Vinotemp WINE-MATE VINO2500HZD, WINE-MATE VINO1500HZD Service Manual

WINE-MATE Cooling Unit

Service Manual

VINO1500HZD

VINO2500HZD

Vinotemp International Inc.

www.winemate.com

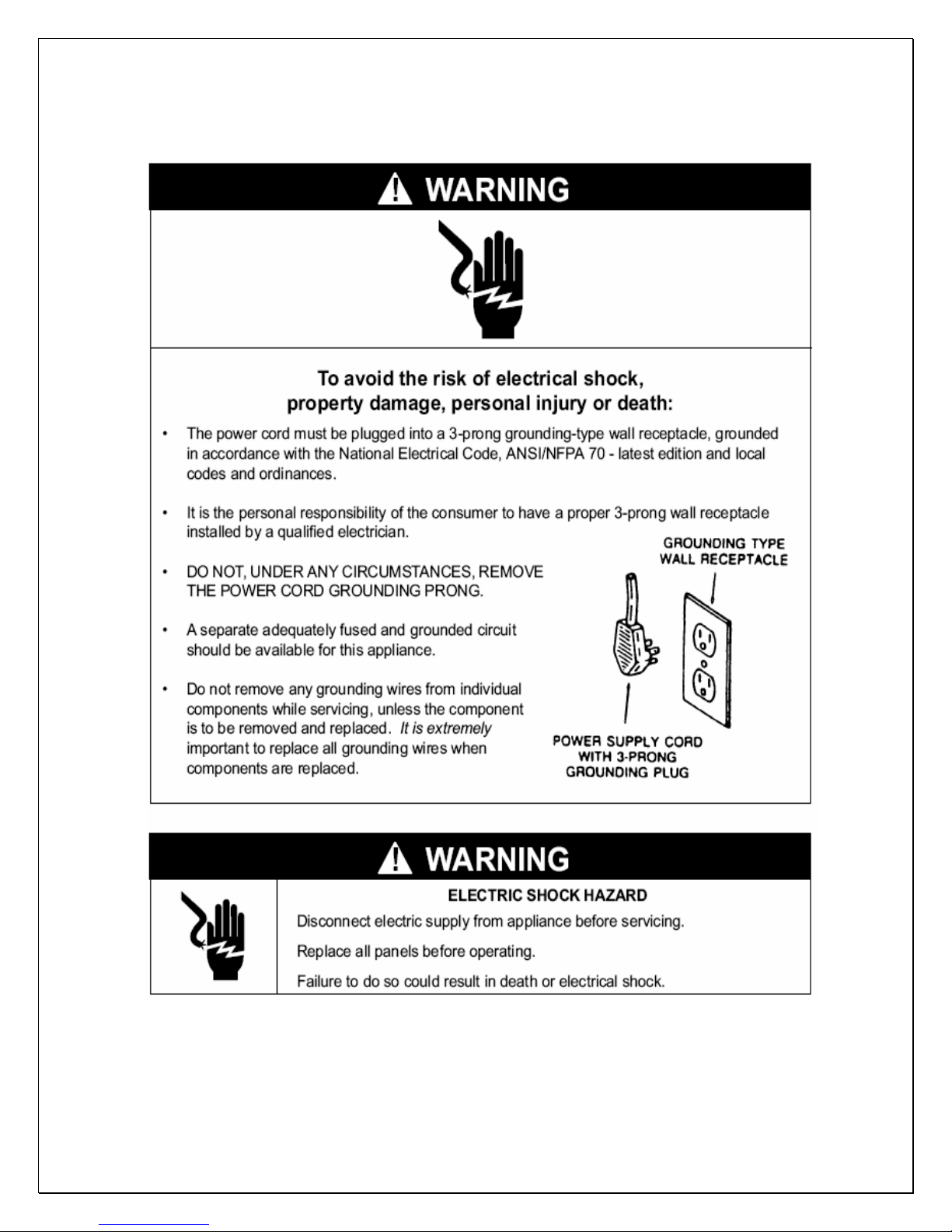

SAFETY INFORMATION

- 1 -

TABLE OF CONTENTS

1. Introduction………………………………………………..3

I. Goals and Objectives…………………….…...……………………………3

II. R134a Refrigerant Service Information.....................…………..…….3

2. Component Information and Access………………….5

I. Model and Serial Label Location…………………………………………5

II. Component Access…………………………………………………………6

1) Removing the Outer Cover…………………………..……………...…..6

2) Removing the Inner Styrofoam Cover…..……………………………..6

3) Removing the Fan Plate….…………………..…………………………..8

4) Removing the Electronic Controller……………..……………………..9

5) Removing the Thermistor………………………………………………..9

6) Removing Fan Motors…………………………………………………...10

7) Removing the Start Relay and Overload Protector …………….....10

8) Removing the Compressor……..………………………………………11

9) Removing the Condenser……..………………………………………..12

10) Removing the Evaporator…..…………………………………………..12

3. Servicing and Diagnosis……………………………….13

I. Identifying Component Problems........…….…….………………….13

1) Terminal Block………………………………………………………….13

2) Compressor……………………………………………………………….14

3) Start Relay…………………………………………………………………15

4) Overload Protector.………………………………………………………16

5) Electronic Controller……………………………………………………16

6) Thermistor..………………………………………………………………..17

7) Fan Motors.………………………………………………………………..17

II. Wiring Diagram.….……..…………………………………..……………..18

III. Troubleshooting Chart.…....…………….………………………………19

4. Customer Support………………………………………22

5. Warranty Information…………………………………..23

I. Limited Warranty …………………………………..……………………..23

II. Limitation of Implied Warranty.………………………………………….24

- 2 -

1. Introduction

VINOTEMP assumes no responsibility for any repairs made on

products by anyone other than authorized service technician

This manual has been prepared to provide the information on installing,

servicing, troubleshooting and repairing procedures for the WINE-MATE

VINO1500HZD & 2500 HZD cooling units.

I. Goals and Objectives

The goal of this manual is to provide detailed information that will enable the

service personnel to properly install and repair the cooling unit, and troubleshoot

and diagnose malfunctions.

The objectives of this manual are that the service personnel will

• Fully understand the proper safety precautions

• Successfully install the cooling unit

• Successfully troubleshoot and diagnose malfunctions

• Successfully perform necessary repairs

• Successfully return the cooling unit to proper operational status

II. R134a Refrigerant Service Information

This cooling unit uses R134a refrigerant. This refrigerant requires synthetic ester

oil in the compressor. This cooling system does not tolerate contamination from

any of the following:

• Other refrigerants

• Moisture

• Petroleum-based lubricants

• Silicone lubricants

• Cleaning components

• Rust inhibitors

• Leak detection dyes

• Any other types of additive

As a result, the following precautions shall be observed:

• Use equipment dedicated to R134a sealed system only.

• Use R134a refrigerant for back-flushing.

- 3 -

• Use dry nitrogen to purge the system.

• Do not overcharge the refrigeration system.

• Do not leave replacement compressor open to the atmosphere for more

than 10 minutes.

• Do not operate the compressor without refrigerant charge in the system.

• Do not use the compressor if the rubber plugs on the replacement

compressor appear to have been tampered or removed.

• Always replace the filter-drier when performing any repairs on the sealed

system.

• The filter-drier must be cut from the sealed system. Never unbraze the

filter-drier from system tubing. Applying heat will drive moisture back into

sealed system.

Table 1-1 Health and Safety Handling of R134a

Allowable Overall Exposure Limit 1,000 ppm

Vapor Exposure to Skin No Effect

Liquid Exposure to Skin Can cause frostbite

Vapor Exposure to Eyes Can cause very slight irritation

Liquid Exposure to Eyes Can cause frostbite

Above Minimum Exposure Limit Can cause asphyxiation, tachycardia

and cardiac arrhythmia's. Wear

appropriate skin and eye care.

Spill Management Combustible sources. Evacuate or

ventilate area.

May decompose if in contact.

Fire and Explosion Hazards Made with flames and heating

elements. Container may explode if

heated due to pressure rise.

Combustion products are toxic.

Storage Conditions The procedures/rules for R12 also

apply to R134a.

Reclaim

- 4 -

2. Component Information and Access

This section provides you the component information and access inside the

cooling unit. The components and their locations are shown Figures 2-1 through

2-11 below.

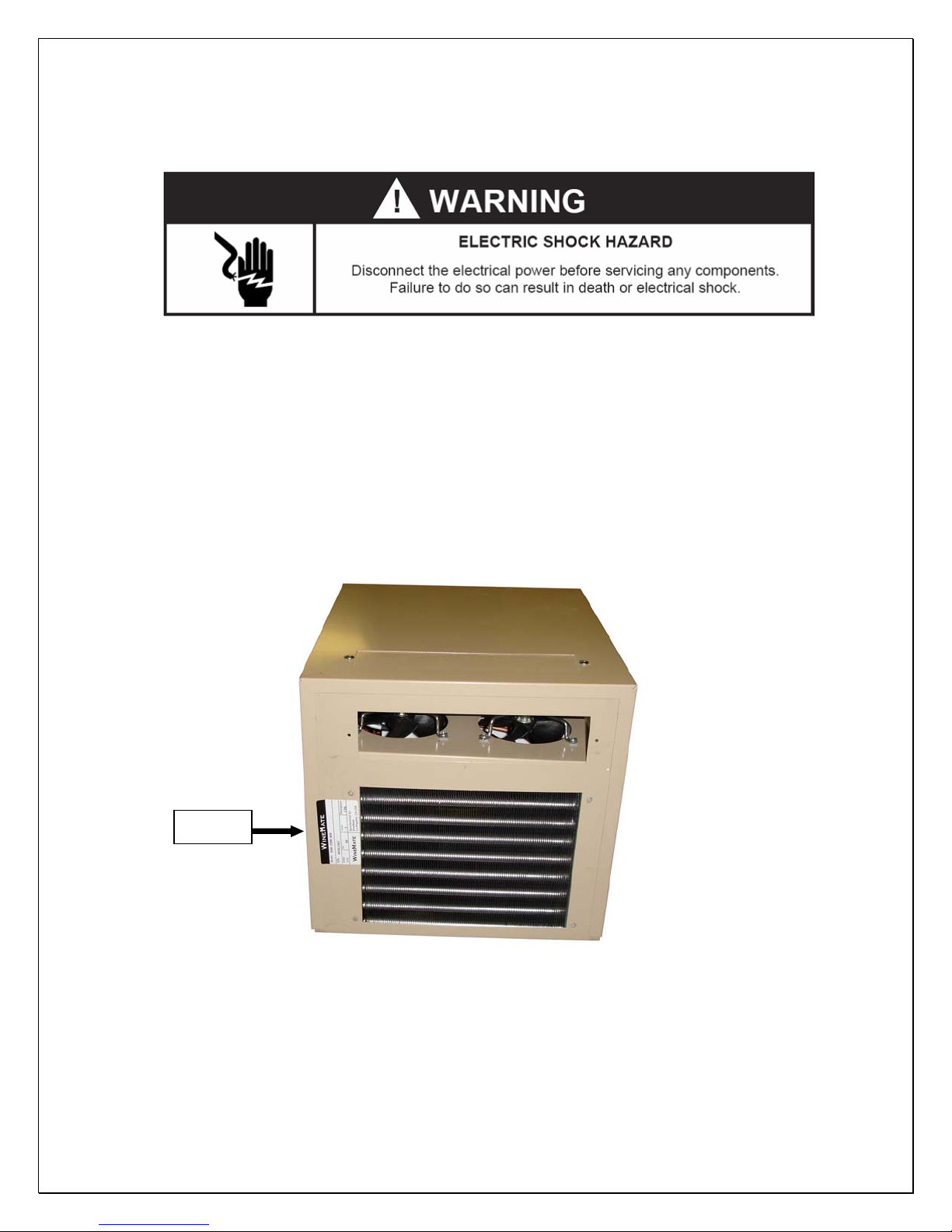

I. Model Number & Serial Label and Component Locations

Label

- 5 -

Figure 2-1

II. Component Access

1) Removing the Outer Cover

1. Unplug the WINEMATE cooling unit or disconnect power.

2. Remove the WINEMATE cooling unit from the enclosure.

3. To remove the outer cover, remove all screws from each side and on the

top.

2) Removing the Inner Styrofoam Covers

Once the outer cover is removed, this will expose the inner styrofams. The top

large Styrofoam cover seals off the condenser and evaporator fan compartments.

To gain access to the other components, the styrofoam covers will need to be

removed. To separate the top styrofoam covers, a knife can be used to cut along

the seam and through the seal. Take care as not to damage any wiring or the

styrofoam pieces.

- 6 -

Figure 2-2

Figure 2-3

- 7 -

Figure 2-4

Loading...

Loading...