Page 1

SERVICE NOTEBOOK

VCWB300 PROFESSONAL MODEL

BUILT-IN FULL HEIGHT WINE COOLER

Page 2

Table of Contents

Technical Information--------------------------------------------------------------------- 4

Sealed System------------------------------------------------------------------------------ 5

Control Panel Assembly------------------------------------------------------------------- 6

Mode of Operation------------------------------------------------------------------------ 6

Temperature Readout and Setting----------------------------------------------- 7

Display Off------------------------------------------------------------------------- 7

Compressor Protection------------------------------------------------------------ 7

Fan Operation---------------------------------------------------------------------- 7

Alarm Security--------------------------------------------------------------------- 8

Holiday Mode---------------------------------------------------------------------- 8

Service Mode----------------------------------------------------------------------- 8

Display Interface Board----------------------------------------------------------- 8

Glass Mullion Shelf---------------------------------------------------------------- 9

Electronic Function Description-------------------------------------------------------- 10

Display Panel Keyboard---------------------------------------------------------- 10

Power Disconnect Switch--------------------------------------------------------- 10

Showroom Switch----------------------------------------------------------------- 10

Display Panel Operation----------------------------------------------------------------- 11

Keyboard Entry Tone------------------------------------------------------------- 11

Zone Pad---------------------------------------------------------------------------- 11

Lower Temp Pad------------------------------------------------------------------- 11

Higher Temp Pad------------------------------------------------------------------ 11

Lights-------------------------------------------------------------------------------- 11

Display Pad------------------------------------------------------------------------- 12

Alarm-------------------------------------------------------------------------------- 12

Wine Cooler Leveling---------------------------------------------------------------------- 12

Door Stop Adjustment---------------------------------------------------------------------- 13

Hinge Adjustment--------------------------------------------------------------------------- 13

Diagnostic Check Points------------------------------------------------------------------ 14

E1 – Display Board Output------------------------------------------------------- 14

E2 – Touch Switch Inputs-------------------------------------------------------- 14

E3 – Outputs and Line Voltage Inputs------------------------------------------ 14

E4 – Thermistor Inputs------------------------------------------------------------ 15

Compressor Relay------------------------------------------------------------------ 15

Alarm Wires------------------------------------------------------------------------- 15

Display Board----------------------------------------------------------------------- 15

Compressor (General Information)-------------------------------------------------------- 16

Thermister Resistance Reading------------------------------------------------------------- 17

Solenoid Valve / Evaporator Fan----------------------------------------------------------- 18

Wiring Schematic---------------------------------------------------------------------------- 19

Wiring Diagram------------------------------------------------------------------------------ 20

3

Page 3

VCWB300

DDWB300 DESIGNER – DFWB300 FULL OVERLAY

BUILT-IN FULL HEIGHT WINE COOLER

VIKING TECHNICAL INFORMATION

*

DUE TO POSSIBLITY OF PERSONAL INJURY OR PROPERTY DAMAGE, ALWAYS

CONTACT AN AUTHORIZED TECHNICIAN FOR SERVICING OR REPAIR OF THIS WINE

COOLER.

The Viking Built-in Full Height 30” W. wine cooler (VCWB series) is designed to meet

the needs of the upscale wine connoisseur while also meeting Viking Range

Corporation’s stringent product standards. The product is 30” (76.2cm) wide and 84”

(213.4cm) tall. The product has adjustable leveling legs to allow the height to be

adjusted from 82 1/2” TO 84 3/4” (209.6 to2120.7cm). The sealed system is located on

the top of the product.

The product has commercial type construction and is available with various features and

color options.

General Specifications

Model VCWB300#

Internal Volume Capacity 150 Bottles

Electrical Requirements 115VAC, 60 HZ and 15 Amps

Maximum Amp Usage 2.0 Amps

Refrigerant Type HFC – 134a

Refrigerant Charge See Rating Label

Overall Width 30 inches (76.2cm)

Overall Depth without Handle

Includes Door Extrusions 24”

(Designer DDWB300) 24 ½”

(Full Overlay DFWB300) 24 ¾” to Front of Grille

Overall Height (Rollers to Top

of Air Grille) 82 ½” to 83 ¾”

4

Page 4

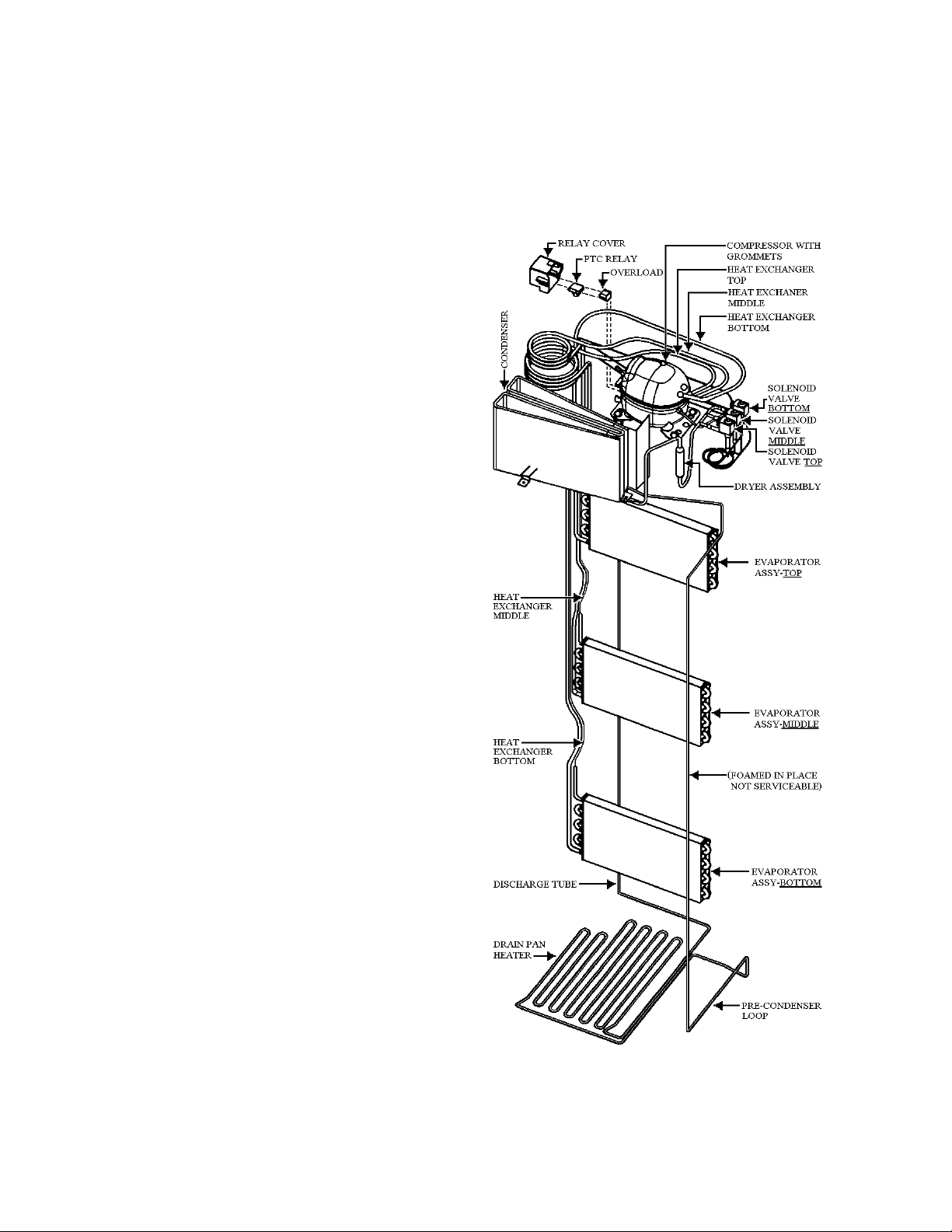

SEALED SYSTEM

The sealed system consists of the following components (listed in order of refrigerant

flow):

1 condenser coil

1 dryer assembly

3 solenoid valves

3 heat exchangers

3 evaporators

1 compressor

1 discharge tube

1 drain pan heater

1 pre-condenser loop

Refrigerant Type – HFC 134a

Refrigerant Charge – 7.3 oz.

Evaporator Temperature Range

14°F to - 31°F

Expanding Device – Cap tube

Compressor Cooling:

LBP 32° C Ambient temp 98 to 140V

LBP 43° C Ambient temp 98 to 140V

Maximum Condensing Pressures:

Operating 230 psig

Peak 293 psig

Electrical Data:

Normal Voltage 115VAC / 60Hz

Start Winding Resistance – 21.20Ω (at

77°F) ± 8%.

Run Winding Resistance – 7.90Ω (at

77°F) ± 8%.

Locked Rotor Amps (60Hz) – 9.80

Amps.

Full Load Amps (60Hz) – 1.20 Amps.

5

Page 5

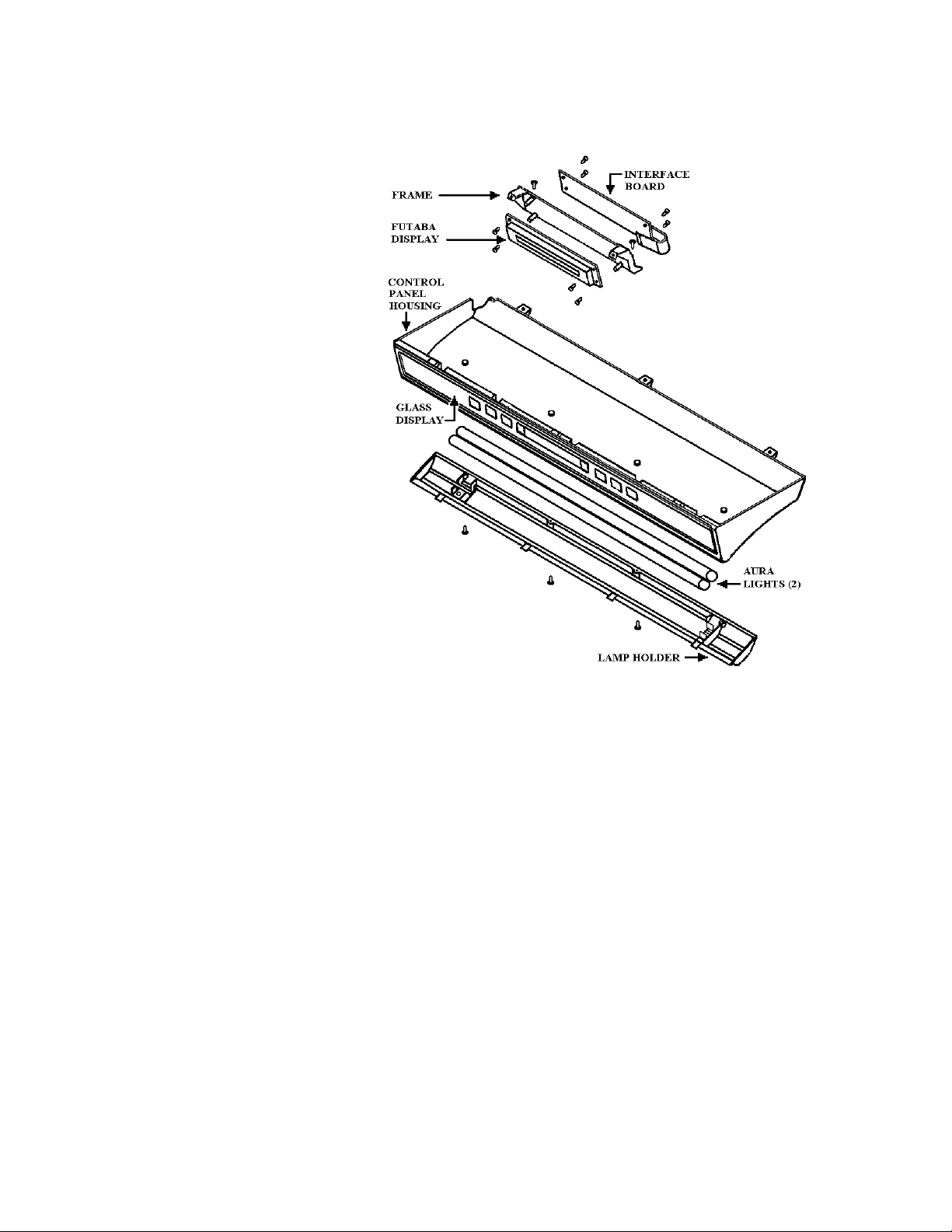

CONTROL PANEL ASSEMBLY

The wine cooler is equipped

with a control panel

conveniently located in the top

front of the top compartment

of the wine cooler. From this

point the user can operate all

functions of the wine cooler’s

temperature management and

various electronic features.

The control panel housing is

constructed of injected molded

plastic. A glass keyboard is

fastened to the housing by

means of snap clips that are

incorporated into the molded

housing. The keyboard is then

secured in place with an

adhesive. The keypad utilizes

a special technology that

senses mass. When the user

places a finger on the glass

surface at designated “button”

locations the control

recognizes this and converts

this to an electronic signal.

This signal is then processed by the wine cooler’s control that promptly results in a

change of temperature settings or some of the other wine cooler electronic features.

On the underside of the control panel a means for attaching two light bulbs is molded in

place. The light tubes are installed into a separate lamp holder, which is then attached to

the control panel by four “molded in” clips and four screws.

Mode of operation: Microprocessor based 3 – channel temperature / logic control.

Normal cooling operation: Control will independently read and regulate the average

temperatures of each chamber to its corresponding set point as shown on the vacuum

florescent display (“VFD”). When cooling is called for, the zone valve will energize and

the compressor will energize 60 seconds later. Only one zone valve / fan can be

energized at a time. Chamber 1 will take precedence over chamber 2, which will take

precedence over chamber 3 in the event that more than one chamber is calling for cooling

at the same time. Each chamber will run for a maximum of 10 minutes after which it will

switch to the next chamber requiring cooling. When a chamber reaches 1º below set

temperature the zone valve is de-energized. The control will energize the compressor

6

Page 6

and appropriate zone valve based upon the temperature at the evaporator thermistor and

will turn off the zone valve based upon the temperature at the chamber thermistor.

Temperature readout and setting: Pressing the zone button will change which chamber

is selected for adjustments. The selected chamber will have a bar displayed over the

temperature reading on the VFD. Pressing the higher or lower buttons will raise or lower

the set point of the selected chamber in one degree F increments. Every time any set

point is changed a “set time” delay will start. When the “set time” delay is completed

without another change in the temperature the currently displayed number will become

the new set point. The new set point will be stored in non-volatile memory. The unit will

begin controlling the particular chamber to the new set point, and the actual chamber

temperature will be displayed. Temperature can be displayed in either Degrees F

(default) or in Degrees C. It can be changed from one to the other by pressing and

holding both the display on/off and the display alarm buttons simultaneously for 5

seconds. The display will show “F” or “C” appropriately. This setting will be stored in

non-volatile memory and will be saved during period of power loss.

Display off: To turn the display off, momentarily press the display. The display will turn

off as soon as the button is released.

To turn the display on, momentarily press the display button. The display will turn on as

soon as the button is released.

Compressor protection: At any time the compressor needs to start, including that power

up the appropriate zone valve will energize for 60 seconds before the compressor is

allowed to start. This is intended to allow to discharge any pressures in the system so that

the compressor will not start under heavy load. Any time that all chambers reach set

temperatures(s), the compressor will continue to run for an additional 30 seconds. This is

intended to reduce compressor start / stop cycles as the various chambers call for cooling.

Fan operation: The evaporator fans, if running will shut off whenever the door switch

opens and turns back on when the door switch closes. When operating in Holiday Mode

the Fan(s) will not turn off, if running, when the door switch opens.

Chamber lighting: The light inside the chambers can be always on, or only on when the

door switch is open. Pressing the lights button on the front panel toggles this setting.

Also see holiday mode.

Alarm security: Alarm operation can be toggled on or off by pressing the alarm front

panel button for 2 seconds. When the temperature inside any chamber is higher than the

set temperature by more than 5 degrees F for longer than the “2 hours” delay, the display

will flash on and off and an audible signal will sound. When the alarm mode is active, an

enunciator will appear in the display. Upon initial power-up, the alarm will be disabled

for a start-up delay to allow for the unit to reach temperature. The alarm can be disabled

by pressing the alarm off button. A door alarm is provided that will sound if the door

switch is open for longer than the door alarm delay. The alarm will shut off upon reclosing the door and the delay time will be reset. Temperature alarm operation will be

inhibited in show room mode. Home security contacts will transfer during an alarm

condition. When operating in Holiday Mode, the high temperature alarm and door

alarms are disabled.

7

Page 7

Showroom mode: This mode, selected by closing the showroom switch is intended to simulate

normal operation in all ways except the cooling and temperature alarm functions. Closure of this

switch will over-ride normal cooling. Temperature displayed for the chambers will be the last

temperatures stored in memory, or the factory defaults setting if they have not been changed.

Lights and functions will occur as in normal cooling operation described above.

Holiday mode (Sabbath mode): Pressing and holding the display button continuously for 10

seconds accesses this mode. (Note: The Display must be “on” before entering Holiday Mode.)

To cancel Holiday Mode, press and hold the display button continuously for 10 seconds. When

Holiday Mode is selected, a random time delay of 15 to 25 seconds will be applied to the

compressor relay start and stop. The chamber lights relay will remain de-energized. The display

will not be illuminated. Audible sound (beep) from the control will be disabled. Fan outputs will

not be affected by opening or closing of the door switch. All front panel buttons will be

inoperative except a 10 second press of the display button causing the control to exit Holiday

Mode. All other functions will continue as in normal cooling described above. The Alarm

sounds is disabled and the home security relay will not transfer.

Service mode: This mode, selected by pressing and holding zone, higher temp and lights buttons

simultaneously for 5 seconds is intended for manual operation of the compressor, valves and fans

for purposed of servicing / diagnosing and repair. When put in to this mode, valve 1 will energize

for 10 seconds to relieve any pressures in the system. The compressor will then energize and

continue to run continuously while in service mode. Pressing the zone button will change which

chamber is active as indicated on the display. The solenoid valve and evaporator fan will

energize in the chamber that is active. To leave the service mode, press and hold the zone higher

temperature and lights buttons simultaneously for 5 seconds, normal operation will then resume.

Charge mode: Pressing the lower temp button while in service mode selects charge mode. In

this mode all zone valves are open and all other functions are “off”. This is to vacuum, evacuate

and charge the sealed system. To exit charge mode the power must be removed, turn “off” the

power switch or unplug the product.

Display interface board: Mode of operation: Interface board for Vacuum fluorescent display

module.

During normal operation, temperatures in all three chambers are displayed and the red lens is

blinking approximately once per second when the RS-232 signal is being received. A “bar”

symbol is displayed over the “active” temperature reading. The “adjusted” temperature will be

displayed as blinking, approximately .5 seconds on .5 seconds off.

When the “alarm mode enabled” signal is being received the “alarm” symbol will be displayed.

If the “alarm” signal is being received, the “alarm” word will be displayed for approximately 4

seconds and the chamber temperature will be displayed for the next 4 seconds. The piezoelectric

sounder will turn on for 100 milliseconds, approximately every 8 seconds. The display will be

on, even if the “display blank” command is being received

.

8

Page 8

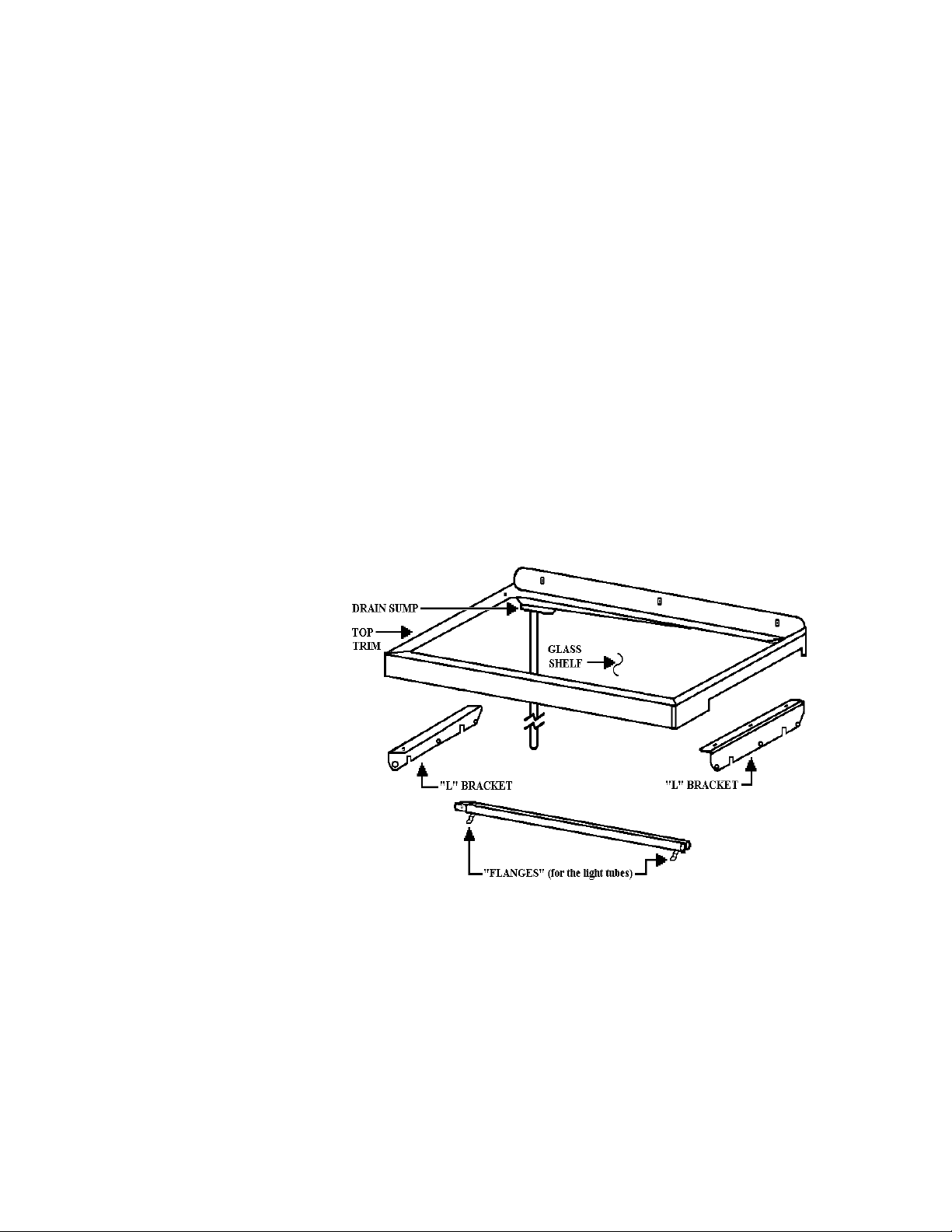

GLASS MULLION SHELF

Each compartment is separated be a fixed glass shelf (“Mullion” – two per wine cooler).

These glass shelves are uniquely designed such that they act not only as an insulated

divider wall, but also provides a means of draining the condensate water from the top and

middle compartments and as a means of attaching and supporting the light tubes for the

middle compartment.

The bottom trim of the shelf has holes for mounting the assembly to the cabinet of the

wine cooler. This is accomplished through the use of “L” brackets that are attached to

the liner walls of the cabinet and then attached to the shelf at an angle of 90° with respect

to the walls of the wine cooler. Two of these “L” brackets are used: one on each side.

The condensate drain nozzle is tapered so that a drain tube can be interference free onto

the outer diameter of the nozzle. The drain tube directs condensate water to a desired

location. For the top compartment, the tube directs water to the middle compartments

mullion drain sump. For the middle compartment, the drain tube directs water to the

sump in the liner bottom.

Each mullion shelf has

two “flanges” and two

screw bosses located at

the front bottom of the

device. The two light

tubes for the middle

compartment are snapped

into the flanges at each

end and are then secured

in place at each end with

a screw and a light tube

clamp. The wires for the

light tubes are then routed

along the left side of the

shelf and secured and

covered with an extruded

wire channel.

9

Page 9

DISPLAY PANEL KEYBOARD

ELECTRONIC FUNCTION DESCRIPTION

Power Disconnect Switch:

The power on/off switch is used to turn the power off to the wine cooler when cleaning it

or changing the light tubes. The wine cooler is shipped with the power on/off switch in

the on position. To turn the power off, remove the center grille assembly by grasping the

three center louvers, lifting up and pulling outward. Press the power on/off switch to the

“ON” position. Replace the center grille assembly by aligning the hooks in the assembly

with the slots in the brackets which are attached to the grille. Push in over the hooks and

slide grille assembly downward.

Showroom Switch:

The showroom switch

allows electronic

controls and interior

lights to function

independently of the

refrigeration system.

Your wine cooler is

shipped with the

showroom switch in

the “OFF” position.

To use the showroom

mode, remove center

grille assembly and

turn the showroom

switch to the “ON”

position. Showroom

mode will be

engaged.

10

Page 10

DISPLAY PANEL OPERATION

Keyboard Entry Tone Indicates a pad was pressed, command read and accept.

Zone Pad 1. Toggle between zones for set point temperature adjustment.

Pressing immediately toggles from Top to mid to bottom,

respectively that order. Entry tone will sound at each depression

of pad.

2. Used in conjunction with “Higher Temp” and “Lights” pads to

enter service mode. Press “Zone”, “Higher Temp” and “Lights”

simultaneously for 5 seconds to activate service mode.

3. Used in conjunction with “Higher Temp” and “Lights” pads to

exit service mode. Press “Zone”, and “Lights” simultaneously

for 5 seconds to exit service mode. Normal operation will then

resume.

4. In service mode toggles between zones. Pressing immediately

toggles from Top to mid to bottom respectively that order.

Lower Temp Pad 1. Lowers Temperature settings in 1 degree increments. Entry tone

will sound at each depression of pad until desired temperature

setting is achieved.

2. Activates charge mode – Press lower temp pad when in “service

mode” to activate charge mode.

Higher Temp Pad Raises temperature settings in 1 degree increments. Entry tone will

sound at each depression of pad until desired temperature setting is

achieved.

1. Used in conjunction with “Zone” and “Lights” pads to enter

service mode. Press “Zone”, Higher Temp” and “Lights”

simultaneously for 5 seconds to activate service mode.

2. Used in conjunction with “Zone” and “Lights” pad to exit service

mode. Press “Zone”, “Higher Temp” and “Lights”

simultaneously for 5 second to exit service mode. Normal

operation will then resume.

Lights Toggle between lights on when door open only and lights always on.

Warning: May affect temp regulation of Wine Cooler. Entry tone

will sound at each depression of pad.

1. Used in conjunction with “Zone” and “Higher Temp” pads

to enter service mode. Press “Zone”, Higher Temp” and

“Lights” simultaneously for 5 seconds to activate service mode.

2. Used in conjunction with “Zone” and “Higher Temp” pads to

exit service mode. Press “Zone”, “Higher Temp” and “Lights”

simultaneously for 5 seconds to exit service mode. Normal

operation will then resume.

11

Page 11

Display Pad 1. Activates control panel. Pressing button for 2 seconds

toggles the display on/off. Entry tone will sound at after 2

seconds of pad depression.

2. Activates Holiday Mode. Pressing button for 15 seconds

toggles the holiday mode on/off.

3. Used in conjunction with “alarm” pad to toggle between

“F” Fahrenheit and “C” Celsius temperature reading. Press

and hold “Alarm” and “Display simultaneously for 10

seconds to change from one to the other (“F” or “C”)

4. Used in conjunction with “Alarm” button, temperature can

be displayed in either Deg F (default) or in Deg C. It can

be changed from one to the other by pressing and holding

both the “Display” and the “Alarm” buttons simultaneously

for 5 seconds. The display will show “F” or “C”.

Alarm Toggles between alarm on and off. By pressing the alarm pad

for 2 seconds.

1. Activates alarm feature.

2. Deactivates alarm feature.

3. Disables alarm in the event of a high temperature condition.

4. Used in conjunction with “Display” button temperature can

be displayed in either Deg F or in Deg C. It can be

changed from one to the other by pressing and holding both

the “Display” and the “Alarm” buttons simultaneously for 5

seconds. The display will show “F” or “C”.

Wine Cooler Leveling:

A. Lift the wine cooler off the rollers, adjust to

the desired height and level wine cooler by

using a 5/16” hex head wrench. (Refer to

Figure at the right).

1. To raise right side rear, rotate the right side

rear hex rod Clockwise.

2. To raise the left side rear, rotate the left side

rear hex rod Clockwise.

3. To raise the right side front, rotate the right

side front hex rod Clockwise.

4. To raise the left side front, rotate the left side

front rod Clockwise.

NOTE: DO NOT use an electric driving device. Over tightening can cause damage.

B. Align wine cooler with sides of cabinets by adjusting leveling legs. Rotate leveling

legs until firmly in place against floor.

C. To secure wine cooler, raise until compartment cover is firmly seated under the soffit

or anti-tip boards.

12

Page 12

LEVELING ADJUSTMENTS

DOOR STOP ADJUSTMENT

1. Using a 3/16” allen wrench, remove door stop pin located in bottom hinge.

2. The pin is factory set 110°. For 120° swing, move the pin to the utmost forward

stop hole. For 90° swing, move the pin to the utmost rear stop hole.

HINGE ADJUSTMENT

1. Using 3/16” allen wrench, remove the door stop

pin located in bottom hinge.

2. Using the height adjustment shim as a wrenching

device, rotate the height adjustment bushing

counterclockwise to raise or clockwise to lower

the location of the door.

3. When proper adjustment is reached, align shim

with door stop pin holes and replace door stop

pin. Firmly tighten pin in place.

13

Page 13

DIAGNOSTIC CHECK POINTS

(Rfer to Wiring Schematic on Page 19)

Number DescriptionA

E1 Display Board Send

1 +5Vdc

2 data signals

3 ground

E2 Touch switch inputs (with switches connected), typical

1 +5VDC

2 Ground Common for measurements on E2

3 Not connected

4 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

5 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

6 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

7 +5Vdc

8 Ground Common for measurements on E2.

9 Not connected.

10 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

11 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

12 When button is touched +4Vdc to +5Vdc, otherwise less than +1Vdc.

E3 Outputs and line voltage inputs (loads connected) typical.

1 Showroom switch off = 0V, on = 120VAC

2 – 7 Not connected.

8 Door switch open = 0V, closed = 120VAC.

9 When Zone* is being cooled or service mode = 115 VAC , off = 0V

10 When Zone* is being cooled or service mode = 115 VAC , off = 0V

11 When Zone* is being cooled or service mode = 115 VAC , off = 0V

12 When zone** is being cooled or service mode = 115 VAC , off = 0V

13 When zone** is being cooled or service mode = 115 VAC , off = 0V

14 When zone** is being cooled or service mode = 115 VAC , off = 0V

15 When zone* lights to be on = 115 VAC , off = 0V

16 Power line neutral. Common for all E3 measurements.

* E3 pin 9 Solenoid #1 / pin 10 Solenoid #2 / pin 11 Solenoid #3

** E3 pin 12 Evap. Fan #1 / pin 13 Evap. Fan #2 / pin 12 Evap. Fan #3.

NOTE: All wiring controlling Fan #3, Sol #3, and both #3 Thermisters have Black strips.

All wiring controlling Fan #2, Sol #2 and both #2 Thermisters have Red strips.

All wiring controlling Fan #1, Sol #1 and both #1 Thermisters have White strips.

14

Page 14

DIAGNOSTIC CHECK POINTS (con’t)

E4 Thermister inputs (measured with thermisters disconnected).

1 to 8 3 to 4.5 VDC – TE2 (Evaporator Thermister #2)

2 to 9 3 to 4.5 VDC – TC1 (Compartment Thermister #1)

3 to 10 3 to 4.5 VDC – TE1 (Evaporator Thermister #1)

4 to 11 3 to 4.5 VDC – TC3 (Compartment Thermister #3)

5 to 12 3 to 4.5 VDC – TE3 (Evaporator Thermister #3)

6 to 13 3 to 4.5 VDC – TC2 (Compartment Thermister #2)

7 to 14 3 to 4.5 VDC

Compressor Relay (use E3 – 16 as common for measurements)

Com 115 VAC continuous (power line supply).

NO 115 VAC when compressor is running.

NC Not connected.

Alarm wires (check for continuity – these are contact closures only)

Black Common

Red Normally closed (in no – alarm condition)

White Normally open (in no – alarm condition)

Display Board

(IDB5D –4330)

E1 Display Board receive

1 +5VDC

2 data signals

3 ground

E2 Futaba VFD display data connection

TE = Thermister / Evaporator -- Cut-in (39°F minimum) for Evaporator Temperature

TC = Thermister / Compartment – Compartment cut-out Temperature.

Thermister Tolerance ± 2 degrees.

15

Page 15

General Information:

Approved Board Certification CSA – UL

Suction 0.256” + 0.005” / - 0.003”

Discharge 0.194” + 0.003” / - 0.003”

Process 0.256” + 0.005” / - 0.003”

Mechanical Data:

Low Starting Torque (LST)

Lubricant Charge 6.76 fl. Oz.

Lubricant type ESTER

Lubricant Viscosity @ 40° C ISO 22

Weight (with Oil Charge) 15.43 lbs.

Nitrogen Charge 2.84 to 4.27 psig.

Application:

Evaporating Temperature range 14°F to -31°F

Refrigerant R134a

Refrigerant Charge 7.5 oz.

Expanding Device Capillary Tube

Compressor Cooling Operating Range (60Hz)

LBP 32° C Ambient Temp. 98 to 140V

LBP 43° C Ambient Temp 98 to 140V

Maximum Condensing Pressures

Operating 230 psig.

Peak 293 psig.

Electrical Data:

Normal Voltage 115VAC – 60Hz

Start Winding Resistance 21.20 Ω (at 77°F) ± 8%

Run Winding Resistance 7.90 Ω (at 77°F) ± 8%

Locked Rotor Amperage (60Hz) 9.80 Amps.

Full Load Amperage (60Hz) 1.20 Amps

Check Point Data:

Test Conditions: @115V - 60Hz (Evaporator Temp.-10°F / Condensing

Temp.130°F)

Cooling Capacity ± 5% 275 Btu/h 81 Watts

Power Consumption ± 5% 75 Watts

Current Consumption ± 5% 0.98 Amps

16

Page 16

THERMISTER RESISTANCE READING

Using a Cup of Water (full of ice) at 32°F , place the Thermister in the water and

you should read approximately 7353 Ω’s.

DEG. F RESISTANCE

25 8989

26 8732

27 8483

28 8242

29 8009

30 7783

31 7556

32 7353

33 7148

34 6949

35 6756

36 6570

37 6389

38 6213

39 6043

40 5879

41 5719

42 5564

43 5414

44 5269

45 5127

46 4990

47 4858

48 4729

49 4604

50 4482

51 4365

52 4250

53 4140

54 4032

55 3927

56 3826

57 3727

58 3632

59 3538

60 3449

61 3361

62 3276

DEG. F RESISTANCE

63 3153

64 3113

65 3035

66 2959

67 2865

68 2814

69 2744

70 2676

71 2610

72 2546

73 2484

74 2424

75 2365

76 2308

77 2252

78 2198

79 2145

80 2084

81 2044

82 1996

83 1948

84 1902

85 1856

86 1814

87 1772

88 1731

89 1690

90 1651

91 1613

92 1576

93 1540

94 1505

95 1471

96 1437\

97 1405

98 1373

99 1342

100 1312

17

Page 17

Solenoid Valve / Evaporator Fan

FEATURES: Direct acting solenoid

valve, designed to shut off refrigerating

media.

MOUNTING: Vertical with coil

upwards preferred. During welding the

central part of the body must not exceed

100° C.

VALVE: Medium temperature from

10° C to + 90° C. Opening time 20 ms –

closing time 20ms.

COIL: Voltage tolerance +10% --15%.

Compartment and Evaporator

Thermister Location.

18

Page 18

VCWB300 WIRING SCHEMATIC

19

Page 19

VCWB300 WIRING DIAGRAM

20

Page 20

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

A. Warm temperature

in all Wine storage

compartments.

2. Unit in Showroom Adjust set-points and listen

Mode for compressor and condenser

3. Unit Recently Energized Allow 24 hours for unit to

pull down.

4. Unit Recently Stocked Instruct customer.

5. High Room Ambient Instruct customer that unit

performs best between 60°F /

15°C --90°F / 32°C.

6. Door Ajar

a. Wine rack obstruction a. Adjust wine rack.

b. Door out of adjustment b. See door adjustment

procedures (See page 11)

in this manual.

c. Door or cabinet hinge c. Check hinges. Replace if

problem. defective.

7. Evaporator Fan Circuit

Fault

functioning. page 14)

b. Only one compartment b1. Check wiring from the

evaporator fan not control module to the

operating. evaporator fan.

(E3 pin # 12 – compartment #1,

E3 pin #13 – compartment #2,

E3 pin #14 – compartment #3)

1. Control set too warm Check set-points. Adjust set-

points colder.

fan operation. If they do not

energize, switch unit OFF then

press and hold upper

compartment colder & warmer

keys while pressing unit On/OFF

key.

a. Evaporator fans in all a. Check for 115VAC input

compartments not to the control module. (See

21

Page 21

TROUBLESHOOTING GUIDE (con’t)

PROBLEM POSSIBLE CAUSE CORRECTION

A. Warm temperature

In all Wine Storage the motor windings of the

Compartments.

pages 14 and 19).

or malfunctioning. and electrical connections.

back to compressor. Check

for 115VAC from compressor

to motor. Reconnect or repair

wires or replace motor if

defective.

or malfunctioning. 15 and 16). Check electrical

connections back to control

board. Replace defective com ponent or repair wiring. Check

for 115VAC from the control

board. Correct any wiring

problems or replace compressor

components if defective. If no

power from control board.

replace control board.

b. Compressor inefficient b. For Compressor specifications,

electrical inputs and output

(See page 16).

c. Compressor locked c. (See page 16).

B. Warm Temperature

in only one wine

storage compartment.

3. Unit Recently Stocked a. Instruct customer

with Wine.

4. High Room Ambient a. Instruct customer that unit

performs best between 60°F /

16°C -- 90°F / 32°C.

inoperative fan motor (See

b2 Check for continuity across

8. Condenser Air / Flow

Condenser Fan Fault

a. Dirty condenser a. Clean condenser

b. Condenser fan blade b. Check fan blade. Tighten or

loose or obstructed. remove obstruction.

c. Fan motor disconnected c. Check fan motor operation.

9. Compressor Fault

a. Compressor electrical a. Check integrity of compressor

components disconnected electrical components (See page

1. Control Set too Warm a. Check set-points. Adjust set-

points.

2. Unit Recently Energized a. Allow time for unit to pull down.

22

Page 22

TROUBLESHOOTING GUIDE (con’t)

PROBLEM POSSIBLE CAUSE CORRECTION

5. Door Ajar a. (See page 21)

6. Evaporator Thermistor

Fault. a. (See page 17)

7. Condenser Air / Con-

denser Fan Fault. a. (See page 22)

8. Check Thermistors a. (See E4 checks, page 15)

9. Refrigerant Valve

Solenoid Fault

a. Solenoid disconnected a. (See solenoid checks page 14)

or malfunctioning.

10. Sealed System leak or

Restriction a. (See compressor data page 16)

C. Product Temperature is actually 10

or more colder than

displayed

temperature.

D. Cold Temper- 1. Control Set too cold a. Check set-points. Adjust setature in all Wine

Storage

Compartments 2. Door Ajar

b. Door out of adjustment b. See door adjustment page 13.

3. Control Set too Cold a. Check set-points. Adjust set points WARMER.

E Cold Temperatures

In only one Wine

Storage Compartment

procedures (See page 11) in

this manual.

OK, replace control board.

1. Compartment a. Check thermistor ohms (See

°

Thermistor Fault page 15 and 17). Replace if

defective. If thermistors are

point Warmer.

a. Wine rack obstruction a. Adjust wine rack

c. Door or cabinet hinge c. Check hinges. Replace if

problem. defective.

4. Room Temperature

Below Set-Point a. Instruct Customer

1. Door Ajar

a. Wine rack Obstruction a. Adjust wine rack.

b. Door out of adjustment b. See door adjustment

23

Page 23

TROUBLESHOOTING GUIDE (con’t)

PROBLEM POSSIBLE CAUSE CORRECTION

2. Refrigerant Valve a. Initiate manual valve activation

Solenoid Fault, mode on opposite

Stuck Open suspected. Toggle to evaporator

temp readings associated with

suspected valve to verify it is

closed. If it is open, check

solenoid electrical connections

to make sure they are not

crossed. Unplug solenoid to

see if valve closes. If valve

closes, replace solenoid. If valve

does not close, replace valve.

3. Room Temperature

Below Set-Point a. Instruct customer.

F. 1. “Extremely”

Cold Temperatures

Displayed (3

2. If outside US –

Could be “Extremely” 2. If Outside US – Control 2. Initiate temperature units

Warm Temperatures

Displayed (38° to 65°) heit but Customer Celsius units of measure.

Thought it was Celsius.

G. Lights Stay on in 1. Lights Switched “On” 1. Press & release lights On/Off

Either Wine Storage

Compartments. 2. Fan and Light Switch 2. Check wiring at fan & light

Wiring Crossed switch, and at control board.

Rewire if incorrect.

3. Light Switch 3. Press & release lights On/Off

Malfunction key, then depress light switch.

Repeat steps. If no effect,

H. Lights will not

Energize in One or

All Wine Storage they work, replace defective

Compartments

3. Light Switch Discon- 3. Check light switch operation

nected of Malfunction- and electrical connections.

ing. Check for 115VAC to and from

Switch. reconnect wires or

Replace switch if defective.

°

1. Control Set to Display 1. Initiate temperature units

Celsius but Customer selection mode and select

to 18°) Thought it was Fahrenheit units of measure.

Fahrenheit.

Set to Display Fahren- selection mode and select

100% key.

replace switch.

1. Unit in Holiday Mode 1. Press & release unit On/Off key.

2. Light Burned Out 2. Plug in known good lights. If

lights.

valve as that

24

Page 24

TROUBLESHOOTING GUIDE (con’t)

PROBLEM POSSIBLE CAUSE CORRECTION

4. No Power from 4. Check E15 to ground (See

Control Board page 14).

I. Control Panel

Keys Inoperative or Cable Plugged in cable (silver area on the ribbon

Malfunctioning

facing away from the control

board). Plug in correctly if

Incorrect.

2. Control Panel or Ribbon 2. Check E2 test points page 14.

Cable Defective (Or)

No Signal Read at

Control Board.

J. LED’s Do Not

Illuminate.

Plugged in Wrong. in correctly if incorrect.

3. No Data from Control 3. Replace control board.

Board.

K. All LED’s Stay

Illuminated. Board.

L. Same Segment(s)

Missing From All Board.

Display Windows

M. Segment(s) MissIng From Only one Control Panel.

Display Window.

N. Door or Unit

2. LED Ribbon Cable 2. Check LED ribbon cable. Plug

1. Control Panel Ribbon 1. Check control panel ribbon

Wrong cable terminal should be

1. Unit Switched Off 1. Press unit On/Off key

1. Bad Data from Control 1. Replace control board.

1. Bad Data from Control 1. Replace control board.

1. Bad LED Board in 1. Replace control panel assembly.

1. See Page 12 this Manual 1. See page 12 this manual.

25

Loading...

Loading...