Vinotemp VINO2500CD, VINO2500CTED, VINO1500CTED, WINE-MATE VINO-4500SSR, WM-2500CD Use And Care Manual

WINE-MATE Cooling Unit

Use & Care Manual

VINO1500CD, CTED

VINO2500CD, CTED

VViinnootteemmpp IInntteerrnnaattiioonnaall CCoorrpp..

wwwwww..vviinnootteemmpp..ccoomm

wwwwww..wwiinneemmaattee..ccoom

m

Important Safety Information

• DO NOT PLUG IN UNTIL 24 HOURS AFTER DELIVERY.

• DO NOT USE A GROUND FAULT INTERRUPTER (GFI).

• A DEDICATED 20 AMP CIRCUIT IS REQUIRED.

- 1 -

TABLE OF CONTENTS

Features & Specifications…………….………….…………..3

Installation Instruction………………………………………..5

Temperature Control & Humidity Adjustment………….9

Care Guide……………………………………………………12

Troubleshooting……………………………………………..13

Wiring Diagram……………………………………….………16

Customer Support……………………………………………17

Warranty……………………………………………………….18

- 2 -

Features and Specifications

• VINO1500CD, CTED and VINO2500CD, CTED cooling units are designed

and used to provide a subtle temperature between 50~65

space at a normal environment.

• The refrigerated space will maintain humidity of 50~70% RH even when

the environment becomes dry and humid.

• These temperatures and humilities ar e optimized for long term storage of

wine.

• Bottom cold-air supply is optimized for use in the wine cabinets.

• Multiple options for top and rear hot air exhaust

• Self-contained ready for use and easy for installation

°F for suitable

- 3 -

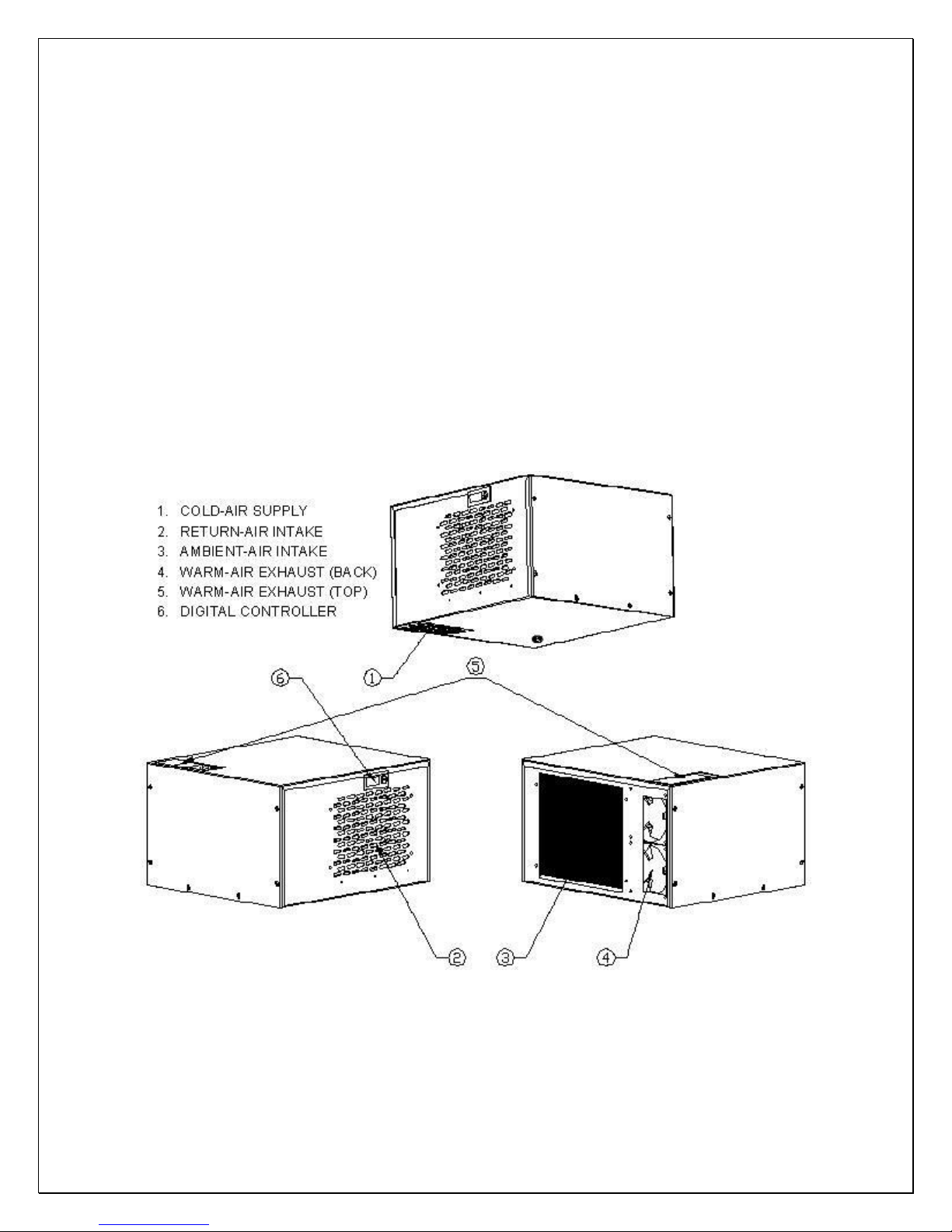

Fig. 1.1 FEATURES

Fig. 1.2 DIMENSIONS (in)

The dimension and capacity are specified as follows:

Model Exhaust CFM

Capacity cu ft

(55°F/75°F)

Electrical

Weight

(lb)

1500cd

1500cted Top Exhaust 120 90 115V/60Hz/4A 50

2500cd Rear Exhaust 180 200 115V/60Hz/5A 55

2500cted Top Exhaust 180 200 115V/60Hz/5A 55

Rear Exhaust

120 90 115V/60Hz/4A 50

NOTES:

• See the voltage, frequency and current specified on the label at the

cooling unit.

• Capacity is determined under the cabinet and ambient temperatures of

55°F and 75°F with R11 interior and R19 exterior insulations. Any lower

cabinet and higher ambient temperatures will reduce the capacity.

- 4 -

Installation Instruction

NOTES:

1) DO NOT INSTALL ANY DUCTS ONTO THE SUPPLY, INTAKE AND

EXHAUST.

2) MOUNTING BRACKETS, SCREWS, GASKETS AND OTHER SEAL

MATERIALS ARE NOT INCLUDED.

3) THERE IS A GROMMET ON THE POWER CORD. PRESS AND FIT THE

GROMMET INTO THE HOLE AT THE BOTTOM OF THE COOLING UNIT

TO SEAL THE EXHAUST AIR NOT GOING TO THE CABINET.

1. Cabinet Location

• Place the wine cabinet in a properly ventilated location. Otherwise, heat

exhausted by the cooling unit will build up and it will not operate properly.

• The exhaust area must not be a closed space and must be ventilated. The

ambient temperatures shall not be higher than 78°F for a VINO-1500CD

unit and 95°F for a VINO-2500CD unit or lower than 50 °F.

1) Rear Exhaust Location

• Leave min 6 “clearance from the rear to the wall.

• Leave min 12” clearance from the top to the ceiling.

• Leave min 6” clearance from the left and right sides.

2) Front Exhaust Location

• Leave min 6” clearance from the front if left and right sides unobstructed.

• Or, leave min 36” clearance from the front if left and right sides obstructed

3) Top Exhaust Location

• Leave min 12” from the top to the ceiling.

• Leave min 2 “clearance from the rear to the wall.

• Leave min 2” clearance from the left and right sides.

4) Side Exhaust Location

• Leave min 6 “clearance from the left or right side to the wall.

• Leave min 12” clearance from the top to the ceiling.

2. Cooling Unit Installation

• The cooling unit produces cooling supplied into the cabinet, and it also

generates heat that must be exhausted outside the cabinet. So the cold

supply side and hot exhaust side must be separated and sealed (see Fig.

2.1). Foam tape may be used to seal them. The cooling unit must intake

adequate fresh ambient-air to work properly. The ambient-air intake and

warm-air exhaust must not be short-circulated. A piece of wood may be

used to separate them.

- 5 -

Loading...

Loading...