YYoouurr ssaaffeettyy aanndd tthhee ssaaffeettyy ooff ootthheerrss

iiss vveerryy iimmppoorrttaanntt..

We have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that

can kill or hurt you and others.

All safety messages will be

preceded by the safety alert

symbol and the word “DANGER” or

“WARNING”. These words mean:

YYoouu wwiillll bbee kkiilllleedd oorr sseerriioouussllyy iinnjjuurre

edd iiff yyoouu

ddoonn’’tt ffoollllooww iinnssttrruuccttiioonnss..

YYoouu ccaann bbee kkiilllleedd oorr sseerriioouussllyy iinnjjuurreedd iiff

yyoouu ddoonn’’tt ffoollllooww iinnssttr

ruuccttiioonnss..

All safety messages will identify the

hazard, tell you how to reduce the chance

if injury, and tell you what can happen if

the instructions are not followed.

INSTALLATION

INSTRUCTIONS

BUILT-IN SIDE-BY-SIDE REFRIGERATOR/FREEZER

Retain for Future Reference

VIKING RANGE CORPORATION

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

IMPORTANT - PLEASE READ AND FOLLOW

Make sure that incoming voltage is the same as unit rating. An electric rating plate specifying voltage, frequency, wattage,

amperage, and phase is attached to the product.

To reduce the risk of fire, electric shock, or injury to persons, installation work and electrical wiring must be done by qualified

people in accordance with all applicable codes and standards, including fire-rated construction.

The installer should leave these instructions with the consumer who should retain them for local inspector’s use and for

future reference.

GENERAL INFORMATION

It is your responsibility to :

-comply with installation specifications and dimensions

-properly install refrigerator

-remove any moldings or decorative panels that prevent the refrigerator

from being serviced

-make sure that you have these materials (not provided with your

refrigerator), which are necessary for proper installation:

1/4” (6 mm) copper tubing with shutoff valve

6 - #8 x 3” (7.6 cm) wood screws (Longer screws may be required.)

1 - Saddle valve (Do not use self-piercing feature of the valve)

-assure that floor will support refrigerator, door panels and contents

(approximately 1200 pounds [540 kg])

-provide a properly grounded electrical outlet

-assure that location will permit appliance doors to open 90

o

minimum

TTIIPP OOVVEERR HHAAZZAARRDD

RReeffrriiggeerraattoorr iiss ttoopp hheeaavvyy aanndd ttiippss eeaassiillyy

wwhheenn nnoott ccoommpplleetteellyy iinnssttaalllleedd..

KKeeeepp ddoooorrss

cclloosseedd uunnttiill rreeffrriiggeerraattoorr iiss

ccoommpplleetteellyy iinnssttaalllleedd aanndd sseeccuurreedd ppeerr

iinnssttaallllaattiioonn iinnssttrruuccttiioonnss..

UUssee ttw

woo oorr mmoorree ppeeooppllee ttoo mmoovvee aanndd

iinnssttaallll rreeffrriiggeerraattoorr.. FFaaiilluurree ttoo ddoo ssoo ccaann

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

MMoosstt ooff tthhee rreeffrriiggeerraattoorr’’ss

wweeiigghhtt iiss aatt tthhee ttoopp.. EExxttrraa ccaarree

iiss nneeeeddeedd wwhheenn mmoovviinngg tthhee

rreeffrriiggeerraattoorr t

too pprreevveenntt ttiippppiinngg..

UUssee ccaarrddbbooaarrdd sshhiippppiinngg

mmaatteerriiaall oorr ppllyywwoooodd uunnddeerr

rreeffrriiggeerraattoorr uunnttiill iitt iiss iinnssttaalll

leedd iinn

tthhee ooppeerraattiinngg ppoossiittiioonn ttoo

pprrootteecctt fflloooorr ssuurrffaaccee..

WARNING

DANGER

WARNING

2

BASIC SPECIFICATIONS AND DIMENSIONS - PROFESSIONAL MODELS

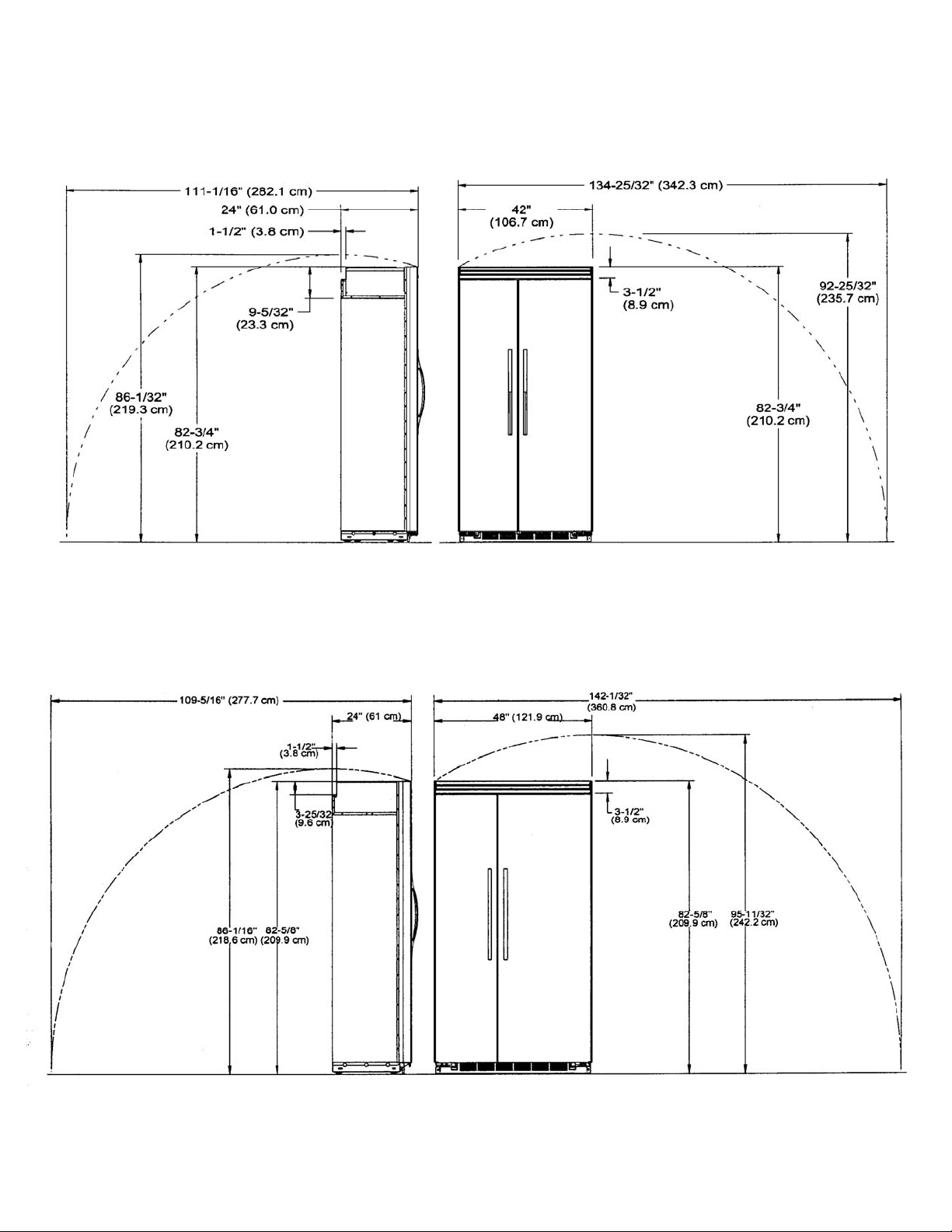

42” W. MODELS

48” W. MODELS

DDEESSCCRRIIPPTTIIOONN VVCCSSBB448833 VVCCSSBB448833DD

Overall Width 48” (121.9 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To rear edge of side trim 22 3/16” (56.4 cm)

To front of top grille 24 11/16” (62.7 cm)

To end of handle 27 1/4” (69.2 cm)

Cutout Width 47 1/2” (120.7 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 18.5 cu. ft. (524 liters) 17.9 cu. ft. (507 liters)

•Freezer 8.9 cu. ft. (252 liters) 8.5 cu. ft. (241 liters)

•Total Capacity 27.4 cu. ft. (776 liters) 26.4 cu. ft. (748 liters)

Approximate Shipping Weight 650 lbs. (292.5 kg)

DDEESSCCRRIIPPTTIIOONN VVCCSSBB442233 VVCCSSBB442233DD

Overall Width 42” (106.7 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To rear edge of side trim 22 3/16” (56.4 cm)

To front of top grille 24 11/16” (62.7 cm)

To end of handle 27 1/4” (69.2 cm)

Cutout Width 41 1/2” (105.4 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 15.0 cu. ft. (425 liters) 14.5 cu. ft. (411 liters)

•Freezer 9.0 cu. ft. (255 liters) 8.6 cu. ft. (244 liters)

•Total Capacity 24.0 cu. ft. (680 liters) 23.1 cu. ft. (654 liters)

Approximate Shipping Weight 525 lbs. (236.2 kg)

3

BASIC SPECIFICATIONS AND DIMENSIONS - DESIGNER MODELS

42” W. MODELS

48” W. MODELS

DDEESSCCRRIIPPTTIIOONN DDDDSSBB448833 DDDDSSBB448833DD

Overall Width 48” (121.9 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To rear edge of side trim 23 13/16” (60.5 cm)

To front of top grille 24” (61.0 cm)

To end of handle 26” (66.0 cm)

Cutout Width 48” (121.9 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 18.5 cu. ft. (524 liters) 17.9 cu. ft. (507 liters)

•Freezer 8.9 cu. ft. (252 liters) 8.5 cu. ft. (241 liters)

•Total Capacity 27.4 cu. ft. (776 liters) 26.4 cu. ft. (748 liters)

Approximate Shipping Weight 650 lbs. (292.5 kg)

DDEESSCCRRIIPPTTIIOONN DDDDSSBB442233 DDDDSSBB442233DD

Overall Width 42” (106.7 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To front edge of side trim 23 13/16” (60.5 cm)

To front of top grille 24” (61.0 cm)

To end of handle 26” (66.0 cm)

Cutout Width 42” (106.7 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 15.0 cu. ft. (425 liters) 14.5 cu. ft. (411 liters)

•Freezer 9.0 cu. ft. (255 liters) 8.6 cu. ft. (244 liters)

•Total Capacity 24.0 cu. ft. (680 liters) 23.1 cu. ft. (654 liters)

Approximate Shipping Weight 525 lbs. (236.2 kg)

4

BASIC SPECIFICATIONS AND DIMENSIONS - FULL OVERLAY MODELS

42” W. MODELS

48” W. MODELS

DDEESSCCRRIIPPTTIIOONN DDFFSSBB448833 DDFFSSBB448833DD

Overall Width 48” (121.9 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To front edge of side trim 23 13/16” (60.5 cm)

To front of top grille 24 3/4” (62.9 cm)

To end of handle 24” (61.0 cm)*

Cutout Width 48” (121.9 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 18.5 cu. ft. (524 liters) 17.9 cu. ft. (507 liters)

•Freezer 8.9 cu. ft. (252 liters) 8.5 cu. ft. (241 liters)

•Total Capacity 27.4 cu. ft. (776 liters) 26.4 cu. ft. (748 liters)

Approximate Shipping Weight 650 lbs. (292.5 kg)

DDEESSCCRRIIPPTTIIOONN DDFFSSBB442233 DDFFSSBB442233DD

Overall Width 42” (106.7 cm)

Overall Height from Bottom Min. 82 3/4” (210.2 cm) to Max. 84 1/16” (213.5 cm)

Overall Depth from Rear To front edge of side trim 23 13/16” (60.5 cm)

To front of top grille 24 3/4” (62.9 cm)

To end of handle 24” (61.0 cm)*

Cutout Width 42” (106.7 cm)

Cutout Height 82 7/8” (210.5 cm) min.; 84 1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with

grounded 3-prong plug attached to product.

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi;

maximum 120 psi

Overall Interior Dimensions

•Refrigerator 15.0 cu. ft. (425 liters) 14.5 cu. ft. (411 liters)

•Freezer 9.0 cu. ft. (255 liters) 8.6 cu. ft. (244 liters)

•Total Capacity 24.0 cu. ft. (680 liters) 23.1 cu. ft. (654 liters)

Approximate Shipping Weight 525 lbs. (236.2 kg)

*Full overlay models fit flush in 25” (63.5 cm) deep cabinet openings. They can be installed in standard 24” (61.0 cm) deep

openings. The door faces and top grille will protrude 34” (1.9 cm) into the room.

5

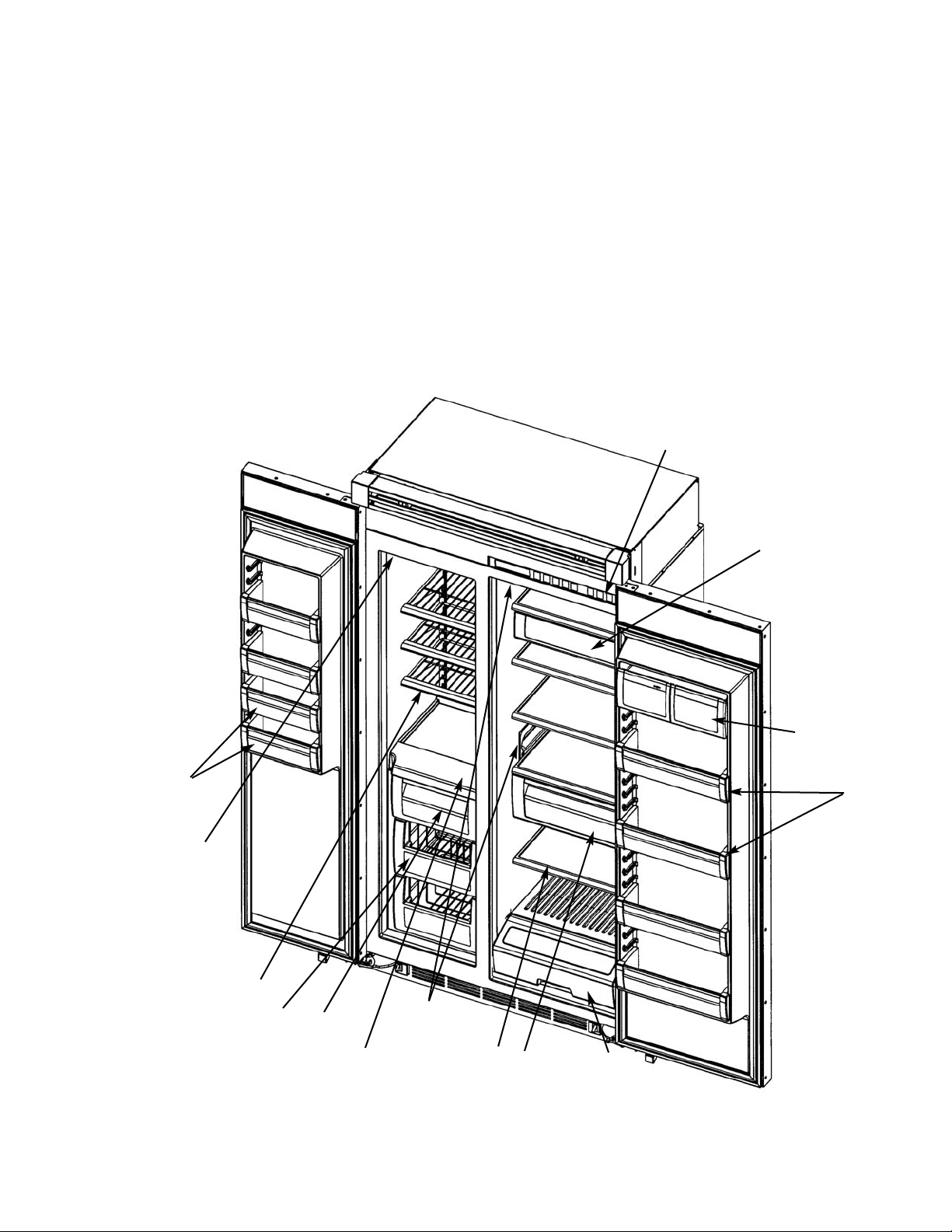

FEATURES OF YOUR REFRIGERATOR

(NON-DISPENSER MODEL)

1. Electronic controls

2. Dairy compartments (2)

3. Adjustable door bins (4)

4. Meat SavorTM/Produce Drawer (1)

5. Moisture-controlled produce drawer

42” W. models (1) full width

48” W. models (2) half width

6. Spillproof shelves (5)

7. Deli Compartment drawer

42” W. models (1) full width

48” W. models (2) half width

8. Non-adjusting freezer shelf (1)

9. Ice bucket (1)

10. Glide-out freezer baskets (2)

11. Adjustable freezer shelves (3)

12. Adjustable freezer door bins (4)

13. Lights

11

44

33

1133

22

55

66

77

88

99

1133

1122

1111

1100

4422”” WW.. MMooddeell SShhoowwnn

6

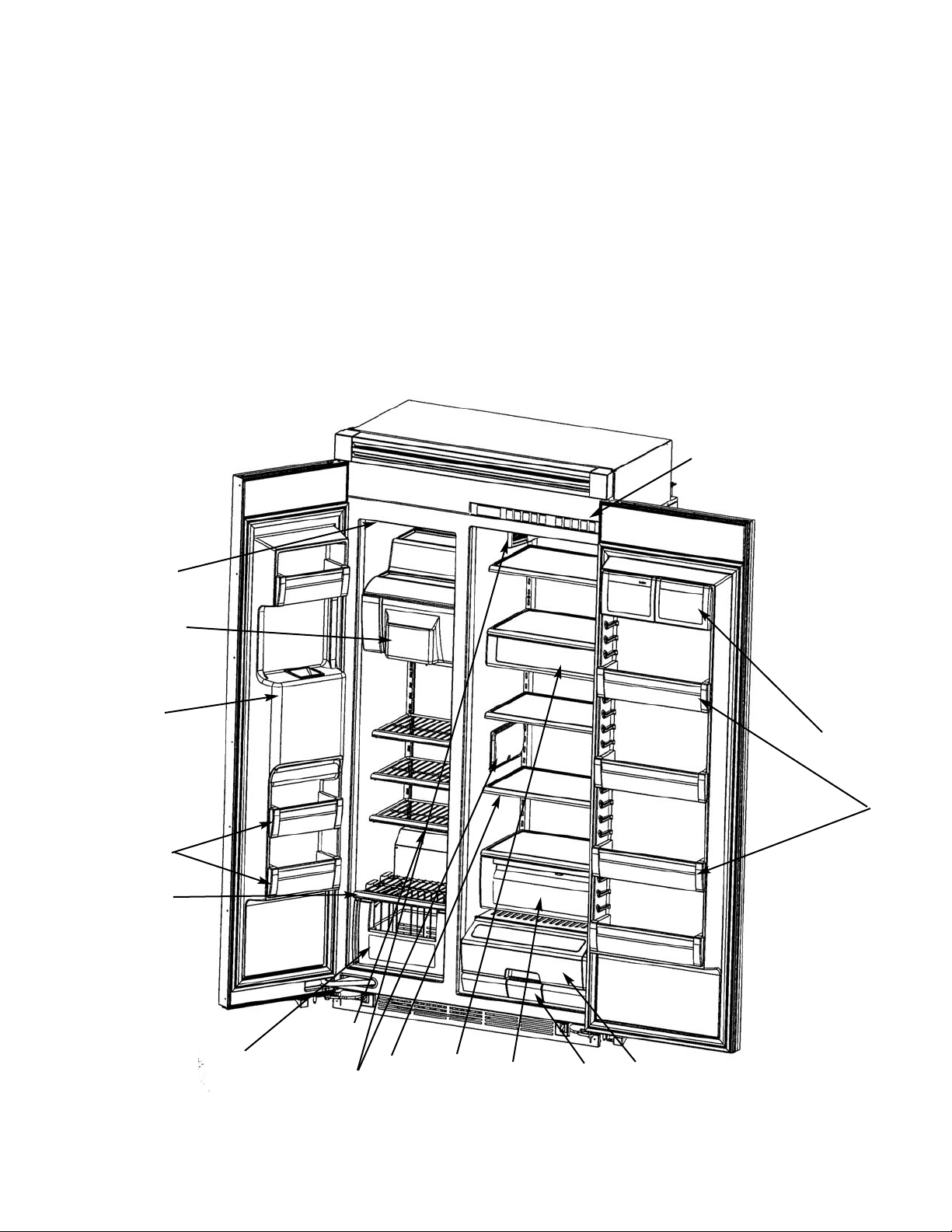

FEATURES OF YOUR REFRIGERATOR

(ICE AND WATER DISPENSER MODEL)

1. Electronic controls

2. Dairy compartments (2)

3. Adjustable door bins (4)

4. Meat SavorTM/Produce Drawer (1)

5. Moisture-controlled produce drawer

42” W. models (1) full width

48” W. models (2) half width

6. Water filter

7. Deli Compartment drawer

42” W. models (1) full width

48” W. models (2) half width

8. Spillproof shelves (5)

9. Adjustable freezer shelves (3)

10. Non-adjusting freezer shelf (1)

11. Adjustable freezer door bins (4)

12. Glide-out freezer baskets (2)

13. Ice and water dispenser (1)

14. Ice storage bucket (1)

15. Lights

11

44

33

22

55

66

77

88

99

1100

1111

1133

1144

1155

1155

1122

4422”” WW.. MMooddeell SShhoowwnn

7

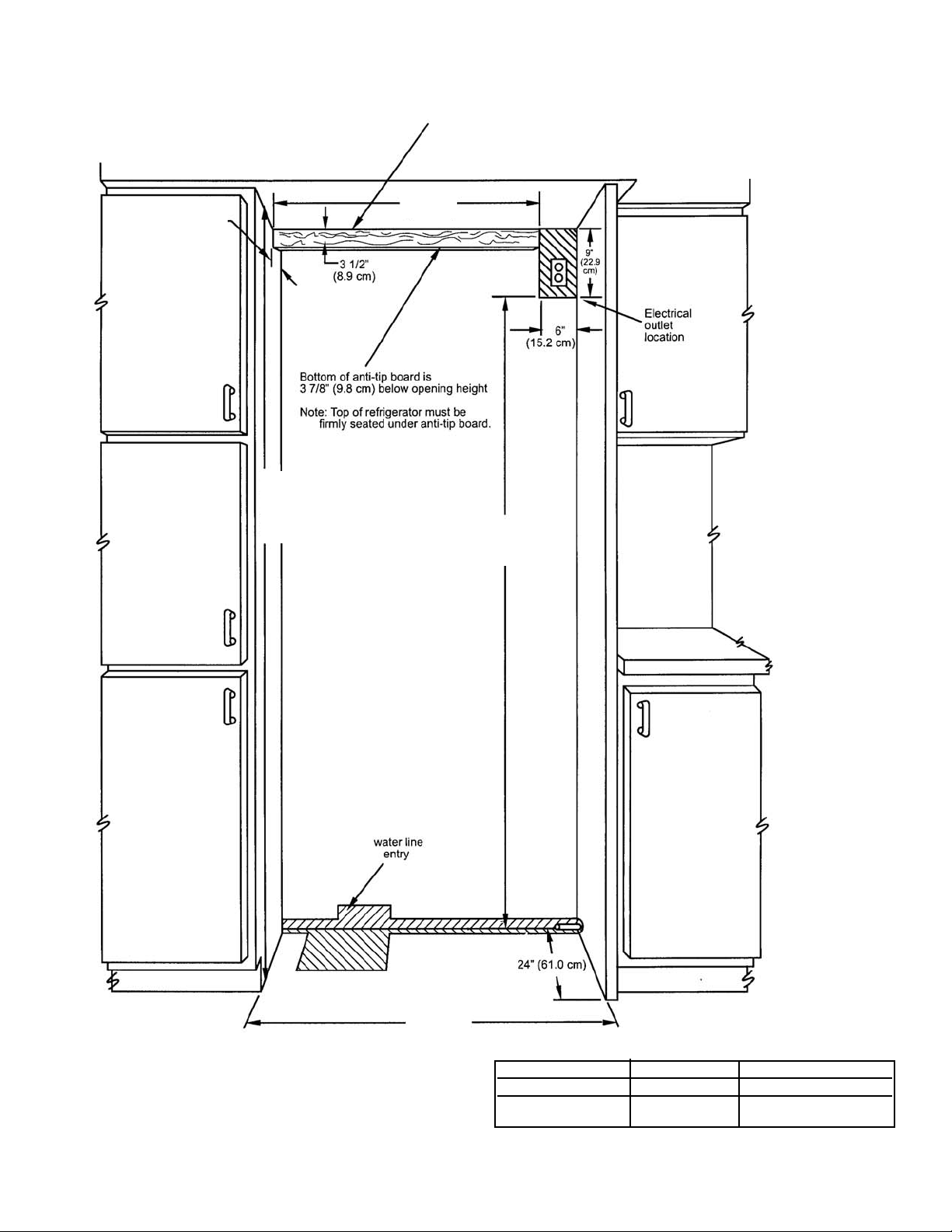

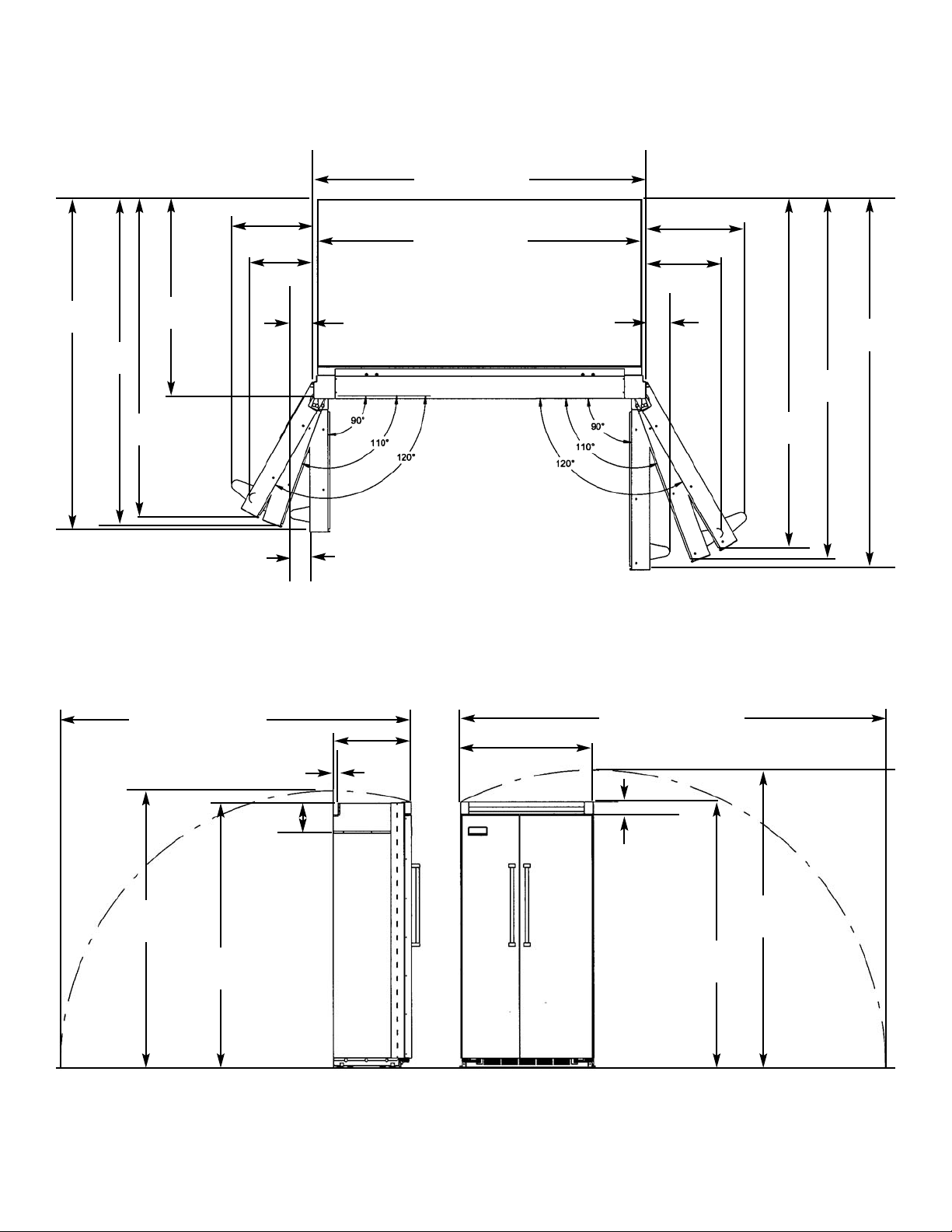

SITE PREPARATIONS AND CONSIDERATIONS

PROFESSIONAL MODEL SIDE-BY-SIDE CABINET OPENING DIMENSIONS

((22)) 22””xx44”” MMoouunnttiinngg bbooaarrdd

((11 11//22”” ((33..88 ccmm)) xx 33 11//22”” ((88..99 ccmm))

NNoottee:: IIff uunniitt iiss iinnssttaalllleedd ddeeeeppeerr tthhaann

2244”” ((6611..00 ccmm)),, tthheenn iinnccrreeaassee tthhee

mmoouunnttiinngg bbooaarrddss bbyy tthhee ssaammee aammoouunntt

33””

((77..66 ccmm))

BB

AA BB

42” W. Models 35” (88.9 cm) 41-1/2” (105.4 cm)

48” W. Models 41” (104.1 cm) 47-1/2” (120.7 cm)

AA

73 3/8”

(186.4 cm)

82 7/8” min. (210.5 cm)

anti-tip board and opening height

84 1/16” max. (213.5 cm)

anti-tip board and opening height

8

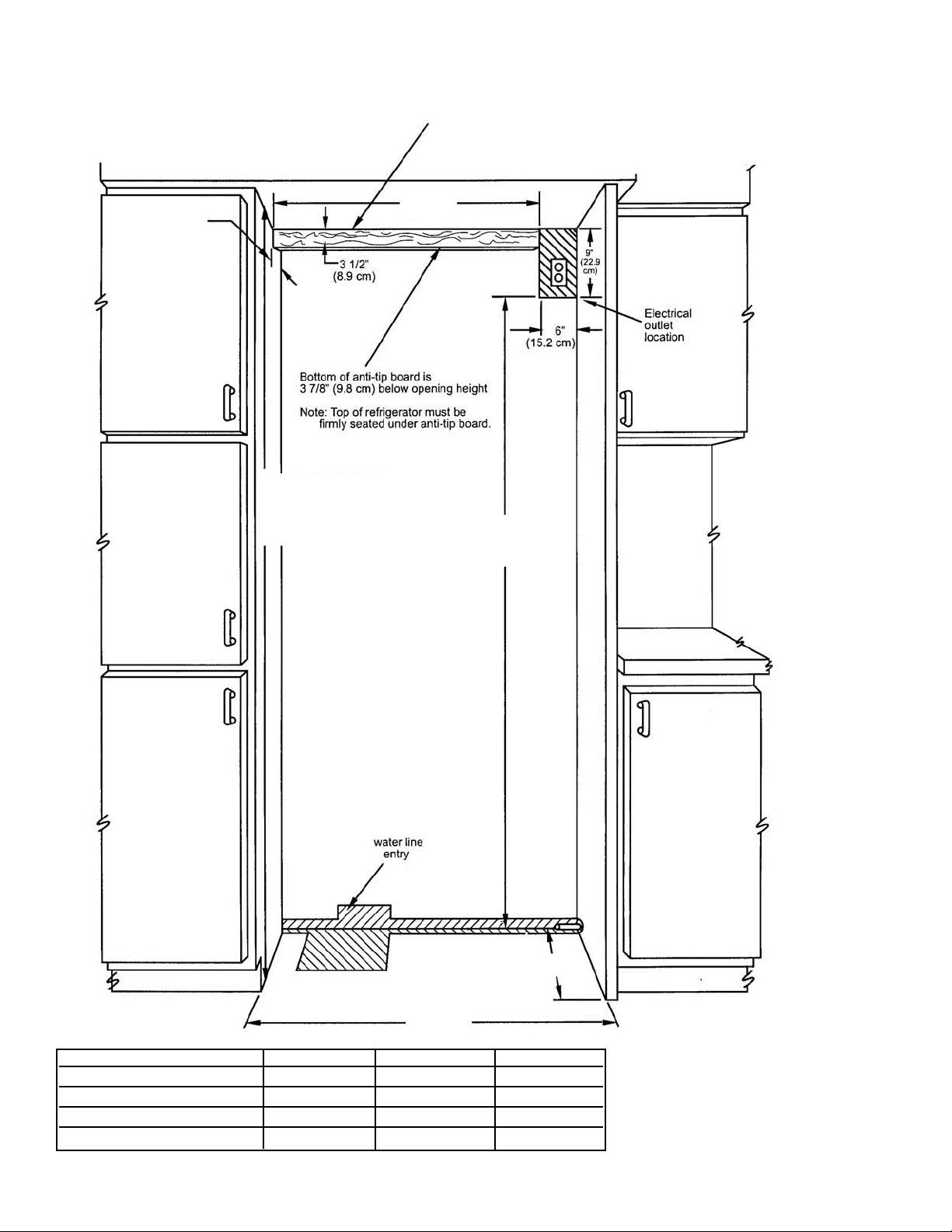

SITE PREPARATIONS AND CONSIDERATIONS

DESIGNER/FULL OVERLAY MODEL SIDE-BY-SIDE CABINET OPENING DIMENSIONS

((11)) 22””xx44”” MMoouunnttiinngg bbooaarrdd ((11 11//22”” ((33..88 ccmm)) xx 33 11//22”” ((88..99 ccmm))

NNoottee:: IIff uunniitt iiss iinnssttaalllleedd ddeeeeppeerr tthhaann

2244”” ((6611..00 ccmm)),, tthheenn iinnccrreeaassee tthhee

mmoouunnttiinngg bbooaarrddss bbyy tthhee ssaammee aammoouunntt

BB

AA BB CC

42” W. Designer 35” (88.9 cm) 42” (106.7 cm) 24” (61.0 cm)

42” W. Full Overlay 35” (88.9 cm) 42” (106.7 cm) 25” (63.5 cm)

48” W. Designer 41” (104.1 cm) 48” (121.9 cm) 24” (61.0 cm)

48” W. Full Overlay 41” (104.1 cm) 48” (121.9 cm) 25” (63.5 cm)

AA

CC

*Full overlay models fit flush in 25”

(63.5 cm) deep cabinet openings. They

can be installed in standard 24” (61.0

cm) deep openings. The door faces

and top grille will protrude 3/4” (1.9 cm)

into the room.

73-3/8”

(186.4 cm)

1-1/2”

(3.8 cm)

82 7/8” min. (210.5 cm)

anti-tip board and opening height

84 1/16” max. (213.5 cm)

anti-tip board and opening height

9

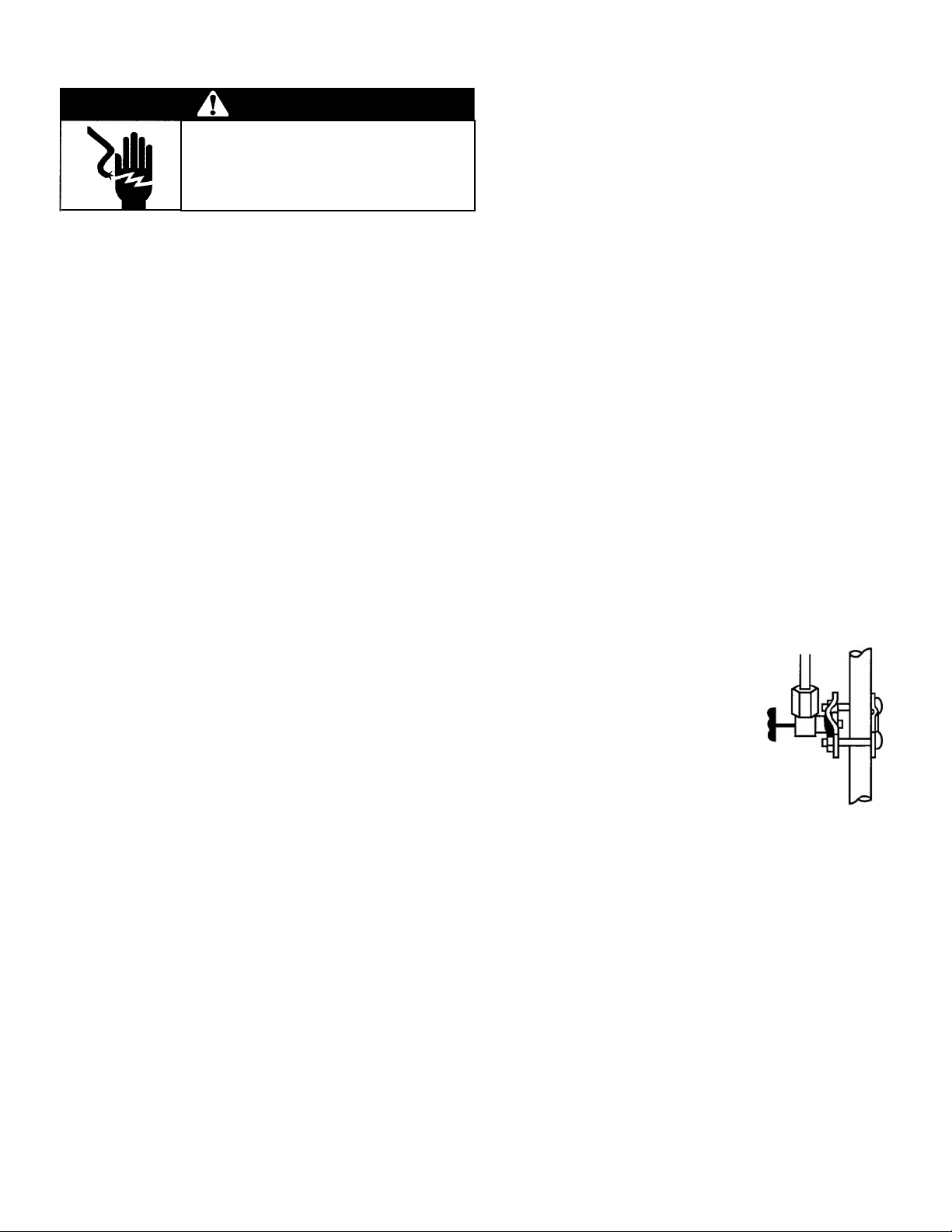

WATER SUPPLY REQUIREMENTS

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

SSoommee wwaatteerr mmaayy rreemmaaiinn iinn lliinnee.. EElleeccttrriicc

ddrriillll mmuusstt bbee ggrroouunnddeedd ttoo pprreevveenntt s

seevveerree oorr

lleetthhaall sshhoocckk iiff wwaatteerr iiss iinn lliinnee aanndd eenntteerrss ddrriillll

dduurriinngg uussee..

UUssee oonnllyy 11//44”” ((66 mmmm)) ccooppppeerr ttuubbiinngg ffoorr wwaatteerr lliinnee.. DDoo

NNoott iinnssttaallll ccooppppeerr ttuubbiinngg iinn aarreeaa wwhheerree tteemmppeer

raattuurreess

ddrroopp bbeellooww 3355

oo

FF ((11..77ooCC)).. BBeeffoorree aattttaacchhiinngg ccooppppeerr ttuubbiinngg

ttoo rreeffrriiggeerraattoorr,, fflluusshh aatt lleeaasstt 22 qquuaarrttss ((11..99 LL)) ooff wwaatteerr

tthhrroouuggh

h tthhee ccooppppeerr ttuubbiinngg aanndd iinnttoo aa bbuucckkeett ttoo rreemmoovvee

aannyy ppaarrttiicclleess iinn tthhee wwaatteerr lliinnee..

••VViikkiinngg RRaannggee CCoorrppoorraattiioonn iiss nnoott rreessppoonnssiibbllee ffoorr pprrooppeerrttyy ddaammaaggee dduuee ttoo iimmpprrooppeerr iinnssttaallllaattiioonn oorr wwaatteerr ccoonnnneeccttiioonn..

•Connect 1/4” (6mm) flexible copper tubing to household plumbing in compliance with local codes and ordinances.

•Length of copper tubing must reach from water supply connection to refrigerator connection with an additional length

to facilitate moving the refrigerator out of enclosure for cleaning or service. Tubing should be soft instead of rigid and

ends should be free of burrs.

•Copper tubing route must be above 35oF (1.7oC) to prevent water line from freezing.

••DDoo nnoott uussee ppllaassttiicc wwaatteerr lliinneess..

••DDoo nnoott uussee tthhee sseellff--ppiieerrcciinngg ffeeaattuurree ooff aa ssa

addddllee vvaallvvee..

The hole made by the piercing lance is too small for the water

flow rate required by the ice maker. To use a saddle valve, follow the instructions below located under “To rough in

water line” on how to pre-drill a 3/16” (4.5 mm) diameter hole.

•If saddle valve is not used, place a separate shut-off valve in an easily accessible location between water supply and

refrigerator. Do not locate shut-off valve behind refrigerator.

•

DDoo nnoott uussee wwiitthh rreevveerrssee oossmmoossiiss wwaatteerr ffiillttrraattiioonn ssyysstteemm

. This will void warranty.

•Connect a vertical or horizontal 1/2” (1.2 cm) to 1 1/4” (3.2 cm) COLD water line near refrigerator area.

•Run water line through the floor, back, or side wall. Tubing should lay flat on floor underneath refrigerator. Clamp

tubing to wall or floor.

•Water pressure must be greater than 20 psi and less than 120 psi.

To rough in water line:

1. Turn OFF main water supply. Turn ON nearest faucet long enough to clear line of water.

2. Vertical cold water line: Use grounded electric drill or hand drill to drill 3/16” (4.5 mm) hole

in an easily accessible location in water line.

Horizontal cold water line: Use grounded electric drill or hand drill to drill 3/16” (4.5 mm)

hole in the TOP of the water line. This will keep sediment from collecting in valve.

3. Position washer over hole in water line. Turn saddle valve handle clockwise to expose

piercing lance a maximum of 3/16” (4.5 mm). Align piercing lance over hole in water line.

Place both halves of saddle valve bracket against water line. Turn saddle valve handle

clockwise until piercing lance enters hole in water line and is firmly seated. The saddle valve

is now in the closed position. Tighten packing nut. Evenly and firmly tighten bracket screws

so washer will make a water-tight connection. Do not overtighten screws: copper tubing

could be crushed.

4. Check that both ends of copper tubing are cut square. Slide compression nut and sleeve onto copper tubing.

Insert end of copper tubing completely into valve outlet. Tighten compression nut to outlet with adjustable wrench.

Do not overtighten.

5. Turn on main water supply. Check for leaks. Turn saddle valve handle counterclockwise and run 2 quarts (1.9 L) of

water through copper tubing and into a bucket. Turn saddle valve clockwise to shut off water to copper tubing.

6. Route copper tubing to refrigerator area.

7. Leave an additional length of copper tubing coil to facilitate moving the refrigerator out of enclosure for cleaning or

service.

8. See page 13 for water connection instructions.

WARNING

10

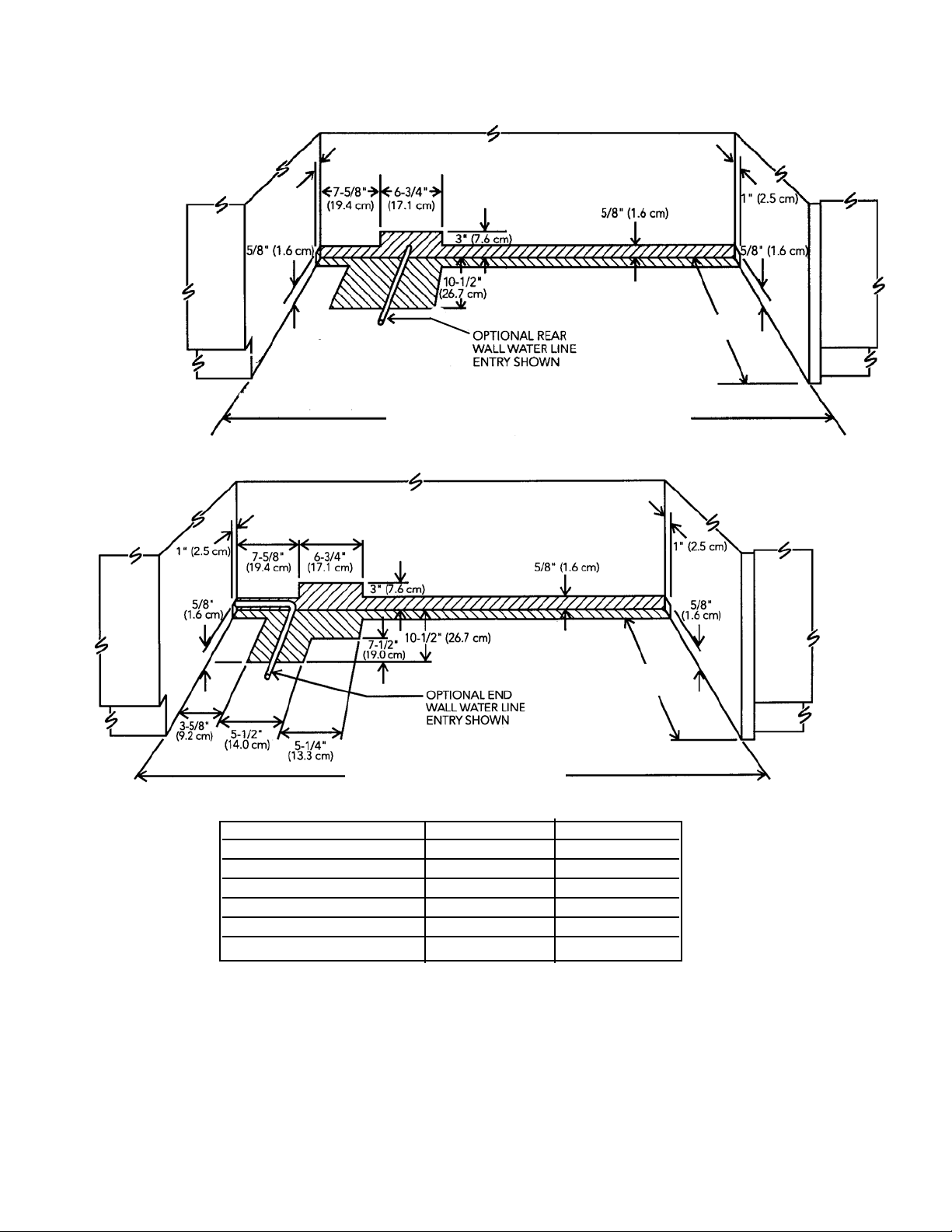

Plumbing Dimensions

A

NON-DISPENSER MODEL

BB

A

DISPENSER MODEL

BB

AA BB

42” W. Professional 41-1/2” (105.4 cm) 24” (61.0 cm)

48” W. Professional 47-1/2” (120.7 cm) 24” (61.0 cm)

42” W. Designer 42” (106.7 cm) 24” (61.0 cm)

48” W. Designer 48” (121.9 cm) 24” (61.0 cm)

42” W. Full Overlay 42” (106.7 cm) 25” (63.5 cm)

48” W. Full Overlay 48” (121.9 cm) 25” (63.5 cm)

**NNOOTTEE:: MMuusstt

bbee uunnddeerr 11”” ((22..55

ccmm)) ffrroomm bbaacckk

wwaallll

*1”

(2.5 cm)

11

ELECTRICAL REQUIREMENTS

AREA REQUIREMENTS

IItt iiss tthhee ccuussttoommeerr’’ss rreessppoonnssiibbiilliittyy ttoo::

•contact a qualified electrical installer.

•assure that the electrical installation is adequate and in conformance with the

National Electrical Code, ANSI/NFPA 70-latest edition or Canadian Electrical

Code C22.1-1998 and C22.2 No. 0-M91 (or latest edition), and all local

codes and ordinances. (115 volt, 60-Hz, 15 amp, fused, electrical supply is

required. It is required that a separate circuit serving only this appliance be

provided. This appliance is equipped with a power supply cord having a 3prong grounding plug. To minimize possible shock hazard, the cord must be

plugged into a mating 3-prong, grounding-type wall receptacle. Do not use

an extension cord.)

IIff ccooddeess ppeerrmmiitt aa sseeppaarraattee ggrroouunnddiinngg wwiirree ttoo bbee

uusseedd,, iitt iiss rreeccoommmmeennddeedd tthhaatt aa qquuaalliiffiieedd eelleeccttrriicciiaan

n

ddeetteerrmmiinnee tthhaatt tthhee ggrroouunnddiinngg ppaatthh iiss aaddeeqquuaattee..

DDoo NNoott

ggrroouunndd ttoo aa ggaass ppiippee.. CChheecckk wwiitthh aa

qquuaalliiffiieedd eelleeccttrriicciiaann iiff yyoouu aarree nnoott ssuurree tthhee

aapppplliiaannccee iiss pprrooppeer

rllyy ggrroouunnddeedd.. DDoo NNoott hhaavvee aa

ffuussee iinn tthhee nneeuuttrraall oorr ggrroouunnddiinngg cciirrccuuiitt..

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

PPlluugg iinnttoo aa ggrroouunnddeedd 33--pprroonngg oouuttlleett..

DDOO NNOOTT

rreemmoovvee ggrroouunndd pplluugg..

DDOO NNOOTT

uussee aann aaddaapptteerr..

DDOO NNOOTT

uussee aann eexxtteennssiioonn ccoorrdd..

FFaaiilluurree ttoo ffoollllooww tthheessee iinnssttrruuccttiioonnss ccoouulldd rreessuulltt iinn

ffiirree oorr eelleeccttrriiccaall sshhoocckk.

.

VVeerriiffyy tthhee ffoolllloowwiinngg::

•Refrigerator can fit into residence and can be moved around corners and through doorways.

•Floors can support refrigerator’s weight plus food weight (approximately 1200 pounds total).

•Rear wall is solid and is able to support two (2) horizontally mounted 2X4s (included) bolted to 2 wall studs. The 2X4

board bolt heads must be flush with 2X4 to prevent obstruction.

•Remove anything attached to rear or side walls that can obstruct refrigerator installation.

•Cutout dimensions are accurate.

•Electrical outlet is in correct location.

•Water line is in correct location.

Anti-Tip Requirements

The anti-tip boards should be fastened

into position prior to moving the unit into

the opening.

Note: Additional mounting boards may

be required if the refrigerator does not

touch the back wall of the enclosure.

To prevent refrigerator from tipping

forward, it must be secured in place

with a solid soffit or wood block.

TTIIPP OOVVEERR HHAAZZAARRDD

RReeffrriiggeerraattoorr iiss ttoopp hheeaavvyy aanndd ttiippss eeaassiillyy wwhheenn nnoott

ccoommpplleetteellyy iinnssttaalllleedd..

KKeeeepp ddoooorrss

cclloosseedd uunnttiill rreeffrriiggeerraattoorr iiss ccoommpplleetteellyy

iinnssttaalllleedd aanndd sseeccuurreedd ppeerr iinnssttaallllaattiioonn iinnssttrruuccttiioonnss..

UUssee ttw

woo oorr mmoorree ppeeooppllee ttoo mmoovvee aanndd iinnssttaallll

rreeffrriiggeerraattoorr.. FFaaiilluurree ttoo ddoo ssoo ccaann rreessuulltt iinn ddeeaatthh

oorr sseerriioouuss

iinnjjuurryy..

WARNING

WARNING

12

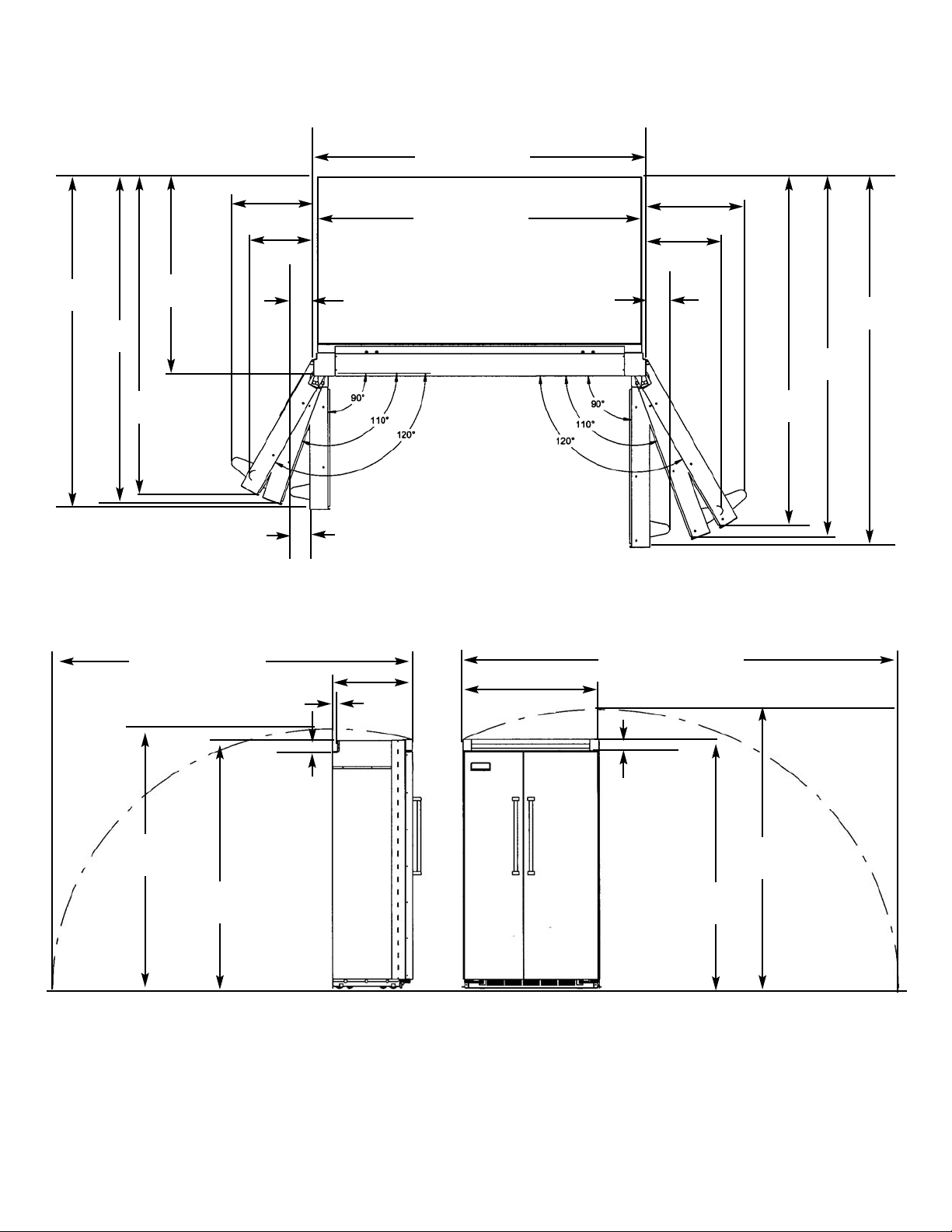

DOOR SWING AND TIPPING CONSIDERATIONS

42” W. PROFESSIONAL MODEL

42” (106.7 cm)

41-5/16”

(104.9 cm)

24-23/32”

(62.8 cm)

10-19/32”

(26.3 cm)

8-1/8”

(20.6 cm)

12-21/32”

(32.1 cm)

9-1/16”

(24.6 cm)

2-1/2”

(6.4 cm)

40-19/32”

(103.1 cm)

39-15/32”

(100.3 cm)

43-1/2”

(110.5 cm)

45”

(114.3 cm)

45-31/32”

(116.8 cm)

3”

(7.6 cm)

3”

(7.6 cm)

41” (104,1 cm)

111 1/16” (282.1 cm)

1 1/2” (3.8 cm)

86 11/32”

(219.3 cm)

42”

(106.7 cm)

24 23/32”

(62.8 cm)

82 3/4”

(210.2 cm)

9 5/32”

(23.3 cm)

134 25/32” (342.3 cm)

92 25/32”

(235.7 cm)

82 3/4”

(210.2 cm)

3 1/2”

(8.9 cm)

13

DOOR SWING AND TIPPING CONSIDERATIONS

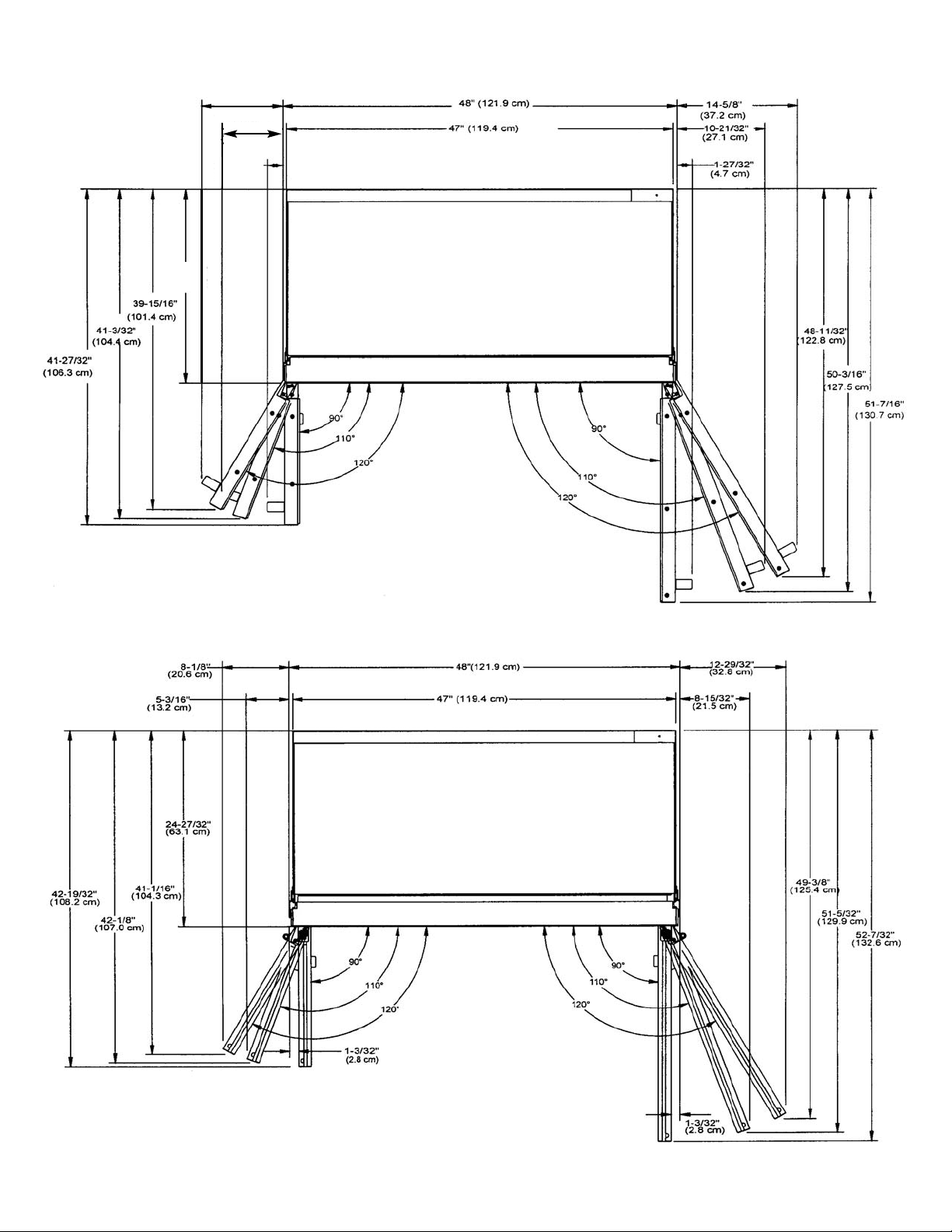

48” W. PROFESSIONAL MODEL

48” (121.9 cm)

41-27/32”

(106.3 cm)

15-13/32”

(39.1 cm)

11-9/16”

(29.4 cm)

2 1/2”

(6.4 cm)

41-1/8”

(104.4 cm)

39 15/16”

(101.4 cm)

48-1/4”

(122.6 cm)

50-1/8”

(127.3 cm)

51-7/16”

(130.7 cm)

2-31/32”

(7.5 cm)

2-31/32”

(7.5 cm)

47” (119.4 cm)

48”

(121.9 cm)

24-11/16”

(62.7 cm)

3-29/32”

(9.9 cm)

142-5/32” (361.1 cm)

95-7/16”

(242.4 cm)

82-3/4”

(210.2 cm)

3-19/32”

(9.1 cm)

111 1/16” (282.1 cm)

1 1/2” (3.8 cm)

86 11/32”

(219.3 cm)

82 3/4”

(210.2 cm)

8-1/8”

(20.6 cm)

10-19/32”

(26.3 cm)

24-23/32”

(62.8 cm)

DOOR SWING - 42" W. DESIGNER MODEL

DOOR SWING - 42" W. FULL OVERLAY MODEL

14

42”

(106.7 cm)

41-5/16”

(105.0 cm)

24”

(61.0 cm)

39-15/32”

(100.3 cm)

40-19/32”

(103.1 cm)

43-1/2”

(110.5 cm)

44-31/32”

(114.3 cm)

45-31/32”

(116.8 cm)

9-1/2”

(24.1 cm)

7-5/32”

(18.2 cm)

1-27/32”

(4.7 cm)

11/27-32”

(30.1 cm)

8-3/4”

(22.2 cm)

1-27/32”

(4.7 cm)

41”

(104.1 cm)

15

DOOR SWING - 48" W. DESIGNER MODEL

DOOR SWING - 48" W. FULL OVERLAY MODEL

24-3/32”

(61.2 cm)

9-13/16”

(25.0 cm)

7-3/8”

(18.7 cm)

1-27/32”

(4.7 cm)

16

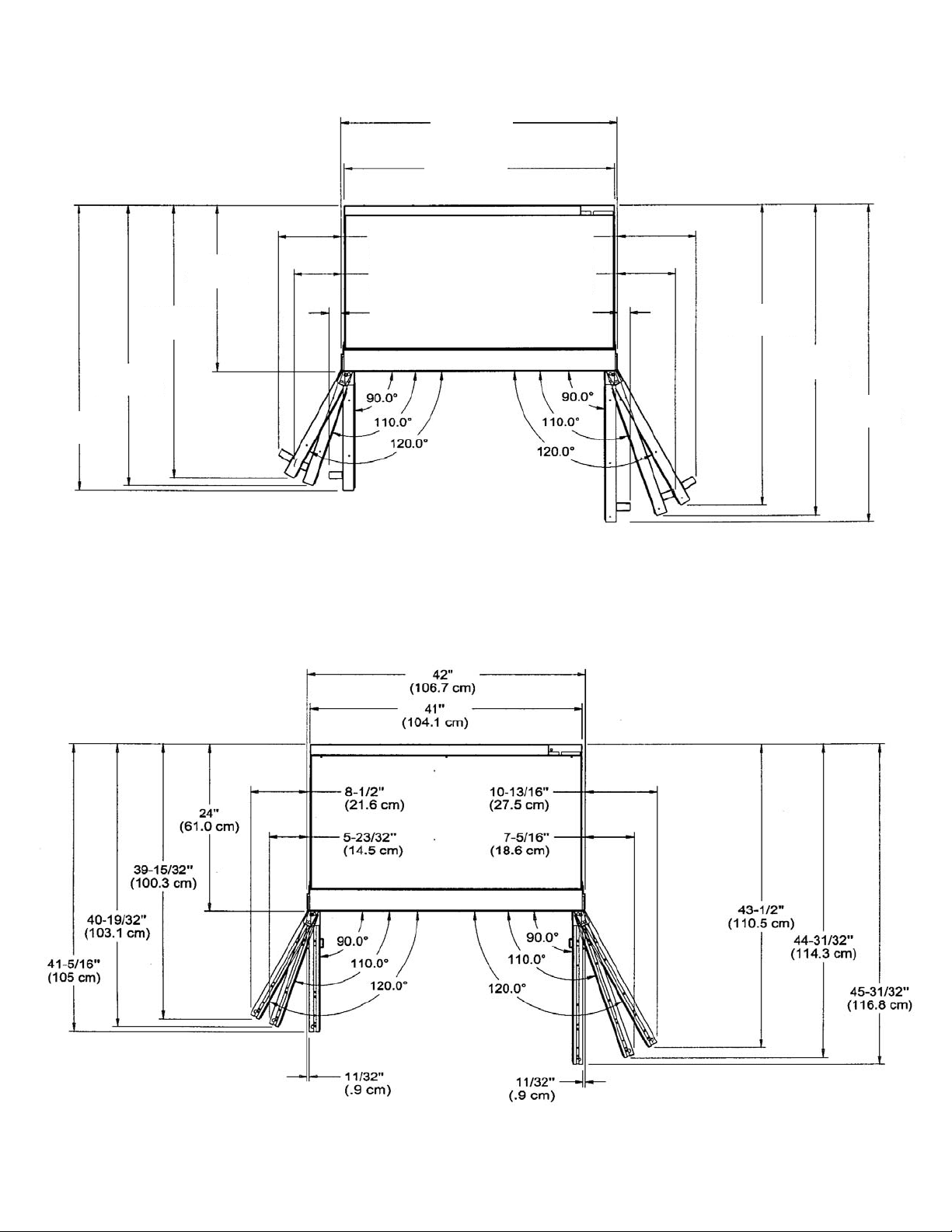

TIPPING CONSIDERATIONS

42” W. DESIGNER AND FULL OVERLAY MODELS

TIPPING CONSIDERATIONS

48” W. DESIGNER AND FULL OVERLAY MODELS

SIDE-BY-SIDE REFRIGERATOR OVERALL DIMENSIONS

PROFESSIONAL MODEL

17

A

B

SS

SS

SS

A

22 3/16”

(56.4 cm)

24 3/4”

(62.9 cm)

5/16”

(0.8 cm)

9/32”

(0.7 cm)

5/16”

(0.8 cm)

DDOOOORR

Side Trim

C

75 15/16”

(192.9 cm)

82-7/8"

(210.5 cm)

min.

to

84-1/16"

(213.5 cm)

max.

1 1/2”

(3.8 cm)

9 5/32” (23.3 cm)

20 3/4”

(52.7 cm)

22 3/16”

(56.4 cm)

(to rear edge of cabinet side

trim)

24 11/16” (62.7 cm)

24 1/4” (69.2 cm)

TTOOPP

FFRROONNTT

SSIIDDEE

AA BB CC

42" W 41-1/2"(105.4 cm) 41"(104.1 cm) 42" (106.7 cm)

48" W 47-1/2"(120.7 cm) 47" (119.4 cm) 48"(121.9 cm)

18

CABINET INFORMATION - PROFESSIONAL MODELS

Professional models fit “semi-flush” in standard 24” (61.0 cm) deep cabinet openings. The door face protrudes 2-1/2”

(6.4 cm) from the cabinet face. The handle protrudes an additional 2-1/2” (6.7 cm) into the room

DETAIL A-A

A-A

AA

AA

42" W 41-1/2" (105.4 cm)

48" W 47-1/2" (120.7 cm)

19

CUSTOM SIDE PANEL DIMENSIONS - PROFESSIONAL MODELS

FOR 3/4" (1.9 cm) SIDE PANELS

6” (15.2 cm)

82-7/8” (210.5 cm) TO

84-1/16” (213.5 cm)

DEPENDING ON HOW

HIGH LEVELING FEET

ARE RAISED AND

CABINET ENCLOSURE

HEIGHT

OPTIONAL KICKPLATE

NOTCH - DIMENSIONS

DETERMINED BY CABINETS

OPTIONAL KICKPLATE

NOTCH - DIMENSIONS

DETERMINED BY CABINETS

20

SIDE-BY-SIDE REFRIGERATOR OVERALL DIMENSIONS - DESIGNER MODELS

TTOOPP

FFRROONNTT

SSIIDDEE

AA

AA

AA

BB

8822--77//88""

((221100..55 ccmm))

mmiinn..

TTOO

8844--11//1166""

((221133..55 ccmm))

mmaaxx..

AA BB

42" W 42"(106.7 cm) 41"(104.1cm)

48" W 48"(121.9 cm) 47"(119.4 cm)

DDOOOORR

21

CABINET AND PANEL INFORMATION - DESIGNER MODELS

Designer models fit flush in standard 24” (61.0 cm) deep cabinet openings with no protrusion into the room except 2”

(5.1 cm) curved handle depth

DETAIL A-A DETAIL B-B

DETAIL A-A DETAIL B-B

WITH ADJACENT CABINETS;

OVERLAPPING CABINET DOORS

WITH ADJACENT CABINETS;

FLUSH MOUNT CABINET DOORS

AA

AA

42" W 42"(106.7 cm)

48" W 48"(121.9 cm)

22

SIDE-BY-SIDE REFRIGERATOR OVERALL DIMENSIONS - FULL OVERLAY MODELS

TTOOPP

FFRROONNTT

SSIIDDEE

AA

BB

AA

AA

8822--77//88""

((221100..55 ccmm))

mmiinn..

TTOO

8844--11//1166""

((221133..55 ccmm))

mmaaxx..

AA BB

42" W 42"(106.7 cm) 41"(104.1 cm)

48" W 48"(121.9 cm) 47"(119.4 cm)

23

BB--BB

AA--AA

DDEETTAAIILL AA--AA

DDEETTAAIILL BB--BB

AA

AA

AA

42" W 42"(106.7 cm)

48" W 48"(121.9 cm)

CABINET AND PANEL INFORMATION - FULL OVERLAY MODELS

Full overlay models, (with 3/4” [1.9 cm], thick panels and custom handles locally supplied), fit flush in 25” (63.5 cm) deep (countertop

depth) cabinet openings with no protrusion into room except custom handles

24

CABINET AND PANEL INFORMATION - FULL OVERLAY MODELS

(CONTINUED)

Full overlay models can be installed in standard 24” (61.0 cm) deep openings. However, the door faces and top ventilation grille

will protrude 3/4” (1.9 cm) into the room. This is ideal for alignment with full overlay cabinet doors.

CC--CC

DDEETTAAIILL CC--CC

25

AA AA

BB

AA AA

18 3/16”

(46.2 cm)

22 13/16”

(57.9 cm)

75 1/4”

(191.1 cm)

75 1/2”

(191.8 cm)

42” W. MODELS

Non-Dispenser Model

1/8” (0.3 cm) TYP

Four Sides

11//44"" ((00..66 ccmm)) BBaassee PPaanneell

33//44”” ((11..99 ccmm)) FFuullll OOvveerrllaayy PPaanneell

AA

AA

AA

AA

18 3/16”

(46.2 cm)

22 13/16”

(57.9 cm)

1/8” (0.3 cm) TYP

Four Sides

11//44"" ((00..66 ccmm)) BBaassee PPaanneell

33//44”” ((11..99 ccmm)) FFuullll OOvveerrllaayy PPaanneell

Dispenser Cutout Detail

31 5/8”

(80.3 cm)

31 5/8”

(80.3 cm)

10 11/16”

(27.1 cm)

12 3/8”

(31.4 cm)

3 5/32”

(8.0 cm)

1/8” (0.3 cm)

1/8” (0.3 cm)

1/4"(0.6 cm)

3/4"

(1.9 cm)

DDOOOORR

SSEECCTTIIOONN AA--AA

SSHHOOWWNN AASS MMOOUUNNTTEEDD OONN DDOOOORR

NNOO SSCCAALLEE

SSEECCTTIIOONN BB--BB

NNOO SSCCAALLEE

11//44"" ((00..66 ccmm))

BBaassee PPaanneell

BB

Dispenser Model

CUSTOM DOOR PANEL DIMENSIONS - FULL OVERLAY MODELS

33//44”” ((11..99 ccmm))

FFuullll OOvveerrllaayy

PPaanneell

75 1/4”

(191.1 cm)

75 1/2”

(191.8 cm)

26

48” W. MODELS

Non-Dispenser Models

CUSTOM DOOR PANEL DIMENSIONS - FULL OVERLAY MODELS

XX XX

YY

XX XX

18 11/16”

(47.5 cm)

28 5/16”

(71.9 cm)

75 1/4”

(191.1 cm)

75 1/2”

(191.8 cm)

1/8” (0.3 cm) TYP

Four Sides

11//44"" ((00..66 ccmm)) BBaassee PPaanneell

33//44”” ((11..99 ccmm)) FFuullll OOvveerrllaayy PPaanneell

XX

XX

XX

XX

18 11/16”

(47.5 cm)

28 5/16”

(71.9 cm)

1/8” (0.3 cm) TYP

Four Sides

11//44"" ((00..66 ccmm)) BBaassee PPaanneell

33//44”” ((11..99 ccmm)) FFuullll OOvveerrllaayy PPaanneell

Dispenser Cutout Detail

31 5/8”

(80.3 cm)

31 5/8”

(80.3 cm)

10 11/16”

(27.1 cm)

12 3/8”

(31.4 cm)

3 5/32”

(8.0 cm)

1/8” (0.3 cm)

1/8” (0.3 cm)

1/4"(0.6 cm)

3/4"

(1.9 cm)

DDOOOORR

SSEECCTTIIOONN XX--XX

SSHHOOWWNN AASS MMOOUUNNTTEEDD OONN DDOOOORR

NNOO SSCCAALLEE

SSEECCTTIIOONN YY--YY

NNOO SSCCAALLEE

11//44"" ((00..66 ccmm))

BBaassee PPaanneell

YY

Dispenser Model

33//44”” ((11..99 ccmm))

FFuullll OOvveerrllaayy

PPaanneell

75 1/4”

(191.1 cm)

75 1/2”

(191.8 cm)

27

1. Remove cabinet side trim with a phillips

screwdriver.

2. Remove handle-side door trim with a phillips

screwdriver.

3. Install “Z” brackets (see page 25 for details).

4. Align panel in door trim and push evenly. For

smoother installation, apply liquid soap to door

trim and “Z” brackets.

5. Install handle-side door trim with screws. Install

door trim inserts (supplied) on top and both sides

of door by starting in one corner and pushing the

strip in place.

6. Install cabinet trim.

ICE AND WATER DISPENSER BEZEL REMOVAL AND INSTALLATION

FULL OVERLAY MODELS

To Remove:

1. Remove packaging material surrounding bezel.

2. Grasping the sliding lever, pull away from bezel.

3. Remove spill tray from lower part of bezel exposing two screws.

4. Remove screws 1 & 2.

5. Locate two additional screws underneath top section of bezel.

6. Remove screws 3 & 4 and upper mounting support.

7. Grasping the bezel on both sides, pull away from the door cavity.

NNOOTTEE::

Bezel needs to be pulled slightly downward to clear water dispensing tube.

8. Store bezel and spill shelf in safe and secure place until installation.

Sliding Lever

Screw 4

Screw 2

Screw 1

Screw 3

Spill Tray

Upper

Mounting

Support

To Install:

1. Install custom wood panels per product’s

installation instructions.

2. Locate opening cavity on door and position bezel

in opening.

NNOOTTEE::

Graphics on bezel will be on

top end, tilt slightly forward to allow water tube

clearance.

3. Push bezel firmly into cavity until lower screw

holes align with mounting holes on cavity.

4. Install screws 1 & 2 but do not tighten all the way.

5. Locate mounting holes underneath top section of

the bezel.

6. Position upper mounting support over holes

underneath top section of bezel.

7. Install screws 3 & 4 but do not tighten all the way.

8. Adjust and reposition bezel as necessary.

9. Tighten all screws securely and replace spill shelf

in lower part of bezel.

10. Align cube switch with sliding lever and firmly

push until sliding lever is flush with bezel.

DOOR PANE INSTALLATION

FULL OVERLAY MODELS

HANDLE SCREW

INSERT (NOTE:

MOUNTING SCREWS

LOCATED BEHIND

DOOR TRIM INSERT

(MOUNTING

SCREWS LOCATED

BEHIND)

1/4” (0.6 cm)

BASE PANEL

3/4” (1.9 cm)

OVERLAY PANEL

3/4” (1.9 cm) OVERLAY PANEL

1/4” (0.6 cm) BASE PANEL

FFRREEEEZZEERR DDOOOORR

RREEFFRRIIGGEERRAATTOORR

DDOOOORR

28

“Z” BRACKET INSTALLATION - FULL OVERLAY MODELS

NNoonn--DDiissppeennsseerr MMooddeell DDiissppeennsseerr MMooddeell

DOOR

DOOR

29

CUSTOM SIDE PANEL DIMENSIONS

DESIGNER/FULL OVERLAY MODELS

FFOORR 33//44”” ((11..99 ccmm)) SSIIDDEE PPAANNEELLSS

NNOOTTEE:: AAddddiinngg aa 33//44”” ((11..99 ccmm)) ssiiddee ppaanneell aaddddss aann aaddddiittiioonnaall 33//44””((11..99 c

cmm)) ttoo tthhee oovveerraallll wwiiddtthh ooff tthhee pprroodduucctt ffoorr eeaacchh

ssiiddee ppaanneell uusseedd..

NNOOTTEE:: RReeqquuiirreess ssiiddee ppaanneell hhaarrddwwaarre

e kkiitt ((KKiitt MMooddeell NNuummbbeerr -- SSPPHHKKDDSS))

CUSTOM 3/4” (1.9 cm) SIDE PANELS (BY OTHERS) FOR DESIGNER SERIES, AND FULL OVERLAY.

30

CUSTOM FINISHING OPTIONS

Door Clearances

All installations must allow for the refrigerator and freezer door to open a minimum of 90o.

•For side wall or corner installation, allow for a standard 3” (7.6 cm) cabinet filler to assure doors open to 90

o

. If a

custom handle is used a wider filler may be necessary.

•Panel thickness must not exceed 1” (2.5 cm) on hinge side. Thicker panels will interfere with door swing and

clearance.

•Panels must not exceed 50 pounds per door.

Door Panel Requirements

Verify panel sizes, handle clearances, and placement before beginning installation. See “Custom Panel Dimensions” on

pages 25-26.

•In some instances, raised panels may require a handle recess (see pages 25-26).

•Panels thicker than 1” (2.5 cm) require special consideration with door swings and clearances (see page 14-15).

Custom Air Grille Panel (Optional)

A louvered aluminum air grille is supplied with the

refrigerator. For custom wood grille application see

template in “Custom Air Grille Panel Dimensions” on pages

31-32.

Right hinge application:

Item Qty Description Size

A 2 End 3”x 3 3/4” x 3/4”

B 2 Top & Bottom See table page 32 Item G

C 2 Insert End 1 1/2” x 2 3/4” x 3/4”

D 1 Hinge Cover See table page 33 Item H

E 1 Insert See table page 33 Item J

F Min. Air Opening See table page 31

IInnssttaallll wwoooodd ggrriillllee bbyy ccoommpplleettiinngg tthhee ffoolllloowwiinngg::

1. Remove air grille center blade.

2. Remove (2) 1/4” (.6 cm) screws with a magnetic extended screwdriver at least 8” (20.3 cm) long.

3. Pull air grille assembly forward.

4. Remove (2) mounting brackets from the air grille assembly.

5. Using (8) screws removed from the mounting brackets, attach mounting brackets to the custom wood grille using

predrilled pilot holes. (See page 31 for proper alignment of custom air grille to mounting brackets and pilot hole

placement.)

6. Replace air grille assembly by reversing Step 2.

C

A

E

B

A

D

F

Optional 1/2” (1.3 cm) hinge cover

is fastened to bottom of wood

grille. (Hinge cover will protrude

9/32” [0.7 cm] from wood grille.)

Wood grille is made

of 3” (7.6 cm) filler

stock.

Screws

Bracket

Custom air grille front

31

OPTIONAL CUSTOM AIR GRILLE DIMENSIONS

OPTIONAL CUSTOM AIR GRILLE DUCT LIP EDGE LOCATIONS

FFRROONNTT VVIIEEWW

A B Min. Air Opening

42” SXS 41 1/2” 40” 38 1/2 x 1”

(105.4 cm) (101.6 cm) (97.8 x 2.5 cm)

48” SXS 47 1/2” 46” 44 1/2 x 1”

(120.7 cm) (116.8 cm) (113.0 x 2.5 cm)

42” SXS Disp. 41 1/2” 40” 38 1/2 x 1”

(105.4 cm) (101.6 cm) (97.8 x 2.5 cm)

A

B

3/4” (1.9 cm) TYP

1 1/2”

(3.8 cm)

3”

(7.6 cm)

3 3/4”

(9.5 cm)

Front of Air Grille

TOP OF CUSTOM AIR GRILLE

Bracket

Custom Air Grille

4 7/8”

(12.3 cm)

4”

(10.2 cm)

32

REAR VIEW DIMENSIONS

TOP AND BOTTOM VIEW DIMENSIONS

ENDS DIMENSIONS

CDEF

42” SXS 26 3/16” 24 27/32” 5 17/32” 4 11/64”

(66.5 cm) (63.1 cm) (14.1 cm) (10.6 cm)

48” SXS 32 3/16” 30 27/32” 11 17/32” 10 11/64”

(81.8 cm) (78.3 cm) (29.3 cm) (25.8 cm)

42” SXS Disp. 26 3/16” 24 27/32” 5 17/32” 4 11/64”

(66.5 cm) (63.1 cm) (14.1 cm) (10.6 cm)

G

42” SXS 40” (101.6 cm)

48” SXS 46” (116.8 cm)

42” SXS Disp. 40” (101.6 cm)

C

G

D

E

F

3/8” (0.95 cm)

1/2” (1.3 cm)

3/4” (1.9 cm)

3 3/4”

(9.5 cm)

3 3/4”

(9.5 cm)

3”

(7.6 cm)

1/2”

(1.3 cm)

1/2” (1.3 cm)

1/8”

(0.3 cm)

1/8”

(0.3 cm)

3/4” (1.9 cm)

1/2” (1.3 cm)

3/4” (1.9 cm)

3 3/4”

(9.5 cm)

3”

(7.6 cm)

1/2”

(1.3 cm)

R1/4”

R1/4”

Top View

Bottom

View

Right View

Front View

Left View

Bottom View

Bottom View

Right View

Front View

33

HINGE COVER DIMENSIONS

INSERT DIMENSIONS

INSERT END DIMENSIONS

1/2”

(1.3 cm)

1/2”

(1.3 cm)

1/2”

(1.3 cm)

1/2”

(1.3 cm)

2 3/4”(7.0cm)

1/2”(1.3 cm)

1/2”(1.3 cm)

1/4”(0.6 cm)

H

J

3/8”

(0.95 cm)

7/8”

(2.22 cm)

3 5/8” (9.2 cm)

1 3/8” (3.5 cm)

2 1/8”

(5.4 cm)

3 1/8”

(7.9 cm)

H

42” SXS 41 1/2” (105.4 cm)

48” SXS 47 1/2” (120.7 cm)

42” SXS Disp. 41 1/2” (105.4 cm)

J

42” SXS 39 15/16” (101.4 cm)

48” SXS 45 15/16” (116.7 cm)

42” SXS Disp. 39 15/16” (101.4 cm)

3 5/8”

(9.2 cm)

R1/4”

3/4”(1.9 cm)

1 1/2”

(3.8 cm)

R3/8”

Top View

Top View

Right View

Front View

Front View

NNOOTTEE::

Insert end is recessed 7/8” (2.2 cm) from

the front edge of the air grille (see page 31).

Top View

Front View

Right View

NNOOTTEE::

Adding 3/8” (0.9 cm) radii is

designer’s choice.

34

MMoosstt ooff tthhee rreeffrriiggeerraattoorr’’ss wweeiigghhtt iiss aatt tthhee ttoopp.. EExxttrraa ccaarree iiss nneeeeddeedd wwhheenn mmoovviinngg tthhee rreeffrriiggeerraattoorr ttoo pprreevveenntt ttiippppiinngg..

DDoo NNoott

rreemmoovvee pprrootteeccttiivvee ffiillmm uunnttiill rreeffrriiggeerraattoorr iiss iinn ooppeerraattiinngg ppoossiittiioonn.. AAllll ffoouurr lleevveelliinngg lleeggss mmuusstt ccoonnttaacctt tthhee fflloooorr ttoo

ssuuppppoorrtt aanndd ssttaabbiilliizzee tthhee ffuullll wweeiigghhtt.. DDoo nnoott ddrroopp rreeffrriiggeerraattoorr..

1. Remove exterior shipping materials prior to moving

refrigerator into home. Remove top and bottom strap (see

Figure 1).

2. Remove top cap (see Figure 1).

3. Cut carton rear approximately 1/4” (.64 cm) to 1” (2.5 cm)

from right corner (see Figure 2) with a utility knife extended

1/4” (.6 cm). Remove carton and exterior packaging. Save

cardboard shipping material to protect floor surface when

installing refrigerator. Do not remove

nylon cord from power cord. Remove

anti-tip board and kickplate from rear

of refrigerator (see Figure 3).

4. Remove shipping brackets from skid

by removing 4 bolts (2 each side) with

a 1/2” socket head screwdriver (see

Figure 4).

•Tilting refrigerator is not required to

remove shipping brackets.

5. Slip cart between refrigerator and

skid. Remove refrigerator from skid.

Use excess packaging

to protect decorative

trim. Verify that

leveling legs are up (0”

adjustment) (see

Figure 5).

6. To avoid floor damage,

use protective material

(see Figure 6).

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

UUssee ttwwoo oorr mmoorree ppeeooppllee ttoo mmoovvee aanndd iinnssttaallll

rreeffrriiggeerraattoorr.. FFaaiilluurree ttoo ffoollllooww tthhiiss iinnssttrruuccttiioonn ccaann

rrees

suulltt iinn bbaacckk oorr ootthheerr iinnjjuurryy.. TToo aavvooiidd ppeerrssoonnaall

iinnjjuurryy,, wweeaarr gglloovveess wwhheenn ppeerrffoorrmmiinngg aannyy

iinnssttaallllaattiioon

n pprroocceedduurree aanndd wweeaarr eeyyee pprrootteeccttiioonn

wwhheenn ccuuttttiinngg mmeettaall ssttrraappss..

TTIIPP OOVVEERR HHAAZZAARRDD

RReeffrriiggeerraattoorr iiss ttoopp hheeaavvyy aanndd ttiippss eeaassiillyy

wwhheenn nnoott ccoommpplleetteellyy iinnssttaalllleedd.. KKeeeepp

ddoooorrss

cclloosseedd uunnttiill rreeffrriiggeerraattoorr iiss

ccoommpplleetteellyy iinnssttaalllleedd aanndd sseeccuurreedd ppeerr

iinnssttaallllaattiioonn iinnssttrruuccttiioonnss..

UUssee ttwwo

o oorr mmoorree ppeeooppllee ttoo mmoovvee aanndd

iinnssttaallll rreeffrriiggeerraattoorr.. FFaaiilluurree ttoo ddoo ssoo ccaann

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss i

innjjuurryy..

REFRIGERATOR INSTALLATION

SSKKIIDD

BBAACCKK VVIIEEWW

SECURING THE REFRIGERATOR (3 OPTIONS)

OPTION 1

If a solid soffit is 1” (2.5 cm) or less above the refrigerator, anti-tip boards are not

required.

OPTION 2

If a solid soffit is not available or soffit is more than 1” (2.5 cm) above refrigerator,

center wood boards on rear wall 1/4” (.6 cm) maximum above refrigerator. Attach

wood boards to wall studs with six of the provided wood screws, making sure that

screws are engaged in wall studs 1 1/2” (3.8 cm) minimum.

OPTION 3

Create “L” bracket assembly by securing “L” brackets to each end of (1) 2x4 with

provided screws (Item A). If 2x4 does not extend 2” (5.0 cm) beyond rear ledge,

attach (1) 2x4 to wall (Item B), attach (1) 2x4 to rear ledge of cabinet (Item C) and

attach “L” bracket assembly to 2x4 mounted on wall (Item A).

EElleeccttrriiccaall SShhoocckk HHaazzaarrdd

DDiissccoonnnneecctt ppoowweerr aatt bbrreeaakkeerr oorr ttuurrnn ppoowweerr ddiissccoonnnneecctt sswwiittcchh ttoo OOFFFF ppoossiittiioonn

bbeeffoorree

ppeerrffoorrmmiinngg aannyy iinnssttaallllaattiioonn pprroocceedduurree.. FFaaiilluurree ttoo ddoo ssoo ccaann rreessuulltt iinn ddeeaatthh oorr eelleeccttrriiccaall

ssh

hoocckk..

35

(ITEM B)

OPTION 2

OPTION 3

(ITEM A)

(ITEM C)

OPTION 1

36

Before moving the refrigerator in place, confirm the finished dimensions, electrical location, minimum door and shelf

clearances, and door panel instructions. (See pages 7 & 8).

1. Position refrigerator in front of cutout.

2. Verify operation by plugging power cord in receptacle.

PPoowweerr sswwiittcchh wwiillll bbee sshhiippppeedd iinn tthhee ““OONN”” ppoossiittiioonn aanndd

sshhoowwrroooomm sswwiittcchh wwiillll bbee iinn tthhee ““OONN”” ppoossiitti

ioonn..

(If showroom switch is switched to the “OFF” position, showroom

mode is engaged and power is shut-off to the compressor. This mode is for showroom display only).

3. Roll refrigerator into cutout to within 3” (7.6 cm) of being flush with cabinets. To avoid kitchen cabinet damage,

place cardboard between cabinets and refrigerator. Push cardboard back with refrigerator and remove cardboard

when refrigerator is in place. NOTE: When moving the unit into position, be careful not to crimp, kink or crush

the copper water supply line.

4. Lift the refrigerator off the rollers, adjust to desired height and level refrigerator by using a 5/16” hex head wrench.

(Refer to Figure at the right)

a) To raise (clockwise)/lower (counterclockwise) right

side rear, rotate the right side rear hex rod.

b) To raise (clockwise)/lower (counterclockwise) the

left side rear, rotate the left side rear hex rod.

c) To raise (clockwise)/lower (counterclockwise) the

right side front, rotate the right side front hex rod.

d) To raise (clockwise)/lower (counterclockwise) the

left side front, rotate the left side front hex rod.

NNOOTTEE

: DO NOT use an electric driving device.

Overtightening can cause damage.

5. Align refrigerator with sides of cabinets by adjusting leveling legs. Rotate leveling legs until firmly in place against

floor.

6. To secure refrigerator, raise unit until compartment cover is firmly seated under the soffit or anti-tip boards.

7. Open door. Display should flash. Press any key. There is a 6 minute delay before the refrigerator starts. Verify the

position of the power on/off and showroom switch if there is no power to refrigerator.

PPoowweerr

SSwwiittcchh

SShhoowwrroooomm

SSwwiittcchh

VVIIEEWW SSHHOOWWNN WWIITTHH KKIICCKKPPLLAATTEE RREEMMOOVVEEDD

37

WATER CONNECTION

•Refer to water supply requirement section for preliminary installation and site preparation (see page 9 & 10).

••DDoo nnoott uussee ppllaassttiicc wwaatteerr lliinneess bbeettwweeeenn rreeffrriiggeerraattoorr aanndd ssuuppppllyy.. PPllaassttiicc wwaatteerr lliinneess ccaann ffaaiill dduuee

ttoo ffaattiigguuee oovveerr ttiimmee

aanndd ccaauussee eexxtteennssiivvee ddaammaaggee ttoo pprroodduucctt aanndd tthhee hhoommee..

••UUssee oonnllyy 11//44"" ((00..66 ccmm)) ccoop

pppeerr ttuubbiinngg ffoorr wwaatteerr lliinnee..

••DDoo nnoott ccoonnnneecctt ttoo rreevveerrssee oossmmoossiiss wwaatteerr ffiillttrraattiioonn ssyysstteemm..

The 1/4" (0.6 cm) brass compression union is located in the literature packet.

1. Pull copper supply tubing from plumbing forward from underneath refrigerator (see Figure A).

2. Flush air and impurities from water line by turning on water supply and running two (2) quarts (1.9 L) of water into a

bucket.

3. Bend the open end of the supply tube to point toward the open end of the Water Valve Tube (see Figure B). Note:

The Water Valve Tube is designed to flex or bend as necessary to line up with the supply tube, so union can be

connected easily.

4. Remove brass nuts and ferrules from union and slide onto open ends of Water Valve Tube and supply tubing (see

Figure C).

5. Connect nuts on copper tubing to union (see Figure D). Be sure both nuts are fully seated in union before tightening

nuts. Do Not over tighten.

6. Turn on water supply to refrigerator and check for leaks.

7. Turn off water supply to refrigerator and correct any leaks. Repeat this process until no leaks exist.

8. Completely turn on water supply to refrigerator.

9. Verify drain pan is installed and aligned. Drain pan must be pushed past and over initial stopping point.

Figure A

Figure B

Copper tubing

Water valve tube

Figure D

Figure C

Brass nuts and

ferrules

38

WATER CONNECTION (ICE AND WATER DISPENSER MODEL)

•Refer to water supply requirement section for preliminary installation and site preparation (see page 9 & 10).

•Do not use plastic water lines between refrigerator and supply . If moved repeatedly, plastic water lines can fail

due to fatigue over time and cause extensive damage to product and the home.

•Use only 1/4” (0.6 cm) copper tubing for water line.

•Do not connect to reverse osmosis water filtration system.

The 1/4” (0.6 cm) brass compression union and tube insert are located in the literature packet.

1. Pull copper supply tubing from plumbing forward from underneath refrigerator (see Figure A).

2. Flush air and impurities from water line by turning on water supply and running two (2) quarts (1.9 L) of water into a

bucket.

3. Bend the open end of the copper supply tube toward the open end of the 1/4” (0.6 cm) plastic filter tube. (see

Figure B).

4. Remove tube insert, located in literature packet, and slide into the plastic filter tube. (see Figure B).

5. Remove brass nuts and ferrules from compression union, located in the literature packet. and slide onto open ends of

plastic filter tube and copper supply tube (see Figure C).

6. Connect brass nut on plastic/copper tubing to union (see Figure D). Be sure both tubes are fully seated in union

before tightening nuts.

DDoo NNoott oovveerr ttiigghhtteenn..

7. Turn on water supply to refrigerator and check for leaks.

8. Turn off water supply to refrigerator and correct any leaks. Repeat this process until no leaks exist.

9. Completely turn on water supply to refrigerator.

10. Verify drain pan is installed and aligned. Drain pan must be pushed past and over initial stopping point.

FFiigguurree AA

FFiigguurree BB

FFiigguurree DD

FFiigguurree CC

Copper tubing

Copper supply

tubing

Plastic filter

tube

Brass nuts and ferrules

Plastic filter

tube

Water solenoid

valve

39

IINNIITTIIAALL IINNSSTTAALLLLAATTIIOONN OOFF WWAATTEERR FFIILLTTEERR

1. Locate water filter door. The door is located under the Meat SavorTM/Produce drawer handle. (See figure 1)

2. Push upper left corner of door to release latch and pull door downward

3. Insert filter cartridge into circular opening in filter housing. Move filter cartridge horizontally until filter head is

engaged. Rotate gently clockwise until filter stops.

4. Flush air from the system by running water through the dispenser continuously for 3 minutes. Continue to run water

if water spurts occur until water runs steady. Additional flushing may be required in areas with poor quality water.

NNOOTTEE::

Allow 1-2 minute delay in water dispersal to allow internal water tank to fill.

RREEPPLLAACCIINNGG WWAATTEERR FFIILLTTEERR

IIMMPPOORRTTAANNTT:: AAiirr ttrraappppeedd iinn wwaatteerr ffiillttrraattiioonn ssyysstteemm mmaayy ccaauussee wwaatteerr aanndd ccaarrttrriiddggee ttoo eejjeecctt.. UUssee ccaauuttiioonn wwhheenn

rreemmoovviinngg..

1. Repeat steps 1 and 2 under “Initial Installation of Water Filter”

2. Turn filter cartridge counterclockwise until it releases from filter head.

3. Drain water from filter into sink and dispose of cartridge.

4. Wipe up excess water at filter location and continue with steps 2 and 3 above.

WWHHEENN TTOO CCHHAANNGGEE TTHHEE WWAATTEERR FFIILLTTEERR

IIMMPPOORRTTAANNTT:: CCoonnddiittiioonn ooff tthhee wwaatteerr aanndd aammoouunntt uusseedd ddeetteerrmmiinneess lliiffee ssppaann ooff wwaatteerr ffiilltteerr ccaarrttrriiddggee.. IIff wwaatteerr uussee iiss

hhiigghh,, oorr iiff wwaatteerr iiss ooff ppoooorr qquuaalliittyy,, rreeppllaacceemmeenntt mmaayy nneeeedd ttoo bbee mmoorree ffrreeqquueenntt..

The water filter should be changed approximately every 9 months or after

775500

gallons of water is used (whichever

comes first). Replace cartridge when flow becomes too slow.

HHOOWW TTOO OORRDDEERR RREEPPLLAACCEEMMEENNTT FFIILLTTEERR CCAARRTTRRIIDDGGEESS

Replacement filters are available through your local Viking Range dealer. You may also order them by calling Viking

Range Customer Service at 1-888-845-4641 or online at www.vikingrange.com.

WATER FILTER INSTALLATION

WARNING

CAUTION

To avoid serious illness or death, do not use unit where water is microbiologically

unsafe or of unknown quality without adequate disinfection before or after the system.

Systems certified for cyst reduction may be used on disinfected water that may contain

filterable cysts. The contaminants or other substances removed or reduced by this

water treatment system are not necessarily in your water.

Be sure to have replacement cartridge available when filter change is required.

•If water filtration system has been allowed to freeze, replace filter cartridge.

•If system has not been used for several months, and water has an unpleasant taste or

odor, flush system by dispensing 2-3 glasses of water. If unpleasant taste or odor

persists, change filter cartridge.

Figure 1

(42” W. model shown)

PPuusshh

40

SSYYSSTTEEMM SSPPEECCIIFFIICCAATTIIOONN AANNDD PPEERRFFOORRMMAANNCCEE DDAATTAA SSHHEEEETT

This system has been tested according to NSF/ANSI 42/53 for reduction of the substances listed below. The

concentration of the indicated substances in water entering the system was reduced to a concentration of less than or

equal to the permissible limit for water leaving the system, as specified in NSF/ANSI 42/53.* (100% safety factors builtin for unmetered usage for health claims only.)

Standard No. 42: Aesthetic Effects

Parameter USEPA Influent Influent Effluent %Reduction Min. Req.

McL Average Challenge Average Maximum Average Minimum Reduction

Concentrations

Chlorine 1.88 mg/L 2.0 mg/L + 10% <0.05mg/L 0.06 mg/L >97.26% 96.84% >

50%

T&O

Particulates** 5,700,000 #/mL at least 29.83#/mL 140 #/mL 99.98% 99.91% >

85%

10,000 particles/mL

Standard No. 53: Health Effects

Parameter USEPA Influent Influent Effluent %Reduction Min. Req.

McL Average Challenge Average Maximum Average Minimum Reduction

Concentrations

Turbidity 1 NTU*** 10.73 NTU*** 11 + 1 NTU 0.36 NTU .049 NTU 97.09% 95.20% 0.5 NTU

Cysts 99.95% Reduction 200,000 #/L min. 50,000/L <1 <1 >99.99% >99.99% >99.95%

Asbestos 99% Reduction 155 MF/L 10

7

& 108fibers/L <1 <1 >99.99% >99.99% 99%

fibers>10micrometers

Lead at pH 6.5 0.015 mg/L 0.153 mg/L 0.15mg/L + 10% <.001 <.001 >99.35% >99.35% 0.010 mg/L

Lead at pH 8.5 0.015 mg/L 0.150 mg/L 0.15mg/L + 10% <.001 <.001 >99.35% 97.35% 0.010 mg/L

Mercury at pH 6.5

0.002 mg/L 0.006 mg/L .006mg/L +

-10% 0.00026 0.0005 98.72% 90.91% 0.002mg/L

Mercury at pH 8.5 0.002mg/L 0.006 mg/L .006mg/L + -10% 0.0008 0.0015 98.72% 75.93% 0.002mg/L

Lindane 0.0002 mg/L 0.002 mg/L .002mg/L + 10% 0.000025 0.00007 98.72% 96.50% 0.0002mg/L

Atrazine

0.003 mg/L 0.00873 mg/L .009mg/L +

10% <.002 mg/L <.002 mg/L 76.99% 75.31% 0.003 mg/L

Toxaphene 0.003 mg/L 0.015 mg/L .015mg/L + 10% <0.001 <0.001 92.97% 91.67% 0.003mg/L

*Tested using a flow rate of 0.5 gpm; pressure of 60 psig; pH of 7.5 + 0.5; temp of 68o+ 5oF (20o+ 3oC)

**Measurement in particles/mL. Particles used were 0.5 - 1 microns

***NTU = Nephelometric Turbidity units

OOppeerraattiinngg SSppeecciiffiiccaattiioonnss

Capacity: Certified for up to 750 gallons (2,838 L); up to nine months

Pressure Requirement: 20 - 120 psi (2.8 - 8.2 bar)

Temperature: 33-100

o

F (0.6 - 38oC)

Flow rate: 0.78 gpm (2.9 l/min.)

Check for compliance with the state and local laws and regulations.

Note: While the testing was performed under standard laboratory conditions, actual performance may vary. Must be

installed and operated in accordance with manufacturer’s recommended procedures and guidelines. Installation

instructions, parts and service availability, and standard warranty are included with the product when shipped. This

drinking water system must be maintained according to manufacturer’s instruction, including replacement of filter

cartridges.

System tested and certified by NSF International against Standard 42 for the reduction of chlorine taste and

odor, particulate Class I and Standard 53 for the reduction of Lead, Lindane, Atrazine, Mercury, Toxaphene,

Cyst, Turbidity, and Abestos.

Manufactured by: PentaPure Incorporated

1000 Apollo Road

Eagan, MN 55121

(651) 554-3140

41

Align the holes on both ends of the louvered panel

with the holes in the base of the refrigerator.

Adjust the kickplate to the desired height and fasten

in place by tightening the screws in the slot. Attach

the kickplate to the refrigerator on each side with the

two black phillips head screws provided.

DOOR STOP ADJUSTMENT

1. Using a 3/16” allen wrench, remove door stop pin located in bottom hinge.

2. The pin is factory set 110

o

. For 120oswing, move the pin to the utmost forward stop hole. For 90oswing, move the

pin to the utmost rear stop hole.

HINGE ADJUSTMENT

1. Using a 3/16” allen wrench, remove the door stop pin located in bottom hinge.

2. Using the height adjustment shim as a wrenching device, rotate the height adjustment bushing counterclockwise to

raise or clockwise to lower the location of the door.

3. When proper adjustment is reached, align shim with door stop pin holes and replace door stop pin. Firmly tighten

pin in place.

Attach to unit with

screws

(on both ends)

Slots for

adjustments (on

both ends)

Door stop

pin

120

o

position

90

o

position

KICKPLATE INSTALLATION

WIRING DIAGRAM

BUILT-IN SIDE-BY-SIDE 42” / 48” W. REFRIGERATOR - NON-DISPENSER MODEL

42

WWAARRNNIINNGG::

EELLEECCTTRRIICCAALL

GGRROOUUNNDDIINNGG

IINNSSTTRRUUCCTTIIOONNSS

This appliance is

equipped with a

three prong

grounding plug for

your protection

against shock

hazard and should

be plugged directly

into a properly

grounded three

prong receptacle.

DO NOT CUT OR

REMOVE THE

GROUNDING

PRONG FROM

THIS PLUG.

RREEFFEERR OONNLLYY TTOO

FFEEAATTUURREESS WWHHIICCHH

AARREE EEQQUUIIPPPPEEDD

WWIITTHH TTHHIISS UUNNIITT..

43

WIRING DIAGRAM

BUILT-IN SIDE-BY-SIDE 48” W. REFRIGERATOR - DISPENSER MODEL

WWAARRNNIINNGG::

EELLEECCTTRRIICCAALL

GGRROOUUNNDDIINNGG

IINNSSTTRRUUCCTTIIOONNSS

This appliance is

equipped with a three

prong grounding plug

for your protection

against shock hazard

and should be

plugged directly into

a properly grounded

three prong

receptacle. DO NOT

CUT OR REMOVE

THE GROUNDING

PRONG FROM THIS

PLUG.

RREEFFEERR OONNLLYY TTOO

FFEEAATTUURREESS WWHHIICCHH

AARREE EEQQUUIIPPPPEEDD WWIITTHH

TTHHIISS UUNNIITT..

WIRING DIAGRAM

BUILT-IN SIDE-BY-SIDE 42” W. REFRIGERATOR - DISPENSER MODEL

VIKING RANGE CORPORATION

111 Front Street • Greenwood, Mississippi 38930 USA • (662) 455-1200

Specifications subject to change without notice

For more product information, call 1-888-VIKING1 (845-4644), or visit our web site at http://www.vikingrange.com

F20286C

(PS1204VR)

WWAARRNNIINNGG::

EELLEECCTTRRIICCAALL

GGRROOUUNNDDIINNGG

IINNSSTTRRUUCCTTIIOONNSS

This appliance is

equipped with a

three prong

grounding plug for

your protection

against shock

hazard and should

be plugged directly

into a properly

grounded three

prong receptacle.

DO NOT CUT OR

REMOVE THE

GROUNDING

PRONG FROM THIS

PLUG.

RREEFFEERR OONNLLYY TTOO

FFEEAATTUURREESS WWHHIICCHH

AARREE EEQQUUIIPPPPEEDD

WWIITTHH TTHHIISS UUNNIITT..

Addendum for DTSB483 Trim Models

Only

CABINET AND PANEL INFORMATION-48" W. DESIGNER TRIM MODELS

Trim models with 1/4” (.6 cm) panels (not included) fit flush in standard 24” (61.0 cm) deep cabinet openings. The

extruded handles protrude 1” (2.5 cm) into the room.

DETAIL “A”

DETAIL “B”

A

B

48” (121.9cm)

WALL

NO SPACE

3/4” (1.9 cm)

FULL END

OVERLAY

3/4” (1.9 cm)

FULL END

PANEL

FREEZER DOOR

24” (61.0 cm)

STANDARD

CABINET

DEPTH

24” (61.0 cm)

STANDARD

CABINET

DEPTH

FLUSH

FLUSH

1/4” (0.6 cm)

PANEL

1/4” (0.6 cm)

PANEL

REFRIGERATOR

DOOR

WALL

48” (121.9 cm)

NO SPACE IF 24” (61.0 cm)

STANDARD CABINET

DEPTH IS USED

COUNTERTOP

OVERHANG

CABINET AND PANEL INFORMATION-48" W. DESIGNER TRIM MODELS (continued)

C

D

48” (121.9cm)

NO SPACE

24” (61.0 cm)

STANDARD

CABINET

DEPTH

REFRIGERATOR

DOOR

WALL

1/4” (0.6 cm) PANEL

WITH ATTACHED 3/4”

(1.9 cm) RAISED PANEL

1” (2.5 cm)

2 7/8”

(7.3 cm)

RAISED PANEL

CABINET DOOR

24 3/4”

(62.9 cm)

DETAIL “C”

DETAIL “D”

NOTE: Trim models with 1/4” (.6 cm) panels (not included) can be mounted up to 3/4” (1.9 cm) forward in cabinet opening to align

refrigerator door face with overlay cabinet door faces. When doing so, additional anti-tip mounting boards are required.

48” (121.9cm)

WALL

24”

(61.0 cm)

STANDARD

CABINET

DEPTH

24 3/4”

(62.9 cm)

3/4” (1.9 cm) SPACE IF

24” (61.0 cm) STANDARD

CABINET DEPTH IS USED

3/4” (1.9 cm)

FORWARD

REFRIGERATOR

DOOR

1/4” (0.6 cm)

PANEL

REFRIGERATOR

AND CABINET

DOOR FLUSH

DOOR PANEL INSTALLATION-48" W. DESIGNER TRIM MODELS

Panels must not weigh more than 50 pounds per door. Refer to “Custom Panel Dimensions” on page 4 for detailed

panel instructions.

1. Remove cabinet side trim with a phillips screwdriver

2. Remove handle with a phillips screwdriver.

•For ease of panel installation, 2 people are required to lift and guide panel into trim.

•Install 1 panel at a time.

3. Align panel in trim and push evenly. For smoother installation apply liquid soap on door trim and refrigerator trim.

If panel binds, loosen top or side door trim, adjust panel, and retighten.

4. Install handle with screws. Install door trim inserts (supplied) on all four sides of door by starting in one corner and

pushing the strip in place. For smoother installation, apply liquid soap.

DDOOOORR TTRRIIMM IINNSSEERRTT

((NNOOTTEE:: MMOOUUNNTTIINNGG SSCCRREEWWSS LLOOCCAATTEEDD BBEEHHIINNDD))

BASIC SPECIFICATIONS AND DIMENSIONS-48” W. DESIGNER TRIM MODELS

To end of handle bracket

26” (66.0 cm)

plug attached to product.

DESCRIPTION DTSB483

Overall Width 48” (121.9 cm)

Overall Height from Bottom Min. 82-3/4” (210.2 cm) to Max. 84-1/16” (213.5 cm)

Overall Depth from Rear To rear edge of side trim 23 13/16” (60.5 cm)

To front of top grille 24” (61.0 cm)

Cutout Width 48” (121.9 cm)

Cutout Height 82-7/8” (210.5 cm) min.; 84-1/16” (213.5 cm) max.

Cutout Depth 24” (61.0 cm) min.*

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with grounded 3-prong

Maximum Amp Usage 9.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 20 psi; maximum 120 psi

Overall Interior Dimensions

~Refrigerator

~Freezer

~Total Capacity

18.5 cu. ft. (524 liters)

8.9 cu. ft. (252 liters)

27.4 cu. Ft. (776 liters)

Approximate Shipping Weight 650 lbs. (292.5 kg)

*Full overlay models fit flush in 25” (63.5 cm) deep cabinet openings. They can be installed in standard 24” (61.0 cm)

deep openings. The door faces and top grille will protrude 3/4” (1.9 cm) into the room.

Loading...

Loading...