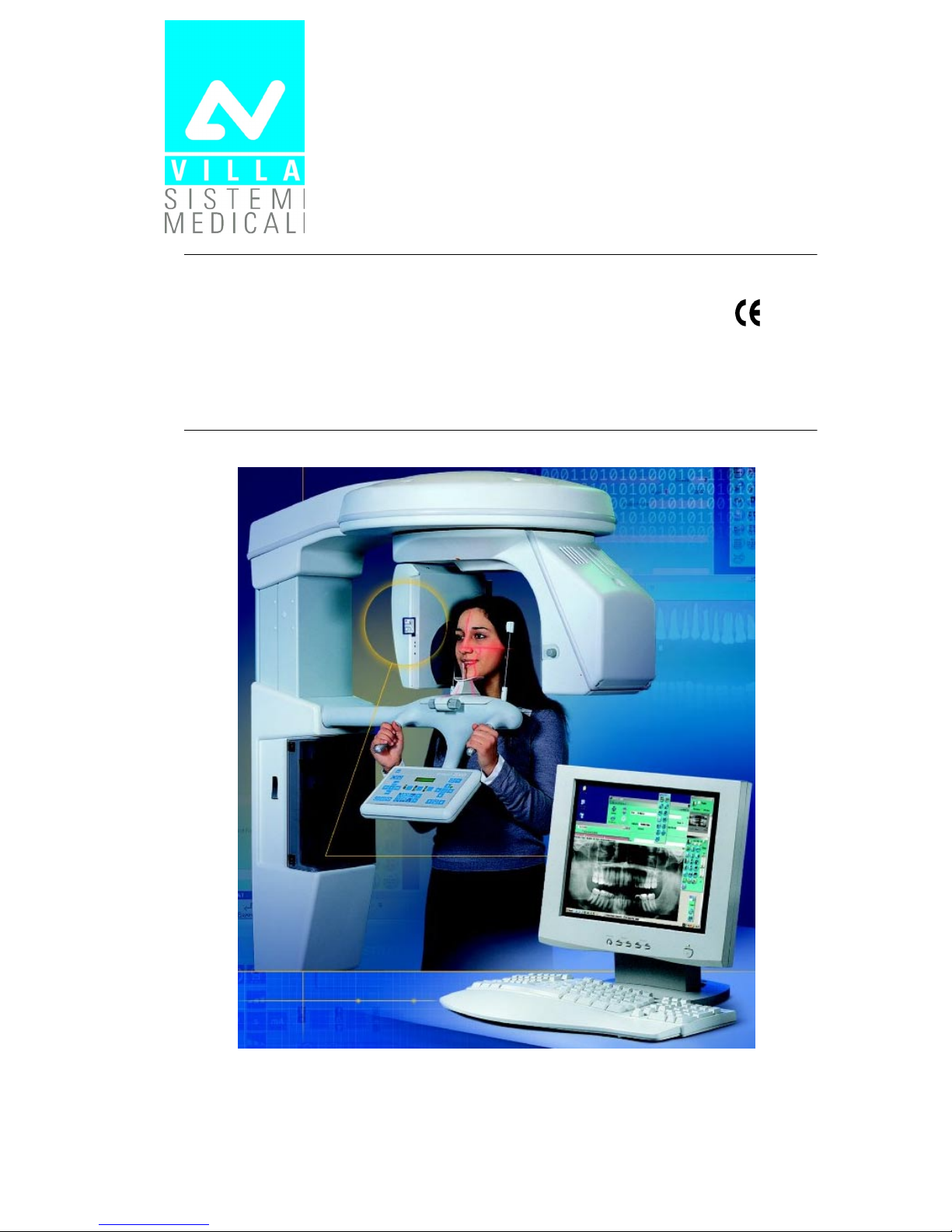

Villa Sistemi Medicali STRATO 2000 Digital Service Manual

Release 30 January 2008 (Rev. 3)

STRATO 2000

STRATO 2000STRATO 2000

STRATO 2000 0051

Digital

DigitalDigital

Digital

Service Manual

Service ManualService Manual

Service Manual

SERVICE MANUAL

Revision history

(Rev. 3) STRATO 2000 Digital

Revision history

Revision historyRevision history

Revision history

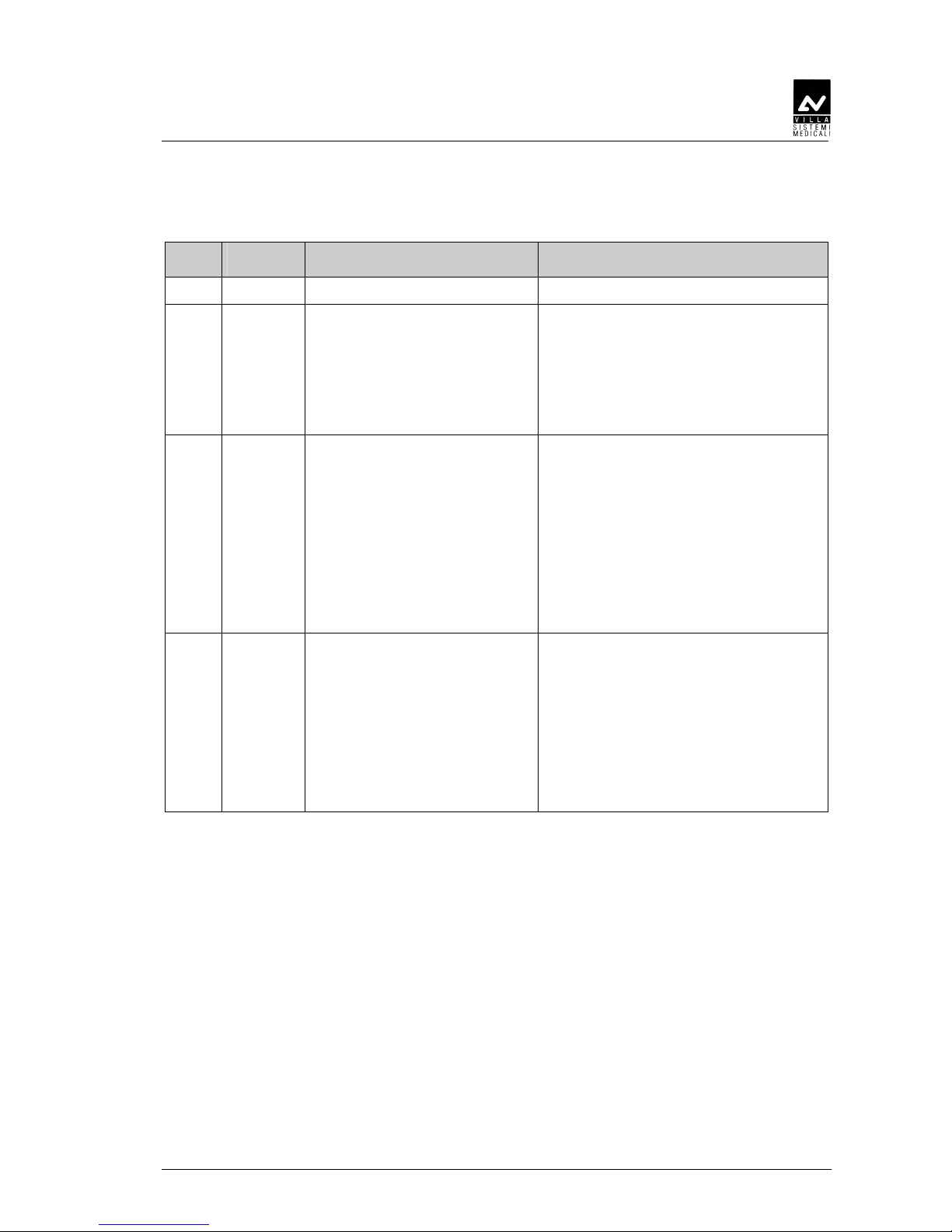

Rev. Date Page/s Modification description

0 05.05.06 - Document approval.

1 05.09.06 i, ii, iii, iv, 3-20, 3-21, 4-1,

from 6-15 to 6-24,

from 7-12 to 7-54,

from 8-1 to 8-106,

from 9-3 to 9-49,

9-85, 10-12, 10-16,

10-17, 12-2

Release of SW version 6.02 (Ceph arm

calibration procedure, Soft Tissue

Filter setting procedure, password 93 Soft Tissue Filter motor selection).

Release of SW version 6.03 (password

95 – Minimum kV value setting).

(Ref. RDM 6447, RDM 6483)

2 11.01.07 iv, 1-1, 1-2, 2-5, 3-2, 3-3,

3-4, 3-17, 3-18, 3-19,

from 4-1 to 4-5,

from 6-18 to 6-22,

7-6, 7-21,

from 7-27 to 7-31,

7-33, 7-34,

from 7-44 to 7-54,

8-2, 8-4, 8-9, 8-25, 8-87,

8-88, 8-89, 9-85, 10-10,

10-16, 10-17

Improvement of Installation,

Maintenance and servicing and

Troubleshooting procedure.

Release of “DXP 2007 Edition” kit

including Implant examination.

(Ref. RDM 6540, RDM 6566)

3 30.01.08 All New CPU board.

Improvement of Ceph arm mounting

procedure.

New Implant bite block.

Schematics and drawings update.

Spare Parts update.

Modified name from "STRATO 2000 D"

to "STRATO 2000 Digital".

(Ref. RDM 6554, RDM 6639, RDM 6666,

RDM 6679, RDM 6680, RDM 6684, RDM 6768)

SERVICE MANUAL

Revision history

STRATO 2000 Digital (Rev. 3)

THIS PAGE IS INTENTIONALLY LEFT BLANK

SERVICE MANUAL

Contents

(Rev. 3) STRATO 2000 Digital

i

Contents

1. INTRODUCTION 1-1

1.1. Icons appearing in the manual ............................................................1-2

1.2. How to contact VILLA SISTEMI MEDICALI technical service ................ 1-2

2. SAFETY INFORMATION 2-1

2.1. Warnings ............................................................................................. 2-2

2.2. Environmental risks and displacement ................................................2-5

2.3. Symbols used ...................................................................................... 2-6

3. DESCRIPTION 3-1

3.1. Identification labels and laser labels .................................................... 3-1

3.2. Function, Models and Version .............................................................3-3

3.2.1. Panoramic examination ....................................................................3-3

3.2.2. Version with cephalometric device ....................................................3-3

3.2.3. DXP (Digital Extended Program) .......................................................3-4

3.3. Parts location....................................................................................... 3-5

3.4. Location of electronic components ....................................................... 3-7

3.5. Block diagram ..................................................................................... 3-8

3.5.1. Power supply assembly.....................................................................3-9

3.5.2. CPU Board (A1) ..............................................................................3-10

3.5.3. HF Board (A2) and Tubehead..........................................................3-12

3.5.4. Keyboard .......................................................................................3-13

3.6. Control panel - Descriptions and functions........................................ 3-16

3.6.1. Key functions description ............................................................... 3-19

3.7. Service programs description ............................................................. 3-20

3.7.1. Hardware configuration password...................................................3-20

3.8. Service tools ...................................................................................... 3-21

4. TECHNICAL DATA 4-1

4.1. Applied safety regulations.................................................................... 4-6

4.2. Loading curve of the tube and cooling curve of the anode .................... 4-7

4.3. Measurement method of technical factors............................................ 4-9

4.4. Verify method of exposure parameters ............................................... 4-10

4.5. Dimensions........................................................................................ 4-14

5. PRE-INSTALLATION 5-1

5.1. Electrical setting up............................................................................. 5-2

5.2. Packaging ............................................................................................ 5-4

5.3. Space requirements ............................................................................. 5-5

5.3.1. Version without CEPH......................................................................5-5

5.3.2. Version with CEPH...........................................................................5-6

SERVICE MANUAL

Contents

STRATO 2000 Digital (Rev. 3)

ii

6. INSTALLATION 6-1

6.1. Setting of the wall ................................................................................6-2

6.2. Column mounting................................................................................ 6-3

6.3. Mounting of the rotating arm assembly................................................6-6

6.4. Mounting of the chin-rest arm ............................................................. 6-8

6.5. Digital sensor holder mounting ............................................................6-9

6.6. Mounting of ceph-arm (Optional) .......................................................6-10

6.7. Mechanical alignment check ..............................................................6-14

6.7.1. PANORAMIC alignment check ........................................................ 6-14

6.7.2. CEPH alignment check................................................................... 6-16

6.8. How to mount the coverings............................................................... 6-24

6.9. Covering mounting for the Ceph arm ................................................. 6-25

7. MAINTENANCE AND SERVICING 7-1

7.1. Verification and centering adjustment .................................................7-3

7.1.1. Axes alignment for the PANORAMIC function....................................7-3

7.1.1.1. Centering the RO(tation), AX (X-axis) and

AY (Y-axis) axes via the laser ............................................... 7-5

7.1.2. Centering the X-ray beam for the PANORAMIC function.................. 7-10

7.1.3. Axes alignment for the CEPH function ............................................ 7-14

7.1.3.1. Rotation arm alignment ....................................................7-16

7.1.3.2. Ear Centering Circles setting............................................. 7-20

7.1.3.2.1. Projection of Non-Concentric Ear Centering Circles......7-23

7.1.3.2.2. Projection of Vertically Non-Concentric Ear

Centering Circles ........................................................... 7-24

7.1.3.3. Secondary collimator centering .........................................7-25

7.1.3.4. CEPH Sensor centering ..................................................... 7-28

7.1.3.5. Soft Tissue Filter (STF) adjustment.................................... 7-32

7.2. Verify of kV and exposure time ..........................................................7-35

7.2.1. kVp ...............................................................................................7-38

7.2.2. Time ..............................................................................................7-38

7.3. mA Check .......................................................................................... 7-39

7.4. Storing of automatical exposure parameters ...................................... 7-40

7.4.1. Exposure parameter....................................................................... 7-40

7.4.2. Soft Tissue Filter............................................................................ 7-41

7.4.3. Storing parameters ........................................................................ 7-41

7.4.4. Table of pre-set anatomic parameters ............................................. 7-42

7.5. STRATO 2000 Digital Software Utilities.............................................. 7-45

8. TROUBLESHOOTING 8-1

8.1. Displayed messages ............................................................................. 8-1

8.2. LEDs.................................................................................................... 8-7

8.2.1. CPU board LED................................................................................8-8

8.2.2. H.F. board LED................................................................................ 8-9

8.2.3. Power supply LED group..................................................................8-9

SERVICE MANUAL

Contents

(Rev. 3) STRATO 2000 Digital

iii

8.3.

Service programs descriptions ........................................................... 8-10

8.3.1. Password 89 ..................................................................................8-12

8.3.2. Password 90 ..................................................................................8-13

8.3.3. Password 92 ..................................................................................8-14

8.3.4. Password 93 ..................................................................................8-15

8.3.5. Password 94 ..................................................................................8-16

8.3.6. Password 95 ..................................................................................8-17

8.3.6.1. Input ports test.................................................................8-18

8.3.6.2. Keyboard test....................................................................8-21

8.3.6.2.1. ERROR 560: One or more buttons pressed at

start-up ......................................................................... 8-22

8.3.6.2.2. ERROR 561: X-ray button released during emission ... 8-24

8.3.6.2.3. ERROR 562: X-ray button pressed during start-up or

during exam preparation ..............................................8-24

8.3.6.2.4. ERROR 563: Remote X-ray button pressed during

start-up or during exam preparation ............................ 8-24

8.3.6.3. kV / mA Piloting Circuits Test ...........................................8-25

8.3.6.3.1. ERROR 550: No voltage present on HF board ..............8-27

8.3.6.3.2. ERROR 551: Overvoltage .............................................. 8-28

8.3.6.3.3. ERROR 552: Overload................................................... 8-29

8.3.6.3.4. ERROR 553: Broken filament ....................................... 8-29

8.3.6.3.5. ERROR 554: No X-ray output....................................... 8-30

8.3.6.3.6. ERROR 555: X-ray output too long............................... 8-31

8.3.7. Password 102.................................................................................8-32

8.3.8. Password 118.................................................................................8-33

8.3.8.1. X-Axis Zero (M5 Motor)......................................................8-35

8.3.8.1.1. ERROR 500................................................................... 8-37

8.3.8.2. Y-Axis Zero (M4 Motor)......................................................8-39

8.3.8.2.1. ERROR 501................................................................... 8-42

8.3.8.3. Rotation Axis Zero (M3 Motor) ...........................................8-44

8.3.8.3.1. ERROR 502................................................................... 8-47

8.3.8.3.2. ERROR 542: Collision of the rotating arm .................... 8-49

8.3.8.3.3. ERROR 541 / ERROR 543: panoramic sensor holder

not in Panoramic / Ceph position................................. 8-49

8.3.8.3.4. ERROR 600: Reset button pressed during movement

or exam preparation...................................................... 8-49

8.3.8.4. X-Y-Rotation time-out motor zeroing..................................8-50

8.3.8.4.1. ERROR 504................................................................... 8-50

8.3.8.5. Primary Collimator motor (M7) ..........................................8-51

8.3.8.5.1. ERROR 580: Zero sensor always darkened /

ERROR 592: Unexpected limit switch activation /

ERROR 595: Motor timeout during slit primary

collimator movement / ERROR 546: Primary slit

collimator limit sensor not found ..................................8-54

8.3.8.6. Soft Tissue Filter motor (M6) .............................................8-56

8.3.8.6.1. ERROR 520: Motor time out during STF movement /

ERROR 521: STF stopped at the limit switch /

ERROR 522: Limit switch not found / ERROR 523

Soft Tissue Filter zero sensor always active...................8-58

8.3.8.7. Column motor (Column test) .............................................8-60

SERVICE MANUAL

Contents

STRATO 2000 Digital (Rev. 3)

iv

8.3.9. Password 124 ................................................................................ 8-63

8.3.9.1. Rotation axis position .......................................................8-67

8.3.9.2. Secondary Collimator motor (M8) ...................................... 8-70

8.3.9.2.1. ERROR 581 The zero sensor of ceph secondary collimator

is always active / ERROR 591 unexpected limit switch

activation CEPH secondary collimator motor / ERROR 594

CEPH secondary collimator Motor timeout / ERROR 545

CEPH secondary collimator Limit sensor not found .....8-73

8.3.9.3. CEPH sensor motor (M9) ................................................... 8-75

8.3.9.3.1. ERROR 582 The zero sensor of ceph sensor is always

active / ERROR 590 Unexpected limit switch activation

CEPH sensor motor / ERROR 593 CEPH sensor zeroing

timeout / ERROR 544 CEPH sensor motor limit sensor

not found.......................................................................8-78

8.3.9.4. Lining-up test ...................................................................8-79

8.3.9.5. Soft Tissue Filter (STF) offset............................................. 8-80

8.3.9.6. Soft Tissue Filter (STF) % of correction .............................. 8-82

8.3.10. Password 130 ................................................................................ 8-84

8.3.11. Password 143 ................................................................................ 8-85

8.4. Memory errors ...................................................................................8-87

8.4.1. ERROR 570: Checksum error on flash eprom ................................. 8-87

8.4.2. ERROR 571-572-573-574-575 .......................................................8-87

8.5. Generic errors....................................................................................8-88

8.5.1. ERROR 503 ................................................................................... 8-88

8.5.2. ERROR 506 / 515.......................................................................... 8-88

8.5.3. ERROR 507 ................................................................................... 8-88

8.5.4. ERROR 601 ................................................................................... 8-89

8.5.5. ERROR 602 ................................................................................... 8-89

8.5.6. ERROR 9xx.................................................................................... 8-89

8.6. Search and correction of possible defects in dental radiographies ......8-90

8.6.1. Defects due to incorrect position of the patient ............................... 8-90

8.6.2. Defects due to incorrect radiological data input ..............................8-91

8.6.3. Defects due to the unit................................................................... 8-92

8.7. Analysis of the problems on the panoramic examinations ..................8-93

8.7.1. Proper positioning of the patient..................................................... 8-94

8.7.2. Error due to a bad patient's positioning.......................................... 8-96

8.7.3. Images with artefacts ................................................................... 8-104

9. SCHEMATICS AND DRAWINGS 9-1

10. SPARE PARTS 10-1

11. FIXING TEMPLATE 11-1

12. APPENDIX 12-1

12.1. Appendix A: Setup parameters table .................................................. 12-1

12.2. Appendix B: Installation checklist ...................................................... 12-3

This publication can only be reproduced, transmitted, transcribed or translated into

any human or computer language with the written consent of VILLA SISTEMI

MEDICALI S.p.a.

This manual in English is the original version.

SERVICE MANUAL

Introduction

(Rev. 3) STRATO 2000 Digital

1-1

1.

1.1.

1. INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

NOTE:

The present manual is updated for the product it is sold with in order to

grant an adequate reference in performing diagnostics and repair

operations normally carried out by the service engineer.

The manual may not reflect changes to the product not impacting service

operations.

STRATO 2000 Digital is an X-ray device for the radiographic

examinations of the maxillo-facial complex.

The device is designed to operate in conjunction with the Direct Digital

System, manufactured by Owandy – France.

Two models are available:

• PAN ONLY model equipped with a fixed primary collimator (NOT

upgradable with CEPH arm)

• PAN UPGRADABLE to DIGITAL CEPH model equipped with a slit

primary collimator that has two slots one for PAN type examinations

and the other for CEPH type examinations

The following options are available and must be ordered separately:

• Digital Extended Program (DXP); it allows the execution of the

following examinations:

– TMJ: Specific examinations for temporo-mandibular joint

– SINUS: Examination of nasal sinus

– A.D.A.: Advanced Dental Applications including: improved

orthogonal projection, frontal dentition and reduced

dose panoramic examinations

– IMPLANT: Linear Tomography for implantation procedure.

• DIGITAL CEPH (only on PAN UPGRADABLE machines); it allows the

execution of the following examinations, all available in high

resolution and normal resolution (high speed) modality:

− CEPH exam in different formats

− CARPUS exam.

This manual is limited to the description of the X-ray device; instruction

on the Digital Acquisition System are given in the relevant Manuals,

supplied with the Direct Digital Sensor.

The device must be used complying with the procedures described and

never be used for purposes different from those herewith indicated.

Please read this manual thoroughly before starting using the machine; it

is advisable to keep the manual near the device to refer to it while

operating.

SERVICE MANUAL

Introduction

STRATO 2000 Digital (Rev. 3)

1-2

STRATO 2000 Digital is an electro-medical device and it can be used only

under the supervision of a physician or of highly qualified personnel,

with the necessary knowledge on X-ray protection.

The user is liable as concerns legal fulfilment related to the installation

and the operation of the device.

1.1.

1.1.1.1.

1.1. Icons appearing in the manual

Icons appearing in the manualIcons appearing in the manual

Icons appearing in the manual

This icon indicates a NOTE; please read thoroughly the items marked

by this picture.

This icon indicates a WARNING message; the items marked by this

icon refer to the safety aspects of the patient and/or of the operator.

1.2.

1.2.1.2.

1.2. How to contact VILLA SISTEMI MEDICALI technical

How to contact VILLA SISTEMI MEDICALI technical How to contact VILLA SISTEMI MEDICALI technical

How to contact VILLA SISTEMI MEDICALI technical

service

serviceservice

service

For any technical quieries please contact the following:

• Telephone number +39 02 48859288

• Fax number +39 02 48859222

• E-mail: dentalservice@villasm.com

SERVICE MANUAL

Safety information

(Rev. 3) STRATO 2000 Digital

2-1

2.

2.2.

2. SAFETY INFORMATION

SAFETY INFORMATIONSAFETY INFORMATION

SAFETY INFORMATION

WARNING:

Please read this chapter thoroughly.

Villa Sistemi Medicali designs and builds its devices complying with the

related safety requirements; furthermore it supplies all information

necessary for a correct use and the warnings related to danger associated

with X-rays generating units.

Villa Sistemi Medicali, has not to be held responsible for:

• use of STRATO 2000 Digital different than the intended use,

• damages to the unit, to the operator, to the patient, caused both by

installation and maintenance procedures different than those

described in this manual and in the service manual supplied with the

unit, and by wrong operations,

• mechanical and/or electrical modifications performed during and

after the installation, different than those described in the service

manual.

Installation and any technical intervention must only be performed

by qualified technicians authorised by Villa Sistemi Medicali.

Only the authorised personnel can remove the covers and/or have

access to the components under tension.

SERVICE MANUAL

Safety information

STRATO 2000 Digital (Rev. 3)

2-2

2.1.

2.1.2.1.

2.1. Warnings

WarningsWarnings

Warnings

This device has not been designed for use in environments where

vapours, anaesthetic mixes flammable with air, or oxygen and nitrous

oxide can be detected.

Avoid pouring water, even accidentally, or other liquids into the device,

as this could cause short-circuits.

Before cleaning the device, be sure that main power supply has been

disconnected to the equipment. Pushing the ON/OFF button on the

basement of the equipment, it doesn’t have to switch on.

Wherever necessary, use the fit accessories, such as the leaded aprons,

to protect the patient from radiations.

While performing the radiography, no one, apart from the operator and

the patient, must remain in the room.

STRATO 2000 Digital has been built to support a continuous operation

at intermittent load; therefore please follow the described use cycles to

enable the device cooling down.

Though this unit has been designed with a quite acceptable protection

level from electromagnetic interference, it is advisable to install it at a

certain distance from electric energy transformation chambers, from

Uninterruptible Power Supply (UPS) units, from receiving-transmitting

units for amateurs use. Mobile telephones are only admitted at a

distance of more than 1,5 mt. from any component of the device.

Other medical instruments and devices that could be used in the

installation area of the device, must comply the Electromagnetic

Compatibility rules in force. Non-complying instruments, of which the

poor immunity from electromagnetic fields is well known, must be

installed at least 3 mt far from the STRATO 2000 Digital and supplied by

a different electrical line.

STRATO 2000 Digital must be off while using devices such as electrical

lancets or similar.

Please clean and disinfect, when necessary, all parts that can be in

contact with the patient.

Never try to rotate the moving arm manually when the units is

switched on, to avoid permanent damage to the unit.

After use, please replace the bite and the ear-centring devices.

SERVICE MANUAL

Safety information

(Rev. 3) STRATO 2000 Digital

2-3

The authorised technician must be sure that the unit is disconnected

from the main power supply before removing the coverings.

Though the X-ray quantity supplied by dental X-ray units is quite low

and distributed on a small surface, the operator must adopt the

precautions and/or fit protections for the patient and himself, during the

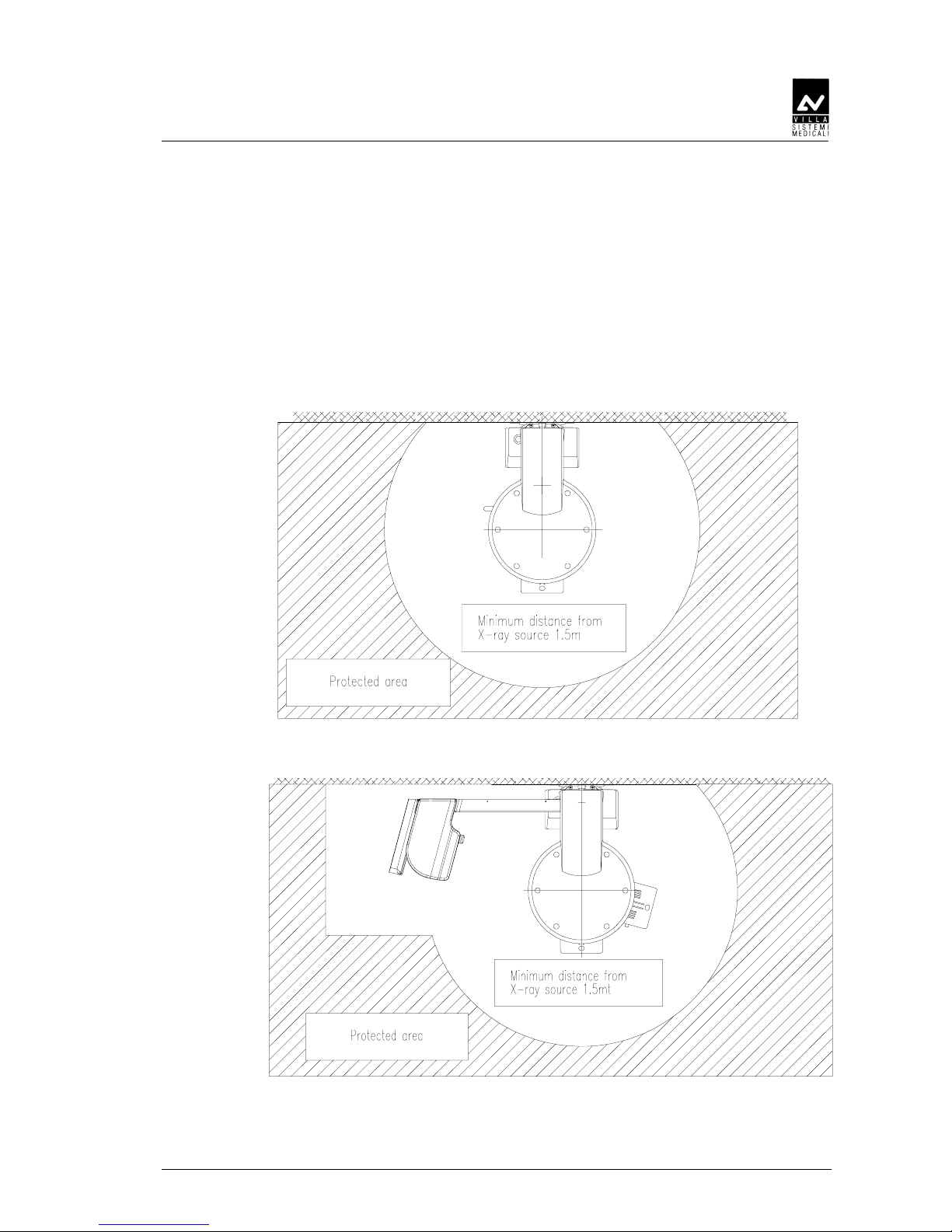

execution of radiography. It is advisable to control the X-ray emission

from a protected area, by means of a remote control. In case it is

necessary to operate near the patient, please stay as far as the cable of

the remote control allows it, or at least 1,5 mt far both from the X-ray

source and from the patient, as shown in the pictures below.

Figure 2-1 - Panoramic version

Figure 2-2: Cephalometric version

SERVICE MANUAL

Safety information

STRATO 2000 Digital (Rev. 3)

2-4

WARNING: PRECAUTIONS WHILE USING LASER CENTRING

DEVICES

• It is necessary an adequate illumination in the room.

• Do not look into the output windows of laser centring units.

• Do not stare at the reflections of laser pointers.

• Instruct the patient to keep his/her eyes closed as long as the laser

pointers are active.

• Before starting an examination, the patient must remove earrings,

glasses, necklaces and whatever else could reflect the laser beam or

be impressed on the radiographic image.

• Do not clean the openings of laser centring devices with tools that

could modify the optics. Necessary cleaning must be performed only

by authorised technicians. Different operations than those indicated

could cause the ejection of dangerous non-ionising radiations.

WARNING: PRECAUTIONS DURING INSTALLATION AND SERVICE

INTERVENTIONS

• Please take highest care while mounting the column at the wall and

strictly follow the instructions included in this manual.

• Before removing the covers of the supply unit located at the base of

the column, or before removing the covers of the HF generating

board, disconnect the supply to the device, both switching the main

switch and the magneto-thermal differential off, and wait at least

1 minute.

• Once removed the covers, pay the highest attention since high

tension is generated in the supply unit, and the voltage is at about

360 Vdc on the HF generator board. This is indicated by the green

LED H1. Should the LED be off, before any other intervention,

disconnect the device from the main power supply, wait at least 1

minute, then check the fuses F2 (10A) in the supply unit, or F1

(500mA) on the HF generator board (see circuit diagram code

58094016).

• Each intervention must be performed after having disconnected the

device from the main power supply and after LED H1 is OFF. It is

anyway advisable to wait at least 1 minute from the LED's switching

off.

SERVICE MANUAL

Safety information

(Rev. 3) STRATO 2000 Digital

2-5

2.2.

2.2.2.2.

2.2. Environmental risks and displacement

Environmental risks and displacementEnvironmental risks and displacement

Environmental risks and displacement

The device contains in some of its parts, materials and liquids that at the

end of the units life, must be disposed of at the fit disposal centres.

Particularly the device contains the following materials and/or

components.

• Tubehead: dielectric oil, lead, copper, iron, aluminium, glass,

tungsten.

• Control panel and remote control: iron, copper, aluminium, glass-

resin, non-biodegradable plastic material packaging.

• Column, rotating arm, and extensions: iron, lead, aluminium,

copper, glass-resin, and non-biodegradable plastic material.

SERVICE MANUAL

Safety information

STRATO 2000 Digital (Rev. 3)

2-6

2.3.

2.3.2.3.

2.3. Symbols used

Symbols usedSymbols used

Symbols used

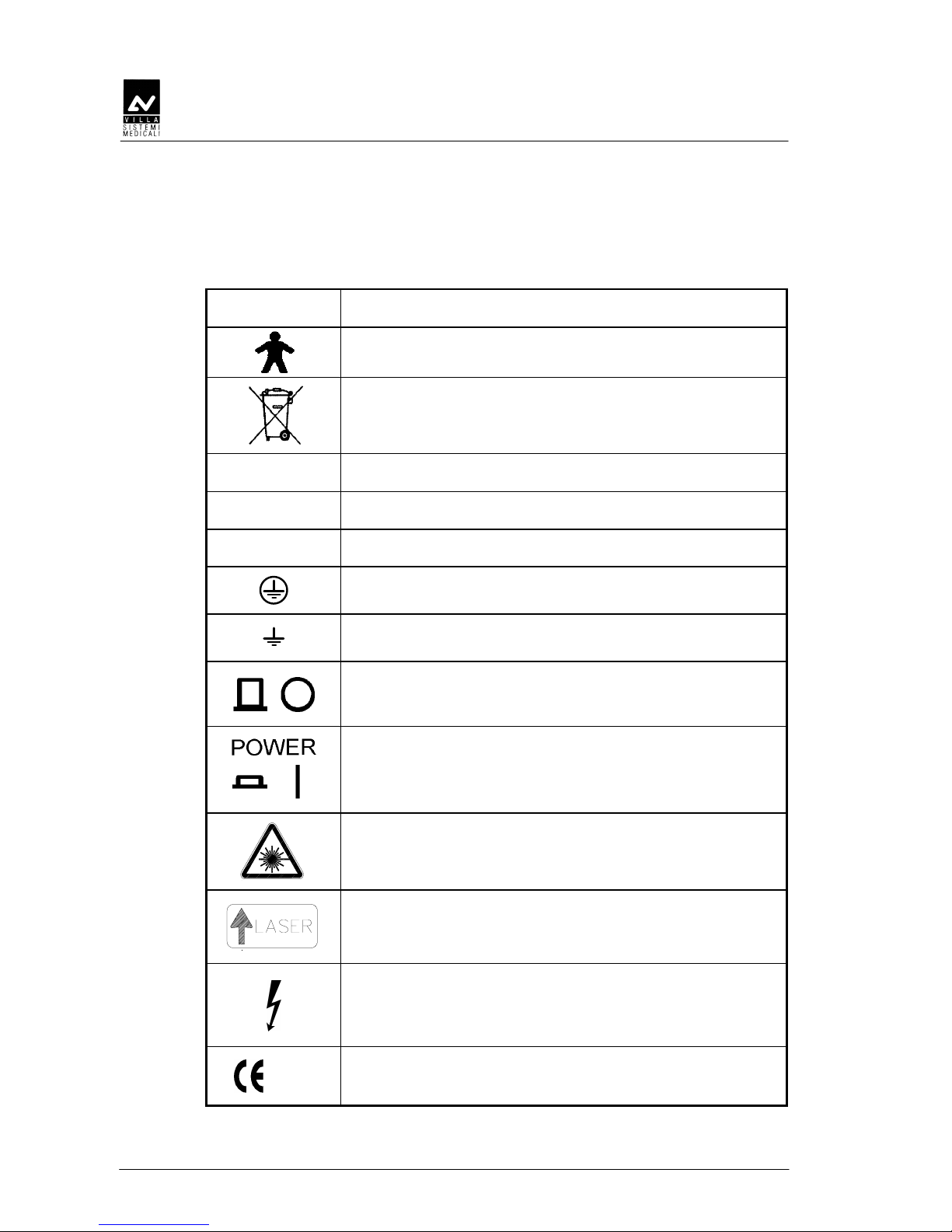

In this manual and on the STRATO 2000 Digital itself, apart from the

symbols indicated on the control panel, also the following icons are used:

Symbols Description

Device with type B applied parts

The device contains in some of its parts, materials and

liquids that at the end of the units life, must be

disposed of at the fit disposal centres

∼∼∼∼

A.C.

N

Connection point to the neutral conductor

L

Connection point to the line conductor

Protection grounding

Operation grounding

OFF ; device not connected to the main power supply

ON ; device connected to the main power supply

Laser

Laser source output

Dangerous voltage

0051

Conformity to the CE 93/42 Directive

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-1

3.

3.3.

3. DESCRIPTION

DESCRIPTIONDESCRIPTION

DESCRIPTION

3.1.

3.1.3.1.

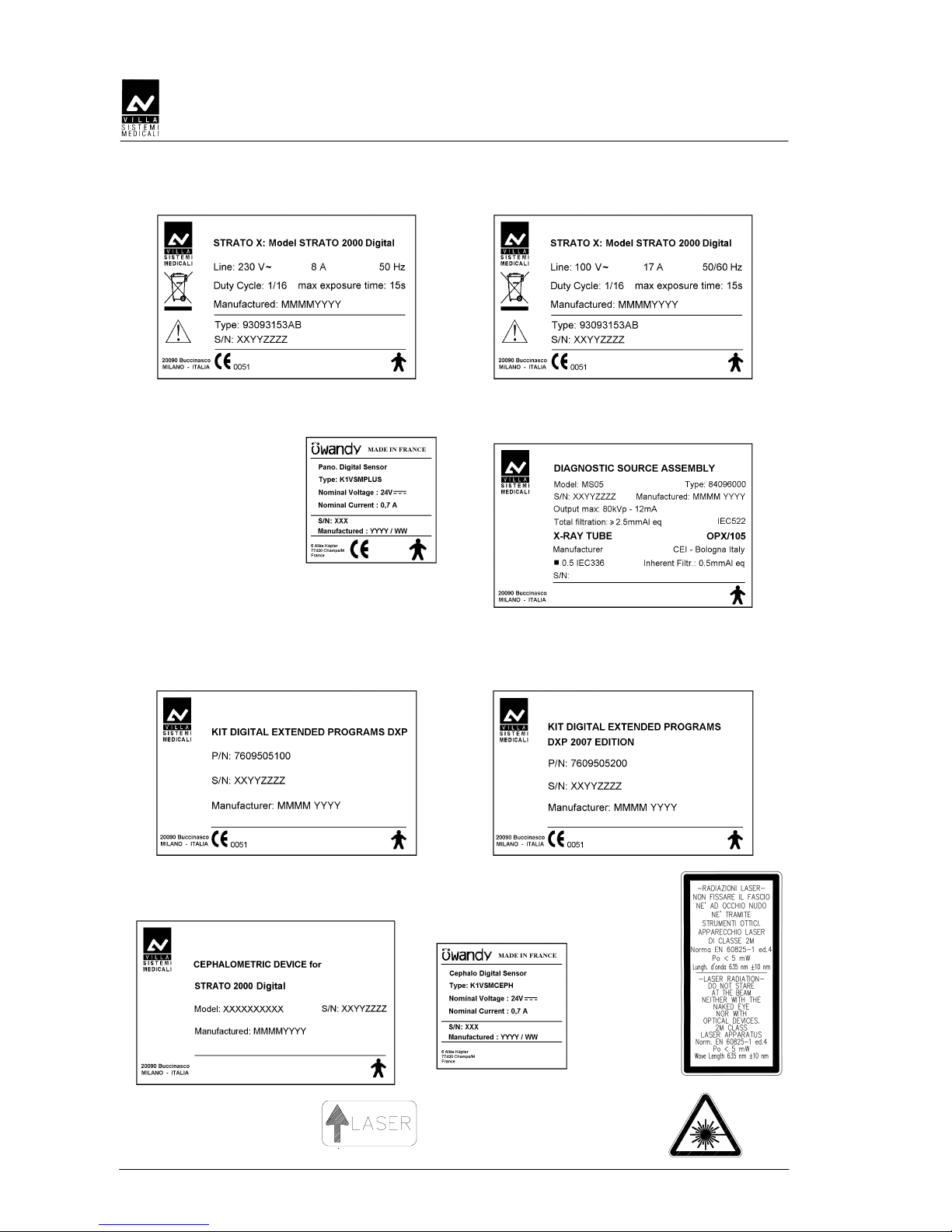

3.1. Identification labels and laser labels

Identification labels and laser labelsIdentification labels and laser labels

Identification labels and laser labels

5, 6

7

1, 2, 3, 4

8, 9

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-2

1a

STRATO 2000 Digital

identification label (230V version)

1b

STRATO 2000 Digital

identification label (100V version)

2

PAN Digital Sensor

identification label

3

Tube-head

identification label

4a

DXP - Digital Extension Program -

identification label

4b

DXP - Digital Extension Program -

2007 Edition

identification label

5

CEPHALOMETRIC device

identification label

6

CEPH Digital Sensor

identification label

7

Laser

Warning

label

8

(N° 2) Spot Laser

identification label

9

(N° 2) Laser

symbol label

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-3

3.2.

3.2.3.2.

3.2. Function, Models

Function, Models Function, Models

Function, Models and Version

and Versionand Version

and Version

3.2.1.

3.2.1.3.2.1.

3.2.1. Panoramic examination

Panoramic examinationPanoramic examination

Panoramic examination

The Panoramic and DXP tests are carried out using a single slot of the

primary collimator.

The user can select between Adult and Child and among 3 sizes and 3

dental arch types for a total of 18 combinations in Automatic selection; in

manual selection it is possible to select high voltage between 50 kV and

80 kV, in 2 kV steps and anodic current from 4 mA to 10 mA in 1 mA

steps.

The basic version performs Panoramic and Emi-panoramic (for right or

left dental arch) examinations.

3.2.2.

3.2.2.3.2.2.

3.2.2. Version with cephalometric device

Version with cephalometric deviceVersion with cephalometric device

Version with cephalometric device

The version with cephalometric device enables to perform the following

examinations:

• Panoramic with the same characteristics described for the panoramic

examinations (paragraph 3.2.1)

• Digital cephalometry for Adult and Child with 3 Sizes. For each

combination it is possible the selection between High Resolution and

Normal Resolution for up 12 combinations in automatic selection. In

the Normal Resolution modality the scanning time is lower than in

High Resolution with a greater dose reduction. The Manual mode

enables to change the high voltage from 60kV to 80kV in 2kV steps

and the anode current from 4mA to 10mA or 12mA (on the basis of

selected kV) in 1mA steps. The positioning of slit primary collimator,

secondary collimator and sensor (placed inside its cover) is automatic

according to the selected image size and exam projection; the Soft

tissue filter (STF) is motorized and can be adjusted to get the best

projection of the face profile.

• Digital Carpus exam only for Child with 3 sizes. It is possible the

selection between High Resolution and Normal Resolution for up 6

combinations in automatic selection. In the Normal Resolution

modality the scanning time is lower than in High Resolution with a

greater dose reduction. The Manual mode enables to change the high

voltage from 50kV to 80kV in 2kV steps and the anode current from

4mA to 10mA or 12mA (on the basis of selected kV) in 1mA steps.

The positioning of slit primary collimator, secondary collimator and

sensor (placed inside its cover) is automatic according to the selected

image size and exam projection.

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-4

3.2.3.

3.2.3.3.2.3.

3.2.3. DXP (Digital Extended Program)

DXP (Digital Extended Program)DXP (Digital Extended Program)

DXP (Digital Extended Program)

The DXP tests are carried out using the same primary collimator single

slot used for Panoramic tests.

This option adds the following examinations:

• A.D.A. (Advanced Dental Applications)

Allowing to perform improved orthogonality Panoramic examination,

frontal dentition and reduced dose panoramic examination.

The improved orthogonality Panoramic examination reduces the

overlapping of teeth in order to improve diagnosis of interproximal

caries.

The reduced dose panoramic examination allows the examination of

the dental arch exluding the temporo-mandibular joint structure.

The frontal dentition examination allows to get a better view of the

frontal part of the dental arch (aproximately from canine to canine)

thanks to a wider focal through in this region than in standard

panoramic examination.

• Sinus

Used to obtain images of the paranasal sinusis in frontal (front/back)

or lateral projection for right or left side.

• Implant

Used to obtain images of cross-sections of the dental arch, for

Implant medical treatment.

• TMJ

Used to carry out the following examinations:

– TMJ closed/open mouth in lateral projection

– TMJ in biaxial projection.

NOTE:

The code inserted into STRATO 2000 Digital to enable the optional

examinations is protected by an Unique Identification Code (UIC); in case

the UIC is not present or is faulty, an error E601 will be shown.

The Enter key "23" pressure will reset this condition, but at the

end of the start-up procedure only standard Panoramic examinations will

be enabled.

The UIC can be visualized on the system console by pressing at the same

time the Column up "27" and Column down "29" arrows.

The UIC is simply an identifier of the single STRATO 2000 Digital unit; in

case of error E601 contact Villa Sistemi Medicali Service department.

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-5

3.3.

3.3.3.3.

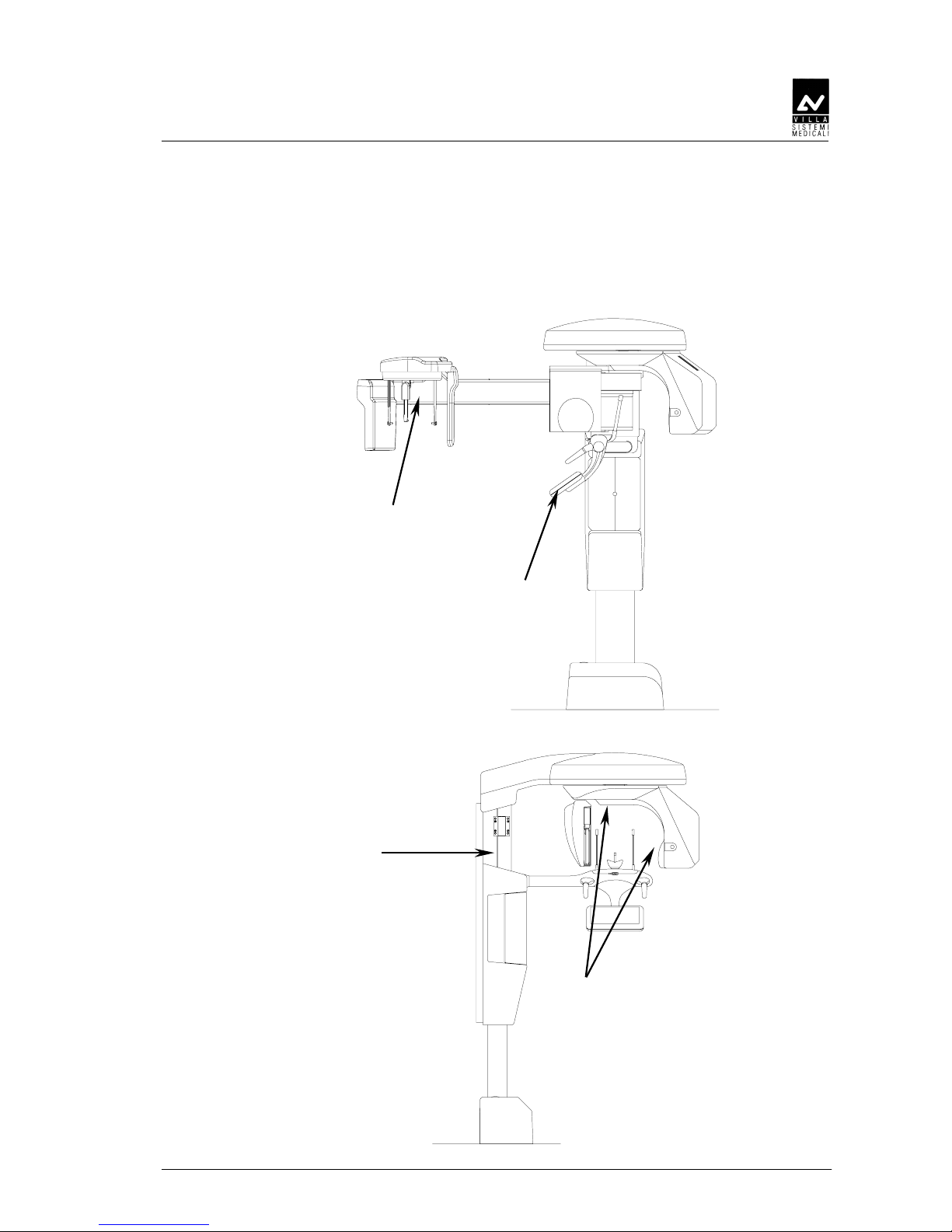

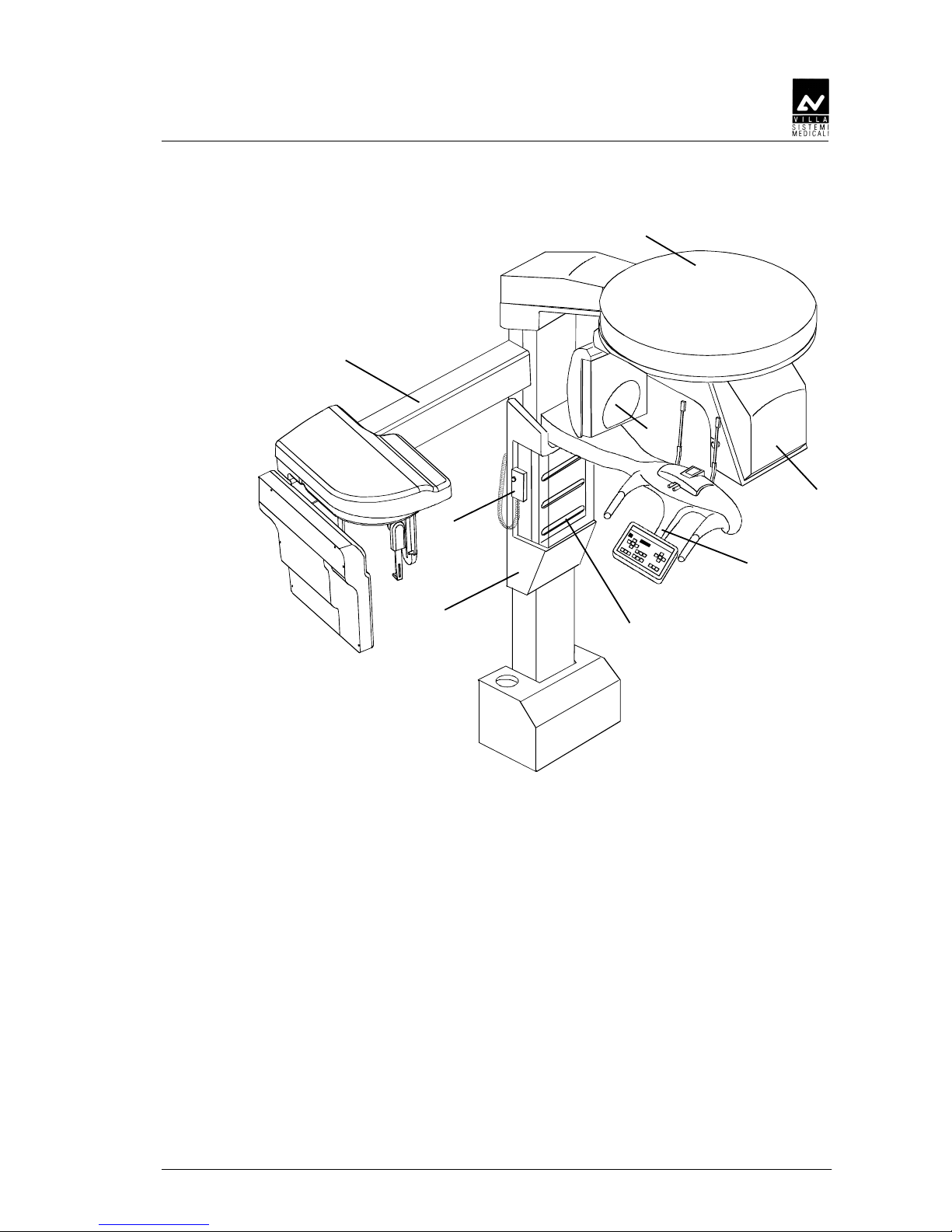

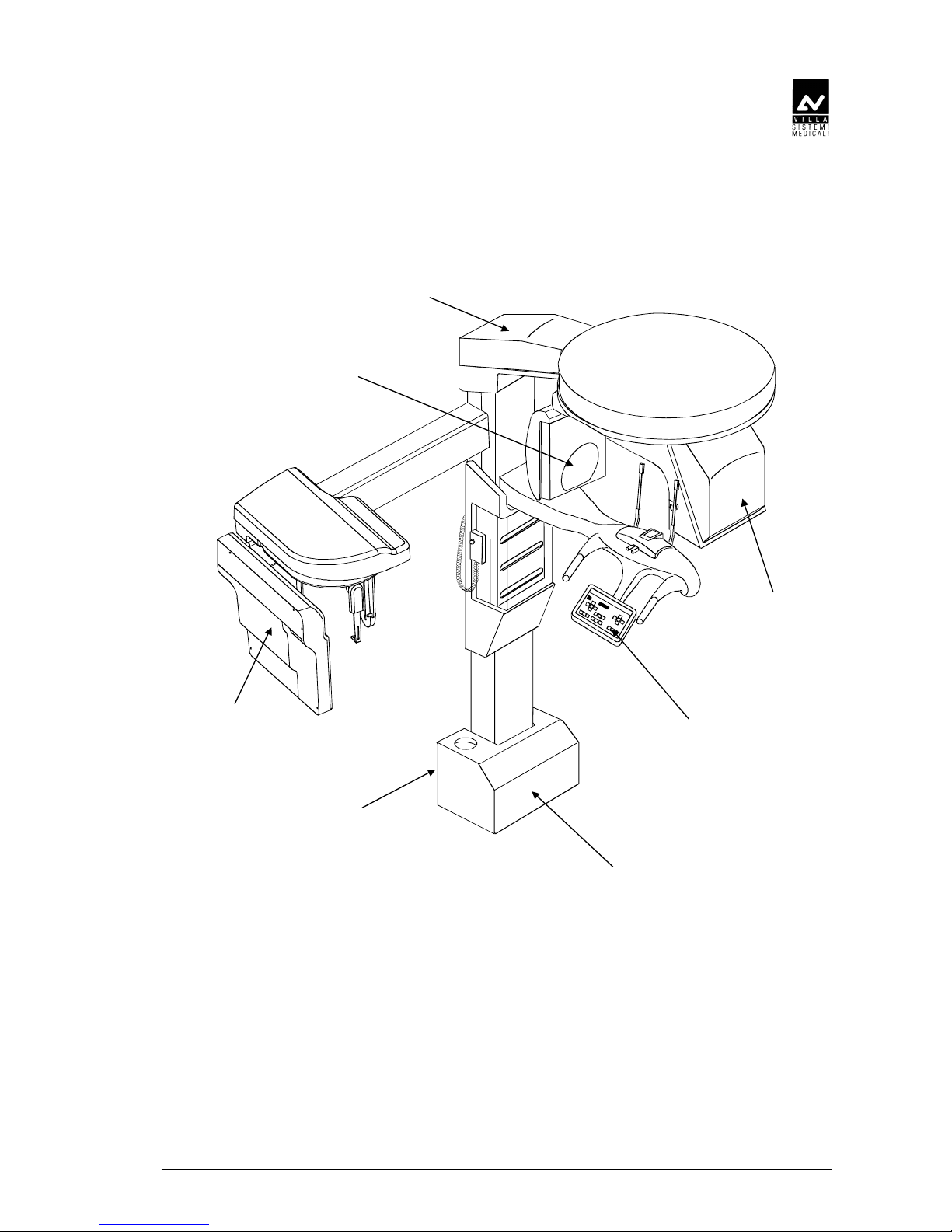

3.3. Parts location

Parts locationParts location

Parts location

Figure 3-1

1

1 1

1 ----

Column with base equipped with electrical power part and cursor

with motorised vertical movement. The column must be fixed at the

wall by 4 dowels, two fixing the upper part and two fixing the lower.

The front part of the column is equipped with an housings closed by

two covers, within which it is possible to set 4 trays (1a) containing

the consumables (bites, rods, etc.) and options (supports, etc.).

2

2 2

2 ----

X, Y axes movement unit and rotation support, (CPU board) with

rotating arm equipped with: HF tubehead with power supply board

(2a), primary collimator and laser centring devices.

5

3

4

1

2

30

1a

2a

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-6

3

3 3

3 ---- Digital sensor holder.

4

4 4

4 ---- Chin support arm equipped with: control keyboard, temple support,

chin-rest, centring bite and handles. The control panel is equipped

with a soft-key keyboard, indication LED for the selected functions

and an alphanumeric two-row display for all technical, operative

and warning messages.

5555---- Cephalometric arm (optional - not available on PAN ONLY version),

including cephalometric device, digital sensor, secondary collimator

and patient centering device (with laser alignment pointer directly

from the rotating arm), positioned on the left of the column.

30

30 30

30 ---- X-ray push button equipped with extendible cable, which allows the

user to operate the unit from proper distance as required by the

safety rules.

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-7

3.4.

3.4.3.4.

3.4. Location of electronic components

Location of electronic componentsLocation of electronic components

Location of electronic components

Figure 3-2

COMMAND

PANEL

POWER SUPPLY GROUP

HF GENERATOR

&

TUBEHEAD

BOARD

CPU BOARD

PANORAMIC

DIRECT DIGITAL

SENSOR AND

ELECTRONICS

USB/2 CONNECTOR

CEPHALOMETRIC

DIRECT DIGITAL

SENSOR AND

ELECTRONICS

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-8

3.5.

3.5.3.5.

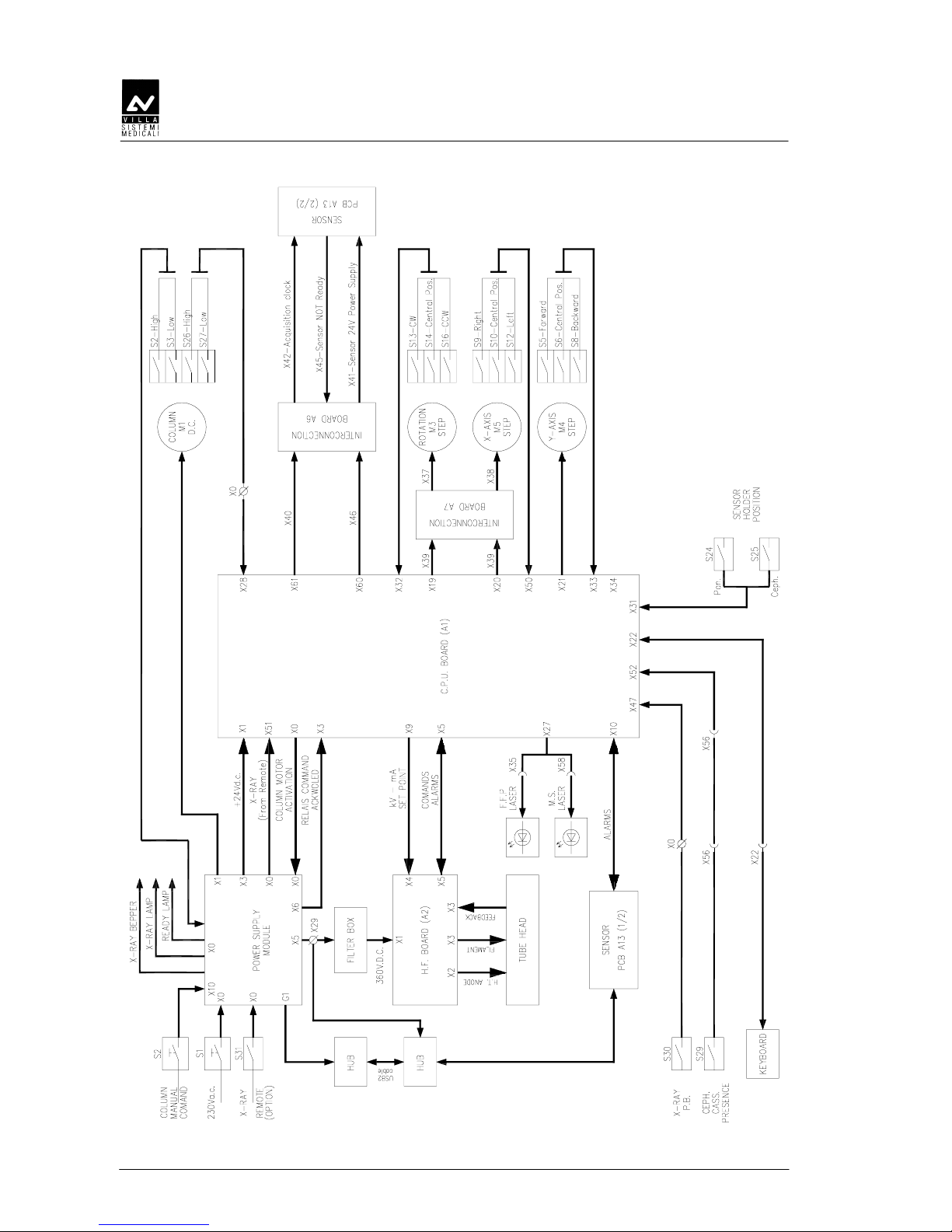

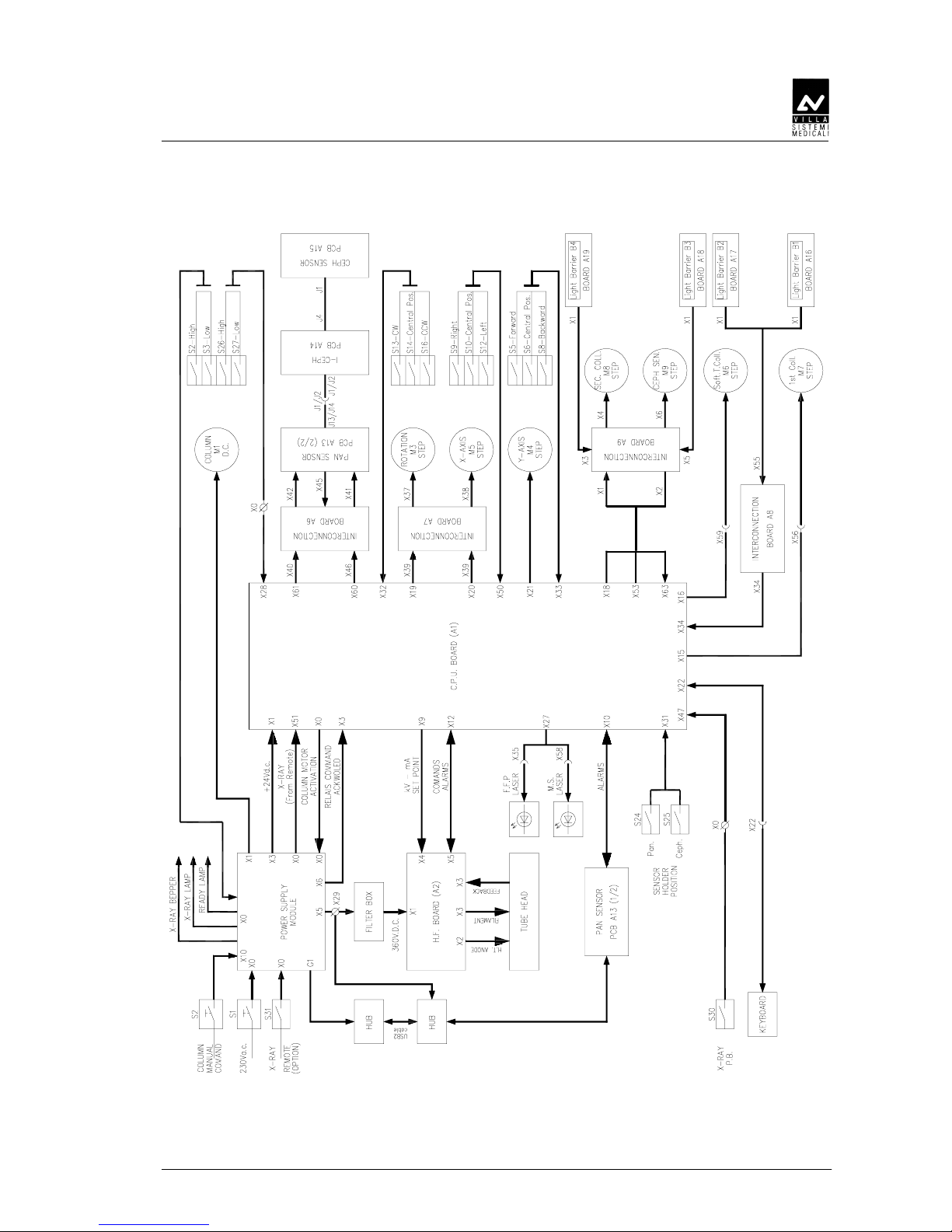

3.5. Block diagram

Block diagramBlock diagram

Block diagram

This paragraph provides a brief description, at block diagram level, of the

STRATO 2000 Digital. Aim of this paragraph is to provide a brief

description of the system. More details about the electronic circuits

which compose the system can be obtained by analyzing the schematics

provided in chapter 9.

During the description of the block diagram, please refer to Figure 3-4.

From the electrical point of view, the system can be divided into 4 main

blocks:

• Power supply assembly

• CPU board (A1)

• HF board (A2) and tubehead

• Keyboard

Each of the main blocks above listed is here after described.

For information on the electronics of the Direct Digital Sensors, make

reference to the relevant Manual.

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-9

3.5.1.

3.5.1.3.5.1.

3.5.1. Power supply assembly

Power supply assemblyPower supply assembly

Power supply assembly

It is located in the base of the system and is mainly composed by the

mains switch (S1), a 24Vdc 7A switching mode power supply which

supplies all circuits of the machine excluding the column motor, and a

further power supply which supplies the column motor and the enabling

circuit for X-ray emission.

A further voltage of 230Vac is directly provided to the HF board and is

aimed at suppling the HF group (A2 board and tubehead).

The power supply assembly also acts as interface with a number of

external signals and circuits like:

• Input for remote X-ray push button (S31) and output to the CPU of

the same signal.

• Outputs for an "X-ray ON" external buzzer and for the "Ready" and

"X-ray ON" lamps.

• Driving of the DC column motor (M1): this motor can be activated

either through the CPU board, in case the movement is requested by

the operator acting on the keyboard, or through the switch S2

located in the rear part of the column base. This switch can be used

to raise/lower the column during the installation phase when the

CPU has not been yet connected to the system.

• Input for the emergency column motor microswitches (S2 and S3):

these microswitches indicates the limit for the movement of the

column. If for any reason, the column goes beyond these

microswitches, the motor is de-activated by cutting the voltage.

Normally, the position of the column is also monitored by other two

microswitches (S26 and S27) that, as for all the other positioning

sensors, provide their signals to the CPU board.

The unit does not include a voltage selector circuit for the mains voltage.

Therefore, the unit is manufactured in different versions, depending on

the line voltage of the installation place.

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-10

3.5.2.

3.5.2.3.5.2.

3.5.2. CPU Board (A1)

CPU Board (A1)CPU Board (A1)

CPU Board (A1)

The STRATO 2000 Digital carries a dedicated CPU Board which can be

interfaced with the Digital Sensor.

It is located in the arm movement assembly on top of the unit. Main

tasks are:

• General controlling of the unit, receiving the signals from the

keyboard and from the different microswitches.

• Driving of the motors (combination of DC and stepper motors) which

compose the system.

• Monitoring the functioning of the motors through the analysis of the

signals coming from the positioning sensors.

• Driving of the HF group (HF board and tubehead) in order to provide

the X-ray doses set by the operator on the keyboard (kV and mA set

point) and in the meantime, check the functioning of this group

through the managing of the relevant alarm signals.

• Activation of the 3 luminous centering devices.

• Managing of the alarms that can be generated by anomalous

conditions present in the unit and caused by the operator or by a

fault.

The CPU board is based on a 32 bit Motorola Microprocessor MC68332,

mounted on a piggy-back PCB, which also includes:

• 512 Kbytes of Flash EPROM, containing the software and the system

configuration data (2 EPROM's for ODD and EVEN data)

• 512 Kbytes of RAM, (2 chips, ODD and EVEN)

• 12 bit, 8 channel serial A to D converter

• 2 channel, 8 bit serial D to A converter

• three bus transceivers

• a 32 kHz quartz

• other logic and passive components.

The CPU board also includes a number of input/output channels

necessary for the functioning of the system and stepper motors driving

stages based on integrated motor drivers. Each of these motors is

associated to positioning sensors that monitor their functioning. The

signals of these sensors is fed back to the CPU board, except the signals

of microswitches S2 and S3 (column motor) that, as already described

are fed back to the power supply assembly.

The number and the type of sensors depend on the function of each

motor, in general, microswitches are used.

Depending on the physical location of the motors on the machine, their

signals and the ones of the relevant positioning sensors are routed

directly to the CPU through dedicated cables, or passing through

interconnection boards located nearby.

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-11

The transmission of the motion from the motor to the relevant movement

assemblies is achieved through toothed belts (rotation motor, X axis

motor and Y axis motor) or through actuators (column motor and

primary collimator, soft tissue filter, secondary collimator and ceph

sensor).

The functioning of the different motors and relevant positioning sensors

can be tested through the use of the Service Programs (Passwords). For

more details, please refer to paragraph 8.3.

The circuits of the CPU board are supplied starting from the +24Vdc

provided by the Power supply assembly and generating on board the

requested voltages (+5V, +5VS and +12VS). Three LED's on the board

indicate the presence of these 3 voltages (+5V=LED H11,

+12VS=LED H13, +5VS=LED H10).

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-12

3.5.3.

3.5.3.3.5.3.

3.5.3. HF Board (A2) and Tubehead

HF Board (A2) and TubeheadHF Board (A2) and Tubehead

HF Board (A2) and Tubehead

The HF board and the tubehead are located on the rotating arm, very

close to each other. The power supply voltage (230Vac) is directly

provided by the Power supply assembly, passing through a filtering box

having the function to rectify the input voltage to generate a 360Vdc

voltage.

Dedicated switching circuits, directly located on the board, generate the

voltage used on the board itself (+12V/-12V).

Managing of the HF board is done by the main CPU board of the unit.

The high frequency (HF) circuit is based on an inverter circuit working at

the frequency about 30kHz, which drives the tubehead through an

output stage based on IGBT components.

The HF board receives the signals concerning the X-ray dose to provide

(kV and mA), directly from the CPU board. The HF board provides to the

tubehead the voltages that drive the high voltage transformers that then

drive anode and filament of the X-ray tube, also giving the relevant

timing.

The tubehead is composed by the radiogenic tube (CEI OPX/105)

inserted in a sealed container, together with the high voltage

transformers, filled with dielectric oil.

Checking of proper functioning of the X-ray emitting system is achieved

through the analysis of feed back signals generated inside the tubehead

and transmitted to the HF board. Possible anomalous conditions are then

communicated to the CPU board which in turn generates error codes to

alert the operator.

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-13

3.5.4.

3.5.4.3.5.4.

3.5.4. Keyboard

KeyboardKeyboard

Keyboard

The keyboard is the interface with the operator, and is composed by the

following items:

• Matrix of keys, constituted by microswitches with short stroke,

necessary to activate the different available functions

• Signalling LED integrated in the touch panel

• LCD display equipped with back-light, composed by a matrix of 16

characters and 2 rows

• Keyboard PCB.

The keyboard PCB is directly connected to the CPU board which controls

it. The language of the messages shown on the display can be selected

among 5 different options (English, Italian, French, German and

Spanish). The language selection is only available for the messages

dedicated to the user. The messages relative to the service programs

(Password) are always in English.

SERVICE MANUAL

Description

STRATO 2000 Digital (Rev. 3)

3-14

Figure 3-3 - Block diagram PAN only version

SERVICE MANUAL

Description

(Rev. 3) STRATO 2000 Digital

3-15

Figure 3-4 – Block diagram CEPH version

Loading...

Loading...