Viking VDSC305, VDSC365, VDSC485, VESC305 Service Manual

Preferred Service

Service

Manual

This manual is to be used by qualified appliance technicians only. Viking

does not assume any responsibility for property damage or personal

injury for improper service procedures done by an unqualified person.

30 • 36 • 48 Inch

Dual Fuel range

All electric range

This Base Manual covers general and

specific information including, but not

limited to the following models

VDSC305

VDSC365

VDSC485

VESC305

VESC305

TABLE OF CONTENTS

VDSC305 – VDSC365 – VDSC 485

VESC305 – VESC306

COMPONENTS AND FUNCTIONAL PARTS:

Control / Timer -------------------------------------------------------------------------------------------- 4

Auto Reset Switch (Thermostat ) -------------------------------------------------------------------- 4

High Limit Switch----------------------------------------------------------------------------------------- 5

Cooling Fan Limit Switch ------------------------------------------------------------------------------ 5

Selector Switch ------------------------------------------------------------------------------------------- 5

Oven Thermostat ------------------------------------------ -------------------------- -------------------- 5

Door Lock Assembly ------------------------------------------------------------------------------------ 6

Relay #1 --------------------------------------------------------------------------------------------------- 6

Relay #2 and #3 ----------------------------------------------------------------------------------------- 6

Convection Fan ------------------------------------------------------------------ ------------------------ 7

Cooling Fan ----------------------------------------------------------------------------------------------- 7

Oven Light Assembly ----------------------------------------------------------------------------------- 7

Voltage and Resistance checks (Self Clean Timer)-------------------------------------------- 8

Voltage and Resistance checks (Heating elements)-------------------------------------------- 9

Selector Switch Contacts ------------------------------------------------------------------------------ 10

WIRING DIAGRAMS

Bake --------------------------------------------------------------------------------------------------------- 11

Convection Bake ----------------------------------------------------------------------------------------- 12

Convection Cook ----------------------------------------------------------------------------------------- 13

Mini Broil ---------------------------------------------------------------------------------------------------- 14

Maxi Broil ---------------------------------------------------------------------- ----------------------------- 15

Convection Broil ------------------------------------------------------------------------------------------ 16

SELF CLEAN

Self Clean (initiate door lock ) ------------------------------------------------------------------------ 17

Clean (door lock below 575* ) ---------------------------------- --------------------------------------- 18

Clean (door lock above 575* ) ------------------------------------------------------------------------- 19

Clean Finished (door lock above 575* ) ------------------------------------------------------------ 20

Clean Finished (door lock below 575* ) ------------------------------------------------------------ 21

Clean Finished (door unlocked ) -------------------------------------------------------------- ------ 21A

ELECTRICAL CONNECTIONS

3 wire or 4-wire wall plug ------------------------------------------------------------------------------------ 22

Hard wire connection ----------------------------------------------------------------------------------------- 23

SERVICE

Disassembly – Component location-------------------------------------------------------------- 24 - 26

Procedures to unlock door with door motor failure -------------------------------------------- 27

VESC Top removal ------------------------------------------------------------------------------------- 28

VESC Voltage / Resistance / Current checks ---------------------------------------------------- 29

VDSC COMPONENTS

(

WITH COLOR CODED WIRES)

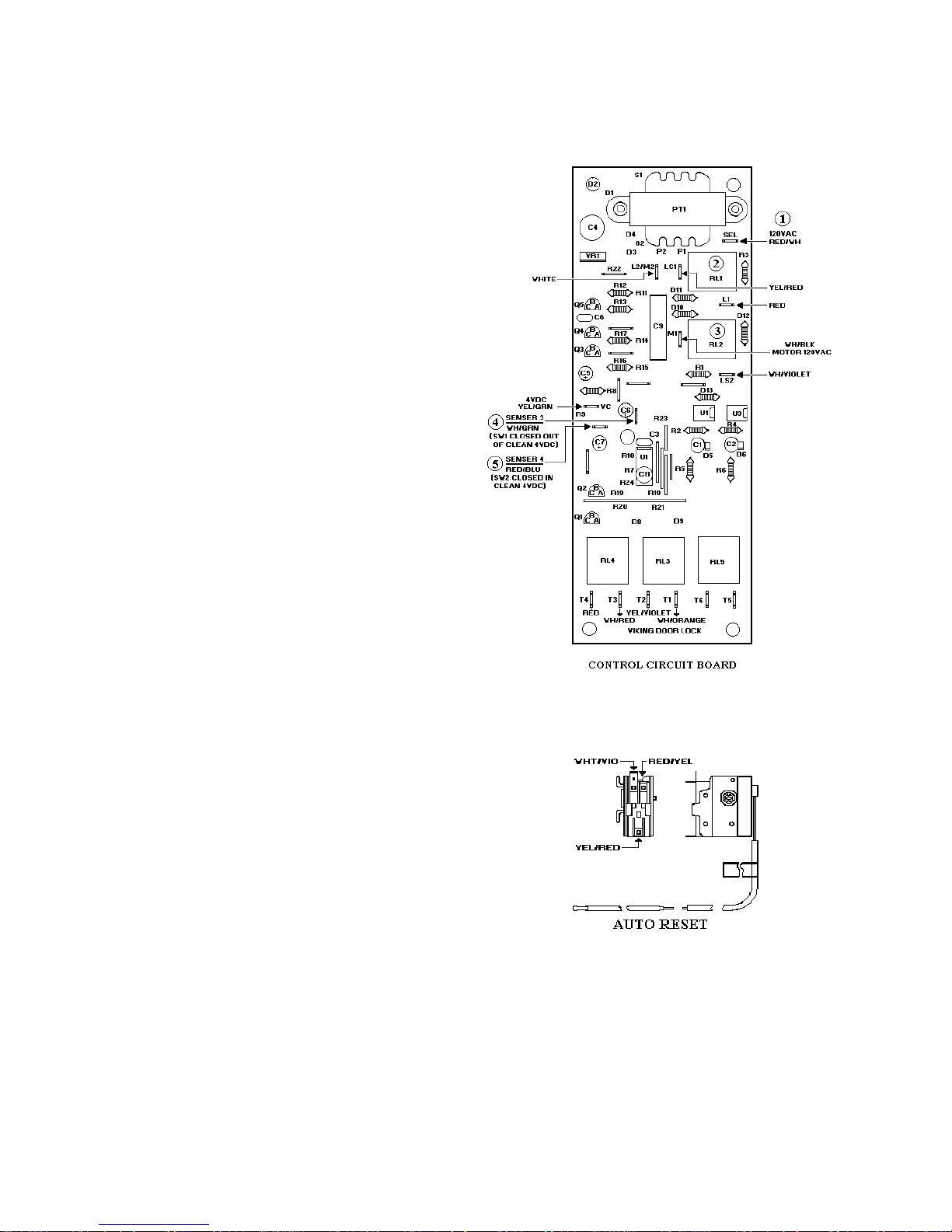

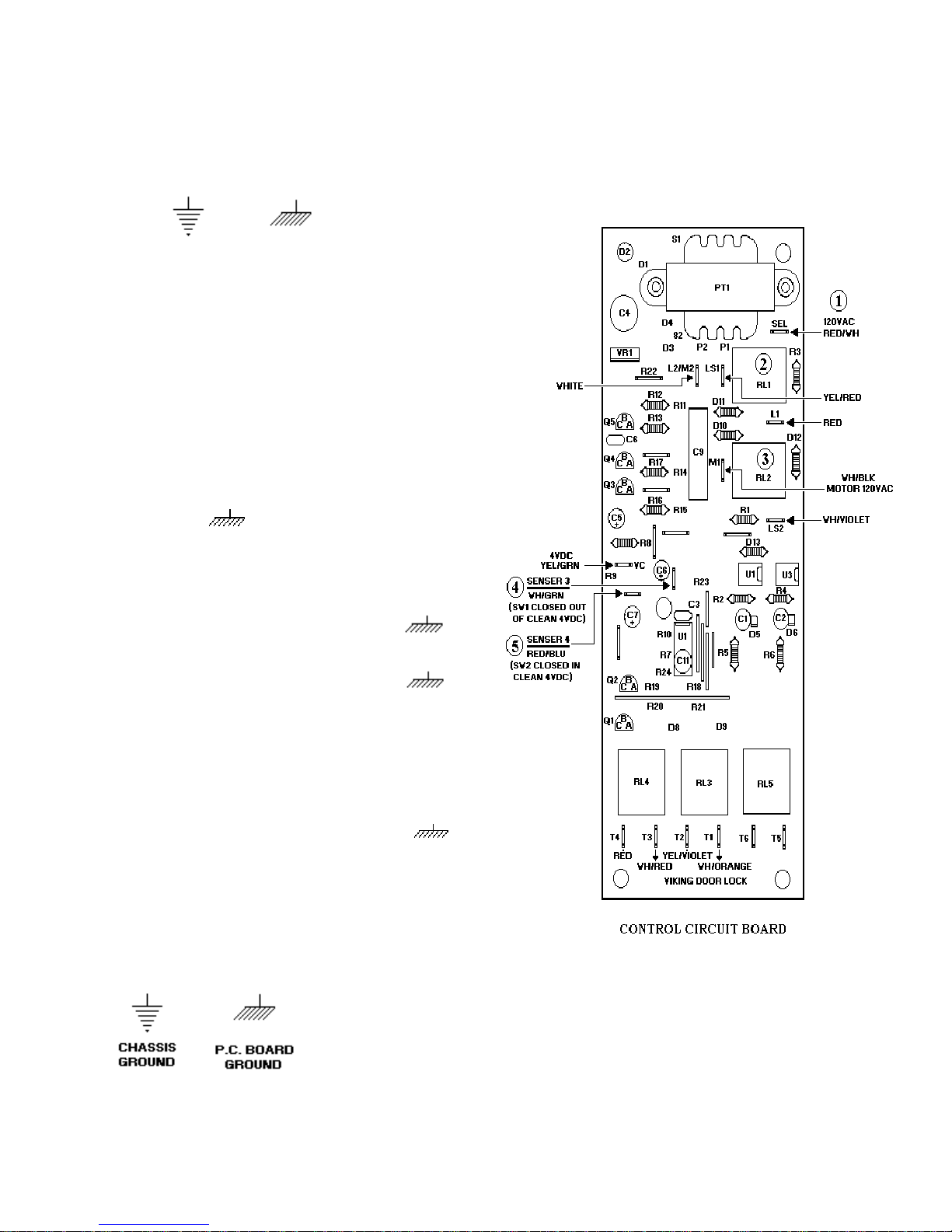

DOOR LOCK CONTROL / TIMER

Function: The Door Lock Control / Timer is

activated by the line voltage at the “ SEL”

( 1 ) contact. Relay “ RL1" ( 2 ) and “RL2"

( 3 ) close providing voltage to the Door Lock

Motor. The Relays stay closed until 10

seconds after sensor #3 ( 4 ) receives a signal

that the Door Lock is fully closed. Once this

happens Relay “RL2" ( 3 ) opens to stop the

Door Lock Motor. Relay “RL1" ( 1 ) stays

closed providing voltage to the Auto Reset

thermostat. Relays “RL3" and “RL4" close

powering the Cooling Fan Motor and Cycle

Relay. “RL3" and “RL4" will stay closed for

3 ½ hours unless power is interrupted to

sensor #3 ( 4 ) or SEL ( 1 ). In which case

“RL3" and “RL4" will open, interrupting the

clean cycle and Cooling Fan, and “RL2" ( 3 )

will close, opening the Door Lock. “RL2" ( 3)

will stay closed until 2 seconds after sensor

# 4 ( 5 ) is powered.

AUTO RESET SWITCH

Function: The Auto Reset Switch is a single

pole / double throw switch ( thermostat )

which is activated by a thermobulb and lever

which is calibrated to 575* F plus / minus 25*

F. Clean door lock below 575* F. The Door

Lock Motor is energized through the Auto

Reset Switch ( thermostat ) contacts 2 - 1.

Clean door lock above 575* F. Auto Reset

Switch ( thermostat ) switches to contacts 1 -3

turning on the Door Lock indicator Light and

disables the Door Lock Motor circuit. Final

below 575* F. Auto Reset Switch

( thermostat ) switches to contacts 1 -2,

turning off the Door Lock Motor circuit

through door Lock Motor / Timer Relay LS2 M1. Door Lock Motor operates until 2

seconds after sensor 4 is signaled by VC that

the Door Lock switch SW1 has been closed

mechanically by the door lock bolt. The Door

Lock / Timer switches LS2 - M1 and LS1-L1

open and the timer resets.

4

VDSC COMPONENTS ( Con’t )

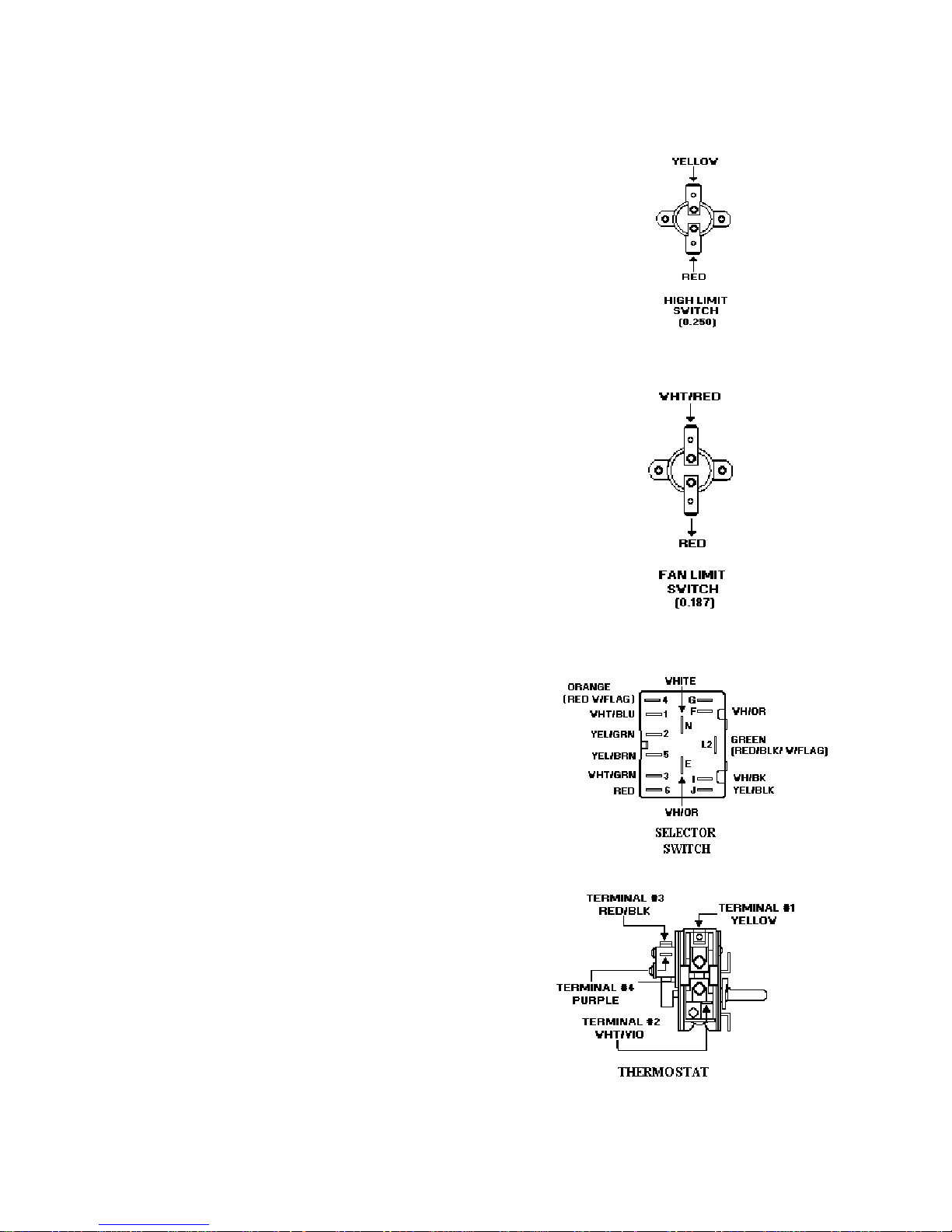

HIGH LIMIT SWITCH

Function: The Switch has a ½ “ bi-metal

disc. The two metals have different thermal

coefficients of expansion which cause the

disc to bow as it heats up. When it reaches

the calibration temperature the disc snaps

open, which opens the electrical contacts.

The Switch opens when temperature reaches

275* F plus or minus 9*F and will close

when temperatures are 248* F plus or minus

9*F.

COOLING FAN LIMIT SWITCH

Function: The Switch has a ½ “ bi-metal disc.

The two metals have different thermal

coefficients of expansion which cause the disc

to bow as it heats up. When it reaches the

calibration temperature the disc snaps closed,

which closes the electrical contacts. The

Switch closes when temperatures reach 230*

F plus or minus 9* F and will open when

temperatures are below 203* F plus or minus

9*F.

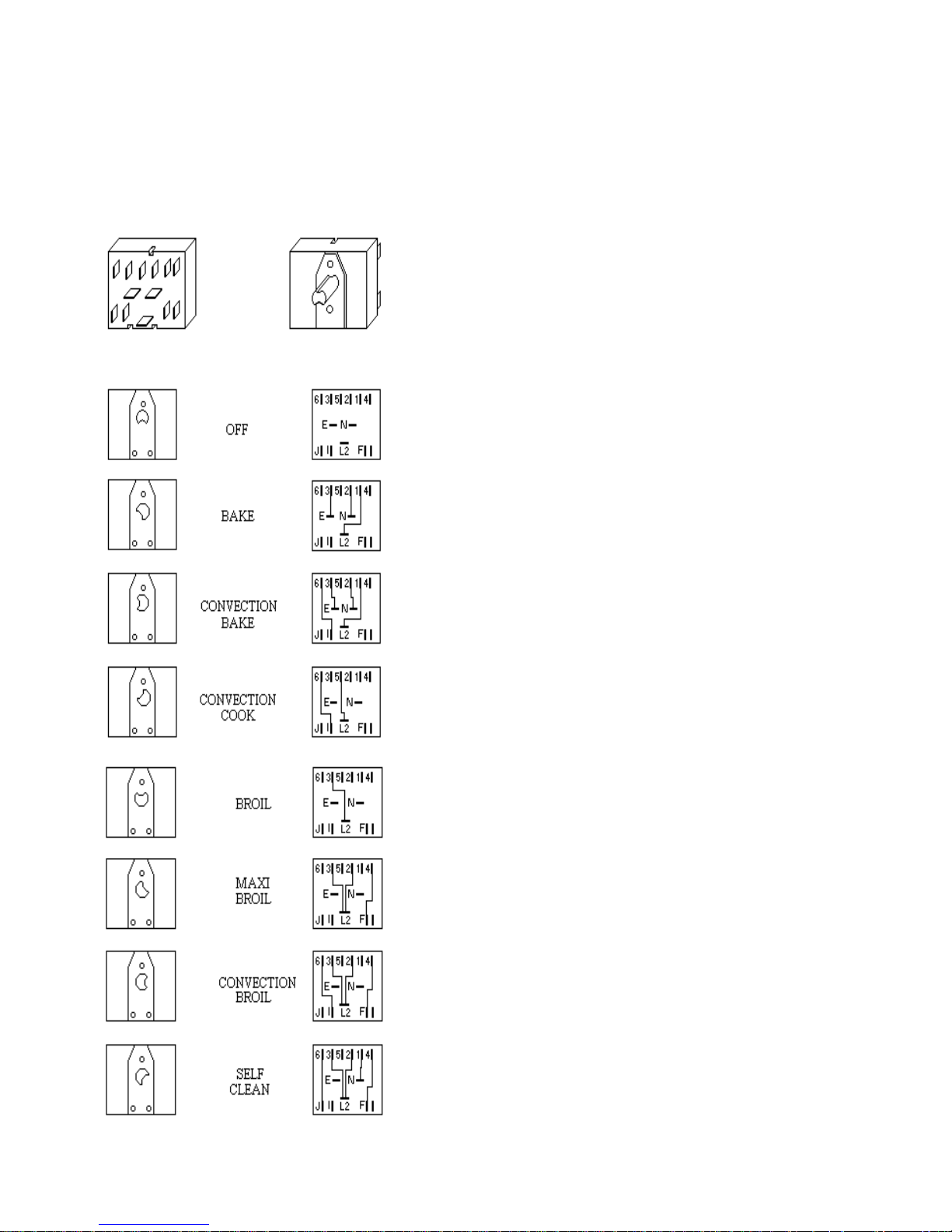

SELECTOR SWITCH

Function: Rotating the shaft twists a cam

which moves one or more spring loaded

levers, which make contact with a terminal

closing the circuit.

OVEN THERMOSTAT

Function: As the shaft is rotated from the

OFF position clockwise, an internal cam

pushes a lever, which increases the

temperature at which the thermostat cycles.

Rotating the shaft 212* (angle *) switches an

external (clean) Micro Switch to the closed

position.

5

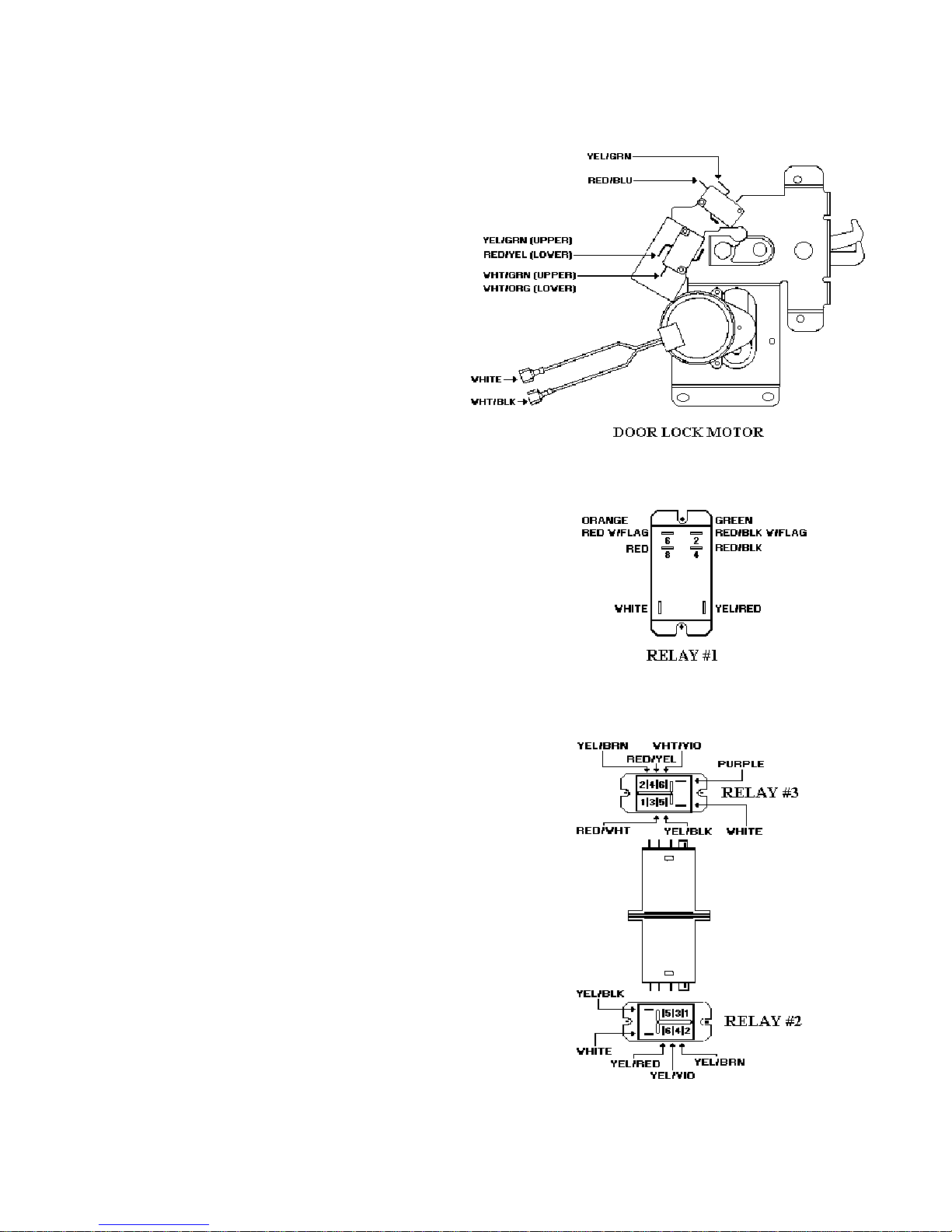

VDSC COMPONENTS ( Con’t)

DOOR LOCK

Function: When the Door Lock Motor is

powered it turned a cam which pulls back a

lever. As the lever moves back it allows a

micro switch (SW1) to open. When the lever

reaches the fully closed position it closes a

double stacked micro switch (SW2 & SW3).

Door lock switch SW2 completes the circuit

to sensor #3 on the Door Lock Control/timer

board. After 10 seconds LS1-M1 opens,

stopping the Door Lock motion. Door Lock

Switch #3 closes T1-T2 and T3-T4 energizing

Power Relay #1 and the Cooling Fan. Closing

Power Relay contacts supplies 240 VAC to

both Broil Elements and 120 VAC to the

Bake Element.

POWER RELAY #1

Function: Relay #1 ( power ) supplies power

to the Bake and Broil Elements.

RELAY #2 and RELAY #3

Function: Setting the selector switch to clean

closes the Heating Element circuits 4-F, 1-N,

2-L2, 3-L2 and Door Lock Module / Timer

circuit J-6, energizing Relay #2.The

thermostat cycling contacts 1 to 2 and the

clean switch contacts 3 to 4 close energizing

Relay #3. Relay #3 allows circuit J-6 to turn

on the Clean Indicator Light and enable the

Door Lock Module / Timer to close Relays

LS1-L1 and LS2 - M1. This powers the Door

Lock Motor until 10 seconds after Sensor 3 is

signaled by VC that Door Lock Switch SW2

has been closed mechanically (along with

SW3) by the Door Lock Bolt.

6

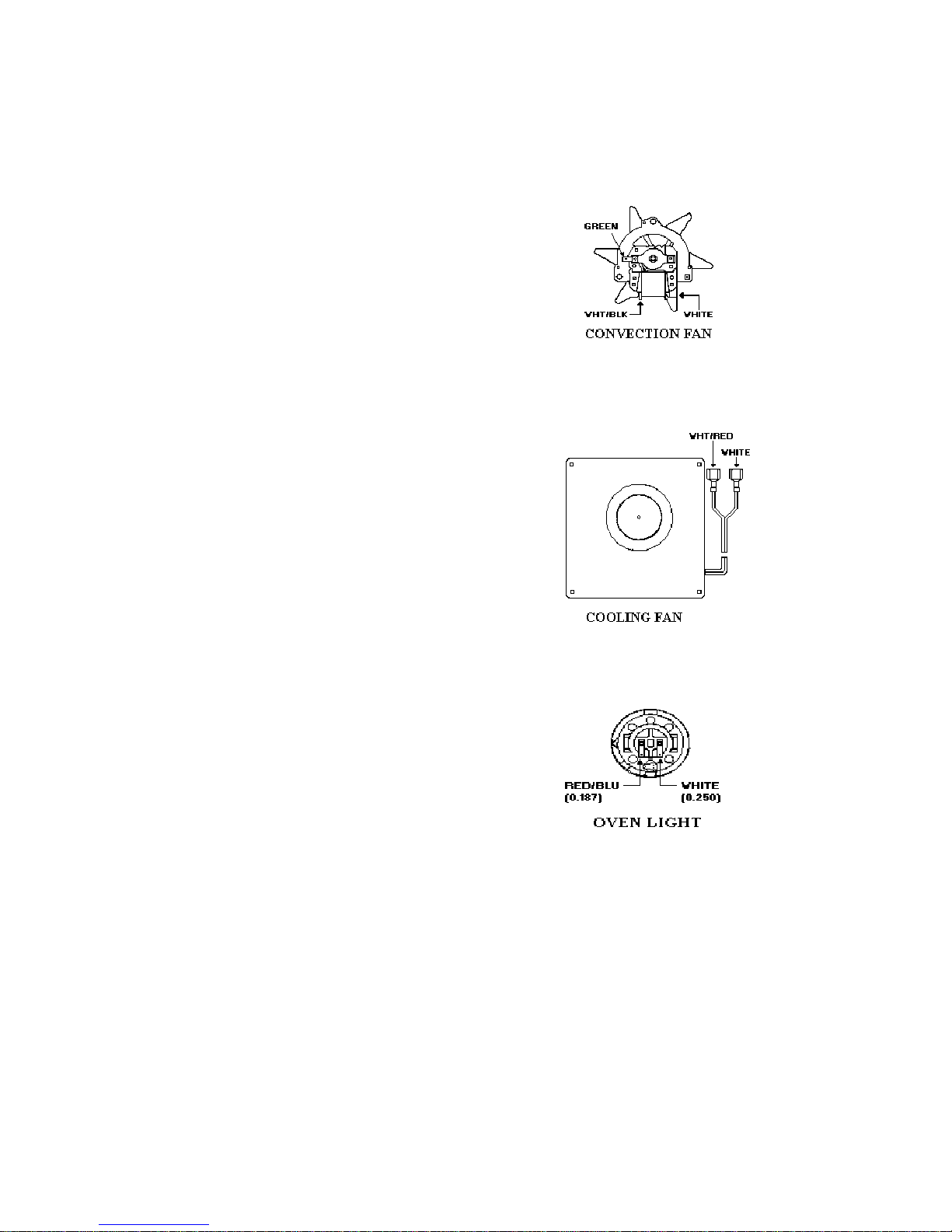

VDSC COMPONENTS ( Con’t )

CONVECTION FAN MOTOR

Function: Provides an even flow of air in the

oven cavity for more even baking.

COOLING FAN MOTOR

Function: Provides a continuous supply of

cool air during self clean cycles to keep the

Door Lock Motor and associated circuits cool.

OVEN LIGHT

Function: Provides interior oven light for

viewing baking products.

7

VOLTAGE READINGS

MEASURED WITH DOOR OPEN

T4 107VAC 70VAC

T3 4VAC 16VAC

T2 4VAC 16VAC

T1 5VAC 1VAC

MEASURED WITH DOOR LOCKED

T4 80VAC 56VAC

T3 85VAC 56VAC

T2 90VAC 56VAC

T1 93VAC 56VAC

VC--4VDC

SENSOR 3--3VDC SW2 closed in self clean

(Locked).

SENSOR 4--4VDC SW1 closed with clean

lock open.

M1--120VAC lock motor supply voltage.

(31VAC in locked position)

LS2--70VAC (unlocked)--55VAC (locked)

L1-- 70VAC (unlocked)--56VAC (locked)

L2/M2--16VAC (unlocked)--32VAC

(locked)

LS1--107VAC (locked or unlocked)

SEL--120VAC SUPPLY

8

VOLTAGE and RESISTANCE READINGS

BAKE ELEMENT:

“A” to “B” 21.1 Ohms

“A” to “B” 240VAC during Bake and

Convection Bake.

BROIL ELEMENT:

“A” to “D” ( outside element ) 32.6 Ohms

“A” to “D” 50VAC during Bake and

Convection Bake.

240VAC during Maxi Broil.

240VAC during Convection Broil

240VAC during Self-clean

“B” to “C” ( inside element ) 45.2 Ohms

“B” to “C” 70VAC during Bake and Convection

Bake.

240VAC during Mini Broil

240VAC during Maxi Broil

240VAC during Convection Broil

240VAC during Self-clean

CONVECTION ELEMENT:

“A” to “B” 26 Ohms

“A” to “B” 240VAC during Convection Cook

9

8 POSITION SELECTOR SWITCH

(With shaft position and internal connections

SELF CLEAN

Selector Switch closes Heating Element contacts

4-F, 1-N, 2-L2, 3-L2, and Door Lock Module

/Timer contacts J-6 energizing Relay #1.

Thermostat Clean Position closes Thermostat

cycling contacts 1-2 and normally open (N) common (C) energizing Relay #3.

Relay # 3 turns on the Clean indicator Light and

energizes Door Lock Module / Timer (PC Board)

relays LS1-L1 and LS2-M1, also supplying

120VAC to SEL on the PC board

Relays LS1 and LS2 turns the Door Lock Motor

on through the Auto Reset Thermostat contacts

2-1.

Door Lock Motor rotates opening SW1 and

closing SW2 and SW3.

Door Lock Switch #2 completes the circuit to

sensor #3 on the PC board. After 10 seconds

LS1-M1 opens, stopping the Door Lock motion.

Door Lock Switch #3 closes T1-T2 and T3-T4

energizing Power Relay #1 and the Cooling Fan

.Closing Power Relay #1's contacts supplies

240VAC to both Broil Elements and 120VAC to

the Bake Element.

CLEAN DOOR LOCK ABOVE 575*F

+/-25*F

Auto Reset Thermostat switches to contacts 1-3

turning on the Door Lock indicator Light and

disables the Door Lock Motor circuit.

CLEAN TEMPERATURE (875*F)

REACHED.

Door Lock Module / Timer opens T3 -T-4 and

T1-T2 turning off the Cooling Fan, now powered

by the Fan Limit Switch when needed, and opens

the circuit to the Power Relay #1 disabling the

Heating Elements.

FINAL BELOW 575*F +/-25*F

Auto Reset Thermostat switches to contacts 1-

2, turning off the Door Lock Motor circuit

through Door Lock Motor / Timer Relay LS2-M-

1. Door Lock Motor operates until 2 seconds

after sensor 4 is signaled by VC that the Door

Lock /Timer switches LS2- M1 and LS1-L1 open

and the Timer resets.

10

Loading...

Loading...