Vimar VIGAS series, VIGAS 16, VIGAS 25, VIGAS 40, VIGAS 60 Installation & Assembly Manual

...Page 1

1

Gasifying boilers VIGAS

Ecological Boilers VIGAS

MANUAL FOR INSTALLATION, ASSEMBLY AND USE

VIGAS and VIGAS

Lambda Control

with AK 3000

Certificate of warranty

VIMAR 2010

Page 2

2

Gasifying boilers VIGAS

Content

Declaration of conformity......................................................................................................

1. Technical description......................................................................................................

2. Technical data................................................................................................................

3. Description of AK 3000 control......................................................................................

4. VIGAS boiler in basic configuration...............................................................................

5. VIGAS boiler in configuration with gases thermometer..................................................

6. VIGAS boiler in configuration with gases thermometer and discharge fan....................

7. VIGAS

Lambda Control

in configuration with gases thermometer..........................................

8. VIGAS

Lambda Control

in configuration with gases thermometer and discharge fan............

9. Time setting....................................................................................................................

10. Hardware and software information...............................................................................

11. Error messages..............................................................................................................

12. Service settings PIN 0000 protected..............................................................................

13. Operating instructions.....................................................................................................

14. Boiler maintainance and repairs....................................................................................

15. Accesories assembly.....................................................................................................

16. Listo fo guarantee and afterguarantee services.............................................................

17. Problems solving............................................................................................................

18. Assembly instruction......................................................................................................

19. Electric scheme of connection VIGAS boilers................................................................

Letter of guarantee.........................................................................................................

Confirmation of VIGAS boilers commissioning..............................................................

Page

3

4

5

7

9

11

12

13

15

17

18

18

18

21

24

26

28

28

29

31

32

33

Page 3

3

Gasifying boilers VIGAS

DECLARATION OF CONFORMITY

Issued according to Section 12, par. 3, letter a) Act No. 264/1999 Coll.

and 97 / 23 EC

We, VIMAR Vigaš Pavel

hereby declare that the undermentioned products comply with technical regulations and the

products are safe if determined conditions are followed and we took all possible measures to

assure the compliance of products with technical documentations as well as with relevant

instructions requirements of government.

Product: Thermal boiler VIGAS and VIGAS

Lambda Control

with AK 3000 control

Type:

VIGAS 16, VIGAS 16

Lambda Control

VIGAS 25, VIGAS 25

Lambda Control

VIGAS 40, VIGAS 40

Lambda Control

VIGAS 60, VIGAS 60

Lambda Control

VIGAS 80, VIGAS 80

Lambda Control

VIGAS 100, VIGAS 100

Lambda Control

VIGAS 29 UD

Producer:

VIMAR Vigaš Pavel

M. Čulena 25, 974 11 Banská Bystrica,

SLOVENSKO

The above-mentioned products comply with the following standards:

STN 07 7401, STN 73 4210, STN EN 303-5, STN EN 61000-3-

2:2000+A1:2001+A2:2001, STN EN 61000-3-3:2000.

Supplementary data:

Certificates, Test report

Issued in:

Banská Bystrica Name: VIGAŠ Pavel

Date of issue: Title: Owner

Signature:

M. Čulena 25

974 11 Banská Bystrica

SLOVAKIA

IČ DPH: SK 1020548001

Page 4

4

Gasifying boilers VIGAS

1. TECHNICAL DESCRIPTION

Thermal boilers VIGAS are designed for combustion of dry wood material, starting from

sawdust up to logs in the length according to the dimensions of gasification chamber,

maximum 20 cm. Sawdust, chippings, splinters and cuttings must be burn together with logs.

Thermal boiler, VIGAS UD 29 is designed for burning brown coal. It is also possible to use dry

wooden material as a substitute fuel.

Boilers are welded from 4- 6 mm steel sheets. Inner boiler sheets that have contact with

boiler waste gases are 6 mm thick, others are made of 4 mm sheet. Heat exchanger is

welded from steel pipes, 57x 5 mm. Exterior boiler shell is made of 0.8 mm sheet. Thermal

insulation of the boiler is made of insulation material, NOBASIL, 20 and 50 mm thick. Boiler

waste gases go away through steel neck to chimney.

Inner boiler space consists of gasification chamber, where fuel is dried and gasified. Then

created gas goes through fireproof /concrete/ nozzle into combustion chamber, where it

burns with the help of secondary air. Boiler waste gasses are intensively cooled in

exchanger. Wood that is not burnt must be removed from combustion chamber. The boiler has a

lighting up damper that is controled by operating rod at the front part of boiler.

In order the boiler complies with the requirements for non-demanding operation, it is equipped

with AK 3000 control unit that is situated in the upper part of boiler. The used system of control

allows very effective combustion of various kinds of fuel. AK 3000 control with grpahical display,

in basic configuration allows:

to control temperature of heated water in range 60 ÷ 85 °C

smooth and automatic control of forced draft fan according to required output and

to connect discharge fan

to connect circulation pump

to connect gases thermometer

to connect and to control boiler by space temperature regulator

to connect extended regulation (EXPANDER) via AK BUS

to connect module with Ethernet interface and SD-card for data saving and concsequtive

evaluation via PC

grpahical scheme indication of hydraulic connection as requested

real time set

In configuration VIGAS

Lambda Control

also allows :

Utilizes informations from lambda sensor of oxygen overflow in gases, to control the

chimney flap of primary and secundary air.

Gases thermometer as a standard

Boilers are equiped with thermal fuse that ensures disconnection of forced draft fan if boiler

is overheated above 100 0C and safety exchanger against overheating according to the

standard, STN EN 303/5. Its recommended, by producer, to buy a release valve Honeywell TS

130 ¾” for safety exchanger against over heating.

Page 5

5

Gasifying boilers VIGAS

2. Technical data

Tab.1

THERMAL BOILERS

VIGAS 16 25 40 60 80 100 UD 29

Nominal boiler output kW 16 25 40 60 80 100 29

Boiler class according to EN 303-5 3

Max. operating pressure bar 3

Fuel Wood, max. moisture 20% ;heating min. 15 MJ/kg

Brown coal

Output capacity kW 12 - 18 5 - 31 8 - 41 15 - 72 25 - 92

25-100

8-35(8-29)*

Fuel consumption with

nominal output

kg/hod 4,5 7,6 11,2 19 25 30,4

7,8 (8,0)*

Substituite fuel

Wood waste, splinters, saw dust, saw dust briquettes (for UD 29 also wood

of max. moisture 20%)

Chimney daught mBar 0,20 – 0,25 0,20 – 0,35 0,30 – 0,40 0,20 – 0,25

Weight kg 400 430 460 760 930 950 430

Height with regulation A mm 1135 1135 1385 1420 1120

Height of exhaust branch B mm 975 1045 1310 1400 1045

Height of inlet branch C mm 115 125 215 110

Height of feed-water valve D mm 55 60 70 135 55

Height of chimney neck E mm 890 1110 1170 890

Width including rod F mm 645 785 645

Width including shell G mm 590 760 590

Depth H mm 840 1070 1260 1650 1070

Exhaust brand I mm 240 520 240

Diameter od draught neck J mm 160 200 160

Dimmension from edge of

boiler

K mm

188 305 880 1210 230

Spacing of feed pipes L mm 405 70 350

Diameter of inlet brand G/mm 2“

Diameter of exhaust brand G/mm 2“

Diameter of feed-water valve G ½“ ¾“ ½“

Volume of water l 75 93 180 205 215 75

Gases temperature

With nominal output

With minimal output

0

C

0

C

240

150

Dimensions of gasification

chamber

Depth

mm 370

560 750 1150 1090 490/440

Height mm 490 750 730 500

Width mm 440 575 440

Dimensions of gasification

chamber

(width-height)

mm 435 -255

575 – 318 435 - 255

Max. weight of fuel kg 20 30 40 80 150 30

Capacity of gasification

chamber

dm3 80

120 185 315 483 457 105

Noisness dB 45 45,5 47,7 51,4 54,2 45,5

Max. electric input W 70 140 70

Voltage/Frequency V/Hz 230ACV / 50 Hz

Pressure loss of water :

Δt 10 0C

Δt 20 0C

mBar

mBar

9,70

1,00

9,75

1,05

10,48

2,55

12,77

3,19

11,83

2,96

11,53

2,84

9,97

1,15

Time of burning with nominal

output

hod 4,5 4,20 4,30 4,20 4,20 4,0 5,60 (4,10)

Cooling exchanger of heat

- temperature of inlet water

- pressure of inlet water

0

C

bar

4 – 15

min 1 – max 4

Release valve Honeywell TS 130 ¾” for safety exchanger against over

heating, Opening temperature 95°C

Safety

STB fuse, blow temperature 100oC (tolerance: -6oC –- 0 oC)

Weight flow of gases kg/s 0,034 – 0,047

* specification for wood fuel

Page 6

6

Gasifying boilers VIGAS

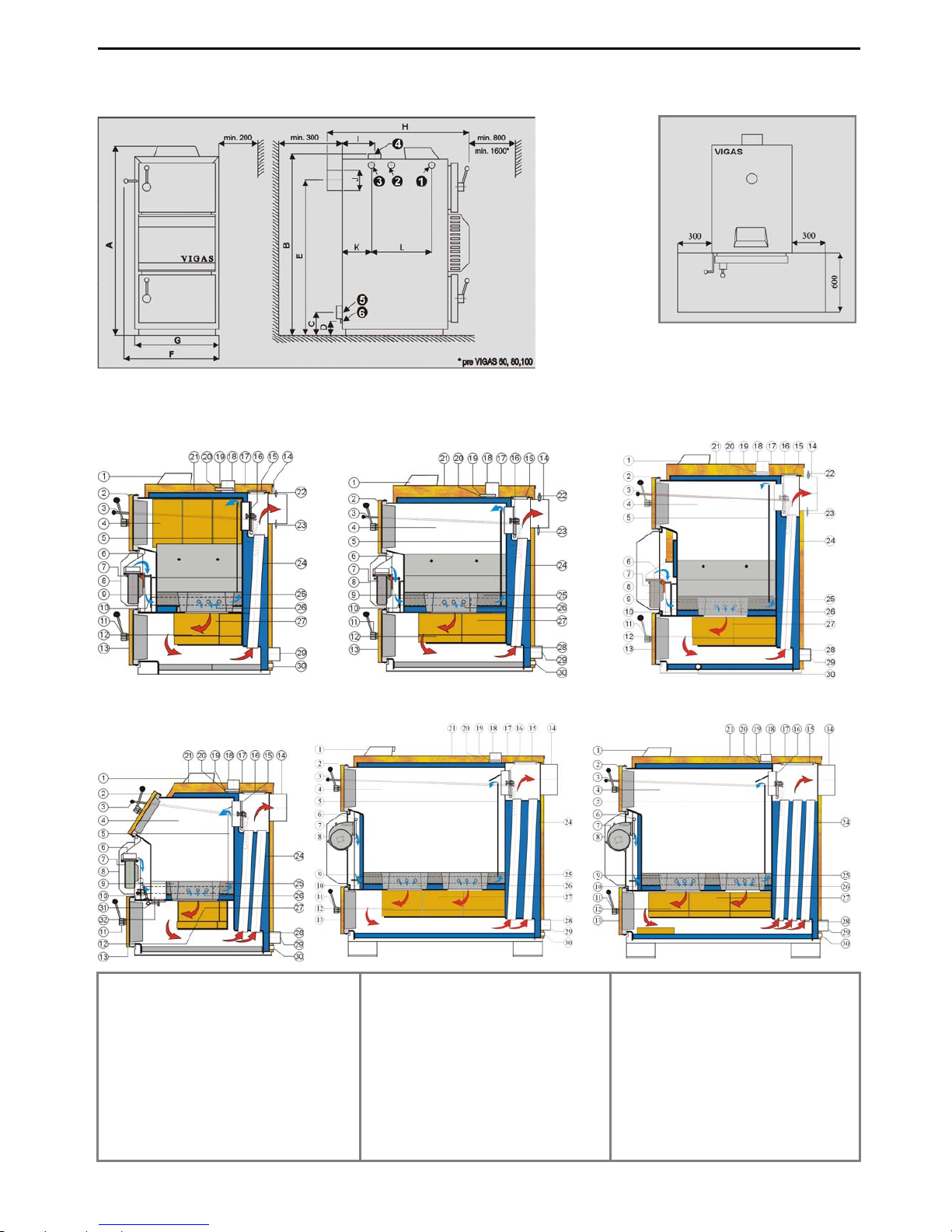

2.1 DIMENSION CHART AND THE POSITION OF PROTECTIVE SUPPORT PLATE ON

EASILY IGNITABLE FLOOR

2.2 BOILER SCHEMATICS

Pic.1 Pic.2

KEY

1. AK 3000 control

2. Upper door

3. Chimney flap operating rod

4. Fuel bunker

5. Primary air conduction

6. Flap for Lambda control servo

7. Fan

8. Fan cover

9. Heatproof nozzle

10. Secondary air screen

11. Door closing device

12. Fireclay bricks

13. Bottom door

14. Chimney neck

15. Exchanger cap

16. Lighting up damper

17. Upper back cover

18. Outlet water neck

19. Thermal fuse

20. Thermometer

21. Upper front cover

22. Lambda sensor

23. Gases thermometer

24. Exchanger pipes

25. Heat proof /concrete/ filling

26. Secondary air

27. Combustion chamber

28. Direction of gases

29. Neck of reversible water

30. Fillng neck

31. Cleaning flap for 29UD

32. Cleaning hole for 29UD

Scheme VIGAS 60,80

Scheme VIGAS 25 Scheme VIGAS 40

Scheme VIGAS 100

Scheme VIGAS 16

Scheme VIGAS 29 UD

Pic.3

Inlet water neck

for valve (Danfoss)

Hole for

submersible case

(Danfoss)

Exhaust brand of

cooling water

Exhaust water

neck

Inlet water neck

Filling neck

Page 7

7

Gasifying boilers VIGAS

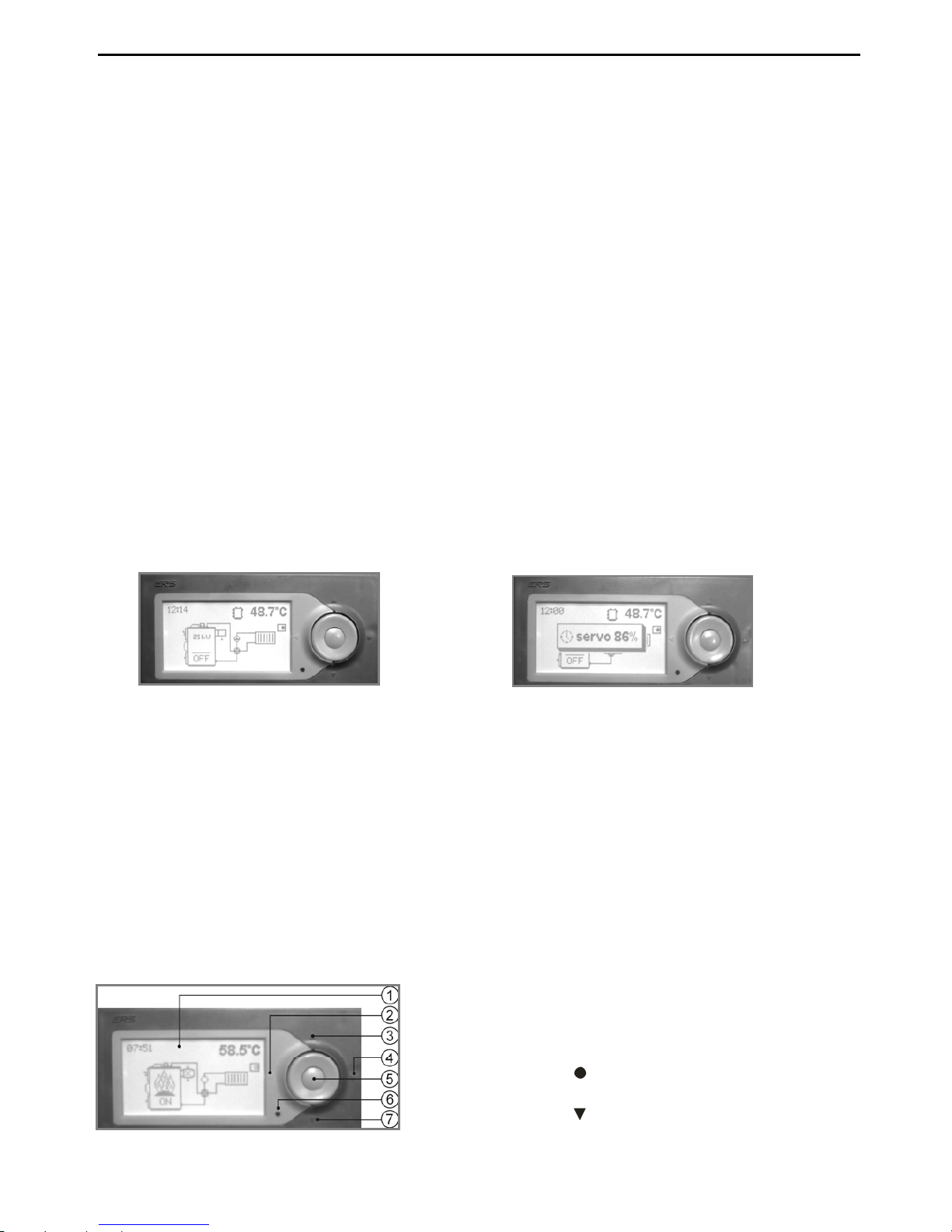

3. DESCRIPTION OF AK 3000 CONTROL

3.1 Safety Instructions

Check protection (cover) metal sheet before plug-in the power wire

Avoid any contact of power wire with hot parts of the boiler (f.e. chimney)

Make sure, no water is allowed under the upper isolation (risk of short circuit)

Do not stress the power wire

Always disconnect the power wire when a new electrical components are connecting (f.e.

indoor thermostat, discharge fan or circulation pump)

Do not remove protection (cover) metal sheet during the boiler operation, especially from

fan

Compare working voltage displayed on the label with your distribution network

Always observe safety regulations

3.2 Connecting to the distributing network

AK 3000 control is integral part of VIGAS boilers.

Control is connected when power wire is plugged in to the distributing network 220/230V. Display

is active when power wire is plugged-in (Pic.4). Servo-flat used in VIGAS

Lambda Control

is set to

base position (Pic.5).

3.3 Working conditions

Operation temperature range of AK 3000 control is +5°C to +45 °C. Control may not be used in

humid enviroment or direct sunlight.

3.4 Maintainance of AK 3000 control

Keep in clean and dust-free enviroment. Antistatic, or wet wipper is adivsed to wipe-off dust and

impurities from metal cover and control panel.

3.5 Control panel

Part of the electronic control is panel, equipped with buttons, pictograms and display. Futher

informations will be available in the next part of this manual.

Pic.6

Pic.5

1. Graphical display 128 x 64 pixels

2. Button ◄ with functions

3. Button ▲ with functions

4. Button ► with functions

5. Button (ENTER) with functions

6. LED control

7. Button with functions

Pic.4

Page 8

8

Gasifying boilers VIGAS

Functionality of each button are composite and their functionality deppends accompanying

description on display and from manufacture settings.

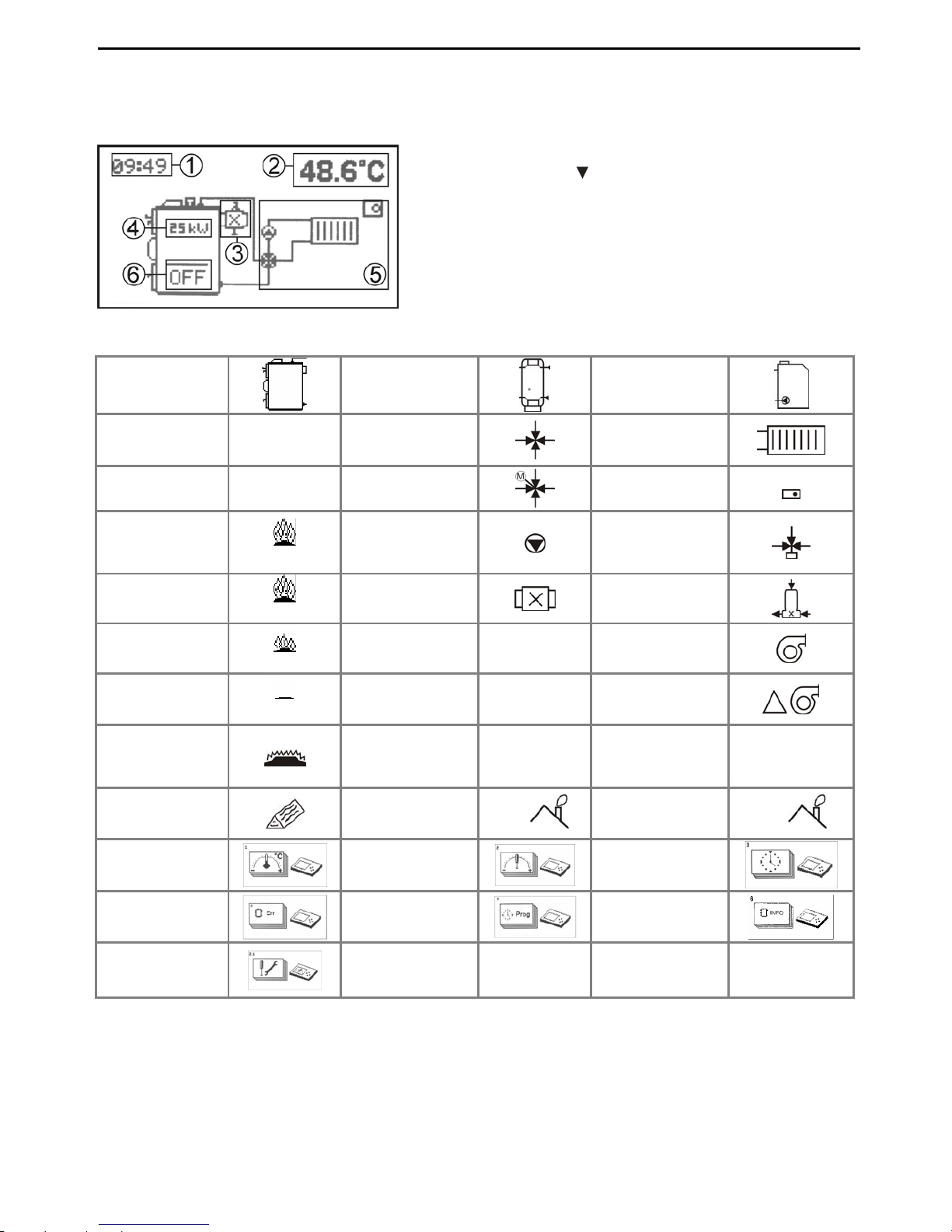

3.6 Symbols

1. Real time indication.

2. Indication of current boiler values.

Modification ▲ or .

3. Indication od discharge fan, lambda sensor, gases

thermometer

4. Indication of nominal boiler output when switched off.

5. Graphically indicated hydraulic scheme of

connection.

6. Indication of boiler status.

Pic.

7

Boiler

Storage tank

External boiler

Boiler „ON“

ON

DUOMIX

Heating circuit

Boiler „OFF“

OFF

DUOMIX with

servomotor

Indoor

thermostat

Heating

ON

Pump

3-way

thermostatic

valve

Burning

73 0C

Discharge fan

LADOMAT

Afterflaming

52 0C

Lambda

λ

Fan

End of burning

END

Thermometer

T

Fan change

output

Indoor

termostat

decay

Error indication

value

x

Open flap servo 50%

Adding fuel

Minimal value

of gases

min

Maximal value

of gases

max

Temperature

settings

Parameter

settings

Time setting

Error

messages

Program

Konfiguration

informations

Service

message

Page 9

9

Gasifying boilers VIGAS

4. VIGAS BOILER IN BASIC CONFIGURATION

(without discharge fan, gases thermometer and lambda sensor)

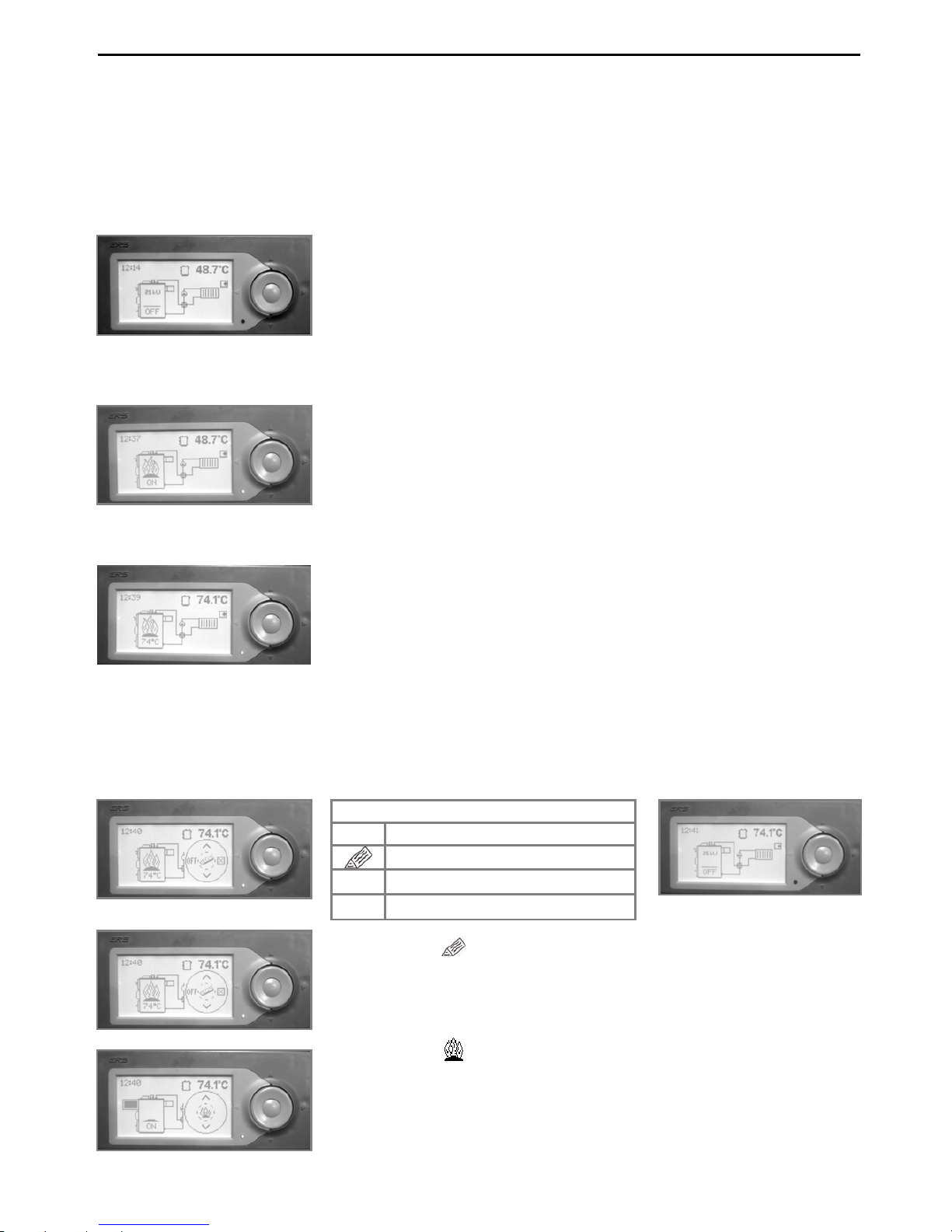

4.1 VIGAS BOILER OPERATING

4.1 .1 Boiler activation

4.1.2 Boiler activated – heating mode

4.1.3 Boiler activated – burning mode

4.1.4 Adding fuel, Disconnection the boiler (manually)

Using graphical control. To call the graphical control, press central button ENTER. Graphical

control offers option to switch off, adding fuel or cancel the graphical control.

If boiler is in unactive status with symbol „OFF“, as displayed on

the picture, by pressing the central button ENTER the boiler start

the operation.

Choose one option

OFF Switch-off

Add fuel

⌧

Cancel the control

bc

Change the indicated value

By pressing „ “ fan will be switched off. By using the rod open

the chimney flap, consequently open the upper door. You can add

fuel, if necessary. Close the upper door and chimney flap.

By pressing „ “ adding fuel will be stopped. Fan will be switchedon automatically.

Boiler is set to heating mode, if temperature of outgoing water is

lower, then set shotdown temperature of the boiler. Shotdown

temeperature is in settings. Usually is set to 50

0

C. Pump is pulse

working in dependence on temperature of the boiler water! The

pump is working, when symbol flash.

The burning mode is active after the shotdown temeprature is

higher + time deviation. In this mode pump is working pulse (bolie

r

protection against low-temperature corrosion), 50C before set

temperature constantly. The pump is working, when symbol flash.

Boiler is responsive to indoor thermostat, when indoor thermostat is

switched off boiler slowly decreasing its output.

Page 10

10

Gasifying boilers VIGAS

„ENTER“

By ▲ buttons set the parameter you want to edit and by

pressing „ENTER“ button, the value starts to flash. ▲ buttons

set requested value.

end

Choose shotdown temperature of the boiler

„ “

Increase or decrease the value, maximal output will be

changed. Is adviced to decrease the value in transition

period (boiler tar level will drop).

Â

Brightness

Roll

Press „yes“ will acitivate the value rolling (Pic.6/2)

Help 0s

Set the time when graphical control will be indicated

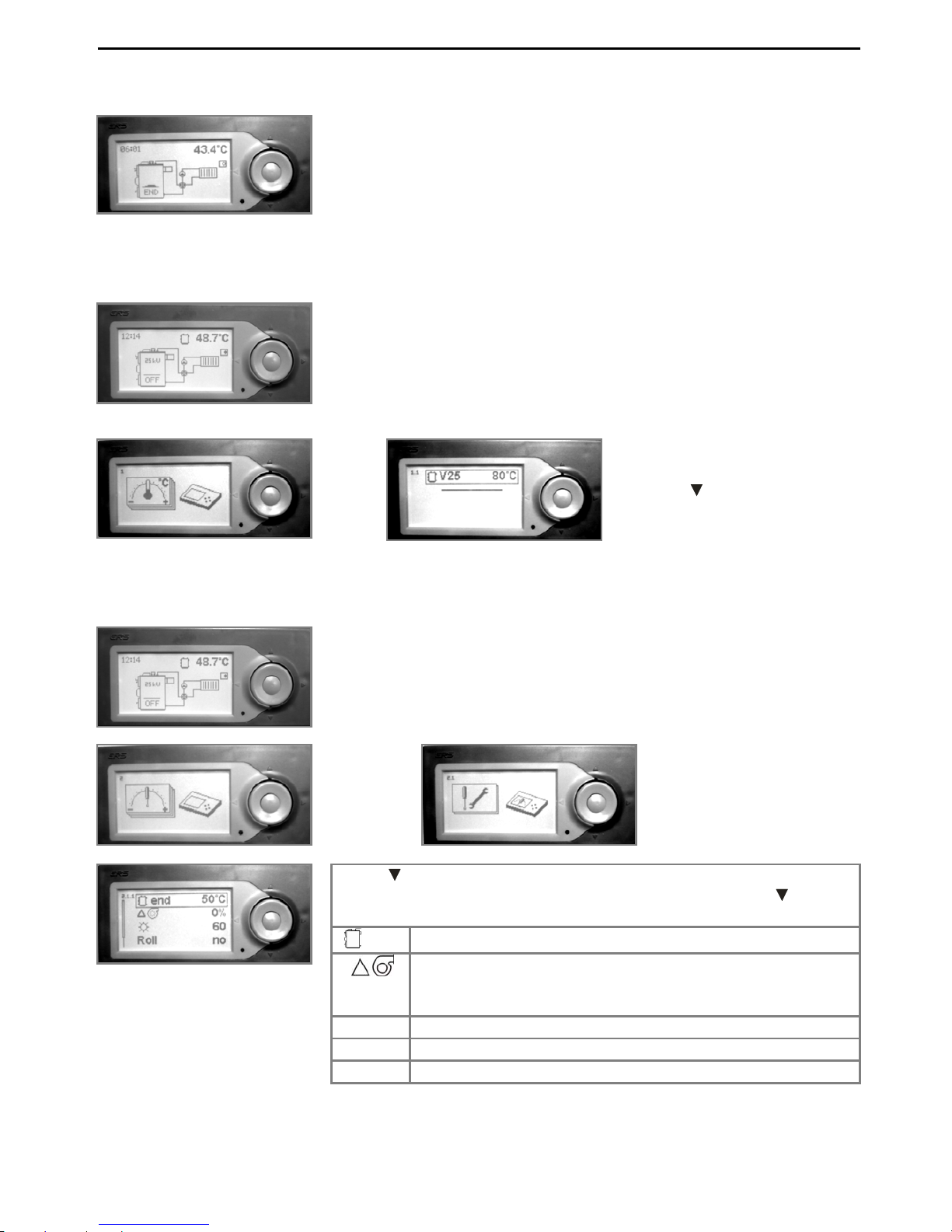

4.1.5 Disconnection the boiler (Automatically)

4.2 TEMPERATURE SETTINGS OF OUTLET WATER

4.3 PARAMETERS SETTING OF VIGAS BOILER

When temperature drops under the shotdown temperature (see

Parameter settings of Vigas boiler in basic configuration) boiler is

switch-off automatically. „END“ will be indicated on the display. By

pressing „ENTER“ boiler will start operating again.

To call temperature setting hold „ENTER“ button at any boile

r

status. Symbol of the temperature setting will be indicated on the

display. Press „ENTER“ again. Symbol of the nominal output will

be indicated on the display with value, together with temperature of

outlet water in °C. By pressing the „ENTER“ button, the value start

to flash.

„ENTER“

Temperature is flashing, by using

buttons ▲

choose requested

value. Button ► will exit the

temperature settings.

To call parameters setting hold „ENTER“ button at any boile

r

status and by pressing ▲ button. Press „ENTER“ again Symbol of

the parameters setting will be indicated on the display. By pressing

the „ENTER“ button twice, the values you can set will be indicated

on the display.

„ENTER“ „ENTER“

Page 11

11

Gasifying boilers VIGAS

5. VIGAS BOILER IN CONFIGURATION WITH GASES

THERMOMETER

(without discharge fan and lambda sensor)

The advantage of the gases thermometer is elimination of the maximal gases temperature, if it will

be reached, it will effect the speed drop of fan. As consequence will be increased efficiency

followed by low fuel consumption. In configuration with storage tank, its used for boiler to

shotdown when burn-out all fuel, water boiler temperature in tank has no influence to shotdown.

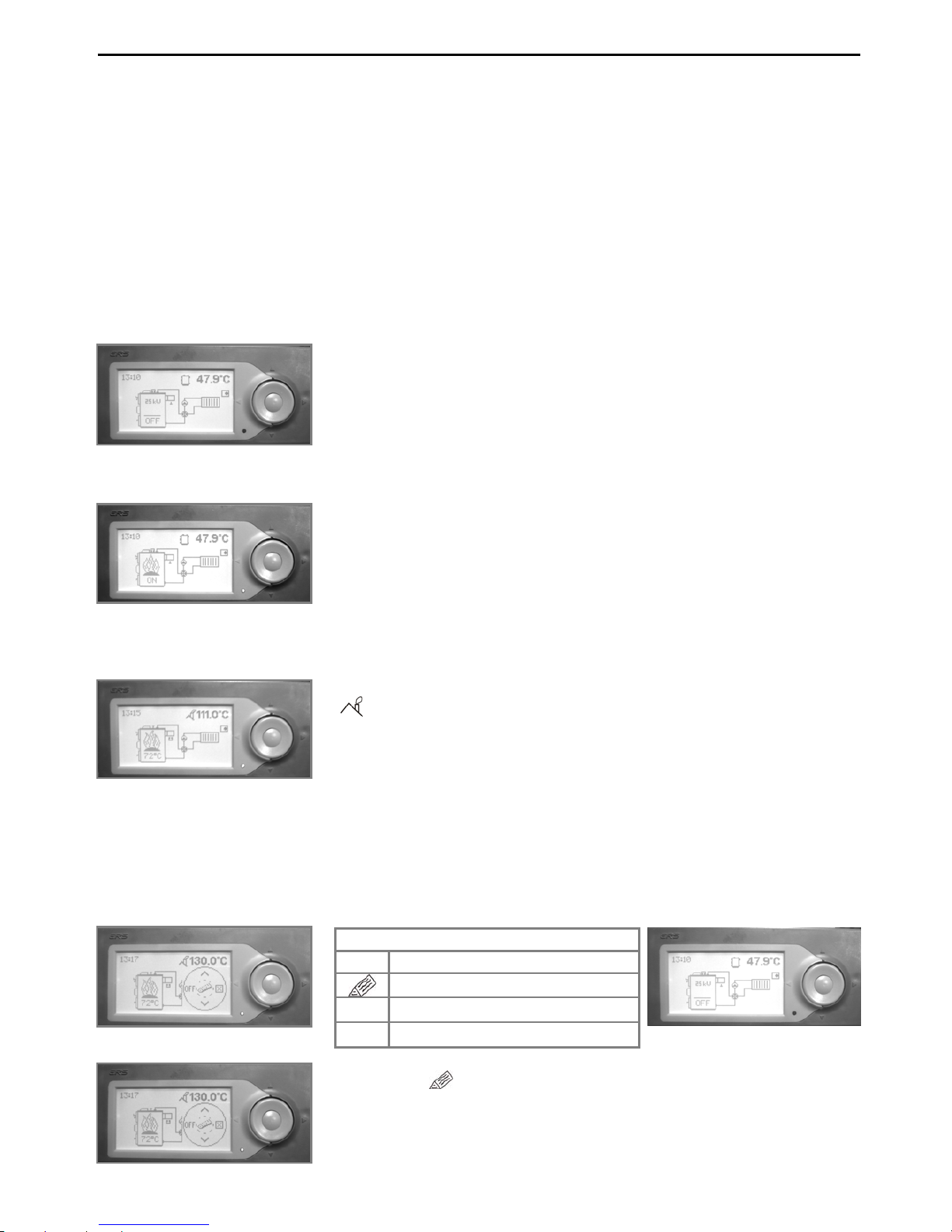

5.1 VIGAS BOILER CONTROL

5.1.1 Boiler activation

5.1.2 Boiler activated – heating mode

5.1.3 Boiler activated – burning mode

5.1.4 Adding fuel, Disconnection the boiler (manually)

Using graphical control. To call the graphical control, press central button ENTER. Graphical

control offers option to switch off, adding fuel or cancel the graphical control.

Boiler is set to heating mode, if outgoing gases temperature is

lower, then set minimal gases temperature. Minimal gases

temperature, as well as, maximal gases temperature can be set in

boiler settings. Minimal gases temperature is set on 90°C, maximal

gases temperature is on 200°C, which are standard settings.

Pump is pulse working in dependence on temperature of the boile

r

water!

If boiler is in unactive status with symbol „OFF“, as displayed on

the picture, by pressing the central button ENTER the boiler start

the operation.

The burning mode is active after the gases temeprature is highe

r

( end) + 20

0

C. In this mode pump is working pulse (bolie

r

protection against low-temperature corrosion). The pump is

working, when symbol flash. Boiler is responsive to indoo

r

thermostat, when indoor thermostat is switched off boiler slowly

decreasing its output.

Choose one option

OFF Switch off

Add fuel

⌧

Cancell the control

bc

Change the indicated value

By pressing „ “ fan will be switched off. By using the rod open

the chimney flap, consequently open the upper door. You can add

fuel, if necessary. Close the upper door and chimney flap.

Page 12

12

Gasifying boilers VIGAS

Choose one option

+60 Discharge fan active for 60s. (Using when heating)

ON Boiler activation

⌧

Cancell the control

bc

Change the indicated value

If „+60“ is chosen, new graphical control is indicated. In left

corner is running time of discharge fan.

+60 Another 60s. could be added. 300s. maximum

ON Boiler activation

0 Discharge fan disconnection

bc

Change the indicated value

5.1.5 Disconnection the boiler (Automatically)

6. VIGAS BOILER IN CONFIGURATION WITH GASES

THERMOMETER AND DISCHARGE FAN

(without lambda sensor)

Advantages of gases thermometer are described in Chapt.5. Main advangate of discharge fan is

increased comfort during heating or adding fuel. When discharge fan is active during adding fuel

there is significant decrease of smudging into boiler-room. During the heating, discharge fan will

accelerate the burning.

6.1 VIGAS BOILER CONTROL

6.1.1 Boiler activation

When gases temperature drops under the set temperature

( end) boiler is switch-off automatically. „END“ will be indicated

on the display. By pressing „ENTER“ boiler will start operating

again.

If boiler is in unactive status with symbol „OFF“, as displayed on

the picture, by pressing the central button ENTER the boiler start

the operation.

By pressing „ “ adding fuel will be stopped. Fan will be switched

on automatically.

Page 13

13

Gasifying boilers VIGAS

6.1.2 Boiler activated – heating mode

6.1.3 Boiler activated – burning mode

6.1.4 Adding fuel, Disconnection the boiler (manually)

5.1.6 Disconnection the boiler (Automatically)

Boiler is set to heating mode, if outgoing gases temperature is

lower, then set minimal gases temperature ( end). Minimal gases

temperature, as well as, maximal gases temperature can be set in

boiler settings. Minimal gases temperature is set on 90°C, maximal

gases temperature is set on 200°C, which are standard settings.

Pump is pulse working in dependence on temperature of the boile

r

water!

The burning mode is active after the gases temeprature is highe

r

( end) + 20

0

C. In this mode pump is working pulse (bolie

r

protection against low-temperature corrosion). The pump is

working, when symbol flash. Boiler is responsive to indoo

r

thermostat, when indoor thermostat is switched off boiler slowly

decreasing its output.

Choose one option

OFF Switch off

Add fuel

⌧

Cancell the control

bc

Change the indicated value

By pressing „ “ fan is swithed off and discharge fan is

automatically activaed on 300s. In left corner is running time o

f

discharge fan. If „+60“ is chosen, new graphical control is indicated.

By using the rod open the chimney flap, consequently open the

upper door. You can add fuel, if necessary. Close the upper doo

r

and chimney flap. By pressing „0“ discharge fan is swithed off. By

pressing adding fuel is finished, discharge fan is switched off

automatically and fan will switched on.

When gases temperature drops under the set temperature

( end) (boiler is switch-off automatically). „END“ will be

indicated on the display. By pressing „ENTER“ boiler will start

operating again.

Using graphical control. To call the graphical control, press central button ENTER. Graphical

control offers option to switch off, adding fuel or cancel the graphical control.

Page 14

14

Gasifying boilers VIGAS

7. VIGAS BOILER IN CONFIGURATION WITH

Lambda Control

(without discharge fan)

Advantages of gases thermometer are described above. VIGAS

Lambda Control

boiler is delivered with

built-in gases thermometer. VIGAS

Lambda Control

boiler utilizes informations from lambda sensor of

oxygen overflow in gases, to control the flap of primary and secundary air. This system allows to

burn all kinds of wood more efficiently and at the same time decreaseing the fuel consumption by

20-25%.

7.1 VIGAS

Lambda Control

BOILER CONTROL

7.1.1 Boiler activation

7.1.2 Boiler activated – heating mode

7.1.3 Boiler activated – burning mode

7.1.4 Adding fuel, Disconnection the boiler (manually)

Using graphical control. To call the graphical control, press central button ENTER. Graphical

control offers option to switch off, adding fuel or cancel the graphical control.

If boiler is in unactive status with symbol „OFF“, as displayed on

the picture, by pressing the central button ENTER the boiler start

the operation.

The burning mode is active after the gases temeprature is highe

r

( end) + 200C. Servo-controled flap wokrs in this mode as in

heating mode. In this mode pump is working pulse (bolie

r

protection against low-temperature corrosion). The pump is

working, when symbol flash.

Servo-controled flap will move to open position (servo 100%)

when „ENTER“ button is pressed. Consequently, futher steps

(from 100% up to 45%) is moved that, value of lambda sensor is

kept close to set value (λ 1,35). In position (servo 45%)

secundary air is closed, in position (servo 0%) also primary air is

closed. To position 0% will be moved only if the boiler is „OFF“ o

r

„END“. Boiler is set to heating mode, if outgoing gases

temperature is lower, then set minimal gases temperature (

end). Minimal gases temperature, as well as, maximal gases

temperature can be set in boiler settings. Minimal gases

temperature is set on 90°C, maximal gases temperature is set on

200°C, which are standard settings. Pump is pulse working in

dependence on temperature of the boiler water!

Choose one option

OFF Switch off

Add fuel

⌧

Cancell the control

bc

Change the indicated value

Page 15

15

Gasifying boilers VIGAS

Choose one option

+60 Discharge fan active for 60s. (Using when heating)

ON Boiler activation

⌧

Cancel the control

bc

Change the indicated value

If „+60“ is chosen, new graphical control is indicated. In left corner

is running time of discharge fan.

+60 Another 60s. could be added. 300s. maximum

ON Boiler activation

0 Discharge fan disconnection

bc

Change the indicated value

7.1.5 Boiler disconnection (automatically)

8. VIGAS

Lambda Control

BOILER IN CONFIGURATION WITH

GASES THERMOMETER AND DISCHARGE FAN

Advantages of gases thermometer and discharge fan are described above. VIGAS

Lambda Control

boiler utilizes informations from lambda sensor of oxygen overflow in gases, to control the flap of

primary and secundary air. This system allows to burn all kinds of wood more efficiently and at the

same time decreaseing the fuel consumption by 20-25%.

8.1 VIGAS

Lambda Control

BOILER CONTROL

8.1.1 Boiler activation

If boiler is in unactive status with symbol „OFF“, as displayed on

the picture, by pressing the central button ENTER the graphical

control will be called.

By pressing „

“ fan is switched off. By using the rod open the

chimney flap, consequently open the upper door. You can add

fuel, if necessary. Close the upper door and chimney flap. By

pressing „ “ adding fuel will be stopped. Fan will be switched on

automatically. During fuel adding, servo-controled flap is in the

same position as before fuel adding. When adding is finished,

servo-controled flap will be moved to position (servo 100%).

Consequently, futher steps (from 100% up to 45%) is moved that,

value of lambda sensor is kept close to set value (λ 1,35). In

position (servo 45%) secundary air is closed, in position (servo

0%) also primary air is closed. To position 0% will be moved only

if the boiler is eighter „OFF“ , „END“ or switched-off fan.

When gases temperature drops under the set temperature

( end) (boiler is switch-off automatically). „END“ will be

indicated on the display. Servo-controled flap will be moved to

position (servo 0%). In this position secondary air is closed as

well as primary air. By pressing „ENTER“ boiler will start

operating again.

Page 16

16

Gasifying boilers VIGAS

8.1.2 Boiler activated – heating mode

8.1.3 Boiler activated – burning mode

8.1.4 Adding fuel, boiler disconnection (manually)

Using graphical control. To call the graphical control, press central button ENTER. Graphical

control offers option to switch off, adding fuel or cancel the graphical control.

Servo-controled flap will moves to open position (servo 100%)

when „ON“ button is pressed. Consequently, futher steps (from

100% up to 45%) is moved that, value of lambda sensor is kept

close to set value (λ 1,35). In position (servo 45%) secundary air is

closed, in position (servo 0%) also primary air is closed. To position

0% will be moved only if the boiler is „OFF“ or „END“. Boiler is set

to heating mode, if outgoing gases temperature is lower, then set

minimal gases temperature ( end). Minimal gases temperature,

as well as, maximal gases temperature can be set in boiler

settings. Minimal gases temperature is set on 90°C, maximal

gases temperature is set on 200°C, which are standard settings.

Pump is pulse working in dependence on temperature of the boile

r

water!

The burning mode is active after the gases temeprature is highe

r

( end) + 200C. Servo-controled flap wokrs in this mode as in

heating mode. In this mode pump is working pulse (bolie

r

protection against low-temperature corrosion). The pump is

working, when symbol flash.

Choose on option

OFF Switch off

Add fuel

⌧

Cancell the control

bc

Change the indicated value

By pressing „ “ fan is swithed off and discharge fan is

automatically activaed on 300s. In left corner is running time o

f

discharge fan. If „+60“ is chosen, new graphical control is indicated.

By using the rod open the chimney flap, consequently open the

upper door. You can add fuel, if necessary. Close the upper doo

r

and chimney flap. By pressing „0“ discharge fan is swithed off. By

pressing adding fuel is finished, discharge fan is switched off

automatically and fan will switched on. During fuel adding, servocontroled flap is in the same position as before fuel adding. When

adding is finished, servo-controled flap will be moved to position

(servo 100%). Consequently, futher steps (from 100% up to 45%)

is moved that, value of lambda sensor is kept close to set value (λ

1,35). In position (servo 45%) secundary air is closed, in position

(servo 0%) also primary air is closed. To position 0% will be moved

only if the boiler is eighter „OFF“ , „END“ or switched-off fan.

Page 17

17

Gasifying boilers VIGAS

By ▲ buttons set the parameter you want to edit and by

pressing „ENTER“ button, the value starts to flash. ▲ buttons

set requested value.

max

Choose maximal gases temperature that will result in

decreasing the operating speed

end

Choose shotdown temperature of the boiler

λ

Lambda value, that servo-controled flap keeps.

Recommended is 1,35.

„ “

Increase or decrease the value, maximal output will be

changed. Is adviced to decrease the value in transition

period (boiler tar level will drop).

Â

Brightness

Roll

Press „yes“ will acitivate the value rolling (Pic.7/2)

Help 0s

Set the time when graphical control will be indicated

8.1.5 Boiler disconnection (automatically)

8.2 PARAMETERS SETTING VIGAS

Lambda Control

BOILER AND VIGAS BOILER

WITH GASES THERMOMETER

9. TIME SETTING

Set time and date, when boiler is pluged first time. In left corner is time is indicated.

When gases temperature drops under the set temperature

(

end) (boiler is switch-off automatically). „END“ will be

indicated on the display. Servo-controled flap will be moved to

position (servo 0%). In this position secundary air is closed as

well as primary air. By pressing „ENTER“ boiler will start

operating again.

To call parameters setting hold „ENTER“ button at any boielr status

and by pressing ▲ button.

„ENTER“

To call parameters setting press longer „ENTER“ button at any

boielr status and by pressing ▲ button twice.

By ◄ button set date or time, that will be edited. ▲ buttons

choose date and time. Button ► will exit the settings

.

Mon – Monday, Tue – Tuesday, Wed – Wednesday, Thu –

Thursday, Fri – Friday, Sat – Saturday, Sun – Sunday

Page 18

18

Gasifying boilers VIGAS

STB

10. HARDWARE AND SOFTWARE INFORMATION

11. ERROR MESSAGES

11.1 STB failure

At „STB“ failure boiler is overheated. Thermal

fuse is activated (Pic.3/21). The fan is

disconnected from voltage. Boiler is activated

again only if „STB“ protection is mechanical

pressed. Boiler is need to be switch-on by

„ENTER“ button.

12. SERVICE SETTINGS PIN 0000 PROTECTED

To call informations setting hold „ENTER“ button at any boiler

status and by pressing button.

▲ buttons choose modul and confirm „ENTER“. Information

about the module will be indicated on display.

To call error messages hold „ENTER“ button at any boielr status

and by pressing 3 times. By pressing „ENTER“ error with

description will be indicated on display.

Service settings PIN 0000 protected can be used only in restricted

cases. Only trained service engineer can do these settings. (In

necessary cases client can do also). In service settings are

adjusted boiler type with accessories and hydraulic connection

scheme, etc.

To call the service setting PIN 0000 protected as follows:

1. Hold „ENTER“ button at any boielr status

2. Press ▲ button

3. Hold ◄ button for 4s - „PIN 0000“ will be indicated

4. Press „ENTER“ 4 times

5. Service settings symbol will be indicated on display

6. Press „ENTER“ and buttons ▲ choose service setting of

boiler type, hydraulic connection scheme, micro SD card,

service operation and press „ENTER“ .

Page 19

19

Gasifying boilers VIGAS

12.1 Settings for micro SD card

AK 3000 control can be extenended by SD modul (Pic.8). Micro SD card of different capacity is

plugged into SD module.

12.2 Service settings boiler type with accessories

WARNING

Graphical control unit AK 3000 is used to control all types of VIGAS

boilers. It is important, software settings must be same as type of

the boiler. In deactivated boiler status „OFF“ boiler type is

indicated on the display, that is equal to boiler nominal output. For

correct boiler operation, boiler type must match with boiler

type marked on boiler label.

In case of control unit exchange, always must be AK 3000

checked!!!

Continue Chapt.14

7. Press „ENTER“, display indicates :

Boiler type V- VIGAS, xx – nominal output, L – lambda

TVZ – hot-air, UD – coal – wood, DP – wood – pellets

λ

yes – boiler with lambda sensor, no – boiler without

lambda sensor

yes – boiler with gases thermometer, no – boiler

without gases thermometer

yes – boiler with discharge fan, no – boiler without

discharge fan

8. Buttons▲ choose parameter and press ENTER

9. Button ► will exit the settings

Boiler List

V 16 V 80

V 16L V 80L

V 25 V 100

V 25L V 100L

V 40 V 25TVZ

V 40L V 29UD

V 60 V 18DP

V 60L

By pressing „ENTER“ symbols that micro SD cards allows will be

indicated on the display. Buttons ▲ choose the task, you want to

realize and then press „ENTER“.

Pic.

8

Micro SD card allows:

Loading of back-up software to control unit of the boiler

Software back-up to SD card

Loading of updated software from SD card to control unit o

f

the boiler

Selected parameters boiler back-up (f.e. boiler temperature,

fan speed, lamdba sensor value, etc.)

SD card erasing

Page 20

20

Gasifying boilers VIGAS

12.3 Service settings hydraulic scheme connection

12.4 Service tools

WARNING

The output contol of the pump will be changed by hydraulic

connection. It is important, that software setting of hydraulic pump

match the setting of the boiler in connection with central heating

system. Basic memory of control contains 4 schematics. It is

possible to add more schematics if necessary. Schematics that are

used for additional module „EXPANDER“ are delivered on mini

SD card, or will be available on www.ers.sk , free to download,

through PC to memory card that will be inserted to the module of

the boiler control (Chapt.13).

If necessary, is it possible to return to last scheme to press „last“

Continue Chapt.14

7. Press „ENTER“, scheme 1 indicates on the display

8. Buttons ▲ choose requested scheme and press ENTER.

9. Button „ENTER“ confirm „Yes“ – to save scheme

10. To exit use ► button

Scheme 1 :

Scheme is dedicated for boiler with storage tank. „LADOMAT“

provides reverse water protection. Pump is connected to boiler

control and working over 40 oC. Requested temperature is possible

to set up to 90 oC. T3 contact on mother board AK 3000 S is used

for connection to thermometer PT 1000, which is able to measure

temperature in stogare tank.

Warning: It is not possible to connect indoor thermostat to T3

contact.

Scheme 2 :

Scheme is dedicated to central heating systems, where reverse

water protection provides external control system. Pump is

connected to the control and it is working pulse in dependence of

boiler water temperature. T3 contact on mother board is used to

connect indoor thermostat.

Scheme 3 :

Scheme with 3-way thermostatic valve. Pump is connected to the

control and it is working pulse in dependence of boiler water

temperature. T3 contact on mother board is used to connect indoor

thermostat.

Scheme 4 :

Scheme is set as a standard. Pump is connected to the control and

it is working pulse in dependence of boiler water temperature. T3

contact on mother board is used to connect indoor thermostat.

Funcionality of each system can be check in service settings by

symbols indicated on display. Press „ENTER“ and selected

system will be activated.

Page 21

21

Gasifying boilers VIGAS

13. OPERATING INSTRUCTIONS

13.1 Before operation:

13.2 Boiler operation

1. Connect boiler to distributing network (230V/50Hz) by power wire.

2. Wait when dispay will be activated to basic indication:

a) without lambda sensor – immediately,

b) with lambda sensor – 30 sec., approx. ( automatical server initialization).

3. Chapt. 4 – 8 choose the configuration that match to your boiler configuration with accesories,

that will help to control AK 3000.

4. Set the boiler with AK 3000 control to deactvated mode "Off".

5. Fuel heating:

a) by using the rod open the chimney flap (Pic.3/3),

b) open the upper door (Pic.3/2) on fireproof ceramics (Pic.3/9) put the paper so that

small piece of paper extend to lower burning chamber (Pic.3/25), woodchips, cleft

timber,and fill-up with fuel,

c) close upper door and open slightly lower (Pic.3/13) to start heating the fuel(obr.3/4), in

configuration with discharge fan, the heating will be quicker to activated the fan.

d) close lower door and chimney flap when fuel is burning; 10 – 15 minutes,approx.,

6. Activate the boiler to „ON“. Boiler starts to gasyfing and control its output automatically to

set temperature.

7. To refil the fuel follow steps in chap. 4 – 8.

8. To deactivate the boiler, follow steps in chap. 4 – 8.

13.3 Keeping operation and output regulation

Fuel in boiler is moved spontaneously in the direction to fireproof nozzle. Ash falls through

nozzle and deposits in combustion chamber. Boiler output is regulated automatically according to

the set temperature of outlet water. If there is mains failure during a longer period of time or if

automatic regulation fails, it is possible to heat as follows (it is only applicable for the systems of

central heating with gravitation flow): open chimney flap and let bottom door open a little. If this

heating is used, it is necessary to check outlet temperature more frequently and to add less fuel.

The boiler may easily become overheated if the whole fuel bunker is filled.

▪ to be informed with operatong instructions and how to operate the electronic control AK 3000,

▪ to check teh water pressure in the system of cental heating (3 bars. max),

▪ to connect accessories (f.e. pump, discharge fan or indoor thermostat),

▪ to check the placing of fireclay bricks in combustion chamber pic.3,

▪ to check the cover metal sheets,

▪ to check the power to mains (230V/50Hz),

▪ to prepare sufficient amount of fuel for heating and burning.

Burning fuler

Lower door open

Page 22

22

Gasifying boilers VIGAS

13.4 Refilling the fuel bunker with fuel

▪ open chimney flap with the help of operating rod (Pic.3/3),

▪ on graphical control press ( Available in Chapt. 4 – 8)

▪ open upper door with caution, to smoke venting

▪ refill necessary volume of fuel through upper door (Pic.3/2)

▪ close upper door (Pic.3/2) and chimney flap (Pic.3/3),

▪ button will exit refuel

Important !!!

▪ Use correct fuel only

▪ Is adviced to not overload with fuel when operating the boiler in transition peridod, boiler

tar level will drop.

▪ When adding fuel, do not let it remain between flange and chimney flap, which might

prevent flap to close properly.

▪ Lay fuel to boiler not to prevent upper door to close. Forcible closing may damage lining.

▪ We recommend to supervise boiler according to operation conditions by the person older than

18 years.

13.5 Boiler cleaning

If wood burning is optimal and minimum

temperature of return water is kept, 60°C,

gasification chamber, completing combustion

space and exchanger are sooted minimally. If wet

fuel is used, steam is condensed on the walls of

combustion chamber and tar is created on surface.

▪ Gasification chamber cleaning

It is necessary to remove tar from gasification chamber once per week. We recommend to

burn it with upper door and chimney flap open. With regard to the fact that inner walls of

boiler have aluminium coating, we do not recommend to scrape tar off mechanically ( it is only

applicable for VIGAS 16, 25,40,UD29).

Excessive quantity of ash, that did not fall through nozzle (9) picture 3 into fireclay combustion

Primary air hole

Pic. VIGAS 60,80,100

Page 23

23

Gasifying boilers VIGAS

chamber, must be removed from time to time. Thus you will increase the space of fuel bunker

to original size and you will release the flow of primary air into gasification chamber. Check

the continuity of openings for the intake of primary air on regular basis. If the openings are

clogged, release them.

Combustion chamber cleaning

Sweep ash and dust that fell to combustion chamber with a scraper. It is sufficient to sweep

ash dust that settles in combustion chamber once per 3-5 days.

Exchanger cleaning

It is necessary to clean exchanger pipes once per month with a “cleaning plate”.

Put cap away, (15) picture 3, and thus you will have an access to exchanger

pipes.

Recommendation: If you do not clean the exchanger on time and it is too dirty,

do not use any dissolvent for tar. Boiler must be clean while it is hot. Heat boiler through open

chimney flap and upper door approx. at 800C ( without fan). Then close flap and door.

Carefully (use gloves) open exchanger cap. Clean dirty exchanger with relevant accessories.

After cleaning, close exchanger cap and let boiler burn / gasification/ approx 5 hours as

maximum output in order the rest of tar might burn.

Warning: Boiler room must be properly ventilated during burning.

Air piping cleaning

The clearness of boiler piping system is a necessary condition for right burning. If you mainly

use sawdust, it is necessary to clean the piping system once per heating season. After putting

fan cover (8) picture 3 and sheet cover of piping away, you will get access to two pipes. Use

vacuum cleaner to remove sawdust and check continuity.

Step

3

.

Secondary air

Primary air

Step 1. Step 2. Step 3.

Primary air

Secondary air

Page 24

24

Gasifying boilers VIGAS

VIGAS UD 29 cleaning

If you use brow coal, clean boiler as stated for wood. Clean fuel bunker with a cleaning flap (12) picture

3 and ashtray drawer (31)picture 3 as follows

1. Open bottom door (15) picture 5, stuff ashtray drawer and close door

2. Open cleaning flap and upper door (2) picture 5.

3. Use relevant accessories to pile up ash from fuel bunker space to drawer

4. Wait some time, open bottom door, take drawers and close it

WARNING: Do not leave ashtray drawer in boiler during operation.

14. BOILER MAINTENANCE AND REPAIRS

The contractor ensures regular checks and boiler maintenance. During boiler operation, it is

necessary to check water pressure, door tightness, chimney flap tightness, exchanger cap

tightness, chimney tightness and fan performance.

NOTE: Before boiler shutting down during summer season, clean combustion chamber properly

not to leave any condensed moisture there and open bottom door and chimney flap.

14.1 Door tightness:

Boiler door are stabilized in three points, on two revolving pins and

on closing. If door does not fit tightly, besides revolving closing it is

also possible to fix it from hinge side. You can slightly turn hinge

bolt with releasing and turning nuts and thus you turn door in a

desired direction. In case of sealing rope exchange “1” is a

connecting point.

14.2 Chimney flap tightness:

When cleaning exchanger pipes (Pic. 3/24), check if flap closes tightly. Check chimney flap

(Pic. 3/16) for the same as well. Leakage may result in decreased boiler output.

14.3 Heatproof nozzle

Heatproof nozzle is block made of heatproof concrete used to mix gases

with secondary air and so efficient burning is in progress. Nozzle is located

on water cooling rack. Nozzle is surrounded with heatproof concrete in the

same height as nozzle.Nozzle lifetime depends from mechanical damage

during fuel adding or poke the fire. Therefore, the nozzle is considered as

spare part. Cracks on nozzle are not reason to nozzle exchange, this is

necessary only when nozzle drops. If the nozzle is damaged, its necesary to remove bits and

pieces of old nozzle and then insert new nozzle int the hole. Check if new nozzle fits in the hole.

Ashtray drawer

Page 25

25

Gasifying boilers VIGAS

14.4 Setting the position of servo VIGAS

Lambda Control

boiler

Correct setting of servo and flap for secondary air control is a key factor for burning with minmum

emission. Servo and flap can be set in follows:

Step1: Disconnect power wire from distributing network

230V/50Hz,

Step2: Loose screw „1“ with fork wrench,

Step3: Turn the shaft with screwdriver „2“ to maximal

position, anti-clockwise and push softly in direction to the

boiler, shaft must be rotate easily!!!

Check the flap movement in hole „3“,

Step4: Draw close screw „1“

Step5: Connectpower wire into distributing network

230V/50Hz. Automatical initialization, indicated on display, starts when power wire is connected

into distributing network. During initialization servo will be pushed. When boiler is activated to

„ON“ mode, flap will be moved to opposite position in anti-clockwise direction, where is

controled eighter primary and secondary air to requested value λ.

14.5 Setting the position of secondary air flaps of VIGAS boiler

The quality of burning can be increased by secondary air

flaps. VIGAS

Lambda Control

boilers regulate amount of

secondary air automatically, therefore the quality of the

burning is high. In VIGAS boilers withouth lambda sensor is

adjusted with screws „1“. Optimal settings form production

is adjusted to 2,5 turns „1“. When change or check the

setting follow the steps:

Step1: „1“ loose the safety nut,

Step2: Draw close screw „1“ in direction to the boiler,

Step3: Loose the screw, back on 2,5 turns (optimum),

Step4: Draw close the safety nut.

Boiler without lambda sensor, safety flap is located above the

fan „2“, that avert burning without fan (chimneay draught). If

boiler has lack of output , check flap functionality „2“.

14.6 Lambda sensor and gases thermometer

Cleanness is important for correct functionality of lambda

senosor and gases thermometer. Gently wipe dust from

lambda sensor „1“ and gases thermometer „2“, when

cleaning.

Important: Gases thermometer must be in correct

position. Correct position of gases thermometer „2“ –

end of the metal gases thermometer must be together

with end-socket. (to change the position of the gases

thermometer, indicated value will be changed significantly).

Disconnect („3“ and „4“) gases thermometer or lambda

sensor if changed. If boiler does not contain terminals „3“ and „4“ disconnection must be realized

directly from mother board AK 3000S.

TURN FUEL

0 Not recommended

1 Wet wood

1,5 Wet softwood

2 Dry softwood

2,5 Dry hardwood

2,5 and

more

Very dry, hardwood, small

pieces

Page 26

26

Gasifying boilers VIGAS

Discharge

Hole for submersible case

Drain valve – cold water input

15. ACCESSORIES ASSEMBLY

15.1 Drain valve

Usage of safety cooling exchanger:

Safety cooling exchanger together with drain valve,

Honeywell TS 130, serves as boiler protection

against overheating in case of power failure. If

there is forced circulation, pump will be switched off

and water circulation in the system of central

heating stopped. If you have not ensured the

automatic transition into gravitation (self-flowing)

flow, or minimum heat consumption, 5 kW, boiler

may be overheated.

Drain valve Honeywell TS 130, together with cooling

exchanger are preventing to boiler overheating.

Assembly of drain valve TS 130:

On boiler socket “1” screw TS 130 valve on one of ¾“ boiler coupling so that TS 130

might close water prior flowing to boiler. Safety exchanger must be without water. The

second coupling “3” will lead to canalization. Screw thermal sensor onto ½“ “2”.

Warning:

- Assemble valve and thermal sensor prior filling the central

heating system with water.

- Pressure of the cooling water can not be dependent on electrical

voltage.

- Do not loose ¾“ socket „2“ when assembling, watere leak

possibilty. Under the socket is aluminium ring „4“ with sealing „3“,

that seals copper pipe „1“ in socket „5“.

If water leak, draw close ¾“ socket „2“.

Principle of operation:

Drain valve is regulated by hot water. If hot water temperature is 95°C, valve will open.

Water running from water main absorbs temperature from boiler and thus it prevents

overheating or boiler damage.

The system of boiler protection correspond with the standard, EN 303/5.

Page 27

27

Gasifying boilers VIGAS

15.2 Discharge fan

The discharge fan “2” is designed to discharge boiler waste gases

from the gasification chamber during the adding of fuel into the

log magazine. Its recommended to add discharge fan if you do

not meet parameters „A“ and „B“.

Its mounted between chimney neck and chimney. Capacitor „3“ is

mounted aboard of the boiler. Electricaly connect to control board

AK 3000S. Its suppleid in two sizes in accordance of chimney

neck.

V25 – for boilers VIGAS 16, VIGAS 25, VIGAS 29 UD

V80 – for boilers VIGAS 40, VIGAS 60, VIGAS 80, VIGAS 100

15.3 Pump

AK 2000 electronic regulation, in its basic equipment,

allows to connect one circulation pump. Pump control

is depend on boiler water temperature and from

selected scheme. Advantage is the pulse control of

pump bolier protection against low-temperature

corrosion. Its recommend, in connection with ladomat to

set hydraulic scheme with storage tank, in acc. Chapt.

14.2

Breaker 0,8 A

Max. input 180 W

15.4 Indoor thermostat

Comfort is increased with indoor thermostat connection. Indoor

thermostat is connected to mother board AK 3000S. Jumper is on T3

contact, standardly. Contact is switching, no voltage.

When T3 contact is disconnect, „OFF“ indicate on display. Fan will be

disconnected. Boiler status is indicated by

symbol. After reclosre,

boiler is in „ON“ mode and boiler is activated.

Warning:

If indoor thermostat is disconnected for longer than 1 hour, then boiler will be blown through for

short time to keep glowing embers.

BOILER TYPE Min A Min B

VIGAS 16, VIGAS 25, VIGAS 29 UD 8 m 160 mm

VIGAS 40 8 m 200 mm

VIGAS 60, VIGAS 80, VIGAS 100 12 m 200 mm

Drawning with dimmensions for V25 and V80 available on www.vimar.sk

Page 28

28

Gasifying boilers VIGAS

16. LIST OF GUARANTEE AND AFTER GUARANTEE

SERVICES

In order quality and safe operation might be kept, repairs of boiler must be done by authorized

specialists:

VIMAR Vigaš Pavel, Príboj 796, Slovenská Ľupča,

tel. 00421 48 41 87 022.

tel. 00421 48 41 87 159

mail: vimar@vimar.sk

See the current list of sale and service places:

www.vimar.sk , www.vigas.eu

17. PROBLEMS SOLVING

Problem Cause/Solution

When heating with wood, boiler output is

smaller that it was when it was new.

Clean ventilation system.

Clean fan blades.

Too wet fuel.

After closing chimney flap, fuel burns a little

and then smokes.

Small volume of primary air. Clean primary ventilation

system. Check if fan flap opens.

Bigger pieces of not burn out fuel are in

combustion chamber.

Enlarged opening of nozzle. Change nozzle. Set

secondary air to the position: 3 revolutions of flap back

from the position of closing.

Smoke leaks through seal after closing

door.

Fix . See door tightness. Take out and turn sealing.

Change sealing.

It is not possible to open chimney flap. Chimney flap is glued by tar. Increase boiler operation

temperature. Use dry fuel. Increase boiler shutting

down temperature

A

fter opening upper door and chimney flap,

boiler room becomes smoky.

Small chimney effect. Chimney diameter must be larger

than the diameter of outlet chimney from boiler. See

15.2

Cracked fireproof /concrete/ lining. No defect. Separates combustion chamber from

gasification chamber.

Fan does not turn. It starts to turn after

turning by hand..

Starting capacitor is defective. Change capacitor.

After the position “Heating” , boiler will shut

down.

Incorrectly selected temperature of boiler shutting down.

See the chapter „Configuration of boiler shutting down

temperature“.

Boiler is shut down but fan still works. Damaged cabling to fan.

Pump works and does not signal pump

operation

Neutral conductor is connected with earth conductor.

Damaged cabling to pump.

Warning signals and signs Cause/Solution

!!!STB!!! See 11.1

Tmax Display indicated Tmax if boiler overheat adjusted

temperature by 0 3

o

C.

Page 29

29

Gasifying boilers VIGAS

18. ASSEMBLY INSTRUCTION

For connection, as shown on picture 9, boiler is

delivered standardly. In cease of need is possible to

mount pump to boiler circuit. In such case, both

boilers are connected together in terminal on AK

3000S. Sum of input power both pumps can not be

higher than 150W.

For connection, as shown on picture 10, its

recommend to set graphical scheme on

display in accordance chapt. 12.3.

See other schemes of connection and

other possible regulations

www.vimar.sk.

18.1 Assembly and maintainance instructions

Boiler can only be connected to the system of central heating whose thermal capacity

correspond with boiler output.

When forced circulation used and there is mains failure (boiler and pump stop to

operate), the system of central heating must be adapted to ensure minimum boiler

power take-off, 5 kW. This is provided with safety cooling exchanger with drain valve,

Honeywell TS 130( Honeywell is not a component part of delivery, it should be ordered

separetly).

Boiler must be connected correctly and as short as possible to chimney. Other

appliances must not be connected to chimney. Chimney shaft must be dimensioned

according to the standards: STN 734201 and STN 734210.

We do not recommend permanent connection to water supply through feed water valve

to avoid not allowed increase in pressure if valve is not tightly sealed. Maximum

overpressure is 0,3 MPa.

The room where boiler is placed must be ventilated properly.

Recommended schema of basic connection with AK 3000 regulation.

1. VIGAS boiler

2. Safety valve

3. Indoor thermostat

4. Circulation Pump

5. Hot water storage tank

6. Four-way blender

7. Central heating circuit

8. Exp. bin

9. Storage tank

10. Gases thermometer

R- Distributer

Z- Collector

Pic.10

Pic.9

Page 30

30

Gasifying boilers VIGAS

Boiler assembly must be done by specialists of assembly firms.

Boiler need not be placed on a firm base.

Minimum temperature of reversible water at boiler inlet is 60 0C.

Boiler room must be ventilated permanently through the opening of min. diameter 0,025

m2. The diameter for air inlet and outlet must equal approximately.

Boiler must be installed in the surrounding that is common, basic in accordance with the

standard, STN 33 2000-3.

Work and health safety regulations must be followed in accordance with current

instruction requirements, UBP SR No. 718/2002 Coll. and seq.

Z hľadiska požiarno-technické vlastnosti hmôt v blízkosti kotla musia byť splnené

požiadavky normy STN 73 0823:1983/z1 - Stupeň horľavosti stavebných hmôt.

18.2 Safety regulations for control and maintenance of VIGAS boiler electric

equipment

The boiler operator must follow relevant regulations and standards, as well as the following

principles:

If boiler is in operation, none of the following may be done with electric equipment:

o uncover electronic equipment, e.g. boiler electronics, fan, thermostat,

o to exchange fuse,

o to repair damaged cable insulation etc.

Maintenance and repairs of boiler with uncovered electric equipment may only be done by

persons authorized to do so according to 74/1996 Coll.

Before uncovering boiler or any electric equipment connected to boiler, it is necessary to

disconnect any mains /unplug/. You can only plug in after placing covers on original

places.

If there is any defect of electric equipment or boiler installation is damaged it is important: - do

not touch any part of boiler

o disconnect boiler from mains /unplug/.

o to call an authorized service technician that will correct defect.

Apart from common maintenance of boiler, it is strictly forbidden:

to manipulate electric equipment and boiler installation if plugged in,

to touch damaged electric equipment and boiler installation, mainly damage cable insulation ,

etc.,

o to operate boiler if uncovered,,

o to operate boiler with defective electric equipment or defective boiler installation,

o to repair damaged boiler electric parts by persons unauthorized by the producer

Page 31

31

Gasifying boilers VIGAS

19. ELECTRIC SCHEME OF CONNECTION VIGAS BOILERS

Flow diagram of basic connection VIGAS AK 3000 boiler

Flow diagram of basic connection VIGAS

Lambda Control

AK 3000.1 boiler

1. Servosystem air control, power supply 24 VDC / 0,5A

2. Discharge fan, power supply 230 VAC / 0,6A

3. Circulation pump, power supply 230 VAC / 0,5A

4. Fab, power supply 230 VAC / 0,3A

5. Emergency thermostat STB 100

o

C

6. Power supply 230 VAC, 50 Hz

7. T1 Thermometer KTY, T2 Thermometer PT1000, T3 Indoor thermostat, no voltage, for hydraulic

scheme 2,3,4. For hydraulic scheme 1 thermometer PT 1000.

8. Lambda sensor

WS – white

WS – white

G - grey

SW - black

Page 32

32

Gasifying boilers VIGAS

LETTER OF GUARANTEE

Certificate of Quality and Completeness

Product

Serial number :

The producer confirms that the boiler comply with the standards, STN EN 303-5,

STN EN 61010-1+A2:2000, STN EN 50081-1:1995, STN EN 50082-1:2002, STN

EN 61000-3-3:2000, STN EN 61000-3-2:2000+A1+A2:2001.

Production inspection date

Date of sale

Date of commissioning:

Stamp and signature of seller

Instructions for customers and guarantee conditions.

Claims regarding the completeness of delivery must be in accordance with Commercial

Code and Civil Code of the supplier,

Damage and defects due to transport must be claimed by customers to a carrie

r

when goods is taken over.

Guarantee period is 24 month from the date of sale.

Guarantee is valid if boiler is commissioned by an authorized serviceman.

Guarantee is valid if all the electric equipment is connected to regulation by an trained

specialist and if recorded in relevant documents..

Guarantee applies to construction, used material and product manufacture.

Transport of serviceman is not included into guarantee repair ( it is paid by a custome

r

in its full amount).

Guarantee does not apply to:

consumer material: door seal, seal of exchanger cap, seal under fan, heatproof

nozzle, heat proof / concrete/ filling, fireclay bricks,

defects caused by a customer,

defects due to not following assembly instructions, incorrect operation and

maintenance or if the product is used otherwise than instructed and for a different

purpose than specified in normal conditions; incorrect or unauthorized handling,

otherwise the guarantee follows relevant provisions of Civil Code.

The producer reserves the right to execute changes within the framework of the product nnovation.

Stamp a signature of producer

VIGAS kW

Page 33

33

Gasifying boilers VIGAS

Confirmation of VGAS boiler commissioning

Product VIGAS kW

Production No. / Year of production

Name and adress of user:

When commissioning, we did the following:

▪ we informed the customer how to operate the boiler,

▪ we checked the boiler prior heating,

▪ we heated the boiler,

▪ we filled in and confirmed data of the Letter of Guarantee.

Signature of the boiler user

Confirm and send to the producer !

!

Date of sale

Date of commissioning

Signature of serviceman

Stamp and signature of producer

Page 34

34

Gasifying boilers VIGAS

Page 35

35

Gasifying boilers VIGAS

Records of electric equipment connection (pump, discharge fan, indoor

thermostat, expander, etc.

Date Equipment Name of

serviceman

Certificate No. Signature of

serviceman

Records of guarantee and after guarantee repairs

Date Record od repair

No.

Name of

serviceman

Certificate No. Signature of

serviceman

Notes

Page 36

36

Gasifying boilers VIGAS

Ecological and gasifying boiler

Producer:

VIMAR Vigas Pavel

M. Culena 25

974 11 Banska Bystrica

SLOVENSKO

Production plant:

VIMAR Vigas Pavel

Priboj 796

976 13 Slovenska Lupca

SLOVAKIA

tel.: 00421 48 4187 022

fax: 00421 48 4187 159

WWW.VIMAR.SK

vimar@vimar.sk

Serial number

All technical changes are reserved for VIMAR 2009 ver.1

Pictures are illustrative and might be different from the reality

!

Loading...

Loading...