Villagepump 500 Standard Operation And Maintenance Manual

O&M Manual v.1.42 October 2017

1

Operation and Maintenance Manual

Villagepump 500 Standard

Villagepump 500 Standard, the leading solution for producing clean

drinking water without the need of any external energy source.

Villagepump BV

Lisdoddelaan 80

1087 KA Amsterdam

The Netherlands

info@villagepump.org

www.villagepump.org

+31 20 620 09 58

O&M Manual v.1.42 October 2017

2

Inhoud

1 Introduction ........................................................................................................................ 3

2 Unpacking and handling ..................................................................................................... 4

3 Installation Villagepump 500 Standard .............................................................................. 7

4 Preparing Villagepump 500 Standard for first use ............................................................. 8

4.1 Mounting Pump Handle and adjusting the Feed Pump ............................................... 8

4.2 Connecting Inlet Hose and Drain Hose ....................................................................... 9

4.3 Connecting Mesh Filter ............................................................................................. 10

4.4 Assembling Activated Carbon cartridge (optionally) ................................................ 10

5 First use ............................................................................................................................ 12

5.1 Pumping up water first time and first backwash cycle .............................................. 12

5.2 First back-wash is not working .................................................................................. 13

6 Maintenance ..................................................................................................................... 16

6.1 General ....................................................................................................................... 16

6.2 Cleaning Mesh Filter ................................................................................................. 16

6.3 Disinfect the Villagepump with a chlorinated detergent ........................................... 17

6.4 Replacing Activated Carbon cartridge (optionally) ................................................... 18

6.5 Replacing UF Membrane ........................................................................................... 19

6.6 Exchanging Valve ...................................................................................................... 20

6.7 Cleaning system and valve ........................................................................................ 23

6.8 Storage of Villagepump and/or UF membrane for a longer term .............................. 24

6.9 Cleaning the UF membrane ....................................................................................... 24

7 Protocol water analysis ..................................................................................................... 25

7.1 Preliminary analysis .................................................................................................. 25

7.2 Regular Analysis ........................................................................................................ 25

8 Troubleshooting ............................................................................................................... 27

9 Datasheet Villagepump ................................................................................................... 28

10 Limitation of warranty and liability ................................................................................. 29

11 Contact / helpdesk / ordering spare parts ......................................................................... 30

O&M Manual v.1.42 October 2017

3

1 Introduction

The Villagepump 500 yields up to 500 litre of fully purified drinking water an hour, meeting

WHO standards regarding the removal of bacteria's, viruses and turbidity. This manual version 1,42, October 2017 - is meant for Villagepumps with serial number VP500S-07-

XXXXXX-XXX – series 7 or higher, manufactured at March 31, 2017 or later

Schematic drawing of the Villagepump 500 standard.

1. Inlet hose

2. Drain (Outlet)

3. Feed Pump

4. Activated Carbon filter

5. 0,05 mm Mesh Filter

6. Backwash buffer

7. Ultra-Filtration (UF) membrane

8. Valve

9. Disinfectant dispenser

10. Pump Handle

11. Backwash pressure indicator (manometer)

12. Tap

13. Water Meter (𝑚3)

O&M Manual v.1.42 October 2017

4

2 Unpacking and handling

The installation of the Villagepump should be performed by at least 2 people to move and

install the Villagepump properly and safely.

Required tools for installation (this tools are included in standard delivery):

- open-end wrenches (10/11, 12/13, 16/17)

- screwdriver flat 4 - 6 mm

- Allen keys 3, 4 and 6 mm

In case of any doubts or questions, please contact your local distributor. Look for other

possible contacts or information at www.villagepump.org.

The standard package includes the following components:

- Villagepump

- Pump Handle (blue)

- Mesh Filter 0,05 millimetre

- Foot Plate

- Drain Hose, length 1 meter

- Inlet Nose, length 10 meter

Inside the Villagepump:

- Padlock

- Chlorine dioxide tablets (120 pcs of 1 gr or 30 pcs of 4 gr)

- Tool Set (Allen keys, wrenches)

- Grease (Silicon Compound)

- Hose Nipple and Hose Clamps (3x)

- Floater and Tie Wrap

- Spacers length 3 cm

- M8 bolt for mounting Pump Handle (2x)

- Self-locking M8 nuts and rings (4x)

- Manual

And optionally:

- Activated Carbon filter cartridge 20"

- Wrench for 20” Activated Carbon housing

For specific client related reasons this standard configuration might have been changed.

Standard packaging Villagepump 500

O&M Manual v.1.42 October 2017

5

The Villagepump is strapped onto a pallet further protected by a cardboard box.

- Open the box at the upper side and take out carefully any loose parts;

- Remove the packaging from the pallet and ensure environmentally friendly disposal;

- Unpack the remaining loose (spare) parts like Pump Handle, Activated Carbon cartridge

(optionally), Foot Plate, Mesh Filter and Hoses.

- Untie the Villagepump from the pallet and put the Villagepump carefully upright on a stable,

flat surface;

- Remove the tie-wrap that locks the Villagepump and remove the plastic bag.

- Unlock the cover (at the right sight) by pushing down the small handle; unpack the loose

parts that are stored inside the Villagepump like the Floater, Toolset, Manual, Fasteners,

ClO2 tablets etc.

- Remove both white plastic covers. Without these covers the Villagepump is easier to pick

up and move. The covers can easily be lifted vertically from their hinges. One cover (the right

one) is locked on the outside, the other cover (the left one) is locked from the inside. First

open the cover that is locked on the outside, enabling you to unlock the other cover.

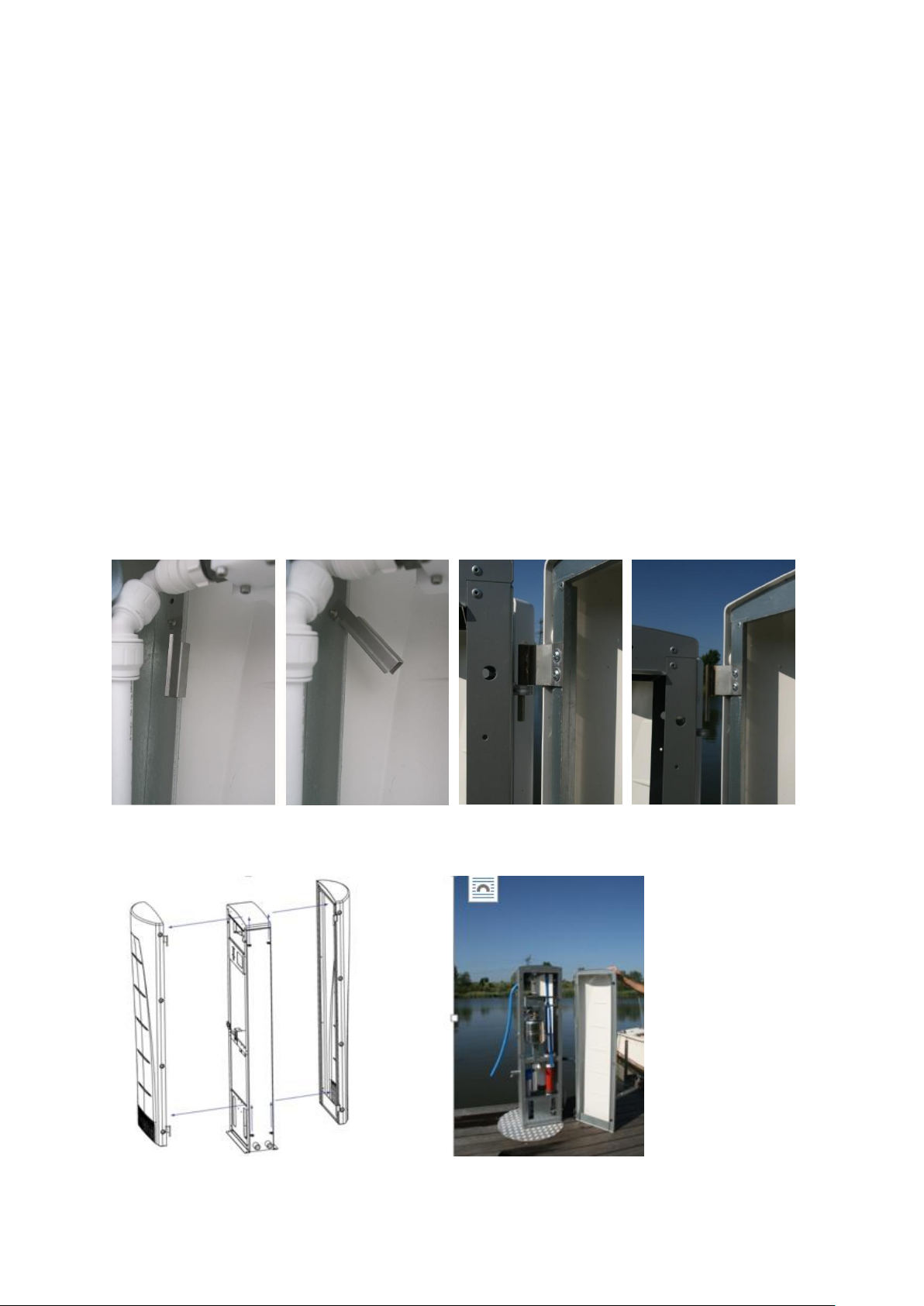

Internal lock of one cover; unlocking the covers by lifting the covers from the hinges;

O&M Manual v.1.42 October 2017

6

- Move the Villagepump always with at least two people and use the tap and the centre

console as targets.

To move the Villagepump, please use tap and centre console.

O&M Manual v.1.42 October 2017

7

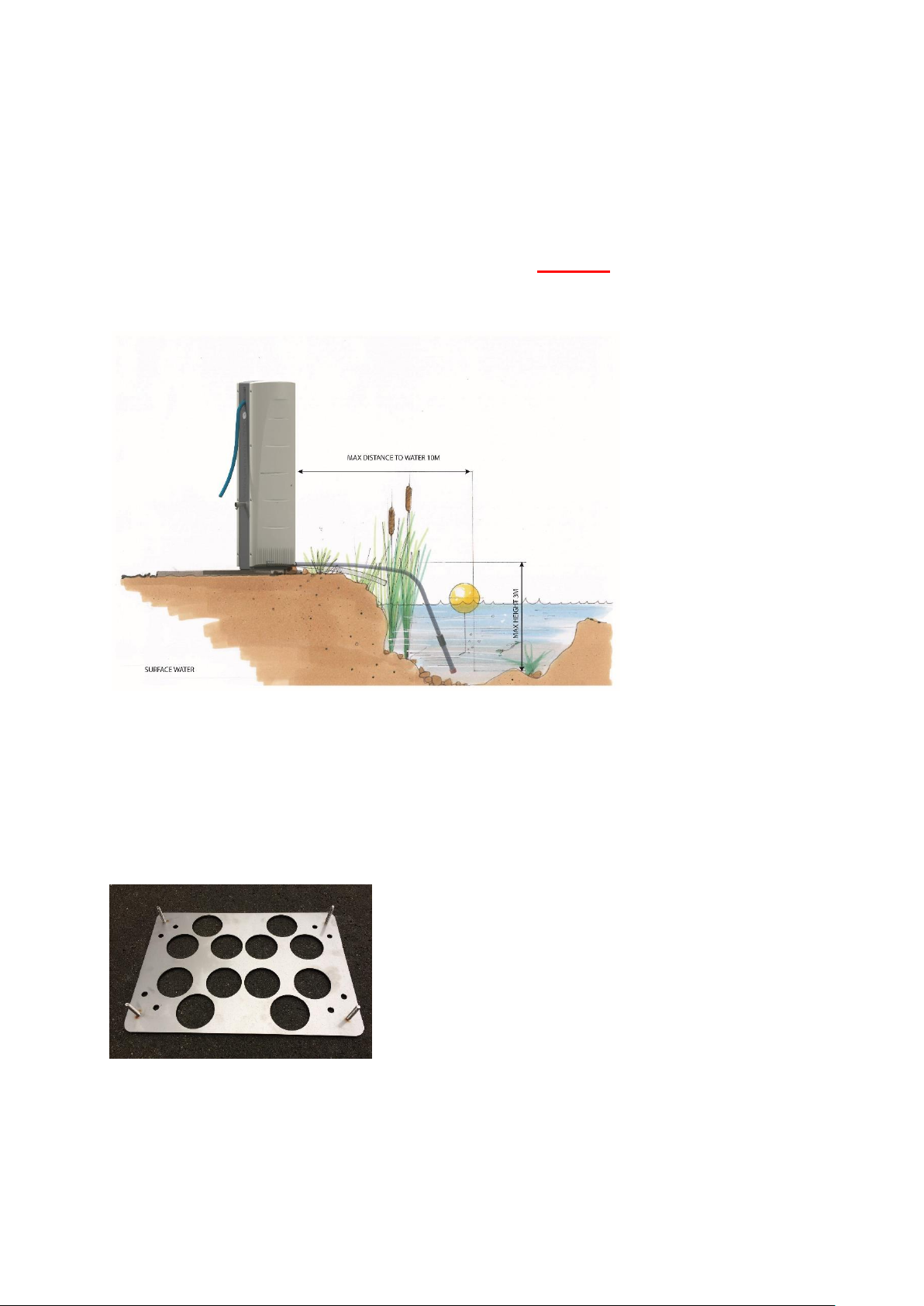

3 Installation Villagepump 500 Standard

The Villagepump 500 Standard is suitable for low or average polluted surface water,

rainwater harvesting, ponds and streams.

Please note that:

- the bottom of the Villagepump should be mounted not more than 3 meters above the

water level (maximum static head of 3 meter);

- the length of the Inlet Hose that is included in the delivery, is 10 meter. This is the

maximum distance to be covered with the priming system of the Villagepump.

- Install the Villagepump on a flat, hard (concrete, metal, wood) smooth and level surface,

with a minimum size of 60 by 120 cm.

- A Foot Plate / Installation Frame is delivered together with the Villagepump 500 Standard,

with the studs (M8) at the right position (distance 40 x 25 cm). This footplate should be

mounted on a sturdy, flat floor or can be moulded in a cement of concrete base. If you

choose this option, please take care that the bolts are at least 45 mm above the surface of

the cement/concrete base.

Installation Plate / Foot Plate with four M8 rods

- Apply the supplied spacers (length 3 cm) to the studs / bolts; place the Villagepump over

the studs / bolts and secure it with four self-locking M8 nuts. The Villagepump is now firmly

anchored to the floor.

O&M Manual v.1.42 October 2017

8

4 Preparing Villagepump 500 Standard for first use

Once installed the Villagepump 500 Standard has to be prepared for first use. Follow the

instructions below:

- Mounting Pump Handle and adjusting the Feed Pump (see par 5.1)

- Connect Inlet Hose and Drain Hose (see par 5.2)

- Connect Mesh Filter to Inlet Hose (see par 5.3)

- Install Activated Carbon (AC) cartridge (optionally)

Please note: install the AC cartridge only after the Villagepump has been used already

for at least 2 back wash cycles (see par 5.5)

4.1 Mounting Pump Handle and adjusting the Feed Pump

The blue Pump Handle is packed separately and has to be mounted. Find below the

instructions.

- Unpack the Pump Handle and put the Pump Handle in the aluminum block.

Mounting pump handle

- Attach the Pump Handle firmly with 2 supplied bolts (use 5 mm Allen key). Pump a few

strokes and check the bolts.

At installation, the Fork of the Feed Pump has been mounted usually at the first hole of the

lever (closest to the handle) This leads to the lightest way of pumping.

Fork installed at third hole of lever.

O&M Manual v.1.42 October 2017

9

If the distance (static head) between Villagepump and water level is higher than 3 meters, we

recommend to put the Fork on the second or third hole. The Feed Pump will create a higher

vacuum and more water can be primed from a higher level.

4.2 Connecting Inlet Hose and Drain Hose

Mounting hoses for inlet (A) and drain (B)

Connecting the Inlet Hose (A)

The Inlet Hose is directly connected to the Feed Pump, through a hole in the frame.

- Put the Inlet Hose through the hole and put the Hose Clamp on the hose.

- Push the Inlet Hose from outside over the nipple as far as possible.

- Shift the Hose Clamp at the right spot and connect the Hose Clamp firmly!

Note: be aware that this connection should be completely air-tight because the Feed

Pump operates with a vacuum.

Note: keeping the Inlet Hose out of full sunlight will extend the life time. We

recommend to bury the Inlet Hose in the ground or cover the hose with sand of other

materials

Loading...

Loading...