Page 1

VKI Publication # 100218-001 February 2012

Oper atio n & Service M anual

Page 2

2

Contents

Safety In fo rmatio n ......................................................................... 4

Coffee Maker Specifications.......................................................... 6

Coffee Maker Overview ................................................................. 8

Parts Ident ificat ion ................................................................................................8

System St at us LED I ndicator Panel ..................................................................9

Produc t Selec ti on Handle ....................................................................................9

Pod Slot Cover (Pr ofessional M odel Only) .....................................................10

Cup Warmers (Profe s si onal M odel Only) .......................................................10

Connecting to a W ate r S upply..................................................... 11

Drain Installation ......................................................................... 13

Installing the Milk Canister .......................................................... 15

Using the Co ffee Maker ............................................................... 16

Coffee Pods .........................................................................................................16

Brewing a Beverage ...........................................................................................16

Type s of Beverages Available ..................................................... 17

Connecting the Progra m m er ....................................................... 18

Power-Up Diagnostic Routine...........................................................................19

Software Features ....................................................................... 20

Sof tware Menu Navigation ................................................................................20

Downloadi ng S oftwa re Update s .................................................. 23

Maintenance ................................................................................ 24

Empty the W aste B in..........................................................................................24

Clea ning a M ilk Overflow...................................................................................24

Empty the Drip Tray ...........................................................................................25

Quick-Rins e Cycle ..............................................................................................26

For c ed Quick -Rinse............................................................................................26

Prim ing the W ater System (on Power-Up) .....................................................27

Di spe nsin g Spout and Pr oduc t T ube P lace ment...........................................27

Usi ng the Cleaning Tab ............................................................... 28

In-Place Cl eaning (Sanit izing Cy c le) ...............................................................28

Emptying the Milk and Water Using the Clea ning Tab .................................31

Cleani ng the M ilk Conveyor ........................................................ 32

Open the Cover...................................................................................................32

Clea ning the Milk Conveyor Using a Wet/Dr y V ac uum ................................33

Manual Cleani ng of t he Milk Conveyor ...........................................................34

Page 3

3

Contents

Removing the Coffee Maker ........................................................ 37

Empty the Milk Conveyor...................................................................................37

Drain t he Wat er ( Reservoir and Heater) .........................................................38

St or ing the Cof fee Maker...................................................................................39

Genera l Informa tion .................................................................... 40

Replacing Maj or Compone nts ..................................................... 41

Opening the Cover .............................................................................................41

Re moving t he Cover and Contour P anel ........................................................42

Removing the Cover....................................................................................... 42

Removing the Contour Panel ......................................................................... 43

Brewer ..................................................................................................................44

Brewer Heads ................................................................................................ 44

Brewer Motor .......................................................................................................45

Selection Rin g & B oar d......................................................................................45

Water Heater .......................................................................................................46

Temp er ature P r obe ............................................................................................47

Ther m al Cut-Off Switch .....................................................................................47

Water Res er voir ..................................................................................................48

Water Level Float Swit c h...................................................................................49

Inlet Valv e ............................................................................................................50

Outlet Valv es .......................................................................................................51

Rebu ilding an Out let Valve................................................................................52

Contr ol B oard & O ptions Board........................................................................53

Water P ump Assem bly ......................................................................................54

Water P ump H ar ness/Diode-Brid ge A ssembly ..............................................55

Milk Conveyor and Dispenser Mot or ...............................................................56

Whipper Motor .....................................................................................................57

Flow Meter ...........................................................................................................58

Exhaust Fan .........................................................................................................59

M ain Power Switch .............................................................................................60

5 Amp Circuit B r eaker ........................................................................................61

15 Amp Fuse Holder A s se mb ly ........................................................................61

Replacing the 15 Amp Fuse ........................................................................... 61

Power Sup ply ......................................................................................................62

Sensor Boards .....................................................................................................63

Cup Warmer (P r ofessi onal M odel)...................................................................63

Troubleshooting .......................................................................... 64

Error Messages...................................................................................................64

FAQ (Fre quently Asked Question s) ............................................. 67

Page 4

4

Safety Information

Your safety is very important to us. It is imperative that you read and

understand this safety information before

proceeding with the

ins tallation and operation of this coffee maker.

This coffee maker is designed for interior use ONLY and must

never be inst alled outdoor s.

This equipment must be pos itioned so that the wall plug and the

main power switch are both easily accessib le.

Do n ot c onne ct the coffee maker to a volta ge supply ot her tha n the

voltage ind icated on the serial number decal.

Do not im me r s e t h is coffee maker or any pa rt of this e qu ipme nt in

liquid.

This coffee maker must be installed securely on a level surface. If it

does not appear to be a stable location, select another installation

location.

Whe n the coffee maker is sw it che d ON , a s mal l quantit y of wa te r

may be dispens ed as t he system is pur ged. T his w ate r may be hot so

keep clear of the dispensing area.

To pr event s erious in jury or bur ns, do not place f inge rs direct l y int o

the c offee pod slot a nd do not place any pa rt of your body d ir ec tly

ove r the coffee pod slot.

Keep hands clear of the dispensing area at the front of the coffee

maker. Liquids be ing d ispensed are extremely hot and can cause

severe burns.

Never disc onnec t the coffee maker by pu ll in g o n the se rvice cord,

a nd never us e t he coffee maker if the service cord is damaged.

Never a tte mpt to ove rr ide the sa fe ty f ea tur es inc orpor at ed int o the

e qui pment . T hey are there f or your prot ection and should never be

bypass ed under any circ umstance s.

This equipment must be used specifically for the purpose for

which it is designed. The manufacturer is not responsible for

damage or injury resulting from improper use of this equipment.

Page 5

5

Safety Information

Always switch the power OFF and disconnect the service cord

whe n c le a ning t he inte ri or of t he coffee maker. Compone nts ins ide

the coffee maker can cause electrical shock resulting in personal

injury.

If the coffee maker is not working properly or appears to have a

fa ult , s witc h off the pow e r, d is con ne ct the se rvice c ord a nd cal l a n

authorized technician immediately for service. Only qualified

per sonn el sh ould p erform ser vice on this equipm ent.

The major ity of the electrical c om ponent s in the E spr es so C af é are

low vo lta ge (and not

120 vo lts AC). Never connect these electrical

c omponent s t o 120 vo lts AC.

The wa ter s ys tem in this coffee maker is pressurized dur ing a br ew

cycle. T his pres sure must be released usin g t he drai n ins ert prior to

servicin g t he syst em.

Use caution when servicing the water heater or the outlet valves as

they may be ext reme ly hot and can cause s ever e burns .

Us e caut io n whe n w orking ins ide the coffee maker as t here ma y be

sharp edges on s ome components t hat can cause cuts.

To prevent electrical shock, remo ve all jewelry (rings, watches, etc.)

when servicing the coffee maker.

Use onl y ori gi nal manufac ture r repl ace ment parts in t h is coffee

maker. Una pprove d re plac e ment pa rt s ca n res ult i n per sona l inj ury,

fire and/or fur t her damage t o t he equip ment .

Do not lift the coffee maker using the drip tray. Lift the coffee

maker by t he sides only.

Do not allow children to access this equipment. They are not aware

of t he potential dangers that exis t.

NOTE:

Whenever the unit is switched OFF, wait at least 5

seconds b efore switching it ON again.

U nau t ho rized modif icati on s made to t hi s coff ee maker can re sul t

in se r ious pe r s ona l in jury a nd/ or da m a ge to t he e qui pm e nt , a nd

v oids all warran t ies and cert ificati on s.

Page 6

6

Coffee Maker Specifications

Voltage Rating 120 volts AC

Heater Wat tage 1000 watts

Weight 38 lbs (17 kg)

Cup Siz es – Espresso 1.5 fl. oz (45 ml)

– Cappuccino

7.0 fl. oz (210 ml)

– Caffè Latte

7.0 fl. oz (210 ml)

– Ameri cano 6.0 fl. oz (175 ml)

Water Heater Capacity 14 fl. oz (420 ml)

Water Reservoir Capacity 34 fl. oz (1 liter)

Temperature Control

Electronic Temperature Probe

Heating Time

2 minutes after initial installation

Brew Temperature*

194°F (96°C)

Brew Times – Espresso 30 seconds

– Cappuccino 50 seconds

– Caffè Latte 45 seconds

– Ameri cano

50 seconds

Heater Protection

Yes

Overflow Prote ction

Yes

Circuit Protection • 5-amp circuit breaker for electronics, valves &

motors

• 15-amp fuse for heater

Certification • UL Listed • CSA Appro ved

• NSF Approved

*NOTE: For installations at higher elevations, please contact your distributor or the

manufacturer for special “

HIGH ALTITUDE” software.

Coffee Maker Dimensions

Height:

16 ¾ inches (42.5 centimeters)

Width:

20 ⅛ inches (51 centimeters)

Depth:

15 ¼ inches (39 centimeters)

Installation Requirements

Height:

16 ¾ inches (42.5 centimeters)

Width:

20 ⅛ inches (51 centimeters)

Depth:

17 ¾ inches (45 centimeters)

Page 7

7

To ma int a in the NSF Ce r tific a t ion of t his e quipm ent , only origina l

OEM parts must be used. Using parts from an alternate source

wil l void NSF Certi f ication as well as the equ ipment wa rranty.

Page 8

8

Serial Number

Decal

Drip Tray

Waste

Bin

Inlet

Valve

Service

Cord

Pow er

Sw itc h

Fuse &

Circuit

Breaker

Rear View of Machi ne

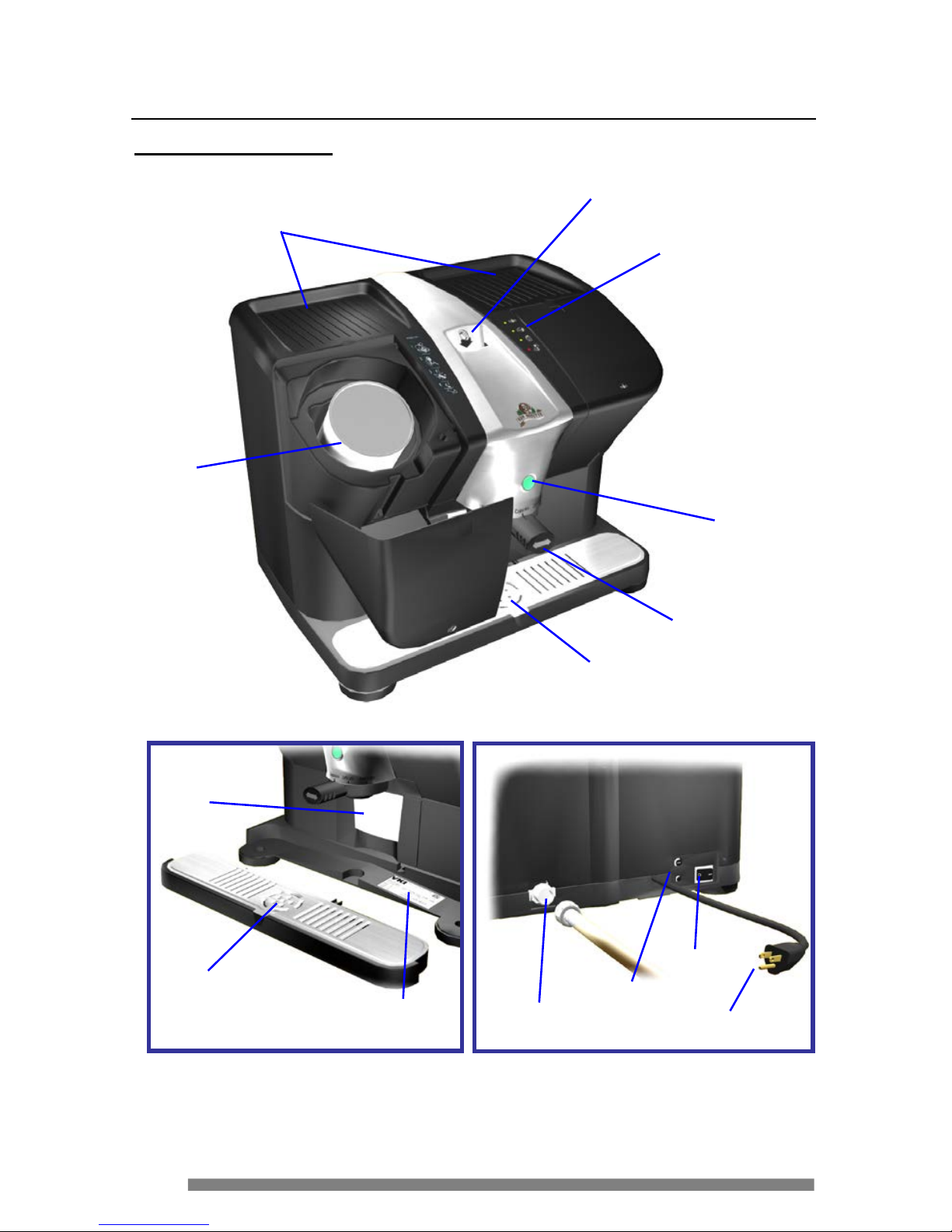

Coffee Maker Overview

Parts Identification

Coffee Pod Slot

System Status

Indicator Panel

Drip

Tray

START

Button

Product Selection

Handle

Milk

Canister

Receptacle

Cup Warmers

(Professional Model On ly)

Page 9

9

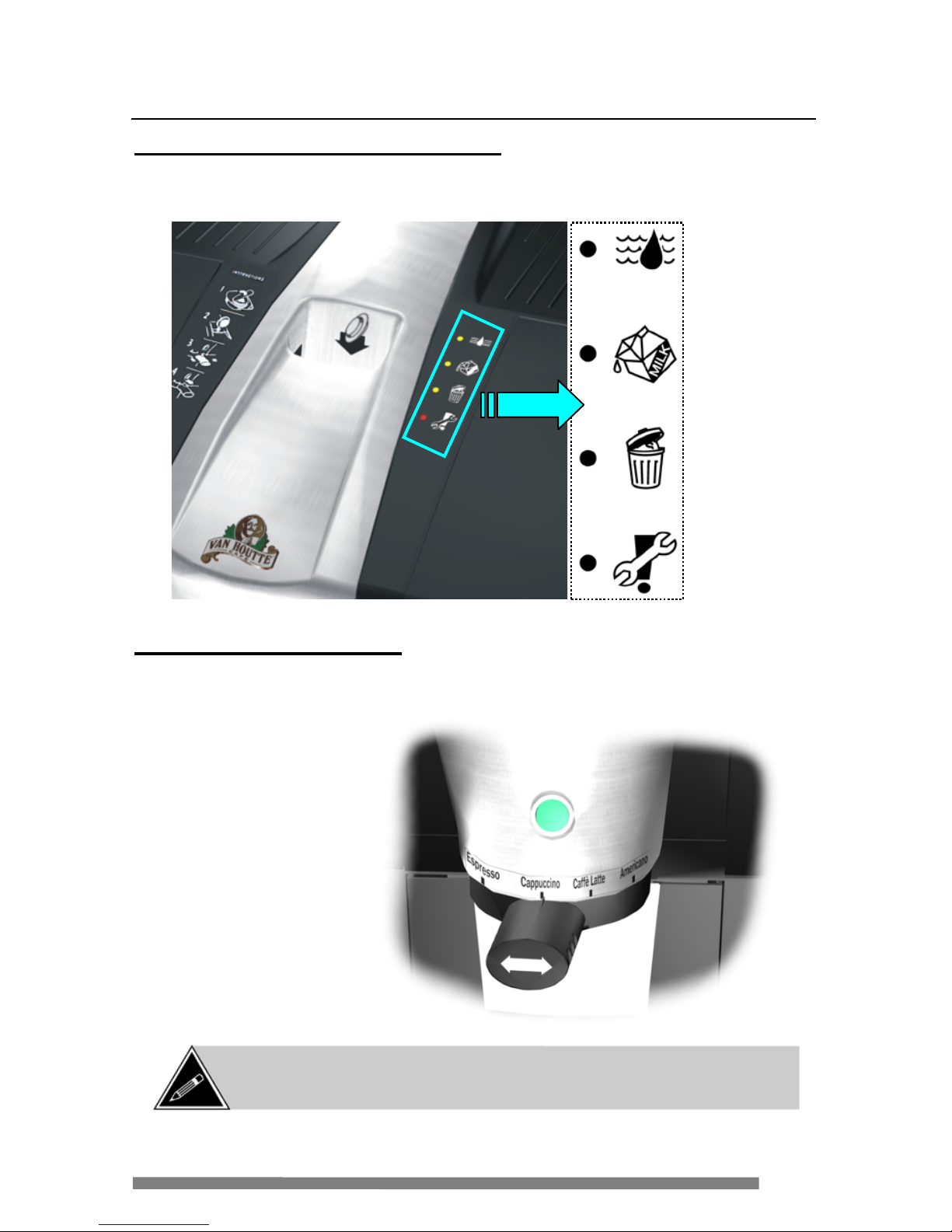

Coffee Maker Overview

System Status LED Indicator Panel

The s ystem status indicator panel (located to the right of the pod slot) provides

inf ormation a bout a ny mai nt e na nc e t ha t may be r e quired.

Product S election Handle

To select a product, move handle left or right until it is aligned with the desired

beverage and press the green

START button to be gin the br e w cycle.

N o w ater –

check water

supply

Replace milk

canister

Em pty w a ste

bin

Call for

Service

*See page 17 for a

descr ipt ion of the

products av ailable.

NOTE: The handle is designed to snap off if it is subjected to too muc h

pressure. If this happens, simply snap it back into pos ition at an upw ard

angle.

Page 10

10

Coffee Maker Overview

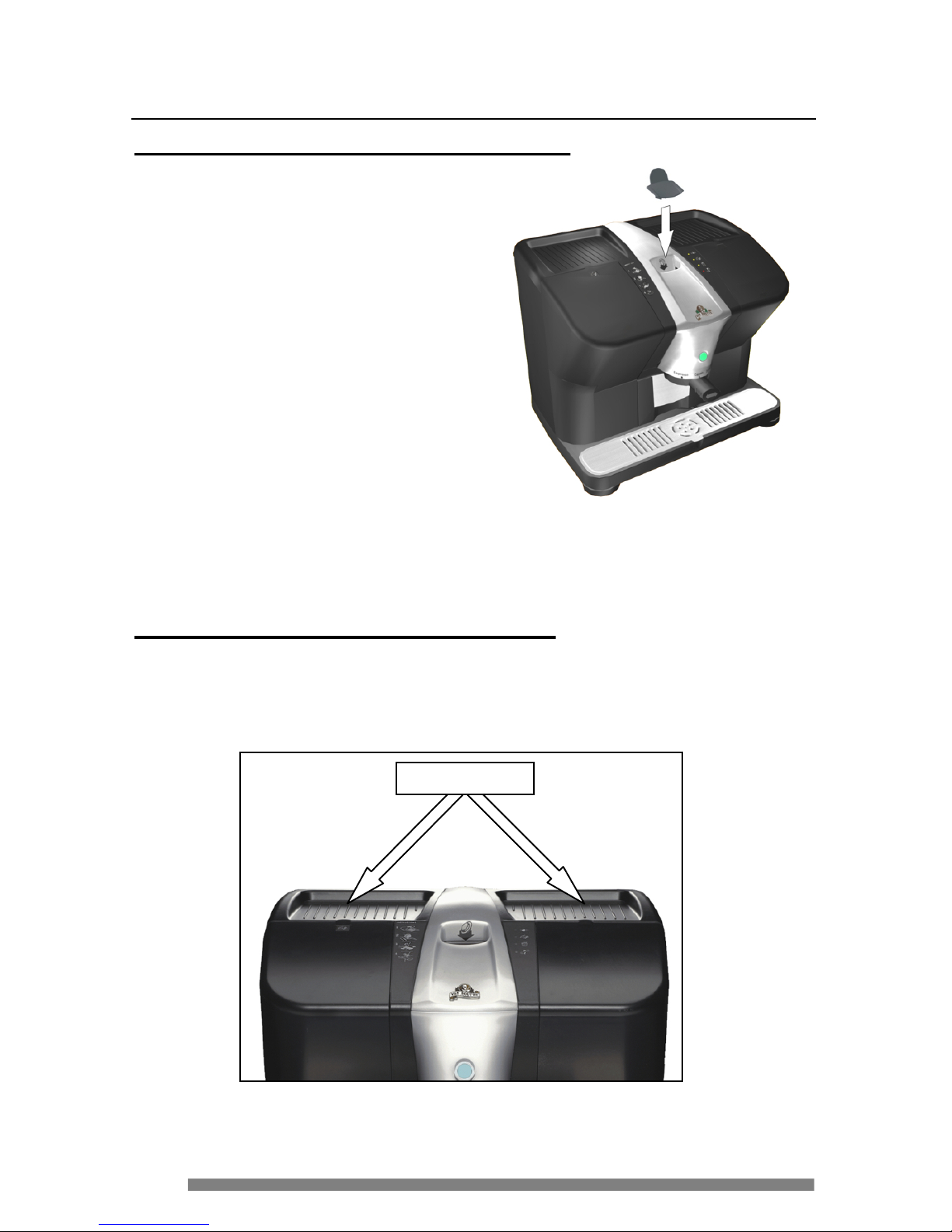

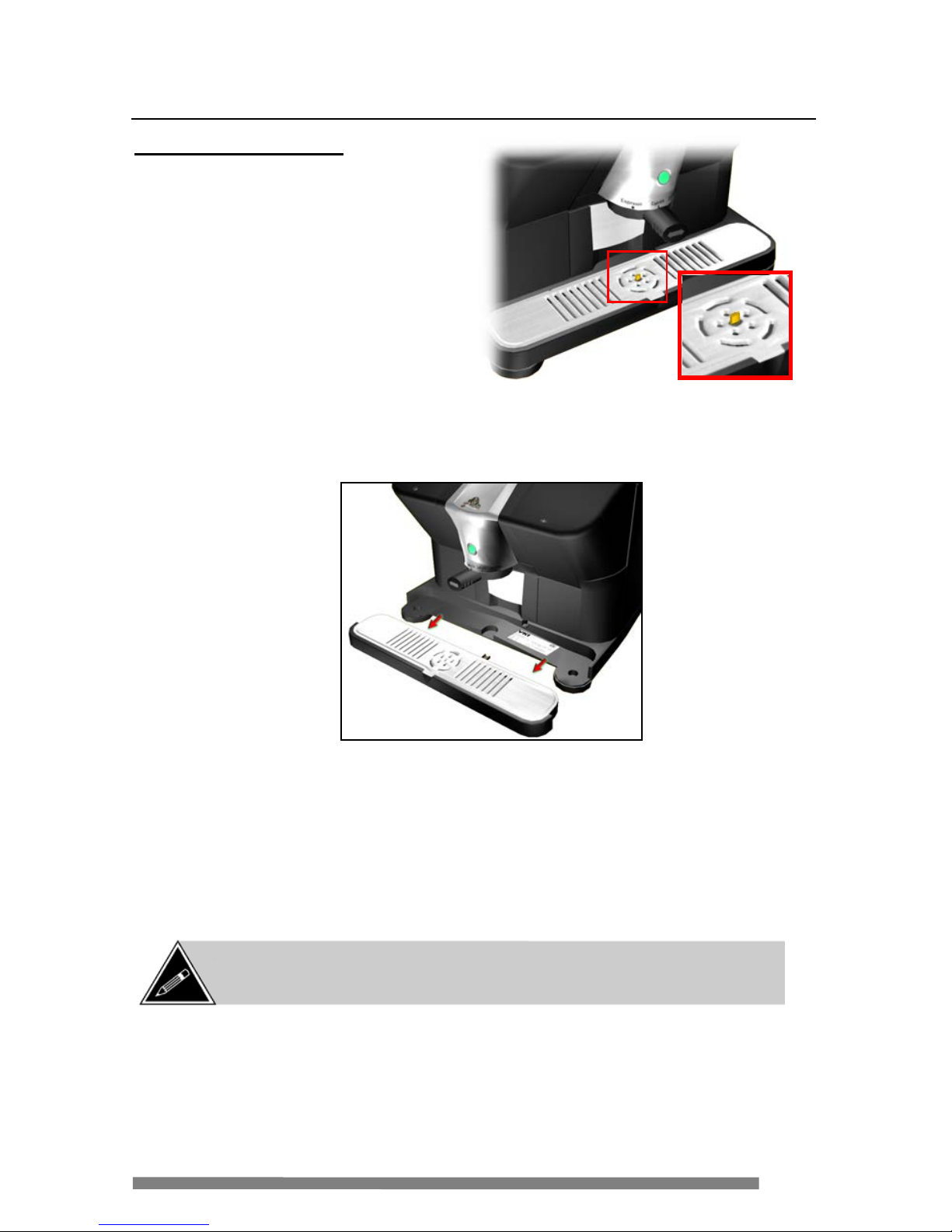

Pod Slot Cover (Pro fessional Model Only)

The Espresso Café Professional model

is shipped with a cover for the coffee

pod slot. The cover should remain

installed on the equipment when it is

not in use, and should only be

removed when making a beverage.

After the beverage is prepared, reinstall the pod slot cover to prevent

foreign matter from falling into the

brewer.

Cup Warmers (Professional Model Only )

The Espresso Café Professional model is equipped with cup warmers. Place

glass or ceramic mugs upside down on the cup warmers and leave them in

place unt il the y a re require d (at which time they will be w arm to the t ouc h).

Cup Warmers

Page 11

11

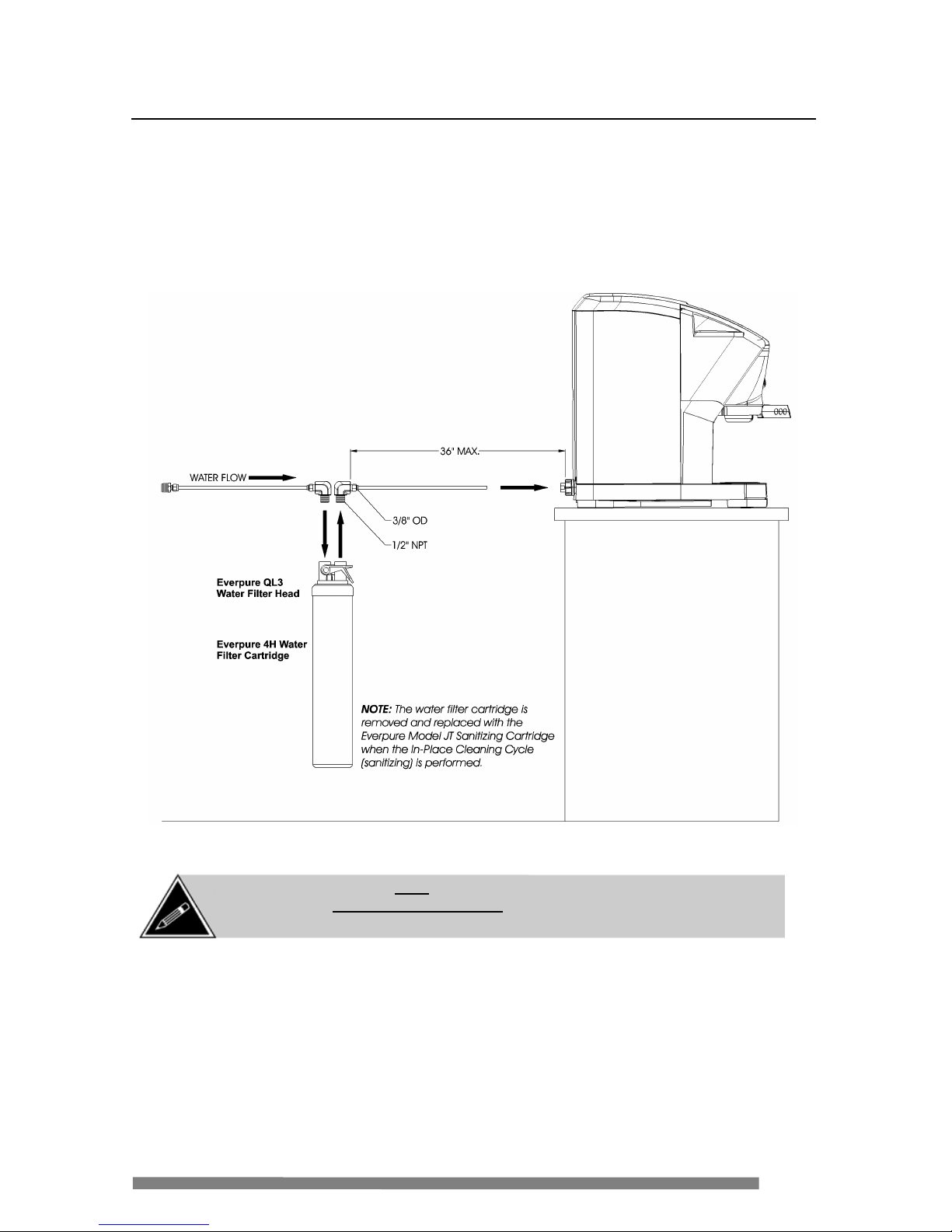

Connecting to a Water Supply

All Espresso Café machines mus t be installed with an Everpure water filtration

system. This system consists of a QL3 filter head (with shut-off valve) and 4H

water filter cartridge. This system is compatible with the Everpure Model JT

Sanitizing Cartridge, which is required to perform the In-Place Cleaning

(sanitizi ng) Cycle in compliance with NSF standards.

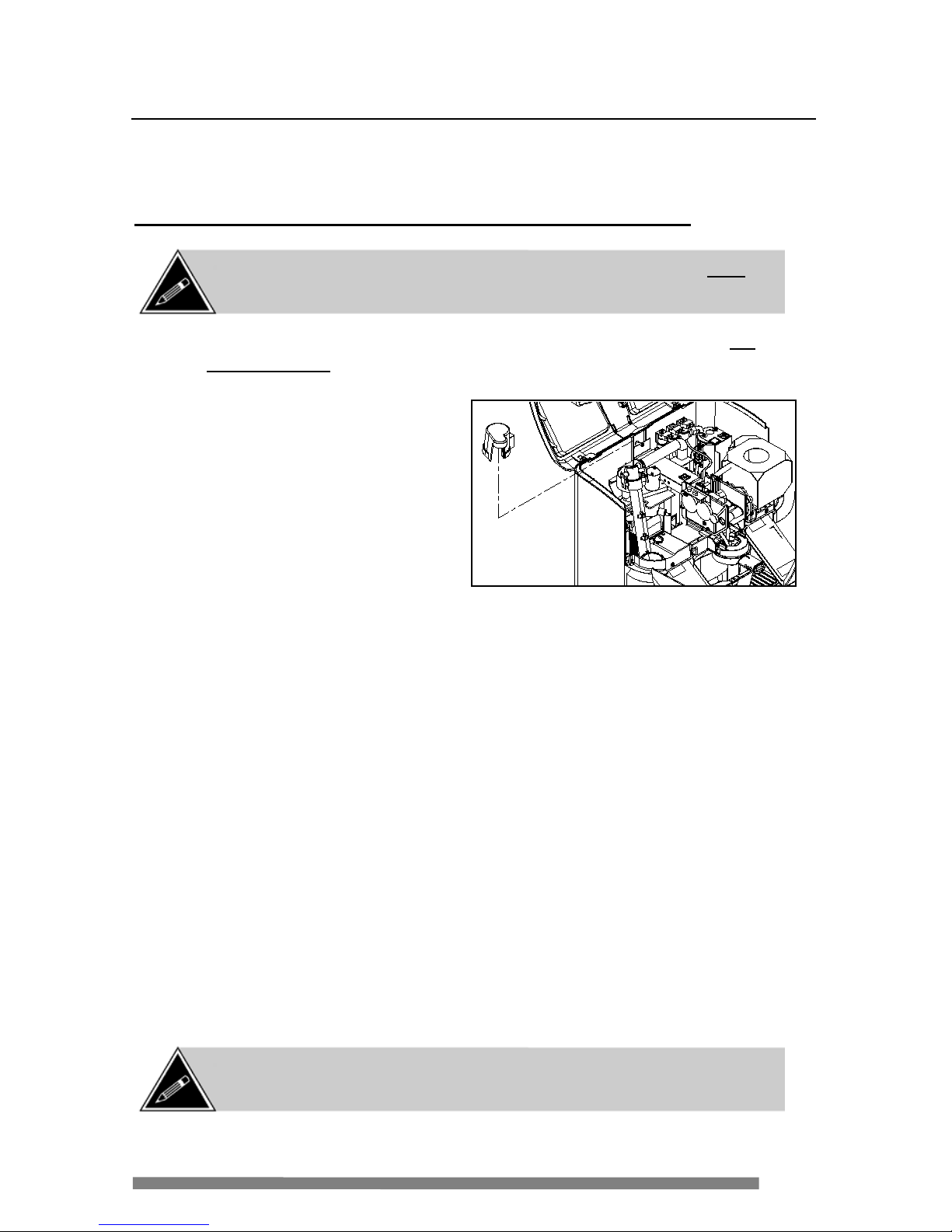

NOTE: The water filter must be installed between the water source and the

coffee maker (maximum 3 feet away). Also note that the inlet valve is

equipped with a flo w regulator and back flo w p revention system .

Page 12

12

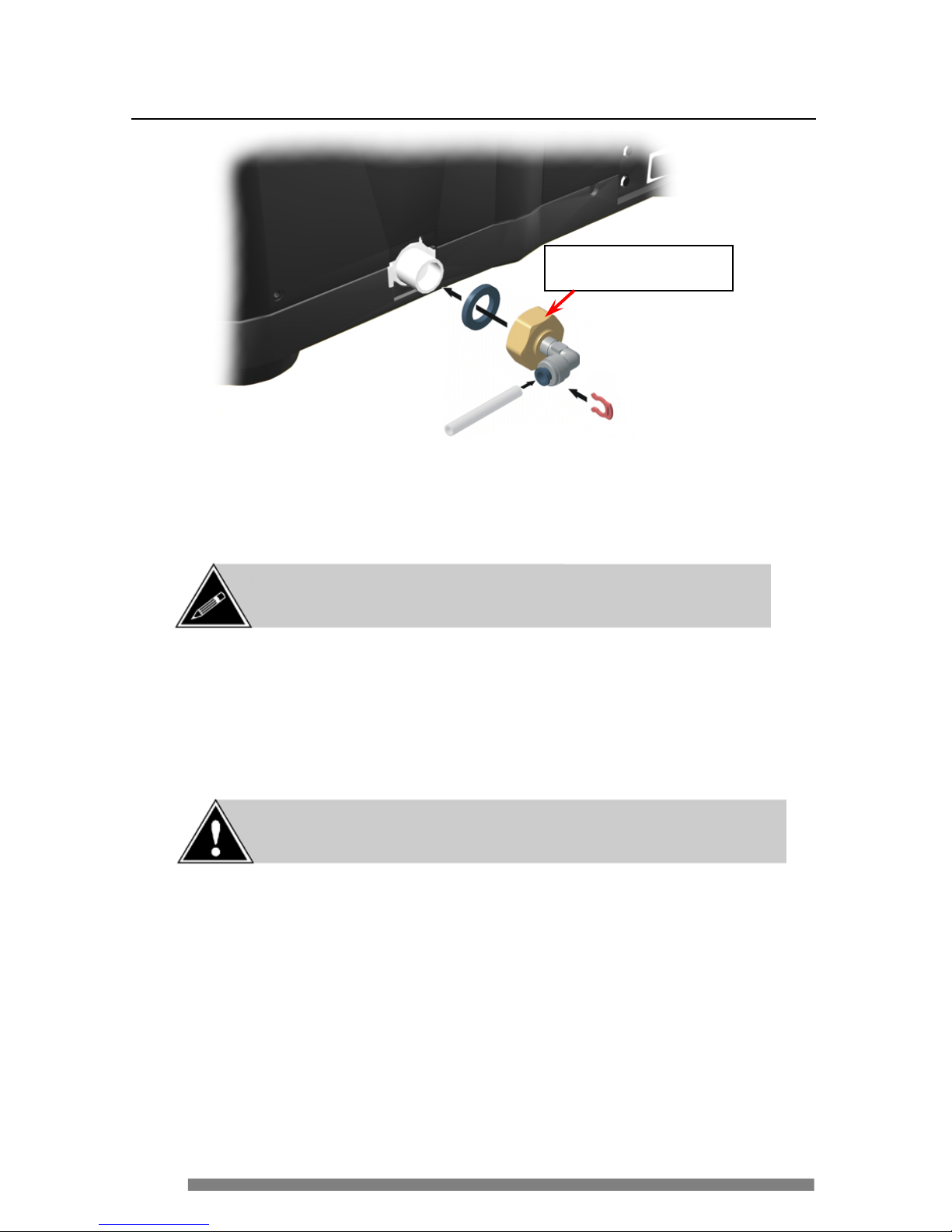

Connecting to a Water Supply

1. C onnect a ¾” inle t fitti ng to t he inl e t va lve at the rea r of the coffee make r,

maki ng c e rtain the rubber w a sher is inserted be tween the fitt ing and the

inlet valve.

2. Tighten the fitting onto the inlet valve – hand-tig hten only. Connect t he

water tubing to the fitting and install the lock clip to lock it in place.

3. Turn the water on at the source, check for l eaks and repai r, if necessary.

4. P lug the ser vice cord into a wa l l outl e t a nd switch ON the power to the

coffee ma ker.

5. C heck for leaks once more and repai r, if necessary.

NOTE: Installation of this equipment must comply w ith all local,

state/provincial and federal plumbing codes.

CAUTION: Place a cup o n the drip t ray w hen the co ffee maker is

init ially f illed with wate r. Approximately 50 ml (1.7 oz) of water will

be dispensed by the spout due to the purging of the water system .

* Illustration is for refer ence

purposes only.

Do not over-tighten the inlet

fitting as this may prevent water

fr om entering the inlet valve.

Page 13

13

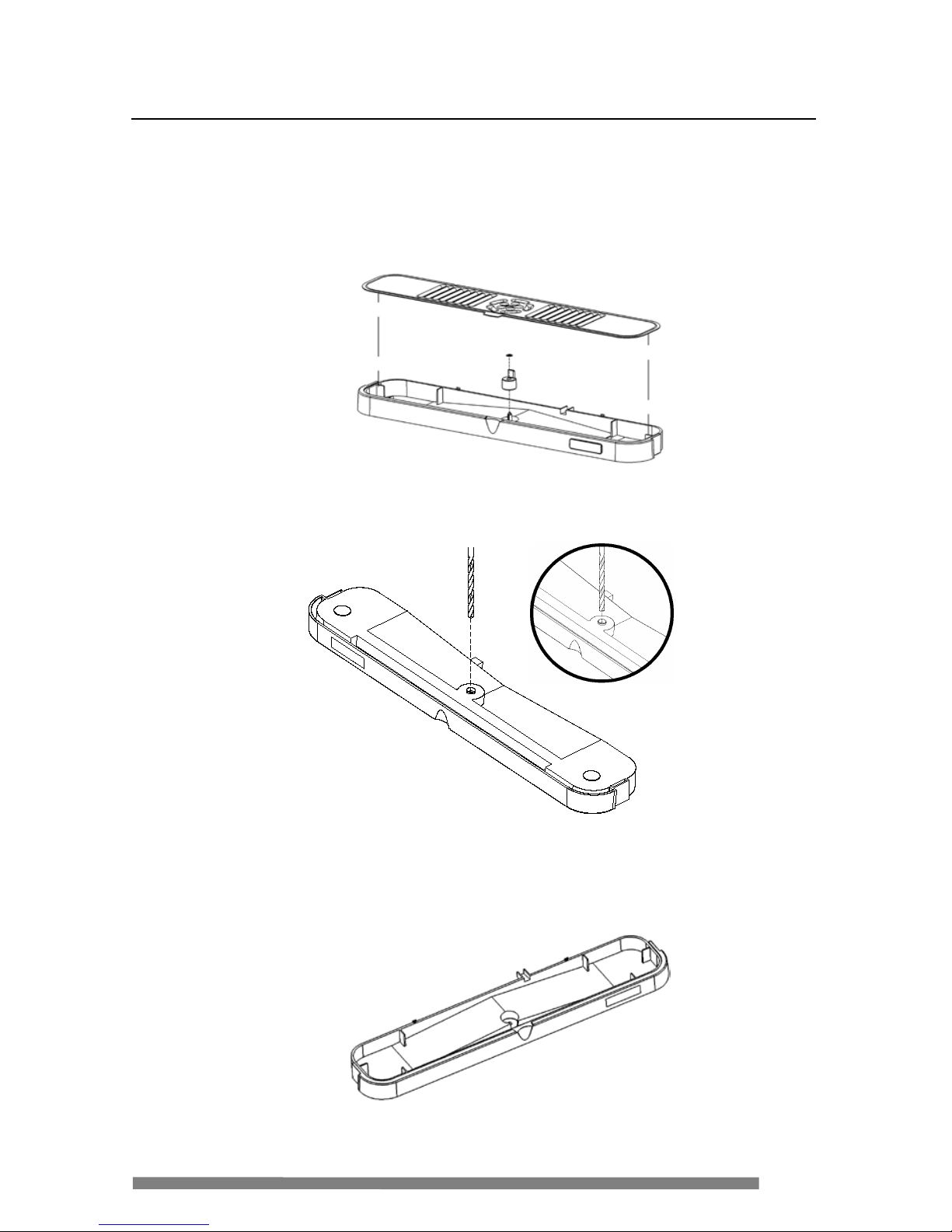

Drain Installation

To ins tall a drain kit on an Es pres so Café, the drip tray mus t first be modified to

r emove the float post and create a drai n hole.

1. Remove the drip tray grill .

2. Remove the retaining clip that sec ures the floa t to t he post.

3. Remove the float.

4. Turn the drip tray upside down.

5. Using a ¼” drill bit, align the bit in the ce nt e r guide of the drip tra y a nd

carefully drill a pilot hole.

6. Change t o a 3/8” drill bit and ca refully drill another hole where the pilot

hole was drill ed to enlarge it.

7. This r emoves the float post f rom the drip tray and creates a channel for the

dr a in syst e m.

Page 14

14

Drain Installation

8. Connect the d rain hose to the drai n fitt ing under the front of the machine.

The hose must g o straight down – d o not route the hose un de rneath the

machine.

9. S e c ure the drain hose to the fitting with the plastic clamp.

10. Conn e c t t he other e nd of the ho se to t he drai n syste m that will be used at

the installation location.

11. Conn e c t t he programmer and power u p the machine.

12. Scroll to the “

DRAIN INSTALLED?” menu and press t he green < START>

button on the machine.

13. Press the “+” butt on on the progra mmer – the lower li ne on t he display

should re a d “

YES ”.

T his lets the s oftware kn ow that a drain is installed, reducin g user

interaction with th e e q uipme nt during an “

IN-PLACE

CLEANING

/SANITIZING CYCLE” , should this cycle ever be required.

14. Press the “

SCROLL UP” button to save the setting.

Plastic Clamp

Drain Hose

Drain Fitting

Page 15

15

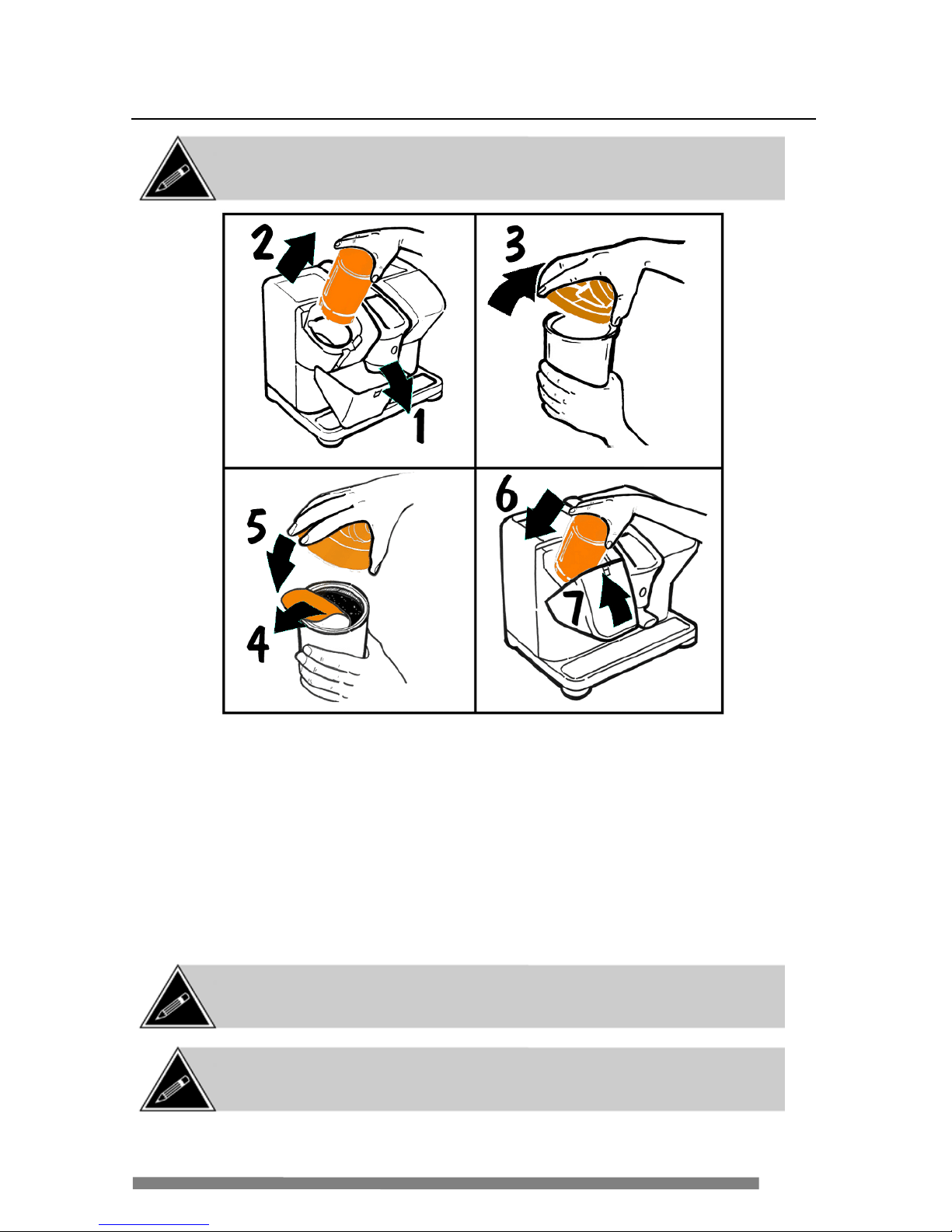

Installing the Milk Canister

1. O pen the milk door on the top lef t of the coffee ma ker.

2. Pull the empty milk canister str aight out (if replac ing).

3. Remove the canister lid from the em pty canister.

4. R emove the fr eshness se al from the new milk cani ster.

5. Install the canister li d ont o th e ne w milk can ister.

6. I nstall the new milk canister into the coffee ma ker by pushing it down into

the canister receptacl e.

7. Close the milk door on the coffee ma ker.

NOTE: Do not install and remove the milk canister repeatedly as this will pack

the mi lk at the bott om of the auger and may c ause it to ja m. Once ins talled,

leave it in place until it is absolutely necessary to remove it.

NOTE: When the milk canister is empty, any selections requiring milk are

disabled and the green START button wil l not ill um inate.

NOTE: When the milk c anister is initially inst alled, or when it is r eplac ed, the

mi lk dispens er motor may automatically activate to prime the milk thr ough the

system. Once primed, the motor will stop automatically.

Page 16

16

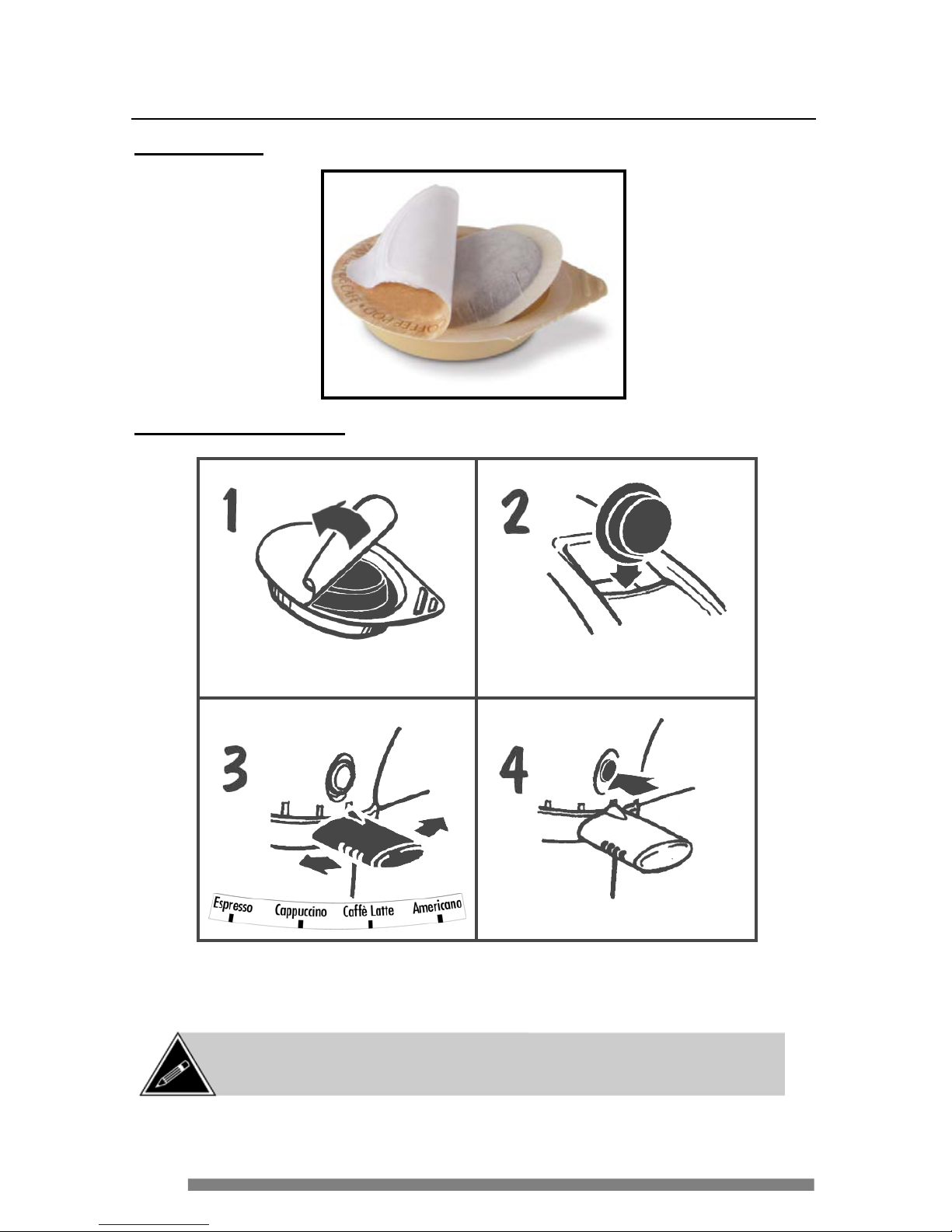

Using the Coffee Maker

Coffee Pods

Brewing a Beverag e

NOTE: Never ins ert a coff ee pod into the pod s lot w hile the coffee maker is

already in the proc ess of preparing a bev erage. Do not ins ert def ormed c off ee

pods into the slot as they could get jammed in the brewer.

Open the pod package

and r em ove the pod .

Drop the pod into the slot

on top of the coffee maker.

Select the desired product

by moving the selection

handle to the lef t or right.

Press the green START

butto n located above the

selection handle.

Single Dose Coffee Pod & Packaging

Page 17

17

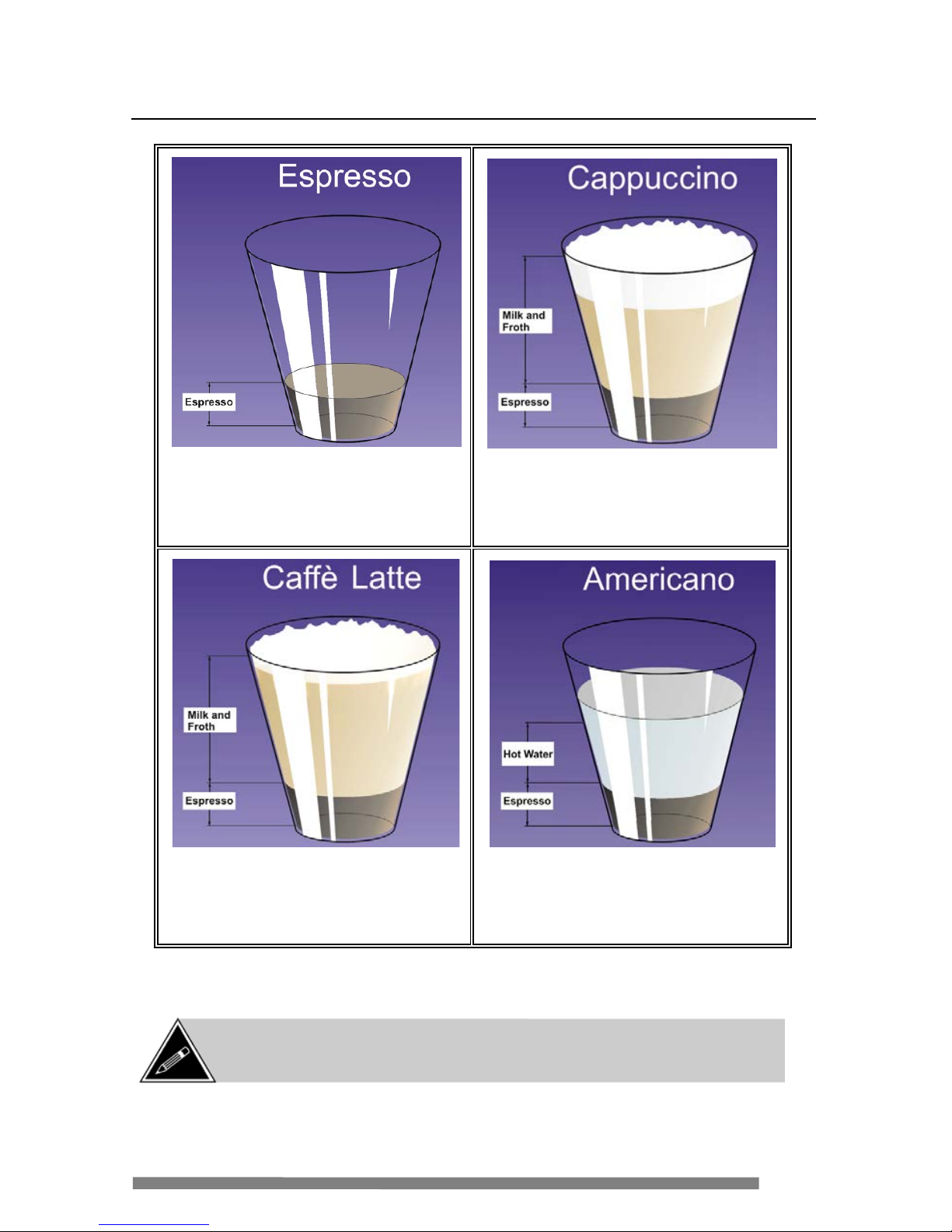

Types of Beverages Available

Espresso – The or iginal, with

intense l ong-

la sting flavors, c r owned

with a golden foam ca lled crema

Cappuccino – A single espresso

topped with hot milk and milk froth

Caffè Latte – A sing le Espresso

blen ded with a generous portion of

creamy hot milk

Americano* (Regular Model Only) – A

single e spresso m ixed with hot

water

*this option app lies only to the Regular Model. The “Americano” beverage is replaced

by “Hot Wa te r” on the Professional Model.

NOTE: The illustrations above are intended to be used simply as a description

of the pr oduct . The finished pr oduc ts may not look exac tly as s how n in these

illustrations.

Page 18

18

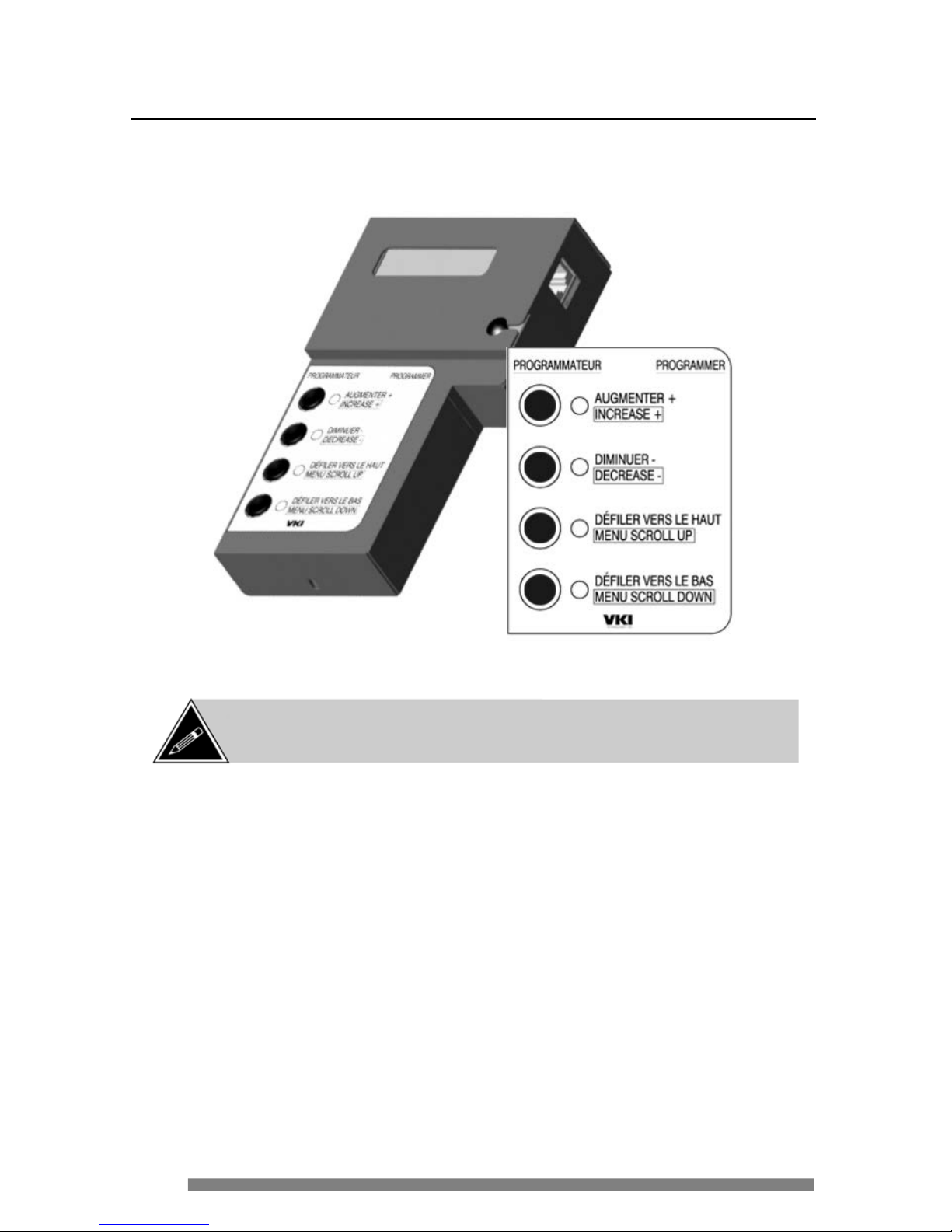

Connecting the Programmer

The ha ndhe ld programmer (sold separately – p/n A210024) acts as an i nterface with

the coffee maker, allowing you to view system errors and allo wing access to th e

softw are featur es incorpor a t e d into the coffee maker .

Espresso Café Handhel d P r ogr ammer

NOTE:

The system status LED’s provide feedback for any minor action

required on the c offee maker. How ever, if the r ed LED is lit, the programmer

must be connected to view the a ctive erro r.

Page 19

19

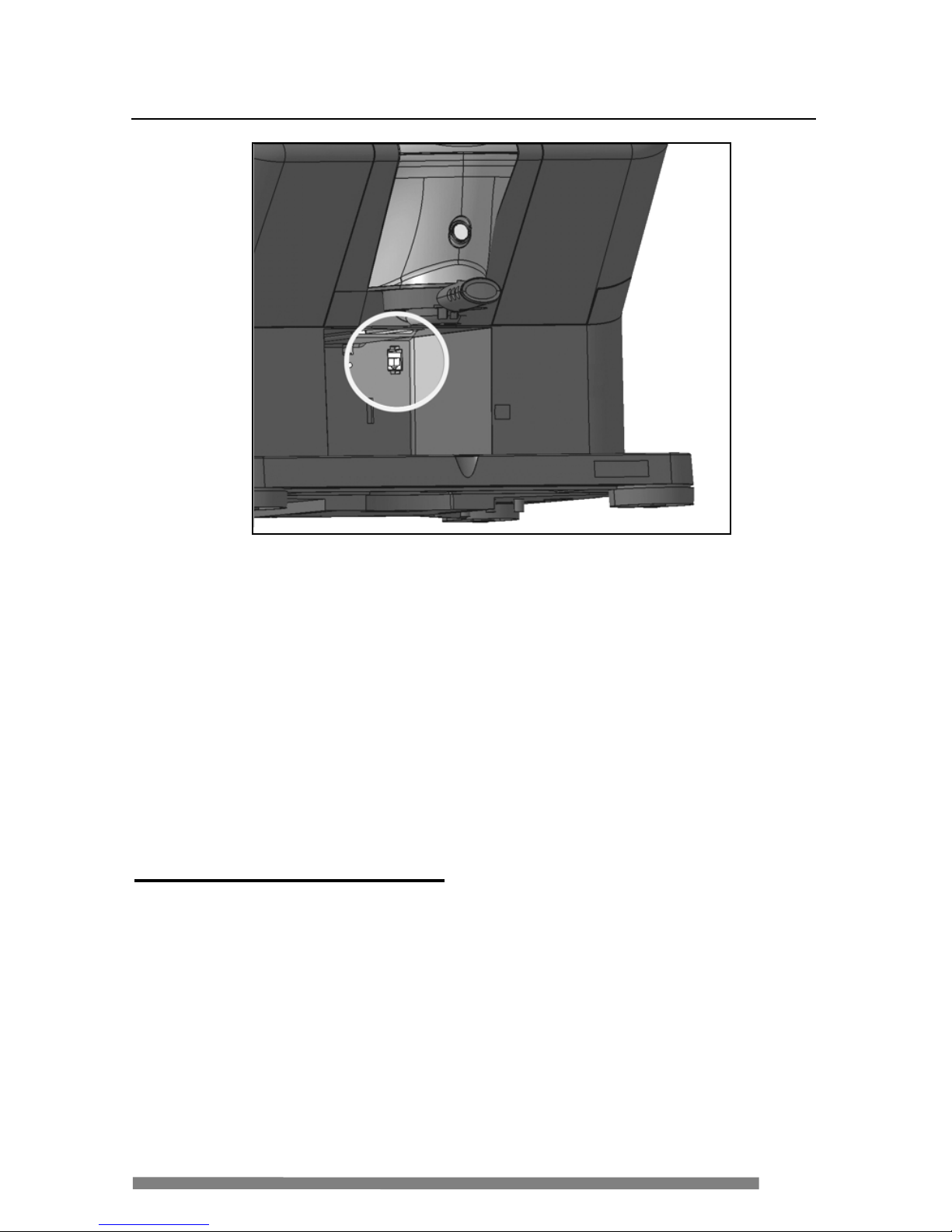

Connecting the Programmer

To c onne c t the handheld programmer to the coff ee maker:

1. Swi tch O FF the power to the coffee m aker.

2. Remove the waste bin.

3. Locate the program m er interface por t on the re a r wall of the wa ste bin

area (illustrated above).

4. Connect the phone type ca ble f rom the progr ammer to the interfa c e

port.

5. Swi tch ON the power to the coffee maker.

Power-Up Diagnostic Routine

After the programmer is connected and the coffee make r is powered-up, the

software version is displayed and a diagnostic routine is then initiated to

search for any errors with the equipment. Should a problem be detected, t he

pr ogrammer c a n be used to identif y the problem are a.

More detailed informat ion about error messages, and how to correct them can

be found in the “Troubleshooting” section of this manual (page 64).

Page 20

20

Software Features

Switch OFF the power and connect the handheld programmer to the coffee maker

- use the <

SCRO LL U P> and <SCRO LL DOWN> buttons to navigate through the

software.

Software Menu Navigation

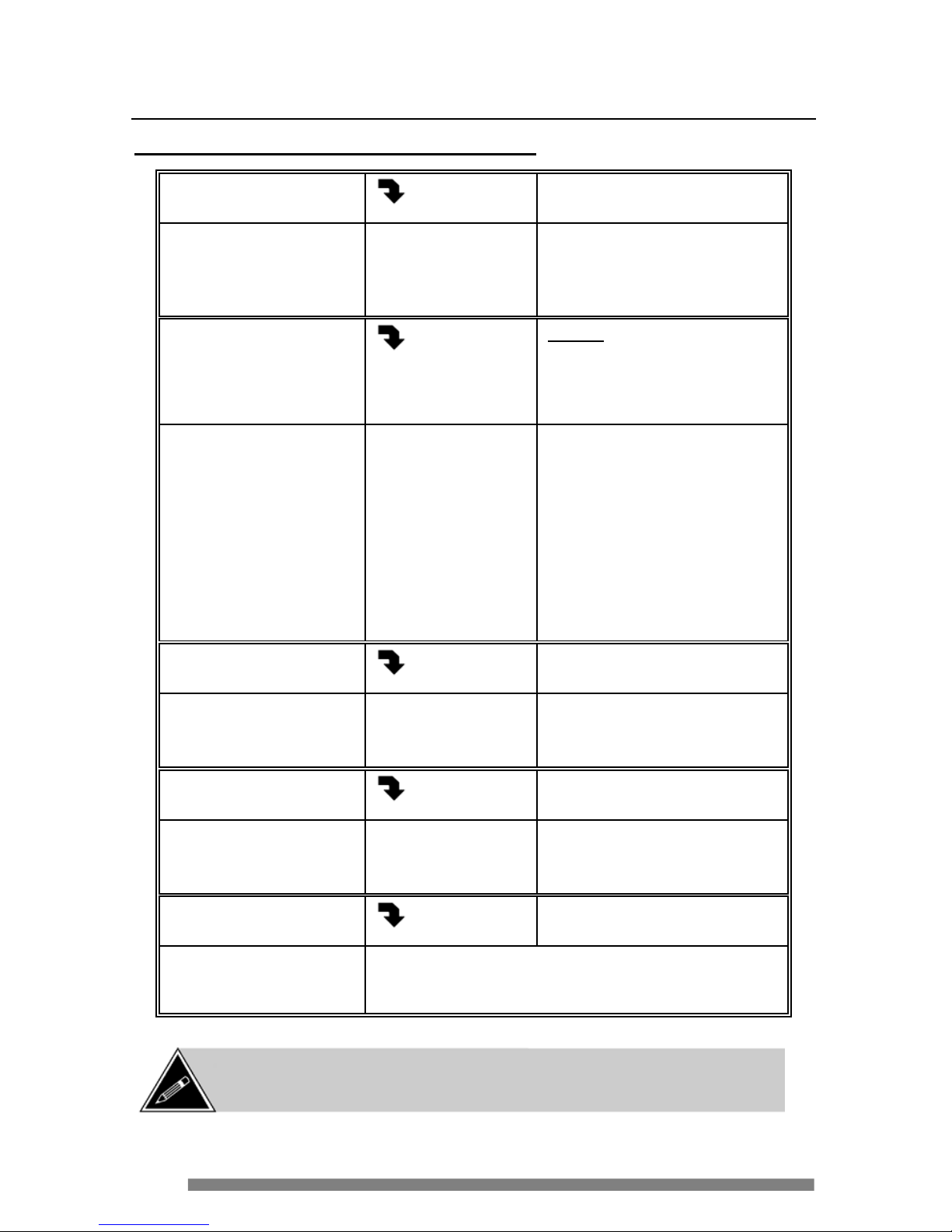

MA IN MEN U

S UB MENU

Procedure

Empt y cycle

Pre ss st art

Press green <START> button to

enter menu.

Empty milk

Press start

Remove milk can ister and press

START to empty the conveyor.

Close milk

Door

The milk door must be closed to

continue this cyc le.

Emptying

Please wait

Wa it until the cycle is comp lete.

rem ove

mil k caniste r

* If the milk can ister has not

been removed, this reminder

appears on the display.

Emp ty water

Press start

Discon nect the water supply

from the coffee maker. When

the “

EMP TY MILK” cy cle i s

complete, this message appears

on the display. At this point,

place the waste bin under the

dispens ing spout.

Emptying

Please wait

Water will be dispensed from

the spout, into the waste bin.

Wa it until the cycle is comp lete.

Instal l drain

insert - star t

Install the drain insert to the

drain plug underneath the coffee

maker. Press START to drain

the remaining water from the

water heater.

Emptying-power

Off when done

Wa it until the cycle is comp lete,

switch the coffee maker power

OFF and disconne ct the service

cord from the power outlet.

NOTE:

Product and w ater settings are calibrated w hen the coffee maker is

manufactured at the factory

. Th e se se tting s cann ot be chan ged (e xcept for settin g

a 6 or 7 fl.oz cup) as no adjustments are required on this equipment.

Page 21

21

Software Features

Software Menu Navigation (continued)

MA IN MEN U

S UB MENU Procedures

Handle position

xxxxxxxxxxx

Once the menu is displayed,

move the selection handle to

each pro duct position to test.

Handle position

Cappuccino

This message is displayed when

the select ion handle is moved to

the Cappuccino position.

Handle position

Espresso

This message is displayed when

the select ion handle is moved to

the Espr esso position.

Handle position

Americano

(hot Water – o n

Professional model)

This message is displayed when

the select ion hand le is moved to

the Americano po sition (Hot

Water on Professional model).

Handle position

Caff e latte

This message is displayed when

the select ion handle is moved to

the Caffè Latte position.

Handle position

Error

An error has been detected with

the position of the handle.

Se ri al nu mbe r

Pre ss st art

Press START to enter menu.

Pnb control

xxxx- xxxx- xx x

The serial number of the control

board is displayed.

Options type 1

xxxx- xxxx- xx x

The serial number of the options

board is displayed.

Se t cu p size

Pre ss st art

Press START to enter menu.

Set cup size

7 oz

Press the “+” or “-” button on the

programmer to set to either 6-oz

or 7-oz cup s ize.

NOTE: Press the “SC ROLL UP ”

or “

SCROLL DOWN” button to

save the changes.

Page 22

22

Software Features

Software Menu Navigation (continued )

Sele ct reg/pro

Pre ss st art

Press START to enter menu.

Sel ect reg/pro

reg

Press the “+” or “-” button on the

programmer to set to REG

(regular model ) or PRO

(Professiona l model).

Se t hot wate r

Pre ss st art

NOTE: This menu appears

only if the machine is set to

PRO (Professional Model).

Press START to enter menu.

Se T h o t water

press-hold

Press the “+” or “-” button on the

programmer to set quantity of

hot water to be dispensed.

Hot water can be set to “

PRESS

& HOLD” (water is dispensed as

long as the green <

START>

button is pressed) or “by-thecup” in ounces (starting at 1-oz

and incrementing by 0.5-oz to a

maximum of 10-oz).

Drain installed?

Pre ss st art

Press START to enter menu.

Drain installed?

no

Press the “+” or “-” button on the

programmer to toggle between

“

YES” or “NO”.

Pour over mode

Pre ss st art

Press START to enter menu

Pour Over Mode

off

Press the “+” or “-” button on the

programmer to toggle between

“

OFF” or “ON”.

Check for errors

Pre ss st art

Press START to enter menu.

When this feature is activated, the coffee ma ker

performs a quick diagnostic routine. Should any errors

be dete cted, they will be displayed in this menu.

NOTE: Sw itch OFF the pow er to the coffee maker before disconnecting the

programmer.

Page 23

23

Downloading Software Updates

Should a software update be required for the Espresso Café, the update will be

shipped in the form of an EPROM. With the exception of the Espresso Café

downloader, no s pecial tools or change of parts is required to perform the software

upgrade.

To upda te the software in the Espresso C afé:

1. Install the EPRO M with the sof tware up grade into the Espres so Café

programmer.

a) Re move the s crew s at the top and bott om of the housing (figure 1),

then lift and remove the cover.

b) With a f lat screwdriver, gently pry the top and bottom of an existing

EPROM (if installed) and rem ov e it w he n it is loos e .

c) With the notc h on the

EPROM poi ntin g upw ards, line up the two rows

of pins w i th t he tw o rows on the socket, an d slowly inser t the

EPROM

(figure 2). Make cer tain not to bend any of the pins be t ween the

EPROM and t he socket.

d) I nspect the pi ns o n c e more to make cer t ain they ar e all inse rted

prope rly into the socket.

e) Re-ins tal l t he cover onto the programmer.

2. Switch O FF the power t o the machine and remove the waste bi n.

3. Connect the programmer.

4. P ress and h old the <

MENU SC ROLL DOW N> bu t ton (lowe st button) on the

pr ogrammer a nd switch

ON the p ow er to the Espresso Café. Once the

dow nload begins ( L EDs star t to flash), rel ease the button.

5. When the download is complete, switch off the power t o the Espre sso

Café , disconnect the progr a mmer and r eplace the w aste bin.

Remove

Screws

EPROM location

Notch on

EPROM

Figure 1

Figure 2

LCD DISPL AY

Page 24

24

Maintenance

Empty the Waste Bin

The waste bin inside the coffee maker holds approximately 30 used coffee

pods. The system is equipped w ith an optical sensor that detects when the was te

bin is full, and advises you b y li ght ing the yellow “Empty Waste Bin” LED on

the system status indi cator panel .

To e mpty the w a ste bin:

1. G rasp the handle on the front of t he waste bin.

2. Pull the w aste bin out towards you.

3. Discard the content s.

4. If required, use a sponge or absorbent paper towe l to clean a ny liqui ds

from the ar ea beneath where the w aste bin is i nstalled (base).

5. S lide the waste bin back i nt o position.

Cleaning a Milk Overflow

This equipment is equipped with a Milk Overflo w detection system. Should the

w hipper bowl over flow, milk will pour on to t wo overflow contacts and a “Milk

Overflow” error will be displayed on the Programmer.

To clean the milk overfl ow:

1. With the top cover open, clean the milk fro m the whipper bowl, whipper

chamber a nd milk tubi ng.

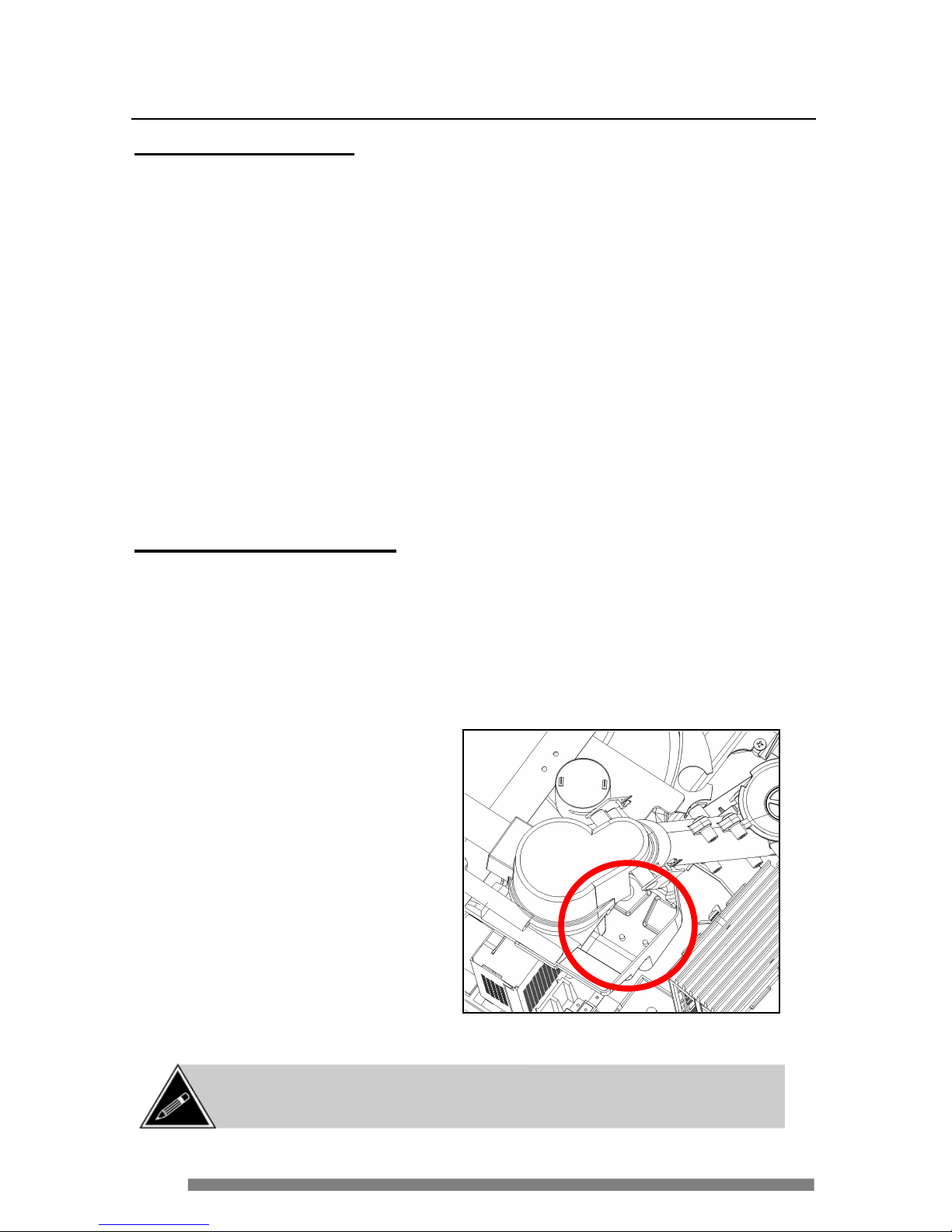

2. Locate the milk overflow

sensors (on the deflector

beneath the whipper bowl)

and clean the overflow by

pouring water directly onto

the deflector and sensors.

If the milk has hardened,

us e a s mall brush to loosen

it. The milk and water will

flow down the deflector

and into the w a ste bin.

3. Once cleaned, cl ose the top

cover.

NOT E: If a Mil k Ov erflow is detected, the red Se rv ice LED w ill ligh t when a

Cappuc cino or Caff è Latte selected. The “ Rinse Cycle”, “ In-Place Cle aning”

and “Empty Cycle ” are also disabled until the m ilk overflow is cleaned.

Page 25

25

Maintenance

Empty the Drip Tray

The drip tray on the front of the

coffee maker holds approximately

50 0 m l ( 1.7 o z ) of liquid. When too

much liquid has accumulated inside

the tray, a float will rise and

protrude through the drip tray grill.

At this point, the drip tray must be

emptied.

To e mpty the dr ip tra y:

1. Grasp the outer sides of the drip tr ay.

2. Pull the drip tray out tow a rds you.

3. Empty the c ont e nts of the tray, and cl ean it under running wat e r.

4. Remove the waste bin.

5. If required, use a sponge or absorbent paper towe l to clean a ny liqui ds

from the ar ea beneath where the w aste bin is i nstalled (base).

6. Re-install the waste bin and re-i nstall t he drip tra y by sliding it back

into posi t ion until it locks in place.

NOTE: With the drip tray r emoved, t he serial number decal c an be v iew ed.

This decal also shows the electrical specifications of the equipment, as well as

the equipment certification (C SA, UL, etc.).

Page 26

26

Maintenance

Quick-Rinse Cyc le

The rinse cycle must be performed to clean the milk system every time the

customer i s visi te d by servic e or deli very pe rsonnel.

1. With the power to the coffee maker O N, place the selection handle

between

two s elections . The green <START> button LED w ill switch

off.

2. Pull out the w aste bin and place it below the di spensing area.

3. Press and release the green <

START> button to acti vate t he cycle.

4. R epeat the cycle (i f nece ssar y) by pressi ng the green <

START> button

once more.

Forced Quick-Rinse

Should a Cappuccino or Café Latté cycle be interrupted for any reason (loss of

power, error detected, etc) and is not comp leted, the red sys tem s tatus LED w ill

flash. If this occurs, a quick-rinse cycle mus t to be performed to clear it and to

pre vent milk from accumulating in the w hipper a nd milk lines.

NOTE: I f the RED error LED (wrench) is flashing, a quick-rinse cycle m ust be

performed, as this is the only way to clear this erro r.

NOTE: The quick-

rinse cycle can be canceled at any time by

pressing the green <STAR T> button.

NOTE: Do not sw itch OFF the pow er to the coffee maker for at leas t 20

minutes af ter a quick-

rinse is performed. Moisture present inside the coffee

maker after a quick-rinse needs to be vented by the exhaust fan.

Page 27

27

Maintenance

Priming the Water System (on Power-Up)

When servicing the wate r system (or w he n removing an Espre ss o Caf é ), the water

system must first be completely emptied. If not properly emptied, you risk

energizing the heater with no water in the s ystem and damag ing water system

components . Normally, a minimu m of 50 ml (1.7 fl. oz) of water is dispensed

when the Es presso Café is powered-up (possibly more depending on whether the

heater is full or empty). If little or no water is dispensed on power-up, the

water s ystem mus t be pri me d immediately

. To prime the water s yste m,

1. Pull the w aste bin f orward unti l it is directly below t he dispensing spout.

2. Place the sel ection handle in between two sel ections.

3. P ress and h old the green <START> button (it will not be lit at this poi nt )

to start pr iming the wa ter system.

4. Once water starts dispensing, r elease the green <

START> button.

Dispensing Spout and Product Tube Placement

If the dispensing spout is removed, it is imperative that the product tubes be

r e placed in their pr ope r posi t ions. To r emove the spo ut,

1. Sli de the spl a sh guard towards you unt il it comes of f.

2. Lift the t ube s out of the sp out a nd l ift the spout str a ight up.

3. To install the spout, sl ide i t into the selection ring assembly.

4. I nstall the tubes i nto t he spout (milk on left , hot wate r on r ight).

5. Slide the splash guard into the top of the selection ring assembly to

secure the t ubes i n pl ac e.

6. I nstall brewer t ube t hrough the center of the splash guard i nto the spout.

Milk Tube – left side Coffee Tube – center Water Tube – right side

Page 28

28

Using the Cleaning Tab

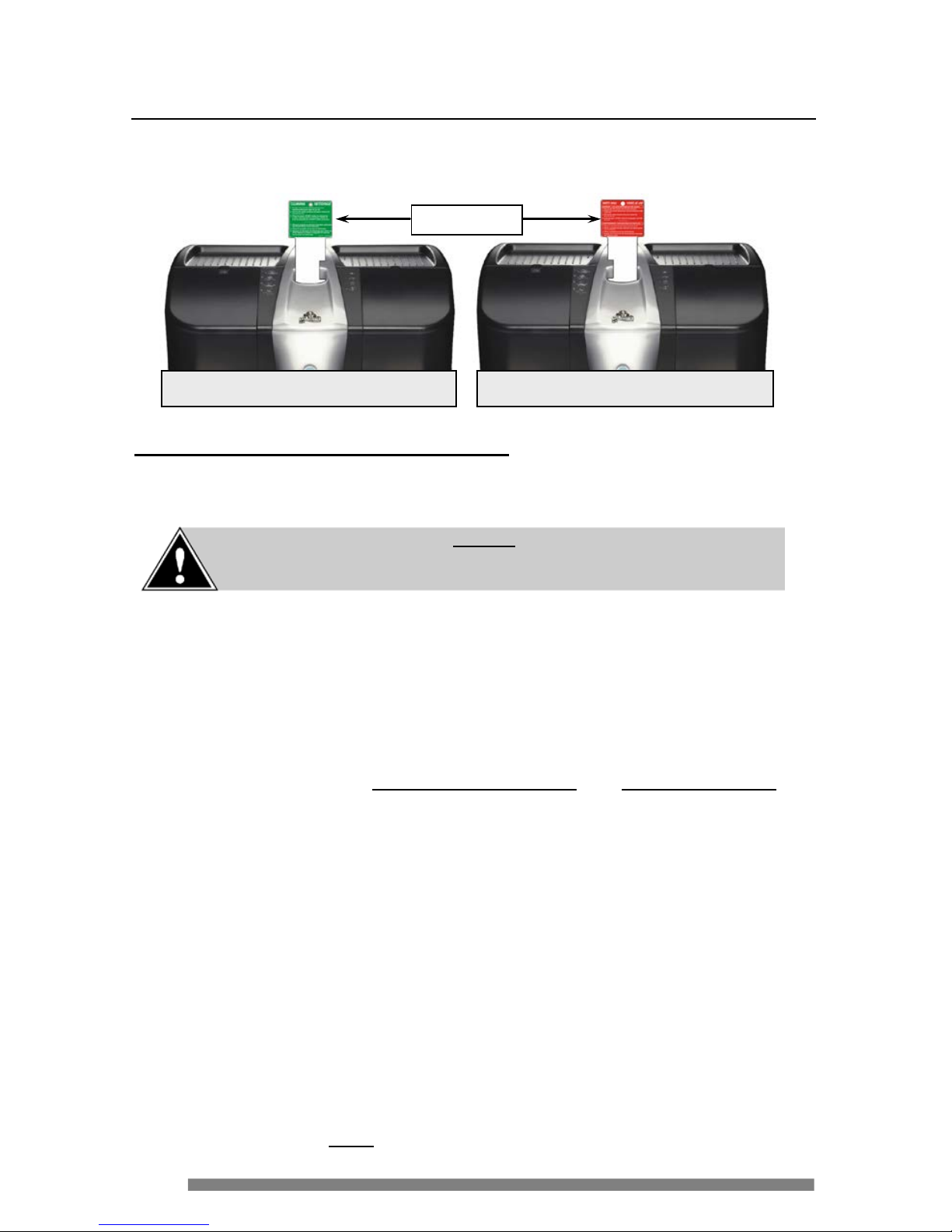

The cleaning tab performs t wo functions – t h e in-place c leaning/sanit izin g cyc le

(green side of tab) and the emptying of milk from the Espresso Café without the

use of a programmer (red side of tab).

In-Place Cl eaning (Sanitizing Cyc le)

This cycle must be perf ormed as require d by local he a lth authorities and health

regulations.

1. S witch mac hine pow e r off and shut off water by lif t ing the valve handle

on top of the Ever pure QL3 filter head.

2. R emove the E ver pure water filter from the fil ter head (the filter head

must be installe d less than 3 f eet away fr om the i nlet of the machi ne).

a) L ift car tridge slightly and turn completely counter-clockwise.

b) L ower the c artri dge to disen gage it from the head br acket.

3. Fill the Everpure JT San itizing Ca rtridge with SC Johnson J-512

sanitizing sol ut ion ( a va il a ble thr ou gh your loc a l distributor ).

a) U npl ug th e c artridge top on t he Sanitizing Cartridge.

b) Pour sanit izing solutio n i nto the Sanitiz ing C artridge (4 m l of

sanitize r per 1 liter of water ) and r e-install the car t ridge t op o nto

the Sanitizing Cartr idge.

c) Re-install the cartridg e top onto the S anitizin g Car trid ge.

4. I nstall the Sa nitizing Cartridge into the f ilter head.

a) I nser t Sanit izing Cartridge all the w ay into the head bra cket.

b) Turn cartridge c ompletely clockwise until it stops.

5. Turn on the valve at the water fil ter.

6. Swi tch machi ne power ON.

7. I nsert the c leaning tab ( must be inser te d al l the w a y do wn) into the pod

slot with the green

side of the tab facing you.

CAUTION: Th e E sp resso Café must be plumbed-in (“POUR OVER MODE = OFF”

in the set -up) and should be connected to a drain system to perform this cycle.

If a drain is not availabl e, place the waste bin under the dispensing area.

In-Place C le aning (green)

Emptying the Milk (red)

Cle aning Ta b

Page 29

29

Using the Cleaning Tab

In-Place Cl eaning (continued)

8. P osition the selection handle be t ween two sel e c t ions ( t he green light will

switch off).

9. Place the waste bi n under the dispensing area.

10. Press the green <

START> button to a c t ivate the i n-place cleani ng cycle.

a) T he machine will di spense approximat e ly o ne l it e r (34 fl. oz) of

water – this introduces t he sanitiz ing agen t int o the water sy stem.

The yellow status i ndicator LEDs will flash.

b) T he Espresso Café will now pause for approximately t hre e

m inutes . T he wate r w ill heat and the sanitizing a ge nt will start

cleaning the water system . The yellow LEDs will flash.

c) After the th ree minute p ause, t he Espresso Café will dis pe n se a

small amount of water (100-150 ml ) thro ugh ea c h v al v e

(alter nating f rom one to another), t o introduce sanitizi ng agent

thro ugh the product valve s and tubing. The yellow LE Ds will

flash.

d) T he Espresso Café will dis pe nse a sma ll a mount of w at e r (35-60

m l ) throug h e ac h v alve (alterna t ing f rom one t o another). The

yellow LEDs will f las h.

e) When the cycle is complete, the green <

START> button will flash

rapidly, and the yellow L E Ds will f lash.

11. Turn off the w ater at the filter head.

12. Remove the Everpure saniti z ing cartridge and install a new Everpure

water fil ter.

a) Empty the conte nts of the saniti zing car tridge and r inse it w ith

water so that it is ready for us e the nex t time this cycle is

performed.

b) Empty the was t e bi n under the dispensing area, if app lica bl e .

13. Turn on the water at the filter head.

14. Press the green <

START> button (when it lights) to pe rform the purge

phase of t he c leaning process.

CAUTION:

The water bei ng dispensed is extremely hot. Keep clear

of the water flow and use caution when working around the

dispensing area.

Page 30

30

Using the Cleaning Tab

In-Place Cl eaning (continued)

15. The Espr e ss o Caf e wil l now purge t he remaining sanitizing agent by

intr o duc ing fresh w ater i nto t he system. The pu rging cycle dispenses

about 1.8 li t e rs (60 fl. oz) of water.

16. When the gr ee n <

START> button and yellow LEDs fl a sh, empty the

w a ste bin under the dispen sing area, if appl icable.

17. Press the green <

START> button a ga in to per form the final phase of t he

cl eaning process.

18. The Espr e ss o Caf e wil l now rinse the water sys te m by int roduci ng fresh

w a t e r into the syst e m. The rinsing cycle dispen ses about 1.8 l iter s (60 fl .

oz ) of water.

19. Once the purging cycle stops, remove the cleaning tab a nd let the

machine si t for 30 minutes (do not use it dur ing this period). D uring

these 30 minutes, perf orm the following:

a) Em pty the waste bin under the dispens ing area, if applicable.

b) Wipe any liquid spills t hat may hav e occurred during the cycl e ,

including a ny liqui d t hat may have accum ul ated inside the

m achine at the waste bi n area.

c) Fill a c le an spr ay bot tle with a maximum of 2 ml (0.06 fl. oz) of

SC Johnso n J -512 sanitizing so lution per one liter ( 34 fl. oz) of

water.

d) L ight ly spray t he solution t o t he e x t e rior and to the dis pensing

spout s of the E spre sso Café. Do not w ipe away the solution – let it

dry nat urally.

e) Remove the drip tr ay and grill an d rinse both with warm wat e r.

f) Lightl y spray the sani tizing s o luti on onto the dr ip tray & grill,

and the waste bin and allow to dry (do not wi pe aw ay the

solution).

20. After 30 minutes have e lapse d, re-i nstall the drip tr a y a nd grill .

21. The sani tizing cycle is compl ete.

CAUTION: If the In-Pl ace Clea ning/sa nitizing cycle is interrupted and is

not completed, you will be prompted to restart the cycle when the

machine is powered up (a ll 3 yellow LEDs will flash simultaneously).

Page 31

31

Using the Cleaning Tab

Emptying the Milk and Water Using th e Cleaning Tab

This cycle must be perf ormed prior to cleaning the milk conveyor. It is

recommended that a Wet/Dry vacuum cleaner (Shop-Vac type) is available to

completely remove the milk from the c onve yor.

1. R emove the mi lk canister from the m achi ne.

2. I nsert the c leaning tab into the pod sl ot (must be i n serted all t he way

dow n) with t he red

si d e of the tab facing you.

3. P osition the selection handle be t ween two sel e c t ions ( t he green light will

switch off).

4. P ull out the waste bin and pl a c e it below the dispensi ng a rea.

5. Press the green <START> butt on for approximatel y 5 seconds to activate

the cycle.

6. The machi ne will now dispense milk from the milk tube until the

conveyor is empty.

7. O nce the milk system is empty, the cold wa t e r r e servoir wil l al so be

emptied (fr om the water tube at the di spensi ng a rea) .

8. When the cycle is complete, the green <

S TAR T> button will f lash to

i ndi cate that the water heater is ready to be em pti e d.

9. Empty the w a ste bin, an d place the bin on the floor near the rear of the

machine.

10. Conn e c t t he drai n insert to the drai n fitt ing under ne a t h the right rear

corner of the machi ne base. Pl ace the drain insert ho se i nto the waste bin

( whic h should be on the fl oor).

11. Press the green <

START> button to drai n t he water heater.

12. Empty and r e -install t he wa ste bin, and remove the c leaning tab.

13. If a Wet/Dry vac uum is available, insert the vacuum nozzle into t he milk

canister r eceptacle and switch the vacuum on. Leave the nozzle in place

f or several m inutes to re move any r esidua l dehydr a t e d milk from the

system.

CAUTION: T h is pro cedure wi l l em pt y the mi lk fr om t he Espre s so C afe .

If only a cleaning is required, make certain the green side of the cleaning

tab is facing you.

Page 32

32

Cleaning the Milk Conveyor

Open t h e Cover

Opening the cover allows access to the inter ior of the Espresso C a fé.

1. Af te r unplugging the ser vice cord, open the m ilk door and remove the mi lk

canister, then open the water door.

2. O peni n g the doors exposes the screws securing the cover to the coff e e

mak er’ s m ainframe. Remove these two screw s (figure 1).

3. Lift the front of the c ove r until it is comple tely open (figure 2). The hi nge s

at the rear of the cover will keep it open.

WARNING: T he majority of the electrical components in the

Espresso Café are low vo lta ge ( a nd not 120 volts AC) . Never

conn ect t hese elect rical compon ents to 120 volts AC.

WARNING: Drain the water system, switch OFF the power to

the coffee maker, and disconnect the service cord prior to

servicing the equipment.

Figure 1 Figure 2

Page 33

33

Figure 3

Cleaning the Milk Conveyor

The following method can be used only if a Wet/Dry (Shop-Vac t ype) vacuu m is

avail a ble. If one is not avail a ble, proceed to the ne xt section.

Cleaning the Milk Con veyor Using a Wet/Dry Vacuum

1. Fill a clean spray bottle wi th a maximum of 2 ml (0.06 fl. oz) of SC

Johnson J-512 sanitizing solution per one lite r (34 fl. oz) of water. If a

spra y bottl e is not ava il a ble, mix the sani ti z ing solution in a clean le a kpr oof container.

2. With the cover open, re move

the vacuum cap from the top

of t he c onve yor (figur e 3).

3. Libera lly spray (or wipe using

a clean cloth) some of the

sanitizing sol ut ion i nto t he top

of t he c onve yor.

4. S pray (or wipe usi ng a c lean cloth) some sani t izing solut ion di rectly i nt o

the milk cani ster r eceptacle.

5. Let the solution sit for approxi mately five minutes.

6. Af te r the f ive minutes have elapsed, insert the nozzle from the Wet/Dry

vacuum into the milk canister receptacle.

7. S witch on the power to the Wet /Dry vacuum and vacuum the sani tizing

sol ution from the c onve yor for approxi mately tw o minutes.

8. Let the unit sit f or approximate ly 30 minutes for t he saniti zi ng solution to

completely dry insi de t he c onve yor (top c ove r should be left ope n).

9. Af te r 30 minutes have el apsed, re-install the vacuum cap ont o the milk

conveyor.

10. Cl ose the top cover, and re -i nstall the tw o screw s to secure it.

11. Close the water door, insert a milk cani ster and close the milk door.

12. Conn e c t t he service c ord to the w al l outlet.

13. The next time the m achine i s switched on, the conveyor will activate to

prime the system with milk.

NOTE: When c losing the cov er, it may be nec essar y to press dow n slightly

on the lef t and r ight sides of the cov er w hile tightening the scr ew s , otherw ise

the two doors may not close p roperly.

NOTE: The milk system must be purged of all milk product prior to

removing the cover and contour panel.

Page 34

34

Cleaning the Milk Conveyor

I f a Wet/Dry vac uum (Sho p-Vac type) is not availa ble, t he milk conve yor must be

r emoved from the machine for sani t iz ing.

Manual Cleaning of the Milk Conveyor

1. Wi t h the t op c over a lre a dy ope ne d, remove the vacuum cap f rom the top of

the c onveyor (figure 3 on previ ous page).

2. D isconnect the wiring f rom the upper and lower IR (infrar ed) sensors -four

connections (figure 4).

3. O pen the wir ing clip on the right si de of the conveyor and remove the

w i ring ha rness from the c l ip.

4. U sing a Philips scr e wdriver with a long shaft, remove the four scre ws

securing the convey or assembl y t o the base (figure 5).

5. Lift the conve yor assembl y up a few inc he s and c a refully disconnec t t he

pow er wire s and the ground wire from the dispenser motor.

6. Wi t h the conv e yor assembl y out of the cof fee make r, r emove the four

screw s secur ing the motor to t he bott om of the c o nve yor using a Philips

screwdriver.

NOTE: The milk system must be purged of all milk product prior to

removing the cover and/or the contour panel.

Figure 4

Figure 5

Page 35

35

Cleaning the Milk Conveyor

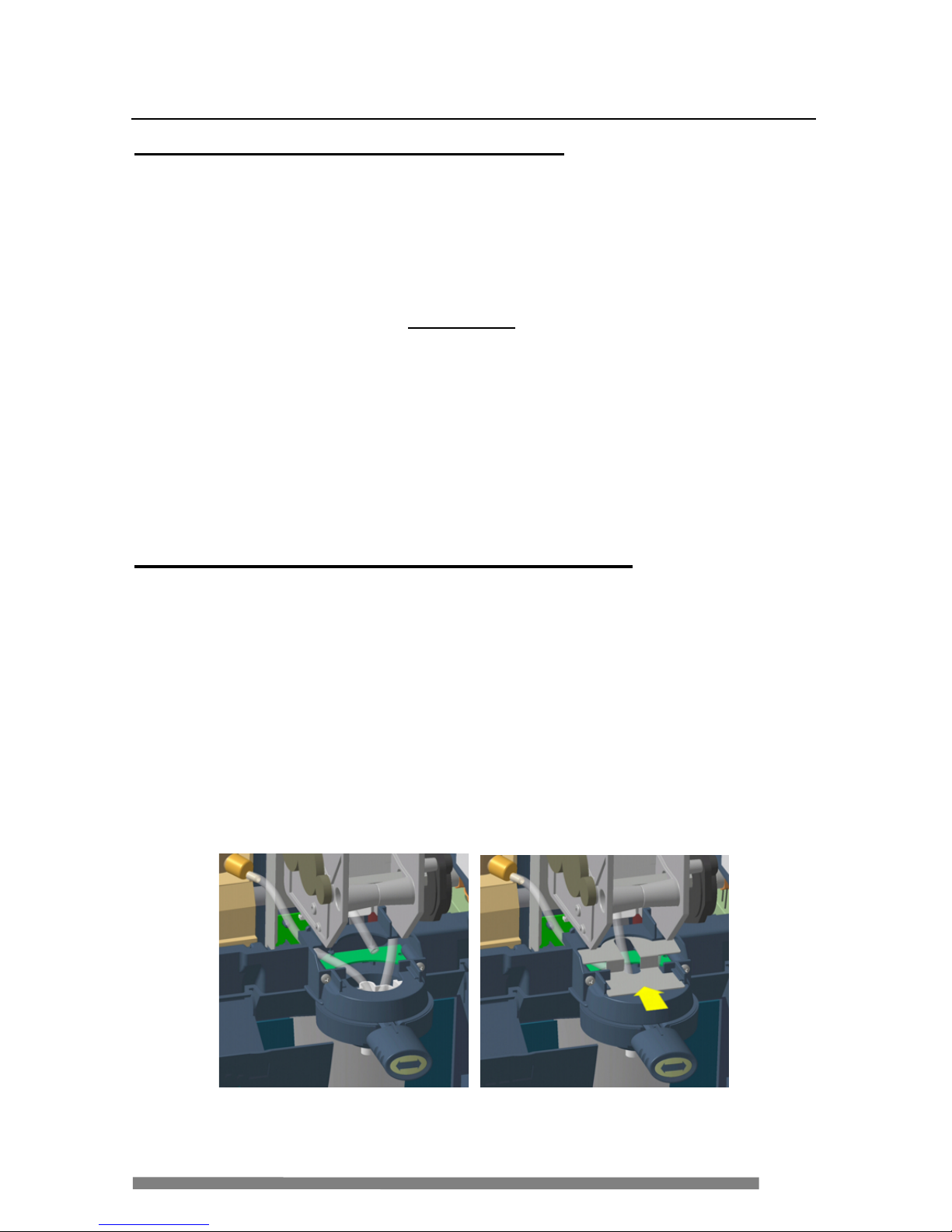

7. Caref ul ly i nsert the screwdriver into the c onve yor through the small grill

wher e the milk cani ster w ould sit (figure 6).

8. P osition the e nd of the screwdrive r a ga inst the a uge r (spir a l) inside the

conveyor to prevent it from turning (f i gure 6a).

9. I nsert a qua rter (coi n) into the coupling at the bottom of the c onve yor.

10. With the screwdr iver j amming the auge r in place, turn the a uge r coupl ing

clockwise

to loosen it. O nc e it is l oose, it ca n be removed by hand by

turning i t clockwise

until it comes off.

11. Once the coupli ng is r emoved, remove the screwdriver from the grill a nd

turn the conveyor a ssembly up side down. The auge r will now slide out of

the c onveyor.

NOTE: There is a s mall O-ring at the bas e of the auger (se e f ig ure

6a). Be v ery c ar ef ul not to lose this O-r ing as it mus t be re-installed

prior to re-assembling the conveyor.

Figure 6

Figure 6a

O-Ring

Page 36

36

Cleaning the Milk Conveyor

12. Fill a clean spray bottle w ith a maximum of 2 ml (0.06 fl. oz) of SC

Johnson J-512 sanitizing solution per one lite r (34 fl. oz) of water. I f a

spra y bottl e is not ava il a ble, mix the sani ti z ing solution in a clean le a kpr oof container.

13. Rinse the auger wi th fresh running w a ter, then spray (or wipe using a cl ean

cloth) the a uge r with sanitizing solution.

14. Ri nse the c onveyor with fresh r u nning wa te r, then spr a y (or wipe using a

clean cloth) the interior of the conveyor with sanitizi ng solution.

15. Set the auger and the conveyor aside until t he y a re completely dry.

16. Once the auge r and conveyor ar e completely dry, mak e certai n the small

O-ring is installed at the bot tom of the a uge r, and a pply some f ood grade

lubr icant to it (and t he surrou nding a rea) .

17. Insert the auger into the convey or, and re -instal l the coupli n g by turning

the c oupli ng counter-clockwise

. The coupling must be hand-tightened

only

– do not use any tools to tighten i t .

18. Install the four screws securing the motor to the bot tom of the c onve yor

usi ng a Philips screwdriver.

19. Re-connect t he wiring to the lower IR sens or boards (blue wires – they

must be routed be hind the conveyor) and t he power wires and ground wire

to the dispenser motor.

20. Install the conveyor assembl y on to t he base of the machine with four

screws.

21. Reconnect the wiring to the upper IR sensor boards (red wires – they must

be routed in front of the conve yor).

22. Insert the wiring harness into the c li p on the right side of the co nve yor, and

cl ose the cl ip to secure the harness.

23. Re-install the vacuum cap onto t he t op of the conveyor.

24. Cl ose the top cover, and re -i nstall the tw o screw s to secure it.

25. Cl ose the water d oor.

26. Insert a m i lk canister and close the milk door .

27. Conn e c t t he service c ord to the wall outlet.

28. The next time the m achine i s switched on, the convey or will activate to

prime the system with milk.

NOTE: When c losing the cov er, it may be nec essary to press dow n slightly

on the lef t and r ight sides of the cov er w hile tightening the scr ew s , otherw ise

the two doors may not close p roperly.

Page 37

37

Removing the Coffee Maker

Should the coffee ma ker need to be relocated or removed for any reason, the milk

sys tem and the water system must

be purged (emptied) beforehand. This is

especia lly im portant if the coffee ma ker i s to be transpor te d t o a nother location.

Empty the Milk Conveyor

1. Switch OFF the po wer to the coffee maker.

2. R emove the mi lk canister.

3. Remove the waste bi n.

4. Con ne c t t he programmer to the coffee maker (see “Connecting the

Programmer” section).

5. S witch the power ON .

6. Sc roll to the “

EMPTY CYCLE” menu and pr e ss <START>. Th e top l ine of

the display now r e a ds “

EMPTY MILK”.

7. Place the w aste bin at the dispensing spout a rea.

8. Press <

START> to activate the cycl e. The message on t he display now

reads “

EMPTYING – PLEASE WAIT”.

9. Once compl ete, the coffee mak er will automati cally proceed to the

“

EMPTY WATER” menu.

10. Using a Shop-Vac type vacuum, pl ace the vacuum nozzle dir ectly over

the mi lk canister receptacle (the grill onto whi c h the milk canister lid

check valve engages).

11. Switch

ON t he va c uum and a llow a pproxim a t e ly one minute fo r the

vacuum to pul l any r ema ining milk from the c onve yor sy stem.

NOTE: As a saf ety precaution, the milk door must remain closed

throughout the entire procedure. If the door is opened, the auger w ill

stop.

NOTE: The next time the milk canister is re-inserted (after running the

“EMPTY MILK” cycle), dispense two cups of Caffè Latte or Cappuccino to

completely refill the conveyor.

WARNING: Do n ot ins t a l l t he dr ai n inse r t into the dr ai n fi tt i ng du r ing

the “

empty milk

” cycle.

Page 38

38

Removing the Coffee Maker

Drain the Water (Reservoir and Heater)

If continuing from the “EM PTY THE MILK CON VEYOR” section on the previous page,

proceed directly to step #4.

1. Dis connect the water source (if applicable).

2. Wi th t he power OFF , remove the w aste bin a nd c onnect the programmer to

the cof fee mak er and switch the p ow er ON.

3. Scroll to the “

EMPTY CYCLE” menu and pr ess <START>. Scroll again until

the display r e ads “

EMPTY WATE R – PRESS START ”.

4. Place the waste bin below the dispe nsing s pout .

5. Press <

START> t o activate the cycle. The messa ge on t he display n ow read s

“

EMPTYING – PLEASE WAIT”.

6. When reservoir is empty, the display will read “

INSTAL L DRAIN INSERT –

STA RT”. Install the drain insert into the drain fitting underneath the base.

a) C arefull y po sition the coffe e mak er so that only the r ight rear leveler

is ‘hanging’ from the end of the counter top.

b) Locate the drain fitting beside the right rear leveler a nd pl ace the

was te bi n directly under it.

c) While pressing the lock latch, install the drain insert into the fitting

an d lock it i n pl ace by releasing t he loc k l atch.

7. Pr ess th e <

START> button to acti vate the dr ain cy cle. Water will now start

dr a ini ng from the inse rt.

8. The display now read s “

emptying – power off when done”. Once the water

i s emptied, switch of f the power t o the coffee maker.

9. R emove the drain insert and dis con nect t he service cord f rom t he w all ou tlet.

Page 39

39

Removing the Coffee Maker

Storing the Coffee Maker

Should the coffee make r need to be stored indefin it ely, or if it will not be us ed for a

week o r more, precaut ion s must be taken to prevent damage to internal compo nents

of t he e quipment.

To properly store the coffee maker, perform these simple procedures and the

equipment will be r eady to use when it is to be installed at a c ustomer l oc a tion.

1. R emove the mi lk canister.

2. Empty the milk c onve yor (see page 37 for detai led instruct ions) .

3. Drain the water fr om the reservoi r and heater (see page 38 for detail ed

instructions).

4. U sing a Shop-Vac type vacuum , place the vacuum nozzle di rectly over

the mi lk canister receptacle (the grill ont o whic h th e milk canister lid

chec k valve enga ge s). It is not nec essary t o o pe n the top cover of t he

coffee ma ker – only the milk door.

5. Switch

ON t he va c uum and a llow a pproxim a t e ly one minute fo r the

vacuum to pul l any r ema ining de hydrated milk from the con ve yor

system.

6. Empty and clean t he waste bin.

7. Empty and clean t he drip tra y.

WARNING: If all t he dehydrated m i lk is not remove d from t he coffee

maker prio r to storage or a pr o lo nge d period of no n-use, it will harden

and dama g e t h e mil k co nv eyo r a nd whi pp er.

NOTE: Milk can also ac cumulate ins ide the unit and should be c leaned us ing a

Shop-

Vac type vacuum . This requires removal of the top cover and contour panel

and can be done befo re storing the unit (r ecommended), or before installing it.

Page 40

40

General Information

• Most of the electrical components in the Espresso Café are low vol tage

(and not

120 volts AC ). Never connect the se electri cal components to 120

volts AC .

• When the Espresso Caf é i s powered up, a small quantity of water will be

dispensed from the spout. This is a normal as air i s being purged from the

water system.

• The water system is pressurized and it is equi pped with a pressure rele ase

f itting. Should the pr e ssure e xceed 185 psi, the fitting will automatically

open to rel ease the excess pressure.

• Drain the water from the c offee maker bef ore replac ing any

component in the w at er lin e or a c o n trol board.

• I t is not nece ssar y to insta ll a backflow prevention system as one is already

incorporated in the inlet valve.

• When inst a ll ing the fittings i nside the coffee maker, t he y should be ha nd-

tightened, and then tighte n e d a n a ddi tional ¼ turn w ith a wrench. If a

f itting i s leaking, ti ght e n the fit ting i n ¼ t urn intervals until the leaking

stops.

• The milk canister sys te m uses sensor s to dete c t when the product level runs

l ow. These sam e sensors are use d to prime the system once a new milk

canister is installed.

o When the milk canister is initially installed, or when replaced, the milk

dispenser motor may automatically activate to prime the milk through the

system. Once primed, the dispenser motor will stop automatically.

o When the milk canister empty, any selections requiring milk are disabled and

the green START button will not illuminate.

• If the cover of the c offee make r is open i n a ver y brightly l it room ( for

testing pur poses), the optical sensors may gi ve in a c c urate r e adings. If t his

i s the case, te st the coffee maker with the cover closed.

• To simplify moving the coffee make r, only the fr ont levelers are equipped

w ith non-sk id pads. Simply li ft the f ront of the coffee ma ker, and slide it

w here requir e d. When the front is place d ba c k onto the countert op, the

non-sk id l evelers prevent the unit from sliding.

• All the w i ring in t he coffee ma ke r is labeled point-to-point to identi fy the

component(s) on which they a re connected.

• When the wate r heater is first use d, a slight odor may be detected. This is

nor mal and the odor w i ll qui ckly dissi pa t e .

Page 41

41

Replacing Major Components

Opening t h e Cover

Opening the cover allows access to the interior of the Espresso Café. Some

ma intenance or s ervice can be performed with the cover open, but in other cases the

cover needs to be removed completely (see “Removing the Cover and Contour

Panel” on page 42).

1. After unpl ugging the service cord, open the milk door and remove the mi lk

canister, then open the water door.

2. O pening the doors exposes the screws securing the cover to the coffee

maker’s mainfra me. Remove these two screws (figu re 1).

3. Lift the front of the c ove r until it is comple tely open (figur e 2). The hi nge s

at the rear of the cover will keep it open.

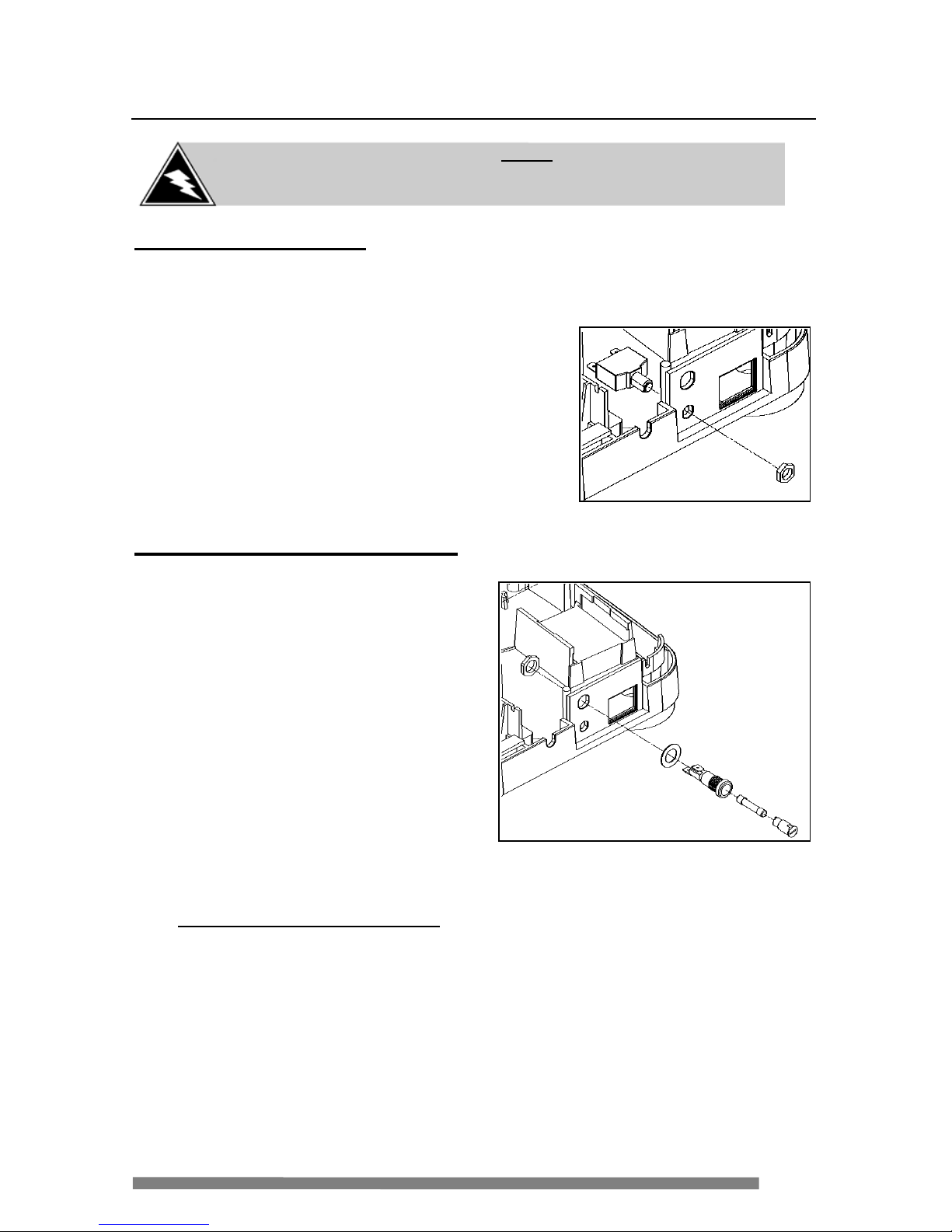

WARNING: Switch OFF the power to the coffee maker,

disconnect the service c or d a nd dr a in the w a t e r s yst e m pr ior

to servicing the equipment.

NOTE: When c losing the cov er, it may be nec essary to press dow n slightly

on the lef t and r ight sides of the cov er w hile tightening the screws, otherwise

the two doors may not close p roperly.

WARNING: T he majority of the electrical components in the

Espresso Café are low vo ltage (and not 120 volts AC) . Never

conn ect t hese elect rical compon ents to 120 volts AC.

Figure 1 Figure 2

Page 42

42

Replacing Major Components

Rem oving the Cov er and Contour Panel

For many repair procedures, removing the cover provides suffic ient acces s to coffee

maker components. For greater access to components, the contour panel can also be

removed.

Removing the Cover

1. Af te r unplugging the ser vice cord, ope n t he milk door a nd remove the

mi lk canister, then open the water door.

2. O peni n g the doors exposes the screws securing the cover to the coff e e

mak er’ s m ainframe. Remove these two screw s.

3. Lift the front of the c ove r until it is comple tely open. The hinges at the

rear of the cover will keep i t open.

4. Disconnec t t he wiring ha rness from the <

START> but ton boa rd and t he

System S tatus LE D panel. Disconne ct the inline connec tor for the milk

door IR sensor .

5. Remove the wiring from the routi ng c lips built i nt o the unde rside of the

cover.

6. P ull the cove r forw a rd then lif t it u pwards to remove it from the quick-

release hi nges.

NOTE: When c losing the cov er, it may be nec essary to press dow n slightly

on the lef t and r ight sides of the cov er w hile tightening the scr ew s , otherw ise

the two doors may not close p roperly.

Page 43

43

Replacing Major Components

Removing the Contour P a nel

7. Remove the drip tray and r ot a te t he coffee ma ker 90 degrees.

8. From the rear of the coffee ma ker, remove the two screws located at the

exterior bottom of the c on tour panel.

9. Remove the screw above t he bridge mount at the inter ior top of the

contour pane l (inside ce nt e r of pane l).

10. Rem ove the two screws securing the contour pa ne l to the mainfr ame.

These screws are located at the outer side of both fli p door areas.

11. Slide the contour panel towar ds the rear unt il it is fr e e from the

mainfra me.

NOTE: The two doors are simply snapped into place on the mainf r ame. No

tools are required to install replacement doors.

Page 44

44

Replacing Major Components

Brewer

With the cover already open:

1. Disconnect the wir ing har ne ss connector from the bre wer cir c u it boar d.

2. Disconnect the brewer motor harness.

a) Open the t wo cli ps securing the ha rness to the s upport a nd remove

the brewer w iring.

3. R emove the screw securing the left side of the brewer to the mainframe.

4. Lift the front of the brewe r and pu ll t he brewer str a ight up and out (note

that the right side of the br e wer is secur e d to t he mai nframe by snap clip).

5. I nsert the new brewer assembly making sur e t he right side snaps i nto t he

mainfra me. Secure the l eft si de to the m ainfram e with a screw.

6. R econnect all wiring harnesses.

Brewer Heads

Wi t h the b rewer in the open position:

1. Grasp the front and rear of the inlet or outlet

head.

2. P ull the hea d straight up and out of the brewer.

3. Dis connect the tubing on the inlet head

by opening the plastic clip and pulling

of f the tubing.

4. Prior to re-installing the brewer head

assemblies, insert the brew hose into

the pour s pout.

5. Align and push the brewer heads into

position.

NOTE: Fro m this point forward, it is assumed the coffee maker cover and/or

contour panel is removed for servicing and pow

er is OFF. Once service is

complete, re-install the coffee maker cover and contour panel.

Page 45

45

TORX

Screws

Screws

Replacing Major Components

Brewer Motor

1. Disconnect the brewer wiring

harnesses and remove the brew er.

2. Remove the three la rge

TO RX screws

securing the motor to the brewer

assembly.

3. P ull the motor straight out.

4. Secure the new brewer motor to the

brewer assembly with the three

TO RX

screws.

5. Re-install the brew e r and reconnect the brewer wiring harnesse s.

Sel ection Ring & Board

1. Wi t h the cover open, remove the spi ll pla t e a nd spout.

2. Remove the two screws from the

retainer securing the s election ring

to the mainfra me.

3. Remove the retainer, and pull out

the selection ring.

4. Dis connect the wiring harness from

the rear of the s election board and

pull the board out to re move it.

5. Slide the new sel e c t ion boar d into position.

6. In s ta ll th e selection ring and secure it to the mainframe by screwing the

retainer in place.

7. Connect the wiring har ne ss t o t he rear of the selection board.

8. I nstall the spout a nd t he spill plate.

Page 46

46

Replacing Major Components

Wa ter Heater

1. Drain the water from the coffee maker (see page 38).

2. Disconnect the two el ement wires at the bottom of the heater.

3. D isconnect the ground wir e at the side of the hea t e r.

4. Remove the thermal cut-off switch assembly by removing t he t wo hex nuts

securing the retai ning bracket to the heater as sembly.

5. D isconnect the lar ge inl e t fitting at the bot tom side of the hea ter.

6. D isconnect the outl e t fit ting at the top side of the heater.

7. Remove the two hex nuts on top of the heater securi n g it to the heater

support. The tempera ture probe c an now a lso be removed.

8. Pull the hea te r towa rds the r ear a n d the n t o the side to remove it.

9. Re-i nstall the new heater (making sure the t e mpera t ure probe is also

installed on top of the he a te r) and connect all the w ater fittings.

10. Re-install the thermal cut-off switch assembly.

11. Reconnect the red & black wir e pair to the the rmal cutoff switch (if they

were disconnec ted).

12. Reconnect the white & bl ack wire pair to the heater assembl y termi nals

identifie d by the plastic red

collars (diagonally). Do not connect the

wiring to the ter minals with the white collars .

NOTE: If dis connecting the ther mal cut-off sw itch w ires , hold on to

the body of the switch to relieve any excess pressure that may

damage it when the wires are pulled.

WARNING: Use caution when servicing the water h eater as it may be

ex tremely hot and can cau se sev ere bur ns.

NOTE: When any component of the water system is replaced, a quick-rinse

cycle must be perfo rmed to purge air out of the sy stem.

Red

Collars

Page 47

47

Fla t side up

Replacing Major Components

Temperature Probe

1. Disconnect the inline

connector on the temperature

probe wiring har ne ss.

2. Loos en the hex nuts securing

the top of the heater to the

heat e r su pport.

3. Remove the old temperature

probe.

4. Slide the ring terminal of the new temperature probe (the flat side must be

up) ove r the thr e aded stud ne xt to the out let of t he heater.

5. Place the ceramic washer over the temperature probe ring terminal.

6. I nstall the heate r sup port over t he two thre a de d stud s on top of the heater.

The te mpera t ure probe ring terminal a nd flat wa sher must be between the top

of the heater and the heate r sup port.

7. Tighten the two hex nuts securing the top of the he a t e r to the heate r supp ort.

8. Reconne ct the inline connec to r on the tempera t ure probe wiring harne ss.

Th erma l Cut-Off Switch

1. Disconnect the two wires from the therm al cut-off switch.

2. Remove the thermal cut-off switch

assembly by removing the two hex nuts

securing the retaining bracket to the

heater assembly.

3. Install the n ew therma l cut-off sw itch and

secure it in place by installing the

r e t a ini ng bracket with two hex nuts.

4. Reconnect the two wires to the thermal

cut-off switch.

NOTE: When disc onnec ting the thermal c ut-off switch wires, hold

on to the body of the switch to relieve any excess pressure that may

damage it when the wires are pulled.

WARNING: Use caution when servicing the water h eater as it may be

ex tremely hot and can cau se sev ere bur ns.

Page 48

48

Replacing Major Components

Wa ter Reservoir

1. Drain the water from the coffee ma ker (see page 38).

2. R emove the inlet tubing connected on the bre wer side of the reservoir.

3. Remove the outlet tubing con n e c te d to the bottom of the re servoir.

4. Disconnect the float switch w iring (inline c onne c t or).

5. Remove the lar ge screw securing the front of the re servoir to the suppor t.

6. R emove the other large screw securing the side of the reservoi r to the

support.

7. R emove the water reservoir .

8. Install the new reservoi r and secure i t in place wi th the two screws.

9. Reconnect the inlet tubing on the brewe r si de of the r e servoir .

10. Reconnect the outl e t tubing to the bottom of the reservoir.

11. Install a ne w rubber gasket to the top of the reservoir.

NOTE: When any component of the water system is replaced, a quick-rinse

cycle must be perfo rmed to purge air out of the sy stem.

Page 49

49

Replacing Major Components

Water Level Float Switch

1. Loosen and remove the plastic hex nut securing the switch to the reservoir

– l oc ated at t he outside bottom of t he reservoir.

2. U sing wir e c ut ters, cut the t wo float switch w i res at the inli n e c onne c t or

and discard the c onnector .

3. F rom the inside of the re servoir, pull the switch str a ight out.

4. Remove the o-ring installed between the float switch and the water

reservoir. The o-ring may be stuck the bottom of t he float switch or i t may

have fal len into the water reservoir.

5. P a ss t he wiring from the new swit c h from t he inside of the reservoir t o th e

outsid e (so i t is com ing out the bottom) .

6. After making sur e the o-ring i s installed on the bot tom of the float switch,

secure the sw itch into the bot tom of t he reservoir w ith the plastic hex nut.

Hand-tighten only as over-tightening will str ip the thre ads.

7. I nsert the wiring terminals into t he c onnector provided.

8. Reconne ct the inline connec to r.

NOTE: Insert the w ires into the connector only after they have

been passed through the bottom of the reservoir.

NOTE: Once the float switch wire s are cut from the connector, the

switch can no longer be used and must be replaced with a new one.

Install the connector only

after the float is installed

inside the reservoir.

Page 50

50

Replacing Major Components

Inlet Va lve

1. Drain the water from the coffee ma ker (see page 38).

2. D isconnect the inl e t fitt ing from the valve.

3. Disconnect the two w ires from each coil (f our wires total ).

4. D isconnect the tubi ng from the i n let valve.

5. Lift the v a lve stra ight up and out.

6. I nstall the new valve by slidi ng it dow n int o the channel at the rear of the

base.

7. Connect the t ubin g to t he inl e t val ve.

8. Connect the wiring to the inlet va lve (the tw o longer wires connec t to the

rear coil of the val ve) .

NOTE: The inlet valve is equipped w ith a built-in backflow prevention

system as well as a flow regulator.

NOTE: When any component of the water system is replaced, a quick-rinse

cycle must be perfo rmed to purge air out of the sy stem.

Page 51

51

Replacing Major Components

Outlet Valves

1. Drain the water from the coffee ma ker (see page 38).

2. Disconnect the wiring from each valve coil (three pairs of wires).

3. D isconnect the tubi ng from the outlets of the hot water and m ilk valves.

4. Remove the c offee tubing at the brewer head by opening the plastic clip.

5. Disconnect the large fitting from the heater assembly.

6. Lift the v a lve assembly up and out.

7. Place the new outlet valve assembly in position.

8. Connect the lar ge fi tt ing to the hea te r assembl y.

9. Connect the t ubin g going to the whipper bow l.

10. Conn e c t t he c offee tub ing (pa rt of the outlet valve assembly) to the brewer

head and secure it in pl ace wi th the plastic clip.

11. Connec t t he wiring to e a c h of the valve coil s (thr e e p ai rs of c olor coded

wires).

White Wires

Blue Wires

R ed Wires

Milk Valve

Water V alv e

Coffee Valv e

NOTE: The out let valv es ar e available only as an assembly ( three v alv es

with fittings installed). Individual valves are not available.

WARNING: Use caution wh en servicing the outlet valv es as they may

be extremely hot and can cause seve re burns. The water system must

be drained before servicing this component.

NOTE: When any component of the water system is replaced, a quick-rinse

cycle must be perfo rmed to purge air out of the sy stem.

Page 52

52

Replacing Major Components

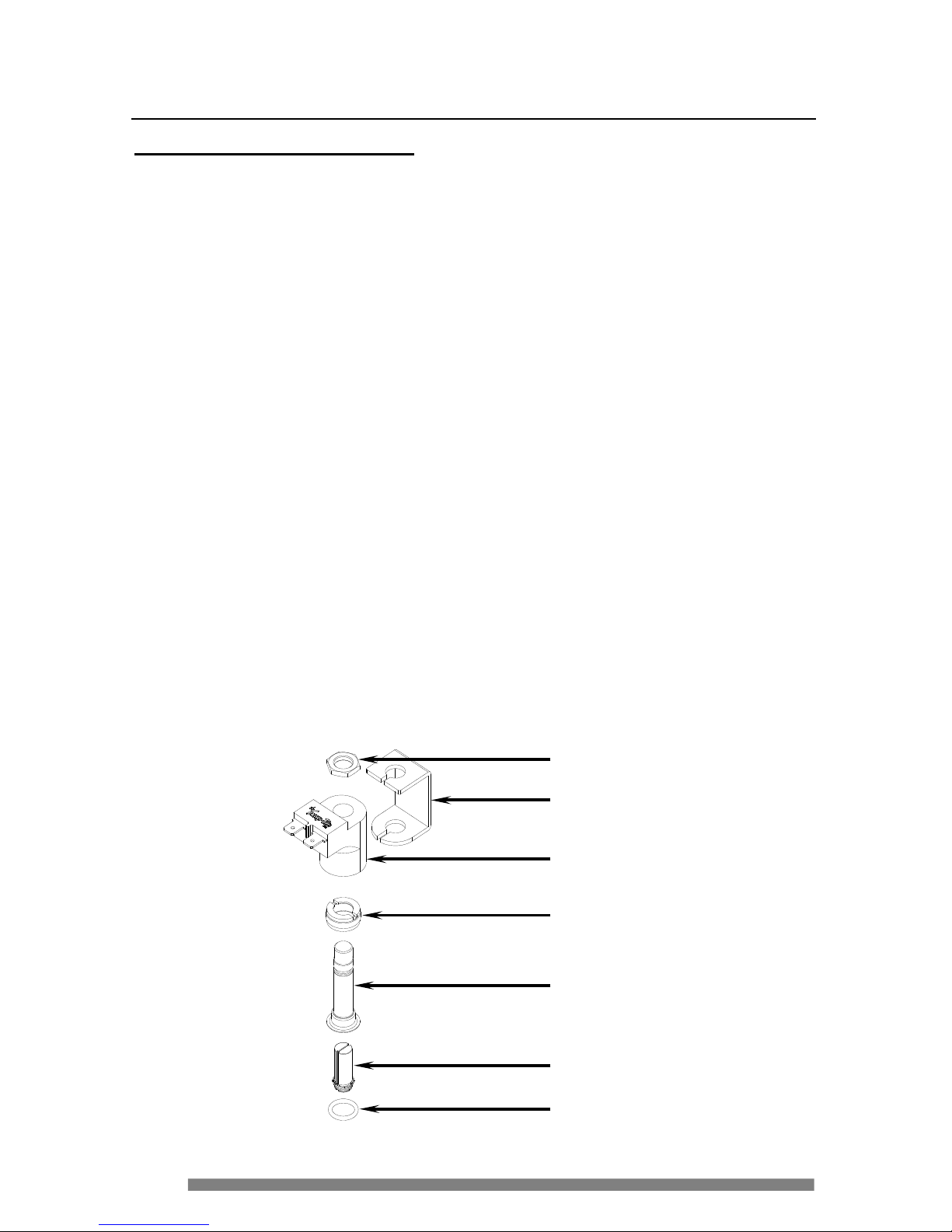

Rebuilding an Outlet Valve

This procedure outlines the steps involved in disassembling, rebuilding and

reass embling a Snap-Tite outlet valve. Required materia ls are a 3/8” socket wrench,

a 3/8” drive torque ratchet, and a special Snap-Tite flange socket tool for 3/8”

flanges (VKI p /n – 100431-001). Th is procedure can be performed with the valve

assembly installed in the coffee m aker.

1. With the unit drained of all water and the cover removed, disconnect the wires from

the outlet valve.

2. Using a 3/8” socket wrench, remove the coil nut. Lift the coil and strap above the

plunger housing.

3. Using the special Snap-Tite flange socket, loosen and remove the flange nut.

4. Slowly lift and remove the plunger housing.

5. Inspect the orifice in the valve body to ensure it is free of nicks, scratches and

debris. Remove any debris by blowing it out.

6. Remove the old o-ring and replace it with a new one. Be sure that the o-ring is

seated properly for re-assembly.

7. Install a new plunger assembly and re-install the plunger housing.

8. Re-screw the flange nut on the plunger housing, first by hand and then tighten

using a 3/8” drive torque ratchet set to 35-45 inc h pounds of torque.

9. Replace the coil and strap over the plunger housing.

10. Install the coil nut onto the plunger housing, then tighten using 3/8” drive torque

ratchet set to 15-25 inch pounds.

11. Reconnect the wires, replace the cover and contour panel, and switch ON the coffee

maker to test for proper operation.

Coil Nut

Strap

Coil

Fla nge Nut

Pl unger Housing

Pl unger Asse m bly

O-Ring

Page 53

53

Options

Board

Control

Board

Replacing Major Components

Control Board & Options Board

1. D isconne ct all of th e w iring harne ss co nnectors a t the r ear of the ci rcuit boards

and disconnect the two ground w ires co nne c ted t o the termina ls on the heat

sink.

2. S li de the board assembl y about one inch towards the rear of the unit, and lift it