Viking pump H224A-CHC1, 224A-CHC2 Series, HL224A-CHC2, K224A-CHC1, K224A-CHC2 Technical & Service Manual

...

VISIT VIKINGPUMP.COM FOR PDF OF CURRENT TSM ISSUE & TO VIEW REPAIR VIDEOS

TECHNICAL SERVICE MANUAL

INSTALLATION, OPERATION & MAINTENANCE

CHOCOLATE PUMP: CAST IRON

SERIES: 224A-CHC1, 224A-CHC2

SIZES: H, HL, K, KK, LQ, LL, LS, Q, QS

TABLE OF CONTENTS

Model Number Chart ..................................................................1

Introduction ................................................................................1

Safety Information & Instructions ............................................... 2

Special Information ....................................................................3

Rotation ..................................................................................3

Circulation Lines ..................................................................... 3

Jacketed Ports ........................................................................ 3

EC1935 Certication ..............................................................3

Maintenance ...............................................................................3

Lubrication .............................................................................. 3

Cleaning Pump ....................................................................... 3

Storage ................................................................................... 3

Suggested Repair Tools ......................................................... 3

Removal: O-Ring Seal Bushing ................................................. 5

Installation: O-Ring Seal Bushing .............................................. 5

Pump Disassembly ....................................................................6

Pump Assembly .........................................................................7

Thrust Bearing Adjustment ........................................................ 8

Installation: Hardened Iron Idler Bushing ..................................9

Spacer Coupling Lengths ..........................................................9

APPENDIX (Formerly TSM 000) ........................................................9

General Installation Notes ..........................................................9

Foundation ............................................................................... 11

Component & Unit Lifting Features ......................................... 11

Alignment .................................................................................12

Piping .......................................................................................13

Start Up ....................................................................................14

Troubleshooting .......................................................................14

Vacuum Gauge - Suction Port .............................................14

Pressure Gauge - Discharge Port ........................................ 15

Rapid Wear .............................................................................16

Preventative Maintenance .......................................................16

Do’s & Don’ts ...........................................................................17

Operation .............................................................................. 17

Maintenance ......................................................................... 17

Declaration of Conformity ........................................................18

TSM 1462

Page 1 of 18

Issue A

MODEL NUMBER CHART

JACKETED O-RING SEAL BUSHING

GROOVED CASING STANDARD CASING

H224A-CHC1 H224A-CHC2

HL224A-CHC1 HL224A-CHC2

K224A-CHC1 K224A-CHC2

KK224A-CHC1 KK224A-CHC2

LQ224A-CHC1 LQ224A-CHC2

LL224A-CHC1 LL224A-CHC2

LS224A-CHC1 LS224A-CHC2

Q224A-CHC1 Q224A-CHC2

QS224A-CHC1 QS224A-CHC2

INTRODUCTION

The illustrations used in this manual are for identication

purposes only and cannot be used for ordering parts.

Obtain a parts list from a Viking Pump representative. Always

give a complete name of part, part number and material with

the model number and serial number of pump when ordering

repair parts. The unmounted pump or pump unit model

number and serial number are on the nameplate. This manual

only applies to the pump models specied in the "Model

Number Chart" on page 1. Pump specications and

recommendations are listed in AD-23, which is available at

vikingpump.com.

Viking Pump® 224A-CHC1 & 224A-CHC2 Pump Series

designed specically for handling chocolate and related

confectionary processes. Viking Chocolate Series Pumps

are suitable for low hazard foods like chocolate according to

each facility’s HACCP plan. They are not a hygienic design

according to 3A or FDA, and are not suitable for services

requiring CIP or COP.

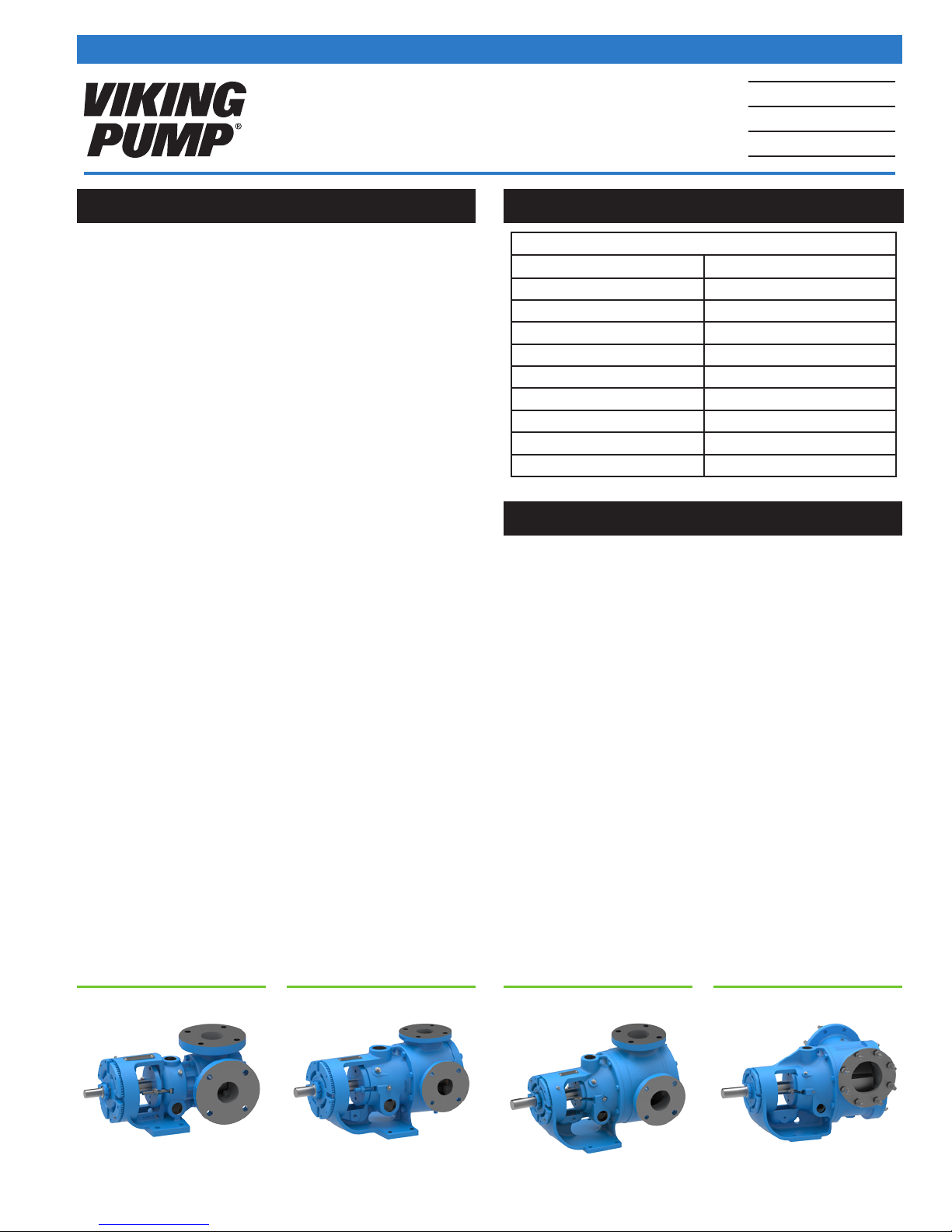

FIGURE 1: HL FIGURE 3: LSFIGURE 2: K FIGURE 4: QS

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

SAFETY INFORMATION & INSTRUCTIONS

IMPROPER INSTALLATION, OPERATION OR MAINTENANCE

OF PUMP MAY CAUSE SERIOUS INJURY OR DEATH AND/OR

RESULT IN DAMAGE TO PUMP AND/OR OTHER EQUIPMENT.

VIKING’S WARRANTY DOES NOT COVER FAILURE DUE TO

IMPROPER INSTALLATION, OPERATION OR MAINTENANCE.

THE FOLLOWING SAFETY INSTRUCTIONS MUST BE FOLLOWED AND ADHERED TO AT ALL TIMES.

DANGER = FAILURE TO FOLLOW THE INDICATED

⚠

INSTRUCTION MAY RESULT IN SERIOUS INJURY

OR DEATH.

⚠

DANGER

BEFORE opening any liquid chamber (pumping chamber,

reservoir, relief valve adjusting cap tting, etc.) be sure that:

• Any pressure in the chamber has been completely vented

through the suction or discharge lines or other appropriate

openings or connections.

• The pump drive system means (motor, turbine, engine,

etc.) has been “locked out” or otherwise been made nonoperational so that it cannot be started while work is being

done on the pump.

• You know what material the pump has been handling,

have obtained a material safety data sheet (MSDS) for

the material, and understand and follow all precautions

appropriate for the safe handling of the material.

THIS INFORMATION MUST BE FULLY READ BEFORE

BEGINNING INSTALLATION, OPERATION OR MAINTENANCE

OF PUMP AND MUST BE KEPT WITH PUMP. PUMP MUST BE

INSTALLED, OPERATED AND MAINTAINED ONLY BY SUITABLY

TRAINED AND QUALIFIED PERSONS.

WARNING = IN ADDITION TO SERIOUS INJURY OR DEATH,

⚠

FAILURE TO FOLLOW THE INDICATED INSTRUCTION MAY

CAUSE DAMAGE TO PUMP AND/OR OTHER EQUIPMENT

⚠

WARNING

INSTALL pressure gauges/sensors next to the pump suction

and discharge connections to monitor pressures.

⚠

WARNING

USE extreme caution when lifting the pump. Suitable lifting

devices should be used when appropriate. Lifting eyes

installed on the pump must be used only to lift the pump, not

the pump with drive and/or base plate. If the pump is mounted

on a base plate, the base plate must be used for all lifting

purposes. If slings are used for lifting, they must be safely and

securely attached. For weight of the pump alone (which does

not include the drive and/or base plate) refer to the Viking

Pump product catalog.

⚠

DANGER

BEFORE operating the pump, be sure all drive guards are in

place.

⚠

DANGER

DO NOT operate pump if the suction or discharge piping is

not connected.

⚠

DANGER

DO NOT place ngers into the pumping chamber or its

connection ports or into any part of the drive train if there is

any possibility of the pump shafts being rotated.

⚠

WARNING

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters from

those the pump was originally supplied, without conrming its

suitability for the new service.

⚠

WARNING

BEFORE operating the pump, be sure that:

• It is clean and free from debris

• All valves in the suction and discharge pipelines are fully

opened.

• All piping connected to the pump is fully supported and

correctly aligned with the pump.

• Pump rotation is correct for the desired direction of ow.

⚠

DANGER

DO NOT attempt to dismantle a pressure relief valve that has

not had the spring pressure relieved or is mounted on a pump

that is operating.

⚠

DANGER

AVOID contact with hot areas of the pump and/or drive.

Certain operating conditions, temperature control devices

(jackets, heat-tracing, etc.), improper installation, improper

operation, and improper maintenance can all cause high

temperatures on the pump and/or drive.

⚠

WARNING

THE PUMP must be provided with pressure protection. This

may be provided through a relief valve mounted directly on

the pump, an in-line pressure relief valve, a torque limiting

device, or a rupture disk. If pump rotation may be reversed

during operation, pressure protection must be provided on

both sides of pump. Relief valve adjusting screw caps must

always point towards suction side of the pump. If pump

rotation is reversed, position of the relief valve must be

changed. Pressure relief valves cannot be used to control

pump ow or regulate discharge pressure. For additional

information, refer to Appendix, General Installation Notes,

item 5 on Pressure Protection or contact your Viking Pump

representative for Engineering Service Bulletin ESB-31.

⚠

WARNING

THE PUMP must be installed in a manner that allows safe

access for routine maintenance and for inspection during

operation to check for leakage and monitor pump operation.

TSM 1462 | Issue A | Page 2 of 18

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

SPECIAL INFORMATION

MAINTENANCE

ROTATION

Viking pumps operate equally well in a clockwise or

counter-clockwise rotation. Some constructions may require

modications, consult Viking Pump representative if unsure.

Shaft rotation determines which port is suction and which is

discharge. Suction port is where pumping elements (gear

teeth) come out of mesh.

If pump rotation is reversed during operation, pressure

protection must be provided on both sides of pump.

Relief valve adjusting screw cap must always point towards

suction side of pump. If pump rotation is reversed, remove

pressure relief valve and turn end for end.

CIRCULATION LINES

This equipment (not utilized on all pumps) must be connected

properly. Packed pumps typically have a ush line from

packing chamber to discharge port. Mechanical seal

pumps typically have a suckback line from seal chamber to

suction port. If pump rotation is reversed, be sure circulation

connections are connected to the suction or discharge port as

noted above to avoid excessive leakage or damage to pump.

If pump is handling heated product, be sure circulation line is

insulated to assure continued ow.

JACKETED PORTS

Jackets are utilized to heat (or cool) the pump and liquid in the

pump prior to startup. Not all pumps have ports for jacketing.

Jacketing port locations vary by model.

EC1935 CERTIFICATION

EC1935/2004 is a European standard covering

materials that come into contact with foods.

It requires that food contact materials may not

transfer substances to foods in quantities which represent a

health risk to people, lead to an unacceptable change in the

composition of the food, or adversely aect the organoleptic

properties of the food. Viking 224A-CHC1 and -CHC2 pumps

comply with this standard, and the EC1935 cup and fork logo

is visible on the pump nameplate.

See back page for Declaration of Conformity.

These pumps are designed for long, trouble-free service life

under a wide variety of application conditions with a minimum

of maintenance. The points listed below will help provide long

service life.

LUBRICATION

External lubrication must be applied slowly with a hand gun

to the bearing houseing lubrication tting every 500 hours

of operation with food grade grease, NLGI # 2. Contact your

Viking Pump representative with specic lubrication questions

or to obtain a copy of Engineering Service Bulletin ESB-515.

The O-Ring Seal Bushing used in the 224A-CHC1 &

224A-CHC2 pumps require external food grade grease

lubrication applied slowly with a grease gun every two weeks

of operation. Approximate grease capacity is 1.5 oz. on H-LS

and 3 oz. on the Q and QS.

CLEANING PUMP

Keep pump as clean as possible. This will facilitate inspection,

adjustment and repair work and help prevent overlooking a

dirt covered grease tting.

STORAGE

If pump is to be stored, or not used for six months or more,

pump must be drained and a light coat of non-detergent light

food grade oil must be applied to all internal pump parts.

Lubricate ttings and apply food grade grease to pump shaft

extension. Viking suggests rotating pump shaft by hand one

complete revolution every 30 days to circulate the oil. Tighten

all pump assembly bolts before putting pump in service after

being stored.

SUGGESTED REPAIR TOOLS

The following tools must be available to properly repair these

pumps. These tools are in addition to standard mechanics’ tools

such as open-end wrenches, pliers, screwdrivers, etc. Most of

the items can be obtained from an industrial supply house.

1. Soft Headed hammer

2. Allen wrenches (some mechanical seals and set collars)

3. O-Ring seal bushing installation sleeve

2-751-002-730 for 1.125 inch seal; H-HL pumps

2-751-003-730 for 1.4375 inch seal; K-LL pumps

2-751-005-630 for 2.4375 inch seal; Q-QS pumps

No sleeve needed for LS pumps

4. Bearing locknut spanner wrench

Source: #471 J. H. Williams & Co. or equal; H-LL pumps

Source: #472 J. H. Williams & Co. or equal; LS-QS pumps

5. Spanner wrench, adjustable pin type for use on bearing

housing

Source: #482 J. H. Williams & Co. or equal; H-QS pumps

Supplied with pump; N-RS pumps

6. Brass or hardwood bar

7. Arbor press

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

TSM 1462 | Issue A | Page 3 of 18

Contact your Viking stocking distributor for available seal and rebuild kits

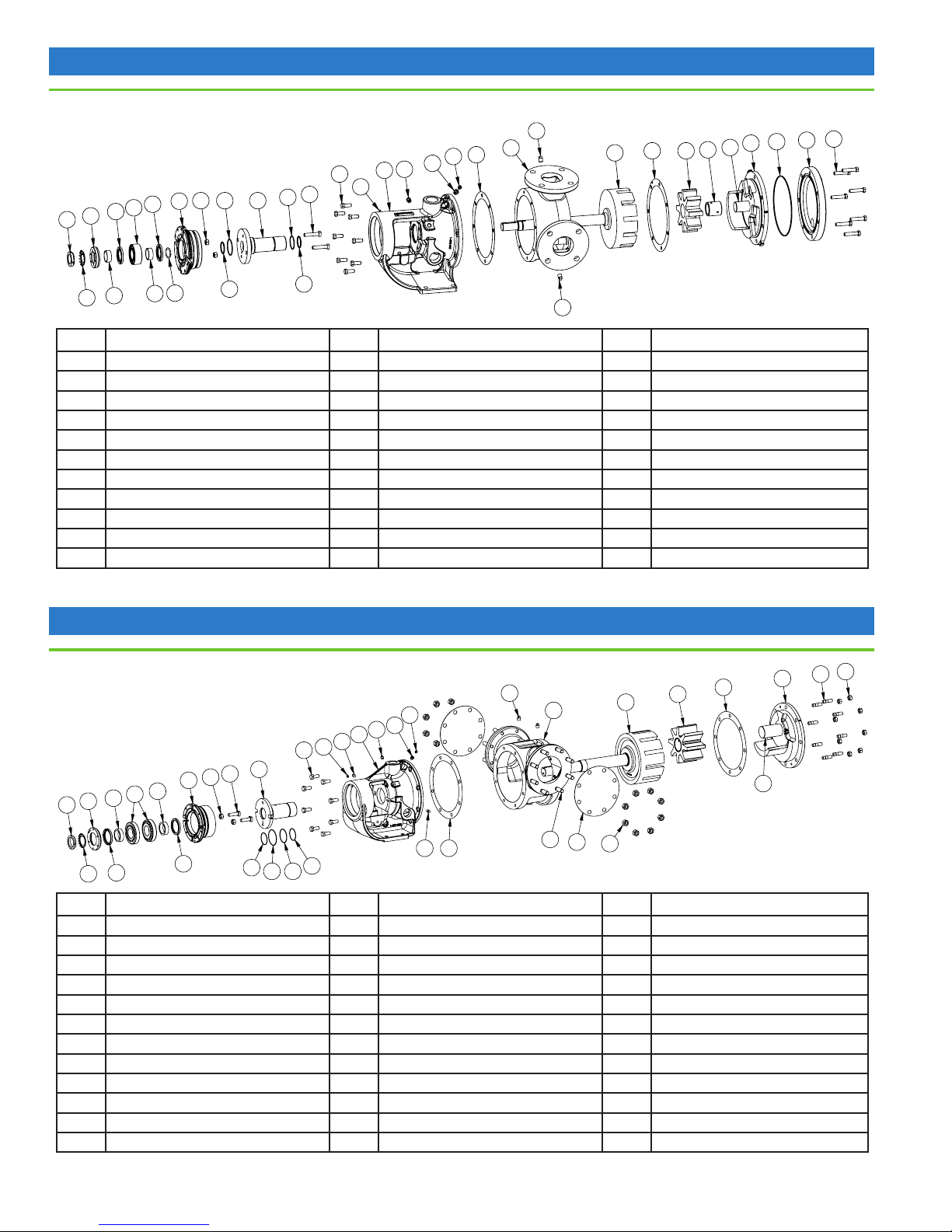

FIGURE 5: EXPLODED VIEW (H, HL, K, KK, LQ, LL, LS SIZES)

30

31

29

26

26A

12B

27

28

17

16

18B

7

6

5

3

1

18C

19

12

35 37

36

38

41

40

39

43

42

8511

4

2

18A

18A

30

ITEM NAME OF PART ITEM NAME OF PART ITEM NAME OF PART

1 Locknut 16 O-Ring Seal Bushing Nut 30 Pipe Plug

2 Lockwasher 17 O-Ring Seal Bushing Capscrew 31 Casing

3 End Cap for Bearing Housing 18A Dynamic O-Ring 35 Head Gasket

4 Bearing Spacer Collar (Outer) 18B Inner Static O-Ring 36 Rotor and Shaft Assembly

5 Lip Seal for Bearing Housing 18C Outer Static O-Ring 37 Idler and Bushing Assembly

6 Ball Bearing 19 O-Ring Seal Bushing 38 Bushing (part of 37)

7 Bearing Housing 26 Pressure Relief Fitting 39 Idler Pin (part of 40)

8 Bearing Spacer Collar (Inner) 26A Reducer Bushing (Not H, HL) 40 Head and Idler Pin Assembly

11 Half Round Ring (Not H, HL) 27 Bracket 41 Jacketed Head Plate Gasket

12 Grease Fitting 28 Capscrew for Bracket 42 Jacketed Head Plate

12B Grease Fitting 29 Bracket Gasket 43 Head Capscrews

Contact your Viking stocking distributor for available seal and rebuild kits

FIGURE 6: EXPLODED VIEW (Q, QS SIZES)

30

26

26A

12B

27

30A

12

28

19

17

16

7

8

6

4

3

1

31

36

35

37

40

39

44

43

5

2

5

18A

18C

18B

18A

ITEM NAME OF PART ITEM NAME OF PART ITEM NAME OF PART

1 Locknut 18A Dynamic O-Ring 34 Pipe Flange Gasket

2 Lockwasher 18B Inner Static O-Ring 35 Head Gasket

3 End Cap for Bearing Housing 18C Outer Static O-Ring 36 Rotor and Shaft Assembly

4 Bearing Spacer Collar (Outer) 19 O-Ring Seal Bushing 37 Idler and Bushing Assembly

5 Lip Seal for Bearing Housing 26 Pressure Relief Fitting 39 Idler Pin (part of 40)

6 Ball Bearing 26A Reducer Bushing 40 Head and Idler Pin Assembly

7 Bearing Housing 27 Bracket 41 Jacketed Head Plate Gasket (not shown)

8 Bearing Spacer Collar (Inner) 28 Capscrew for Bracket 42 Jacketed Head Plate (not shown)

12 Grease Fitting 29 Bracket Gasket 43 Head Capscrews

12B Grease Fitting 30 Pipe Plug 44 Nut for Head

16 O-Ring Seal Bushing Nut 30A Pipe Plug 51 Stud for Flanges

17 O-Ring Seal Bushing Capscrew 31 Casing 52 Nut for Flanges

TSM 1462 | Issue A | Page 4 of 18

51

34

30A

29

52

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

⚠

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, relief valve adjusting cap

tting, etc.) Be sure:

1. That any pressure in the chamber has been

completely vented through the suction or discharge

lines or other appropriate openings or connections.

2. That the driving means (motor, turbine, engine, etc.)

has been “locked out” or made non-operational so that

it cannot be started while work is being done on pump.

3. That you know what liquid the pump has been handling

and the precautions necessary to safely handle the

liquid. Obtain a material safety data sheet (MSDS) for

the liquid to be sure these precautions are understood.

Failure to follow above listed precautionary measures

may result in serious injury or death.

3. Remove the pair of half round rings (K, KK, L, LQ, LL, and

LS sizes only) under the inner spacer collar from the shaft.

4. Loosen the gland nuts securing the O-Ring Seal Bushing

into the bracket and remove the T-bolts.

5. Thread the jack bolts into the tapped holes at the 6 and 12

o’clock position on the face of the O-Ring Seal Bushing.

Remove the OSB through the bearing housing opening.

6. Clean as much old grease and product out of the area

between the pump bracket bore and shaft as possible,

taking care not to nick the finished surfaces.

If the pump is to be disassembled further, refer to "Pump

Disassembly" on page 6.

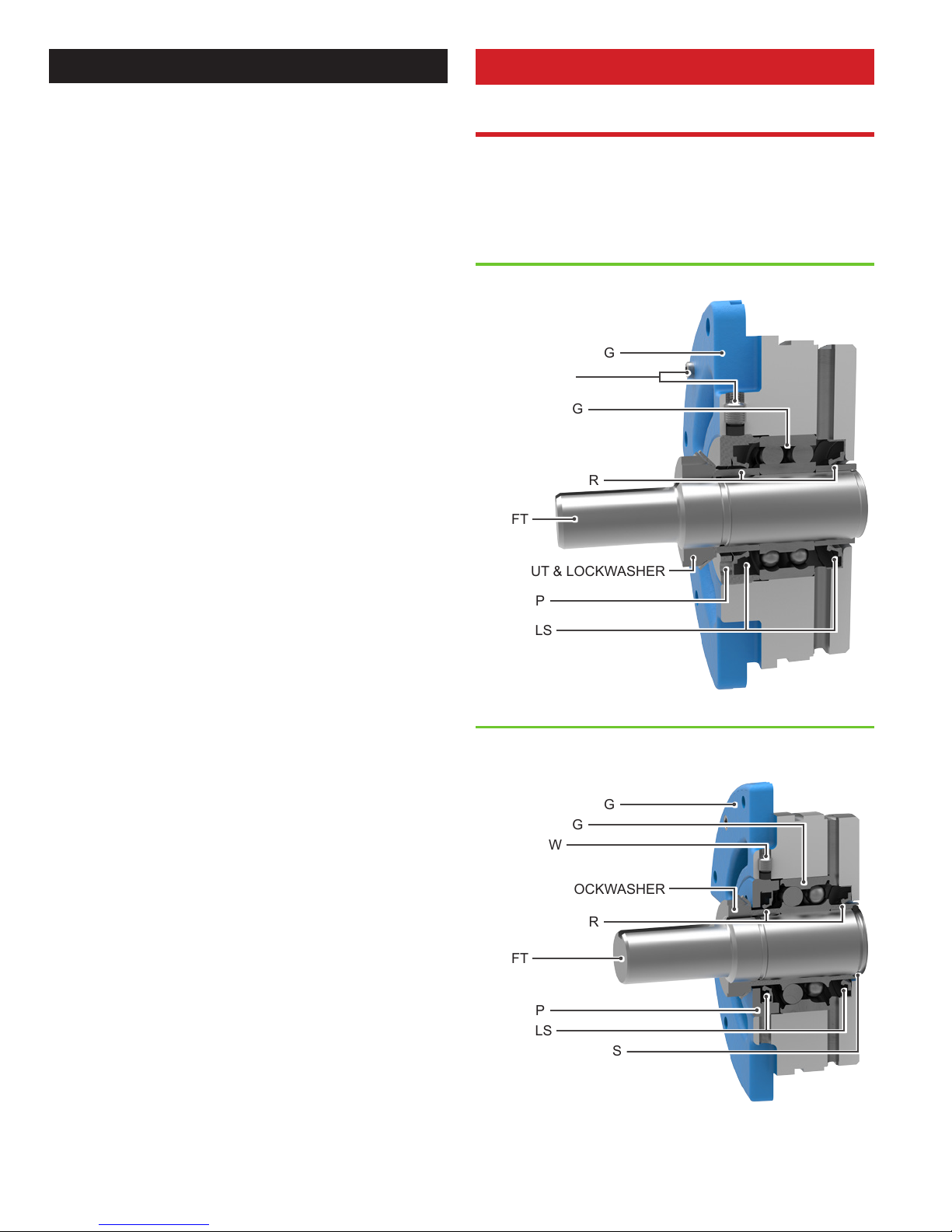

INSTALLATION: O-RING SEAL

BUSHING

FIGURE 7:

Tapered Installation Sleeve

NOTE: Coat rotor shaft, tapered installation

sleeve and inner diameter of O-ring seal bushing

with P-80® or equivalent before assembly.

Shaft

FIGURE 8:

REMOVAL: O-RING SEAL

BUSHING

The O-Ring Seal Bushing (OSB) was specially designed to

that it could be removed and the food grade O-Rings replaced

with minimal pump disassembly.

1. Insert length of hardwood or brass through port opening

between rotor teeth to keep shaft from turning. Bend up

tang of lockwasher and with a spanner wrench, remove

locknut and lockwasher from shaft.

2. Loosen two set screws in the face of the bearing housing

and remove the bearing housing assembly from the

bracket. In order to remove the bearing housing and

O-Ring Seal Bushing with the pump in place, Viking

recommends using Spacer Couplings with at least a 4.75”

gap for the H/HL size pumps, 6.25” gap for the K-LL size

pumps, and a 7.75” gap for the Q/QS size pumps.

1. Lubricate the O-Rings and OSB thoroughly with food

grade O-Ring lubricant or grease.

2. Install the inner dynamic O-Rings and the outer static

O-Rings in the O-Ring grooves in the OSB.

3. Leaving the Rotor Shaft out of the pump, install the O-Ring

Seal Bushing into the bracket. Make sure the gland dimple

is downward. This positions the lubrication groove at the

opposite end in the 6 o’clock position.

4. You will encounter resistance as the first outer static

O-Ring enters the bushing bore area in the bracket. Rotate

the OSB as needed, but do not hammer it or damage to

the O-Rings may occur.

5. Once the OSB is far enough into the bracket bore, you can

use the gland bolts to gently pull the OSB the rest of the

way into the bracket bore.

6. Tighten both nuts on the gland bolts completely.

7. NOTE: Burrs left on the shaft can damage the inner

dynamic O-Rings in the O-Ring Seal Bushing during

installation. Inspect the shaft for burrs and remove any

found with a fine grade of emery cloth.

8. Place tapered seal installation sleeve on shaft (H, HL, K,

KK, LQ, LL, Q, and QS, no sleeve required for LS size).

Coat the rotor shaft & installation sleeve with a generous

amount of food grade grease.

9. Carefully insert the rotor shaft into the pump casing.

Prevent the shaft keyway or threads from contacting the

inner dynamic O-Rings. The shaft threads and keyway

may be taped to ensure the O-Rings aren’t nicked by the

shaft edges.

10. Remove the seal installation sleeve.

11. Reinstall the head with idler gear, using a new head

gasket. Ensure that the crescent is opposite the sealing

area between the ports.

12. Place pair of half round rings in groove on shaft (K, KK,

LQ, LL, and LS sizes only) and turn bearing housing

assembly into bracket.

13. Put lockwasher and locknut on shaft. Tighten locknut and

bend one tang of lockwasher into slot of locknut.

14. Adjust pump end clearance, refer to "Thrust Bearing

Adjustment" on page 8.

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

TSM 1462 | Issue A | Page 5 of 18

PUMP DISASSEMBLY

⚠

CAUTION !

1. Mark head and casing before disassembly to insure proper

reassembly. The idler pin, which is offset in pump head,

must be positioned toward and equal distance between

port connections to allow for proper flow of liquid through

the pump.

Remove nuts and capscrews from head. The use of a

hoist to support head will facilitate its removal

Avoid damaging head gasket. Back head slightly away

from casing. Do not allow idler to fall from idler pin. To

prevent this, tilt top of head back when removing. Remove

head from pump. If a hoist is not available, cribbing or

blocking can be used to support head. This will eliminate

having to lift head into position when reassembling pump.

The pump has jacketed head plate; it will separate from

head when it is removed. The gasket between head and

jacket head plate must be totally removed. Use new

gasket when assembling pump.

2. Remove head gasket, idler and bushing assembly.

3. Insert a length of hardwood or brass through port opening

between rotor teeth or lock coupling end of shaft to keep

shaft from turning. Bend up tang of lockwasher and with

a spanner wrench; remove locknut and lockwasher from

shaft. Remove length of hardwood or brass from port

opening.

4. Loosen the two setscrews in the face of the bearing

housing and remove the bearing housing assembly from

the bracket. See "Figure 9" on page 6.

5. Remove pair of half round rings under the inner spacer

collar from the shaft for K, KK, LQ, LL, LS sizes only.

6. Remove pipe plug from drain hole in casing or bracket,

breaking vacuum behind rotor.

NOTE: Refer to "Removal: O-Ring Seal Bushing" on page

5.

7. Carefully remove rotor and shaft and examine for shaft

and rotor wear. Excessive wear at the O-Ring locations

may require replacement of the rotor shaft to ensure a

good seal.

8. Loosen two radial setscrews in flange of bearing housing

and with a spanner wrench remove the outer end cap with

lipseal and outer bearing spacer collar.

9. Remove the double row ball bearing, (2 tapered roller

bearings on Q, QS, N, R, RS sizes), lipseal and inner

bearing spacer collar from the bearing housing.

10. Clean all parts thoroughly and examine for wear and

damage. Check lipseals, bearings, bushings, and idler

pin and replace if necessary. Check all other parts for

nicks, burrs, excessive wear and replace if necessary.

Consult applicable Inspection Reports, available from

your distributor. Wash bearings in clean solvent. Blow out

bearings with compressed air. Do not allow bearings to spin;

turn them slowly by hand. Spinning bearings will damage

bearing components. Make sure bearings are clean, then

lubricate with light oil and check for roughness. Roughness

can be determined by turning outer race by hand.

Do not intermix inner and outer races of tapered roller

bearing (Q, QS, N, R, RS sizes)

11. Casing can be checked for wear or damage while

mounted on bracket.

12. Inspect bracket bushing for wear and remove if damaged

or worn.

FIGURE 9: BEARING HOUSING ASSEMBLY (H, HL)

BEARING HOUSING

SETSCREWS

BALL BEARING

SPACER COLLAR

SHAFT

LOCKNUT & LOCKWASHER

END CAP

LIP SEALS

FIGURE 10: BEARING HOUSING ASSEMBLY

(K, KK, LQ, LL, LS)

BEARING HOUSING

BALL BEARING

SETSCREW

LOCKNUT & LOCKWASHER

SPACER COLLAR

SHAFT

END CAP

LIP SEALS

HALF ROUND RINGS

TSM 1462 | Issue A | Page 6 of 18

Viking Pump, Inc. • A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Loading...

Loading...