Villa Sistemi Medicali ROTOGRAPH-D Service Manual

Release 11 November 2013 (Rev. 5)

ROTOGRAPH

ROTOGRAPHROTOGRAPH

ROTOGRAPH----D

DD

D

(120V version)

(120V version)(120V version)

(120V version)

Service Manual

Service ManualService Manual

Service Manual

SERVICE MANUAL

Revision history

(Rev. 5) ROTOGRAPH-D (120V)

Revision history

Revision historyRevision history

Revision history Manual code 6908917800

Manual code 6908917800 Manual code 6908917800

Manual code 6908917800

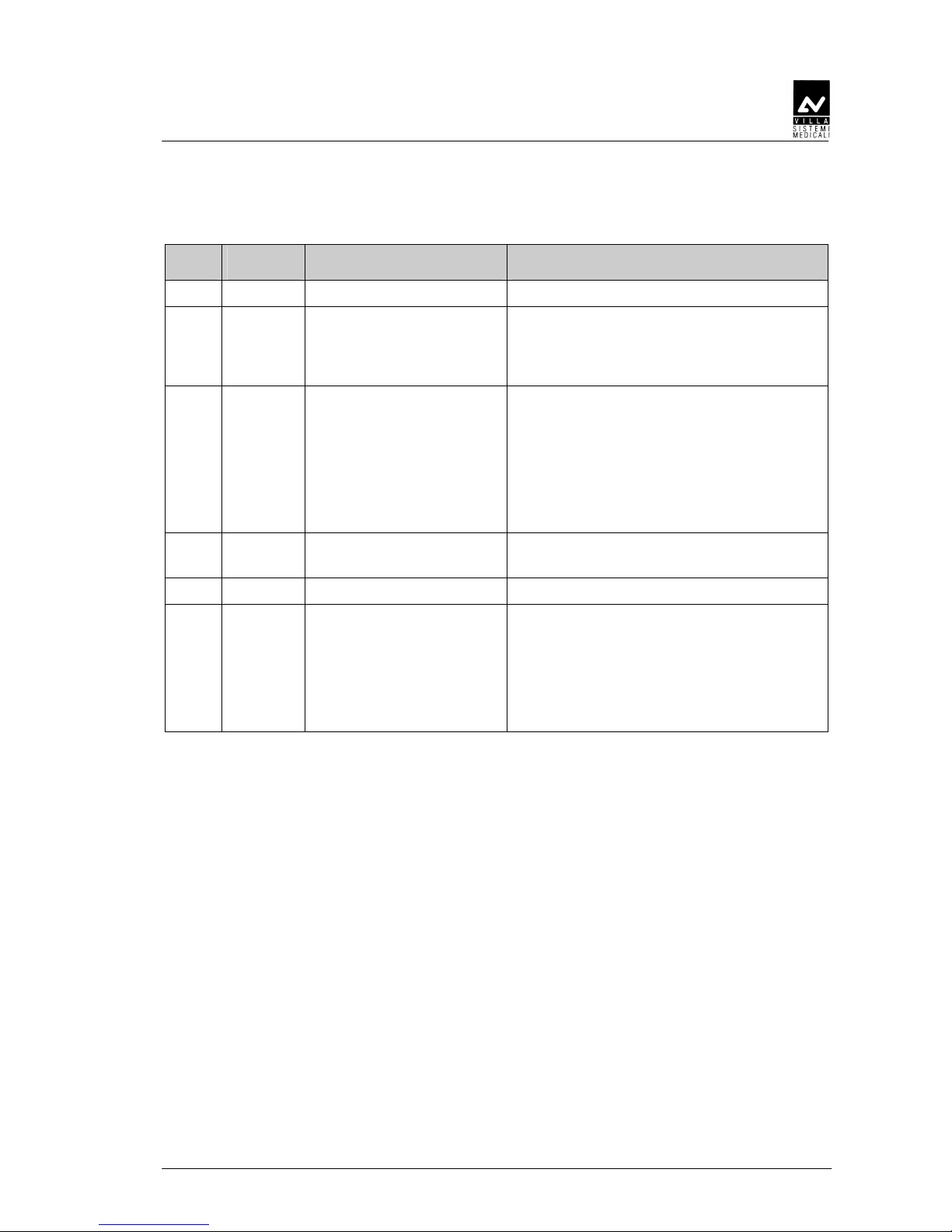

Rev. Date Page/s Modification description

0 26.10.05 - Document approval.

1 16.11.06 from 6-3 to 6-6,

7-32, 7-33,

10-4, 10-10

Installation and adjustment procedure

improvement.

Spare Parts update.

(Ref. RDM 6269, RDM 6446, RDM 6462, RDM 6540)

2 20.09.07 i, ii, from 5-2 to 5-6,

6-6, from 7-9 to 7-47,

9-15, 9-23, 9-25,

9-27, 10-4

Modified Chapter 7: Parts replacements

paragraph added, improvement in

Troubleshooting.

Added NOTE with indication that the

device is supplied as unit to be installed

permanently (EN60601-1 – paragraph 19).

Schematics update.

(Ref. RDM 6620, RDM 6660, RDM 6683, RDM 6701)

3 24.01.08 7-39 New arm rotation motor.

(Ref. RDM 6751)

4 15.07.11 All Release version Restyle 2011.

5 11.11.13 3-2, 4-2,

from 9-4 to 9-8,

from 9-13 to 9-25,

10-2, 10-6, 10-7

Inclusion of magnification factors after

software correction.

Digital Sensor identification label update.

Schematics and drawings update.

Spare Parts update.

(Ref. RDM 6746, RDM 7353, RDM 7575, RDM 7688,

RDM 7809, RDM 7857)

SERVICE MANUAL

Revision history

ROTOGRAPH-D (120V) (Rev. 5)

THIS PAGE IS INTENTIONALLY LEFT BLANK

SERVICE MANUAL

Contents

(Rev. 4) ROTOGRAPH-D (120V)

i

Contents

1. INTRODUCTION 1-1

1.1 Icons appearing in the manual ............................................................ 1-1

1.2 How to contact VILLA SISTEMI MEDICALI technical service................ 1-2

2. SAFETY INFORMATION 2-1

2.1 Warnings ............................................................................................. 2-2

2.2 Environmental risk and disposal .........................................................2-3

2.3 Symbols used ...................................................................................... 2-4

3. DESCRIPTION 3-1

3.1 Identification labels ............................................................................. 3-1

3.2 Description .......................................................................................... 3-3

4. TECHNICAL FEATURES 4-1

4.1 Standards and regulation .................................................................... 4-4

4.2 X-ray tubehead curves ........................................................................ 4-5

4.3 Technical factors measuring method ................................................... 4-7

4.4 Overall dimension................................................................................ 4-8

5. PRE-INSTALLATION 5-1

5.1 Electrical requirements ....................................................................... 5-2

5.2 Environmental condition ..................................................................... 5-4

5.3 Unpacking ...........................................................................................5-4

5.4 Space requirements ............................................................................. 5-5

6. INSTALLATION 6-1

6.1 Version with legs ................................................................................. 6-2

6.2 Version without legs .......................................................................... 6-10

6.3 How to mount the coverings .............................................................. 6-14

7. CHECKOUT AND ADJUSTMENTS 7-1

7.1 Power up ............................................................................................. 7-2

7.2 Set-up ................................................................................................. 7-3

7.2.1 Activation of the set-up programs ....................................................... 7-3

7.2.2 Modification of the values of the "Software DIP-Switches"....................7-4

7.2.3 Non-volatile memory reset .................................................................. 7-8

7.3 Checking and adjusting the AC voltage ............................................... 7-9

7.3.1 Check of line voltage regulation ........................................................ 7-10

SERVICE MANUAL

Contents

ROTOGRAPH-D (120V) (Rev. 4)

ii

7.4 Checking the output current (mA) .....................................................7-11

7.4.1 First solution (rotating arm in movement)......................................... 7-11

7.4.2 Second solution (rotating arm blocked) ............................................. 7-12

7.5 Checking and centering adjustment of the X-ray beam .....................7-13

7.5.1 Alignment of the X-ray beam for the PANORAMIC mode.................... 7-14

7.5.1.1 Oblique regulation ............................................................ 7-15

7.5.1.2 Vertical regulation ............................................................ 7-16

7.5.1.3 Horizontal regulation ........................................................ 7-17

7.6 Angle (A…) and Time (T…) control......................................................7-18

7.7 Set the default angles and times ........................................................ 7-20

7.7.1 PAN-ADULT ..................................................................................... 7-21

7.7.2 PAN-CHILD...................................................................................... 7-23

7.7.3 TMJ1 and TMJ2 - ADULT and CHILD............................................... 7-24

7.7.4 Verification of Panoramic centering and symmetry ............................ 7-26

7.8 Error messages and Troobleshooting ................................................. 7-29

7.8.1 Line voltage too high / too low ......................................................... 7-31

7.8.2 Impossible to regulate the line voltage .............................................. 7-32

7.8.3 Memory data corrupted. Call Technical Assistance............................ 7-33

7.8.4 "NO ANSWR" ................................................................................... 7-33

7.8.5 Out of Order N°1! Call Technical Assistance...................................... 7-34

7.8.6 Asymmetric images (incorrect rotation time) ..................................... 7-34

7.9 Replacing parts.................................................................................. 7-35

7.9.1 Potentiometer replacement/calibration ............................................. 7-35

7.9.2 Rotation Start / Stop Microswitch replacement................................. 7-38

7.9.3 Arm Rotation Motor / Power Board A1 replacement .......................... 7-40

7.9.4 CPU Board A2 replacement .............................................................. 7-42

7.10 Checking (safety) hardware timers .....................................................7-43

7.11 System reconfiguration after testings ................................................ 7-44

8. MAINTENANCE 8-1

9. SCHEMATICS AND DRAWINGS 9-1

9.1 Key to general diagram of the ROTOGRAPH-D.....................................9-2

10. SPARE PARTS 10-1

This publication can only be reproduced, transmitted, transcribed, or translated

into any human or computer language with the written consent of Villa Sistemi

Medicali S.p.a.

This manual in English is the original version.

SERVICE MANUAL

Introduction

(Rev. 4) ROTOGRAPH-D (120V)

1-1

1.

1.1.

1. INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

NOTE:

The present manual is updated for the product it is sold with in order to

grant an adequate reference in performing diagnostics and repair

operations normally carried out by the service engineer.

The manual may not reflect changes to the product not impacting service

operations.

ROTOGRAPH-D, manufactured by Villa Sistemi Medicali, is a radiological

device which allows to carry out radiological examinations of the dento

maxillo facial complex, when used in conjunction with the digital image

acquisition system QuickVision manufactured by Owandy.

ROTOGRAPH-D is available in a single version for the execution of:

•

PANORAMIC examination

•

Temporo-Mandibular Joint (TMJ) examination

•

SINUS examination.

This manual provides to the operator the instructions for proper and safe

use of the appliance.

The appliance must be used strictly following the procedures described

in this manual and never for activities other than those for which it was

designed.

Before using the appliance, we recommend to read carefully this manual.

Keep it in a safe place near the unit for future reference.

ROTOGRAPH-D is an electromedical appliance and may be used only

under medical supervision, i.e. with the supervision of highly qualified

persons with the necessary know-how regarding X-ray protection.

The user is responsible for complying with the legal requirements

regarding the installation and operation of the equipment.

1.1

1.11.1

1.1 Icons appearing in the manual

Icons appearing in the manualIcons appearing in the manual

Icons appearing in the manual

Indicates a “NOTE”; the utmost attention shall be devoted to the

reading of paragraphs marked by this icon.

Indicates a “WARNING”; paragraphs marked with this icon cover

patient and/or operator safety aspects.

SERVICE MANUAL

Introduction

ROTOGRAPH-D (120V) (Rev. 4)

1-2

1.2

1.21.2

1.2 How to contact VILLA SISTEMI MEDICALI

How to contact VILLA SISTEMI MEDICALI How to contact VILLA SISTEMI MEDICALI

How to contact VILLA SISTEMI MEDICALI

technical service

technical servicetechnical service

technical service

For any technical queries please contact the following:

• Telephone number +39 02 48859.1

• Fax number +39 02 48859222

• E-mail: dentalservice@villasm.com

SERVICE MANUAL

Safety information

(Rev. 4) ROTOGRAPH-D (120V)

2-1

2.

2.2.

2. SAFETY INFORMATION

SAFETY INFORMATIONSAFETY INFORMATION

SAFETY INFORMATION

WARNING:

Read this chapter very carefully.

VILLA SISTEMI MEDICALI designs and manufactures equipment in

compliance with safety requirements; moreover, it provides all the

necessary information for correct utilization as well as warnings related

to risks associated to X-ray generators.

Villa Sistemi Medicali shall not be responsible for:

• any use of the ROTOGRAPH-D different from that for which it has

been designed,

• any damage to the equipment, the operator or the patient caused

either by incorrect installation and maintenance not compliant with

the procedures contained in the relevant user’s and installation

manuals provided with the equipment, or by incorrect operation

techniques,

• any mechanical and/or electrical changes effected during or after

installation, different from those reported in the service manual.

Only qualified service personnel, authorized by VILLA SISTEMI

MEDICALI is allowed to perform technical interventions on the

equipment.

Only authorized personnel is allowed to remove the tubehead from

its support and access the internal components.

SERVICE MANUAL

Safety information

ROTOGRAPH-D (120V) (Rev. 4)

2-2

2.1

2.12.1

2.1 Warnings

WarningsWarnings

Warnings

The system has not been designed to be used in presence of vapours,

anaesthetic mixtures that are flammable with air, or oxigen or nitrous

oxide.

Ensure that water or other liquids do not get into the machine so as to

prevent short-circuits and corrosion.

Always disconnect from mains before cleaning the machine.

Where necessary, accessories such as lead-sealed aprons must be used

to protect the patient from radiations.

Only the patient and the operator may remain in the room during the

execution of the radiography examination.

ROTOGRAPH-D has been developed for continuous use with intermittent

load. The prescribed operating cycles to allow the heat accumulated by

the radiogenic source to be discharged must be observed.

Although the appliance has been designed to have a reasonable degree of

protection from electromagnetic interference, it must be installed at a

certain distance from electricity transformer rooms, static continuity

unit, portable two-way hand radios and cellular phones. The latter may

only be used at a distance of over 1.5 meters from all elements of the

machine.

All instruments or equipment for professional use and used near the

machine must be in conformance to the electromagnetic compatibility

standards.

Nonconforming instruments whose low immunity to electromagnetic

fields is known must be installed at least 3 meters away from the

ROTOGRAPH-D and be powered via an independent electric line.

ROTOGRAPH-D must be switched off during the entire period of use of

ESU (Electro Surgery Units) units or similar equipment.

Clean or eventually disinfect the chin support, positioning handles,

temples clamp support and any other part that may come in touch with

the patient.

At the end of the examination, replace the bite.

SERVICE MANUAL

Safety information

(Rev. 4) ROTOGRAPH-D (120V)

2-3

Although the X-ray dosage supplied by dental radiology appliances is on

average low and distributed over a relatively small surface, the operator

must take the necessary precautions and/or follow the safety procedures

for both himself and the patient during an exposure. We recommend

that the X-ray activation always be commanded from an X-ray protected

area via remote control. If it is necessary to operate the exposure near

the patient, remain at the maximum distance allowed by the remote

control cable in the direction opposite to the emission of the rays, at a

distance of at least 78 ¾ inches (2 meters) from both the radiation

source and patient.

2.2

2.22.2

2.2 Environmental risk and disposal

Environmental risk and disposalEnvironmental risk and disposal

Environmental risk and disposal

A number of machine parts contain materials and liquids that upon

completion of the machine’s life cycle must be disposed of at recovery

centers established by the local health units.

The machine contains the following materials and/or components:

• Tubehead: dielectric oil, lead, copper, iron, aluminum, glass,

tungsten, beryllium

• Control box and remote control: iron, copper, glass resin, non-

biodegradable plastic casings

• Column, rotating arm, extensions: iron, lead, aluminum, copper,

non-biodegradable plastic materials, glass resin.

WARNING:

Before disassembling the parts, lock the counterweight of the slider

inserted in the column. This is possible only after having slid the slider

all the way down and inserted a pin approximately 25cm in length and

8mm in diameter. Once the pin has been inserted, move the slider

towards the top until the counterweight rests on the pin. Remove the

tubehead and some of the parts of the rotating arm. Holding the slider

firmly, remove the pin and move the slider towards the top to the

metallic stop of the column. At this point, remove all the remaining

parts.

SERVICE MANUAL

Safety information

ROTOGRAPH-D (120V) (Rev. 4)

2-4

2.3

2.32.3

2.3 Symbols used

Symbols usedSymbols used

Symbols used

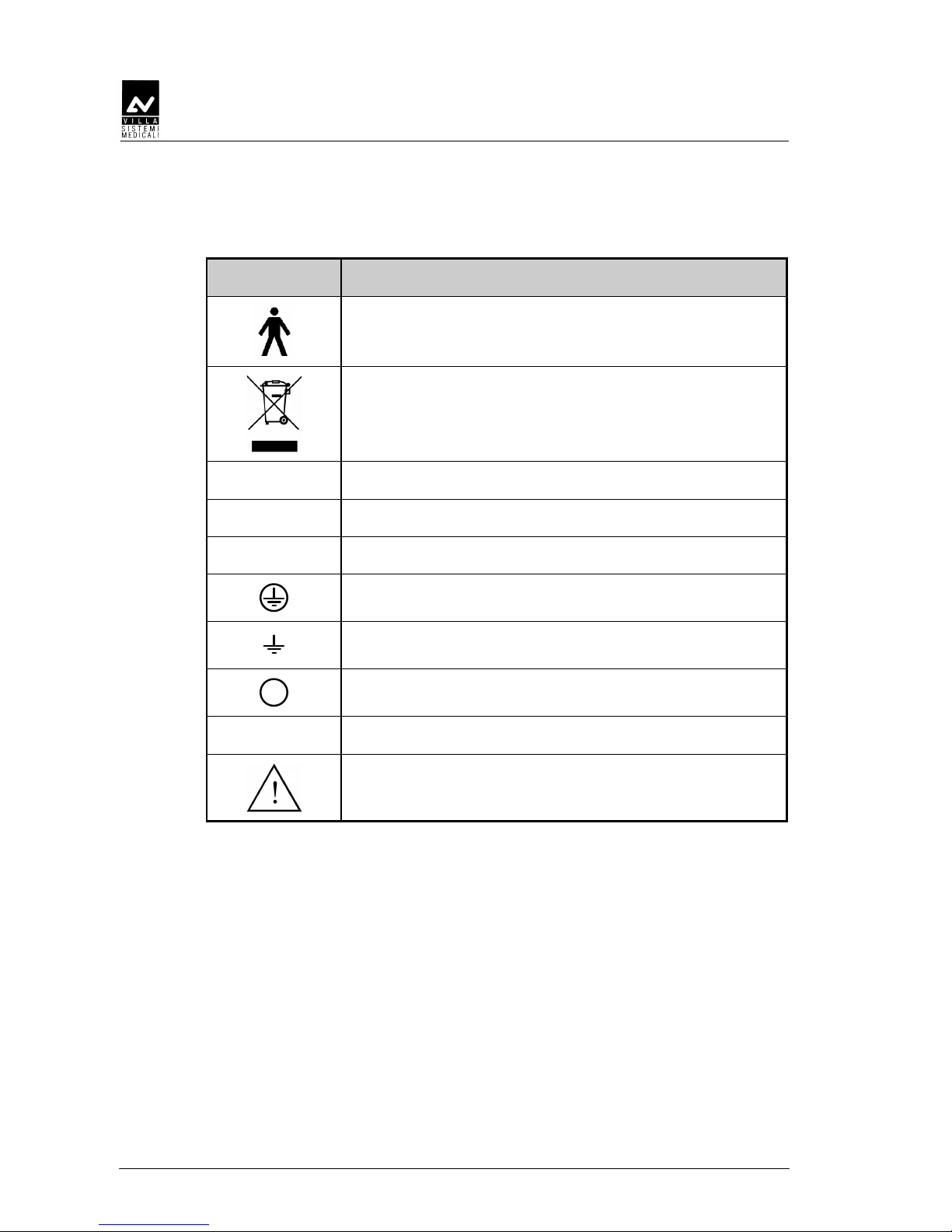

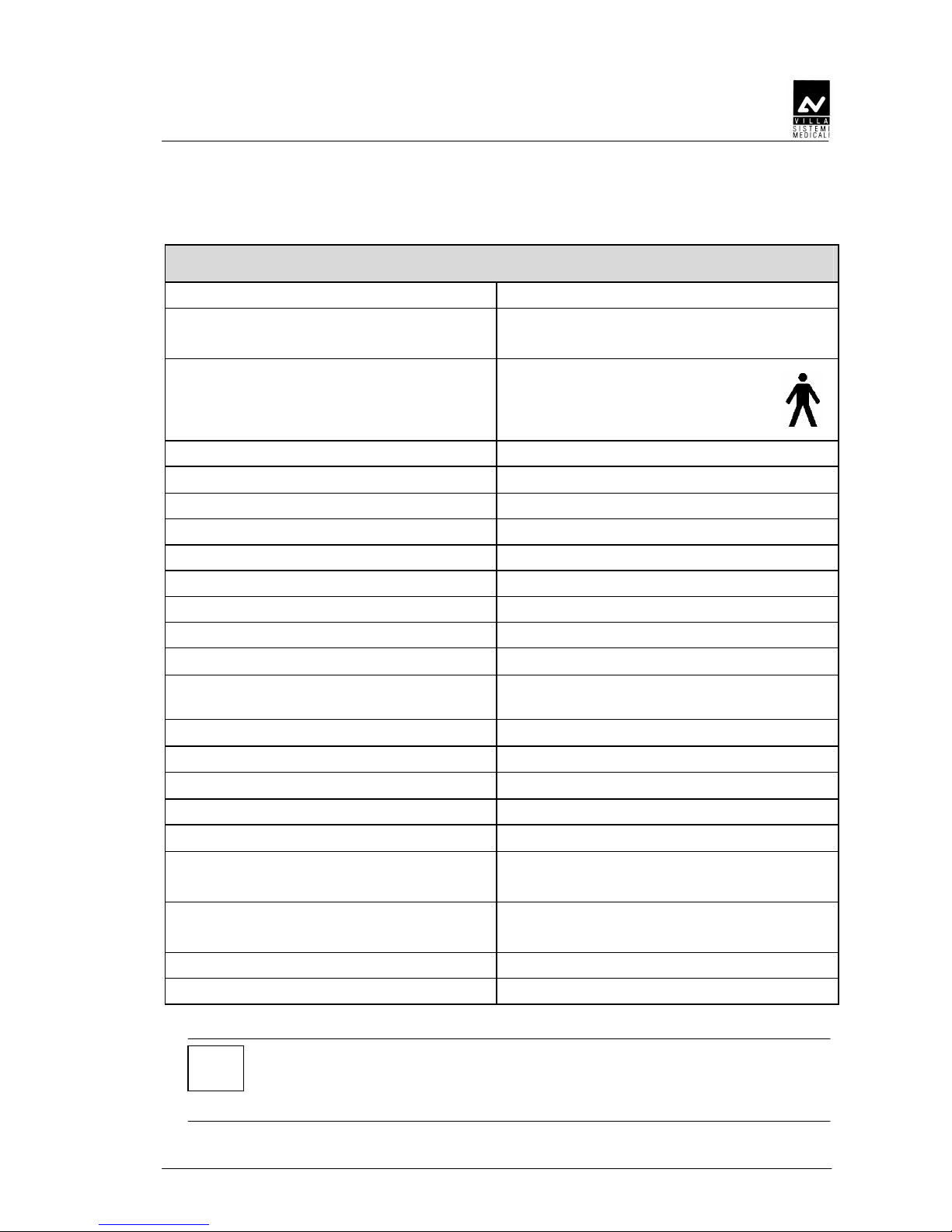

Symbol Description

Equipment with Type B applied parts (according to

IEC 60601-1)

A number of machine parts contain materials and

liquids that upon completion of the machine’s life

cycle must be disposed of at recovery centers

established by the local health units

∼∼∼∼

Alternating Current

N Connection to neutral conductor

L Connection to line conductor

Protection ground

Functional ground

OFF ; equipment not connected to power line

ON ; equipment connected to power line

Warning: read the documentation provided with the

unit

SERVICE MANUAL

Description

(Rev. 5) ROTOGRAPH-D (120V)

3-1

3.

3.3.

3. DESCRIPTION

DESCRIPTIONDESCRIPTION

DESCRIPTION

3.1

3.13.1

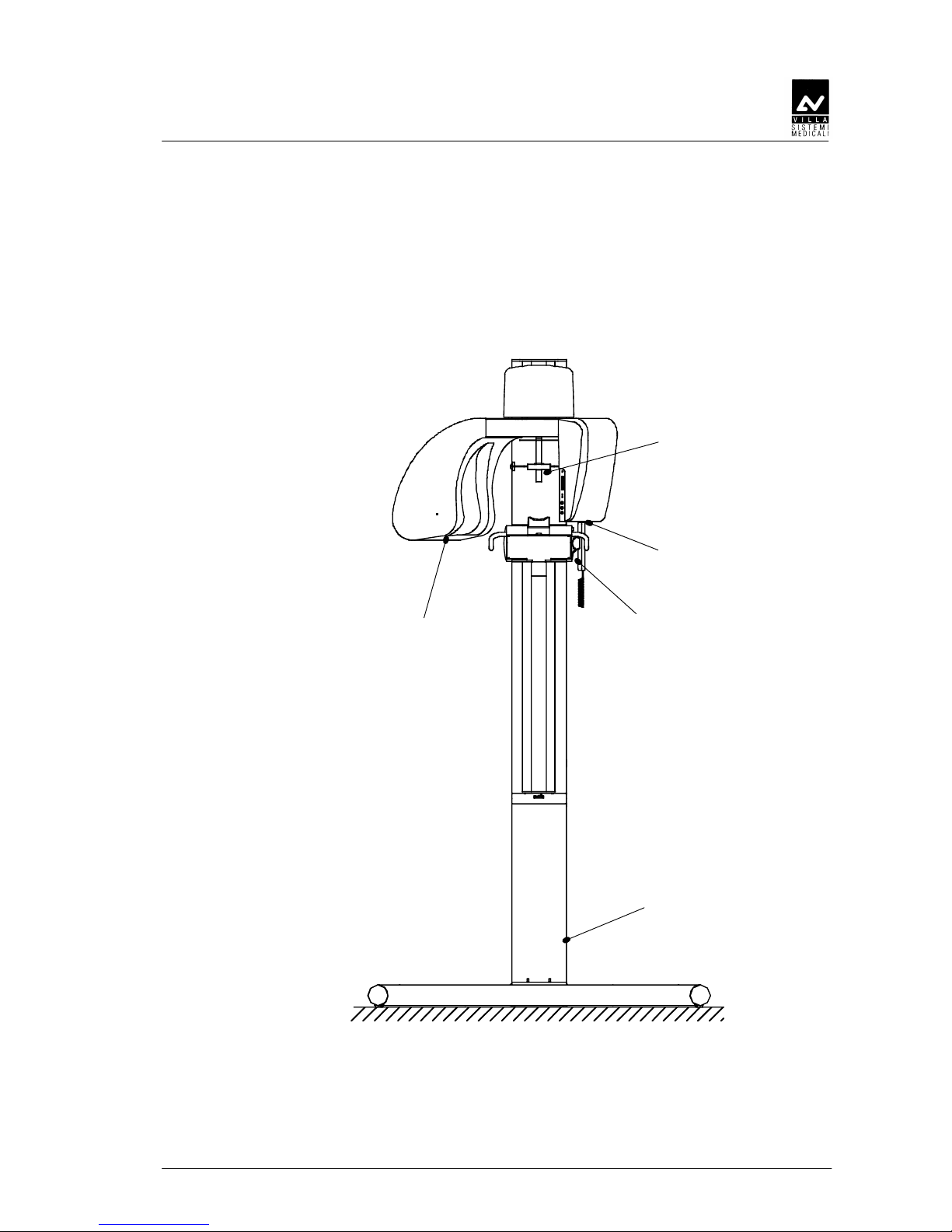

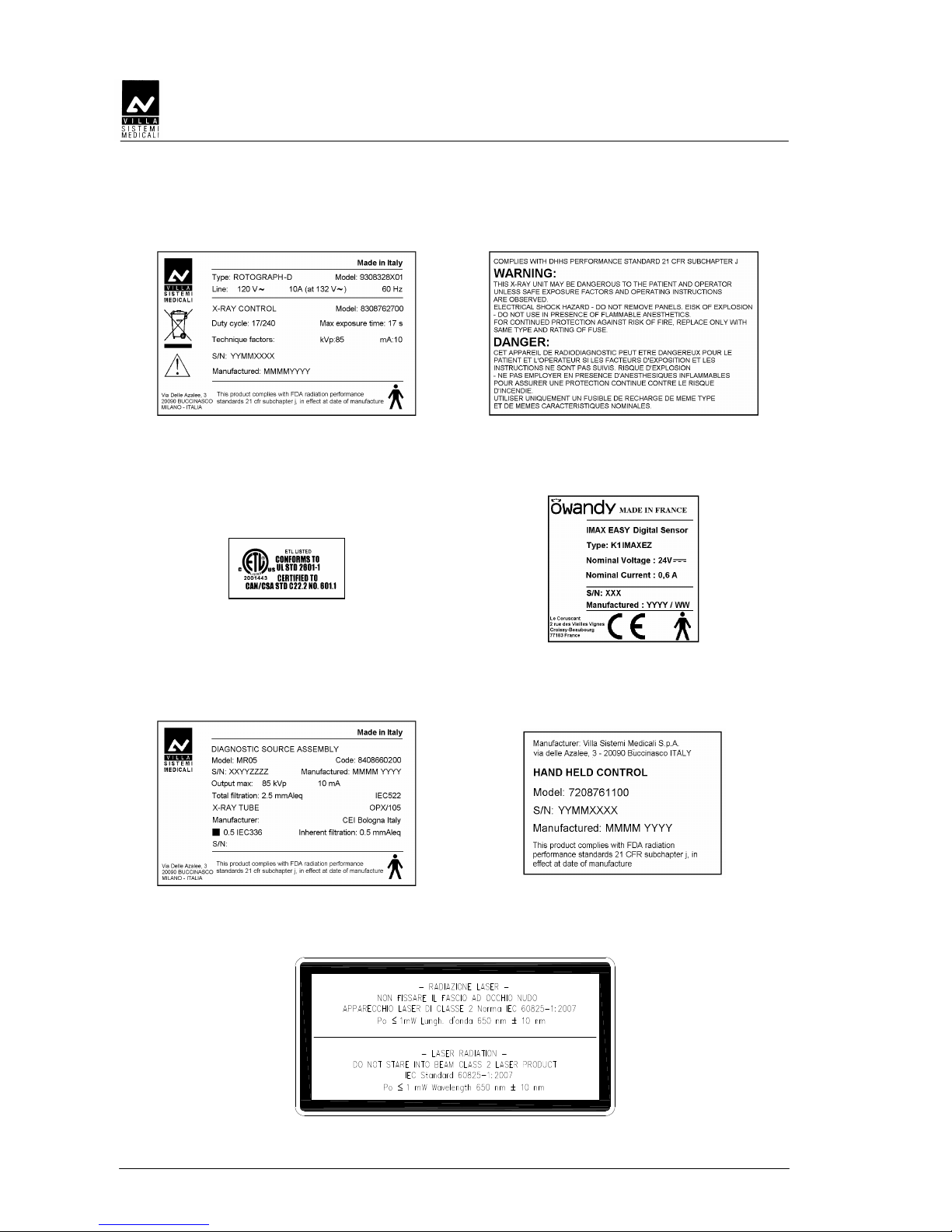

3.1 Identification labels

Identification labelsIdentification labels

Identification labels

1

3

2

4

5

SERVICE MANUAL

Description

ROTOGRAPH-D (120V) (Rev. 5)

3-2

1a

ROTOGRAPH-D

label

1b

WARNING label

1c

ETL certification

label

2

Digital Sensor

identification label

3

Tube head

identification label

4

Remote control

identification label

5

Laser WARNING

label

SERVICE MANUAL

Description

(Rev. 5) ROTOGRAPH-D (120V)

3-3

3.2

3.23.2

3.2 Description

DescriptionDescription

Description

ROTOGRAPH-D has been designed to perform the following

examinations:

• Panoramic examination

• "SINUS" examination of the paranasal sinus

• Examination of the Temporo-Mandibular Joints (TMJ) with open or

closed mouth on a single image

All the allowed examination may be made with different parameters

according to the setting of the remote-control (please refer to Chapter 6

of User’s Manual).

ROTOGRAPH-D is controlled by a soft touch console and equipped with

an alphanumeric digital display for a clear indication of the working

parameters and operative messages.

The operative cycle is entirely run by a microprocessor, controlling its

different modes: from programming of the emission parameters

according to the chosen examination and the patient's size, to the

voltage fluctuation and to the notification of possible anomalies, failures

or errors.

The excellent quality radiographs thus obtained is the result of a clever

design based upon the pseudo-elliptic rotation system, the original light

beam-luminous cross pattern centering system, the use of green emiting

Rare Earth Intensifying screens and most of all the small dimension of

the focal spot.

This particular rotation system allows an orthogonal imaging of all teeth

and wide image layer with an optimum focused zone of 10 mm for the

incisors and 20 mm for the molars.

ROTOGRAPH-D, besides operating in the programmed mode, can also

operate in the manual personalized mode by modification of the

parameters, as described in chapter 5.

In the Panoramic and TMJ modes, with all interlock enabled, it is

possible to activate the TEST push button (31) (see Figure 7-7 at the end

of the manual).

The TEST functioning mode allows the operator to check the

functionality of the selected examination cycle or to show to the patient

the examination he will undergo (including all movements of the

machine) without emitting X-rays.

The TEST push button as X-RAY button is a "dead man" button, which

means thus if it is released during the examination cycle, the latter is

interrupted stopping the movements in progress. To re-start the cycle

first reset the unit by means of the key "32" (Figure 7-7), than start again

the function which was interrupted.

SERVICE MANUAL

Description

ROTOGRAPH-D (120V) (Rev. 5)

3-4

THIS PAGE IS INTENTIONALLY LEFT BLANK

SERVICE MANUAL

Technical features

(Rev. 5) ROTOGRAPH-D (120V)

4-1

4.

4.4.

4. TECHNICAL FEATURES

TECHNICAL FEATURESTECHNICAL FEATURES

TECHNICAL FEATURES

General characteristics

Equipment ROTOGRAPH-D

Manufacturer VILLA SISTEMI MEDICALI

Buccinasco (MI) Italy

Class Class II according to 21 CFR

sub-chapter J.

Class I with type B applied parts

according to IEC.

Degree of protection IP20

Rated line voltage

120V ± 10%

Line frequency 60Hz

Max line current at nominal voltage 10A rms momentary; 0.5A stand-by

Maximum power 1.15 kVA @ 108V

Power fuse 10A T

Command fuse 0.5A T

Filament fuse 0.315A F

Line voltage regulation

≤ 3% at 108V

Compensation of the mains voltage

fluctuation

automatic

Apparent line resistance

0.5 Ω max

High voltage 60-85 kV (5 kV steps)

KV accuracy

± 10% @ 120V ± 10%

Anodic current 10 mA

Anodic current accuracy

± 1.5 mA @ 120V ± 10%

Exposure time (Panoramic) 17s adult

14s child

Exposure time (TMJ1 + TMJ2) 10.4s adult

9.4s child

Exposure interval (PAN & TMJ) 240s (1:16 duty cycle)

Height of irradiated area on sensor 5 ⅝" (143 mm)

NOTE:

Due to technology used to compensate the line voltage fluctuations, the

maximum of line current absorbed from the line is at the lowest voltage

(108V).

SERVICE MANUAL

Technical features

ROTOGRAPH-D (120V) (Rev. 5)

4-2

Image magnification

Geometric

magnification

Magnification after

software correction

Panoramic and TMJ 1.2 : 1 1 : 1 (*)

(*) WARNING:

The declared image magnification value is valid after proper software

calibration.

Tubehead features

Type MR05

Manufacturer VILLA SISTEMI MEDICALI

Buccinasco (MI) Italy

Max peak tube potential 85 kV

Nominal power 0.630 kW (85kVp, 10mA)

Total filtration ≥ 2.8 mm Al eq. at 85 kV

Insulation Oil bath

Cooling Ambient

Leakage radiation at 1 m < 0.25 mGy/h

(85 kV, 10mA, 1:16 duty cycle)

Maximum power 85 kVp, 10mA

Type of circuit Single-phase, self-rectifying

X-ray tube features

Manufacturer CEI – Bologna Italy

Type CEI OPX/105

Focus 0.5 IEC 336

Inherent filtration 0.5 mm Al eq.

Anode tilt 5°

Anode material Tungsten

Nominal voltage 105 kVp

Filament maximum current 4A

Filament maximum voltage 8V

Anode thermal capacity 30 kJ

SERVICE MANUAL

Technical features

(Rev. 5) ROTOGRAPH-D (120V)

4-3

Laser centring device

2 laser beams are used for the patient positioning; beams align mid Sagittal and

Frankfurt planes (please refer to relevant paragraphs for detailed explanation).

Wave length 650 nm ± 10 nm

Divergence < 2.0 mRad

Optical power ≤ 1 mW

Classification Class 2 laser product according to IEC

Standard 60825-1:2007

Weight of apparatus and parts

Slider net weight 108 lbs (49 kg)

Column net weight 106 lbs (48 kg)

Tubehead net weight 42 lbs (19 kg)

Control unit net weight 62 lbs (28 kg)

Slider counterweights net weight 150 lbs (68 kg)

Environmental conditions

Maximum operating temperature range

+50°F ÷ +104°F (+10° ÷ +40°C)

Operating relative humidity range

30% ÷ 75%

Transportation and storage temperature

range

-4°F ÷ +158°F (-20° ÷ +70°C)

Maximum transportation and storage

relative humidity

< 90% non condensing

Minimum atmospheric pressure for

transportation and storage

630 hPa

SERVICE MANUAL

Technical features

ROTOGRAPH-D (120V) (Rev. 5)

4-4

4.1

4.14.1

4.1 Standards and regulation

Standards and regulationStandards and regulation

Standards and regulation

The ROTOGRAPH-D equipment is manufactured according to the

following standards:

21 CFR subchapter J

• General safety:

IEC 60601-1

IEC 60601-2-7

IEC 60601-2-28

IEC 60601-2-32

UL 2601

• Electromagnetic compatibility

IEC 60601-1-2

• Protection from radiation

IEC 60601-1-3

SERVICE MANUAL

Technical features

(Rev. 5) ROTOGRAPH-D (120V)

4-5

4.2

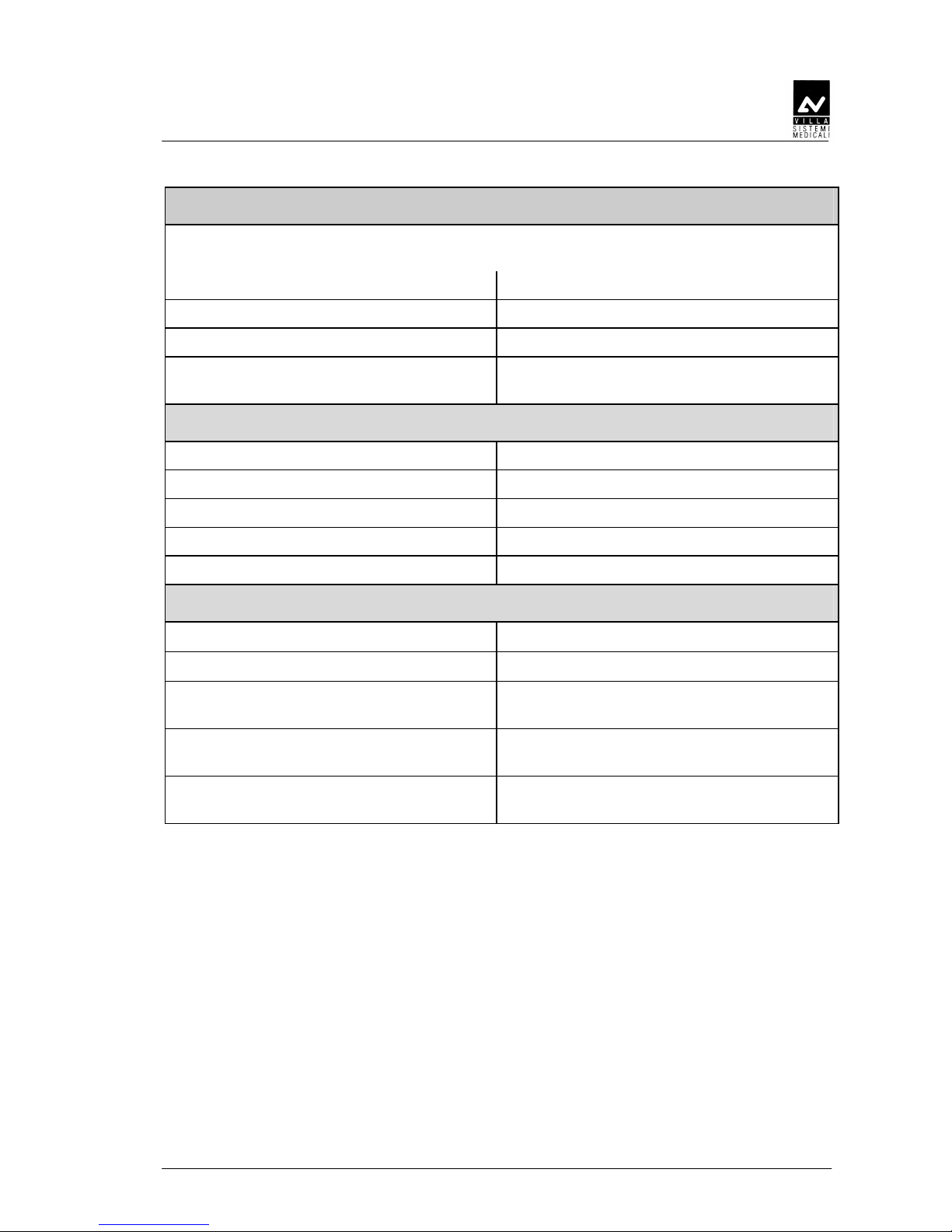

4.24.2

4.2 X

XXX---

-ray tubehead curves

ray tubehead curvesray tubehead curves

ray tubehead curves

Tube "CEI

Tube "CEI Tube "CEI

Tube "CEI ---- OPX/105" (0.5x0

OPX/105" (0.5x0 OPX/105" (0.5x0

OPX/105" (0.5x0.5)

.5).5)

.5)

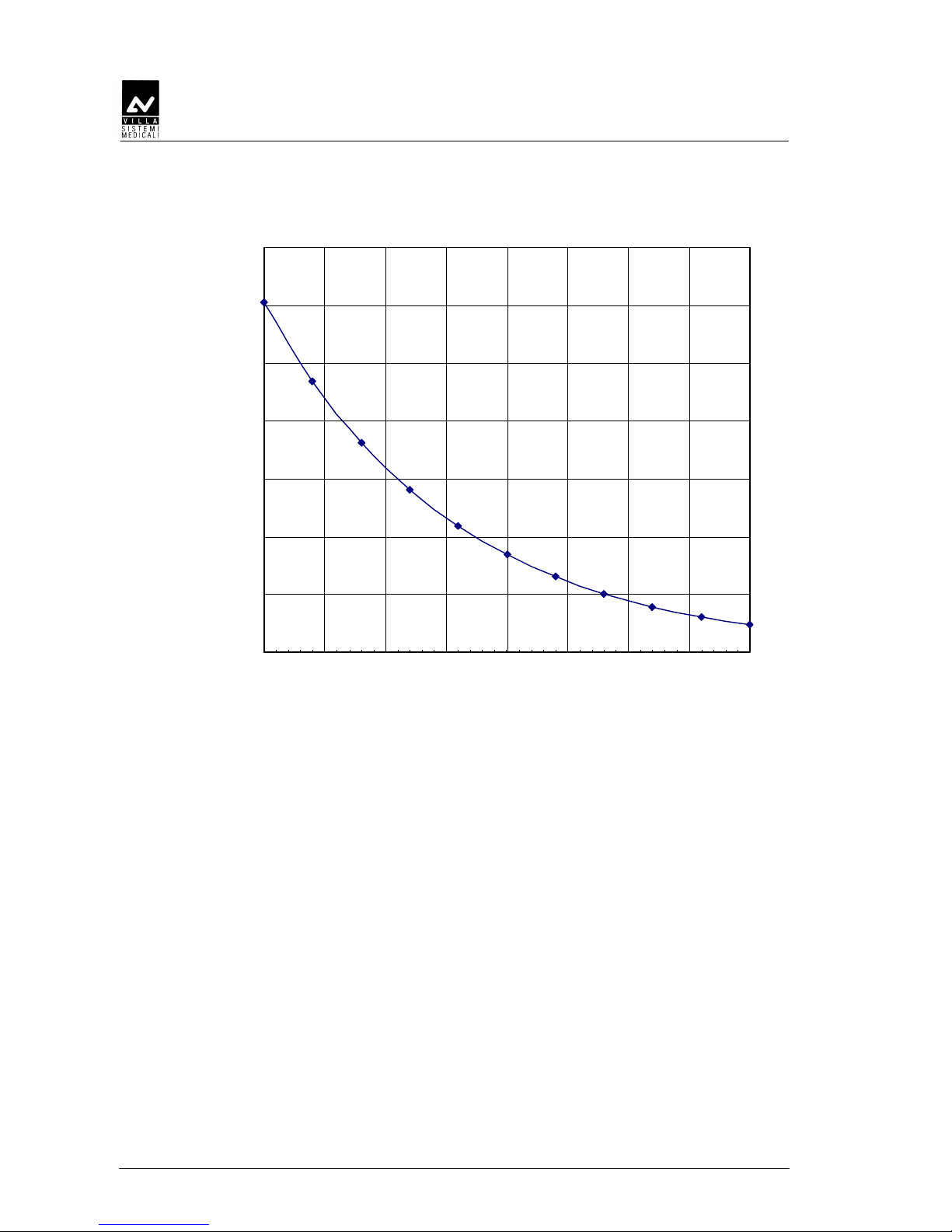

Loading chard

Anode cooling chard

SERVICE MANUAL

Technical features

ROTOGRAPH-D (120V) (Rev. 5)

4-6

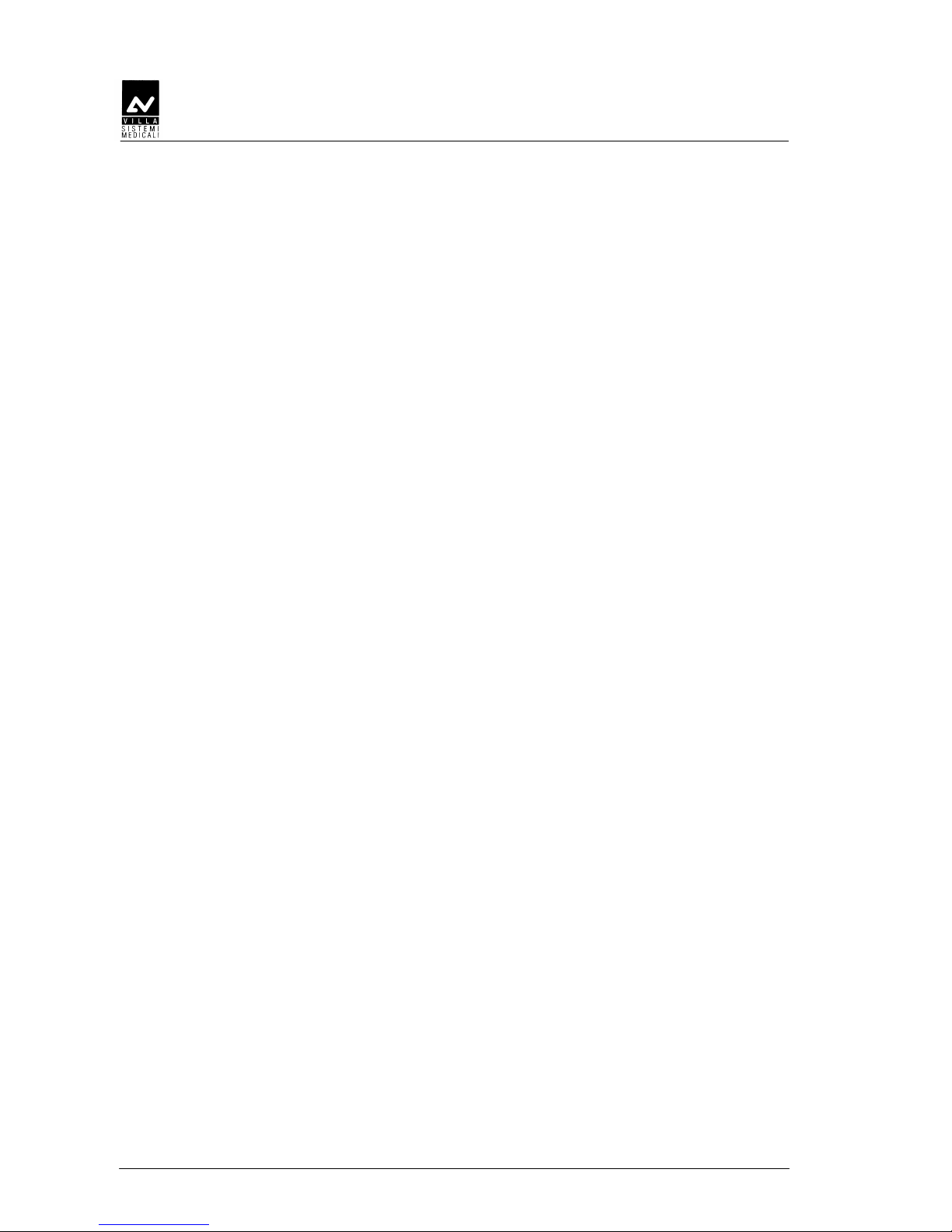

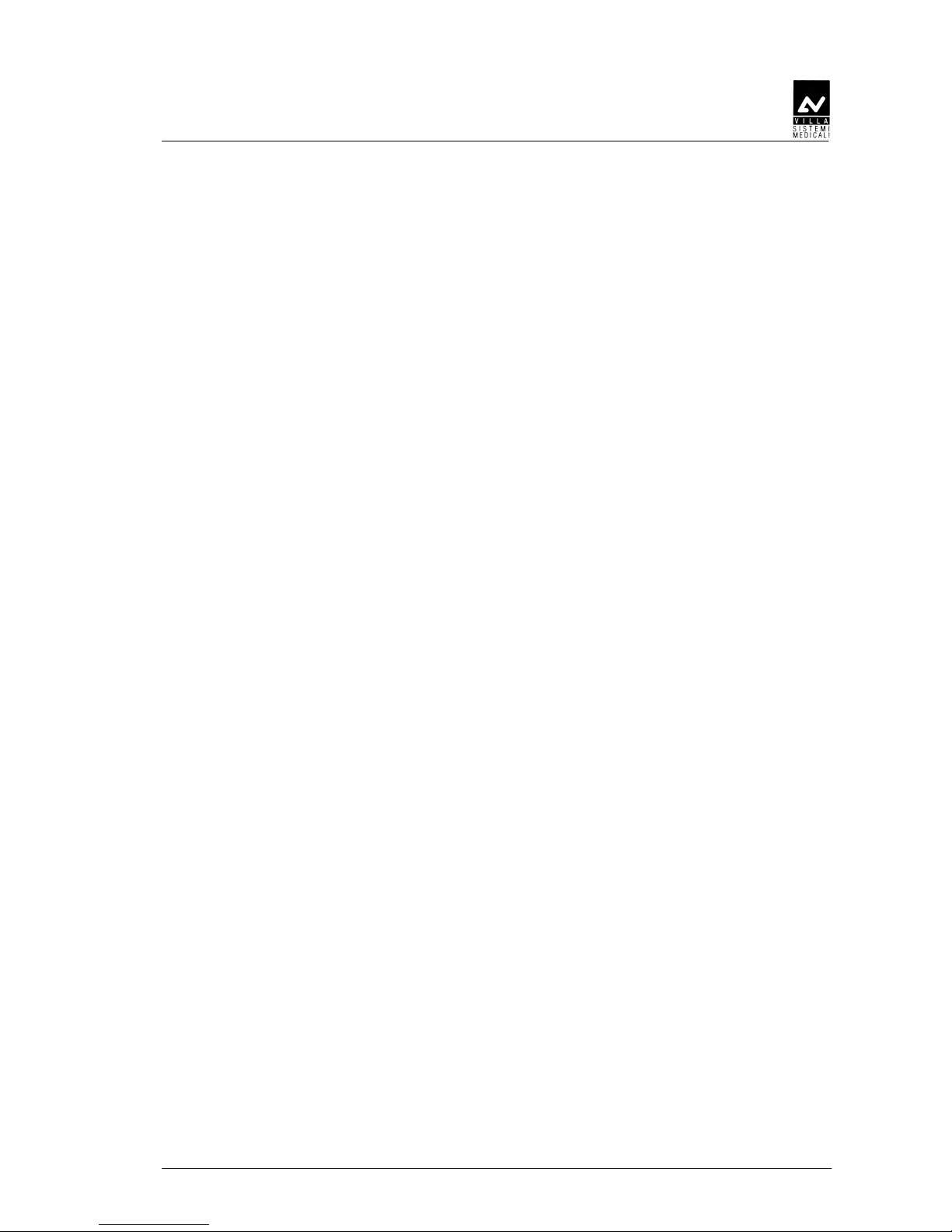

Cooling curve of tubehead

0

100

200

300

400

500

600

700

0 50 100 150 200 250 300 350 400

min

E(KJ)

SERVICE MANUAL

Technical features

(Rev. 5) ROTOGRAPH-D (120V)

4-7

4.3

4.34.3

4.3 Technical factors measuring method

Technical factors measuring methodTechnical factors measuring method

Technical factors measuring method

kVp The peak tube potential is directly measured with a non invasive

kVp-meter, accuracy ±3kVp. When performing the measurement, make

sure that measuring probe is completely covered by the X-ray beam.

A direct measurement of the high voltage can only be carried out by

specialized technicians in a suitable testing laboratory as it requires

disassembling of the tubehead.

mA The output current is determined by measuring the voltage drop on a

resistor (1kΩ, 5%) using a digital multimeter, connected to the

corresponding plugs, as indicated on paragraph 7.4 (digital multimeter

set to VDC 20V, 1V=1mA).

t The exposure times are determined by using a timer/counter, having an

accuracy of 0.1%, measuring the duration of part of the voltage applied

to the primary side of the tubehead, during the exposure phase.

SERVICE MANUAL

Technical features

ROTOGRAPH-D (120V) (Rev. 5)

4-8

4.4

4.44.4

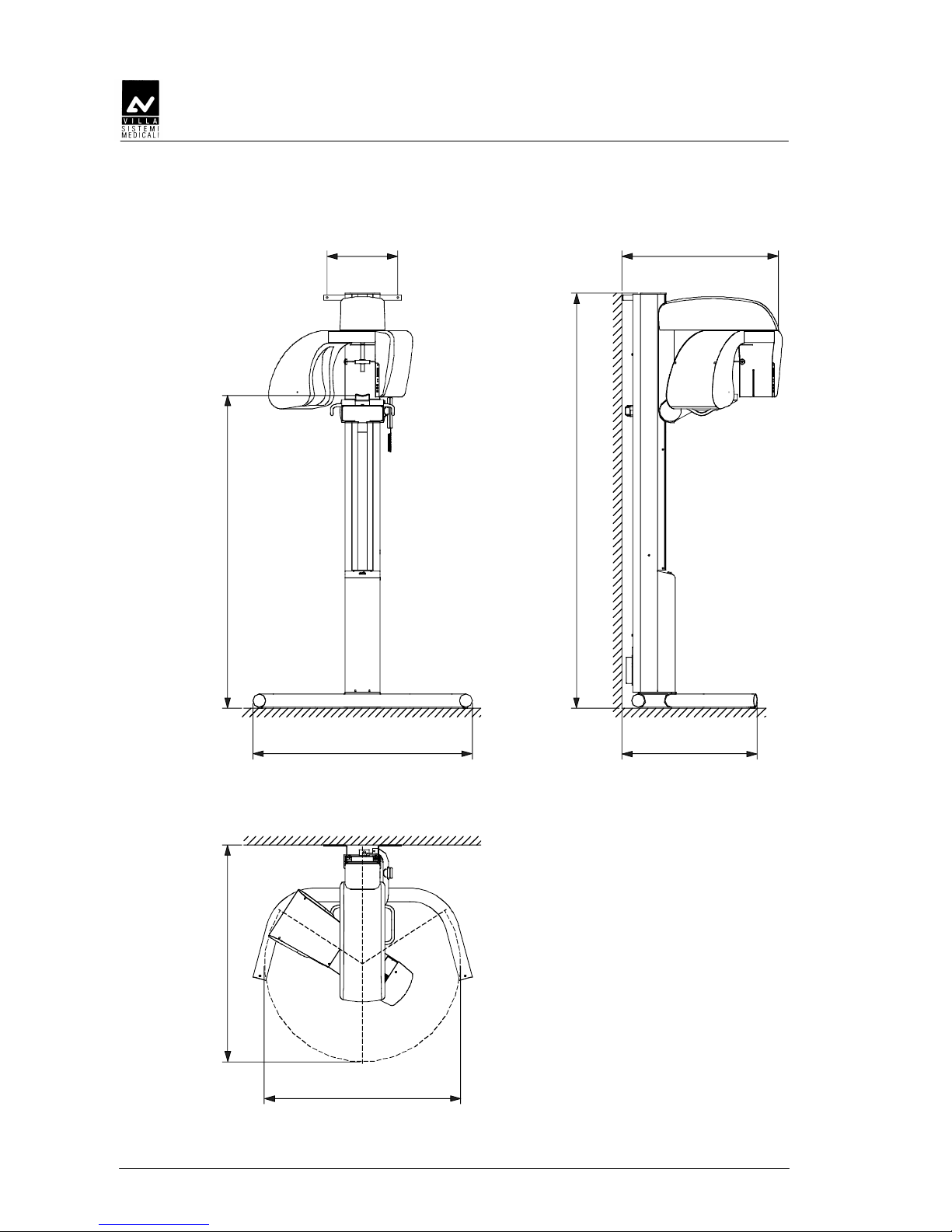

4.4 Overall dimension

Overall dimensionOverall dimension

Overall dimension

1240 (49")

1170 (46")

1256 (50")

957÷1791 (37.7"÷70.5")

774 (30.5")

2378 (93.6")

897 (35.3")406 (16")

Figure 4-1: ROTOGRAPH-D overall dimension

SERVICE MANUAL

Pre-installation

(Rev. 4) ROTOGRAPH-D (120V)

5-1

5.

5.5.

5. PRE

PREPRE

PRE----INSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION

Please read carefully the information provided in this chapter in order to

ensure proper functioning of ROTOGRAPH-D.

The supplier is able to provide assistance and the necessary technical

advice necessary for the pre-installation phase; building works and the

pre-installation phase are to be charged to the customer and must be

made according to the information provided.

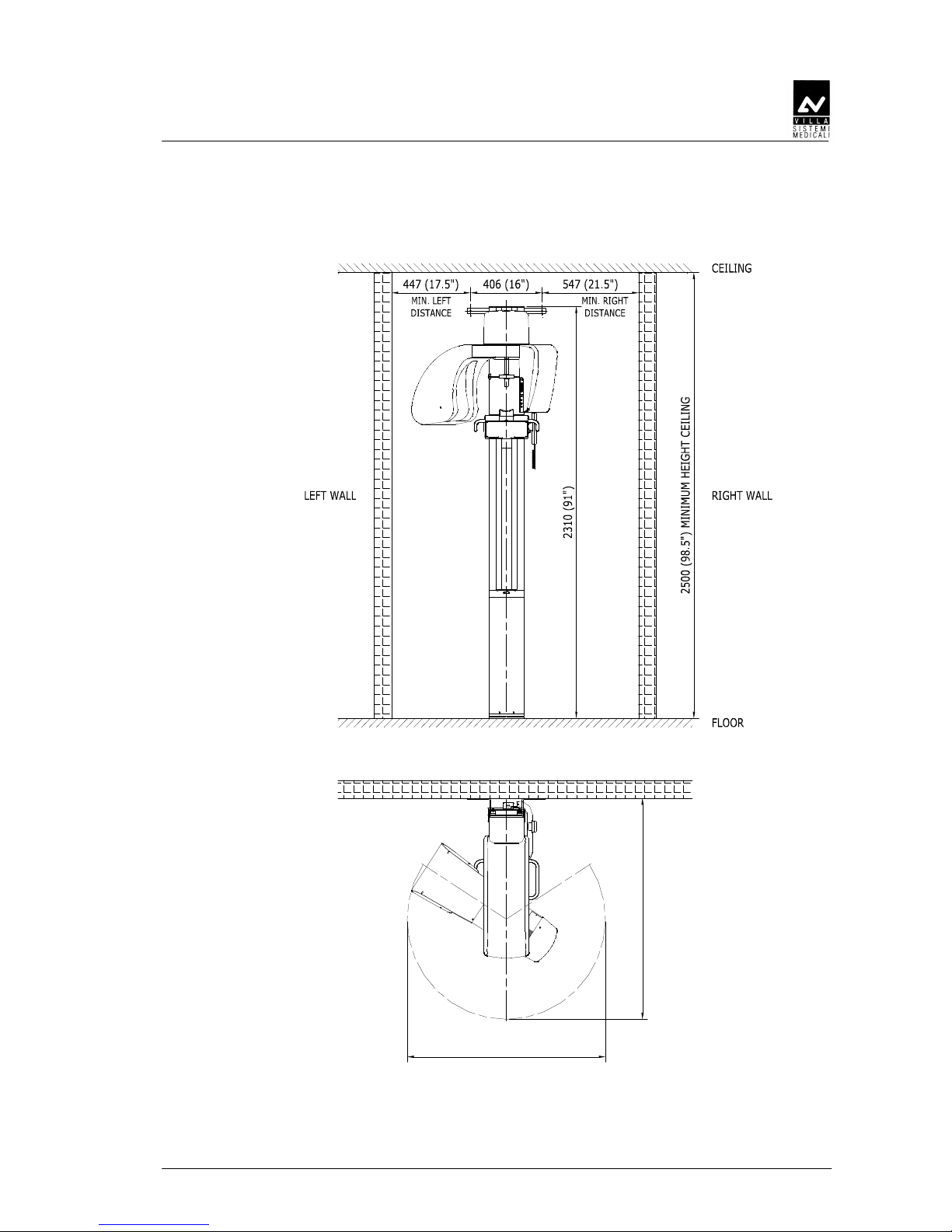

The room pre-installation requirements for a successful installation are:

• a minimum room ceiling height of 8 ft (2,5 mt) and an area to accept

ROTOGRAPH-D with its different configuration as showed in Figure

5-1.

• to transport the system into the room the doors must have a

minimum width of 36" (80cm).

SERVICE MANUAL

Pre-installation

ROTOGRAPH-D (120V) (Rev. 4)

5-2

5.1

5.15.1

5.1 Electrical requirements

Electrical requirementsElectrical requirements

Electrical requirements

• Supply single phase + ground 120V ± 10%

• Frequency 60 Hz

• Power input 1.1 kVA

• Max current 10A (at 108V)

• Apparent line resistance 0.5Ω max

NOTE:

The device is supplied as unit to be installed permanently

(EN60601-1 – paragraph 19).

Please DO NOT connect the unit to the line using a normal socket,

to avoid compromising the electrical safety.

WARNING:

The equipment must be connected to a breaker conforming with the

electrical standards in force in the country of installation.

It is mandatory to use a "Magnetothermal" breaker to separate the

appliance from the mains.

The equipment is provided with a connecting cable of the type SJT

AWG 16 (1,5mm²).

Grounding of this equipment must meet any standards in force.

NOTE:

The ROTOGRAPH-D IS PROVIDED with connections for remote control

and signalling device to be placed at the entrance of the X-ray room with

the following meanings:

• REMOTE EXPOSURE BUTTON: X-ray exposures can be

commanded by means of remote button to avoid operator presence

on the examination room. This push button must be "dead man"

type

• READY Light: (Green light 24V 40W max) signals the unit readiness

to make an X-ray exposure

• X-RAY Light: (Yellow light 24V 40W max) signals "a no entrance

condition" due to radiation emission.

In order to connect these devices, a 5 wire conductors cable of

0,5mm² (AWG 18) must be prepared prior to the complete installation.

SERVICE MANUAL

Pre-installation

(Rev. 4) ROTOGRAPH-D (120V)

5-3

WARNING:

21 CFR requires that indication of the technique factors be visible from

the operator’s position. In case of use of the remote button the

Manufacturer expressly by this warning, disclaims any responsibility, as

to compliance to Federal Regulations. It is responsibility of the installers

to observe and abide by the rules.

NOTE:

The electrical connection has to be made on the X15 terminal (refer to

Figure 6-8 and the general wiring diagram at chapter 9).

SERVICE MANUAL

Pre-installation

ROTOGRAPH-D (120V) (Rev. 4)

5-4

5.2

5.25.2

5.2 Environmental condition

Environmental conditionEnvironmental condition

Environmental condition

The performance of the equipment are assured if the room environment

must be treated in such a way as to ensure a relative humidity between

50% and 75 % and a temperature between +50°F ÷ +104°F (+10° ÷ +40°).

WARNING:

Proper backing is absolutely essential for all wall mounted versions. The

wall bracket supplied must be attached to the wall bearing in mind that

the wall backing has a capacity to sustain a load of 2000N (about

200kg - 441 lbs) per bolt applied. Backing and proper support is the full

responsibility of the owner.

5.3

5.35.3

5.3 Unpacking

UnpackingUnpacking

Unpacking

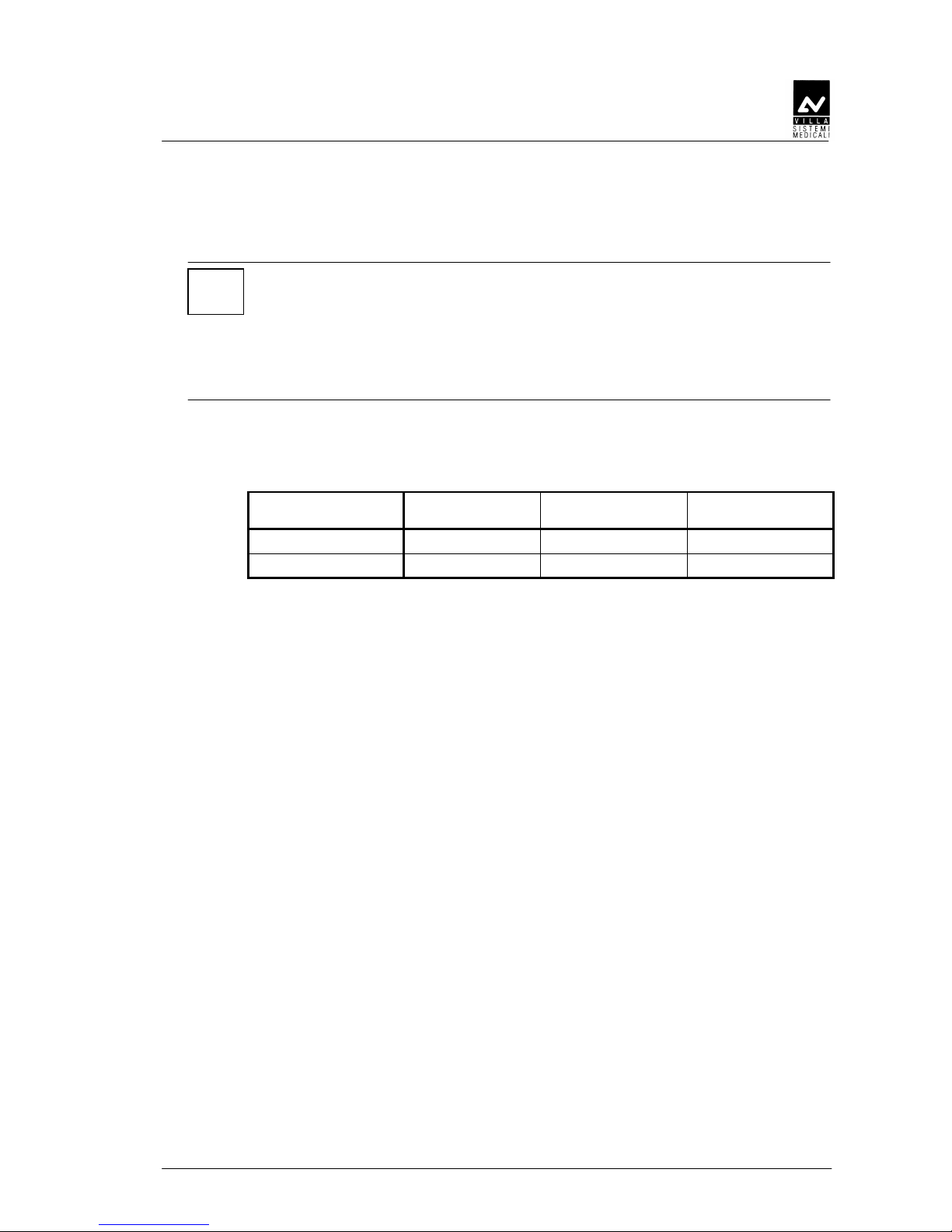

ROTOGRAPH-D is shipped packed in two cartons.

Dimensions, net weight, gross weight and the packing contents are listed

in the following table:

Weight

Packing dimension Contents

Net Gross

100x95x100 cm

(40x37½x40 inches)

WxTxH

- Motor group

- Tubehead

- Counterweights

- Accessories

210 kg

(462 lbs)

235 kg

(517 lbs)

250x25x18 cm

(98½x9¾x7 inches)

WxTxH

- Column

40 kg

(88 lbs)

45 kg

(99 lbs)

SERVICE MANUAL

Pre-installation

(Rev. 4) ROTOGRAPH-D (120V)

5-5

5.4

5.45.4

5.4 Space re

Space reSpace re

Space requirements

quirementsquirements

quirements

1240 (45")

1170 (46")

Figure 5-1

SERVICE MANUAL

Pre-installation

ROTOGRAPH-D (120V) (Rev. 4)

5-6

THIS PAGE IS INTENTIONALLY LEFT BLANK

SERVICE MANUAL

Installation

(Rev. 4) ROTOGRAPH-D (120V)

6-1

6.

6.6.

6. INSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION

NOTE:

ROTOGRAPH-D is dispatched preassembled in groups.

The mechanical assembly consists exclusively in assembling these

groups together.

Calibration of the ball bearing, brakes and eventual tightening torques is

factory preset before delivery; any intervention on these parts, besides

not being necessary, can cause malfunction.

Depending on the configuration of the unit, the following fixing methods

must be used:

Fix legs to floor Use wall bracket Fix column to floor

Version with legs

•

Version without legs

• •

Loading...

Loading...