CV-Series

High-Pressure Valves

USER GUIDE

369 Syringa Ridge

Sandpoint, ID 83864

281.782.8312

www.vindum.com

support@vindum.com

V:1.2 (3-07-17)

1

This page is intenonally blank.

Copyright 2005-2017

Vindum Engineering, Inc. All rights reserved. Reproducon or use of contents in any manner is prohibited

without express permission from Vindum Engineering. While every precauon has been taken in the preparaon of this manual, the publisher assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulng from use of the informaon contained herein.

2

Table of Contents

Chapter 1 General Overview .................................................................................................. 1

1.1 Conguraon ............................................................................................................................ 1

1.2 Main O-Ring Seal Material ........................................................................................................ 1

1.3 Pressure Rang ......................................................................................................................... 1

1.4 Solenoid Pilot Valve .................................................................................................................. 2

1.5 Valve Temperature Rang ........................................................................................................ 2

1.6 Weed Parts ............................................................................................................................. 2

1.7 Everything you need to operate your CV Valve ........................................................................ 2

1.8 Addional Informaon .............................................................................................................. 3

1.8.1 CV Valve Models .................................................................................................. 3

1.8.2 CV Valve Size ....................................................................................................... 4

Chapter 2 Understanding Your Valve ................................................................................... 5

2.1 Principles of Operaon for the 2-Way Valve ............................................................................ 5

2.1.1 Possible Conguraons of the 2-Way Valve .................................................................. 5

2.1.2 Direcon of Flow ............................................................................................................ 5

2.2 Principles of Operaon for the 3-Way Valve ............................................................................ 5

2.2.1 Possible Conguraons of the 3-Way Valve .................................................................. 5

2.2.1.1 Open / Closed Posion (A1 / B2) ...................................................................... 6

2.2.1.2 Closed / Open Posion (B1 / A2) ...................................................................... 6

2.2.1.3 Open / Open Posion (A1 / A2) ........................................................................ 6

2.2.1.4 Closed / Closed Posion (B1 / B2) .................................................................... 6

Chapter 3 Solenoid Pilot Valves & Manifolds .................................................................... 7

3.1 Air Supply Requirements .......................................................................................................... 7

3.1.1 Air Input and Output ............................................................................................ 7

3.2 Electrical Power......................................................................................................................... 8

3.3.1 Power Failure Opons.......................................................................................... 8

3.3 High Temperature CV Valves .................................................................................................... 9

Chapter 4 CV-200 Series & CV-400 Series Valve Maintenance.................................... 11

3

4.1 Tools You Will Need ................................................................................................................ 11

4.2 Disassembling the 2-Way Valve .............................................................................................. 11

4.3 Disassembling the Piston Assembly ........................................................................................ 12

4.4 Disassembling the Sleeve Assembly ....................................................................................... 12

4.5 Inspecng the Sleeve and Cone .............................................................................................. 13

4.6 Reassembling the Sleeve Assembly ........................................................................................ 13

4.7 Reassembling the Piston Assembly ......................................................................................... 14

4.8 Reassembling the 2-Way Valve ............................................................................................... 14

Chapter 5 CV-300 Series & CV-500 Series Valve Maintenance .................................. 17

5.1 Dierences Between the CV 2-Way and 3-Way Valves .......................................................... 17

5.2 Disassembling the 3-Way Valve .............................................................................................. 17

5.3 Disassembling the Piston Assembly ........................................................................................ 18

5.4 Disassembling the Sleeve Assembly ....................................................................................... 18

5.5 Reassembling the Sleeve Assembly ........................................................................................ 18

5.6 Reassembling the Piston Assembly ......................................................................................... 18

5.7 Reassembling the 3-Way Valve ............................................................................................... 18

Chapter 6 Maintenance & Troubleshoong .................................................................... 21

6.1 Air Supply Problems ................................................................................................................ 21

6.1.1 Solenoid Pilot Valve Visual Check ................................................................................ 21

6.1.1.1 If the Light Goes On and O for a Dierent Solenoid Pilot Valve................... 21

6.1.1.2 If No Light Goes On or O ............................................................................... 22

6.1.2 Solenoid Pilot Valve Audio Check ................................................................................ 22

6.1.2.1 No “Air Escaping” Sound When CV Valves Are Opened & Closed .................. 22

6.1.2.2 The Air Supply is Not Dry ................................................................................ 22

6.1.2.3 The Air Pressure is Too Low ............................................................................ 23

6.1.2.4 The Air Pressure is Too High ........................................................................... 23

6.1.2.5 Constant “Air Escaping” Sound ....................................................................... 23

6.1.2.6 Compressed Air Supply Runs Out Quickly ...................................................... 24

6.2 Fluid Supply Problems ............................................................................................................. 24

6.2.1 Fluid Leaks from the CV Valve Bleed Port .................................................................... 24

6.2.2 Fluid Leaks Across a “Closed” Valve ............................................................................. 25

6.2.3 Fluid Leaks Into Air Tubes ............................................................................................ 25

6.2.4 Fluid is Not Traveling Properly ..................................................................................... 25

Appendix 1: Removal & Replacement of the Cone ........................................................ 27

4

Appendix 2: CV-210 & CV-310 Valve Components ......................................................... 30

Appendix 3: CV-405 & CV-505 Valve Components ......................................................... 31

Appendix 4: CV-410 & CV-510 Valve Components ......................................................... 32

Appendix 5: CV-420 & CV-520 Valve Components ......................................................... 33

Appendix 6: Commercially Available Parts ....................................................................... 34

A.6.1 Fluid Fings .......................................................................................................................... 34

A.6.2 Pilot Valves / Air Manifold ........................................................................................................ 35

A.6.3 Lubricants and Adhesives ......................................................................................................... 35

Appendix 7: O-Ring Compability Chart............................................................................ 36

Appendix 8: Quote Request / Order Form ........................................................................ 37

Index ............................................................................................................................................. 38

This page is intenonally blank.

6

Chapter 1

1. General Overview

The Vindum Engineering CV High Pressure Valves are available in two conguraons; either as a 2-posion,

on/o valve, or a 3-way, 4-posion valve. The CV Valves are air-actuated, constant-volume valves with a

switching me of less than .1 second. They are typically used as switching devices in high-pressure uid ow

systems. The valves are designed so that no uid is displaced when they are opened or closed. This allows

them to be useful in systems requiring constant volumes or constant pressures during the switching cycle.

All weed parts on CV Valves ulize either 316 stainless steel, which is corrosion resistant, or Hastelloy© C-

276, which is used for brine applicaons or highly corrosive uids. Our standard valves have a temperature

rang of 180°F (80°C). Valves with our high temperature opon have a temperature rang of 320°F (160°C).

1.1 Conguraon

Each CV Valve is customized to the needs of the user by ulizing the following opons:

The CV Valve can be built as either:

• 2-Way, on/o valve, which uses a single solenoid pilot valve

• 3-Way, 4 posion valve which uses 2 solenoid pilot valves. The 3-way, 4-posion valve contains two inde-

pendently operated valves that are connected with a center ng (tee).

Solenoids to control the valve are sold separately. Solenoids can be ordered singly or in manifold with up to

twelve staons.

1.2 Main O-Ring Seal Material

The following materials are available for the weed O-ring. The weed O-ring material needs to agree with

the uid used. See Appendix 7 or online sources (such as the Parker O-ring handbook) for chemical combability

• Aas

• Buna

• Teon™

• UHMW

• Viton

• Other materials on request

1.3 Pressure Rang

The CV-Valves can have a pressure rang of either 5,000; 10,000; or 20,000 psi.

1

1.4 Solenoid Pilot Valve

The solenoid pilot valves for the 85 to 115 psi air supply can be operated by either:

• 12 Vdc

• 24 Vdc

Note: The standard voltage is 12 Vdc, 24 Vdc is available on request.

1.5 Valve Temperature Rang

• Standard ambient temperature CV-Valves operate up to 180°F (80°C), and have push-in type air line

ngs.

• Oponal high temperature CV-Valves operate up to 320°F (160°C), and have compression type air line

ngs

Note: air line ngs are the only dierence between ambient and high temperature valves.

1.6 Weed Parts

There are two opons of materials for the valve’s weed parts, or the parts of the valve that will come in contact with the uid:

• 316 Stainless Steel for inert materials, or

• Hastelloy C-276 for corrosive materials or brine

1.7 Everything you need to operate your CV Valve

• Valve

• High Pressure Fings

• Pneumac ngs

Sold Separately

• Solenoid Pilot Valves

• 1/8” air tubing

2

1.8 Addional Informaon

1.8.1 CV Valve Models

Valve

Maximum

CV VALVE MODELS

Internal

Approximate

Model

Pressure

Rang [PSI (Bar)]

Volume (cc)

Flow

Coefficient (Cv)

2-Way On-O Valves

CV-210 10,000 (700) 0.11 .06

CV-405 5,000 (350) 0.44 .24

CV-410 10,000 (700) 0,44 .12

CV-420 20,000 (1400) 0.22 .03

3-Way 4 Posion Valves

CV-310 10,000 (700) 0.31 .06

CV-505 5,000 (350) 1.08 .24

CV-510 10,000 (700) 0.74 .12

CV-520 20,000 (1400) 0.62 .03

Table 1-1

3

1.8.2 CV Valve Sizes

Valve Size

Valve

Model

(Autoclave Engineers)

Fings

2-Way On-O Valves

CV-210 W125 - 1/8” Speedbite

SW250 - 1/4” Speedbite

CV-405

CV-410 SW250 - 1/4” Speedbite

CV-420 F250C - 1/4” High Pressure

3-Way 4 Posion Valves

Valve

Dimensions

2” diameter x 1.695”

(5.0 cm x 4.3 cm)

2.25” diameter x 1.95”

(5.7 cm x 4.9 cm)

2.25” diameter x 1.95”

(5.7 cm x 4.9 cm)

2.25” diameter x 1.95”

(5.7 cm x 4.9 cm)

CV-310 W125 - 1/8” Speedbite

CV-505 SW250 - 1/4” Speedbite

CV-510 SW250 - 1/4” Speedbite

CV-520 F250C - 1/4” High Pressure

2” diameter x 3.645”

(5.0 cm x 9.2 cm)

2.25” diameter x 4.435”

(57 cm x 11.3 cm)

2.25” diameter x 4.435”

(57 cm x 11.3 cm)

2.25” diameter x 4.435”

(57 cm x 11.3 cm)

4

Chapter 2

2. UNDERSTANDING YOUR VALVE

2.1 Principles of Operaon for the 2-Way Valve

Each CV 2-Way Valve contains two air supply tubes, A and B, which

are connected to one solenoid-operated pilot valve. Pressurized air

passes from the solenoid pilot valve through one of the air supply

tubes into the 2-Way valve’s piston assembly. Within the piston as-

sembly is a cone that serves as a “gate”, which either opens and allows uid to ow or closes and stops uid from owing.

• Pressurized air passing through air supply tube A moves an inter-

nal cone away from the A air supply port. Because the cone is

pointed towards the A port, this causes the valve to open and uid to ow. This is considered the “open” posion.

CV-210 Open Valve

• Pressurized air passing through air supply tube B moves an inter-

nal cone towards the A air supply port. This causes the valve to

close and uid to stop. This is considered the “closed” posion.

• The C port is a pressure bleed port. It is designed to provide pres-

sure relief in case uid leaks out of the sleeve assembly. If uid is

leaking from the C-Port, there is a problem with your valve. See

secon 6.2.1.

CV-210 Closed Valve

High Pressure

Air

Figure 2.1

Fluid

Path

2.1.1 Possible Conguraons of the 2-Way Valve

The 2-Way CV Valve is an on/o valve. It can be congured in two ways, either normally open or normally

closed. In case of a power failure, it can be set to open or to close. See secon 3.2.1: Power Failure Opons

for informaon on valve conguraons.

2.1.2 Direcon of Flow

The uid can ow through the valve in either direcon. Figure 2.1 shows the uid coming in from the le

side.

2.2 Principles of Operaon for the 3-Way Valve

The CV 3-Way Valve contains two piston assemblies, which are connected by a center ng (tee), and four

air supply tubes. Two air supply tubes run between each piston assembly and solenoid pilot valve. Two solenoid pilot valves are then aached to an air manifold.

5

2.2.1 Possible Conguraons of the 3-Way Valve

Because the three-way CV Valve contains the equivalent

of two 2-Way valves, it can be used as two independently

operated on-o valves, or as a single 3-way, 4-posion

switching valve. The 3-way valve can be operated in the

following four posions.

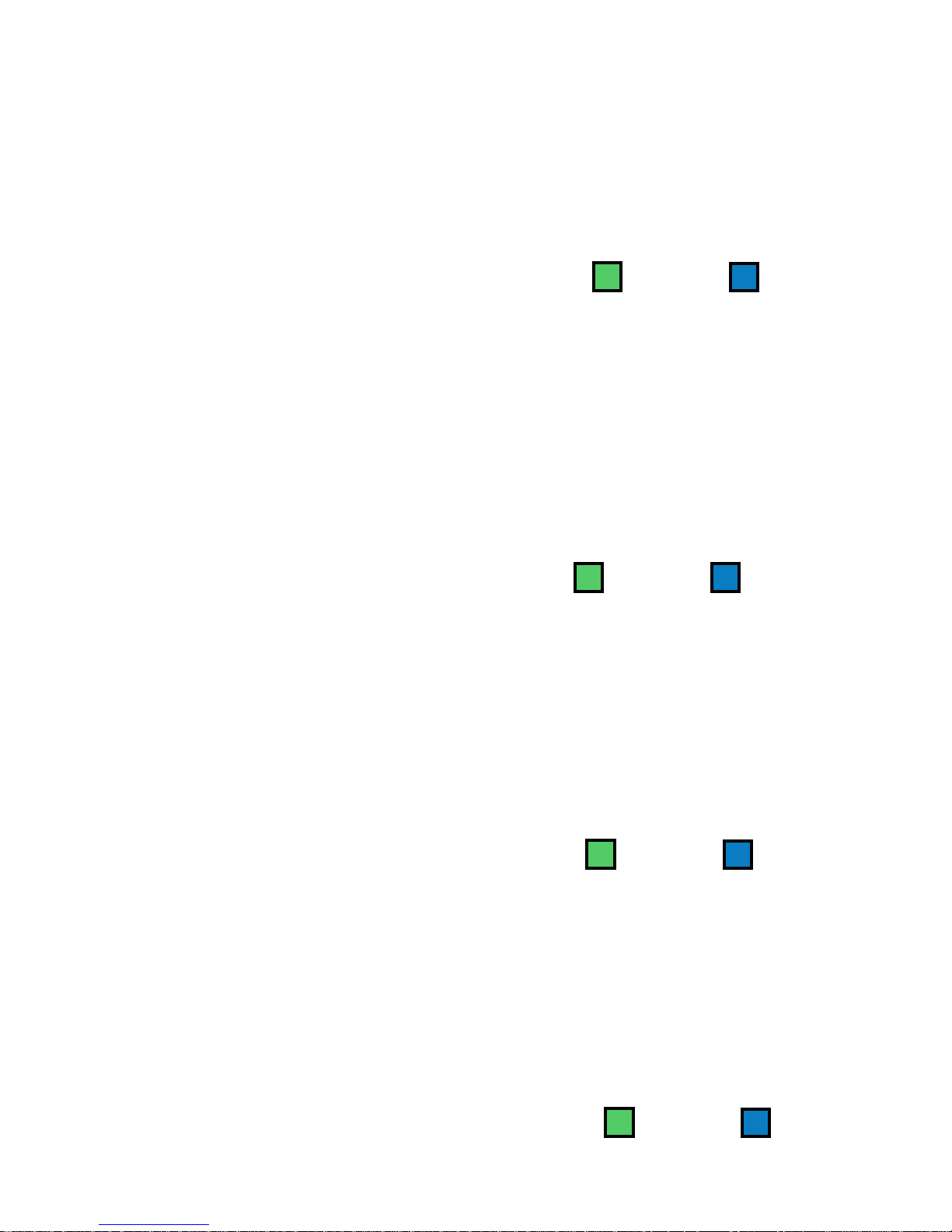

2.2.1.1 Open/Closed Posion (A1 / B2) Fig. 2.2

• Air ows into air-inlet port A1, causing the cone inside

of valve 1’s piston assembly to open.

• Air ows into air-inlet port B2 causing the cone in-

side of valve 2’s piston assembly to close.

2.2.1.2 Closed/Open Posion (B1 / A2) Fig. 2.3

• Air ows into air-inlet port B1 causing the cone in-

side of valve 1’s piston assembly to close.

• Air ows into air-inlet port A2 causing the cone in-

side of valve 2’s piston assembly to open.

2.2.1.3 Open/Open Posion (A1 / A2) Fig. 2.4

A1 C1 B1 B2 C2 A2

Valve 1 Valve 2

High pressure

air

Fluid Path

Figure 2.2 Open/Closed Valve

A1 C1 B1 B2 C2 A2

Valve 1 Valve 2

Fluid Path High pressure

air

Figure 2.3 Closed/Open Valve

A1 C1 B1 B2 C2 A2

• Air ows into air-inlet port A1 causing the cone inside

of valve 1’s piston assembly to open.

• Air ows into air-inlet port A2 causing the cone inside

of valve 2’s piston assembly to open.

2.2.1.4 Closed / Closed Posion (B1 / B2)

• Air ows into air inlet port B1 causing the cone inside

of valve 1’s piston assembly to close.

• Air ows into air inlet port B2 causing the cone inside

of valve 2’s piston assembly to close.

Valve 1 Valve 2

High pressure

air

Fluid Path

Figure 2.4 Open/Open Valve

A1 C1 B1 B2 C2 A2

Valve 1 Valve 2

High pressure

air

Fluid Path

Figure 2.5 Closed/Closed Valve

6

Chapter 3

3. Solenoid Pilot Valves and Manifolds

The CV-Series Valves are completely air actuated. Air is taken into the air inlet and distributed to the solenoid

pilot manifolds. The solenoid pilots then distribute and control the air ow to the valves.

3.1 Air Supply Requirements

Because the CV Valves are completely air-actuated, 85 to 115 PSI of ltered air must be connected to the solenoid pilot valves at all mes. Failure to maintain sucient air pressure at the appropriate port on the CV

Valves can result in valve malfuncon, leakage and subsequent loss of control. Following are the air supply

requirements for all CV Valves.

• The air must be clean.

• The air must be dry because moisture in the air supply will cause the solenoid pilot valves to rust and mal-

funcon.

• The air must be oil-free.

• The air must be 85 - 115 PSI (5.95 to 8.05 bar). If the air pressure is outside this range, the solenoid pilot

valves may stop working.

A standard, ltered laboratory air supply from an air compressor is adequate if it meets the above criteria.

The air compressor should be equipped with a dryer because water vapor in the air lines will cause the pilot

valves to rust and malfuncon. Tanks of compressed air should not be used as a pressurized air source.

3.1.1Air Input and Output

CV Valves are air-actuated. Incoming air must be connected at the solenoid pilot valves’ air inlet port, as

shown in Figure 3-1. The air inlet at the boom of a single solenoid (marked with a “P”) has a 1/8” quickdisconnect ng. This ng should be connected to a pressurized air source (regulated at 85 - 115 PSI) with

a 1/8” air line. Solenoids are also available in groups connected to a manifold for a common air supply, as

shown in Figure 3-2. The manifold air intake uses a 1/4” airline connected to a quick-disconnect ng.

A B

P (Air Inlet)

Figure 3-1: Solenoid Pilot Valve

Figure 3-2: Solenoids

7

The air inlet ngs on the CV Valves are plasc “quick disconnects”, the same as the outlet ngs on the

solenoid pilot valves. Connect the solenoid pilot valves to the CV Valve using 1/8” nylon or Teon™ tubing

(Teon™ tubing is used for high temperature applicaons).

NOTE: Before any of the air lines connecng the solenoid pilot valves to the CV Valves are disconnected, for

any reason, some type of numbered or color-coded tags should be placed on each air line, each solenoid pilot

valve ng, and each CV Valve ng to ensure the correct connecons are made during reassembly.

3.2 Electrical Power

The solenoid pilot valves require electrical power to re-direct air pressure from one valve port to another. If

electrical power is lost, the solenoid pilot valves posion themselves to their default; non-energized posion

and valve control is lost. When the solenoid pilot valve loses power, the “B” port of the soliniod valve becomes pressurized and the “A” port has no pressure in it. In gure 3-3 the “B” port of the solenoid pilot valve

becomes pressured and causes the valve to close. For this reason, electrical failure should be taken into consideraon and the lines should be connected so that if a power failure does occur, a dangerous situaon is

not created.

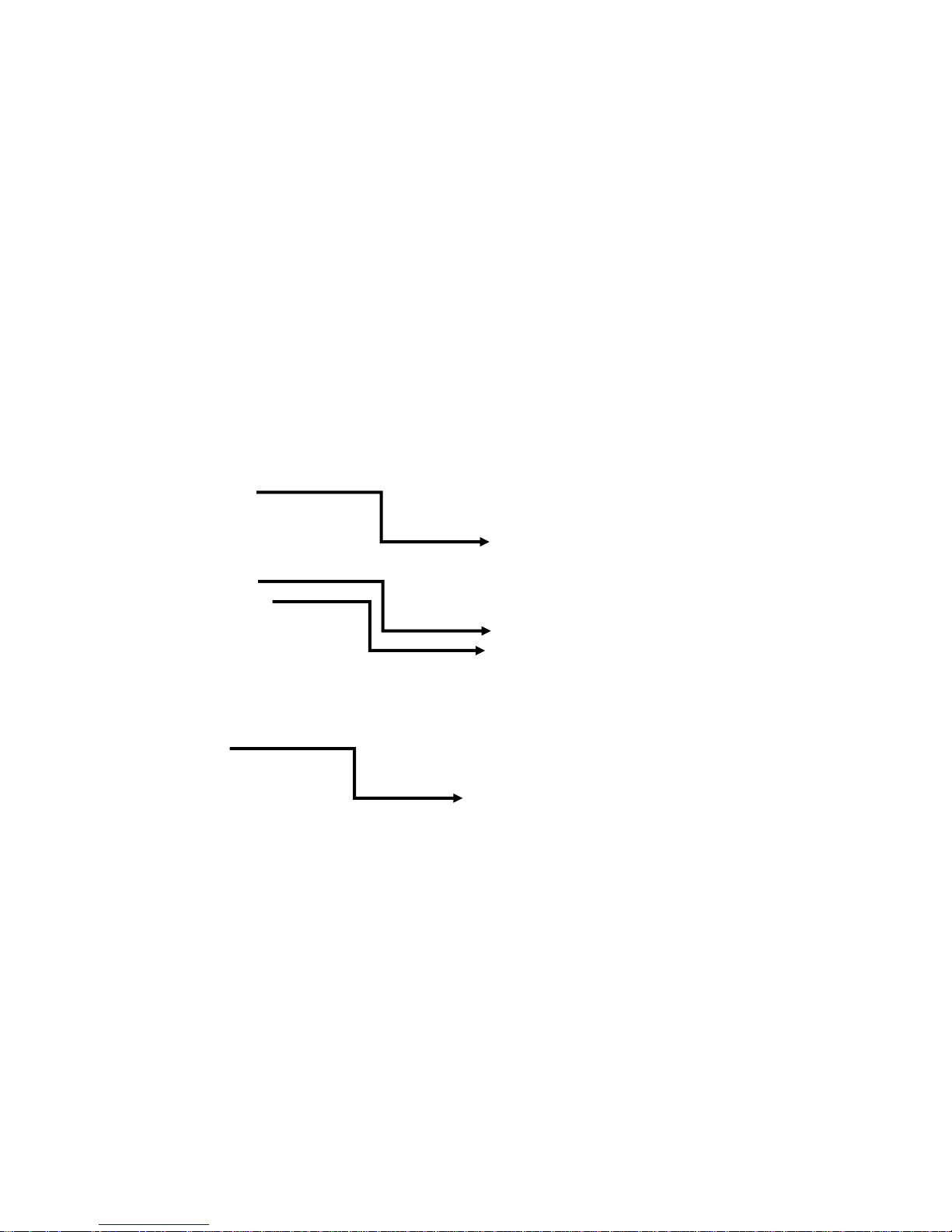

3.2.1 Power Failure Opons

In case of electrical failure, the valves can be congured to either default to a closed or an open posion. To

set up a normally closed conguraon, the “B” ports of the solenoid valve and CV Valve should be connected

together, and the “A” ports should be connected together, as shown in gure 3-3. For a normally open conguraon, the “B” port of the solenoid valve should be plugged into the “A” port of the CV Valve and vice

versa, as shown in gure 3-4.

Figure 3-3 Normally

Closed CV-210 Valve

8

Figure 3-4: Normally Open CV-210 Valve

In the case of the three way CV Valves, the Valves can be set to have both valves open or closed, or it can be

set to have one valve remain open while the other closes. Although this conguraon is not shown, set up

the valve in the normally closed conguraon, then swap the connecons on the valve you wish to be normally open.

• If normally-closed operaon is desired for a CV-310 Valve, connect the solenoid pilot valves to the CV-310

Valve as shown in Figure 3-5.

• If normally-open operaon is desired for a CV-310 Valve, connect the solenoid pilot valves to the CV-310

Valve as shown in Figure 3-6.

A1

B1

B2

A1 B1

A2 B2

A2

Figure 3-5: Normally Closed CV-310 Valve

A1

A1 B1

B1

B2

A2 B2

A2

Figure 3-6: Normally Open CV-310 Valve

3.3 High Temperature CV Valves

If you are connecng a high temperature CV Valve, the following two changes should be made when installing the air lines:

• The 1/8” tubing used for the air connecon between the solenoid pilot valve and the CV Valve must be

made of Teon™ instead of nylon

• The inlet air line ngs on the CV Valve will be swage-type ngs with metal ferrules. The tubing is slid

through the back side of the threaded cap. The metal ferrule is then slid onto the end of the air line, and

the threaded cap is rmly ghtened onto the ng, compressing the ferrule onto the air line.

If using CV Valves in an applicaon where they are placed in an oven, the solenoid pilot valves must be placed

outside of the oven, and the Teon™ air lines connecng them to the CV Valves should be as short as possible. Placing a solenoid pilot valve in an oven will destroy it. Do not use nylon air lines in an oven.

9

This page is intenonally blank.

10

Chapter 4

4. CV-200 Series and CV-400 Series Valve Maintenance

The informaon contained in Chapter 4 explains how to disassemble, reassemble, and service all of the CVseries on-o valves. Chapter 5 will explain how to service the 3-way valves. The piston assemblies and sleeve

assemblies in the 3-way valves are relave to those used in the on-o valves, so most of the informaon in

his chapter also pertains to 3-way valves.

Figure 4-1 is an expanded view of the CV-210 Valve. The CV-400 Series valves are similar, except that they are

slightly larger in size. Throughout this chapter, refer to Figure 4-1 for component numerical references, which

will be shown in brackets. For example, the four 8-32 x 1/2" socket-head cap screws shown as number “1”

will be referenced as “[1]”.

4.1 Tools You Will Need

You will need the following tools in order to maintain your valves.

• 1 each - 9/64 inch Allen wrench

• 1 each - 1/2 inch adjustable wrench, or vice grip with cloth as to not damage end ng

• 2 each - 3/4 inch adjustable wrenches

• 1 each – Wooden toothpick, plasc dental pick or nylon rod approximately 1/8” in diameter and tapered

at one end (No Metal)

1 4 7 8 6 7 4 2

End Fings

5

End Cap

Assembly

Cylinder Shell

O-Ring Piston

3 Support Brack-

Socket Head Cap

Screws

Figure 4-1: Valve for CV-210, CV-405, or CV-410

4.2 Disassembling the 2-Way Valve

To disassemble the CV-200 Series or the CV-400 Series valve, refer to Figure 4-1, above, while following the

instrucons below.

1. Unplug valve from all tubing it is aached to.

11

2. Use a 9/64” Allen wrench to remove the two 8-32 x 1/2” socket head cap screws [1] securing the valve to

the Support Bracket [3].

3. Remove the remaining six 8-32 x 1/2" socket-head cap screws [2] securing both End Caps [4] in place.

4. Grasp the valve in one hand and slide a 1/2” adjustable wrench onto one of the end ngs [5]. Use the

wrench to rotate the End Fing and End Cap in a clockwise direcon while simultaneously applying force

away from the body of the valve. When there is sucient space between the End Cap and the Cylinder

Shell [6], grasp the End Cap by hand and gently separate the two parts. As the End Cap begins to separate from the Cylinder Shell, connue to pull “straight back”, with a minimum amount of “rocking backand-forth”.

NOTE: The End Fing is permanently aached to the End Cap with “Locte® 272”.

5. Inspect the polished stem on the End Fing to make sure that it is free of scratches. If it is scratched, it

needs to be polished using 2,000 grit sandpaper. Polishing the stem is easiest if done on a lathe.

6. Repeat step 3 with the other end of the End Cap/End Fing, and set both pairs of parts aside on a clean

work surface.

7. Gently slide the Piston Assembly [8] out of the Cylinder Shell [6], and set the Cylinder Shell aside.

Note: you can remove the Piston Assembly from the Cylinder Shell easily without removing both end caps

by removing one end cap and acvang the pressurized air to the air ng opposite of the open end cap.

Use as low of pressure air you can to remove the assembly, and make sure to catch the Piston Assembly

as it pops out of the Cylinder Shell.

Figure 4-2: Piston Assembly

12

4.3 Disassembling the Piston Assembly

Refer to Figure 4-2, above, for the following instrucons.

1. Slide two 3/4” adjustable wrenches over the ats on the outside of both the Piston halves [11] and [13].

2. Turn either one of the Piston halves counter-clockwise, while holding the other Piston staonary with the

wrench. Aer the two halves “break free”, connue to gently unscrew them by hand and set both pieces

aside on a clean surface with their threaded sides “up”.

3. Remove the Sleeve Assembly [12] from the Le Piston by hand.

4.4 Disassembling the Sleeve Assembly

Refer to Figures 4-3, 4-4, or 4-5 to Disassemble the Sleeve Assembly for your CV Valve.

The Figures 4-3, 4-4, 4-5 use false colors for illustrave purposes. Teon back-up rings are white, PEEK backup rings are tan, and the O-ring color is material dependent.

14 15 16 15 14 17 18 19 14 15 16 15 14

PEEK back-up

ring

Main O-Ring

Seal

Sleeve Cone

Spacer

Teon™ back-up

Figure 4-3: Sleeve and Cone Assembly for CV-210 and CV-310

20 21 22 21 20 23 24 25 20 21 22 21 20

Ring

PEEK back-up

ring

Teon™ back-

up ring

Figure 4-4: Sleeve and Cone Assembly for CV-405, CV-410, CV-505, and CV-510 Valves

Sleeve

Cone Spacer

Main O-Ring

Seal

13

26 27 30 26 27 28

PEEK Backup ring

Main O-ring Seal

28 27 26 26 27 27 26

29

Sleeve

Figure 4-5: Sleeve and Cone Assembly for CV-420 and CV-520 Valves

Seat

Teon™ Back

-up Ring

1. Grasp the Sleeve Assembly and, using a toothpick or other appropriate tool; GENTLY slide it into the inside of one of the PEEK (tan) Back-Up Rings [14] on either side of the Sleeve Assembly. Only slide the End

Fing (or tool) in far enough to capture the PEEK Back-Up Ring, but not the Teon™ (white) Back-up Ring

[15] or the O-ring [16].

2. Remove the PEEK Back-Up Ring.

3. The objecve of this step is to remove the rings one at a me without damaging the inside surface of the

Sleeve. Repeat steps 1 and 2 for all remaining back-up and O-rings in the Sleeve Assembly, removing

them one at a me, for both ends of the sleeve.

Note: The sleeve assembly is slightly dierent for each CV-Valve Model. The gures below show details for

the CV-210 / CV-310 Valves, (Figure 4-3), the CV-405 / CV-410 / CV-505 and CV-510 Valves, (Figure 4-4) and

the CV-420 / CV-520 Valves, (Figure 4-5).

4.5 Inspecng the Sleeve and Cone

Now that the outside ring, O-rings, and the back-up rings are removed, wipe everything dry with a clean lintfree cloth.

Look inside of the sleeve. Check to make sure the area inside of the sleeve where the O-ring sits is clean and

scratch-free. If there is a build-up, or anything is stuck on the sleeve barrel, remove it. You may use a solvent

and rag to clean the sleeve assembly. DO NOT use steel wool. If you see any scratches inside of the sleeve

where the O-ring sits, a new O-ring may leak. Contact Vindum Engineering to purchase a replacement sleeve.

Next inspect the cone [18, 24], which is inside of the sleeve. Check to make sure the cone has no scratches,

nicks, cracks, or broken-o areas. Make sure the cone does not appear o-center or have an asymmetrical

wear paern. Proceed only if the cone appears in good condion. If the cone displays any of the above problems, refer to Appendix 1 for informaon on replacing it. Replacement cones are available from Vindum Engineering.

For CV-420 and CV-520 valves, the enre sleeve must be replaced if there is damage to the seat. To withstand the high pressures these valves are capable of, the valve seat is permanently embedded in the sleeve.

4.6 Reassembling the Sleeve Assembly

To reassemble the Sleeve Assembly, follow the instrucons below.

14

1. Carefully slide the two PEEK (tan) Back-up Rings [14, 20 or 26] into both sides of the Sleeve, on top of the

spacer [19 or 25] and one into the other side of the Sleeve. Press these Back-up Rings all the way down so

that they are seated at.

2. Next, carefully slide the two Teon™ (white) Back-up Rings [15, 21 or

27] into both sides of the Sleeve on top of the PEEK Back-up Rings.

Again, press these Back-up Rings all the way down so that they are

seated at.

3. Gently insert the Main O-ring [16, 22, or 28] into each end of the

Sleeve. Prevent the O-rings from rolling or binding. When fully

11

pressed in, the Main O-ring should be resng at against the Teon™

Back-up Ring.

Figure 4-6: assembling the Piston

Assembly

4. Carefully slide a second Teon™ Back-up Ring into each side of the

Sleeve on top of the Main O-rings. Press the Teon™ Back-up Ring all the way down unl it is seated at

against the Main O-ring.

5. Slide a second PEEK Back-up Ring into each side of the Sleeve. Make sure it is seated at and does not

protrude outside the outer edge of the sleeve.

4.7 Reassembling the Piston Assembly

Refer to Figure 4-2 to reassemble the Piston Assembly, following the instrucons below.

1. The larger half of the Piston Assembly, the Le Piston [11] has male threads. Slide the Sleeve Assembly

[12] into this part with the point of the Cone facing out.

2. Gently screw the Right Piston into the Le Piston. When the two halves become “snug” use two 3/4” ad-

justable wrenches to ghten them. Keep in mind which way the cone is facing.

3. As shown in Figure 4-2, each Piston half has two O-rings; one larger, external O-ring [10] and one smaller,

internal O-ring [9]. To remove any of these, use a tool such as a small wooden skewer or nylon rod, approximately 1/8” in diameter and tapered at one end. Use care not to scratch or leave parcles in the Oring grooves.

4. Use the tapered end of the tool to gently remove any O-rings. For the larger, external O-rings, gently re-

place them but do not “roll” them into their respecve grooves. When they are in place, they should not

be twisted.

4.8 Reassembling the 2-Way Valve

To re-assemble the Valve, follow the instrucon below.

1. Replace the O-rings [7] on the End Caps [4], aer verifying that there are no foreign parcles of wood, or

any other materials, on any O-rings and that all O-rings are not twisted.

15

2. Apply a small amount of high quality grease (not oil) to the external O-rings [10] and the smaller internal

O-rings [9]. Vindum Engineering uses Dow Corning 55 (M)® for ambient and high temperature valves

Vindum recommends Dupont® Krytox® for extra high temperature valves.

3. Gently slide the Piston Assembly into the Cylinder Shell. Place the piston so the “cone point” is facing

towards the “A” port of the cylinder shell.

4. The End Fings [5] and Main O-rings [16, 22 or 28] must be lubricated on the surfaces that will slide into

the Piston. Apply a drop of lightweight oil on these surfaces on each End Fing and spread the oil completely around them. This oil should be compable with the uids with which this valve will be used.

5. Using a gentle rotang moon, slide both End Caps completely into both sides of the Cylinder Shell.

6. Use the 9/64” Allen wrench to replace the four 8-32 x 1/2" socket-head cap screws on the side of the Cyl-

inder Shell to which the cone is poinng. Tighten all four screws in a cross paern snugly.

7. Use the Allen wrench to replace the two 8-32 x 1/2” screws securing the valve to the Support Bracket,

and the other two 8-32 x 1/2" screws into the end Cap on the bracket side.

Note: The bracket is generally placed on the side of the valve containing the “B” port, with the valve cone

facing away from the bracket. However, depending on user preference, and changes during maintenance,

the bracket may be on the side of the valve containing the “A” port. To avoid confusion, we recommend

always placing the piston assembly into the cylinder shell such that the cone is always facing the “A” port.

16

Chapter 5

5. CV-300 Series and CV-500 Series Valve Maintenance

The informaon contained in Chapter 5 explains how to disassemble, reassemble and service all of the CV

Series 3-way valves.

5.1 Dierences Between the CV 2-Way and 3-Way Valves

The 3-way CV Valve contains all of the same sub-assemblies as the 2-way CV Valve. The 3-way valve is basically two 2-way valves connected in the middle with a Center Fing [40]. As shown in Figure 5-1, the Center

Fing is a symmetrical part with a “nipple-like” appendage on each side which ts into each of the Piston

Assemblies. The Center Fing also has an O-ring [39] on each side to provide a seal with the two Cylinder

Shells. Instead of the Cylinder Shell being threaded on both sides to secure the End Caps, as with the 2-way

valve, one Cylinder Shell is bored and one is threaded so that longer (2-1/2”) socket-head cap screws can be

used to connect the two halves of the valve.

41

41

Piston

5.2 Disassembling the 3-Way Valve

1. Use a 9/64” Allen wrench to remove all of the 8-32 Socket Head Cap Screws [31,32] from both ends of the

valve. Separate the two “valve halves” by grasping the two Cylinder Shells by hand and gently twisng

them in opposite direcons while pulling them apart.

2. When the two valve halves have been separated, pull the Center Fing [40] free of the Cylinder Shell

[37,38] it is sll aached to, and set it aside.

3. Each half of the valve may now be disassembled as if it were a separate 2-way valve.

4. Grasp either of the halves of the 3-way valve in one hand and slide a 1/2" adjustable wrench onto one of

the End ngs [35]. Use the wrench to rotate the End Fing and End Cap [36] in a clockwise direcon

while simultaneously applying force away from the body of the valve. When there is sucient space between the End Cap and the Cylinder shell [37] [38], grasp the End Cap by hand and gently separate the

two parts. As the End Cap begins to separate from the Cylinder Shell, connue to pull “straight back”,

Figure 5-1: 3-Way Valve

17

with a minimal amount of “rocking back-and-forth”.

NOTE: The End Fing is permanently aached to the End Cap with “Locte® 272”.

5. Repeat step 4 with the other End Cap / End Fing, and set both pairs of parts aside on a clean work sur-

face.

6. Gently slide the Piston Assemblies out of the Cylinder shells and set the Cylinder Shells aside.

5.3 Disassembling the Piston Assembly

Refer to Chapter 4, Secon 4.3 Disassembling the Piston Assembly for instrucons (page 14).

5.4 Disassembling the Sleeve Assembly

Refer to Chapter 4, Secon 4.4 Disassembling the Sleeve Assembly for instrucons (page 15).

5.5 Reassembling the Sleeve Assembly

Refer to Chapter 4, Secon 4.6 Reassembling the Sleeve Assembly for instrucons (page 17).

5.6 Reassembling the Piston Assembly

Refer to Chapter 4, Secon 4.7 Reassembling the Piston Assembly for instrucons (page 17).

5.7 Reassembling the 3-Way Valve

To reassemble the valve, follow the instrucons below.

1. Verify that there are no foreign parcles of wood, or any other materials, on any O-rings. Make sure that

all O-rings are not twisted.

2. Replace the O-rings [39] on both End Caps [36].

3. Gently slide the Piston Assembly into the Cylinder shell. Place a small piece of adhesive tape on the out-

side of the Cylinder Shell and draw an arrow on the tape poinng in the direcon of the “cone point”.

4. On the 3-way valve, lubricate the stems on both sides of the Center Fing [40]. The stems will slide into

the two Piston Assemblies.

5. Lubricate the narrow stems of each End Fing [35].

6. Lubricate the O-rings [39] on both sides of the Center Fing being careful to keep lubricaon o other

parts of the Center Fings.

7. Lubricate the other two O-rings.

18

8. Making sure that the “cone points” are each facing AWAY FROM THE CENTER FITTING, gently slide each

of the Cylinder Shell / Piston Assemblies on to the Center Fing.

9. Using a gentle rotang moon, gently slide both End Caps completely into both ends of the Cylinder

Shells.

10. Use the 3/4" adjustable wrench to rotate each of the End Caps unl their four clearance holes are aligned

with those on the Cylinder Shells. Look through the clearance holes on each End Cap to see which End

Cap is on the bored Cylinder Shell and carefully insert the 8-32 x 2-1/2” socket head cap screws [32]

through the End Cap and the bored Cylinder Shell, just unl the screws contact the Center Fing.

11. Hold the Shell staonary, and gently rotate the Center Fing unl the screws can be passed through it.

12. Hold the bored Cylinder Shell and the Center Fing staonary, and gently rotate the threaded Cylinder

Shell unl the screws can be easily threaded into it.

13. Make sure that the Fluid Port on the Center Fing, and the Air Fings on the Cylinder Shells, are

oriented in the correct direcon relave to each other.

14. Use the 9/64” Allen wrench to ghten all four screws in a cross paern snugly.

15. On the other End Cap, thread two 8-32 x 5/8” screws [31] through the Support Bracket [33] and into the

Cylinder Shell [37]. Make sure that the Fluid Inlet Port on the valve is facing the desired direcon.

16. Use the Allen wrench to replace the remainder of the 8-32” socket-head cap screws. Tighten all screws

snugly.

19

This page is intenonally blank.

20

Chapter 6

6. Maintenance & Troubleshoong

This chapter will help the user solve problems that might be encountered when operang the CV Valve. The

following secons are included:

• Air Supply Problems, Secon 6.1

• Fluid Supply Problems, Secon 6.2

• Valve Does Not Seal, Secon 6.3

6.1 Air Supply Problems

CV Valves are air actuated. Filtered air (85 to 115 PSI) must be connected to the solenoid pilot valves at all

mes. When encountering air supply problems, the rst thing to do is complete the following two checks:

• Solenoid Pilot Valve Visual Check, Secon 6.1.1

• Solenoid Pilot Valve Audio Check, Secon 6.1.2

Solenoid Pilot Valves are electrically operated to control air ow. They are used to open or close the uid inlets inside of CV Valves. The solenoid pilot manifold takes in air from the user’s air supply and distributes that

air to the solenoid pilot valves. There is one solenoid pilot valve for each On/O Valve and two solenoid pilot

valves for each 3-Way Valve.

When encountering air supply problems, the user should perform both the Solenoid Pilot Valve Visual Check

and the Solenoid Pilot Valve Audio Check.

6.1.1 Solenoid Pilot Valve Visual Check

The Solenoid Pilot Valve Visual Check conrms that the solenoid pilot valves are operang properly. Some

solenoid pilot valves are equipped with a small red indicator light. When a valve is energized, the corresponding solenoid pilot valve indicator light turns ON and when a valve is de-energized, the corresponding solenoid

pilot valve indicator light turns OFF. If the solenoid pilot valves on your CV Valve are equipped with indicator

lights, perform the Solenoid Pilot Valve Visual Check on the ll and deliver side of each CV Valve in your system.

1. Open and close each CV Valve, using either a computer or manual means, depending on the type of in-

stallaon the valve uses.

2. As each CV Valve is opened, conrm the corresponding solenoid pilot light comes on.

3. As each CV Valve is closed, conrm the corresponding solenoid pilot light turns o.

6.1.1.1 If the Light Goes On and O for a Dierent Solenoid Pilot Valve

If the light acvates for a dierent solenoid pilot valve than the one you are controlling on the computer, the

solenoid pilot cables are switched and must be re-connected properly.

21

6.1.1.2 If No Light Goes On or O

If no light goes on or o while conducng the solenoid pilot visual check, do the following:

• Check that the proper voltage and the proper polarity is connected to the solenoid pilot valve(s)

6.1.2 Solenoid Pilot Valve Audio Check

Listen for an “air escaping” sound when the solenoid pilot valve opens and closes. The sound should be easy

to hear. It will not be a clicking sound. The clicking sound you may hear is simply the solenoid pilot valve

opening or closing. The “air escaping” sound is the same as when you open a can or bole that is under pressure and you hear an immediate gust of air. It is important that you hear this sound when the solenoid pilot

valve opens and closes.

If you do not hear the “air escaping” sound when each valve is opened and closed, then there is not adequate

air pressure to operate the valves. Go back and check that your air tubing has been connected properly and

that it is securely aached. If your air supply has a switch to turn it on, make sure the switch is turned on.

Perform the Solenoid Pilot Valve Visual Check and Solenoid Pilot Valve Audio Check on all the solenoid pilot

valves in your system.

If, aer compleng the Solenoid Pilot Valve Visual Check and Solenoid Pilot Valve Audio Check, there is sll

an air supply problem, the following secons may help you in correcng the problem.

• No “Air Escaping” Sound When Valves are Opened and Closed, Secon 7.1.2

• Constant “Air Escaping” Sound, Secon 7.1.3

6.1.2.1 No “Air Escaping” Sound When CV Valves Are Opened & Closed

If you do not hear the “air escaping” sound when each valve is opened and closed, then there is not adequate

air pressure to operate the valves.

• Check if there are any kinks in the air tubing which runs between the solenoid pilot valves and the CV

Valves.

• Check your air tubing has been connected properly and is securely aached.

• If your air supply has a switch to turn it on, make sure the switch is turned on.

• Make sure the pressurized air supply is a minimum of 85 PSI (5.7 bar).

6.1.2.2 The Air Supply is Not Dry

The air supplied to the CV Valve must be clean and dry. If the air supply is not dry, the solenoid pilot valves

may have rusted and stopped switching, which would result in no “air escaping” sound when opening and

closing the valves. To check this, do the following.

1. Turn o your air supply.

2. Unplug your air line.

22

3. `Check if there is any uid in the line.

4. If the solenoid pilot valves have rusted and no longer operate, they need to be replaced.

6.1.2.3 The Air Pressure is Too Low

Another cause of no “air escaping” sound when opening and closing a valve is the air pressure is too low to

operate the valves. Use a pressure gauge to determine the actual air pressure.

If the air pressure is too low:

• Check that your air tubing has been connected properly.

• If your air supply has a switch to turn it on, make sure the switch is turned on.

6.1.2.4 The Air Pressure is Too High

CV Valves need an air supply between 85 and 115 PSI (5.7 to 7.7 bar) to operate. If the air pressure is too high

(more than 115 PSI (7.7 bar)), install an air regulator to limit the air pressure.

6.1.2.5 Constant “Air Escaping” Sound

If you hear a constant “air escaping” sound when the valves are not being operated, then there is an air leak.

Check the following areas to determine the cause of the air leak.

• Verify that the plasc washers on all air ngs are present and not damaged.

• Check each air tube to see if it is cracked or damaged. Replace any cracked or damaged air tube.

• Verify that all air tubes are fully inserted into the quick-disconnect or compression ngs. All air tubing

should be able to withstand a “slight” tug when properly inserted and the ngs have been ghtened.

• Verify that all compression ngs are fully ghtened.

• Try using a soap and water soluon to detect small leaks.

• If air is escaping from the CV Valve Bleed Port, air is bypassing either the Piston External O-ring [10] or the

Piston Internal O-ring [9].

1. Inspect the Piston External O-rings and the Piston Internal O-rings. Make sure they are not

damaged and are free of contaminants.

2. Verify that the Piston External O-rings and Piston Internal O-rings are properly inserted. They

should be smooth, free of nicks and not twisted.

3. If any problems exist, replace and re-grease the O-rings.

23

• If you suspect air is escaping from the solenoid pilot valves, try the following.

1. Somemes a solenoid pilot valve will get stuck part way open or part way closed and allow air

passage. Try opening and closing the valve to get the soliniod unstuck and moved to a fully

open or fully closed posion. Opening and closing a solenoid pilot valve a few mes may free

up a stuck solenoid pilot. If this does not work, the solenoid pilot valve may have to be re

placed so it does not constantly leak air.

2. Verify that all solenoid pilot valves are securely screwed down to their manifold.

3. Verify that the gasket between the solenoid pilot valve and the air manifold is not damaged or

cracked. If the gasket is cracked, contact Vindum Engineering for a replacement.

4. If air connues to escape from the area between the solenoid pilot valve and the manifold,

apply a light coat of silicone based compound (Dow –Corning Compound 111 Valve Lubricant

and Sealant, or equivalent) to the gasket between the solenoid pilot valve and the air mani

fold.

6.1.2.6 Compressed Air Supply Runs Out Quickly

Tanks of compressed air are not recommended as a pressurized air source. Only a connuous air supply

should be used as the air source and air compressors need to be equipped with a dryer.

6.2 Fluid Supply Problems

If the valve leaks, either of the following can occur:

• It can leak to the outside, in which case the uid will come out the bleed port located between the air in-

lets.

• The cone will let uid pass by it.

• Fluid can leak from one of the high-pressure ngs.

6.2.1 Fluid Leaks from the CV Valve Bleed Port

If uid is coming out the Bleed Port, uid is going by one of the main O-ring seals. To determine where the

problem is, follow the steps below.

• On the Piston Assembly, inspect the piston internal O-ring. Make sure it is not damaged and is free of

wear. If there are any signs of damage or wear, replace the O-ring. Also, make sure the piston internal Oring is free of contaminants. If contaminants are present, replace the O-ring.

• Inspect the smooth stem of the end ng for scratches. If a scratch is present the O-ring will not be able

to properly seal, therefore the end ng would need to be replaced or polished with 2000 grit polishing

paper.

• Check the inside surface of the sleeve. (The sleeve is part of the Sleeve Assembly, which is located inside

24

of the Piston Assembly.) Make sure there are no scratches on the inside surface of the sleeve. If scratches

are present, the sleeve must be replaced.

• For the 3-way valves, also check the Center Fing. Make sure there are no scratches on the stems of the

Center Fing. If scratches are present, the center ng should be replaced or the stems should be polished with 2000 grit polishing paper.

6.2.2 Fluid Leaks Across a “Closed” Valve

If the uid is passing through the valve, or it does not hold pressure when it should be closed, this indicates

that uid is leaking by the closing cone.

• Verify the pressurized air source is 85 to 115 PSI.

• Inspect the Sleeve Assembly cone for signs of damage or wear at the sealing point. Replace if damage or

wear is visible.

• Inspect the Sleeve Assembly for contaminants blocking the cone. If contaminants are present, remove the

contaminants making sure that they have not le an indent in the cone, End Fing, or the conical seat in

the End Fing.

6.2.3 Fluid Leaks into Air Tubes

The most likely cause of uid leaking from the air tubes is water vapor is present in the pressurized air

source.

• Verify that the air compressor is equipped with a dryer and that the dryer is funconing properly.

NOTE: If the air compressor being used is not equipped with a dryer, or if the dryer is not working properly,

water vapor will eventually travel to the pilot valves. This will cause the pilot valves to rust and not work

properly.

6.2.4 Fluid is Not Traveling Properly

If the uid is not following the expected path at the expected me, do the following:

• The solenoid pilot valve air tubes are not connected properly. Manually trace each air tube to its desna-

on to determine which tubes go to which valve. Check to see if the tubes are connected in the proper

conguraon for your setup. See Chapter 3 for the correct tubing conguraons.

25

This Page Intenonally Le Blank

26

APPENDIX 1

Removal and Replacement of the Cone in the Sleeve Assembly

In the CV-200 and CV-300 Series of valves, the Cone [18] and Spacer [19] are “press-t” into the Sleeve Assembly. In the CV-405, 410, 505, and 510 series of valves, the cone must be removed with a specialized tool,

available from Vindum Engineering In the CV-420 and CV-520 series of valves, however, the Cone cannot be

pressed out, and if the valve seat is damaged the sleeve assembly must be replaced.

Removing and replacing the cone from the sleeve assembly requires a specialized tool, available from Vin-

dum Engineering

Hardwood rod

Cone

Spacer

Metal Support Plate

Figure A.1.1 Removing the Cone and Spacer from the Sleeve Assembly

Removing the Cone and Spacer in the CV-200 and CV-300 Series of Valves

1. To remove the “press-ed” Cone and Spacer (gure A.1.1), place the Sleeve Assembly on a metal support plate at least 1-inch thick on an arbor press. The “point” of the Cone should be poinng down. The

support plate must have an opening in it so that the Sleeve is supported, but its inside diameter is unobstructed so the Cone and Spacer can be pushed completely through and out of the Sleeve.

2. Use a thin rod of hardwood or plasc with an outside diameter of 3/16” to press from the backside of the

27

Cone as shown below. Use the arbor press and the thin rod to push the Cone and Spacer out of the

Sleeve.

Cone Install Tool

Cone

Sleeve

Figure A.1.2 Reinstalling the Cone and Spacer in the Sleeve Assembly

Reinstalling the Cone and Spacer in the CV-200 and CV-300 Series of Valves

Looking at the inside diameter of the Sleeve [20] from both sides, noce that on one side the inside shoulder is “farther down” or deeper than it is when looking from the other side. Place the sleeve on a at surface with this “deeper” side up.

Using an arbor press and the cone install tool shown in Figure A.1.2, above, one at a me carefully press

the Cone [18] and the Spacer [19] into the Sleeve. Be sure that the “point” of the Cone is facing “up” towards the outside of the Sleeve, as shown, as the Cone and Spacer are both pressed in all the way to the

shoulder.

28

Removing the Cone and Spacer from the CV-405,410,505, and 510 Series of Valves

Using a toothpick or other non-metal tool used to remove the back-up rings and O-rings from the sleeve,

gently pull the spacer out of the sleeve. Unlike the CV-210 and CV-310 valves, the spacer is not press ed

into the sleeve, and should remove easily. Then line up the prongs on the cone removal tool (gure A.1.3)

with the cone removal holes on the cone (shown in green in Figure A.1.4 and A.1.5) do not place the cone

removal tool in the uid ow holes (shown in blue in Figures A.1.4 and A.1.5). Unscrew the cone from the

sleeve and remove it (Figure A.1.6).

Figure A.1.4

Figure A.1.3

Figure A.1.6

Figure A.1.5

Replacing the Cone and Spacer for the CV-405, 410, 505, and 510 Series of Valves

Place the cone into the deeper side of the sleeve with the threads facing into the sleeve. Place the cone re-

moval tool’s prongs into the cone removal holes (shown in green in gures A.1.4 and A.1.5.) and reghten

the cone unl hand-ght. Do not overghten, as you might strip the threads on the cone.

29

APPENDIX 2

CV-210 and CV-310 Valve Components

Valve Assembly - Refer to Figure 4-1 on page 11 or ( Figure 5-1) on page 17.

Figure

Number

1 & (31)

2 & (32)

(34) Socket Head Cap Screw NA 4 8-32 x 2-1/2-SHSS

3 &(33) Support Bracket 1 410090 1 440060

4 & (36) End Cap 2 440070 2 440070

5 & (35) End Fings 2 440040* 2 440040*

6 & (37) Cylinder Shell 1 440100-TH 1 440100-TH

(38) Cylinder Shell NA 1 440100-BO

7 & (39) O-Ring 2 2-028 4 2-028

8 & (41) Piston Assembly 1 460190* 2 460190*

(40) Center Fing NA 1 440050*

Descripon

Socket Head Cap Screw 8 8-32 x 1/2-SHSS 4 8-32 x 1/2-SHSS

Quanty / Part Number

CV-210 VALVE

CV-310 VALVE

Quanty / Part Number

Piston Assembly - Refer to Figure 4-2 on page 12.

Figure

Number

9 O-Ring (Internal) 2 2-014 4 2-014

Descripon

CV-210 VALVE CV-310 VALVE

10 O-Ring 2 2-125 4 2-125

11 Piston (Male) 1 440110 2 440110

12 Sleeve Assembly 1 460180* 2 460180*

13 Piston (Female) 1 440120 2 440120

Sleeve and Cone Assembly - Refer to Figure 4-3 on page 13.

Figure

Number

14 PEEK Back-up Ring 4 410301 8 410301

15 Teon™ Back-up Ring 4 410302 8 410302

16 Main O-ring Seal 2 2-008** 4 2-008**

17 Sleeve 1 440010* 2 440010*

18 Cone 1 410030 2 410030

19 Spacer 1 410100 2 410100

*Available in Stainless Steel and Hastelloy.

** Weed O-ring, Item #16, available in several dierent materials.

Descripon

Quanty / Part Number

CV-210 VALVE

Quanty / Part Number

CV-310 VALVE

NOTE: O-rings are Viton unless otherwise specied.

30

APPENDIX 3

CV-405 and CV-505 Valve Components

Valve Assy - Refer to Figure 4-1 on page 11 or (Figure 5-1) on page 17.

Figure

Number

1 & (31)

2 & (32)

(34) Socket Head Cap Screw NA 4 8-32 x 3-SHSS

3 & (33) Support Bracket 1 480060 1 480060

4 & (36) End Cap 2 480070 2 480070

5 & (35) End Fings 2 480046 2 480046*

6 & (37) Cylinder Shell 1 480100-TH 1 480100-TH

(38) Cylinder Shell NA 1 480100-BO

7 & (39) O-Ring 2 2-030 4 2-030

8 & (41) Piston Assembly 1 460190* 2 460190*

(40) Center Fing NA 1 480055*

Descripon

Socket Head Cap Screw 8 8-32 x 1/2-SHSS 4 8-32 x 1/2-SHSS

CV-405 VALVE

Quanty / Part Number

CV-505 VALVE

Quanty / Part Number

Piston Assembly - Refer to Figure 4-2 on page 12.

Figure

Number

9 O-Ring (Internal) 2 2-014 4 2-014

Descripon

CV-405 VALVE

Quanty / Part Number

CV-505 VALVE

Quanty / Part Number

10 O-Ring 2 2-129 4 2-129

11 Piston (Male) 1 480110 2 480110

12 Sleeve Assembly 1 480185* 2 480185*

13 Piston (Female) 1 480120 2 480120

Sleeve and Cone Assembly - Refer to Figure 4-4 on page 13.

Figure

Number

20 PEEK Back-up Ring 4 480020 8 480020

21 Teon™ Back-up Ring 4 480025 8 480025

22** Main O-ring Seal 2 2-010** 4 2-010**

23* Sleeve 1 480010* 2 480010*

24 Cone 1 480030 2 480030

25 Spacer 1 480105 1 480105

*Available in Stainless Steel and Hastelloy.

** Weed O-ring, Item #22, available in several dierent materials.

NOTE: O-rings are Viton unless otherwise specied

Descripon

CV-405 VALVE

Quanty / Part Number

CV-505 VALVE

Quanty / Part Number

31

APPENDIX 4

CV-410 and CV-510 Valve Components

Valve Assy - Refer to Figure 4-1 on page 11 or (Figure 5-1) on page 17.

Figure

Number

1 & (31)

2 & (32)

(34) Socket Head Cap Screw NA 4 8-32 x 3-SHSS

3 & (33) Support Bracket 1 480060 1 480060

4 & (36) End Cap 2 480070 2 480070

5 & (35) End Fings 2 480045* 2 480045*

6 & (37) Cylinder Shell 1 480100-TH 1 480100-TH

(38) Cylinder Shell NA 1 480100-BO

7 & (39) O-Ring 2 2-030 4 2-030

8* & (41)* Piston Assembly 1 480195* 2 480195*

(40) Center Fing NA 1 480055*

Descripon

Socket Head Cap Screw 8 8-32 x 1/2-SHSS 4 / 8-32 x 1/2-SHSS

CV-410 VALVE

Quanty / Part Number

CV-510 VALVE

Quanty / Part Number

Piston Assembly - Refer to Figure 4-2 on page 12.

Figure

Number

9 O-Ring (Internal) 2 2-014 4 2-014

Descripon

CV-410 VALVE

Quanty / Part Number

CV-510 VALVE

Quanty / Part Number

10 O-Ring 2 2-129 4 2-129

11 Piston (Male) 1 480110 2 480110

12* Sleeve Assembly 1 480185* 2 480185*

13 Piston (Female) 1 480120 2 480120

Sleeve and Cone Assembly - Refer to Figure 4-4 on page 13.

Figure

Number

20 PEEK Back-up Ring 4 480020 8 480020

21 Teon™ Back-up Ring 4 480025 8 480025

22** Main O-ring Seal 2 2-010** 4 2-010**

23* Sleeve 1 480010* 2 480010*

24 Cone 1 480030 2 480030

25 Spacer 1 480105 2 480105

*Available in Stainless Steel and Hastelloy.

** Weed O-ring, Item #22, available in several dierent materials.

Descripon

CV-410 VALVE

Quanty / Part Number

CV-510 VALVE

Quanty / Part Number

NOTE: O-rings are Viton unless otherwise specied.

32

APPENDIX 5

CV-420 and CV-520 Valve Components

Valve Assembly - Refer to Figure 4-1 on page 11 or (Figure 5-1) on page 17.

Figure

Number

1 & (31)

2 & (32)

(34) Socket Head Cap Screw NA 4 8-32 x 3-SHSS

3 & (33) Support Bracket 1 480060 1 480060

4 & (36) End Cap 2 480070 2 480070

5 & (35) End Fings 2 480130* 2 480130*

6 & (37) Cylinder Shell 1 480100-TH 1 480100-TH

(38) Cylinder Shell NA 1 480100-BO

7 & (39) O-Ring 2 2-030 4 2-030

8* & (41*) Piston Assembly 1 480200* 2 480200*

(40) Center Fing NA 1 480050*

Descripon

Socket Head Cap Screw 8 8-32 x 1/2-SHSS 4 8-32 x 1/2-SHSS

CV-420 VALVE

Quanty / Part Number

CV-520 VALVE

Quanty / Part Number

Piston Assembly - Refer to Figure 4-2 on page 12.

Figure

Number

9 O-Ring (Internal) 2 2-014 4 2-014

Descripon

CV-420 VALVE CV-520 VALVE

10 O-Ring 2 2-129 4 2-129

11 Piston (Male) 1 480110 2 480110

12 Sleeve Assembly 1 480186* 2 480186*

13 Piston (Female) 1 480120 2 480120

Sleeve and Cone Assembly - Refer to Figure 4-5 on page 15.

Figure

Number

26 PEEK Back-up Ring 4 480020 8 480020

27 Teon™ Back-up Ring 4 480025 8 480025

28** Main O-ring Seal 2 2-010** 4 2-010**

29* Sleeve 1 480011* 2 480011*

30 Seat 1 480140 2 480140

*Available in Stainless Steel and Hastelloy.

** Weed O-ring, Item #28, available in several dierent materials.

NOTE: O-rings are Viton unless otherwise specied.

Descripon

CV-420 VALVE

Quanty / Part Number

CV-520 VALVE

Quanty / Part Number

33

APPENDIX 6

Commercially Available Parts

A.6.1 Fluid Fings

Descripon Manufacturer Part Number Notes

Fing Sleeve*

CV210 / CV-310

Fing Sleeve*

CV-405, CV-410

CV-505, CV-310

Collar

CV-420, CV-520

Fing Nut

CV-210, CV-310

Fing Nut

CV-405, CV-410

CV-505, CV-510

Fing Nut

CV-420, CV-520

1/8 inch Tubing Vindum .125” OD x .035” wall SS-316

1/4 inch Tubing

Autoclave SSL20 XX XX is material type:

SS for Stainless 316

HC for Hastelloy C-276

Autoclave SSL40 XX XX is material type:

SS for Stainless 316

HC for Hastelloy C-276

Autoclave ACL-40-316

Autoclave SMN20

Autoclave SMN40

Autoclave AGL-40-316

Hastelloy C-276

Vindum

SS-316

(5 – 10 kpsi)

1/4 inch Tubing

(20 kpsi)

* The weed material for the valves is listed on the warranty card.

Vindum

.250” OD x .065” wall

.250” OD x .083” wall

Hastelloy C-276

SS-316

Hastelloy C-276

34

A.6.2 Pilot Valves / Air Manifold

Descripon Manufacturer Part Number Notes

Pilot Valve SMC SYJ5120-XL0Z-M5

Air Manifold SMC SYJ5-20-XX-00T

Wire and Electrical Con-

nector for Pilot Valve

1/8” Quick-Disconnect Air

Fing for CV Valve and

Pilot Valve

1/8” Swage-type Air Fing

for High Temperature CV

Valve

¼” Quick Disconnect Air

Fing For Air Manifold

Inlet

Air Manifold Plug Dynamco 506-5 or similar The manifold port accepts 1/8’ NPT.

SMC SY100-30-4A-XX X is length of wire in decimeters. (e.g., X

SMC KQ2H 01-32A or similar

Beswick MCB-1018-1 Viton or similar

SMC KQH 07-34S or similar

X is 6 for 12 volt, 5 for 24 volt.

Verify that number on side of pilot

valve is SYJ5120 and voltage is correct.

XX is number of staons, 2 to 20. This

manifold accepts SYJ5120 pilot valves.

Verify pilot valve is SYJ5120 before pur-

is nil for 300 mm (12”), 6 for 600 mm

(24”), 30 for 3 m (120”). This connector

ts in SYJ5120 pilot valves. Verify pilot

valve is SJY5120 before purchasing connector.

The manifold port accepts 1/8” NPT.

11/8” Nylon Air Tubing for

Ambient Temperature

Valves

1/8” Teon™ Air Tubing for

High Temperature Valves

¼” Nylon Air Tubing for Air SMC TISA 07B-20 or similar

SMC TIA01B or similar

Any Supplier 1/8” Teon™ Air Tubing 125

PSI

A.6.3 Lubricants And Adhesives

Descripon Manufacturer Part Number Notes

Grease for Air Seal O-Rings

on Piston for Ambient Temperature Valves

Grease for Air Seal O-Rings

on Piston for High Temperature Valves

Grease for Pilot Valve Gasket

Permanent Bond between Locte® 272

Parker® O-Lube

Dow Corning®

or Dupont®

Dow Corning® 111

55 or 55M

Krytox®

35

APPENDIX 7

O-Ring Compability Chart

(Sourced from “Parker O-Ring® Handbook”)

P = Poor

F = Fair

G = Good

E = Excellent

Butyl

(-75 - 250F) FG G E G F G P G E P GE FG G G G GE

Abrasion Resistance

Chemical Resistance

Acid Resistance

Cold Resistance

Electrical Properes

Dynamic Properes

Flame Resistance

Heat Resistance

Impermeability

Ozone Resistance

Oil Resistance

Set Resistance

Tensile Strength

Tear Resistance

Water / Steam Resist

Weather Resistance

Chlorinated Polyethylene

Chloro-sulfonated

Polyethylene

Ethylene Propylene

Flourocarbon

(Viton)

(-515 - 400F) G E E FP GE F E E G E E GE F GE FG E

Flourosilicone

(-100 – 350F) P FG E GE P E G E P G E GE P F F E

Neoprene

(-45 – 250F) G FG FG FG F F G G G FG GE F FG G F E

Nitrile or Buna N

(-30 – 250F) G F FG G GE F P G G E P GE FG GE FG F

Polyacrylate

(-5 to 350F) G P P P F F P E E E E F FG F P E

Polyurethane

(-40 – 180F) E P F G E FG P F G G E F GE E P E

SBR or Buna S

(-70 – 400F) G F FG G G G P FG F P P G FG GE FG F

Silicone

(-70 – 400F) P FG GE E P E F E P PG E GE P P F E

Teon™

Encapsulated G E E G G G G G

(-70 – 400F)

G F FG FP G G GE G FG E F FG G F E

G G E FG F F G G G F E F G F F E

GE G E GE GE G P E G P E GE GE GE E E

36

APPENDIX 8

Quote Request / Order Form

For CV Series High Pressure Valves

Required Valve Type and Conguraon Informaon.

2-Way Valve 3-Way Valve

Select Weed Material

316 Stainless Steel ________ ________

Hastelloy C-276 ________ ________

Expected Fluid Types

Water (dislled) ________ ________

Brine ________ ________

Mineral Oil ________ ________

Crude Oil ________ ________

(Specify)

Other Oil ________ ________ ________

Solvents ________ ________ ________

Acids ________ ________ ________

Corrosives ________ ________ ________

Polymers ________ ________ ________

Other ________ ________ ________

Expected Operang Temperature

Less than 60ºF (16ºC) ________ ________

If less than 60ºF, how low? ________ ________ ________

Between 60ºF and 150ºF (16º to 65º C) ________ ________

Between 60ºF and 300ºF (16º to 149º C) ________ ________

Greater than 300ºF (149ºC) ________ ________

If greater than 300ºF, how high? ________ ________

________

Customer’s Name _____________________________

Company _____________________________

Address _____________________________

Phone Number _____________________________

Fax Number _____________________________

Email Address _____________________________

Purchase Order Number _________________________

37

A

Air Compressor ............................................. 7,24,25

Air Inlet Fings ...................................................... 8

Air Lines

Numbered or Color Coded Tags ........................ 8

Air Supply

Input and Output ............................................... 7

Requirements .................................................... 7

C

Cone

Inspecng ........................................................ 14

Conguraon .......................................................... 1

2-Way Valve ...................................................... 5

3-Way Valve ...................................................... 6

Closed / Closed .................................................. 6

Closed / Open .................................................... 6

Open / Closed .................................................... 6

Open / Open ...................................................... 6

D

Dimensions ............................................................. 4

F

Fings ............................................................... 4,34

Flow Coecient ...................................................... 3

Flow Direcon ........................................................ 5

Fluid Supply Problems .......................................... 24

M

Maintenance ........................................................ 21

Tools ................................................................ 11

Manifolds ............................................................... 7

O

Operaon Principles

2-Way Valve ...................................................... 5

3-Way Valve ...................................................... 5

O-Ring

Compability Chart ......................................... 36

Greasing ................................................ 16,23,35

Seal Material ..................................................... 1

Disassemble ..................................................... 13

Reassemble ..................................................... 15

Q

Quote

Order Form ...................................................... 37

Request Form .................................................. 37

S

Sleeve

Inspecng ........................................................ 14

Sleeve & Cone Assembly

Diagram ........................................................... 13

Sleeve Assembly

Disassemble ..................................................... 13

Reassemble...................................................... 14

Solenoid Pilot Valve ................................................ 1

Audio Check ..................................................... 22

Connecng ..................................................... 7-9

Visual Check ..................................................... 21

T

Temperature Rang ............................................... 2

Troubleshoong ................................................... 21

V

Valve

Closed Valve Diagram ........................................ 5

CV-210 Connecon Diagram .......................... 8,9

CV-210 Diagram ............................................... 11

CV-310 Connecon Diagram ............................. 9

CV-310 Diagram ............................................... 17

Disassemble 2-Way ......................................... 11

Disassemble 3-Way ......................................... 17

High Temperature ............................................. 9

Connecng Air Lines ..................................... 9

Maintenance ......................................... 11,17,21

Models ............................................................... 3

Open Valve Diagram .......................................... 5

Reassemble 2-Way .......................................... 15

Reassemble 3-Way .......................................... 18

Size .................................................................... 4

Valve-Solenoid Pilot

See Solenoid Pilot Valve .................................... 7

Volume

Internal .............................................................. 3

W

Weed Parts ........................................................... 2

P

Piston Assembly

Diagram .......................................................... 12

Disassemble ..................................................... 13

Reassemble ..................................................... 15

Power

Solenoid Pilot Valve ........................................... 8

Pressure Rang ....................................................... 1

Maximum .......................................................... 1

38

Loading...

Loading...