Viking VUBV515G, VUBV524G Install / Use & Care Manual

Install / Use & Care

MANUAL

5 SERIES

Undercounter Beverage Center

VUBV515G

VUBV524G

Congratulations

We hope you will enjoy and appreciate the care and attention we have put into every detail of your new, state-of-the-art Viking

beverage center.

Your appliance is designed to o er years of reliable service. This Use and Care Guide will provide you with the information

you need to become familiar with your beverage center’s care and operation. For additional information, visit our website at

vikingrange.com..

Your complete satisfaction is our ultimate goal. If you have any questions or comments about this product, contact our Consumer

Support Center at 1-888-845-4641.

We appreciate your choice of our beverage center and hope that you will again select our products for your other major appliance

needs. For more information about the complete and growing selection of our products, visit us online at vikingrange.com

Table of Contents

Safety and Warnng __________________________________________________________________________________ 3

Disposal and Recycling ________________________________________________________________________ 3

Environmental Requirements __________________________________________________________________ 3

Installation _________________________________________________________________________________________ 4

Cutout and Product Dimensions ________________________________________________________________ 4

Side by Side Installation _______________________________________________________________________ 5

Anti-Tip Bracket ______________________________________________________________________________ 6

Leveling ____________________________________________________________________________________ 7

Grille Installation _____________________________________________________________________________ 8

Door Swing _________________________________________________________________________________ 8

Door Adjust _________________________________________________________________________________ 9

Operating Instructions ______________________________________________________________________________ 10

First Use ___________________________________________________________________________________ 10

Control Operation ___________________________________________________________________________ 10

Air ow and Product Loading __________________________________________________________________ 11

Interior Adjustments _________________________________________________________________________ 12

Wine Guide ________________________________________________________________________________ 15

Food Preservation Guide _____________________________________________________________________ 18

Maintenance ______________________________________________________________________________________19

Cleaning __________________________________________________________________________________19

Cleaning Condenser _________________________________________________________________________ 20

Extended Non-Use __________________________________________________________________________ 20

Troubleshooting ____________________________________________________________________________20

Service Information_________________________________________________________________________________ 22

Warranty __________________________________________________________________________________________ 23

2

Safety and Warning

NOTICE

Please read all instructions before installing, operating, or

servicing the appliance.

Use this appliance for its intended purpose only and follow

these general precautions with those listed throughout this

guide:

SAFETY ALERT DEFINITIONS

Throughout this guide are safety items labeled with a

Danger, Warning, or Caution based on the risk type:

DANGER

!

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

WARNING

!

Warning means that failure to follow this safety statement

could result in serious personal injury or death.

CAUTION

!

This equipment is to be installed with adequate back ow

protection to comply with applicable federal, state and local

codes.

Disposal and Recycling

DANGER

!

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take o the doors and leave

shelves in place so children may not easily climb inside.

If the unit is being removed from service for disposal, check

and obey all federal, state, and local regulations regarding

the disposal and recycling of refrigeration appliances, and

follow these steps completely:

1. Remove all consumable contents from the unit.

2. Unplug the electrical cord from its socket.

3. Remove the door(s)/drawer(s)

CAUTION

!

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property, or

equipment damage.

DANGER

!

This unit contains R600a (Isobutane) which is a ammable

hydrocarbon. It is safe for regular use. Do not use sharp

objects to expedite defrosting. Do not service without

consulting the “R600a speci cations” section included in the

User Guide. Do not damage the refrigerant circuit.

WARNING

!

Service must be done by factory authorized service

personnel. Any parts shall be replaced with like components.

Failure to comply could increase the risk of possible ignition

due to incorrect parts or improper service.

CALIFORNIA PROPOSITION 65

This product contains chemicals known to the state of

California to cause cancer and birth defects or other

reproductive harm. www.P65warnings.CA.gov

Environmental Requirements

This model is intended for indoor/interior applications only

and is not to be used in installations that are open/exposed

to natural elements.

This unit is designed to operate between 50°F (10°C) and

100°F (38°C). Higher ambient temperatures may reduce the

unit’s ability to reach low temperatures and/or reduce ice

production on applicable models.

For best performance, keep the unit out of direct sunlight

and away from heat generating equipment.

In climates where high humidity and dew points are present,

condensation may appear on outside surfaces. This is

considered normal. The condensation will evaporate when

the humidity drops.

CAUTION

!

Damages caused by ambient temperatures of 40°F (4°C) or below

are not covered by the warranty.

3

*

Installation

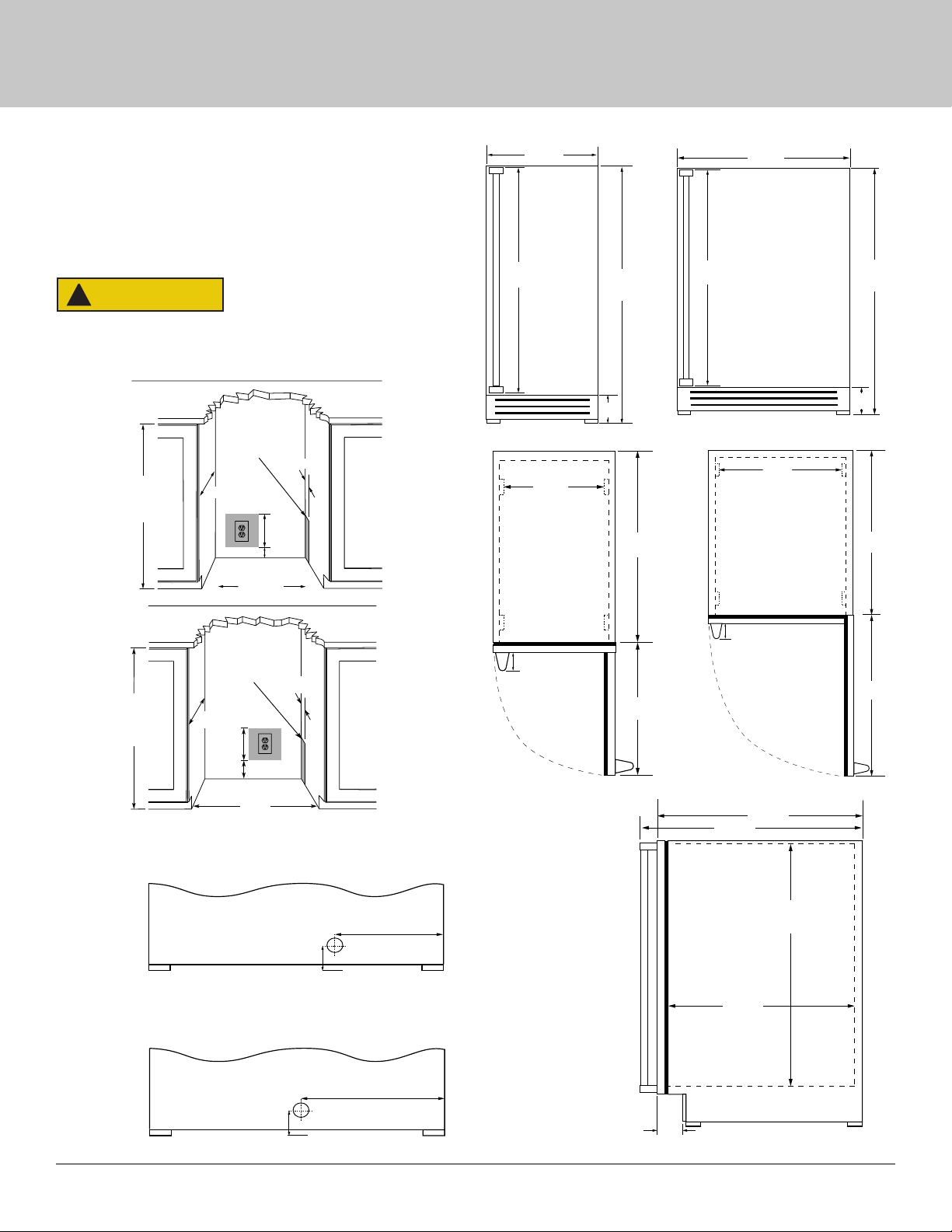

Cutout & Product Dimensions

PREPARE SITE

Your product has been designed for either free-standing or

built-in installation. When built-in, your unit does not require

additional air space for top, sides, or rear. However, the front

grille must NOT be obstructed, and clearance is required for

an electrical connection in the rear.

CAUTION

!

Unit can NOT be installed behind a closed cabinet door.

CUTOUT DIMENSIONS

VUBV515

Preferred location

for electrical outlet

VUBV524

34 ⁄"

(870 mm)

35 ⁄"

(889 mm)

33-⁄"

(860 mm)

to

34-⁄"

(886 mm)

is in an adjacent

cabinet.

24"

to

(610 mm)

Preferred location

for electrical outlet

is in adjacent

cabinet.

24"

(610 mm)

7"

(178 mm)

4"

(102 mm)

(16 mm)

(178 mm)

1 ⁄" (38 mm)

15 ⁄"

(386 mm)

⁄"

7"

⁄"

(16 mm)

FRONT

TOP

VUBV515 VUBV524

14 ⁄”

(379 mm)

29 ⁄”

(754 mm)

(70 mm)

2 ¾”

VUBV515

10 ⁄”

(271 mm)

33 ⁄” to 34 ⁄”

(855 mm

to

881 mm)

3 ½”

(89 mm)

21 /”

(535 mm)

17 ½”

(445 mm)

29 ⁄”

(754 mm)

VUBV524

2 ¾”

(70 mm)

23 ⁄”

(600 mm)

18 ⁄”

(481 mm)

33 ⁄” to 34 ⁄”

(855 mm

to

881 mm)

3 ½”

(89 mm)

21 ⁄”

(535 mm)

26 ⁄”

(664 mm)

PRODUCT DIMENSIONS

REAR

VUBV515

VUBV524

23-⁄"

(607 mm)

1 ⁄”

(35 mm)

Power Cord

6 ft (183 cm)

1 ¾”

(44 mm)

Power Cord

6 ft (183 cm)

6 ⁄”

(159 mm)

11 ¾”

(298 mm)

SIDE

*

22 ⁄”

(583 mm)

25 ⁄”

17 /”

(445 mm)

24 /”

(616 mm)

(652 mm)

4 ⁄“ (111 mm)

*Add ⁄” for integrated models with ⁄” panel installed.

4

Installation

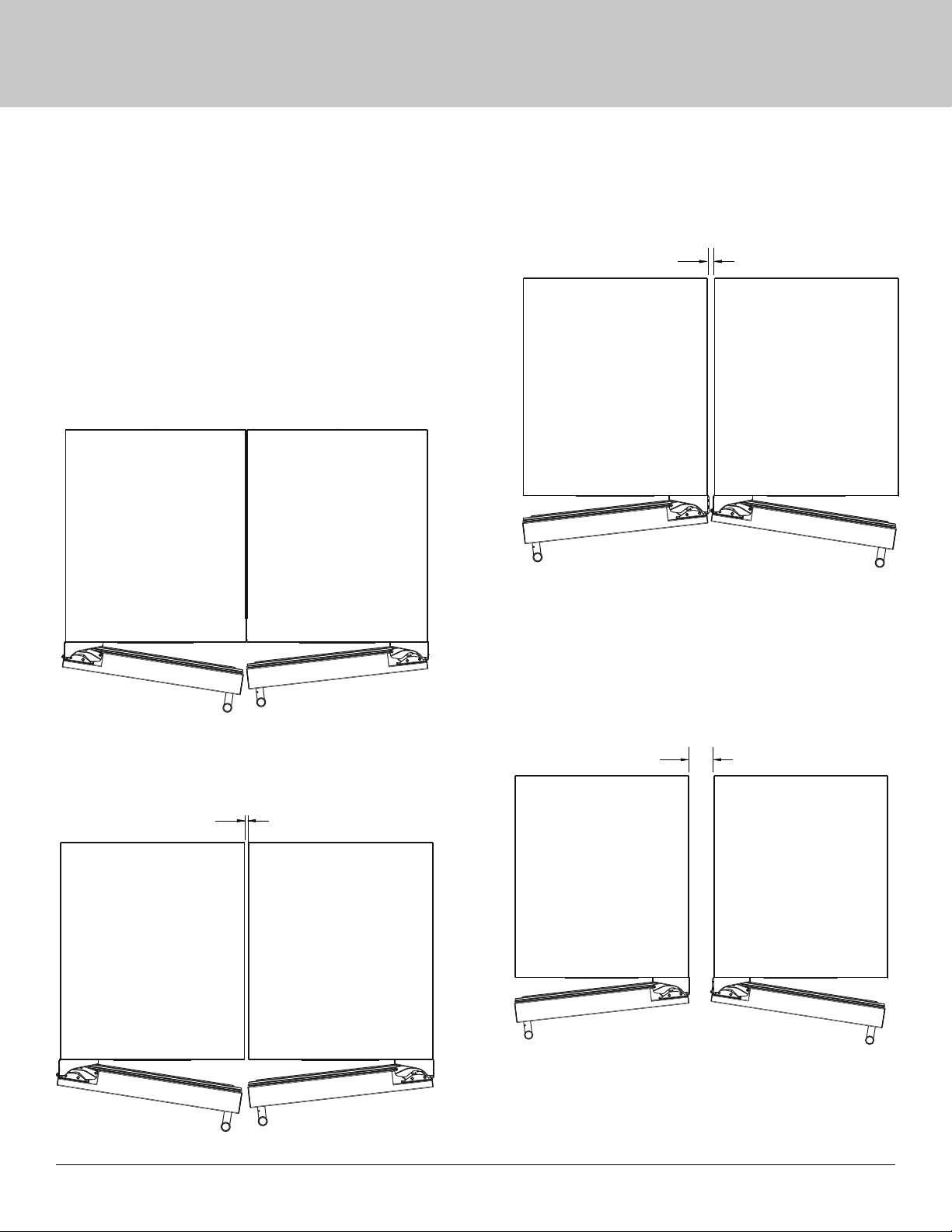

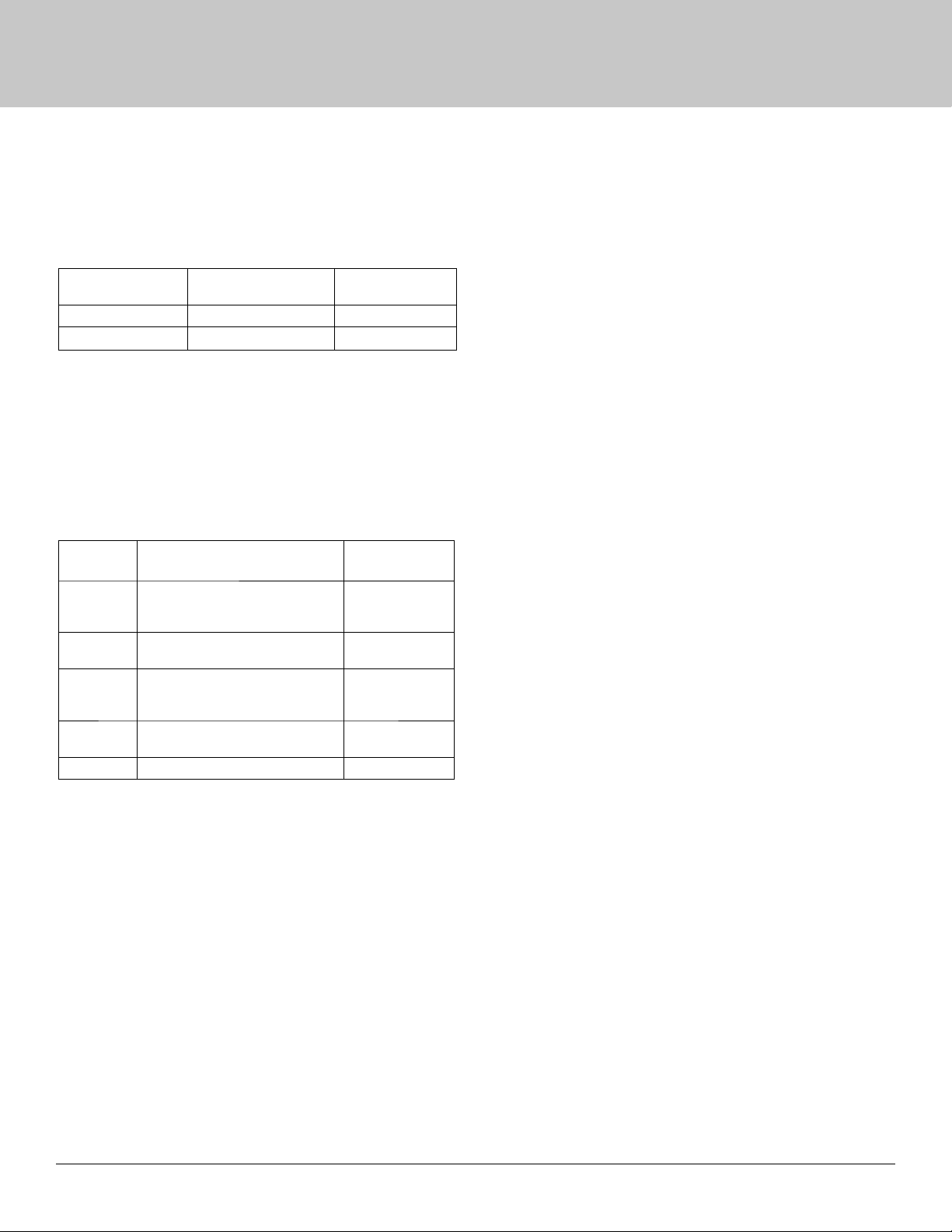

Side-by-Side Installation

OTHER SITE REQUIREMENTS

Side-by-Side Installation

Units must operate from separate, properly grounded electrical

receptacles placed according to each unit’s electrical speci cations

requirements.

Cutout width for a side-by-side installation is the total of the widths

listed under Cutout Dimensions in each unit’s Installation Guide.

Each door can be opened individually (one at a time) without

interference.

Hinge-by-Hinge Installation (Mullion)

When installing two units hinge-by-hinge, 13/16” (22 mm) is

required for integrated models. Additional space may be needed for

any knobs, pulls or handles installed.

13

/16" (22 mm)

However, to ensure unobstructed door swing (opening both doors

at the same time), 1/4” (6.4 mm) of space needs to be maintained

between the units.

1

/4" (6 mm)

Stainless steel models which include the standard stainless handle

will require 4-9/16” (116 mm) to allow both doors to open to 90° at

the same time.

4 - 9/16" (116 mm)

5

Installation

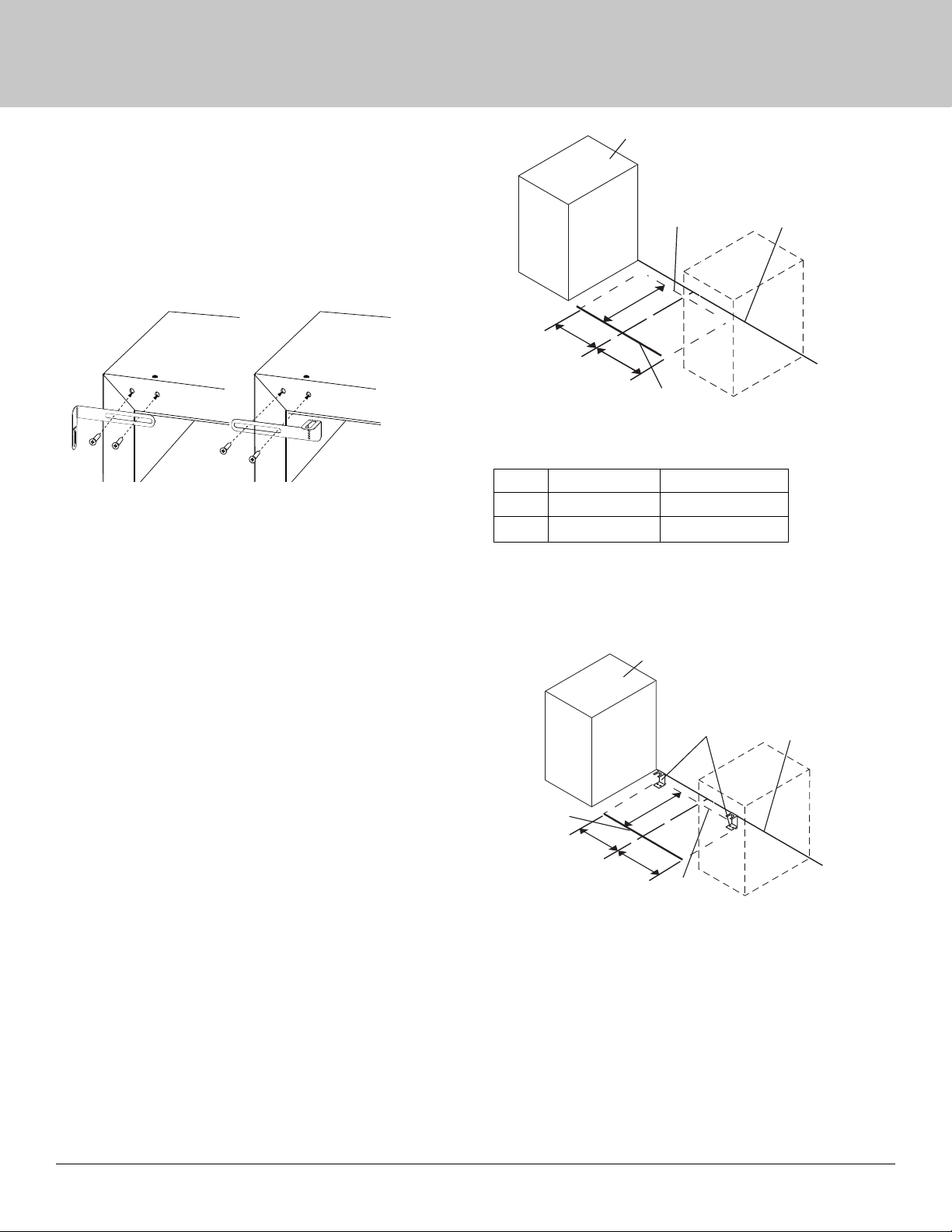

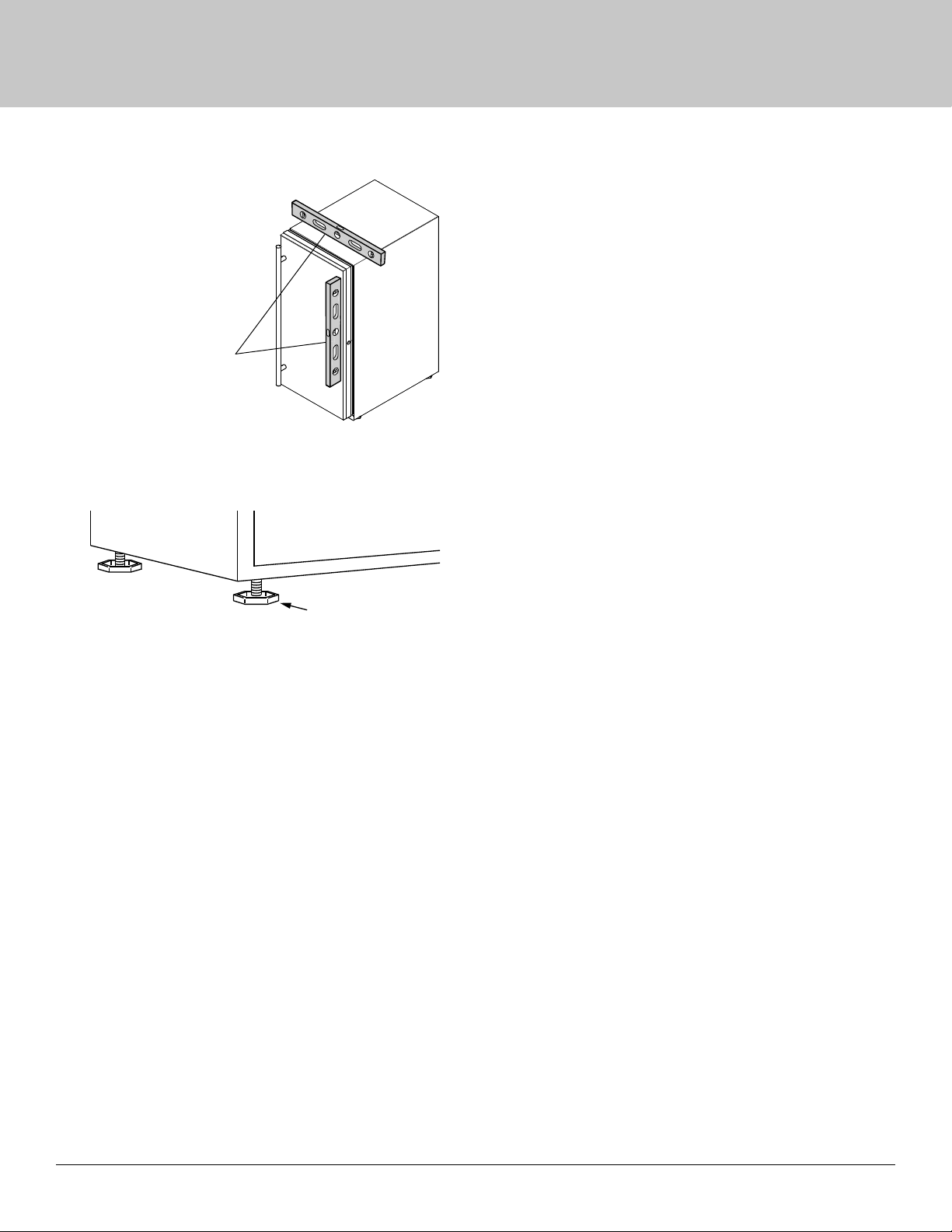

Anti-Tip Bracket

Use one of the methods below to secure the unit

CABINET/COUNTER ANTI-TIP INSTALLATION

(For built-in applications)

1. Slide unit out so screws on front of unit are easily

accessible.

Surrounding

area (Top view)

Back of unit

Back wall

2. Remove the two screws from the front of the unit.

3. Bend bracket along one of the perforations to allow

attachment to the desired adjoining surface.

4. Gently push unit into position. Be careful not to

entangle the electrical cord or water line, if applicable.

5. Check to be sure the unit is level from front to back

and side to side. Make any necessary adjustments. The

unit’s top surface should be approximately ⁄” (3 mm)

below the countertop.

6. Secure bracket to adjoining surface.

B

A

C

A

L

Front of unit

515 524

A

7 ⁄” (194 mm) 11 ⁄” (303 mm)

B

22” (558 mm) 22” (558 mm)

5. Place the anti-tip brackets on the oor against the line

drawn for the outer edge. Mark spots for the screw

holes.

Surrounding

area (Top view)

Drill holes and

mount anti-tip

brackets to floor

Back wall

FLOOR MOUNTED ANTI-TIP INSTALLATION

(For free-standing applications)

1. Locate two anti-tip brackets included with the kit.

2. Place the unit into the area where it will be installed.

Check the door, sides, and top for a proper t. Also test

to make sure the door opens and closes freely.

3. Remove grille and place a mark on the oor at the front

of the unit. Also place a mark on the oor in the center

of the unit.

4. Remove the unit. Using a square, extend center line “B”

(see chart below). This line serves as the back edge for

the anti-tip brackets. From the center line, measure “A”

to the left and right. This line is the outer edge of each

bracket.

Front

of

unit

A

C

L

B

A

Back

of

unit

6. Use a 1/8” drill to make two starter holes and fasten

the anti-tip brackets to the oor using the screws

provided.

7. Place the unit back into position, making sure the

feet engage the anti-tip brackets properly. Check the

alignment of the lines made on the oor in step 3

with the position of the front feet to ensure proper

positioning.

6

Installation

LEVELING INFORMATION

1. Use a level to con rm

the unit is level. Level

should be placed

along top edge and

side edge as shown.

1

2. If the unit is not level, adjust the legs on the corners of

the unit as necessary.

1. Plug in the power/electrical cord.

2. Gently push the unit into position. Be careful not to

entangle the cord or water and drain lines, if applicable.

3. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately ⁄” (3 mm) below the

countertop.

4. Install the anti-tip bracket.

5. Remove interior packing material and wipe out the

inside of the unit with a clean, water-dampened cloth.

3. Con rm the unit is level after each adjustment and

repeat the previous steps as needed.

INSTALLATION TIP

If the room oor is higher than the oor in the cutout

opening, adjust the rear legs to achieve a total unit rear

height of ⁄” (3 mm) less than opening’s rear height. Shorten

the unit height in the front by adjusting the front legs. This

allows the unit to be gently tipped into the opening. Readjust

the front legs to level the unit after it is correctly positioned

in the opening.

Turn to Adjust

7

Installation

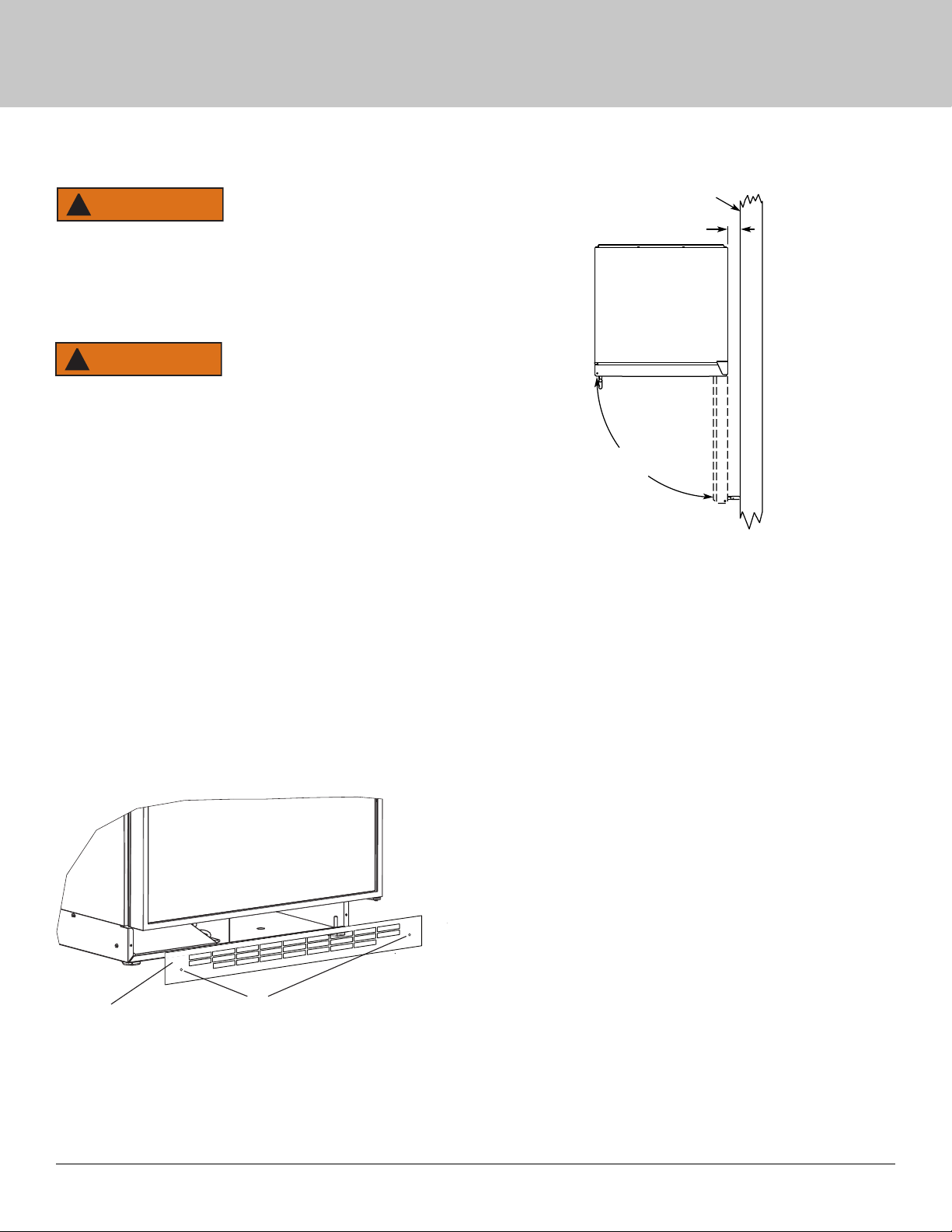

Grille Installation

REMOVING AND INSTALLING GRILLE

WARNING

!

Disconnect electric power to the unit before removing the

grille.

When using the unit, the grille must be installed.

WARNING

!

DO NOT touch the condenser ns. The condenser ns are

SHARP and can be easily damaged.

Removing the grille

1. Disconnect power to the unit.

2. Loosen the two screws (1).

3. Remove grille (2) from unit.

Door Swing

Wall

2-1/8" Min.

(54 mm)

90°

Door Swing

Stainless Steel, Black and White

Installing the grille

1. Align cabinet and grille holes and secure, but do not

over tighten grille screws (1).

2. Reconnect power to the unit.

2

1

Units have a zero clearance for the door to open 90o, when

installed adjacent to cabinets.

Stainless steel models require 2-1/8” (54 mm) door clearance

to accommodate the handle if installed next to a wall.

8

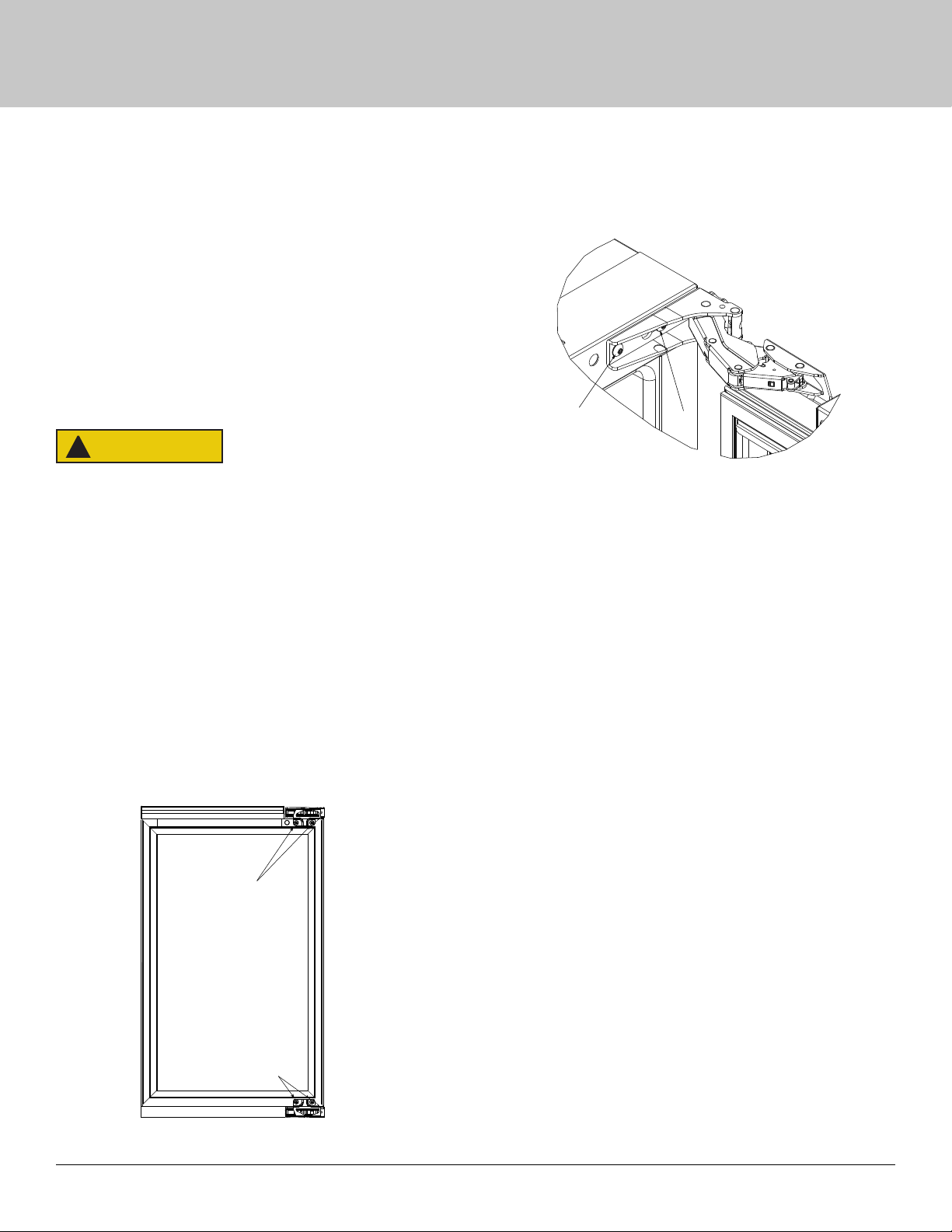

Installation

Door Adjustments

DOOR ALIGNMENT AND ADJUSTMENT

Align and adjust the door if it is not level or not sealing properly. If

the door is not sealed, the unit may not cool properly, or excessive

frost or condensation may form in the interior.

NOTICE

Properly aligned, the door’s gasket should be rmly in contact

with the cabinet all the way around the door (no gaps). Carefully

examine the door’s gasket to ensure that it is rmly in contact

with the cabinet. Also make sure the door gasket is not pinched

on the hinge side of the door.

CAUTION

!

Do not attempt to use the door to raise or pivot your unit. This

would put excessive stress on the hinge system.

Alignment and Adjustment Procedure

REVERSING THE DOOR

1. Open door.

2. Using T-25 Torx bit loosen screw #1 and remove screw #2 on

top and bottom hinge. Slide and remove the door from the

unit.

2

1

Note: One hinge includes a metal spacer. Spacer must be used

with that hinge when reversing the door.

1. Open door and remove gasket near the hinges.

2. Using a T-25 Torx bit, loosen each pair of Torx head

screws both the upper and lower hinge plates.

3. Square and align door as necessary.

4. Tighten Torx head screws on hinge.

5. Reinstall gasket into the channel starting at the corner.

T-25 Torx Screw

3. Remove caps from screw heads on opposite side (2 on top and

2 on bottom). Using #2 Phillips bit, remove the 4 underlying

screws. Reinstall the screws and caps on the opposite side.

4. Partially install screw #1 in the outer most holes on top and

bottom. Rotate door 180o, align hinge over screw #1 and

slide/seat into position. Reinstall screw #2 on top and bottom.

Tighten both screws and install hinge cover.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

T-25 Torx Screw

9

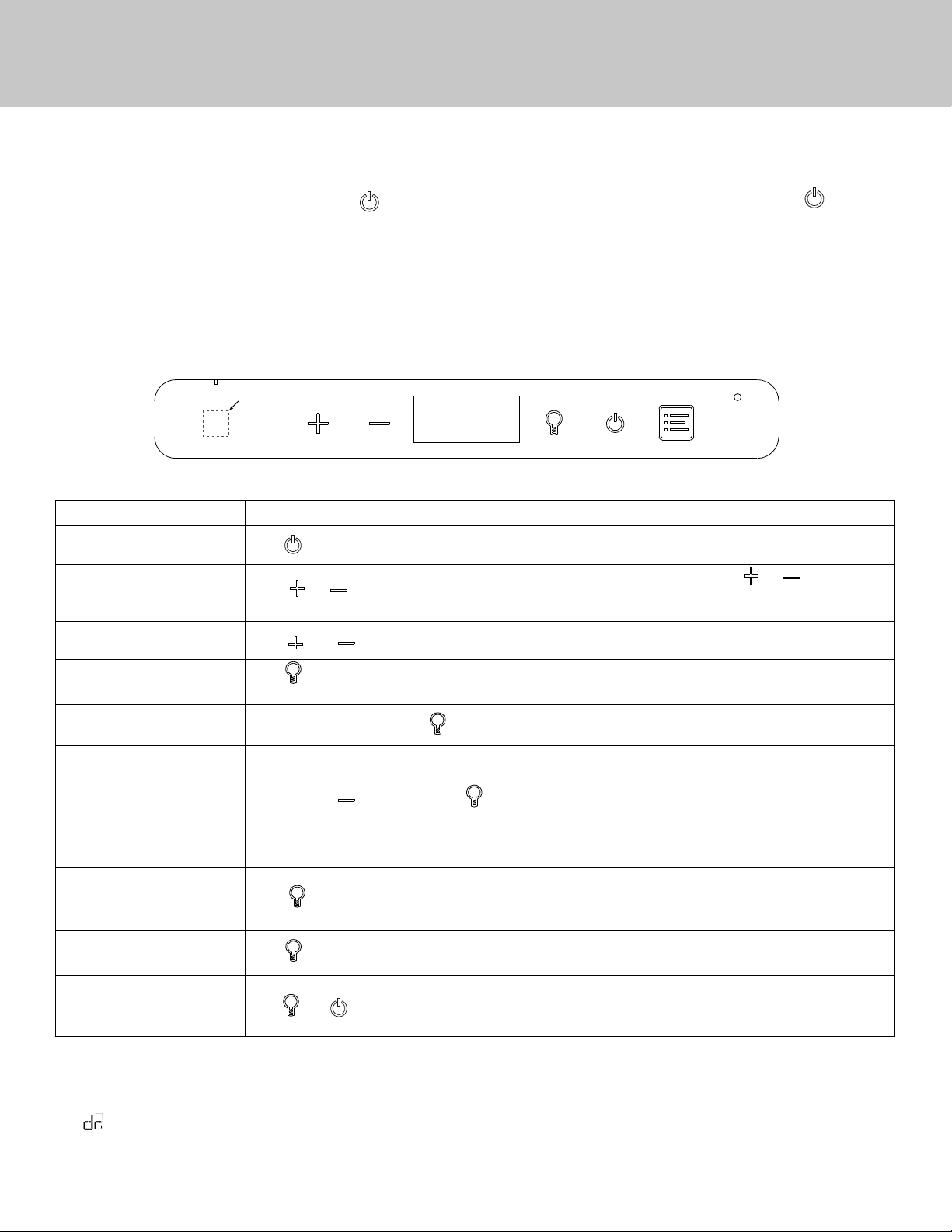

Operating Instructions

First Use

Initial startup requires no adjustments. When plugged in, the unit will begin operating under the factory default settings. If the unit

was turned o during installation, simply press and the unit will immediately switch on. To turn the unit o , press .

NOTICE: Temperature displayed re ects actual temperature inside unit.

If the temperature displayed is di erent than selected, the unit is progressing towards the selected temperature. Time to reach set

point varies based upon ambient temperature, temperature of product loaded, door openings, etc. Viking recommends allowing

the unit to reach set points before loading.

Control Operation

Hidden

Button

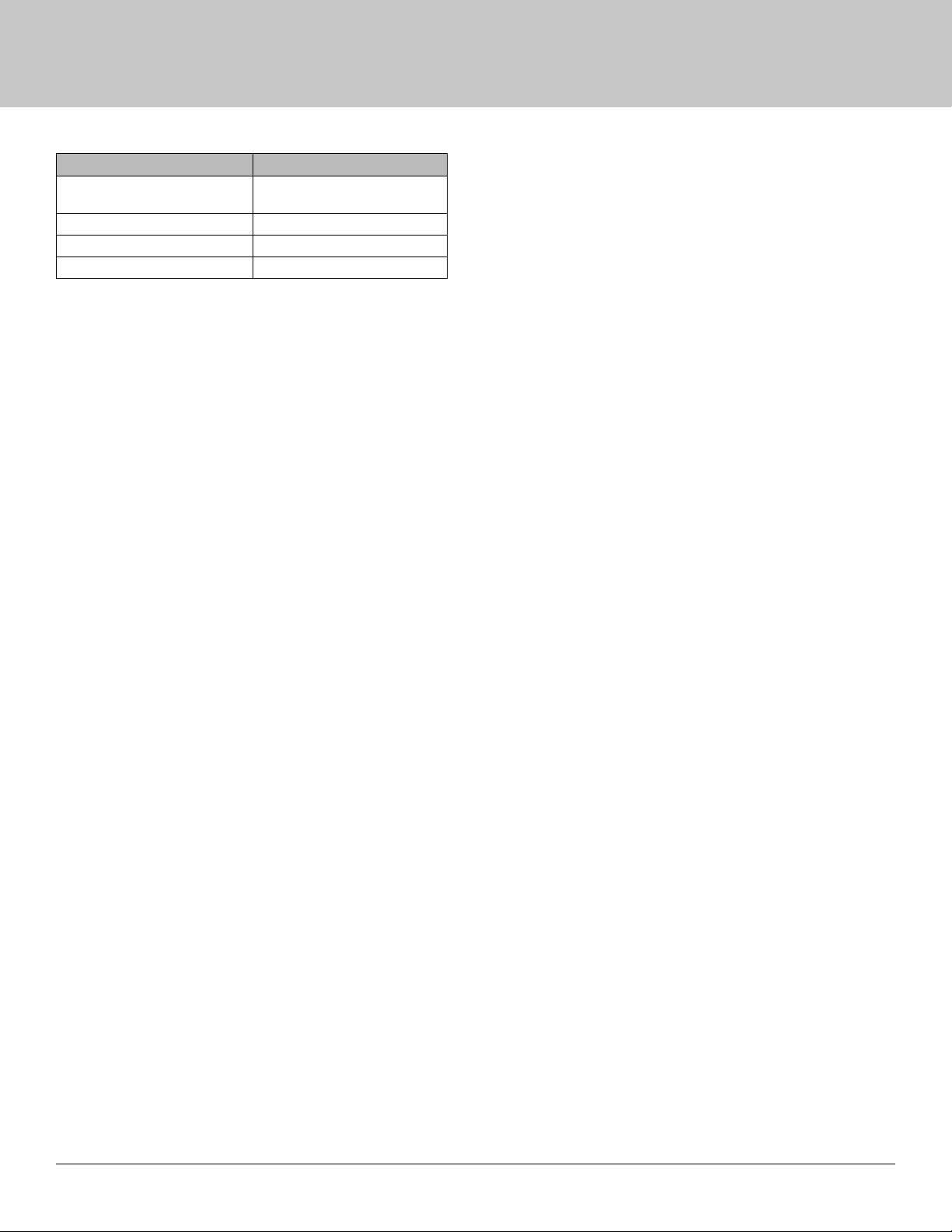

CONTROL FUNCTION GUIDE

FUNCTION COMMAND NOTES

ON/OFF Press and release Unit will immediately turn On or OFF

When the display is ashing, press or to adjust the

Adjust Temperature Press or and release

Toggle between ºF / ºC Hold and for 5 seconds The display will change units

Leave interior light on

Hide Display Hold hidden button and press

Adjust light color

Enable Sabbath Mode Press and hold for 5 seconds and release

Disable Sabbath Mode Press and release Display and interior light return to normal operation

Showroom Mode Hold and for 5 seconds

Press and release to leave interior light on

for 12 hours; press again to deactivate

While holding press and release to

scroll through lighting options

set point temperature. Note: temperature displayed is the

actual temperature inside unit

After 12 hours, factory default is restored; light will turn on

when door is open

Display will turn o when door is closed. Unit will continue

to operate. Repeat command to turn on display

Option Open Door Closed Door

0 0 White White

0 1 Blue Blue

0 2 White Blue

Light will be set at full intensity when door is open, and 50%

intensity when door is closed.

The oF / oC symbol will ash brie y after 5 seconds. Interior

light and display will go dark and remain so until user resets

mode - unit continues to operate

The ºF / ºC symbol will ash. Display will be lit and interior

light will function. Unit will not cool. Repeat command to

return to normal operation

DOOR ALERT NOTIFICATION

When the door is left open for more than 5 minutes:

This unit is Star-K certi ed. See www.star-k.org for more details.

• A tone will sound for several seconds every minute

• will appear in display

• Closed door to silence alert and reset

10

Operating Instructions

Air ow and Product Loading

AIRFLOW

External

• Do not block the front grille - no additional clearance

around sides, top or rear of unit is needed for ventilation

• Do not install behind a closed door

Internal

• When loading, leave space between internal fans, vents,

and side walls to allow air to circulate freely

PRODUCT LOADING

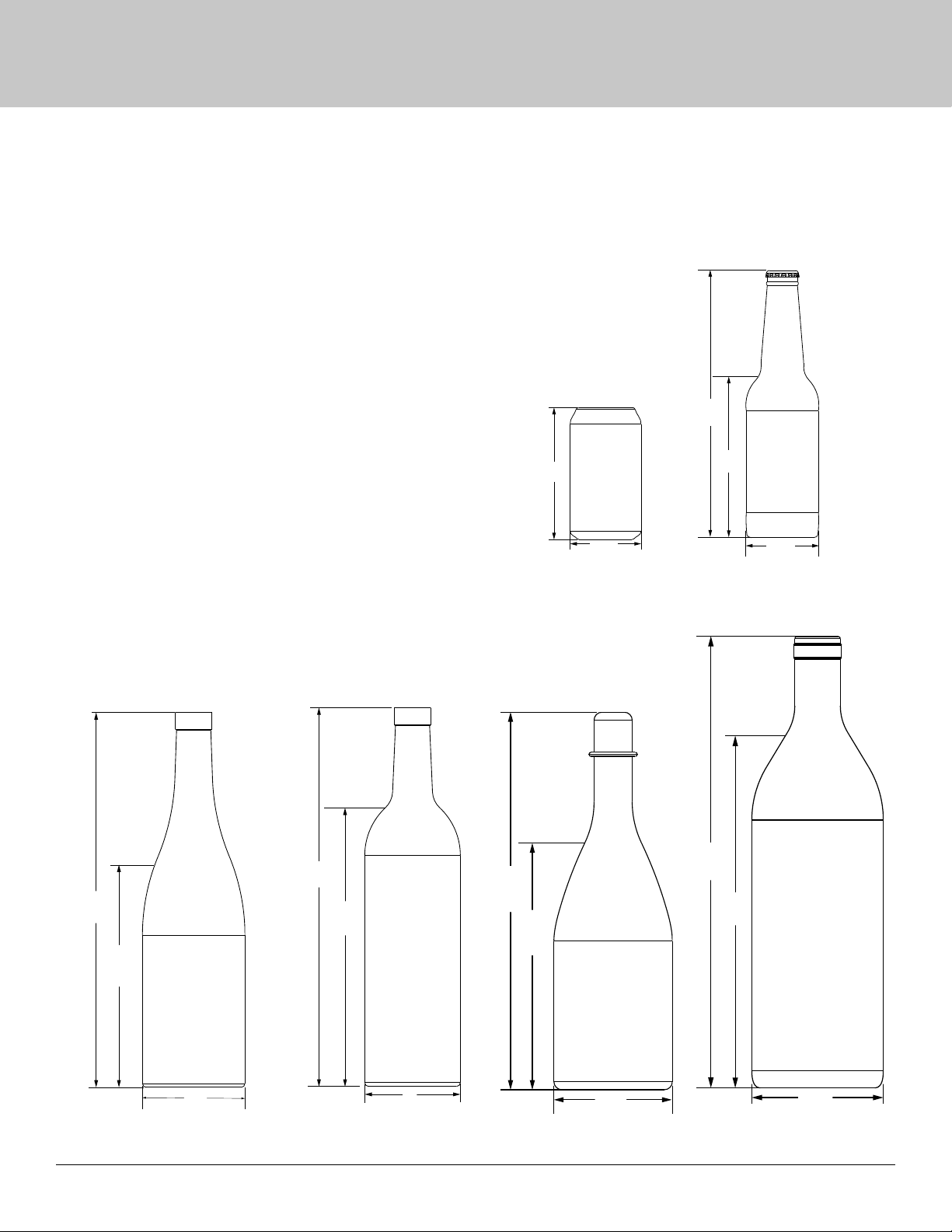

Bottles and cans come in all shapes and sizes. When

determining capacities, refer to the following sizes.

Combinations of red and white bottles are used in Wine

Cellars and Beverage Centers.

NOTICE

Restricting air ow may result in poor product performance,

product failure, and uneven internal temperatures and may

freeze contents.

9”

(229 mm)

Typical Bottle

4

⁄”

(123 mm)

Typical Can

(12 oz)

⁄”

2

(66 mm)

5

(135 mm)

⁄”

(12 oz)

2

⁄”

(64mm)

11

¾”

(298 mm)

(184 mm)

11

¼”

Typical White

Wine Bottle

(750 mL)

3

¼”

(82 mm)

⁄”

11

(302 mm)

(222 mm)

13

⁄”

11

(299 mm)

¾”

8

Typical Red

Wine Bottle

(750 mL)

3”

(76 mm)

7¾”⁄”

(195 mm)

Typical

Champagne Bottle

(750 mL)

3 ⁄”

(94 mm)

(334 mm)

10

(263 mm)

⁄”

Magnum Bottle

(1.5 L)

⁄”

3

(98 mm)

11

Operating Instructions

Interior Adjustments

All 5 Series models feature side mounted rack supports with

19 adjustment positions.

All Beverage Centers ship with 2 wine racks and 2 Storage

bins - Remove and reposition as desired.

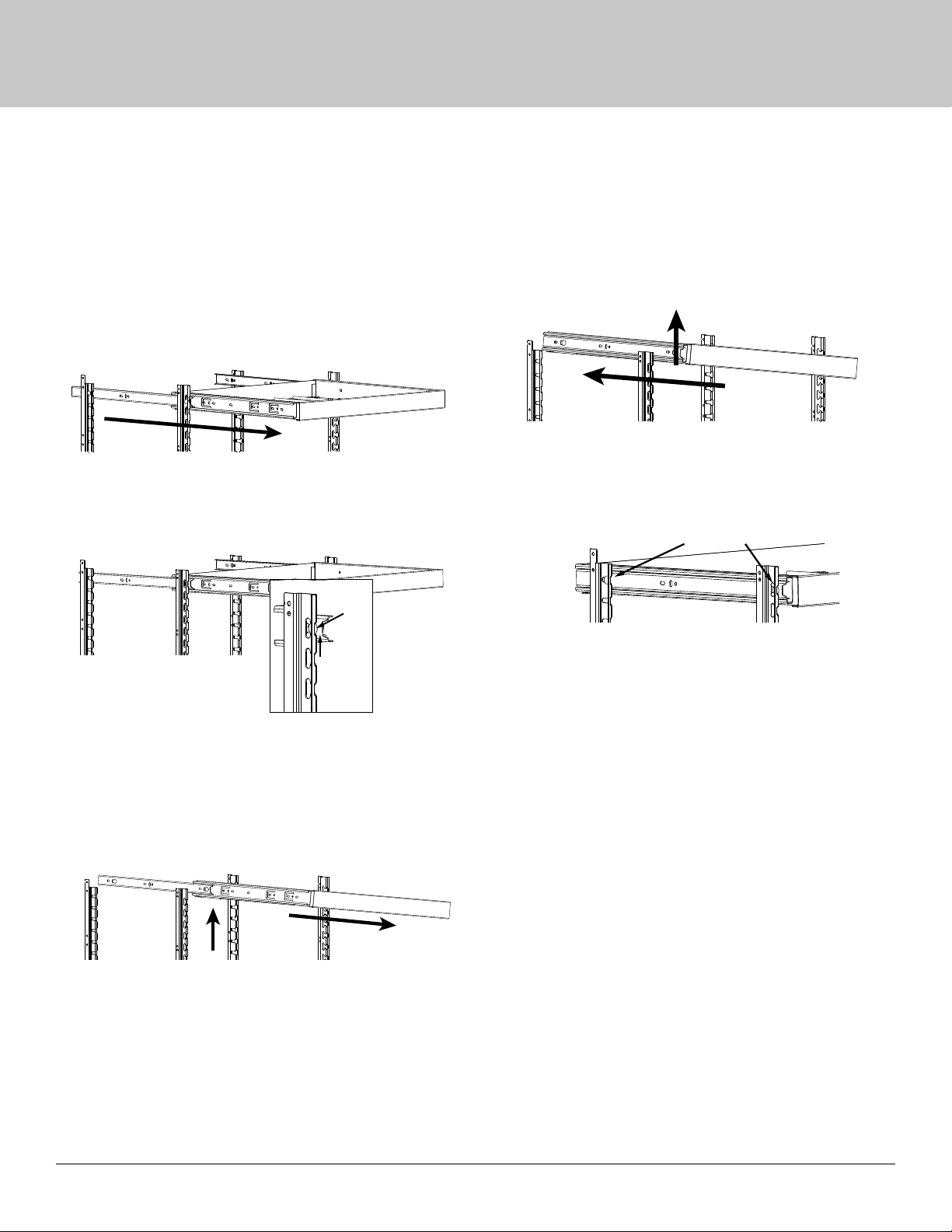

WINE RACK ADJUSTMENT

Wine Rack Removal

1. Fully extend empty rack

2. Firmly grasp both sides of rack and lift front end of rack

slightly (about ¼ ”) to center the pin in the slot

5. Once removed, retract the slides.

Note: The slides on the rack have a thin coating which is

used to block moisture and provide lubrication. Use care

when handling.

Wine Rack Installation

1. Insert empty rack into unit with one side tilted slightly

downward until back pin is between front and rear rail

supports.

2. Tilt rack back to horizontal and line up 2 back pins with

back slots.

Center

the pins

Front Pin

Center

the pin

3. Pull rack towards you until all pins are clear of the slots.

If only repositioning the rack, do not remove completely

- go to “Rack Installation” Step 2.

4. Slightly tilt one side. Gently pull rack towards you to

remove rack from unit.

Note: Take care when removing rack to avoid scratching

interior of unit.

Back Pin

3. Line up 2 back pins with 2 back slots and 2 front pins

with 2 front slots.

4. Continue inserting rack until all four pins are fully

inserted. Front of rack will set down slightly into the

front slots and be locked into position.

12

Operating Instructions

Wine Storage Options

WINE RACK BOTTLE POSITION

Specially designed horizontal wine racks properly position the bottles so the wine remains in contact with the cork, which ensures

the cork does not become dry.

Racks are designed to accommodate typical 750ml wine bottles as follows:

VUBV515 15” Beverage Center Models VUBV524 24” Beverage Center Models

7 Bottles

4 Bottles

13

Operating Instructions

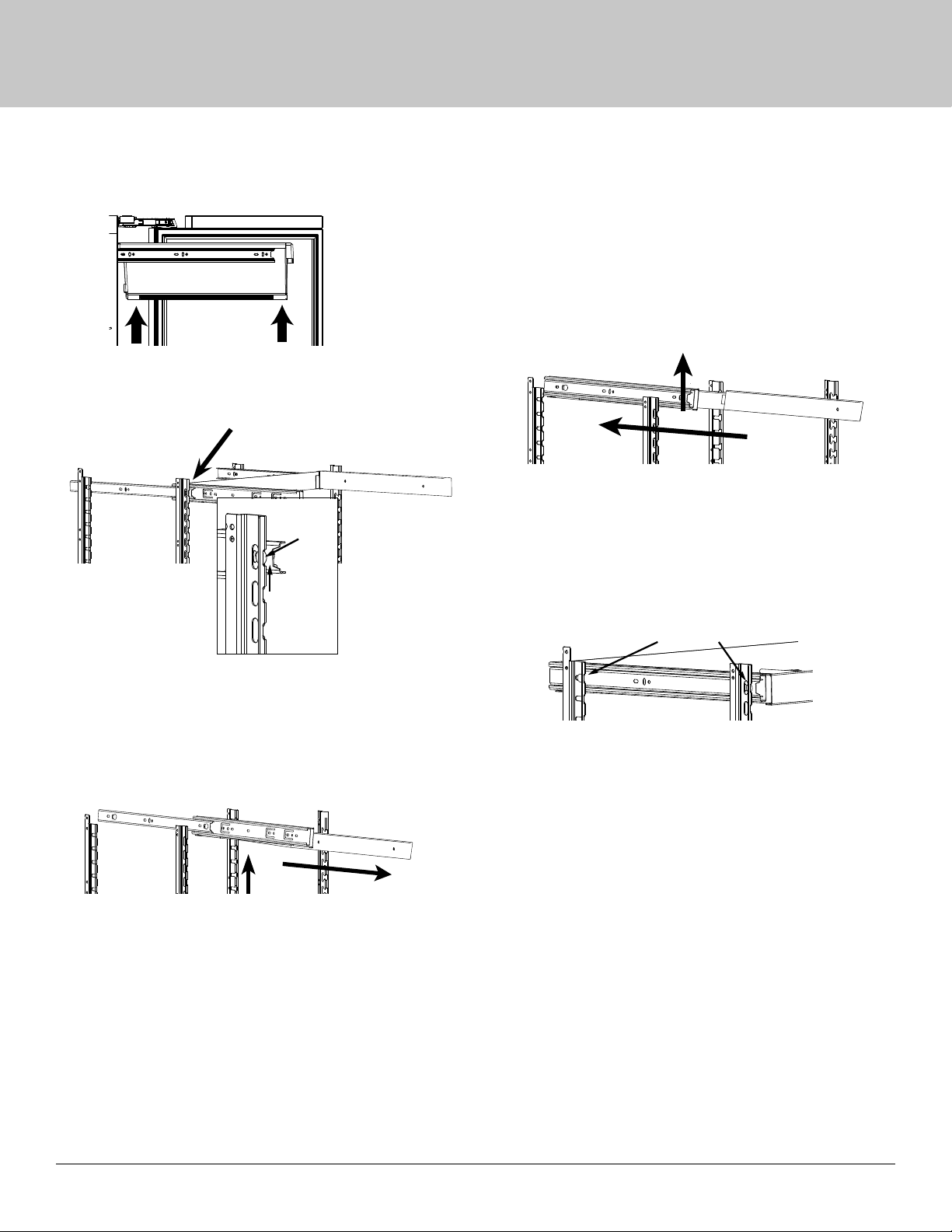

STORAGE BIN ADJUSTMENT

Storage Bin Removal

1. Empty and remove bin.

2. Firmly grasp both sides of storage bin frame and lift

front end slightly (about ¼ ”) to center the pin in the slot.

Center

the pin

3. Pull frame towards you until all pins are clear of the

slots. If only repositioning the frame, do not remove

completely - go to “Storage Bin Installation” Step 2.

5. Once removed, retract the slides.

Note: The slides on the frame have a thin coating which is

used to block moisture and provide lubrication. Use care

when handling.

Slide and Secure Storage Bin Installation

1. Insert empty storage bin frame into unit with one side

tilted slightly downward until back pin is between front

and rear rail supports.

2. Tilt frame back to horizontal and line up 2 back pins

with rear rail support. Line up left side of frame with rear

and front rail support. Continue inserting frame until

both pins engage. The front will set down slightly and

lock into place. Repeat on right side.

Center

the pins

Front Pin

Back Pin

4. Slightly tilt one side. Gently pull frame towards you to

remove from unit.

Note: Take care when removing frame to avoid scratching

interior of unit.

3. Fully extend frame, position bin over frame and lower

(rear rst) into position.

Storage bins

Glass inserts are designed so bottles and cans sit at. The

inserts may be removed when storing produce or other

items. The ridges in the bottom facilitate air ow.

Clean the storage bins with soap and water.

14

Operating Instructions

Wine Guide

LOOKING BEHIND THE LABEL

To most, wine is a delicious mystery. We purchase it, uncork it,

and savor its taste and beauty. But there is so much more to

true wine appreciation. Many secrets are simply too good to

keep bottled up.

WINE SELECTIONS SUGGESTIONS

Selecting the right wine for the right occasion can sometimes

be a seemingly awkward or di cult task for the beginning

wine enthusiast. We would therefore like to present you with

a few suggestions which may provide a little more con dence

and enjoyment when choosing and serving your wines.

When selecting wines, keep an open mind and do not be

afraid to be adventurous. Do not view the subject of wine so

seriously it discourages you from learning and discovering for

fear of embarrassment if something is incorrect. Wine is best

viewed as a hobby and enjoyed.

When assembling your collection, try not to become

obsessed with “Vintages.” Although a chart can be a useful

tool, generalizations about a speci c year have led more

than one collector to disappointment. Often an “O Year” will

provide a better value and more drinking enjoyment.

The primary guideline to the subject of wine is your own

palate. Do not be afraid to make mistakes. Experiment,

discover, but most of all, enjoy yourself and your new product.

Guide To Common Styles Of Wine

Red Wines

Full-Bodied Dry California

French

Italian

Medium-Bodied Dry California

French

Light-Bodied Dry French

Italian

White Wines

Full-Bodied Dry California

French

Medium-Bodied Dry California

French

Light-Bodied, Dry French Chablis, Muscadet,

Full-Bodied, Very Sweet Germany

French

Hungary

Medium-Bodied,

Semi-Sweet

Light-Bodied O Dry Germany Rhine, Mosel Riesling

California

Germany

Zinfandel, Cabernet Rhone,

Chateauneuf-du-Pape

Barbaresco, Barolo

Pinot Noir Bordeaux,

Burgundy

Beaujolais Chianti,

Bardolino

Chardonnay Montrachet,

Meursault PulignyMontrachet

Sauvignon-Blanc

Pouilly-Fuisse, Sancerre,

Vouvray, Graves

Pouilly-Fume

Beerenauslese Sauternes

Tok ay

Gewurtztraminer

Liebfraumilch

Matching Food and Wine

Although there are no hard fast rules for matching wine to

food, observe some guidelines. Delicate dishes should be

accompanied by lighter more delicate wines. Full- avored

foods should be matched with fuller-bodied wines.

As a general rule, one should aim to ascend in avor and

quality of wines served.

Serve a: Before a:

DRY wine SWEET wine

WHITE wine RED wine

YOUNG wine OLD wine

LIGHT-BODIED wine FULL-BODIED wine

Any step back in quality will be noticed. If a ne wine is tasted

prior to a lesser wine, many of the ne wine’s subtle qualities

may be missed.

15

Operating Instructions

Common Food and Wine Matches

Foods Wines

Fish, Shell Fish, Crab, Oysters Dry White Wines, Light Sparkling

or Extra Dry Champagne

Beef, Venison Full-Bodied Red Wines

Pork, Veal, Lamb and Poultry Light-Bodied Red Wines

Fruit Sweet White and Sparkling Wines

A Toast to Wine Truths

Like the grapes themselves, many wine myths have been

cultivated over the centuries.

Myth 1: Most wines taste better when aged.

Truth: In fact, less than 5% of wines produced today are

meant to be aged. Most wines are crafted to be consumed

within the rst one to two years.

Myth 2: Wines should be uncorked and decanted allowing

them to “breathe.”

Truth: To breathe or not breathe? While it is better to allow a

young tannic Red to breathe in a glass or decanter to soften

the tannins, an old Red reaches a stage in its life where it

should be enjoyed soon after opening. Allow an old Red

to breathe for a short time to dissipate any o odors. Most

white wines can be served, ideally, 10-15 minutes after

opening.

The Cork: A Mystery on Its Own

Cork Presentation. The ritual of the presentation of the cork

has a rich and fascinating history dating back to the late

1800’s. A phylloxera (root louse) devastation to the vineyards

severely limited the supply of great wines. Restaurateurs

would remove labels on inferior wines and replace them

with labels from superior wines. This made it necessary for

patrons to protect themselves by checking the branding on

the cork to ensure that what they ordered was, in fact, what

they were served.

When presented with a cork today, feel it to check for its

integrity, read and match the branding on the cork to the

bottle and set it aside. There is little to be learned from the

cork. The proof is in the wine.

“Corked” wines. If you’ve ever had a wine that smelled or

tasted of mold, you’ve experienced a wine that may have

been “corked.” Today, between ve and eight percent of

wines are tainted with Trichloroanisole (TCA). This substance,

found naturally in plants and trees, is imparted to the wine

through the cork. Corked wines are a major concern for

winemakers as it destroys millions of cases per year and

puts reputations at stake. Amazing as it may seem, twist-o

caps may o er a better alternative; many great wineries in

California, Australia and New Zealand are pioneering the

trend.

Myth 3: When age worthy wines peak, they must be

consumed almost immediately.

Truth: Most great wines reach a plateau period rather than

a peak. Great Bordeaux’s may have as much as a 10-year

plateau before fading.

Myth 4: Wine color does not change with aging.

Truth: As red wines age they get lighter in color while

whites get darker.

16

Operating Instructions

Common Tasting Terms

Terminology Description

Acidity A critical element of wine that is responsible for

preserving the wine’s freshness. Excess acidity

results in an overly tart and sour wine.

Balance A desired trait where tannin, fruit and acidity are

in total harmony. Wines with good balance tend to

age gracefully.

Body The weight and presence of wine in the mouth

provided by the alcohol and tannin level.

Full-bodied wines tend to have this strong

concentration.

Bouquet The blending of a wine’s aroma within the bottle

over a period of time, caused by volatile acidity.

Complex A subjective term often used in tasting. A wine is

said to be complex if it o ers a variety of avors

and scents that continue to evolve as it develops.

Flabby A wine that lacks structure, or is heavy to the taste,

lacks acidity.

Full-Bodied Wine high in alcohol and extract, generally

speaking, lls the mouth, powerful.

Lean Generally describes wines that are slim, lacking of

generosity or thin.

Oaky A desirable avor imparted to wine if done in

moderation. Most wines are aged in oak barrels

one to three years, thereby receiving this toasty

oak characteristic. However, if a weak wine is left in

contact too long with an oak barrel, it will tend to

be overpowered with an oaky taste.

Tannin Tannins are extracted from the grape skins and

stems and are necessary for a well-balanced red

wine. Tannins are easily identi ed in wine tasting

as the drying sensation over the gums. Tannins

generally fade as a wine ages.

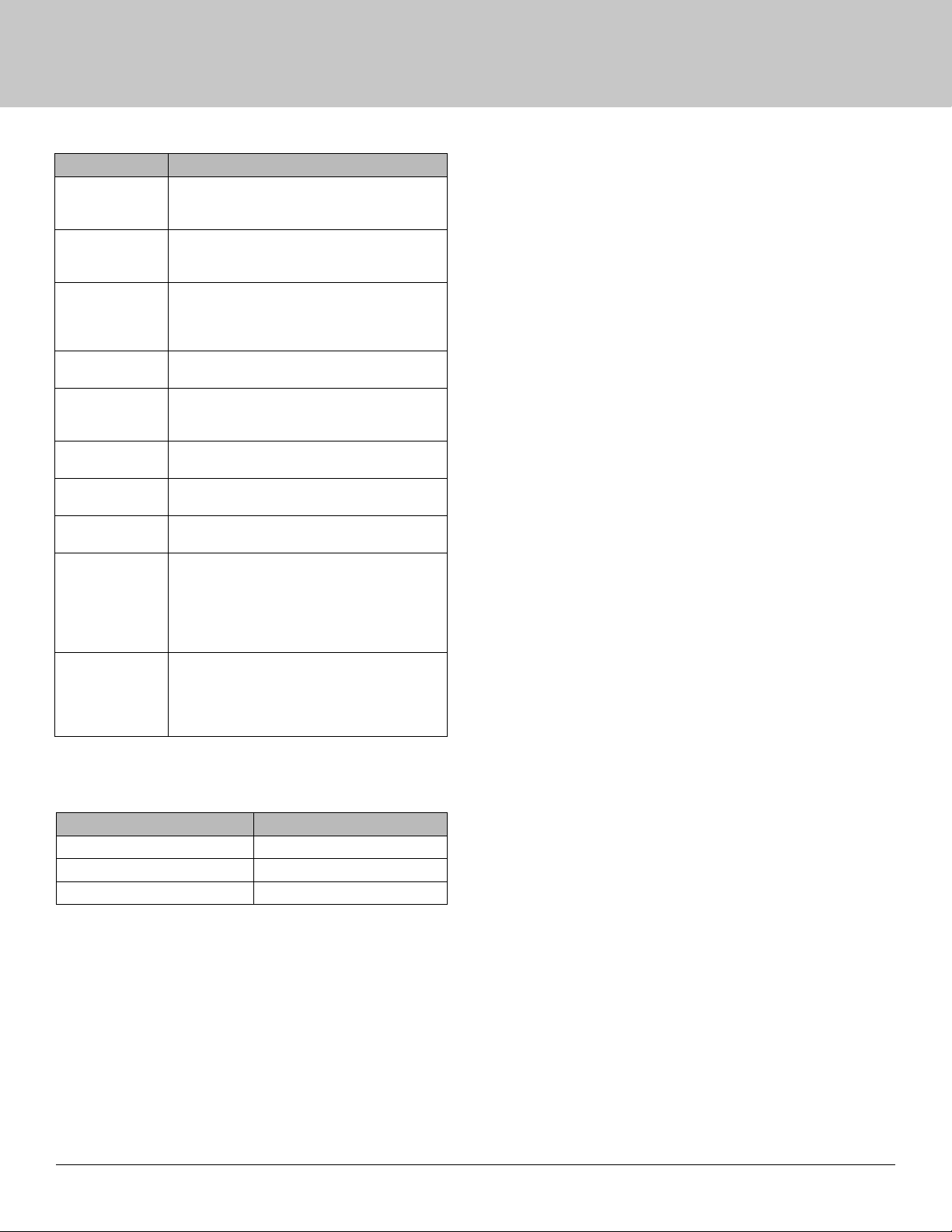

Temperature Wines

Approximately 60

º

F (15ºC)

50ºF - 55ºF (10ºC - 12ºC)

Approximately 45

º

F (7ºC)

Red

White

Sparkling

IDEAL WINE STORAGE CONSIDERATIONS

Temperature: The most important element about

storage temperature is stability. If wine is kept in a stable

environment between 40ºF (7ºC) and 65ºF (21ºC), it will

remain sound. A small 1-2 degree temperature fluctuation

within a stable environment is acceptable. Larger

temperature fluctuations can affect the cork’s ability to seal,

allowing the wine to “leak” from the bottle.

Humidity: The traditional view on humidity maintains

that wines should be stored on their sides in 50% - 80%

relative humidity to ensure cork moisture and proper t in

the bottle. Contemporary wisdom suggests that the cork

surface is too small to be impacted by humidity. Further, the

cork is sealed with a metal or wax capsule making humidity

penetration impossible. The concept of a humid storage

environment was derived from the necessity of wineries to

maintain moisture in their cellars to keep wooden barrel

staves swollen, preventing wine evaporation and product

loss. In fact, vineyards estimate as much as a 10% product

loss per year due to evaporation while wine is aging in the

wooden barrels. Humidity, however, was not intended for

the modern cellar where wine is stored in glass bottles with

sealed corks.

Light: UV rays are not only harmful to people, they are

damaging to wines - especially those in clear bottles. Since

oxygen molecules in wine absorb UV rays, wine should

never be stored in direct light for long periods of time.

Vibration: Provided that sediment is left undistributed

and particles are not suspended, vibration in a storage

environment is not an issue. Wines can become at or

tired when voids and vacuums are created inside the wine

bottle. In order to create voids and vacuums within a liquid,

aggressive motion or shaking of the wine bottle would have

to occur.

17

Operating Instructions

Food Preservation Guide

Viking Beverage Centers are designed to accurately maintain

a consistent temperature and stable humidity levels.

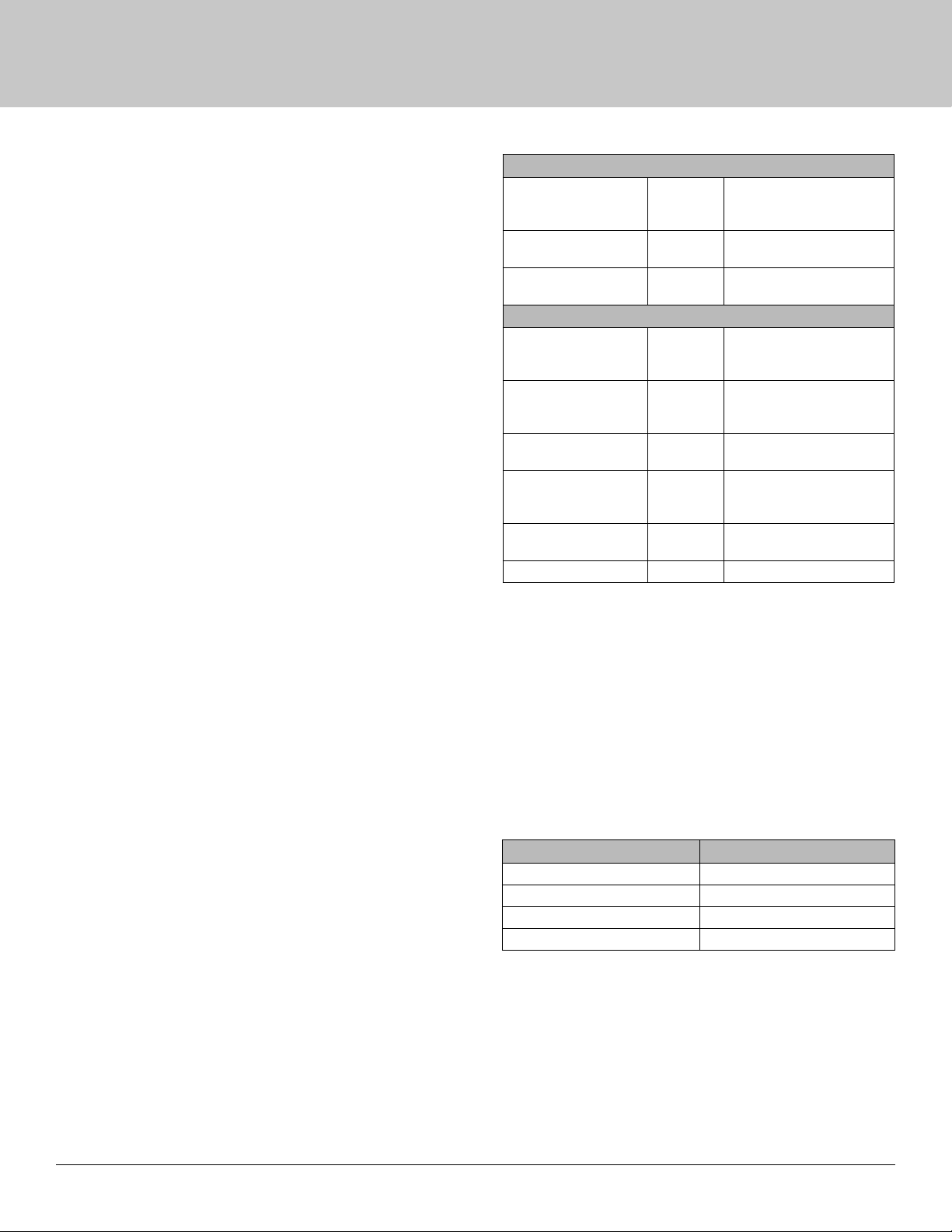

Temperature Settings

Models Factory Default

Temperature oF (C)

Refrigerators 38 (3) 33 - 70 (1 - 21)

Beverage Centers 38 (3) 33 - 70 (1 - 21)

Temperature Range

o

F (C)

Many foods have an optimum storage temperature. Storing

foods at their preferred temperature is the best way to

maintain freshness and avor, and increase the shelf life of

foods, which results in fewer trips to the store and less food

discarded – saving you money.

Food

Groups

Deli

Market

Root Cellar

Pantr y

Beverages All types of Beverages 38 (3)

Meat, Fish, Poultry, Butter, Dairy

Products, Garlic, Oils, Nuts,

Condiments

Fruits, Vegetables, Berries, Leafy

Greens

Root Vegetables, Potatoes, Onions,

Lemons, Limes, Melons, Peppers,

Beans

Dry Goods, Baking Ingredients,

Spices, Seasonings

Food Examples

Recommended

Range oF (C)

36 (2)

38 (3)

50 (10)

42 (11)

18

Maintenance

Cleaning

Stainless Models

Stainless door panels, handles and frames can discolor

when exposed to chlorine gas, pool chemicals, saltwater or

cleaners with bleach.

Keep your stainless unit looking new by cleaning with a

good quality all-in-one stainless steel cleaner and polish

monthly. For best results use Claire® Stainless Steel Polish

and Cleaner. Comparable products are acceptable. Frequent

cleaning will remove surface contamination that could lead

to rust. Some installations may require cleaning weekly.

Do not clean with steel wool pads.

Do not use stainless steel cleaners or polishes on any glass

surfaces.

Clean any glass surfaces with a non-chlorine glass cleaner.

Do not use cleaners not speci cally intended for stainless

steel on stainless steel surfaces (this includes glass, tile,

and counter cleaners).

If any surface discoloring or rusting appears, clean it

quickly with Bon-Ami® or Barkeepers Friend Cleanser® and a

nonabrasive cloth. Always clean with the grain. Always nish

with Claire® Stainless Steel Polish and Cleaner or comparable

product to prevent further problems.

Using abrasive pads such as ScotchBrite™ will cause the

graining in the stainless steel to become blurred.

Rinse the interior using a soft sponge and clean water.

Do not use any solvent-based or abrasive cleaners. These

types of cleaners may transfer taste and/or odor to the

interior products and damage or discolor the interior.

DEFROSTING

Under normal conditions this unit does not require manual

defrosting. Minor frost on the rear wall or visible through the

evaporator plate vents is normal and will melt during each

cycle.

If there is excessive build-up of 1/4” (6 mm) or more, manually

defrost the unit.

Ensure the door is closing and sealing properly.

High ambient temperature and excessive humidity can also

produce frost.

CAUTION

!

DO NOT use an ice pick or other sharp instrument to help

speed up defrosting. These instruments can puncture

the inner lining or damage the cooling unit. DO NOT use

any type of heater to defrost. Using a heater to speed up

defrosting can cause personal injury and damage to the

inner lining.

NOTICE

Rust not cleaned up promptly can penetrate the surface of

the stainless steel and complete removal of the rust may

not be possible.

Integrated Models

To clean integrated panels, use household cleaner per the

cabinet manufacturer’s recommendations.

INTERIOR CLEANING

Disconnect power to the unit.

Clean the interior and all removed components using a mild

nonabrasive detergent and warm solution applied with a soft

sponge or non-abrasive cloth.

The drain pan was not designed to capture the water

created when manually defrosting. To prevent water

from over owing the drain pan and possibly damaging

water sensitive ooring, the unit must be removed from

cabinetry.

To defrost:

1. Disconnect power to the unit.

2. Remove all products from the interior

3. Prop the door in an open position (2 in. [50 mm]

minimum).

4. Allow the frost to melt naturally.

5. After the frost melts completely, clean the interior and

all removed components. (See INTERIOR CLEANING).

6. When the interior is dry, reconnect power and turn unit

on.

19

Maintenance

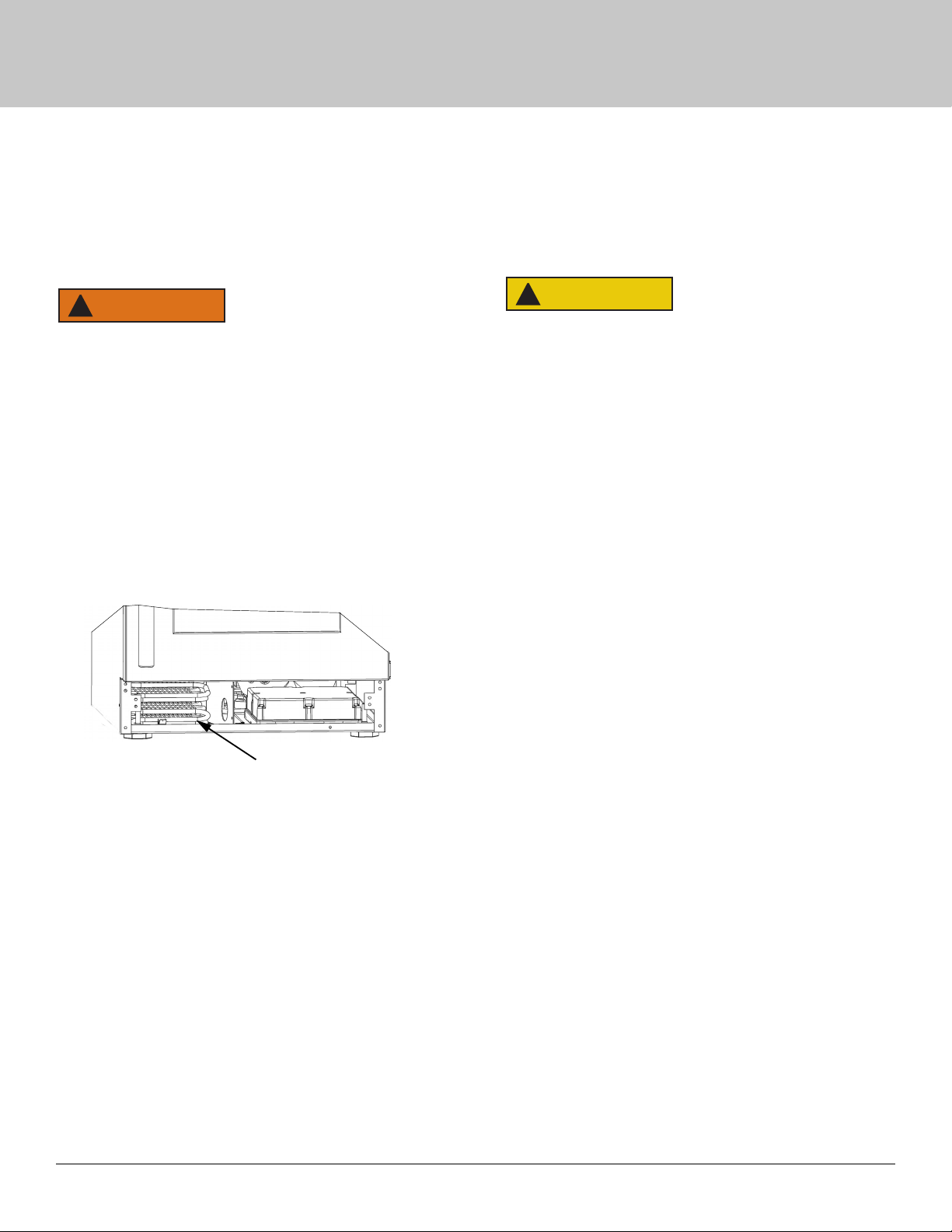

Cleaning Condenser

INTERVAL - EVERY SIX MONTHS

To maintain operational e ciency, keep the front grille free

of dust and lint, and clean the condenser when necessary.

Depending on environmental conditions, more or less

frequent cleaning may be necessary.

WARNING

!

Disconnect electric power to the unit before cleaning the

condenser.

NOTICE

DO NOT use any type of cleaner on the condenser unit.

Condenser may be cleaned using a vacuum, soft brush, or

compressed air.

1. Remove the grille. See GRILLE INSTALLATION).

2. Clean the condenser coil using a soft brush or vacuum

cleaner.

3. Install the grille.

WINTERIZATION

If the unit will be exposed to temperatures of 40oF (5oC) or

less, the steps above must be followed.

For questions regarding winterization, please call Viking

Preferred Service at (888) 845-4641.

CAUTION

!

Damage caused by freezing temperatures is not covered by

the warranty.

Troubleshooting

BEFORE CALLING FOR SERVICE

If you think your product is malfunctioning, read the

CONTROL OPERATION section to clearly understand the

function of the control.

If the problem persists, read the NORMAL OPERATING

SOUNDS and TROUBLESHOOTING GUIDE sections below to

help you quickly identify common problems and possible

causes and remedies. Most often, this will resolve the

problem without the need to call for service.

Condenser

Extended Non-Use

VACATION/HOLIDAY, PROLONGED SHUTDOWN

The following steps are recommended for periods of

extended non-use:

1. Remove all consumable content from the unit.

2. Disconnect the power cord from its outlet/socket

and leave it disconnected until the unit is returned to

service.

3. If any ice is visible inside the unit, allow ice to thaw

naturally.

4. Clean and dry the interior of the unit. Ensure all water

has been removed from the unit.

5. The door must remain open to prevent formation of

mold and mildew. Open door a minimum of 2” (50 mm)

to provide the necessary ventilation.

IF SERVICE IS REQUIRED

If you do not understand a troubleshooting remedy, or your

product needs service, contact Viking Preferred Service

directly at (888) 845-4641.

When you call, you will need your product Model and Serial

Numbers. This information appears on the Model and Serial

number plate located on the upper right or rear wall of the

interior of your product.

NORMAL OPERATING SOUNDS

All models incorporate rigid foam insulated cabinets to

provide high thermal e ciency and maximum sound

reduction for its internal working components. Despite this

technology, your model may make sounds that are

unfamiliar.

Normal operating sounds may be more noticeable because

of the unit’s environment. Hard surfaces such as cabinets,

wood, vinyl or tiled oors and paneled walls have a

tendency to re ect normal appliance operating noises.

20

Maintenance

Listed below are common refrigeration components with a

brief description of the normal operating sounds they

make. NOTE: Your product may not contain all the

components listed.

• Compressor: The compressor makes a hum or pulsing

sound that may be heard when it operates.

• Evaporator: Refrigerant owing through an evaporator

may sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may be

heard.

• Automatic Defrost Drain Pan: Water may be heard

dripping or running into the drain pan when the unit is

in the defrost cycle.

TROUBLESHOOTING GUIDE

DANGER

!

ELECTROCUTION HAZARD. Never attempt to repair or

perform maintenance on the unit before disconnecting the

main electrical power.

Troubleshooting - What to check when problems occur:

Problem Possible Cause and Remedy

Interior Light

Does Not

Illuminate

Light Remains

on When Door Is

Closed.

Unit Develops

Frost on Internal

Surfaces.

Unit Develops

Condensation on

External Surfaces.

Product is Not

Cold Enough

If the unit is cooling, it may be in Sabbath

mode.

Turn o light switch if equipped.

Adjust light actuator bracket on bottom of

door.

Ensure the door is closing and sealing

properly.

The unit is exposed to excessive humidity.

Moisture will dissipate as humidity levels

decrease.

Air temperature does not indicate product

temperature. See CHECKING PRODUCT

TEMPERATURE below.

Adjust the temperature to a cooler set

point.

Ensure unit is not located in excessive

ambient temperatures or in direct sunlight.

Ensure the door is closing and sealing

properly.

Ensure the interior light has not remained

on too long.

Ensure nothing is blocking the front grille,

found at the bottom of the unit.

Ensure the condenser coil is clean and free

of any dirt or lint build-up.

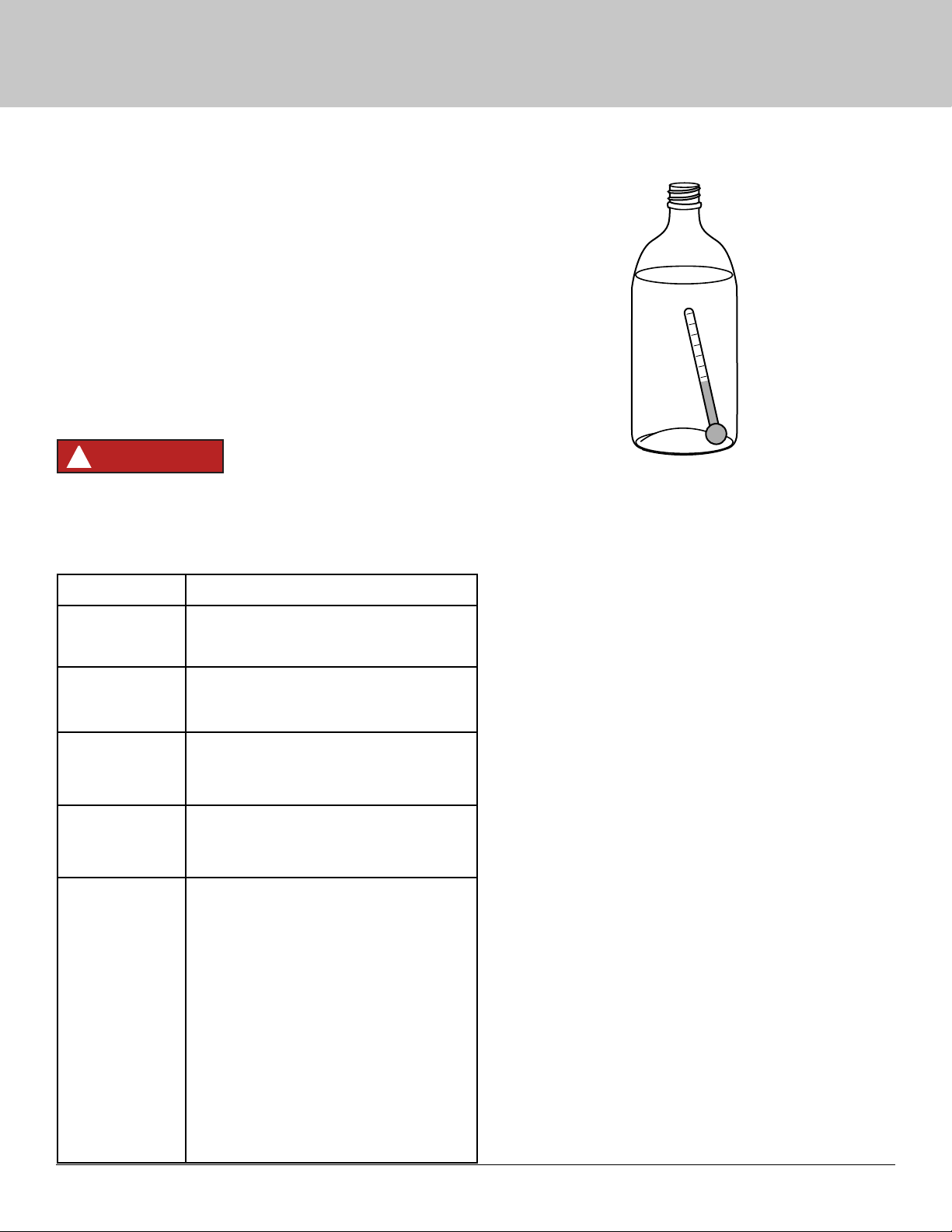

CHECKING PRODUCT TEMPERATURE

To check the actual product temperature in the unit:

1. Partially ll a plastic (nonbreakable) bottle with water.

2. Insert an accurate thermometer.

3. Tighten the bottle cap securely.

4. Place the bottle in the desired area for 24 hours.

5. Avoid opening the unit during the testing period.

6. After 24 hours, check the temperature of the water.

If required, adjust the temperature control in a small

increment (see CONTROL OPERATION).

Causes which a ect the internal temperatures of the

cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Installation in direct sunlight or near a heat source.

• The number of door openings and the time the door is

open.

• The time the internal light is illuminated. (This mainly

a ects product on the top rack or shelf.)

• Obstruction of front grille or condenser.

21

Service Information

If service is required, call your authorized service agency.

Have the following information readily available:

• Model number

• Serial number

• Date purchased

• Name of dealer from whom purchased

Clearly describe the problem that you are having. If you are unable to obtain the name of an authorized service agency, or

if you continue to have service problems, contact Viking Range, LLC at (888) 845-4641 or write to:

VIKING RANGE, LLC

PREFERRED SERVICE

111 Front Street

Greenwood, Mississippi 38930 USA

Record the information indicated below. You will need it if service is ever required. The serial number and model numbers

for your beverage center are located on the upper wall, behind the lighting:

Model No. ______________________________________________________________________________

Serial No. ________________________________________________________________________________

Date of Purchase _________________________________________________________________________

Date Installed ____________________________________________________________________________

Dealer’s Name ___________________________________________________________________________

Address ________________________________________________________________________________

_____________________________________________________________________________________

If service requires installation of parts, use only authorized parts to insure protection under the warranty.

Keep this manual for future reference.

22

Loading...

Loading...