Page 1

Viking Use/Installation Guide

Viking Range, LLC

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-(845-4641)

or visit the Viking website at

vikingrange.com

F21363 EN

Outdoor 15” Wide Double Side Burners

(120913)

Page 2

Important: Please Read and Follow

1. Before beginning, please read these instructions completely and carefully.

2. Do not remove permanently affixed labels, warnings, or plates from product. This may void the warranty

3. Please observe all local and national codes and ordinances.

4. The installer should leave these instructions with the consumer who should retain for local inspector’s use and for

uture reference

f

nstallation must conform with local codes or in the absence of codes, the National Fuel Gas Code, ANSI Z223.1.

I

IInn CCaannaaddaa::

CAN/CGA-B149.2, Propane Installation Code and/or local codes.

Installation must be in accordance with the current CAN/CGA-B149.1, Natural Gas Installation Code or

Safety Tips

•Keep outdoor cooking appliance area free from combustible materials, gasoline and other flammable vapors and

liquids.

•Keep ventilation openings at the rear of the cart and cylinder free and clear to allow proper air flow. Do not obstruct

the flow of combustion and ventilation air.

•Spiders and insects can nest in the burners of the grill and block the gas and air flow to the burner ports. This may

cause a fire from behind the manifold cover. Inspect and clean burners periodically.

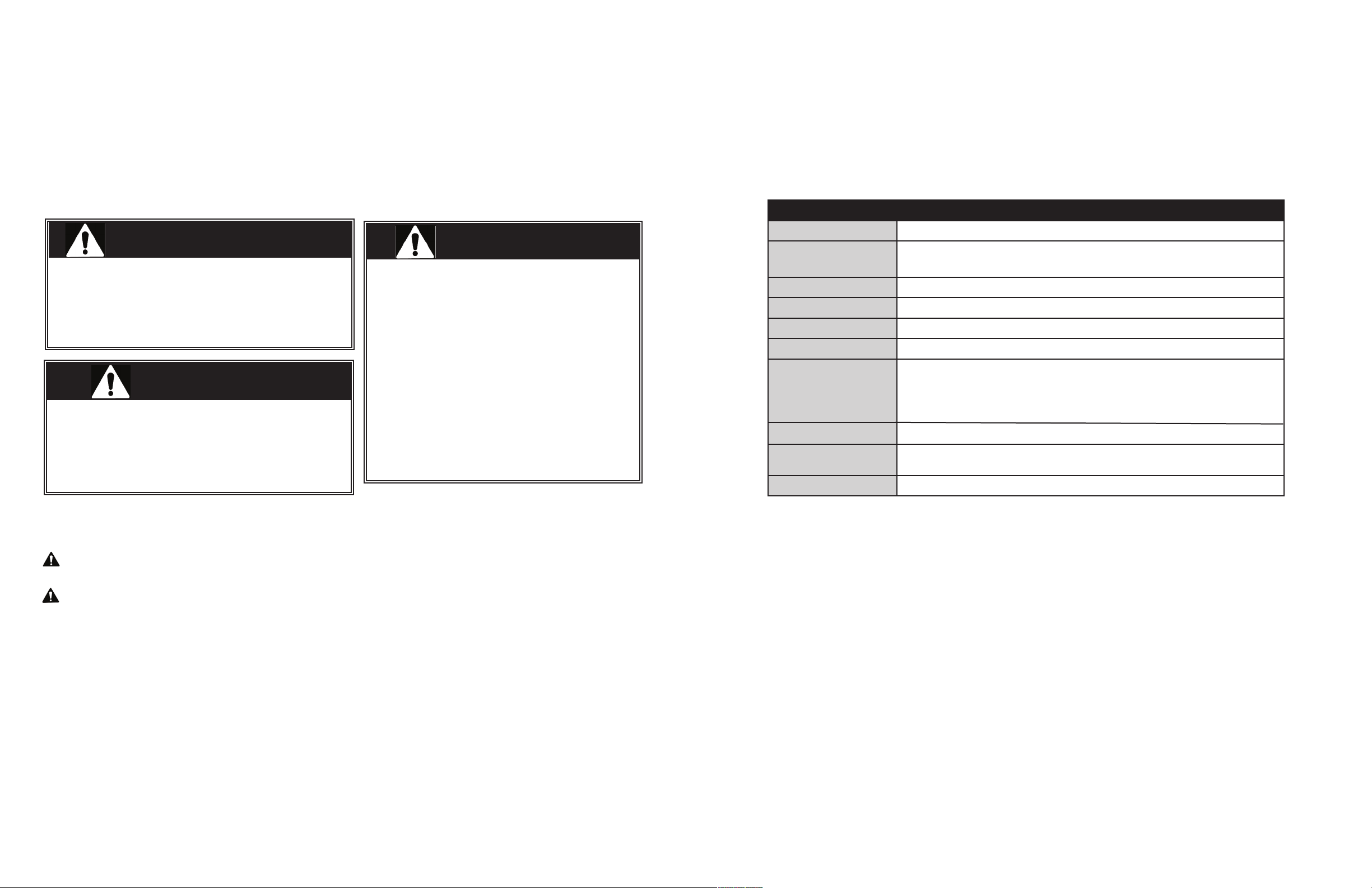

BBAASSIICC SSPPEECCIIFFIICCAATTIIOONNSS

DDeessccrriippttiioonn

VVGGSSBB55115533

FOR YOUR SAFETY

IIff yyoouu ssmmeellll ggaass::

11.. SShhuutt ooffff ggaass ttoo tthhee aapppplliiaannccee..

22.. EExxttiinngguuiisshh aannyy ooppeenn ffllaammee..

33.. OOppeenn lliidd..

44.. IIff ooddoorr ccoonnttiinnuueess,, iimmmmeeddiiaatteellyy ccaallll yyoouurr ggaass ssuupppplliieerr oorr yyoouurr

ffiirree ddeeppaarrttmmeenntt..

FOR YOUR SAFETY

11.. DDoo nnoott ssttoorree oorr uussee ggaassoolliinnee oorr ootthheerr ffllaammmmaabbllee vvaappoorrss

aanndd lliiqquuiiddss iinn tthhee vviicciinniittyy ooff tthhiiss oorr aannyy ootthheerr aapppplliiaannccee..

22.. AAnnyy LLPP ccyylliinnddeerr nnoott ccoonnnneecctteedd ffoorr uussee sshhaallll nnoott bbee ssttoorreedd

iinn tthhee vviicciinniittyy ooff tthhiiss oorr aannyy ootthheerr aapppplliiaannccee..

If not installed, operated and maintained in

accordance with the

product could expose you to substances in fuel or

fuel combustion which can cause death or serious

illness and which are known to cause cancer, birth

defects or other reproductive harm.

WARNING

mmaannuuffaaccttuurreerr’’ss

For example, benzene is a chemical which is

part of the gas supplied to the cooking

product. It is consumed in the flame during

combustion. However, exposure to a small

amount of benzene is possible if a gas leak

occurs. Formaldehyde and soot are byproducts of incomplete combustion. Properly

adjusted burners with a bluish rather than

yellow flame minimize incomplete combustion.

instructions, this

General Information

WWAARRNNIINNGG

and/or boats.

WWAARRNNIINNGG::

• Keep area clear and free from combustible materials, gasoline, and other flammable vapors.

• When the outdoor gas side burner or grill is not in use, the gas supply must be turned off at the LP gas supply

cylinder.

• The pressure regulator and hose assembly supplied with the unit must be used. Replacement pressure regulators

and hose assemblies must be those specified by the manufacturer.

• Finding a leak is not a “do-it-yourself” procedure. Some leaks can only be found with the burner control in the on

position and this must be done by a qualified technician.

• The LP supply cylinder to be used must be constructed and marked in accordance with the specifications for LPgas cylinders of the U.S. Department of Transportation (DOT) or the National Standard of Canada, CAN/CSAB339, Cylinders, Spheres, and Tubes for the Transportation of Dangerous Goods.

• Gas Manifold Pressure -

Natural gas - 4.0” W.C.P.

LP/Propane - 10.0” W.C.P.

• If the following instructions are not followed exactly, a fire causing death or serious injury may occur:

-Do not store a spare LP gas cylinder under or near this appliance.

-Never fill the cylinder beyond 80 percent full.

: This outdoor gas side burner is not intended to be installed in or on recreational vehicles

Keep electrical supply cord and the fuel supply hose away from heated surfaces.

Overall Width 15-5/16” (38.9 cm)

Overall Depth To end of landing ledge 31-9/16” (80.2 cm)

To end of knobs 32-5/8” (82.9 cm)

Overall Height To cooking surface 10 1/2” (26.3 cm)

Cutout Width 14 ” (35.6 cm)

Cutout Depth 27-1/2” (69.9 cm)

Cutout Height 10-1/4” (26.0 cm)

Gas Requirements Natural: standard residential 1/2” (1.3 cm) ID gas service line.

LP/Propane: equipped with high capacity hose/regulator assembly for connection

to standard 5 gal, 20 lb. LP/Propane gas cylinder with Type 1, QCC-1

connection or standard residential 1/2” (1.3 cm) ID gas service line.

Electrical Requirements

Side Burner Rating (2) - 15,000 BTU Nat./13,500 BTU LP

Approximate Shipping Wt. 80 lbs. (36.3 kg)

12 V - (8 AA batteries)

(4.4 kW Nat./4.0 kW LP)

Gas Connection

Verify the type of gas supply to be used, either natural or LP, and make sure the marking on the rating plate agrees

with that of the supply. Never connect an unregulated gas line to the appliance. An installer supplied gas shut-off

valve must be installed in an easily accessible location. All installer supplied parts must conform to local codes, or in

the absence of local codes, with the National electrical Code, ANSI/NFPA 70 and the National Fuel Code, ANSI

Z223.1.

Code or CAN/CGA-B149.2, Propane Installation Code and/or local codes. All pipe sealants must be an approved type

and resistant to the actions of LP gas. Never use pipe sealant on flare fittings. All gas connections should be made by

a competent technician and in accordance with local codes and or ordinances. In the absence of codes, the installation

must comply with the National Fuel Gas Code ANSI Z223.1.

The gas side burner and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPa). The unit must be isolated from the

gas supply piping system by closing its individual manual shut-off valve during any pressure testing of that system at

test pressures equal to or less than 1/2 psi (3.5 kPa).

BBuuiilltt--iinn iinnssttaallllaattiioonnss mmuusstt bbee pplluummbbeedd uussiinngg aa ffiixxeedd//hhaarrdd lliinnee iiff tthhee uunniitt iiss ggooiinngg ttoo bbee ooppeerraatteedd aatt aa

ddiissttaannccee eexxcceeeeddiinngg 33 ffeeeett ((00..9911 mmeetteerrss)) ffrroomm tthhee ffuueell ssuuppppllyy ppeerr AANNSSII ZZ2211..2244.. AAllll ccoonnnneeccttoorrss nneeeedd

ttoo ccoommppllyy wwiitthh AANNSSII ZZ2211..7755// CCSSAA 66..2277.. WWhheenn uussiinngg sseemmii--rriiddggeedd ttuubbiinngg,, aalluummiinnuumm oorr aalluummiinnuumm aallllooyy

ttuubbiinngg iiss nnoott ppeerrmmiitttteedd.. AAllll ccoonnnneeccttiioonnss aarree ttoo bbee vviissiibbllee tthhrroouugghh ddoooorr oorr ooppeenniinngg iinn tthhee eenncclloossuurree..

IInn CCaannaaddaa::

Installation must be in accordance with the current CAN/CGA-B149.1, Natural Gas Installation

2

3

Page 3

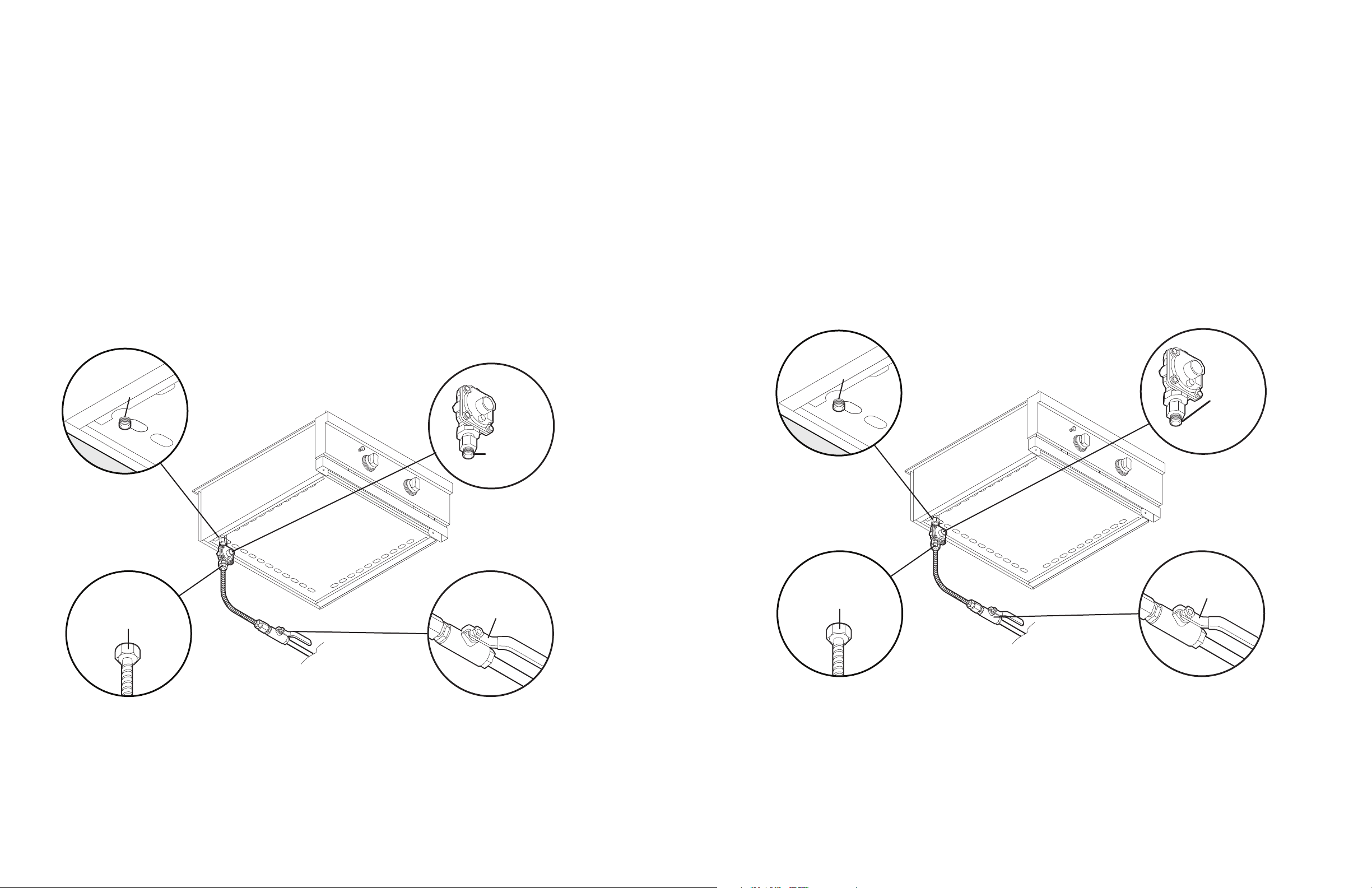

3/8” 3/8”

male male

flare flare

dapterdapter

Installer supplied

flexible gas line

with 3/8” female

adapter

Installer supplied

shut-off valve must

be easily accessible

Regulator

Assembly

3/8” male

flare

adapter

Male Male

couplercoupler

3/8” 3/8”

male male

flare flare

dapterdapter

1/2”

NPT

from

Manifold

Male Male

couplercoupler

Installer supplied

flexible gas line

with 1/2” female

adapter or GHS12

Installer supplied

shut-off valve must

be easily accessible

7/8” male

flare adapter

Regulator

Assembly

3/8” 3/8”

male male

flare flare

dapterdapter

1/2”

NPT

from

Manifold

Natural Fixed Piping Connection

LP/PROPANE Fixed Piping Connection

Connection: Standard Residential 1/2” ID gas service line - 1/2” NPT male.

Operating Pressure: 4.0” W.C.P. Nat.

Supply Pressure: 6” to 10” W.C.P. Nat. If in excess of 10” W.C.P., a step-down regulator is required.

heck with your local gas utility company or with local codes for instructions on installing gas supply lines. Be sure to check on

C

ype and size of run and how deep to bury the lines. If the gas line is too small, the unit will not function properly.

t

To connect the supplied regulator assembly to the incoming flexible gas line, attach with a 7/8” (2.2 cm) female flare adaptor

to the 7/8” (2.2 cm) male flare adaptor on the regulator assembly. Ensure that the regulator arrow points in the direction of the

gas flow towards the unit and away from the supply. Connect the regulator assembly to the grill unit. All connectors need to

comply with ANSI Z21.75/ CSA 6.27. When using semi-ridged tubing, aluminum or aluminum alloy tubing is not permitted.

DDOO NNOOTT ffoorrggeett ttoo ppllaaccee tthhee iinnssttaalllleerr ssuupppplliieedd ggaass vvaallvvee iinn aann aacccceessssiibbllee llooccaattiioonn..

NNOOTTEE:: IIff uussiinngg aa VViikkiinngg GGSSHH1122 fflleexxiibbllee hhoossee,, rreemmoovvee tthhee 11//22”” ffllaarree aaddaapptteerr aanndd aattttaacchh hhoossee ttoo tthhee tthhee 77//88”” ((22..22 ccmm)) mmaalle