Viking VGR30, VGR36-6B, VGR36-4G, VGR48-4Gl, VGR48-6G Service Manual

...

SERVICE MANUAL

FREE STANDING GAS RANGE

TABLE OF CONTENTS

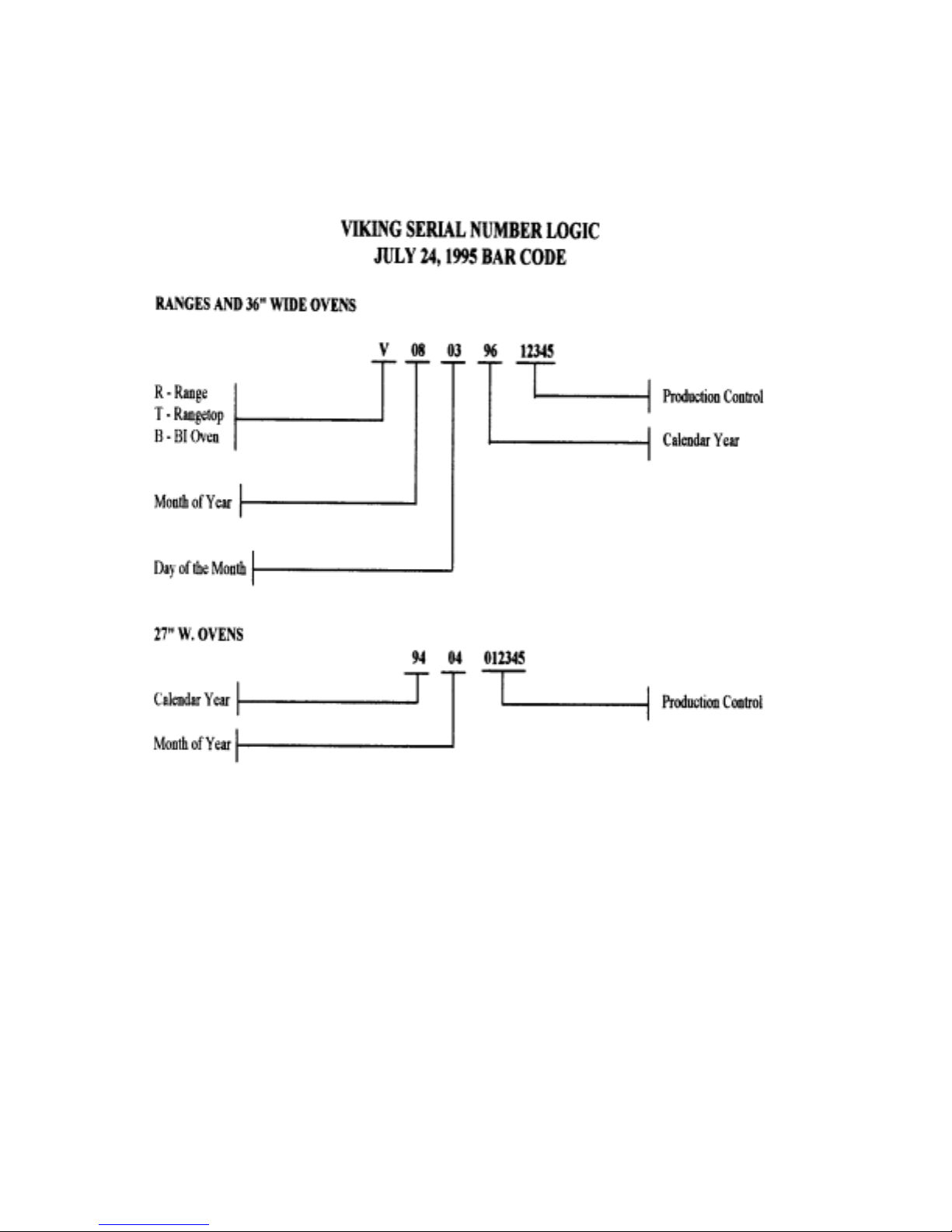

Viking Model Numbers................................... 2

Viking Serial Number logic............................. 3

Viking Product Warrenty................................. 4

Proximity to Side Cabinets Installation........... 6

Gas Connections............................................ 7

Rangetop Cutout and Specifications............... 8

Range Leveling............................................... 9

Combustion of Gas........................................ 10

BTU Requirements......................................... 12

Gas Conversion............................................... 13

I / R Broiler Spud (Orifice) Change.............. 14

Surface Burner Adjustments............................ 15

Oven Burner Adjustments............................... 16

Grill / Griddle Burner Adjustment................... 17

Oven Temperature Calibration Chart................ 18

Oven Thermostat / Calibration.......................... 19

Silicon Carbide (Glow-Coil) Ignition............... 20

Door Removal.................................................. 21

Oven Door Assembly....................................... 22

Hinge and Logo Removal................................ 22

Door Hinge Removal...........................................22

Oven Door Parts..................................................22

Control Panel Removal..................................... 23

Landing Ledge Removal................................... 23

Component Location...........................................24

Top Burner Removal........................................ 25

Top Burner Ignitor Removal........................... 25

Spark Module Removal................................... 25

Indicator Light Removal.................................. 26

Bake / Broil Thermostat Removal.................... 26

Oven Ignitor Removal..................................... 26

Broil Gas Valve Removal................................. 26

Oven Gas Valve Removal................................. 26

Top Burner Valve Replacement........................ 27

Pressure Regulator Removal............................ 27

Convection Fan Removal................................. 27

Oven Burner Removal..................................... 27

Broil Burner Removal...................................... 28

Broil Ignitor Removal....................................... 28

Indicator Light.................................................. 28

Oven Light Switch........................................... 28

Oven Light Switch Removal............................ 28

Oven Gasket Removal..................................... 28

Convection Fan Removal................................. 28

Oven Light Removal........................................ 29

Grill Burner Removal....................................... 29

Grill Ignitor Removal....................................... 29

Griddle Thermostat Removal........................... 29

Trouble Shooting Guide.................................... 30

Griddle Repaie Kit.(12") griddle...................... 34

Griddle Repair Kit (24")................................... 35

Wiring Diagram (Rangetops)............................ 36

Wiring Diagram (convection Ranges)............... 37

2

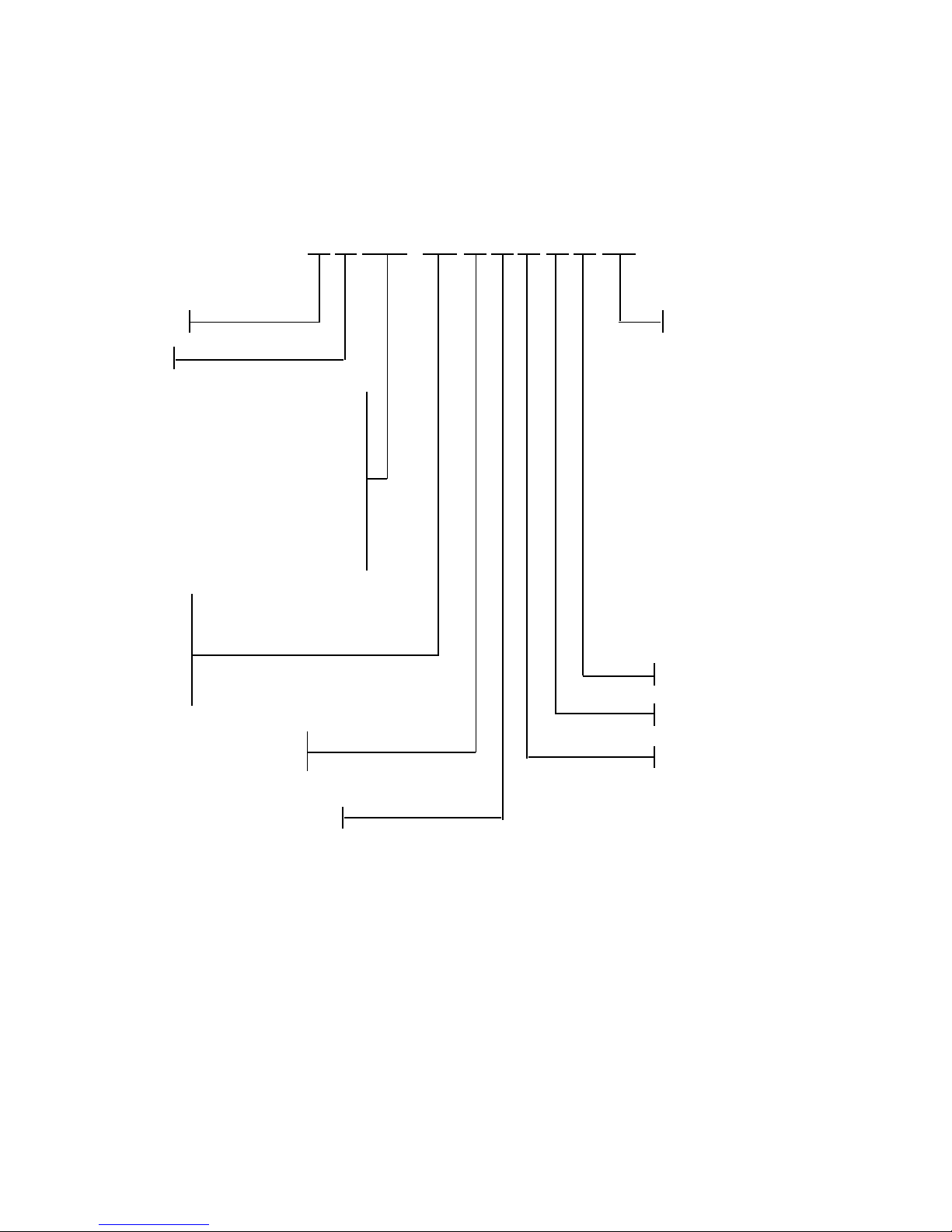

NEW VIKING MODEL NUMBERS

RANGES AND RANGETOPS

V G R C 4 8 5 4 G Q D S S

V-Viking Color

AL-Almond

G-Gas Bk-Black

BU-Burgundy

SS-24" D EW-Euro White

Standard Range (30"W) FG-Forest Green

SC-27" D PL-Plum

Convection Range (30"W) SS-Stainless Steel

VB-Viking Blue

RC-27" D WH-White

Convection Range (36"/48"W) GG-Graphite Gray

RT-24" D LN-Linen

Rangetop

Width

30"

36"

48" D-Oven Door Window

60"

Q-12" Wide Grill

0-Standard Oven

5-Convection Oven G-Griddle

12" Wide

24" Wide

Number of Surface Burners

3

4

VIKING RANGE CORPORATION

PRODUCT WARRANTY

COOKING PRODUCTS

FREE STANDING GAS RANGES

90 DAYS-GLASS, PAINTED, PORCELAIN AND

*

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-SURFACE BURNER,

GRIDDLE TUBULAR BURNER, GRILL TUBULAR

BURNER (PART ONLY)

* 10 YEAR LIMITED WARRANTY-ANY PORCELAIN

OVEN OR PORCELAIN INNER DOOR WHICH RUSTS

THROUGH

DUAL FUEL RANGES

* 90 DAYS-GLASS, PAINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-SURFACE BURNER,

GRIDDLE TUBULAR BURNER, GRILL TUBULAR

BURNER, BAKE ELEMENT, BROIL ELEMENT, OR

CONVECTION COOK ELEMENT (PART ONLY)

* 10 YEAR LIMITED WARRANTY-ANY PORCELAIN

OVEN OR PORCELAIN INNER DOOR PANEL WHICH

RUSTS THROUGH

ELECTRIC RANGES

* 90 DAYS-GLASS, PAINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR-ANY HALOGEN ELEMENT, BAKE

ELEMENT, BROIL ELEMENT, OR CONVECTION

COOK ELEMENT (PART ONLY)

* 10 YEAR LIMITED WARRANTY-ANY PORCEOAIN

OVEN OR PORCELAIN INNER DOOR PANEL WHICH

RUSTS THROUGH

GAS RANGETOPS

* 90 DAYS -GLASS, PAINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-SURFACE BURNERS,

GRIDDLE TUBULAR BURNER, GRILL TUBULAR

BURNER (PART ONLY)

ELECTRIC RANGETOP

* 90 DAYS-GLASS, PAINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR-ANY HALOGEN ELEMENT, BAKE

ELEMENT, BROIL ELEMENT, OR CONVECTION

COOK ELEMENT (PART ONLY)

GAS WALL OVENS

* 90 DAYS-GLASS, PAINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEARS-OVEN TUBULAR BURNER (PART ONLY)

* 10 YEAR LIMITED WARRANTY-ANY PORCELAIN

OVEN OR PORCELAIN INNER DOOR PANEL WHICH

RUSTS THROUGH

ELECTRIC WALL OVENS

* 90 DAYS-GLASS, POINTED, PORCELAIN AND

DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEARS LIMITED WARRANTY-OVEN BAKE,

BROIL,OR CONVECTION HEATING ELEMENTS

* 10 YEAR LIMITED WARRANTY-ANY PORCELAIN OR

PORCELAIN INNER DOOR PANEL WHICH RUSTS

THROUGH

WARMING DRAWERS

* 90 DAYS-PAINTED AND DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-HEATING ELEMENT

VENTILATION PRODUCTS

* 90 DAYS-PAINTED AND DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 2 YEAR LIMITED WARRANTY-BLOWER MOTOR

OR EXTERIOR VENTILATOR MOTOR

KITCHEN CLEAN-UP

DISHWASHER

* 90 DAYS-PAINTED OR DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-MOTOR/PUMP AND

WATER DISTRIBUTION SYSTEM COMPONENTS

* CIRCULATION PUMP

* DRAIN MOTOR/PUMP

* FILL V ALVE

* LOWER WASH ARM

* TUBE TO UPPER WASH ARM

* UPPER WASH ARM

* 25 YEAR LIMITED WARRANTY-STAINLESS STEEL

TANK OR INNER DOOR LINER WHICH DEVELOPS A

WATER LEAK

TRASH COMPACTORS

* 90 DAYS-PAINTED OR DECORATIVE ITEMS

* 1 YEAR FULL WARRANTY-COMPONENTS AND

ACCESSORIES

* 5 YEAR LIMITED WARRANTY-DRIVE SYSTEM

MOTOR

DISPOSERS

* VCFW 1020 AND VBFW

* 7 YEAR FULL WARRANTY

* VCHW 1000 AND VBHW 1030

* 5 YEAR FULL WARRANTY

5

PRODUCT WARRANTY (CONTINUED)

REFRIGERATION PRODUCTS

REFRIGERATION

* 90 DAYS-PAINTED OR DECORATIVE ITEMS

* 2 YEARS FULL WARRANTY

* 6 YEARS FULL WARRANTY ON SEALED SYSTEM

COMPONENTS

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

* 12 YEAR LIMITED WARRANTY-SEALED SYSTEM

COMPONENT (PARTS ONLY)

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

ICE MAKER

* 90 DAYS-PAINTED OF DECORATIVE ITEMS\

* 2 YEAR FULL WARRANTY

* 6 YEAR FULL WARRANTY ON SEALED SYSTEM

COMPONENT

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

* 12 YEAR LIMITED WARRANTY-SEALED SYSTEM

COMPONENT (PART ONLY)

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

WINE COOLER

* 90 DAYS-PAINTED OR DECORATIVE ITEMS

* 2 YEAR FULL WARRANTY

* 6 YEAR FULL WARRANTYON SEALED SYSTEM

COMPONENT

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

* 12 YEAR LIMITED WARRANTY-SEALED SYSTEM

COMPONENT (PART ONLY)

* COMPRESSOR

* CONDENSER

* DRYER/STRAINER

* EVAPORATOR

* CONNECTING TUBING

OUTDOOR PRODUCTS

GAS GRILLS

ITEMS

* 90 DAY-PAINTED, PORCELAIN, AND DECORATIVE

* 1 YEAR FULL WARRANTY

* 5 YEAR LIMITED WARRANTY-CAST IRON BURNER

ASSEMBLIES, INFRARED ROTISSERIE BURNERS,

AND PORCE LAIN GRILL GRATES

* LIFETIME WARRANTY-STAINLESS STEEL PART

WHICH RUST THROUGH

6

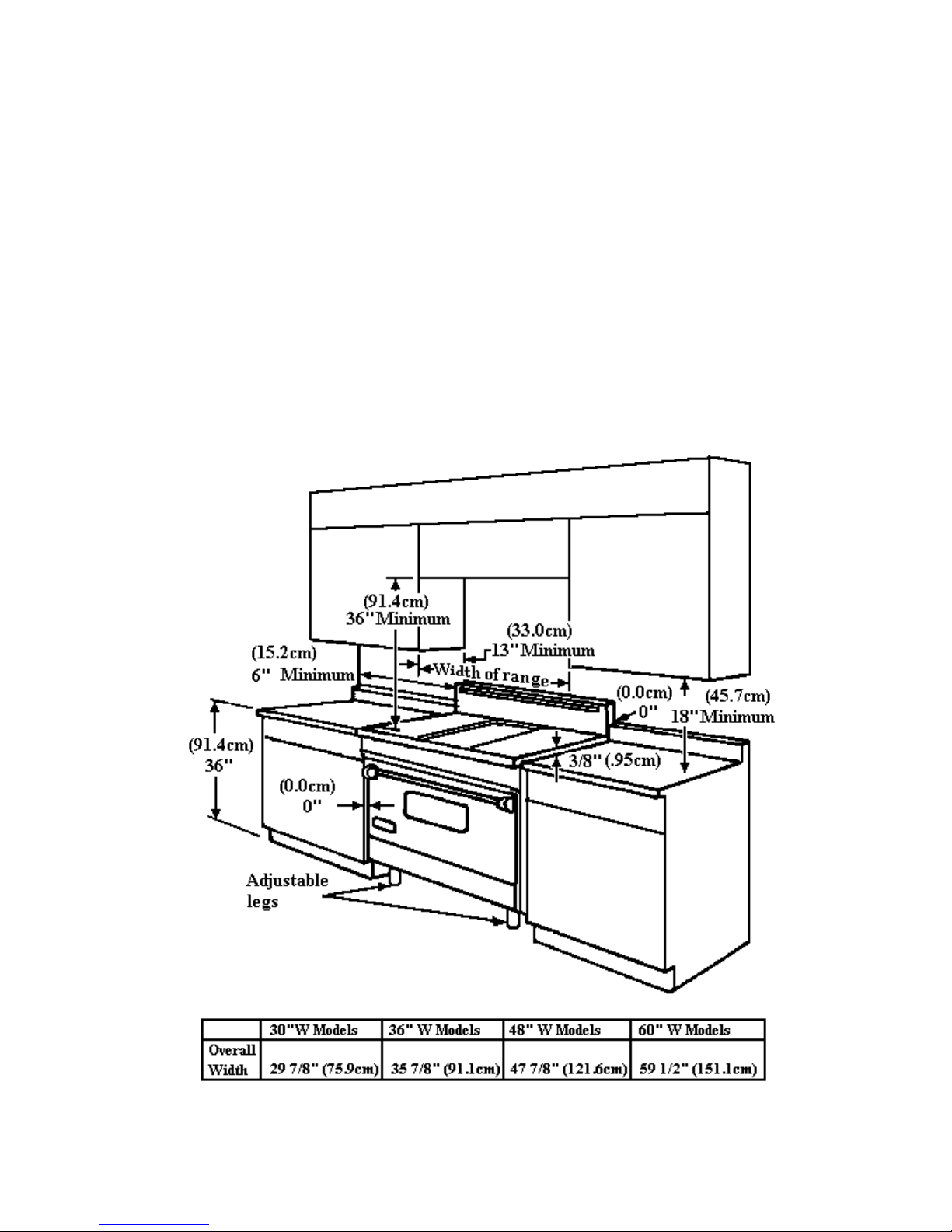

PROXIMITY TO SIDE CABINET INSTALLATION

1. This range may be installed directly adjacent to existing 36" high base cabinets.

IMPORTANT- the top grate support MUST BE 3/8" above the adjacent base cabinet coun tertop. This m ay

be accomplished by raising the unit using the adjustment spindles on the legs. (The countertops CANNOT

be higher than 37 1/2" due to the high BTU burners.)

2. The range CANNOT be installed directly adjacent to sidewalls, tall cabinets, tall appliances, or other side

vertical surfaces above 36" high. There must be a minimum of 6" side clearance from the range to such

combustible surfaced above the counter height.

3. Within the 6" side clearance to com bustible vertical surf aces above 36", the maxim um w all cabinet depth must

be 13" and wall cabinets within 6" side clearance must be 18" above the 36" high countertop.

4. Wall cabinets above the range must be a m inimum of 36" above the range cook ing surface f or the full width of

the range.

7

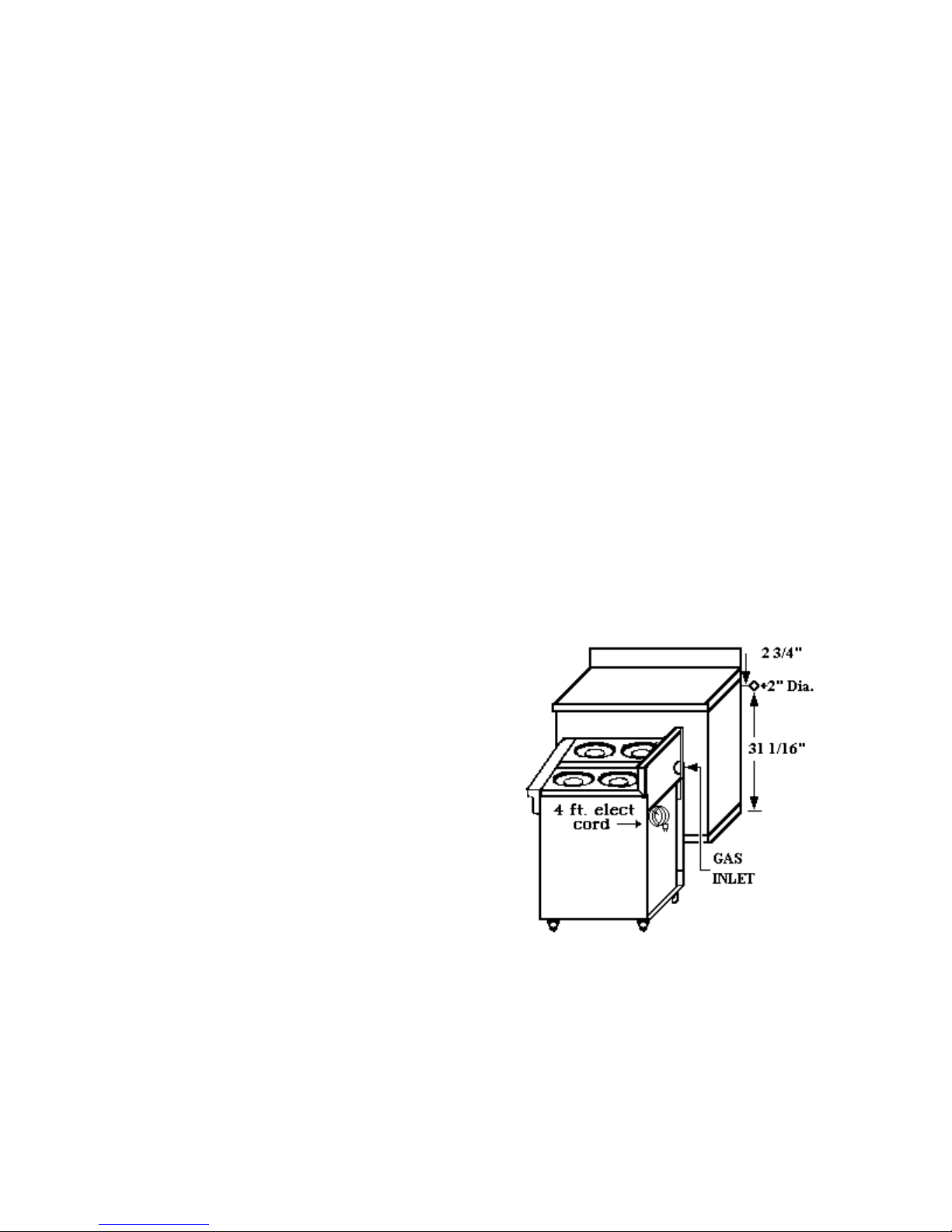

GAS CONNECTIONS

The gas supply (service) line must be the same size or greater than the inlet line of the appliance. This range

uses a ½" I.D. NPT (Sch40) inlet. Sealant on all pipe joints must be resistive to Lp gas.

1. Manual Shut-off Valve:

This installer supplied valve must be installed

in the gas service line ahead of the appliance

and regulator in

reached quickly in the event of an emergency.

2. Pressure Regulator:

a) All heavy-duty, commercial-type cooking

equipment must have a pressure regulator on

the incoming service line for safe and efficient

operation, since service pressure may fluctuate

with local demand. External regulators are not

required on this range, because a regulator is

built into each unit at the factory. UNDER NO

CONDITION BYPASS THIS BUILT-IN

REGULATOR.

b) Any conversion required must be performe d

by your dealer or a qualified licensed plumber

or gas service company. Please provide the

service person with this manual before work is

started on the range.

( GAS CONVERSIONS ARE THE

RESPONSIBILITY OF THE DEALER OR

END USER.)

c) This range can be used with Natural gas or

LP/Propane. It is shipped from the factory

adjusted for use with natural gas. The orifice

hoods must be screwed snug when

LP/Propane is used. (See LP/Propane

conversion).

d) Manifold pressure should be checked w ith a

manometer, natural gas requires 5.0"WC and LP

gas requires 10.0"WC. Incoming line pressure

upstream from the regulator must be 1.0"WC

higher than the manifold pressure in order to

check the regulator. The regulator used on this

range can withstand a maximum

a position where it can be

input pressure

e) The appliance, its individual shut-off valve,

and pressure regulator must be disconnected

from the gas supply piping system during any

pressure testing of that system at pressures in

excess of 1/2psig (3.45kPa).

f) The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure testing

of the gas piping system at test pressures equal to

or less than ½ psig (3.45kPa).

3. Flexible Connections:

a) If the unit is to be installed with flexible

couplings and/or quick-disconnect fittings, the

installer must use a heavy duty, A.G.A. design

certified commercial flexible connector of at lea st

½" ID NPT ( with suitable strain reliefs) in

compliance with ANSI Z21.69.

b) In Canada: CAN 1-6. 10-88 metal

connectors for gas appliance and CAN 1-6.9

M79 quick disconnect devices for use with gas

fuel.

of ½ PSI (14.0" WC). If the line pressure is

in excess of that amount, a step-down

regulator will be required.

8

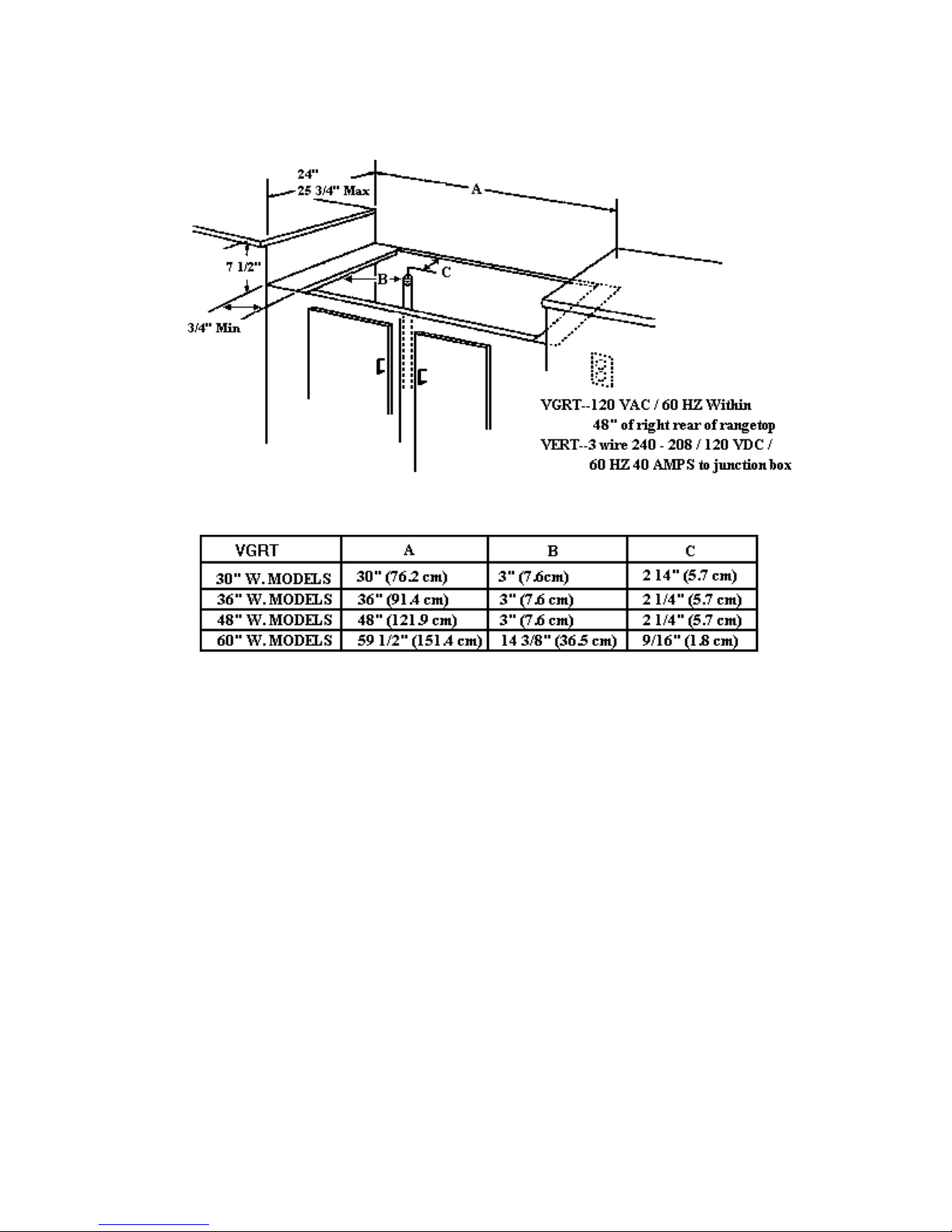

RANGETOP CUTOUT and SPECIFICATIONS

1. Gas Line Requirements:

a. Gas pipe size should be 3/4" (½" inside diameter)

b. Gas pipe should be 3" or less from floor and 6" from left to center of unit to allow for the

flex line.

i.e. 30" range 6"-15" from left 48" range 6"-24" from left

36" range 6"-15" from left 60" range 6"-30" from left

If it is higher than 3" from the floor, the range will not fit flush against the wall and

The shutoff valve will not be accessible.

2. Electrical Requirements: Gas ranges, gas rangetops, and Gas cooktops require a 120 volt

electrical outlet (GFI ground fault outlet not recommended).

a. 3" or less from the floor and 6" from the right to center of the unit.

i.e. 30" range 6"-15" from right 48" range 6"-24" from right

36" range 6"-18" from right 60" range 6"-30" from right

9

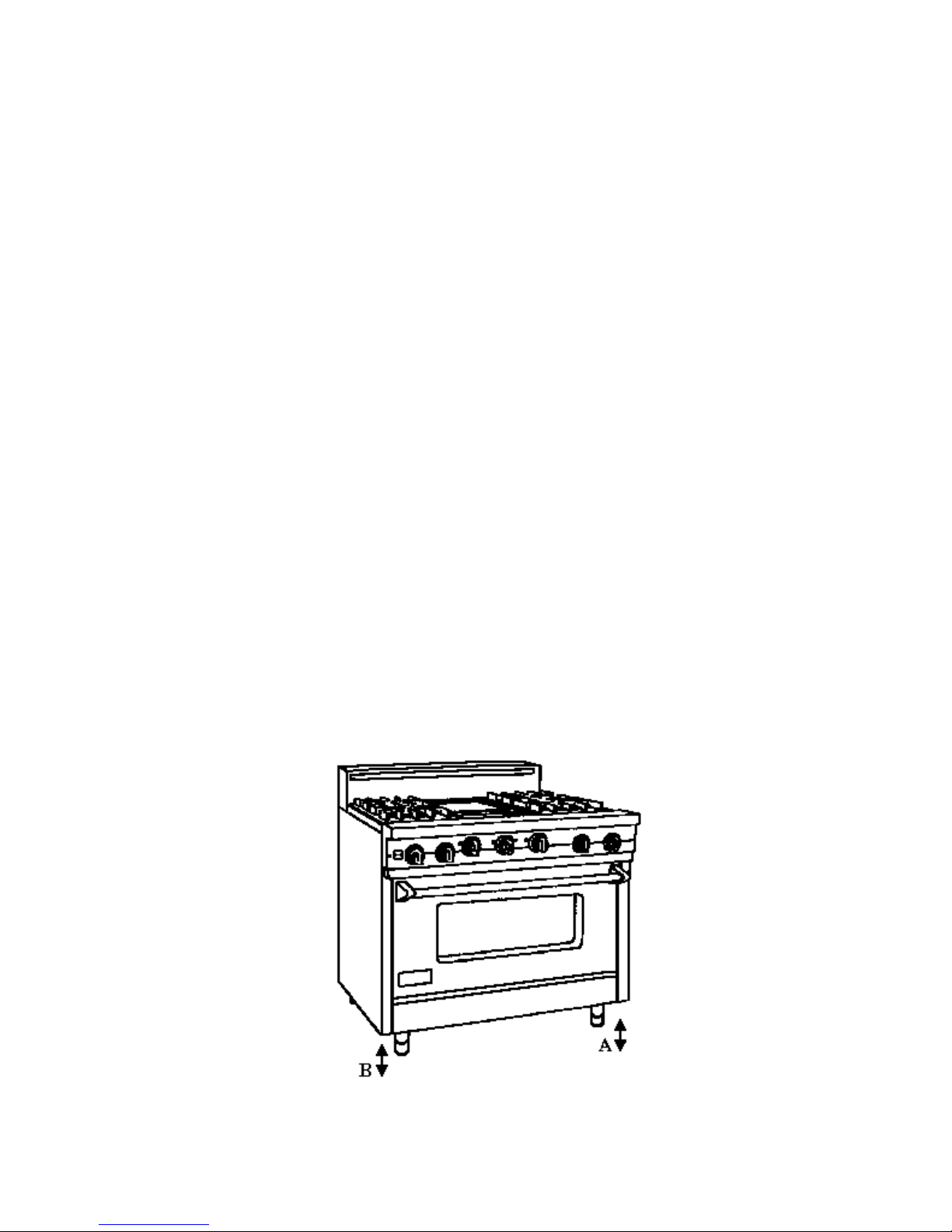

RANGE LEVELING

Careful leveling of the range is critical not only to

performance, but also to allow the alignment of

oven doors and drip tray. Closely follow the

procedures below to ensure proper performance

and appearance of the range. The range being

even slightly out of level will significantly

contribute to misalignment of oven doors.

1. If the floor is smooth and level, level the unit

with the screw thread of the legs. Set the high

corner of the range so that the top of the grate

support is 3/8" above the countertop, and level

the range to the high corner.

2. If the floor is uneven or has a decided slope,

level the unit with metal shims, as the

adjustment required may exceed the thread

available in the leg.

3. Proper and careful leveling of the range is

necessary for proper alignment of the oven

doors.

! The body of the range does n ot have a rigid f rame

to hold it into one position. This non-rigid

framework allows th e range to shift w ith u n-level

floors or slanted cabinets.

! Moving any one of the adjustable leveling leg s u p

or down will shift the range body. Use the

vertical line betw een the edg e of the door an d the

left side trim or center t rim on the 2 door m odels

to adjust the leveling legs.

A. Right Side

Front / Back

Adjusta ble Legs

B. Left Side

Front / Back

Adjusta ble Legs

When adjusted properly this space will be

uniform from the top to the bottom of the

door. The bottom corner of the end panel

will move in or out. Adjust this lower corner

to have an equal space from the top to the

bottom of the door.

! Increasing the length of the right front levelin g

leg will raise the right front corner of the

range, moving the top of the door to the left.

Lowering the right front leveling leg will

cause the top of the door to move to t he rig ht.

! Using the left front leveling leg will give you

the opposite effect. Raising the left front

corner will move the top of the door to the

right. Lowering the corner will move the top

of the door to the left. The rear leveling legs

will also have an effect on th e door alignment.

4. After the range is properly leveled , the drip

tray ha ndle may be aligned by loosening the

screws and a djusting the hand le horizo ntally

within the limits provided by the slotted

screw holes.

5. A carpenters’ spirit level should be placed

across the top of the range and the unit

leveled front-to back, side-to side and

vertically. If it is not level, burner

combustion may be erratic, liquid or semi-

liquid batters will

cook at an angle, and the

unit may not function

efficiently.

10

COMBUSTION OF GAS

A. The Meaning of Combustion

acts with a substance to produce large am ounts of

heat rapidly (and usually light), the process is

called combustion or burning.

B. Requirements for Combustion

needed for combustion to take place are fuel,

oxygen (air) and heat (temperature). All m ust be

present. Take away any one of the three and

burning will stop. Gas ignition temperature is

approximately 1100 - 1200 degrees Fahrenheit.

C. Basic Chemistry of Combustion

of gas is a chemical reaction betw een fuel gas and

oxygen. The basic elements of common fuel

gases are hydrogen (H) and Carbon (C). When

hydrogen burns, water vapor (H2O) is

produced. Complete burning of carbon in fuel

gases form carbon dioxide (C02). Complete

combustion produces harmless carbon dioxide

(C02) and water vapor (H20).

Water is produced as a vapor in the burning of

gas.If the flue products remain hot enough, water

is discharged as vapor to the outside through vent

system. If th e flu e product s shou ld becom e cool ,

as in an air conditioned room, this water vapor

will condense out as a liquid on any cooler

surface. The temperature at which water forms

from vapor is known as the dew-point.

D. Controlled Combustion

takes place when fuel gas and air are

supplied at proper rates to assure complete

combustion (burning) of the gas in a steady flam e.

When a gas appliance is operating

properly, burning starts at the burner ports.

Gas flow is controlled by a gas orifice size and by

gas pressure upstream of the orifice. Burners

which have some air premixed with the gas before

it passes through the B URNER PORTS

are called “blue flame” burn ers. This air added t o

the gas is called primary air. The rest of the air

required for complete combustion is supplied

to the burner flames in the COMBUSTION

CHAMBER and is called SECONDARY AIR.

Adjustments of gas rate and prim ary air prov ide

the key to obtaining stable, blue flames on the

burner using primary air. AIR SHUTTERS or

other devices provide control of primary air.

Proper amounts of prim ary and s econdary air are

needed for quiet and eff icie nt a pplia nce ope ratio n

- When oxygen

- Three things

- Combustion

- Controlled combustion

and for complete combustion of the gas. Size of

the inlet openings and flue outlets control

secondary air flow.

E. Explosive Combustion

very rapid burning which is not under control.

F. Limits of Flammability

mixtures will burn. Mixtures with zero to four

percent natural gas in air are to lean to burn.

Mixtures of four to fourteen percent natural gas in

air can burn with a controlled flame.

Flammability Limits are of interest to those

dealing with problems and everyday ope ratio ns in

the gas industry. For example consider,

FLASHTUBE ignition of rangetop burners. A

gas-air mixture from the burner head passes

through a char ge port into the open e nd of the

flashtube. This mixture is too rich to burn

without secondary air, but some air also enters

the flas htube at the entrance. The additional air

causes the mixture to become leaner to a

composition that is flammable. Wh en t he m ixt ure

travels down the tube to point of ignition, the

flame will carry back from the lighter to the

charge port and light the gas at the burner. If

the mixture in the flashtube has too

much gas (t oo rich) or has too m uch air (t oo le an),

the burner will not light.

Flammability L im its also enter th e picture w hen

primary air adjustm ents are ma de on burner s. For

example, Infra-red (radiant) burners usually

operate with about 100 percent primary air. In

other word the gas air mixture in the bu rn er h ead

contains all the air ideally required for complete

combustion. If too much prim ary air is used, the

mixture may becom e too lean and f all outside the

lower flammability limit and it will not burn on

the burner surface.

Unburned gas should not be allowed to coll ect in

combustion chambers or confined spaces because

gas-air mixture with in the flamm ability li mit s w ill

explode if ignited.

G. Incomplete Combustion - Causes and Effects

To obta in co mple te co mbustio n eno ugh air must

be supplied to the process. This air must have a

Reasonably normal oxygen content. Complete

burning of g as produces harm less carbon dioxide

and water vapor. If not enough air is suppli ed

other products will form. Some of these products

are harmful, especially carbon monoxide.

- An explosion is simply

- Not all air-gas

11

COMBUSTION OF GAS (CONTINUED)

It is vital that an appliance venting system do its

job. The importance of provi ding enough fresh

air to the room in which and appliance is

located can not be stressed too strongly.

Carbon monoxide is a toxic gas. It can cause

death if enough of it is inhaled. This gas has no

odor, color or taste, so that it cannot be detected

by bodily senses. Inhaled carbon monoxide is

absorbed into the blood. It combines with

hemoglobin in the blood to a m uch greater exten t

than oxygen and remains in the blood longer

than oxygen does. In doing so, it acts to reduce

the oxygen- carry ing f uncti on of th e blood. Thus,

a person exposed to carbon mon oxide can die lf a

lack of oxygen.

Carbon monoxide is only one product of

incomplete combustion. AL DEHYDES, another

class of compounds, also may be formed in

incomplete combustion. While carbon monoxide

is odorless, Aldehydes have a s h arp, pen e trat in g

odor. They are readily detected be sm ell, even at

very low concentrations. The odor of aldehydes

differs from odorants added to natu ral gas and the

two should not be confused. The absence of

aldehydes does not as sure t hat carbon m onoxi de

is not present. How ever, if the odor of aldehy des

is present, then carbon monoxides almost always

will be present, aldehydes themselves also are

toxic.

H. GAS BURNER OPERATION

a device to burn gas under control to produce

useful heat.

Primary air is brought into the burner from

outside the appliance at atmosphere pressure.

The gas jet streaming from the orifice draws or

injects primary air into the burner.

PRIMARY AIR:

before the gas leaves a burner port to burn.

SECONDARY AIR:

a burner flame at the point of combustion.

Air which is mixed with gas

Air externally supplied to

- A gas burner is

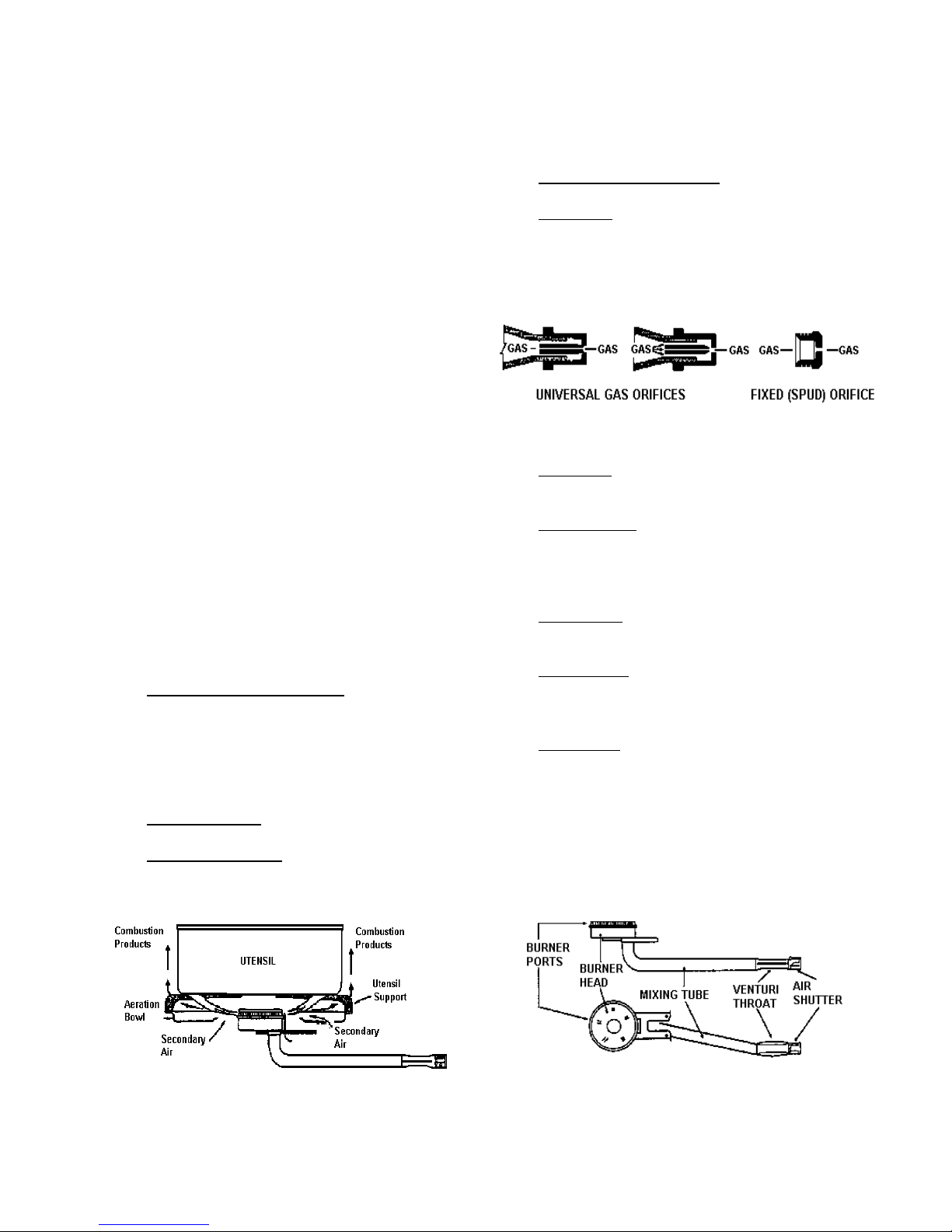

I. BURNER COMPONENTS

Gas Orifice

limits the amount of gas flowing to a burner. Gas

flow rate (volume) depends on the size of the

orifice (hole) and gas pressure at the inlet of the

orifice.

Air Shutter

the openings to control primary air flow.

Venturi Thr oat

body that narrows down and then flares out ag ain .

This neck helps maintain a more constan t prim ary

air injection.

Mixing Tube

from the venturi throat to the burner head.

Burner Head

provides uniform distribution of the air-gas

mixture to those ports.

Burner Ports

heat transfer. They spread the flam es so th ey can

be reached by secondary air. They provide

stable, blue flames.

- An opening o r hole, regulates or

- This is used to adjust the size of

- A section in a pipe or a burner

- Serves to carry the air-gas m ixture

- Contains the burner ports, and

- Distributes f lames to prov ide good

12

Loading...

Loading...