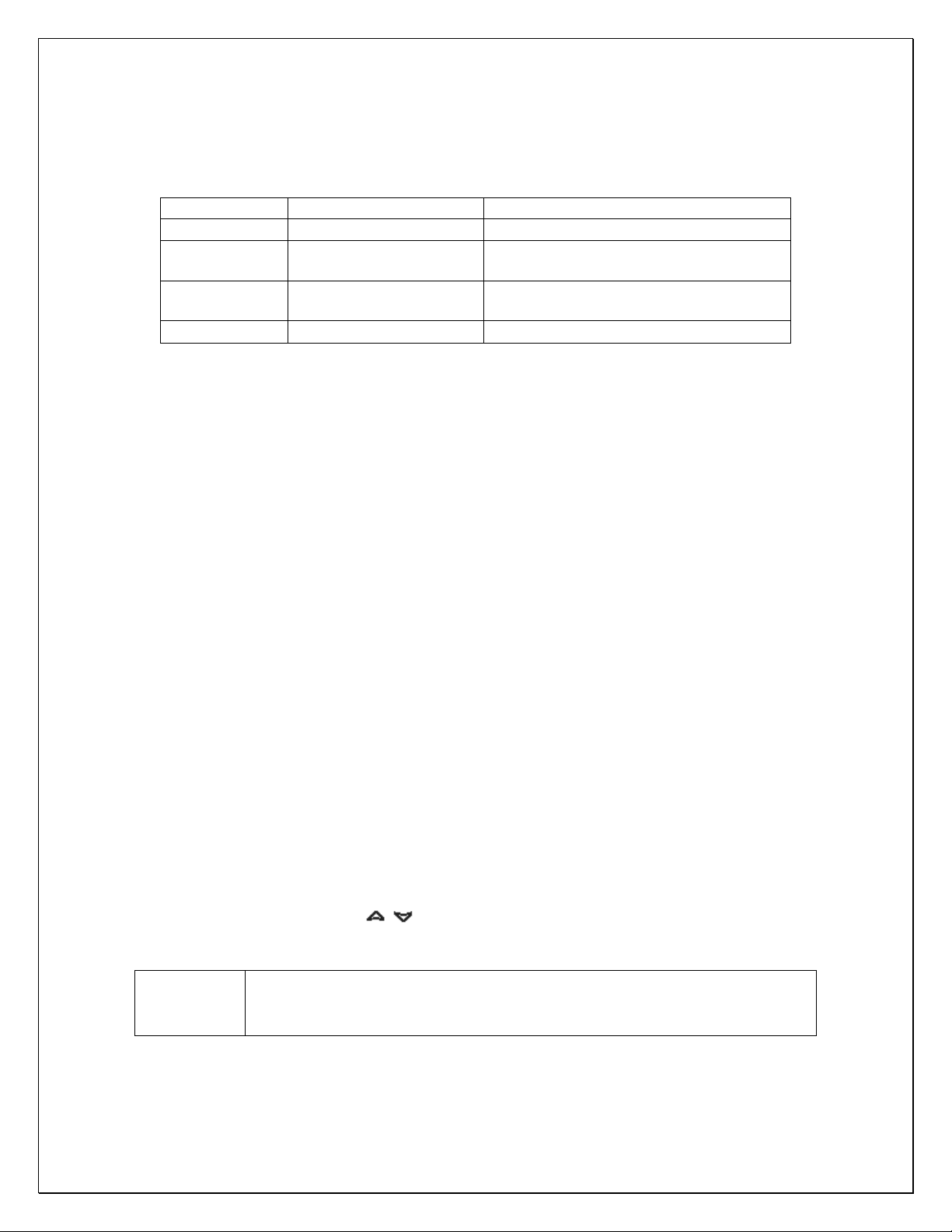

MESSAGE

CAUSE

FUNCTION

P1

Temperature probe faulty

Compressor switching to Con and CoF

HA

High temperature alarm

Probe temperature ALU higher than the

setting temperature; Outputs unchanged

LA

Low temperature alarm

Probe temperature ALL lower than the

setting temperature; Outputs unchanged

CA

External alarm

All outputs off

NOTE

The unit turns on at set-point Set plus regulation differential

Hy after anti-short cycle AC has elapsed; the unit turns off at

set-point Set.

4) Alarm Signals

The alarm codes are described as follows.

Probe alarms P1”, start a few seconds after the fault in the related probe; they

automatically stop a few seconds after the probe restarts normal operation.

Check connections before replacing the probe. Temperature alarms “HA”, “LA”

automatically stops as soon as the temperature returns to normal value. Alarm

“CA” (with i1F=PAL) recovers only by switching off and on the instrument.

2. Temperature Setting

• Set the temperature at 55 °F for the optimum aging of wine

• On initial start-up, the time required to reach the desired temperature will

vary, depending on the quantity of bottles, temperature setting and

surrounding temperature.

• Allow 24 hours to stabilize the temperature for each new temperature setting

operation

3. How to see temperature set-point

1) Press and immediately release the SET key, the display will show the set-point

value.

2) Press again and immediately release the SET key to display the probe value.

4. How to change the set-point

1) Press and hold the SET key until the “°C” or “°F” LED starts flashing and the

set-point is displayed.

2) Press the up/down keys / to change the set-point value within 10 sec.

3) Press the SET key again to store the new set-point value.

:

- 8 -

PARAMETER

DESCRIPTION

DEFAULT VALUE

Set

set-point (°)

55

Hy

temperature regulation differential (°)

4

AC

anti-short cycle delay (min)

10 (hidden)

Con

compress on with probe faulty (min)

15

CoF

compress off with probe faulty (min)

30

CF

temperature unit (°F/ °C)

F: Fahrenheit

rES

display resolution

in: integer

dLy

temperature display delay (min)

1

ot

probe calibration (°)

0

LS

minimum set-point (°)

50

US

maximum set-point (°)

65

idF

defrost interval time (hour)

12

MdF

defrost endurance time (min)

30

ALC

temperature alarm type

rE: relative to set-point

ALU

high temperature alarm (°)

10

ALL

low temperature alarm (°)

10

AFH

alarm recovery differential (°)

5

ALd

temperature alarm delay (min)

60

dAO

temperature alarm delay on startup (hr)

23

SAA

heater set-point (°)

40

SHy

heater regulation differential (°)

4

FSU

fan action

Std

FnC

fan operating mode

C-n: on with compressor & off during defrost

Fon

fan on with compressor off (min)

0

FoF

fan off with compressor off (min)

15

NOTE

Depending on the controller, not all parameters are available

5. Manual Defrost

Press and hold the defrost key until defrost starts. The defrost indicator will be

on.

6. Parameter Programming

1) Press and hold the SET + keys until the “°C” or “°F” LED starts flashing,

then release the keys.

2) Press and hold again the SET + keys until the Pr2 label is displayed, then

release the keys. The first parameter Hy will be displayed.

3) Press up/down keys / to scroll to the required parameter within 10 sec.

4) Press the “SET” key to display its value.

5) Use up/down keys to change its value within 10 sec.

6) Press “SET” to store the new value and the display will flash 3 times.

7) To exit: Press SET + or wait 15sec without pressing a key.

Loading...

Loading...