Viking VDSC367, FDSB5421, VCSB5421, FDSB5481 Service Notebook

Service

Manual

This manual is to be used by qualied appliance technicians only. Viking

does not assume any responsibility for property damage or personal

injury for improper service procedures done by an unqualied person.

Built-In

Side by Side

Non-Dispenser

®

Preferred Service

This Base Manual covers general and

specic information including, but not

limited to the following models:

Refrigerator /

Freezer

FDSB5421

FDSB5481

VCSB5421

VCSB5481

SMR-0020

MAY 2012

Table of Contents

Important Information 3

Safety Information .................................................... 3

Warnings .................................................................. 4

Electrical Requirements ........................................ 4

Tip Over Hazard .................................................... 4

General Information 5

Model - Serial Number Matrix .................................. 5

Operation 6

Settings and Functions ............................................ 6

Electronic Temperature Settings ........................... 6

Electronic Temperature Settings ........................... 6

Key Press Conrmation ........................................ 6

Fast Cool .............................................................. 7

MAX FRZ .............................................................. 7

MAX REF .............................................................. 7

Forced Pull-Down (Forced compressor start) ....... 8

Forced Defrost ...................................................... 8

Showroom Mode .................................................. 9

Sabbath Mode ...................................................... 9

Fahrenheit to Celsius ............................................... 9

Display Panel Operation ........................................ 10

Temperature Control Operation .............................11

Disassembly 12

Parts Location–Control Panel ................................ 12

Upper Grille Assembly ........................................ 13

Control Panel ..................................................... 13

Control Panel (continued) .................................. 14

Overlay Switch .................................................... 14

Overlay Switch (continued) ................................. 15

High Voltage Board ............................................ 15

Low Voltage Board ............................................. 15

Power Disconnect Switch ................................... 16

Inverter ................................................................ 16

Inverter (continued) ............................................ 17

Condenser Fan ................................................... 17

Parts Location–Refrigerator Compartment ............ 18

Light Assembly .................................................... 19

Fresh Food Fan Assembly .................................. 19

Interior Lights ...................................................... 20

Plasma Cluster™ ................................................ 20

Parts Location–Freezer Compartment and Lower

Unit–Non Dispenser ............................................... 21

Ice Maker (shown here with cover off) ................ 22

Thermal Cut Out (TCO) ...................................... 25

Freezer Evaporator Fan ..................................... 25

Freezer Thermistor ............................................. 26

Defrost Heater ................................................... 26

Defrost Terminator ............................................. 28

Float Switch ........................................................ 28

Water Valve ......................................................... 29

Drain Pan Heater ................................................ 29

Service Procedures 30

Program Modes ..................................................... 30

2 ©2012 Viking Preferred Service

Program Mode A .................................................... 30

Display Ref Temperature .................................... 30

Display Frz Temperature ..................................... 30

Defrost mode selection ....................................... 30

Conventional defrost time adjustment (CRTD) ... 30

Compressor low speed frequency ...................... 31

Adjust Cut-In Hysteresis .................................... 31

Adjust Cut-Out Hysteresis .................................. 32

Display Software Version .................................... 33

Exiting Mode A .................................................... 33

Program Mode B .................................................... 34

Adjust Freezer Temperature Offset ..................... 34

Adjust Refrigerator Temperature Offset .............. 34

Adjust MAX FRZ duration ................................... 35

Adjust MAX REF duration ................................... 35

Adjust FAST COOL duration ............................... 35

Adjust Door Open Alarm delay ........................... 36

Adjust Compressor Dwell Time ........................... 36

Adjust Compressor High Frequency ................... 36

Adjust DC Fan Cycling On Time ......................... 36

Adjust DC Fan Cycling Off Time ......................... 36

Exiting Mode B .................................................... 36

Program Mode C .................................................... 37

Set Model type .................................................... 37

Adjust Freezer Upper Temperature Limit ............ 37

Adjust Freezer Lower Temperature Limit ............ 37

Adjust Refrigerator Upper Temperature Limit ..... 38

Adjust Refrigerator Lower Temperature Limit ..... 38

Defrost lockout adder .......................................... 38

Defrost start delay ............................................... 39

Defrost termination delay .................................... 39

Constant Evaporator fan mode ........................... 39

Plant mode .......................................................... 39

ALARMS ................................................................ 40

1. High Temp Alarm ............................................ 40

2. Open Thermistor Alarm ................................... 40

3. Shorted Thermistor Alarm ............................... 41

4. Power Loss Alarm ........................................... 41

5. Door Open Alarm ............................................ 41

TABLE 1 - Model types ......................................... 42

Door Stop Adjustment ............................................ 43

Light Bulb ............................................................... 43

Door Hinge Adjustment .......................................... 43

Height Adjustment .................................................. 44

Diagnostics 46

VCC3 Inverter Diagnostic Codes ........................... 46

High Voltage Board ................................................ 47

Low Voltage Board ................................................. 48

Troubleshooting Guide ........................................... 49

Wiring Diagrams 52

Wiring and Component Testing .............................. 52

High Voltage Board ................................................ 52

Side by Side schematic .......................................... 53

Side by Side Wiring Diagram ................................. 54

Important Information

SAVE THESE INSTRUCTIONS

REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL AND TECHNICAL SHEETS

BEFORE BEGINNING REPAIRS.

Pride and workmanship go into every product to provide our customers with quality products. It

is possible, however, that during its lifetime, a product may require service. Products should be

serviced only by a qualified service technician that is familiar with the safety procedures required

in the repair and who is equipped with the proper tools, parts, testing instruments, and the

appropriate service manual.

Safety Information

We have provided many important safety

messages in this manual and on the appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

To avoid risk of serious injury or death, repairs should

not be attempted by unauthorized personnel.

WARNING!

!

This symbol alerts you to hazards that can kill

or hurt you and others. All safety messages will

be preceded by the safety alert symbol and the

word “DANGER”, “WARNING”, or “CAUTION”.

These words mean:

DANGER!

IMMEDIATE HAZARDS WHICH WILL RESULT IN

SEVERE PERSONAL INJURY OR DEATH.

WARNING!

Hazards or unsafe practices which COULD result in

severe personal injury or death.

CAUTION!

CAUTION!

VIKING will not be responsible for any injury or

property damage from improper service procedures.

If performing service on your own product, you must

assume responsibility for any personal injury or

property damage which may result.

Technical support for authorized servicers:

1-800-914-4799

Address your written correspondence to:

Viking Preferred Service

1803 HWY 82 West

Greenwood, MS 38930

Hazards or unsafe practices which COULD result in

minor personal injury or product or property damage.

All safety messages will identify the hazard, tell

you how to reduce the chance of injury, and tell

you what can happen if the instructions are not

followed.

©2012 Viking Preferred Service 3

Important Information

Warnings

Read and follow all instructions before using

this appliance to prevent the potential risk of

re, electric shock, personal injury, or damage

to the appliance as a result of improper usage

of the appliance. Use appliance only for its

intended purpose as described in this manual.

To ensure proper and safe operation: appliance

must be properly installed and grounded by a

qualied technician. DO NOT attempt to adjust,

repair, service, or replace any part of your

appliance unless it is specically recommended

in this manual. All other servicing should be

referred to a qualied servicer.

Make sure that incoming voltage is the same

as unit rating. An electric rating plate specifying

voltage, frequency, wattage, amperage, and

phase is attached to the product.

Electrical Requirements

WARNING!

TIP OVER HAZARD

Appliance is top heavy and tips easily when not

completely installed. Keep doors closed until

appliance is completely installed and secured per

installation instructions.Use two or more people to

move and install appliance. Failure to do so can

result in death or serious injury.

WARNING!

ELECTRICAL SHOCK HAZARD

Disconnect power or turn power disconnect switch

to “OFF” position before removing top grille. Failure

to do so can result in death or electrical shock.

WARNING!

Assure that the electrical installation is

adequate and in conformance with the National

Electrical Code, ANSI/NFPA 70-latest edition

or Canadian Electrical Code C22.1-1998 and

C22.2 No. 0-M91 (or latest edition), and all

local codes and ordinances. A 115 volt, 60-Hz,

15 amp, fused, electrical supply is required. It

is required that

a separate circuit serving only this appliance

be provided. This appliance is equipped with a

power supply cord having a 3-prong grounding

plug.

To minimize possible shock hazard, the cord

must be plugged into a mating 3-prong,

grounding-type wall receptacle. DO NOT use

an extension cord.

Tip Over Hazard

Most of the unit’s weight is at the top. Extra

care is needed when moving the unit to prevent

tipping. Keep doors closed until appliance is

completely installed and secured per installation

instructions. Use two or more people to move

and install appliance. Failure to do so can result

in death or serious injury.

ELECTRICAL SHOCK HAZARD

Plug into a grounded 3-prong outlet. If a

2-prong wall receptacle is encountered, contact a

qualied electrician.

DO NOT remove ground prong. Unit must be

grounded at all times. DO NOT use an adapter.

DO NOT use an extension cord.

Failure to follow these instructions can result in

death, re, or electrical shock.

WARNING!

BURN HAZARD

DO NOT touch condenser coils near defrost pan.

Doing so can result in burns.

4 ©2012 Viking Preferred Service

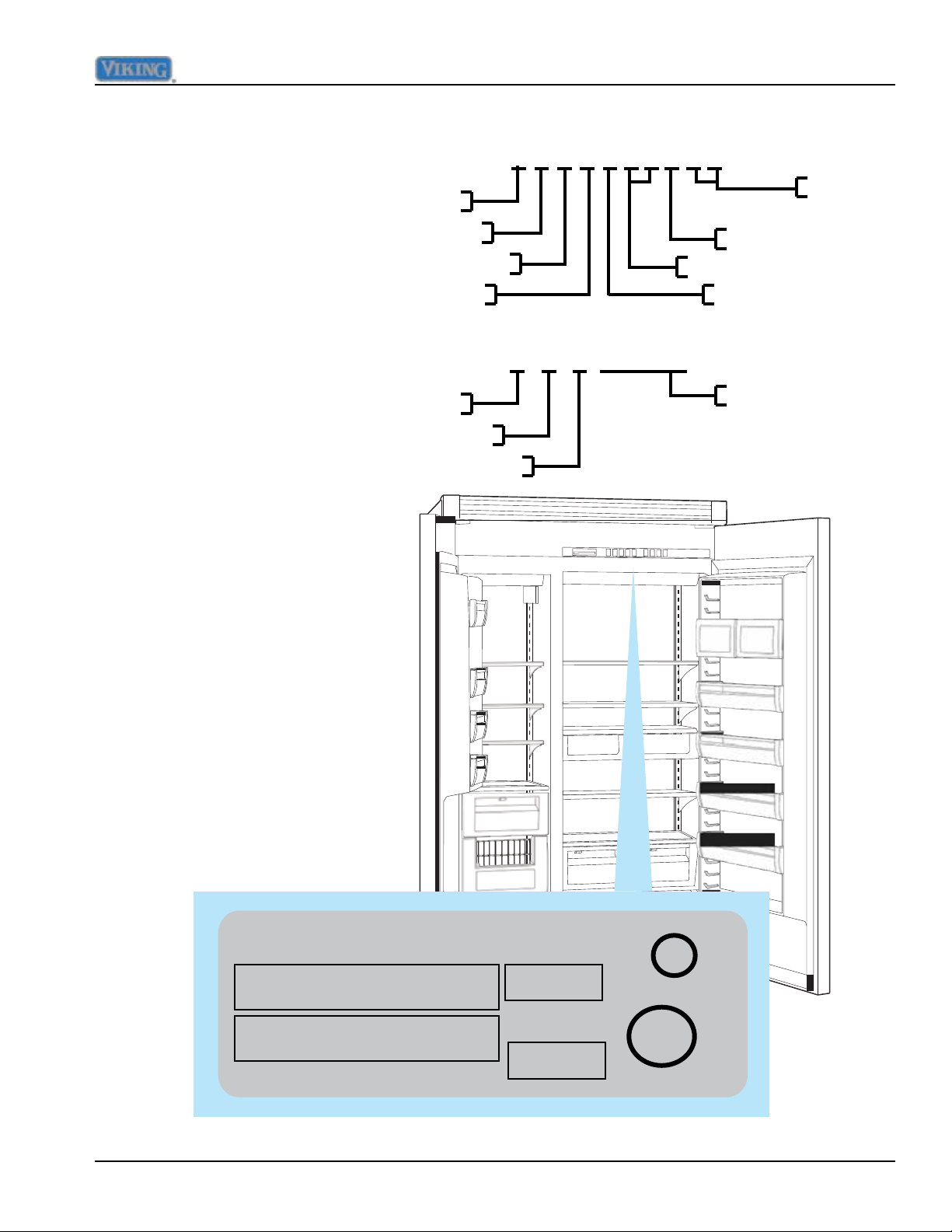

Model - Serial Number Matrix

VIKING RANGE CORP. LISTED HOUSEHOLD

General Information

V C S B 5 4 8 1 S S

Model Numbers

Serial Numbers

The serial number and model

number for your appliance are

located on the identication

plate mounted on the upper

left side of the door opening.

Viking Professional Series

Commercial

Side by Side

Built-In

Month

Year of Manufacture

Stainless

Refresh

48" Wide

Version

02 15 12 R1000264

Serial Number

Day

GREENWOOD, MISSISSIPPI 38930 REFRIGERATOR 35NN

MODEL/MODELE FDSB5421SS 6.25OZ R134a

NUMBER/NUMERO

SERIAL/SERIE 021512R10000264 115 VAC/60 HZ

NUMBER/NUMERO

©2012 Viking Preferred Service 5

AMPS: 9.9

PE920095

c

U

U

L

L

Operation

Settings and Functions

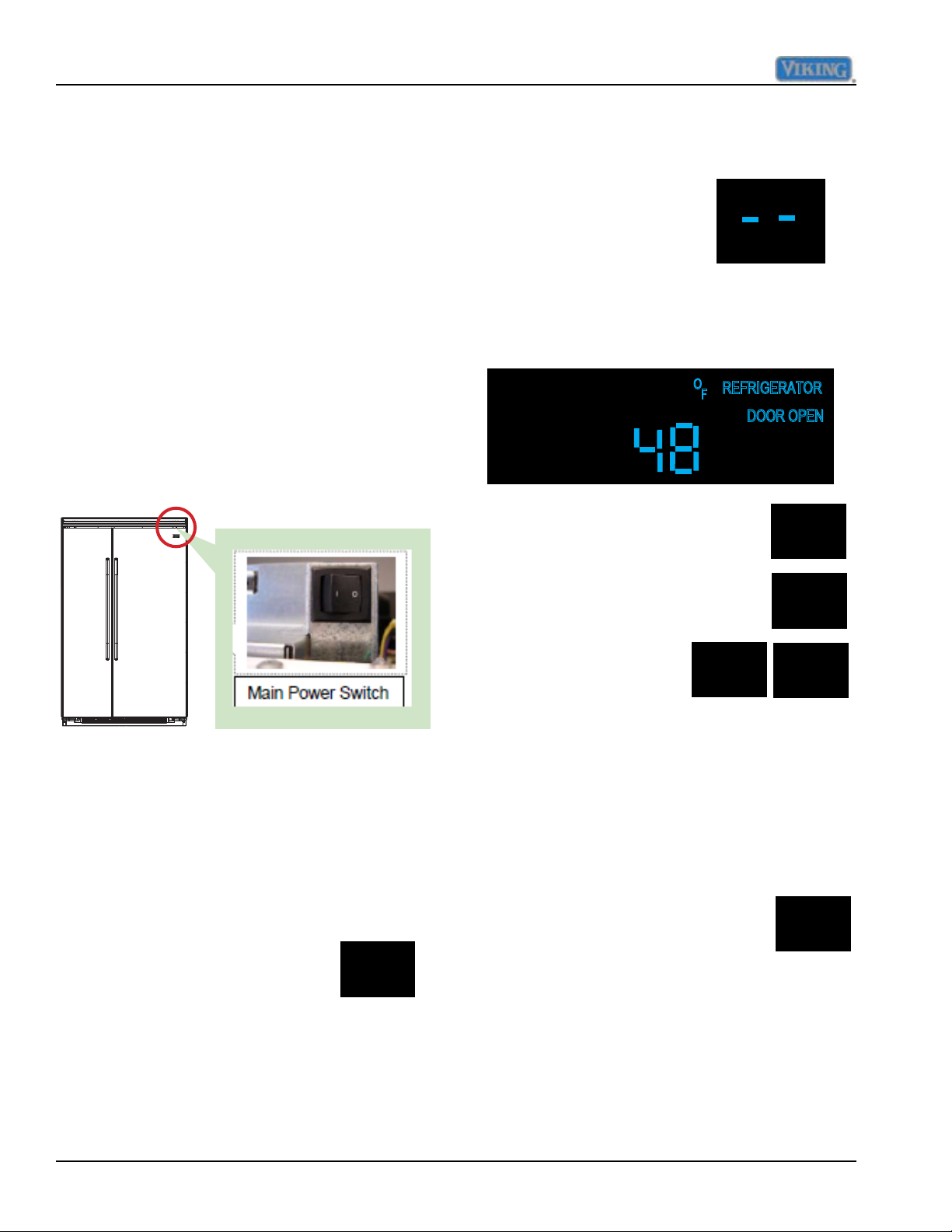

Power On/Off Switch (Power Interruption

Switch) The power on/off switch is located

behind your refrigerator’s top grille. It is used

to turn the power “OFF” when cleaning the

refrigerator or changing the light bulbs. Your

refrigerator arrives from the factory with the

power interruption switch “ON”.

To turn power “OFF”, remove the center grille

blade. Press the power on/off switch to the

“OFF” position.

To turn power “ON”, press power on/off switch

to the “ON” position. Replace the center grille

blade.

Electronic Temperature Settings

When power is first applied to the refrigerator,

there will be two dashes

displayed as in illustration.

After approximately thirty

seconds the digital display

will change to numbers,

indicating temperature in the refrigerator

(default upon initial start-up) compartment

along with the word REFRIGERATOR and

degrees Fahrenheit.

To adjust temperature , enable

the key pad controls by pressing

and releasing the "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS" pad. Select "REF

TEMP" or "FRZ TEMP" pad

for applicable section. The

FRZ

TEMP

temperature is then

adjusted in that section

HIGHER

LOWER

by pressing "HIGHER

or LOWER" pad while

observing digital readout.

IMPORTANT: Be sure the power on/off

switch is in the “ON” position after cleaning or

changing light bulbs.

Key Press Confirmation

The key press confirmation is the "beep" that

is heard when a control pad is pressed. This

audible confirmation can be made active or

Electronic Temperature Settings

Your refrigerator’s electronic controls are

located behind the door above

the cabinet interior. To activate

the electronic control panel,

ACTIVATE

CONTROLS

press “ACTIVATE CONTROLS”

pad. All other pads, except the “Alarm Off”

pad, will remain inactive until the ”ACTIVATE

CONTROLS” pad is pressed. Once activated,

pad remains programmable for at least ten

minutes

6 ©2012 Viking Preferred Service

inactive.

To deactivate the confirmation

ACTIVATE

CONTROLS

beep press and hold "ACTIVATE

CONTROLS" pad for three seconds,

three long beeps will be heard, confirming

deactivation.

To activate the confirmation beep press and

hold "ACTIVATE CONTROLS" pad for three

seconds, three long beeps will be heard,

confirming activation.

Operation

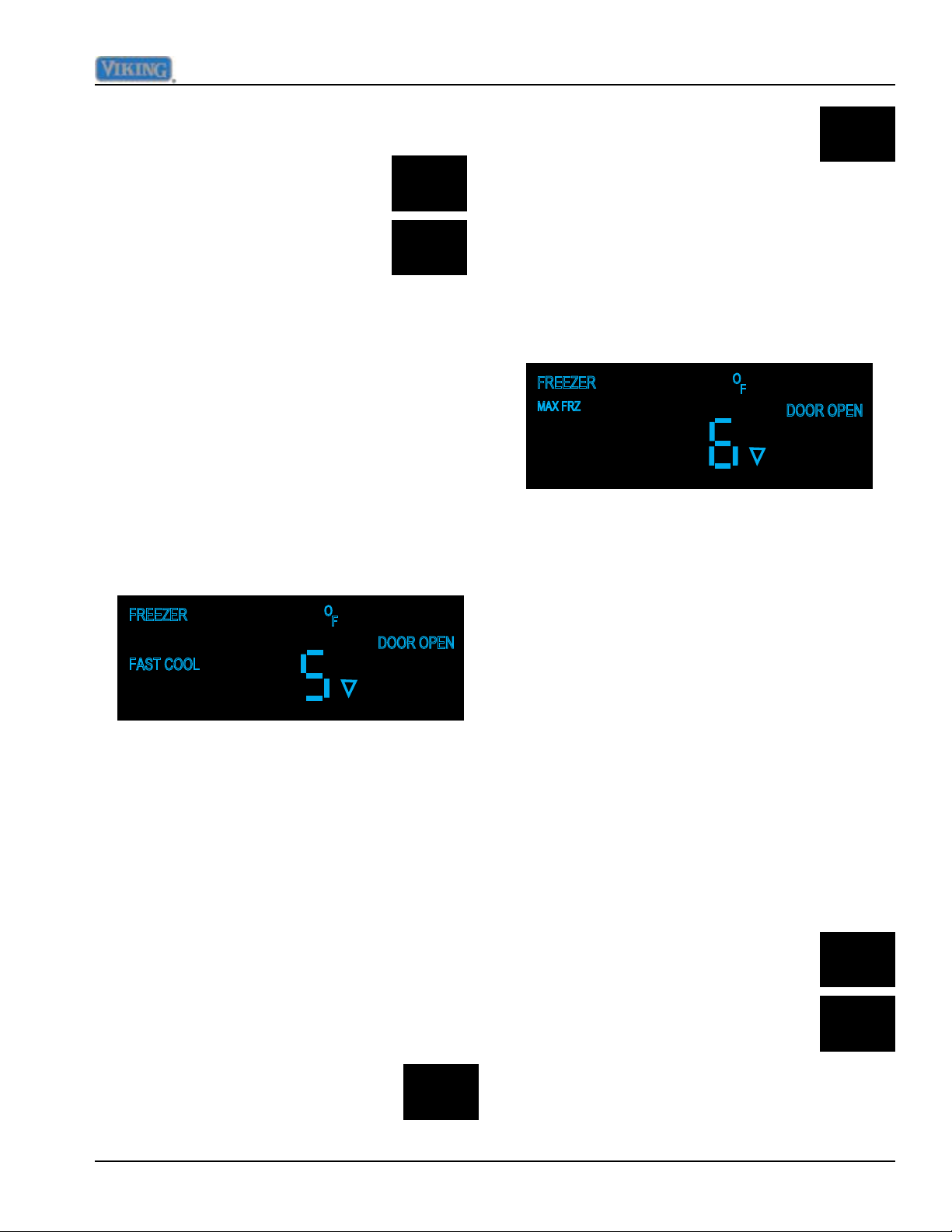

Fast Cool

Fast Cool is enabled by pressing

and releasing the "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS" pad and then

pressing and releasing the "FAST

COOL"pad.

FAST

COOL

This causes the control to

temporarily (predetermined time, factory

default is 2 hours) replace the freezer setpoint

o

to Max Frz temperature (factory default -5

F)

and also the refrigerator setpoint to Max Ref

temperature (factory default 33

o

F).

Max Frz time duration is adjustable in

Program Mode B, range is 1 to 20 hours in 1

hour increments.

The only temperature speed used during this

mode of operation is high speed (115HZ).

and releasing the "MAX FRZ" tab.

MAX

FRZ

This causes the control to

temporarily (factory setting is 6

hours) change the current freezer set point

o

F. This set point temperature is not

to -5

adjustable and is programmed from factory.

The time duration is adjustable in Program

Mode B, range is 1 to 20 hours in 1 hour

increments.

When MAX FRZ is selected, the display

illuminates "MAX FRZ" as shown above. The

temperature display will move towards that

set point temperature (- 5

o

F) as the unit pulls

down.

When "FAST COOL" is selected by pressing

the pad, "FAST COOL" is illuminated on the

display as shown in illustration above.

Fast Cool will terminate after the time

duration has expired or if another mode is

selected or if temperature is increased or

decreased by pressing "HIGHER or LOWER"

tabs. Fast Cool can be cancelled by pressing

"FAST COOL" again, the Fast Cool will

extinguish on the display.

MAX FRZ

Max Frz is enabled by pressing

and releasing the "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS" pad and then Pressing

Max Frz will terminate at the conclusion

of the time duration or if another mode is

selected, or if the temperature is manually

changed by pressing "HIGHER or LOWER"

tabs. Max Frz can also be terminated by

again pressing and releasing "MAX FRZ".

The conclusion or termination of this mode is

confirmed by "MAX FRZ" extinguishing from

display.

MAX REF

Max Ref is enabled by pressing

and releasing the "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS" pad and then

Pressing and releasing the "MAX

FRZ" tab.

MAX

REF

This causes the control to

temporarily (factory setting is 4 hours) change

o

the current refrigerator set point to 33

F.

©2012 Viking Preferred Service 7

Operation

This set point temperature is not adjustable

and is programmed from factory.

The time duration is adjustable in Program

Mode B, range is 1 to 20 hours in 1 hour

increments.

When MAX REF is selected, the display

illuminates "MAX REF" as shown above. The

temperature display will move towards that

set point temperature (33o F) as the unit pulls

down.

Max Ref will terminate at the conclusion of the

time duration or if another mode is selected,

or if the temperature is manually changed by

pressing "HIGHER or LOWER" tabs. Max Ref

can also be terminated by again pressing and

releasing "MAX REF".

The conclusion or termination of this mode is

confirmed by "MAX REF" extinguishing from

display

Forced Pull-Down (Forced compressor

start)

This function will ignore compressor dwell

time and cause immediate compressor start

up in the high speed mode (115HZ).

Forced pull-down will terminate after both

cut-out temperatures are met, or if a defrost

or forced defrost is initiated, or if an extended

power loss occurs.

Forced Defrost

To enter Forced defrost, first

press and release "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS", then press and hold

"HIGHER" pad, then press and hold

"DISPLAY OFF" pad until you get an

HIGHER

audible consisting of three beeps.

This causes the control to

DISPLAY

OFF

immediately suspend all

temperature control operations

and start a defrost cycle, regardless of

compressor dwell time and defrost start delay.

If defrost terminator temperature is satisfied

defrost heaters will come on at this time for a

normal defrost cycle.

Forced defrost will terminate when defrost

terminator opens (completion of cycle defrost)

or if forced pull-down is initiated or if there is a

long power loss..

To enter Forced pull-down, first

press and release "ACTIVATE

ACTIVATE

CONTROLS

CONTROLS", then press and hold

"LOWER" pad, then press and hold

"DISPLAY OFF" pad also until you

LOWER

get an audible consisting of three

beeps.

This causes the control to

immediately energize the

appropriate outputs in an effort to reach both

of the cut-out temperatures (refrigerator and

freezer).

8 ©2012 Viking Preferred Service

DISPLAY

OFF

When forced defrost is initiated the

temperature numbers are replaced with

"dEF" in the seven segment displays, as

shown above. When defrost is complete the

displayed "dEF" will again be replaced with

displayed temperature numerals.

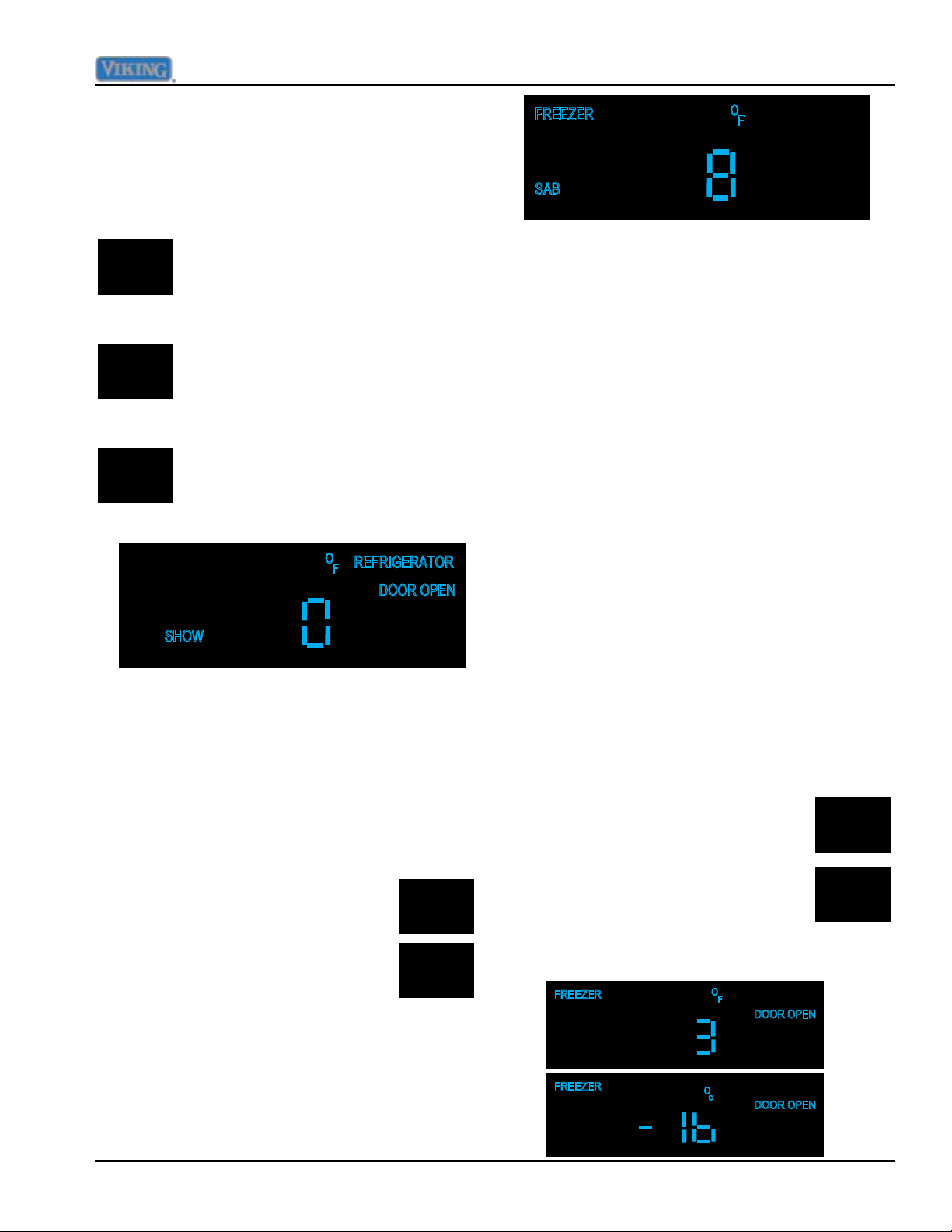

Showroom Mode

Showroom mode allows electronic controls and

interior lights to function independently of the

refrigeration system.

Operation

ACTIVATE

CONTROLS

To enter Showroom mode:

Press and hold the “ACTIVATE

CONTROLS” pad. While holding,

press and hold the “HIGHER” and

“ALARM OFF” pad simultaneously.

HIGHER

Continue holding until three beeps

are heard and then "SHOW" is

illuminated along with Refrigerator

and 38OF or Freezer and 0OF.

Whichever section was active

ALARM

OFF

prior to to showroom mode being

entered will determine which one is

displayed.

To exit Showroom mode: Press and hold the

“ACTIVATE CONTROLS” pad. While holding,

press and hold the “HIGHER” and “ALARM

OFF” pad simultaneously. Continue holding

until three beeps are heard. The display will

revert to normal operation

HIGHER

Sabbath Mode

To enter Sabbath mode, press and

hold "ACTIVATE CONTROLS" pad

ACTIVATE

CONTROLS

then press and hold "DISPLAY

OFF" pad, together for three

seconds this will cause an audible

DISPLAY

OFF

three beeps, signifying that

Sabbath mode has been entered.

When Sabbath mode has been entered the

display goes blank except for the "SAB",

see illustration below, which will remain

illuminated whether the door(s) are open or

closed, it will not change state.

Sabbath mode is used to control the

refrigerator without interior lights, LED

display changes and enunciators. Alarms are

suppressed, you will not get visual or audible

alarms during Sabbath mode, although they

are recorded in memory and will be displayed

upon exiting Sabbath mode.

The freezer/refrigerator outputs (compressor,

fans,etc.) should not have an immediate

reaction from a user action. If the control calls

for an action because the door was opened

or closed, the control shall delay its reaction

randomly (15-25 seconds).

To exit "SABBATH" mode, press and hold

"ACTIVATE CONTROLS" and then "DISPLAY

OFF" together for three seconds, an audible

three beeps will be heard and "SAB" on

display will extinguish. The display will return

to normal and any alarms will be visually and

audibly displayed.

Fahrenheit to Celsius

Factory default for readout is

Fahrenheit, to change to Celsius,

ACTIVATE

CONTROLS

press and hold "ACTIVATE

CONTROLS" and then press and

hold "DISPLAY OFF" for three

seconds and

o

F will change to oC.

DISPLAY

OFF

To change back to Fahrenheit,

repeat same steps.

©2012 Viking Preferred Service 9

Operation

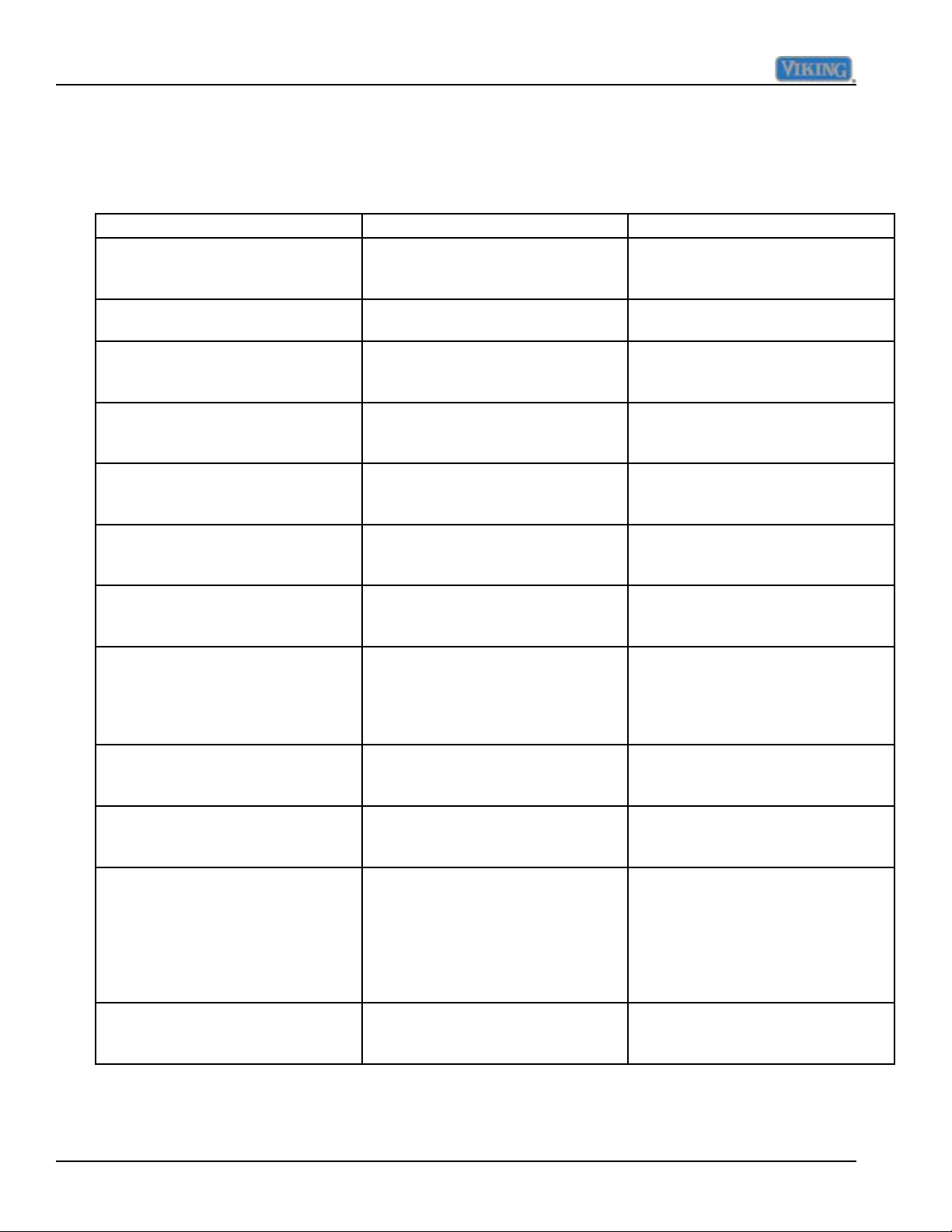

Display Panel Operation

The unit being serviced has a control panel that allows operation of the unit as well as diagnostic abilities.

See the information below for details.

Operation Description How to Access Function

Keyboard Entry Tone Indicates a pad was pressed, com-

mand was read, and accepted

Command Accepted Tone Three short tones sound indicating a

command has been accepted

"ACTIVATE CONTROLS" Pad If the pad is activated, the display

panel remains active at least 10

minutes after the door is closed

"FRZ TEMP" Pad "FREEZER" will light up and buff-

ered freezer temperature will be

displayed. Factory setting is 0

o

F

"REF TEMP" Pad "REFRIGERATOR" will light up and

buffered refrigerator temperature will

be displayed. Factory setting is 38

"HIGHER" Pad Raises temperature settings one

degree at a time

"LOWER" Pad Lowers temperature settings one

degree at a time

"FAST COOL" Pad "FAST COOL" will light up enabling

the fast cool function which changes

the freezer set point to max frz and

the ref set point to max ref for a factory default of 2 hours.

"MAX RFZ" Pad Sets freezer temperature to coldest

setting (-5

o

F). Factory setting is 6

hours

"MAX REF" Pad Sets refrigerator temperature to

coldest setting (33

o

F). Factory set-

ting is 4 hours

"ALARM OFF" Pad Deactivates (partially or fully), audio/

visual alarm signals

"DISPLAY OFF" Pad Deactivates control panel except for

"ACTIVATE CONTROLS" and "DISPLAY OFF" pads

To turn off entry tone, press and hold

“ACTIVATE CONTROLS” pad for 3

to 5 seconds

Press the “ACTIVATE CONTROLS”

pad

Press “HIGHER” or “LOWER” pad

Press “HIGHER” or “LOWER” pad

o

F

Press “HIGHER” pad. To raise

temperature at a faster rate, hold the

pad down

Press “LOWER” pad. To lower

temperature at a faster rate hold, the

pad down

Press "FAST COOL" pad. A second

press will disengage feature.

Press “MAX FRZ” Pad to engage. A

second press will disengage feature

Press “MAX REF” pad to engage. A

second press will disengage feature

Press “ALARM OFF” to terminate

audible alarm, visual alarm indicators will continue to blink until alarm

condition is cleared or permanently

disabled. To reactivate press and

hold “ALARM OFF” pad for 3 seconds.

Press “DISPLAY OFF” pad to deactivate display. Press “ACTIVATE

CONTROLS” pad to reactivate

10 ©2012 Viking Preferred Service

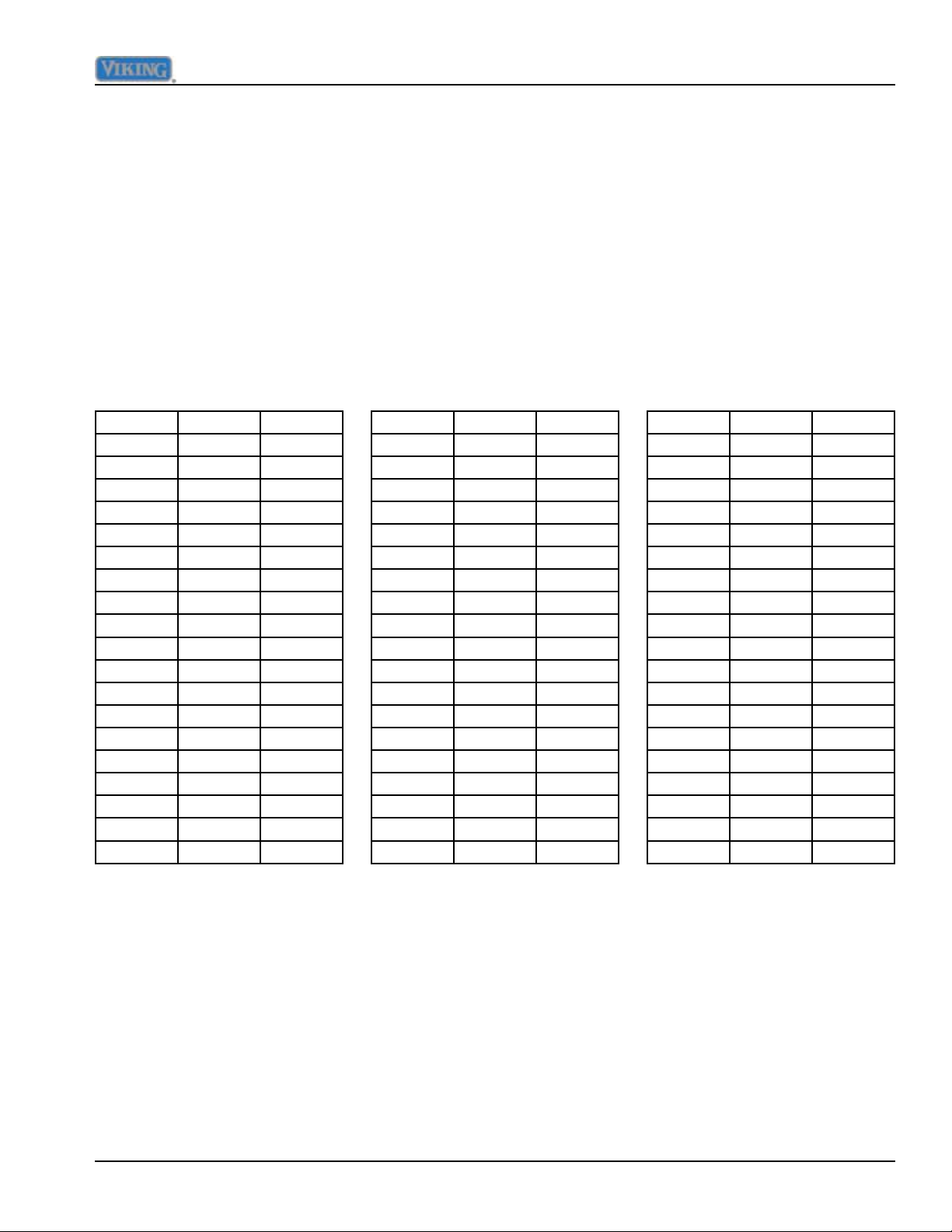

Operation

Temperature Control Operation

For any temperature setting, outputs will be turned off/on based on cut-in/cut-out temperature determined

by resistance levels of freezer or refrigerator thermistors.

Refrigerator and Freezer Thermistor (NTC)

As temperature decreases, resistance increases. As temperature increases, resistance decreases.

Note: Open thermistor or thermistor circuit or a shorted thermistor will result in refrigerator continuing to

cool with error code displayed. The affected section will call for cooling 100 percent of time except during

defrost cycle

Deg F Deg C K-Ohms

-24 -31 565

-22 -30 531

-20 -29 499

-18 -28 469

-16 -27 441

-15 -26 415

-13 -25 391

-11 -24 368

-9 -23 347

-8 -22 327

-6 -21 308

-4 -20 291

-2 -19 274

0 -18 259

1 -17 245

3 -16 231

5 -15 218

7 -14 206

9 -13 195

Deg F Deg C K-Ohms

10 -12 185

12 -11 175

14 -10 165

16 -9 157

18 -8 148

19 -7 141

21 -6 133

23 -5 126

25 -4 120

27 -3 114

28 -2 108

30 -1 103

32 0 97

34 1 93

36 2 88

37 3 84

39 4 80

41 5 76

43 6 72

Deg F Deg C K-Ohms

45 7 69

46 8 65

48 9 62

50 10 59

52 11 56

54 12 54

55 13 51

57 14 49

59 15 47

61 16 44

63 17 42

64 18 41

66 19 39

68 20 37

70 21 35

72 22 34

73 23 32

75 24 31

77 25 30

Freezer temperature setting and thermistor value will determine if compressor/condenser fan and evaporator fan

switches are open or closed. Compressor/ condenser fan switch must be open for 6 minutes before switch can close

again (compressor dwell time). Refrigerator temperature setting and thermistor value will determine if fresh food

switch is open or closed. Cut-out and cut-in temperature values must be reached and maintained for 15 seconds before output state will change (digital delay). Refrigerator and freezer control calibration can be adjusted in Program

Mode A.

©2012 Viking Preferred Service 11

Disassembly

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

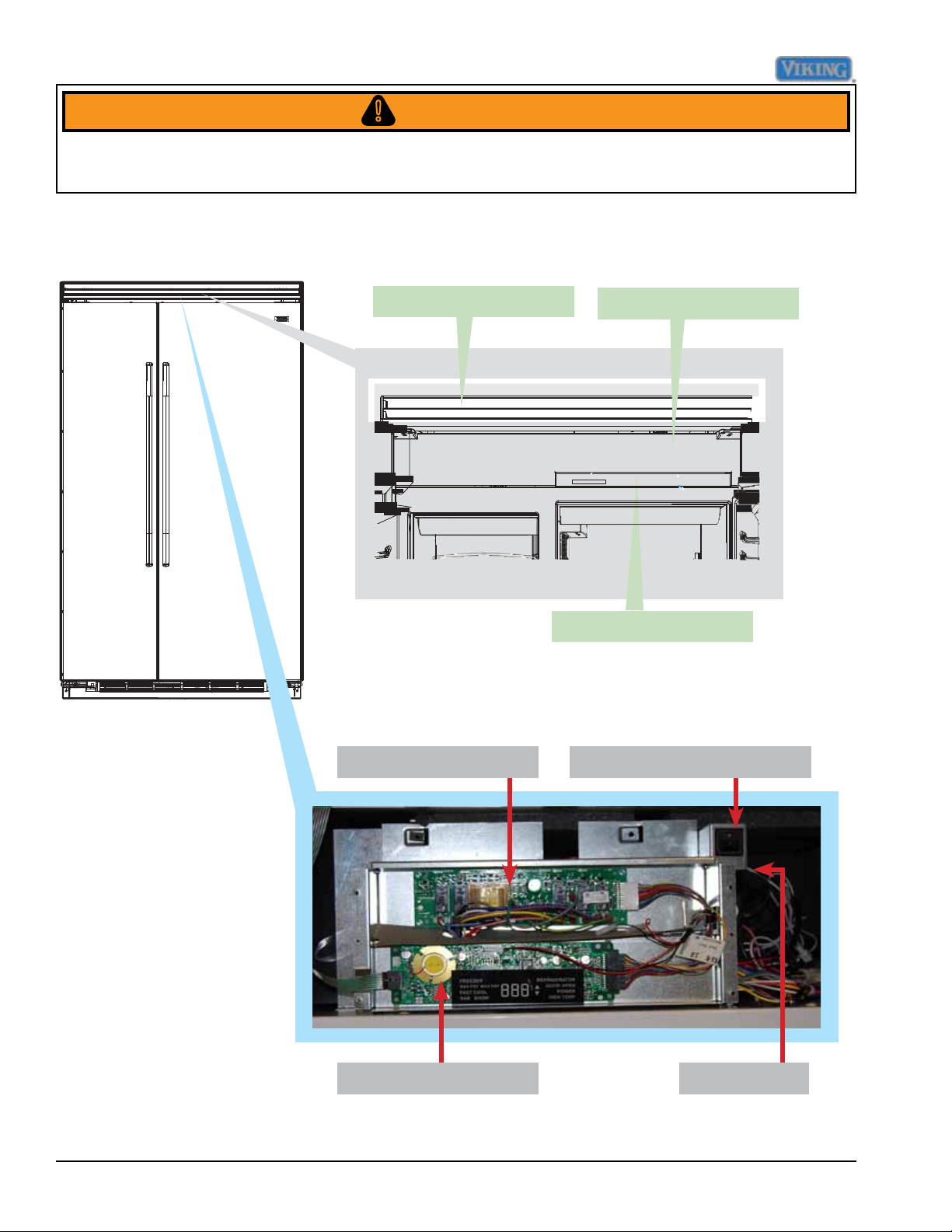

Parts Location–Control Panel

Upper Grille Assembly

Control Panel

Overlay Switch

Power Disconnect SwitchHigh Voltage Board

Low Voltage Board

12 ©2012 Viking Preferred Service

Inverter

Disassembly

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

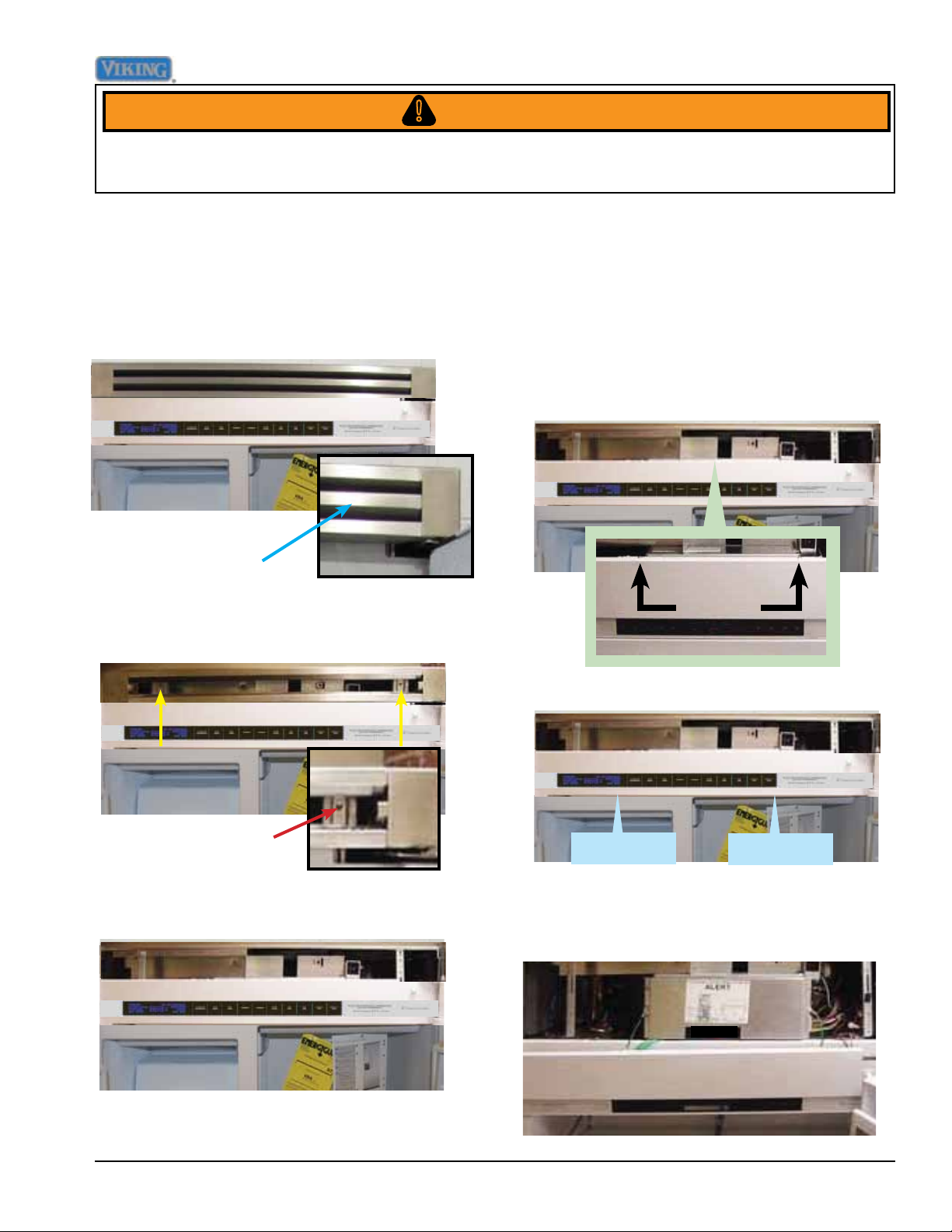

Upper Grille Assembly

Removal of the upper grille assembly allows

access to the control assembly.

1. To remove the upper grille assembly, slide

out the middle air louver.

Middle Air Louver

2. With the middle grille louver removed,

remove the (2) 1/4" hex screws securing

the grille assembly.

Control Panel

The control panel has an overlay switch

attached to it that allows user input to the

control boards.

1. To access the control panel, remove the

upper air grill assembly (see Upper Grill

Removal section), remove (2) screws

securing the control panel.

Screws

Remove 1/4" screw

on each side

3. Remove the grille assembly

2. Pull control panel from securing tabs.

Securing tab

3. Lower the control panel. Take caution with

the ribbon cable to prevent damage.

Securing tab

©2012 Viking Preferred Service 13

Disassembly

O

O

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

Control Panel (continued)

4. Remove the four screws securing the

control board cover. Remove control

board cover.

5. Disconnect the door switches from the

back of the control panel.

7. Remove the two strain relief screws.

8. The control panel can now be removed

and the high voltage and low voltage

boards are accessible

9. Reverse procedure to reinstall

Overlay Switch

The unit uses an overlay switch to

communicate user input to the control boards.

The overlay connects to the control board via

a ribbon cable.

6. Disconnect the ribbon from the control

board.Take caution with the ribbon cable

to prevent damage.

1. To replace the overlay switch, remove

the upper air grill assembly, remove the

control panel (see Air Grill and Control

Panel Removal sections, Page 13).

2. Disconnect overlay switch from control.

Overlay Switch

Release tab and pull

connector out of socket.

14 ©2012 Viking Preferred Service

Disassembly

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

Low Voltage BoardOverlay Switch (continued)

3. Peel overlay off control panel and remove

(remove adhesive to ensure replacement

overlay adheres properly)

4. Reverse procedure to reinstall.

High Voltage Board

A control board is used to operate functions

of the unit. Once an input is received from

the low voltage board, the high voltage board

sends an output to activate the components.

1. To access the high voltage board, remove

the upper air grill assembly, and control

panel (see Air Grill and Control Panel

Removal sections, Page 13).

2. Compress plastic standoffs securing the

high voltage board and pull towards you.

The unit uses a control board in conjunction

with an overlay switch to operate functions

of the refrigerator/freezer. Interaction with

the low voltage board is via the ribbon cable

attached to the overlay switch.

1. To access the low voltage board, remove

the upper air grill assembly, control panel

(see Air Grill and Control Panel Removal

sections, Page 13).

2. Compress plastic standoffs securing low

voltage board, disconnect wiring and

remove.

HV Board

To check low voltage board, refer to chart on

Page 48.

High voltage board is now accessible.

To check high voltage board, refer to

chart on page 47..

3. Reverse procedure to reinstall.

©2012 Viking Preferred Service 15

LV Board

3. Reverse procedure to reinstall

Disassembly

DANGER!

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

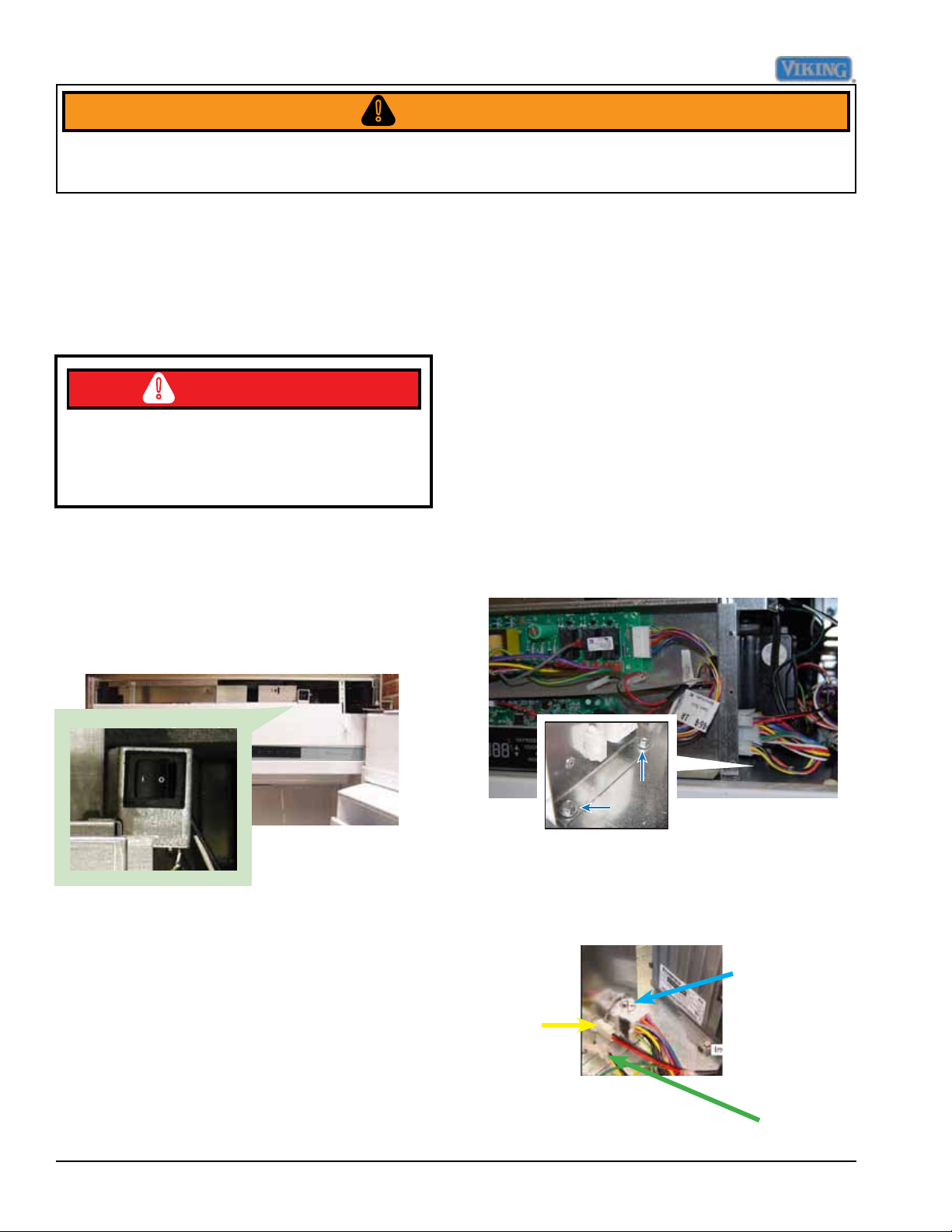

Power Disconnect Switch

The unit has a rocker switch, located in the

upper right corner of the unit, that allows

power to the unit to be turned “OFF” without

removal of the unit.

ON/OFF switch has 120 vac connected

to one side of switch at all times, remove

power with circuit breaker box when

removing switch.

1. To access the power disconnect switch,

remove the upper air grill assembly (see

Air Grill Removal section, Page 13). The

power disconnect is now accessible on

the right side.

Inverter

The Compressor is operated by a Inverter

that varies the voltage to the compressor.

This is determined by the frequency input

from the low voltage board

1. To access the inverter, remove upper

air grill assembly, remove control panel

assembly (see Air Grill and Control Panel

Removal sections, Page 13).

2. Remove the control box in order to gain

easy access to the door hinge area for

service. There are 4 ¼” hex screws (2

on each side) holding the control box to

the refrigerator housing. Remove these

screws.

3. Unplug the 15-pin Molex power plug (A),

as well as the 2-wire converter frequency

Verify contacts 4-5 open when the switch

is in the “0” position and contacts 4-5 close

when in the “|” position. 120 VAC should be

measured when in the “0” position and 0 VAC

should be measured when in the “|” position.

2. Switch bracket is mounted on electronics

box with two 1/4" hex head screws.

3. Reverse procedure to reinstall.

16 ©2012 Viking Preferred Service

cable (B) and the 3-wire thermistor plug

(C).

Molex A

Molex

B

Molex C

Disassembly

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless

test procedures require power to be connected. Ensure all ground wires are connected before certifying unit as

repaired and/or operational.

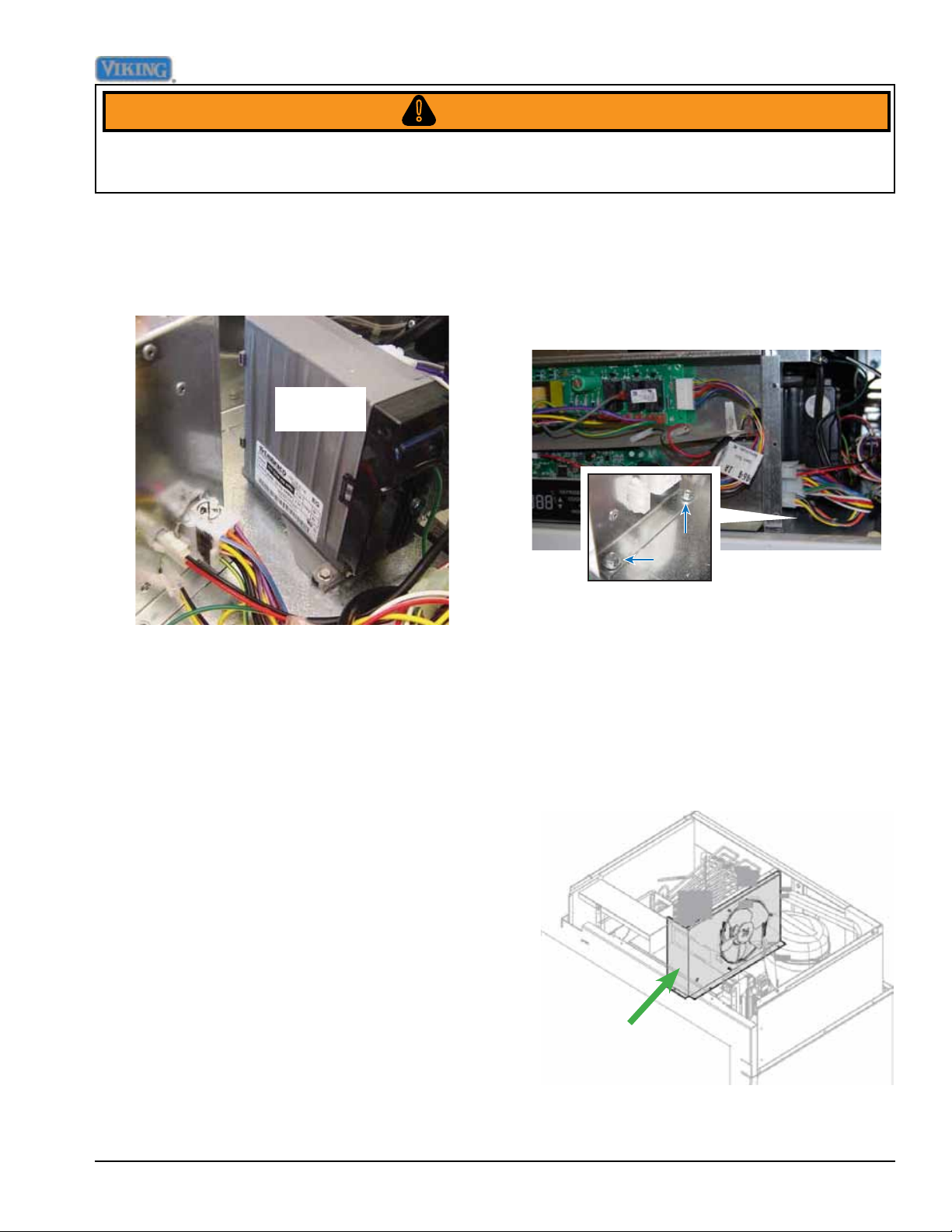

Inverter (continued)

4. The inverter is now accessible on the right

side.

Inverter

120 VAC is supplied to the inverter

from E4 on the High Voltage Board.

The LV board sends 5 VDC to the

inverter to operate the compressor.

5. Reverse procedure to reinstall.

2. Remove the control box in order to gain

easy access to the door hinge area for

service. There are 4 ¼” hex screws (2

on each side) holding the control box to

the refrigerator housing. Remove these

screws.

3. Unplug the 15-pin Molex power plug, as

well as the 2-wire converter frequency

cable and the 3-wire thermistor plug .

Remove electronics box and set aside to

gain access to condenser fan assembly.

4. Remove the three 1/4" hex screws

holding fan assembly in place, remove

fan assembly

Condenser Fan

The condenser fan is located in the upper

machine compartment of the unit. 120 VDC

is supplied to the fan when the Compressor/

Condenser Fan relay closes to E4 on the

High Voltage Board.

1. To access the condenser fan assembly,

remove upper air grill assembly, remove

control panel assembly (see Air Grill and

Control Panel Removal sections, Page

13).

©2012 Viking Preferred Service 17

Condenser Fan

Loading...

Loading...