Vinotemp Wine-Mate VINO4500SSR, Wine-Mate VINO2500-4500SSR, Wine-Mate VINO2500-2500SSR, Wine-Mate VINO2500-6500SSR, Wine-Mate VINO2500SSR Installation & Operation Manual

...

wwwwww..wwiinneemmaattee..ccoomm

WINE-MATE Split System

Installation, Operation & Care Manual

VINO2500SSR VINO4500SSR VINO6500SSR

VViinnootteemmpp IInntteerrnnaattiioonnaall CCoorrpp..

READ AND SAVE THESE INSTRUCTIONS

wwwwww..vviinnootteemmpp..ccoomm

TABLE OF CONTENTS

Important Safety Information…..........................................2

Features & Specifications.…………………….……………..3

Cellar Construction.…………………………….……………..6

Installer’s Instruction…………….…..….……..……………..8

Electrical Wiring...……………..…..….……..………………15

Temperature Control & Humidity Adjustment.………….19

Care Guide…………………………………………………….22

User’ Troubleshooting…….………………………………...23

Customer Support……………………………………………26

Warranty……………………………………………………….27

- 1 -

Important Safety Information

WARNING:

• DO NOT USE A GROUND FAULT INTERRUPTER (GFI).

• A DEDICATED 20 OR 30 AMP CIRCUIT IS REQUIRED (2500-4500SSR OR

6500SSR).

- 2 -

MODEL

VINO-

2500SSR

VINO-

4500SSR

VINO-

6500SSR

Features and Specifications

• Wine-Mate split cooling systems VINO2500-6500SSR are designed and

used to provide a cold temperature between 50~65

insulated wine room at a normal environment.

• The wine room will maintain humidity of 50~70% RH even when the

environment becomes dry and humid. These temperatures and humilities

are optimized for long term storage of wine.

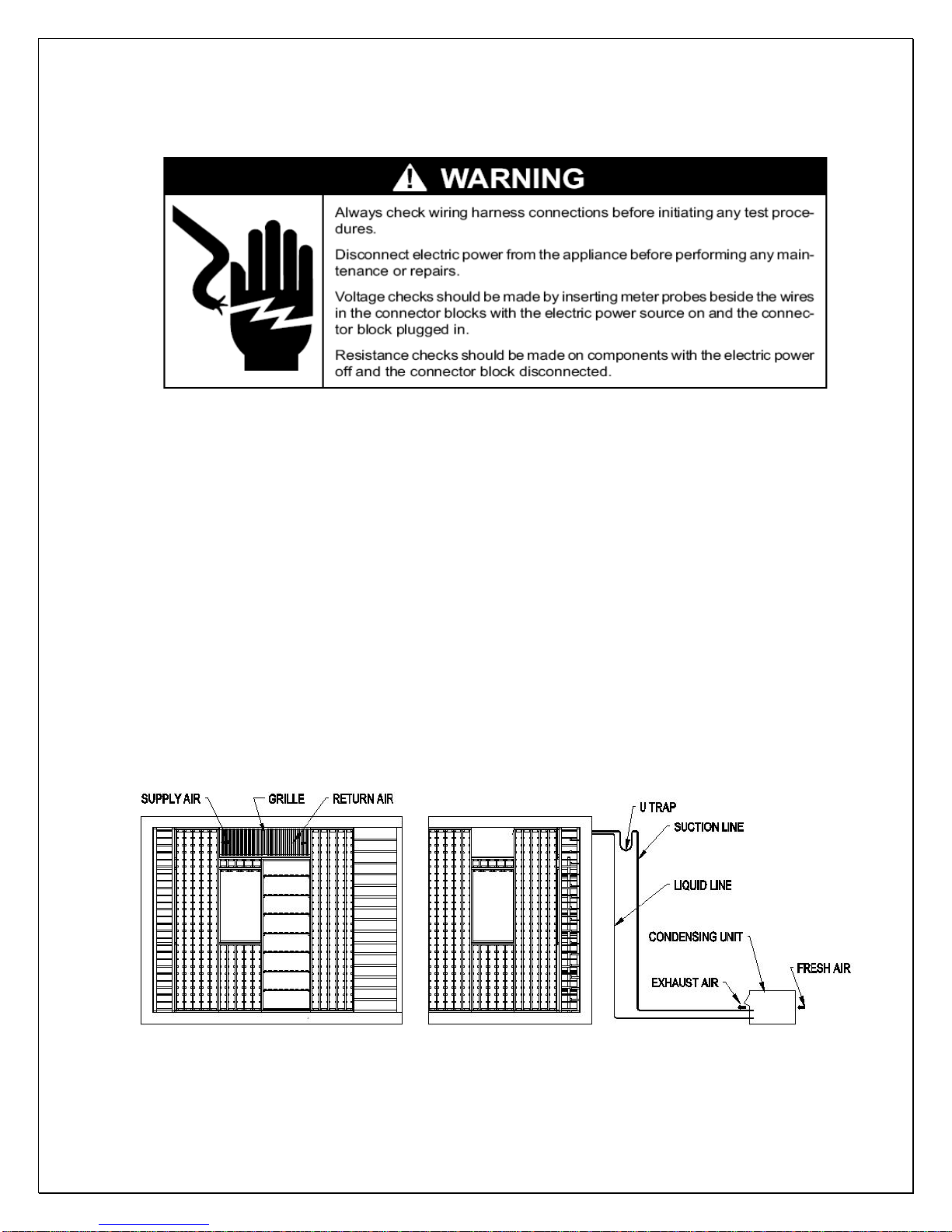

• SSR units consist of a condensing unit and an evaporator unit, and they

are connected by a liquid line and an insulated suction line.

• SSR condensing units can be located away from the evaporator units and

wine cellars as far as 50 ft, which will bring you quiet operation.

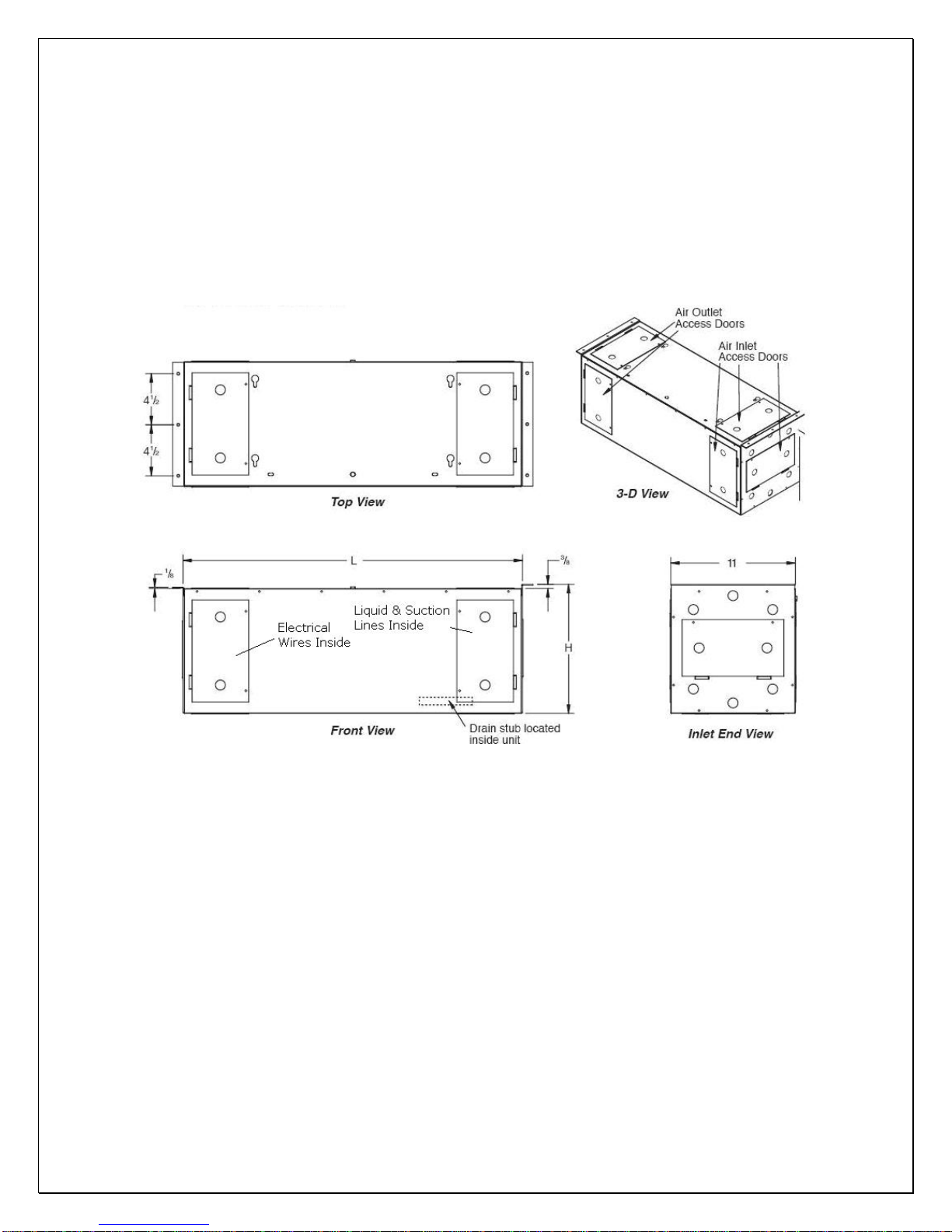

• The SSR evaporator units are designed for installation inside a wine rack

or between two ceiling joists, making them an ideal choice for small and

medium wine rooms. There are also multiple air inlet and outlet doors for

different installations.

The dimensions and capacities are specified as follows:

EVAP UNIT

L”xD”xH”

WM-

25SFCR

30x11.125

x11.375

WM-

45SFCR

36x11.125

x14.375

WM-

65SFCR

42x11.125

x14.375

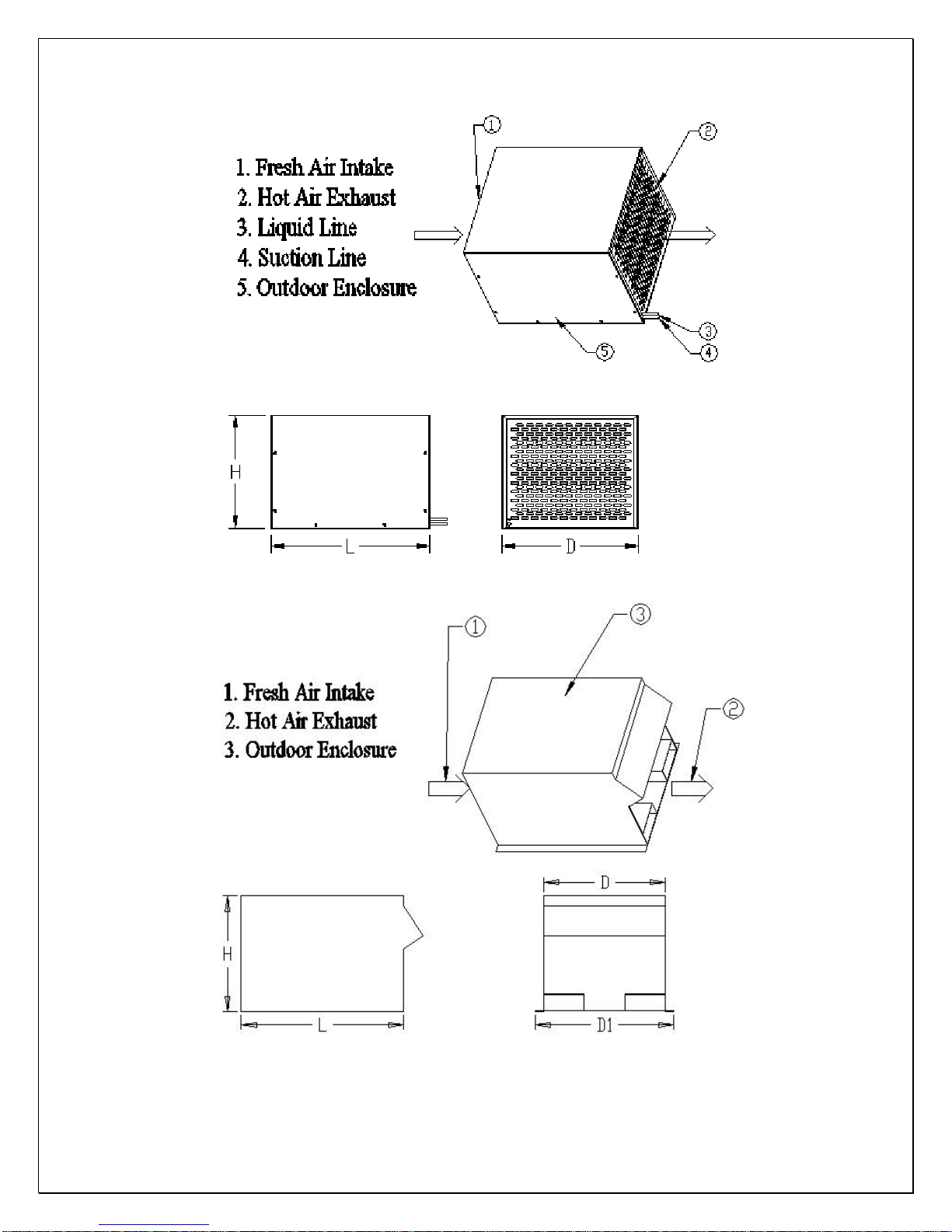

COND UNIT

L”xD”xH”

WM-250SCU

18x12x14

WM-450SCU

18x12x14

WM-650SCU

24x18 x17

Btu/h, CFM

(55/90°F)

2500/220 250 cu ft R134a

4500/335 1000 cu ft R134a

6500/420 1500 cu ft R134a

CAPACITY

(55/75°F)

REFRIGERANT

NOTE:

CAPACITY IS DETERMINED UNDER THE CELLAR AND AMBIENT

TEMPERATURES OF 55

°F AND 75°F WITH R11 INTERIOR AND R19

EXTERIOR INSULATIONS. ANY LOWER CABINET AND HIGHER AMBIENT

TEMPERATURES WILL REDUCE THE CAPACITY.

CAUTION:

LOW AMBIENT TEMPERATURE KIT IS REQUIRED IF THE INSTALLATION

AREA WILL BE BELOW 50

°F.

CAUTION:

LIQUID AND SUCTION LINES MAY DIFFER FROM WHAT ARE SHOWN

HERE, PLEASE CHECK ON THE UNITS FOR PROPER INSTALLATION.

°F for a properly

ELECTRICAL

EVAP UNIT/

COND UNIT

115V-60HZ-

0.77A /115V60HZ-5.7A

115V-60HZ-

0.77A /115V60HZ-6.9A

115V-60HZ-

1.9A /115V60HZ-12A

WEIGHT(lb)

EVAP UNIT/

COND UNIT

26/40

35/60

43/60

- 3 -

NOTE:

LEAVE MINIMUM 3” CLEARANCE FOR ELECTRICAL WIRING AND

REFRIGERATION PIPING.

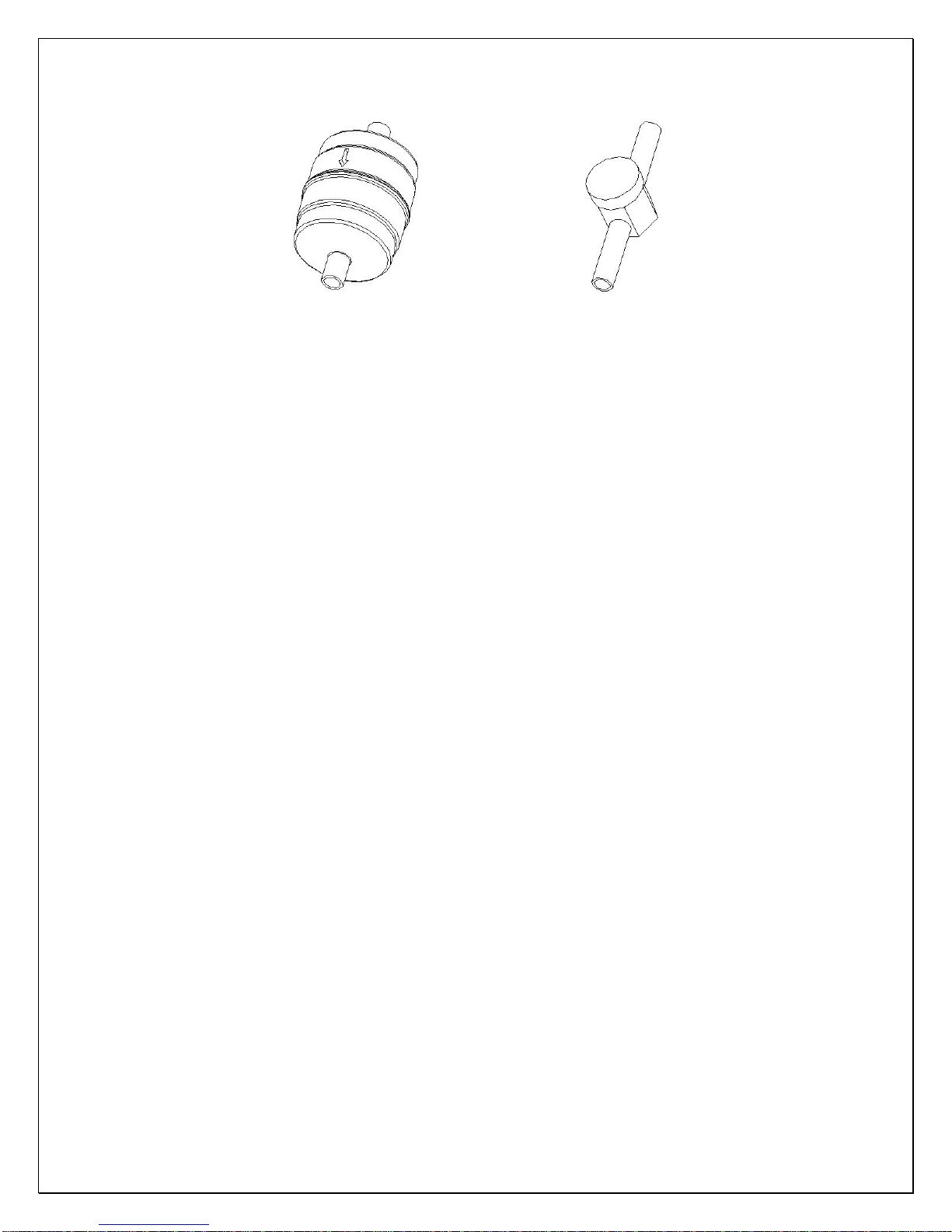

Parts included:

Condensing Unit (discharge and suction valves installed) + Liquid Filter + Liquid

Indicator

Evaporator Unit (liquid line solenoid valve and expansion valve installed)

Temperature Controller + Air Sensor

Fig. 1 WM25-65SFCR Evaporator Unit

- 4 -

Fig. 2 WM250-450SCU Condensing Unit

- 5 -

Fig. 3 WM650SCU Condensing Unit

Fig. 4 Liquid Filter Fig. 5 Liquid Indicator

- 6 -

Cellar Construction

This is only a guide and shall be considered as minimum requirements.

All interior walls and floors shall have a vapor barrier and a minimum of R11

insulation. All exterior walls and ceiling shall have a vapor barrier and a minimum

of R19 insulation. The vapor barrier shall be installed on the warm side of the

insulation. All joints, door frames, electrical outlets or switches and any pipes or

vents that go through the enclosure shall be sealed to prevent air and moisture

leakage into the room. Concrete, rock, and brick are not insulation or vapor

barriers.

Doors shall be of a minimum size, insulated to at least R11 and tightly sealed

with high quality weather stripping. Be sure to seal the bottom of the door and fill

gap between the door’s frame and wall before installing the cap molding.

In order to maintain 55 °F in the wine cellar, the ambient temperature

surrounding the enclosure shall not exceed the temperature of the enclosure by

more than 25 °F. No enclosure wall shall receive direct sun or strong wind.

Lighting shall be of low wattage, with a timer to insure lights are not left on when

the enclosure is not occupied.

The cooling system will not be able to maintain the proper temperature if fresh

moisture-laden air is constantly being introduced to the enclosure. Symptoms of

this condition are; unit runs all the time with only a slight reduction in temperature

and/or water overflows from the unit. Because of the temperature difference

between the inside and outside, very small cracks can allow large amounts of

outside air to enter into the enclosure. Please be aware that moisture can pass

through solid concrete, paint and wood. Often a newly constructed room contains

fresh wood, paint, concrete and other building materials. These materials contain

large amounts of moisture. When placed into operation in this type of

environment, the system will work harder to remove this extra moisture resulting

in increased “run” time.

- 7 -

Installer’s Instruction

Federal law requires that WINE-MATE split cooling systems be

installed by an EPA certified refrigeration technician.

WINE-MATE split system is shipped as components and is ready for use only

after a certified refrigeration technician has properly installed, evacuated,

charged and tested the system. Proper installation is critical. Vinotemp can only

warrant the quality of the components. The installation and proper operation of

the system must be warranted by the installer. Installation of the system must be

done in accordance with all state and local building and electrical codes.

The condensing unit and evaporator unit are connected by a liquid line and an

insulated suction line that are supplied by the installer. These lines must be

properly sized for the distance between the two units. After the units and the lines

are installed, the system must be pressure tested. If no leaks are found,

evacuate and charge system. Refrigerant amount will vary depending on the

length of line set.

- 8 -

Fig. 6 VINO-SSR Installation

Loading...

Loading...