Villager Esprit, ESPRIT BK077 Operating & Installation Manual

PLEASE RETAIN THIS GUIDE FOR FUTURE REFERENCE

Operating & Installation Manual

Rev 06

August 2010

Part No. AFS1399

Esprit

BK077

EN 13240:2004+

Amd. A2:2004

10

Congratulations on your choice of a Villager stove.

More than 40 years experience has been put into the

development of our Villager Esprit stove to ensure

ultimate performance and years of trouble free use

and enjoyment.

Every detail of the stove has been carefully designed and

engineered which is why we are so confident in the

reliability of our products.

Should you have any questions about our Villager Esprit

stove, that are not covered by this manual, please contact

the Villager retailer in your area, or call our technical support

department on 0844 847 5107.

Copyright 2010 Arada Ltd

This booklet has copyright and may not be copied in whole, or part, or used for any

purpose other than that for which it is supplied without express written consent from Arada Ltd

Villager Esprit Stove 2

PLEASE NOTE— Arada has a policy of continuous product development and therefore we

reserve the right to amend the specification without prior notice.

Due to printing cycles, items or options may be described before they are generally available

or after they have ceased, so please check with your retailer or dealer.

All Villager Esprit stoves are approved to European

Standard EN 13240 and CE marked.*

These appliances listed within this manual have been

approved by HETAS Ltd as an intermittent operating

appliance for burning wood only.*

*NOTE : Only applicable to Esprit 8 model.

Contents

Villager Esprit Stove

Page No.

INTRODUCTION

Warning Notice 4

Safety Notices 5

The Principle Of The Stove 5

Check List 6-7

Data Plate Information 7

Technical data 8

INSTALLATION

General Precautions 9

Asbestos 9

Handling 9

Hearth 9

Combustible Materials 9

Air For Combustion 9

Roping Guide For Flue Outlet & Hot Plate 10

Fitting The Flue Outlet & Hotplate 10

Sealing The Terminals 10

Flues & Chimneys 11-14

Firebox Liner Panels 15-16

Adjusting The Self Levelling Feet 17

Final Check 17

Building Control Consent Checklist 18

Page No.

SERVICE & MAINTENANCE

Annual Maintenance 19

Cleaning 19

Chimney Sweeping 19

Door Glass 19

Outer Finish 19

Summer Storage / Non Usage 20

Adjusting The Main Door 20

Fuel Retaining - inspection 20

Main Fire Door Rope Replacement 21

Fire Door Glass Replacement 21-22

Primary Air Inlet 21

Service Record 23

OPERATING INSTRUCTION

Lighting The Fire 24

Burning Wood 25

Reduced Burning 25

Extended Burning 26

Safety Warning 26

Over Firing & Chimney Fires 26

Ash Removal 26

Air Inlet Controls (Primary/Air wash) 27

Multi Purpose Operating Tool 28

(Empty The Ash Pan/ Air Wash /

Primary Control Knob)

Main Fire Door Handle 29

OPTIONAL EXTRA/ACCESSORIES 30

SPARE PARTS LIST 31-33

GUARANTEE 34-35

FACTORY CHECK LIST 36

3

WARNING

IT IS A LEGAL REQUIREMENT THAT THE INSTALLATION OF ALL

NEW OR REPLACEMENT, WOOD OR SOLIDFUEL HEATING

APPLIANCES ARE REQUIRED TO OBTAIN BUILDING CONTROL

APPROVAL FROM YOUR LOCAL AUTHORITY OR THE

INSTALLATION WORK MUST BE CARRIED OUT THROUGH A

GOVERNMENT APPROVED COMPETENT PERSONS SCHEME

SUCH AS OPERATED BY HETAS.

IF IN DOUBT, CONTACT HETAS LIMITED

TELEPHONE NUMBER : 0845 634 5626

www.hetas.co.uk

THIS STOVE MUST NOT BE CONNECTED

TO A SHARED FLUE SYSTEM

TO ALL USERS

PETROLEUM COKE

SOME OF WHOSE BRAND NAMES ARE

„CALCO’, ‘PETROCOKE’ AND ‘WONDERCO’

MUST NOT BE BURNED IN THIS APPLIANCE

BITUMINOUS HOUSE COAL

SHOULD NEVER BE USED IN YOUR STOVE

TO USE THESE FUELS WILL INVALIDATE

THE APPLIANCE GUARANTEE.

IF IN DOUBT CONTACT THE SOLID FUEL ASSOCIATION

TELEPHONE NUMBER 0845 601 4406

www.solidfuel.co.uk

4 Villager Esprit Stove

SAFETY

A fireguard conforming to BS 8423:2002

should be used in the presence of children

and old or infirm people.

Please note, this appliance should be used

with the fire door closed at all times except

when re-fuelling or de-ashing.

Do not use aerosol sprays or any other

flammable materials near the appliance

under fire.

Do not fit an extractor fan in the same

room as the appliance.

Fire cement is caustic, hand and eye

protection should always be worn,

prolonged contact with the skin should be

avoided.

Arada Ltd will not be responsible for any

consequential or incidental loss or

injury however caused.

Before continuing any further, with the

installation of this appliance please read the

following guide to manual handling.

Always obtain assistance when lifting the

appliance

When lifting always keep your back straight,

bend your legs not your back

Avoid twisting at the waist. It is better to

reposition your feet.

Avoid upper body / top heavy bending. Do

not lean forwards or sideways when

handling the fire

Always grip with the palms of your hands

do not use your fingertips for support

Always keep the stove as close to the body

as possible as this will minimise the

cantilever action.

Use gloves to provide additional grip.

THE PRINCIPLE OF THE STOVE

Your Villager stove is built to the highest

standard of craftsmanship using the best

materials and the most modern equipment

available. It is a highly efficient and sophisticated

piece of machinery and when properly installed

and operated it should provide a lifetime of

heating satisfaction.

Safety is the most important consideration when

installing your fire. If not properly installed and

operated a house fire may result. Installation

must comply with the Building Regulations and

conform to all safety standards.

Villager produce a variety of appliances ranging

in physical size and heat output all with

traditional style features and appearance.

The fire door is fitted with a special high

temperature ceramic glass panel through which

the fire can be viewed.

The stove is lined with firebricks or heat

reflective panels which ensure complete

combustion and provide a good heat store to

even out fluctuations in burning.

An internal throat plate produces turbulence to

encourage secondary combustion and direct the

flue gas around the whole upper firebox before

allowing it to escape up the chimney.

Most, Villager stoves are fitted with an „air wash‟

so called because it provides a curtain of high

speed preheated air behind the glass to help

keep it clean and provide secondary air / over

draught.

The provision of two inlets on all stoves gives a

wide range of primary / secondary air, under

draught / over draught combinations. The

optimum setting will only be established by

experience in firing the appliance, and will

depend on the fuel, the position of the appliance

in the house, and conditions of the chimney etc.

Villager Esprit Stove

INTRODUCTION

5

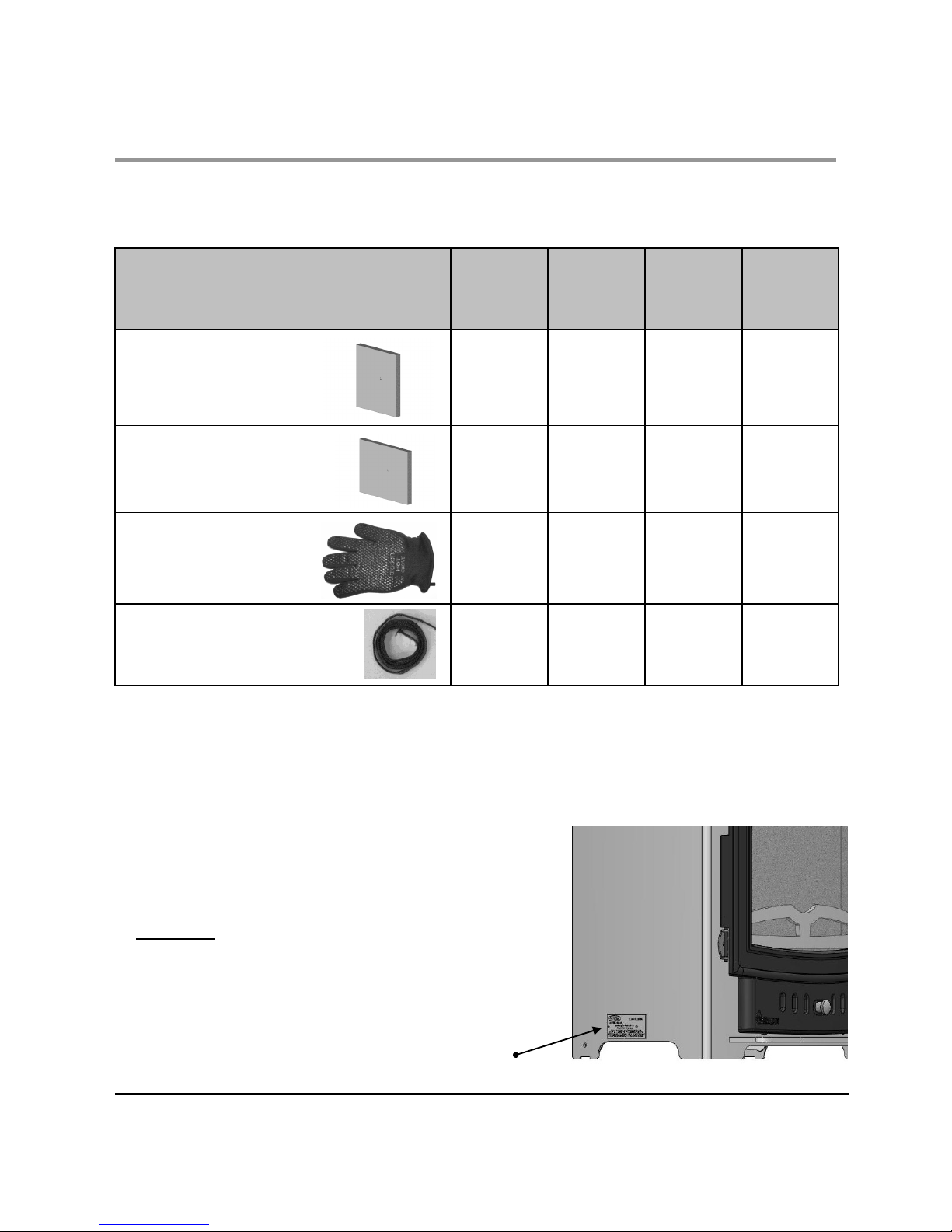

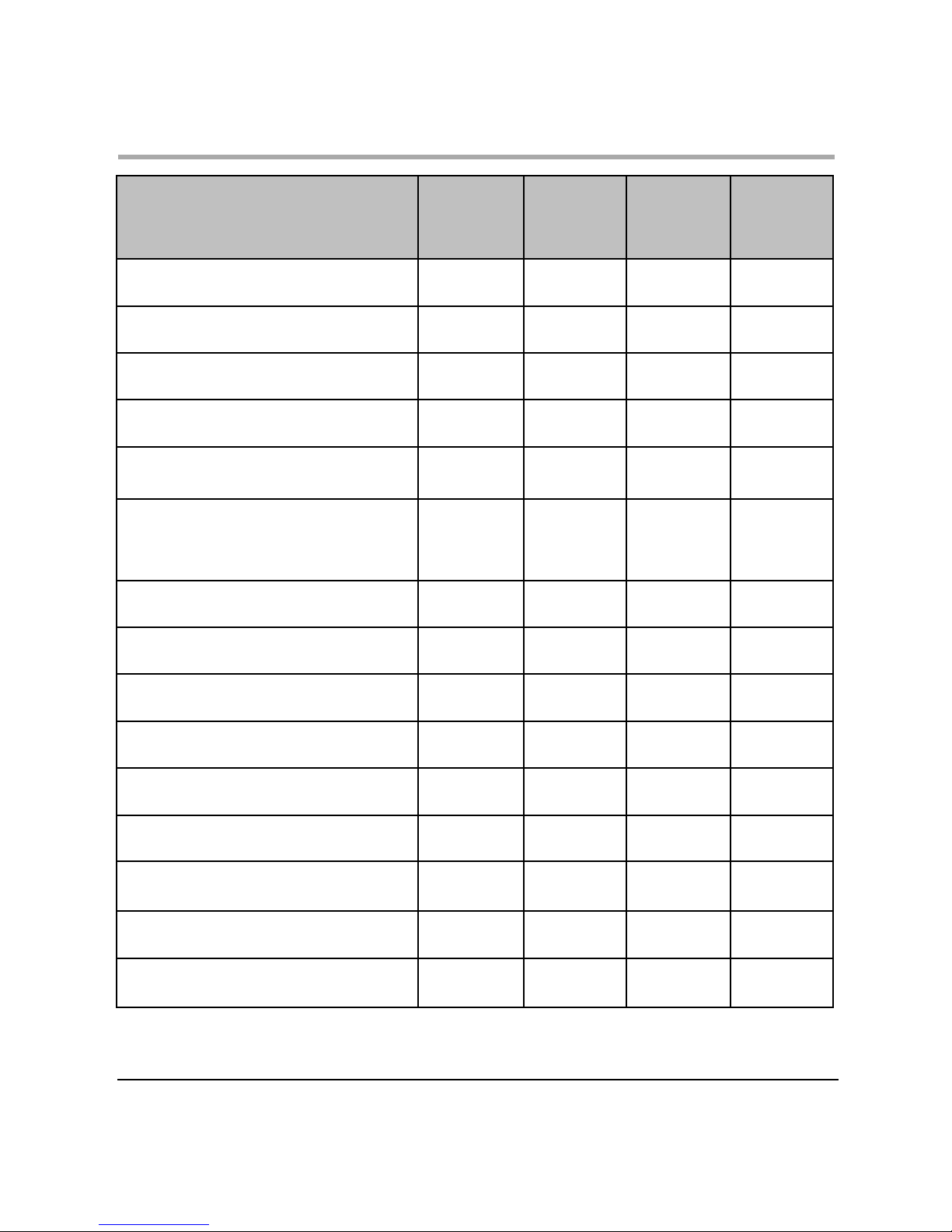

CHECK LIST

6

Inside the appliance body you should find the following:

Part Description & Visual Aid (not to scale)

Esprit

4kw

Esprit

6kw

Esprit

8kw

Esprit

10kw

1. Fuel Retainer

1 1 1 1

2. Wood Burning Tray

1 1 1 1

3. Standard style Throat Plate

1 0 1 0

4. EGD style Throat Plate

0 1 0 1

5. Flue Spigot

1, ( 4" ) 1, ( 5" ) 1, ( 5" ) 1, ( 5" )

6. Hot Plate

1, ( 4" ) 1, ( 5" ) 1, ( 5" ) 1, ( 5" )

7. Ash Pan

1 1 1 1

8. Operating Tool

1 1 1 1

9. Instruction Manual

1 1 1 1

Villager Esprit Stove

CHECK LIST

Inside the appliance you should find the following :

Villager Esprit Stove 7

Description & Visual Aid (not to scale)

Esprit

4kw

Esprit

6kw

Esprit

10kw

Esprit

8kw

9. Side Liners 2 2 2 2

10. Rear Liners 1 1 2 2

11. Stove Glove 1 1 1 1

12. Self Adhesive Sealing Rope

(High Temperature) 1.3 Mtrs

1 1 1 1

Data Plate Information

Please Note- The Esprit stove is fitted with a data plate located

at the left hand side, towards the rear of the stove. The plate

contains important information and must be observed when

installing the stove.

Data Plate

Location

8

TECHNICAL DATA

Villager Esprit Stove

TECHNICAL DATA

Esprit Wood

4kw

Esprit Wood

6kw

Esprit Wood

8kw

Esprit Wood

10kw

Nominal Heat Output (Kw) 4 6 8 10

Efficiency Nett (%) 77.7* 72.1* 80.4 75.8*

Mean Flue Gas Temperature (°C) 263* 307* 290 335*

Mean CO Emission @ 13% O2 (%) 0.61* 0.47* 0.52 0.44*

Flue Mass Gas Flow (g/s) NA NA 5.2 NA

Minimum Distance to Combustible

materials (mm)

NA NA

Side = 700

Rear = 850

NA

Height (mm) 508 520 560 575

Width (mm) Across Canopy 484 540 608 695

Depth (mm) (Inc. Handle) 363 368 355 372

Height To Centre Of Rear Flue (mm) 414 414 449 464

Depth From Back To Flue Centre (mm) 98 112 110 110

Flue Diameter (mm) 102(4”) 127(5”) 127 (5”) 127 (5”)

Weight Packed (Kg) 66.5 77 87 133

Weight Nett (Kg) 62.5 73 82 128

Ideal Log Length (mm) 325 350 400 475

Note: Figures shown with an asterix are in house testing results.

GENERAL PRECAUTIONS

Note : All local regulations, including those

referring to National and European standards need

to be complied with, when installing the appliance.

The Building Regulations for England and Wales

2000 ref Approved Document J 2002 edition

(issued by the DTLR).

The Building Standards (Scotland) (Consolidation)

Regulations.

Detailed recommendations for installation of

appliances, chimneys and flues are outlined in the

current issue of the following British Standards :

BS6461, BS8303 & BS4543.

Any Manufacturer’s Instructions must not

be taken as overriding statutory

requirements.

Before any installation work is undertaken

consideration must be given to the Health

and Safety at Work Act 1974. Safe working

practices should be followed at all times.

During installation ensure that adequate

precautions are taken to avoid unnecessary risk to

yourself or any householder. In particular the

danger from caustic nature of the fire cement

should be avoided by using these accepted

methods :

Wear gloves when handling fire cement

Wear goggles when chiselling or looking up

chimneys.

Make sure that Building Regulations are adhered

to during installation along with any local by-laws.

In the case of heating systems make sure that the

pipe work is correctly bonded to ensure electrical

earth continuity.

ASBESTOS

All Villager stoves contain no asbestos in their

manufacture or construction. If there is a possibility

of disturbing any asbestos in the course of

installation, then please seek specialist guidance

and use appropriate protective equipment.

HANDLING

The safe handling guidelines are set out on page 5

of this manual, to make movement easier, internal

fittings, fuel retainers, grates, firebox liners, flue

outlets, hot plates, throat plates etc, can be

removed. Care should be taken to make sure that

the hinges are not damaged during installation.

HEARTH

The stove shall be installed on a floor with

adequate load bearing capacity. If the existing

construction does not meet this prerequisite,

suitable measures (e.g.: load distributing plate)

should be taken to achieve it.

Ideally, the appliance should stand on a

constructional hearth of non-combustible

materials not less than 125mm (5”) thick

conforming to Building Regulations.

Dimensions of the hearth should project at least

300mm (12”) forward of the front of the appliance

and 150mm (6”) at the sides.

The surface of the hearth should be free of

combustible materials. In most buildings with solid

concrete or stone floors, the requirement will be

met by the floor itself, but mark the hearth to

ensure floor coverings are kept well away or use

different levels to mark the hearth perimeter.

COMBUSTIBLE MATERIALS

Please view the technical data (see page 8) and

observe the minimum distance to combustible

materials, which is applicable to your stove model.

Ideally, adjacent walls should be of suitable non

combustible construction, preferably brickwork. In

large fireplaces take care that any supporting

beam is protected by a 13mm (0.5”) sheet of

Masterboard or Superlux spaced 13mm (0.5”) off

the surface with strips of non combustible material.

Make sure that there is a gap between an

un-insulated flue system and any combustible

material. This gap must be at least 3X the outside

diameter of the flue pipe, or 1.5X the flue diameter

to non combustible surfaces. See illustration on

page 13.

AIR FOR COMBUSTION

There must always be a permanent means of

providing air for combustion into the room in which

the stove is installed. A permanent vent with a total

free area of at least 550mm2 for every KW rated

above 5KW should be connected directly to the

outside air or to an adjacent room which itself has

a permanent vent of the same size direct to the

outside air. The positioning of any air vent must be

so, that it cannot be liable to blockage or

obstruction. Please note : The fitting of an

extractor fan to either of these rooms is not

permitted.

Villager Esprit Stove 9

INSTALLATION

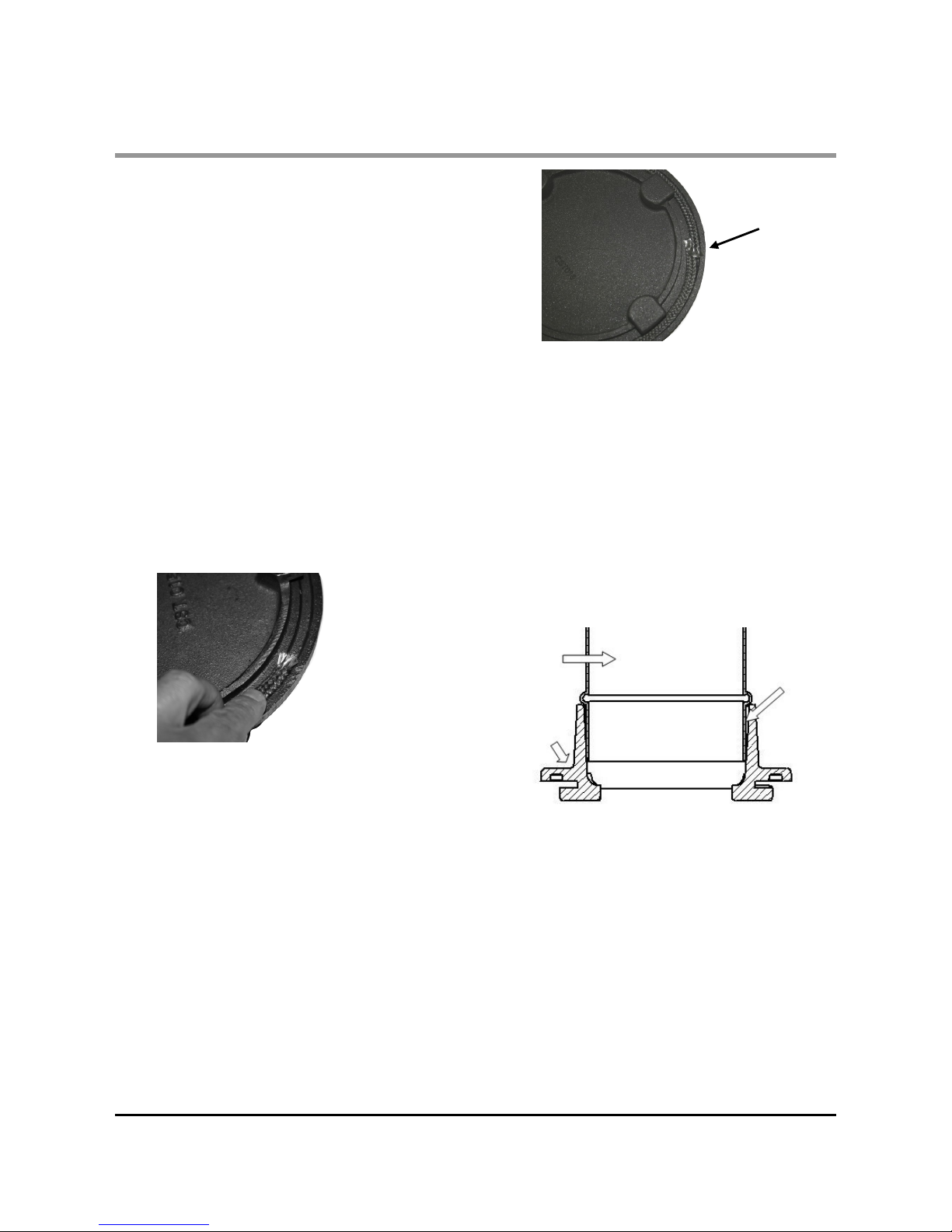

ROPING GUIDE FOR FLUE

OUTLET AND HOT PLATE

All Villager hot plates and spigots are

manufactured with a rope groove to accept our

high temperature self adhesive sealing rope

supplied.

This eliminates the need for messy and caustic fire

cement, and allows for easy removal for inspection

and cleaning, without the accompanying re-sealing

mess associated with fire cement.

To seal the hot plate and spigot proceed as

follows:

1)The self adhesive sealing rope for the hot plate

and spigot is supplied in a single length of

1300mm and needs to be cut in half to begin with.

2) Each length of approximately 650mm should be

fitted into the groove on the mating face of the hot

plate or spigot. See Fig. 1.

3) Start by removing a small section of the

adhesive backing paper (approx. 25mm) and

remove the remaining backing paper as you

proceeded.

4) Begin at the rope overlap point, mid way between the securing lugs and work your way around

the groove making sure the rope is pressed accurately and firmly into the groove. Finish the rope

approximately 10mm past the start point.

5) If the rope is allowed to ride up the side of the

receiving groove, rather than sitting squarely, in

the middle, it will impede the fitting of the hot

plate / spigot and may lead to leaks. See Fig. 2.

6) Finally press round the sealing rope with a steel

rule or similar device, to ensure adhesion is even.

Repeat for the remaining casting.

Villager Esprit Stove 10

INSTALLATION

Fig. 1. Apply Rope To Groove

Inside

Flue

Pipe

Outer

Spigot

FITTING THE FLUE OUTLET AND

HOT PLATE

Take the flue spigot and lock into place by

rotating anti-clockwise and tighten by tapping with

a block of wood and mallet from inside of the

appliance. Similarly, fit the hot plate (blanking

plate) to the unused opening.

Place appliance on the hearth and make sure that

it is level and does not rock.

Connect the chimney ensuring all joints are sealed

with fire cement.

Note : The flue pipe must be fitted inside the outlet

spigot. Failure to do so could result in the spillage

of condensation running down the flue.

SEALING OF TERMINALS

If an add in boiler is not to be fitted, please

ensure that the two partially cut circular terminals

(located on the rear of the appliance) are sealed

with fire cement, and thus preventing surplus air

entering the firebox, resulting in less efficiency

and poor fuel consumption.

Fig. 2. Correct Roped Hot Plate

Joint

Overlap

Fig. 3. Flue & Spigot Fitting

FLUES AND CHIMNEYS

The flue draw is critical on any installation and

should be checked to ensure that it matches what

is specified. If it is higher than recommended,

provision must be made to correct the over draw.

The draw can vary in different weather conditions

and the customer should be made aware of this.

Failure to correct an over-drawing flue will

invalidate the warranty.

Please remember that chimney draught is

dependent on four main factors :

Flue gas temperature

Flue height

Flue size

Flue terminal

The stove must be connected to a suitable and

efficient flue that products of combustion (fumes)

from the stove are expelled to the outside air. To

ensure a good up draught it is important that the

flue gases are kept warm and that the flue size

suits the stove. The termination of the outlet at the

top of the flue also needs to comply with Building

Regulations. The minimum effective height of the

flue must be at least 4.5 metres from the top of the

stove to the top of the flue outlet. When warm the

flue draught should be between 0.1 to 0.2 mb.

A chimney may comply with regulations but still be

subject to down draught and similar problems. A

chimney terminating above the ridge level is

generally less likely to suffer such problems.

If a new chimney is being provided it should fully

comply with the relevant Building Regulations that

specify the requirements for solid fuel burning

installations. Suitable types of chimney include the

following :

Masonry Chimney : Built with clay or concrete

liners, or a chimney block system meeting Building

Regulations. These types of chimney should be

installed in accordance with the Building

Regulations and BS 6461:Part 1.

Factory Made Insulated Chimney : Complying

with BS 4543:Part 2 (often called “Class 1

prefabricated metal chimney”). These types of

chimney should be installed in accordance with

Building Regulations and BS 7566: Parts 1 to 4.

Villager Esprit Stove 11

INSTALLATION

Due to the gradual introduction of Europe Chimney

Standards chimneys will be specified according to

their performance designation as defined in BS EN

1443 that covers the General Requirements for

chimneys. The minimum performance designation

required for use with solid fuel burning stoves is

T450 N2 S D3.

The flue and chimney installation must be carefully

checked by a competent person before fitting the

stove to ensure it is suitable and will work safely.

If the chimney is old (ie: built of brick or stone

without a liner) or being opened up for reuse

additional checks and smoke testing a described in

Appendix E of the Approved Document J 2002

Edition should also be carried out to ensure the

flue and chimney are good operating condition.

If the flue size is more than 225mm (9”) diameter

or 200mm (8”) X 200mm (8”) square, a suitable

lining of 150mm (6”) diameter should be fitted, or if

the flue length is over 5.5 metres one size larger

than the appliance outlet should be fitted. This

should be a double skin stainless steel flexible liner

that is independently certified for use with solid

fuel. Details of suitable linings for use with wood &

solid fuel are given in the Official HETAS guide

that can be viewed on their website at

www.hetas.co.uk.

It is also important that suitable flue pipe complying

with the Building Regulations is used to connect

the stove to the flue in the chimney and that suitable access is provided into the flue for regular

inspection and sweeping of the flue ways.

The installer should comply with Building Regulations requirements in respect of providing a Notice

Plate giving details on the chimney, flue lining,

hearth and fireplace installation. Approved Document J of the Building Regulations for England &

Wales is available from The Stationary Bookshops

and can also be viewed at the ODPM website at

www.safety.odpm.gov.uk/bregs/brads.htm.

Details on the relevant Building Regulations and

BS British Standards are given in the “ General

Precautions” section of these instructions.

Chimneys should be as straight as possible.

Horizontal runs should be avoided except where

Loading...

Loading...