Page 1

Project Name

Item No.

Quantity

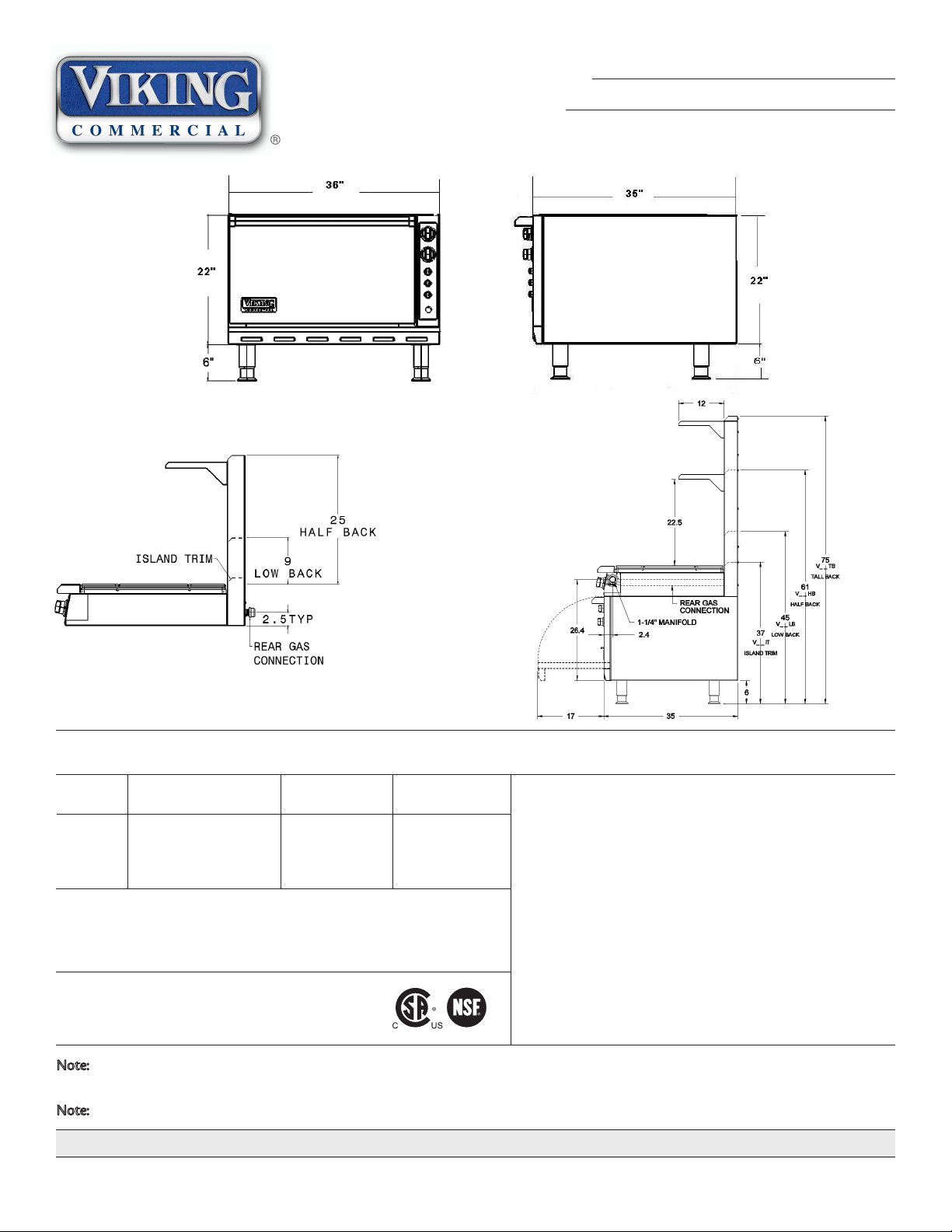

Convection Oven Modular Base

SPECIFICATION

Heavy Duty ermostatically Controlled Convection Oven

36” wide to be used as support base for cooktops, worktops or

stacked oven. Viking Convection ovens are indirect fired. No

flue gasses enter the oven cavity. Oven interior to be stainless

steel with a two piece cast iron oven bottom and stainless steel

removable drip tray. Oven doors are counterweighted: no door

springs requiring replacement. Oven cavity size allows sheet pan

to be front to rear or side to side.

Exterior bottom is insulated for cooler floor temperatures. No

damage to poured floors.

Unit to have stainless steel front, sides and welded steel frame.

Gas supply is interconnected from top mounted cooktop.

Convection Motor has 2 speed settings which varies with the

oven product load.

Integrated “backward curved” cooling fan and impeller made

of corrosion resistant material, producing uniform air velocity

and high static efficiency. It is quiet, dynamically balanced, and

does not require scroll housing.

Permanent split capacitor motor in compact external rotor

motor design, with high efficiency, long life ball bearing, and

class F motor insulation system.

Integrated mounting bracket made of corrosion resistant

and lightweight material, with limited points of conduction for

improved cooking.

STANDARD FEATURES

30,000 Btu Oven Burner with standing pilot

Indirect Fired Design– No flue gasses in cavity

Pilot Safety Valve in cool zone

Two speed fan motor

150 to 550 degree thermostat in cool zone

#304 Stainless Steel Insulated Exterior Oven Bottom

Two piece cast iron interior oven bottom

Four position Rack supports

Two Heavy Duty Chrome plated Racks

Zamak Die Cast Knobs with set screws

Stainless Steel front and sides

Welded Body construction

Hinged Kick Plate

Counterweighted Oven Door

Heavy Duty Integral Riser Mount

Adjustable Legs 6” high with plate mounting

OPTIONS

Stainless Steel Back P

Porcelain Oven Interior P

Rear Gas Connection P

6” High Swivel Casters, 2 with brakes P

6” High Adjustable casters with 1” adjustment P

Double Stacked Ovens (see product specification shee P t)

V36CO

Note: All Viking units are modular. Rangetops are separate units and have separate model numbers from bases. To complete a range there

must be a base item added, such as oven, cabinet base, refrigerated base or legs.

Example: A 6 burner range with oven would be a V36B6 plus a V36SO

Viking Range Corporation, Commercial Division 1511-C E. Orangethorpe Ave. Fullerton, California 92831 (877) 307-8877 vikingcommercial.com

page 1 of 2

Page 2

Project Name

Item No.

UTILITY INFORMATION

Model Description Gas [BTU/HR] Approx SHP WT

V36CO Convection Oven Base 30,000 525 lb

V36COP Convection Oven Base

with porcelain interior

30,000 525 lb

GAS: Each unit to have a 1¼” front manifold that couples

to adjacent equipment or is capped on ends. A 1” male NPT

rear gas connection may be used for a gas supply or capped

if supply is from adjacent unit(s). Minimum gas supply is 6”

W.C. for natural gas and 11” W.C. for propane. Operating

Pressure is 5” W.C. for natural gas and 10” for propane at the

manifold. All units require a regulated gas supply (pressure

ELECTRICAL: 120 Volt, single phase, 60 cycle

regulator must be ordered as an option).

For standard oven see separate spec sheet.

ELECTRICAL: No electrical requirements for top modules.

Only convection oven base or refrigerated base requires

electricity.

Specify type of gas when ordering.

Specify altitude when above 2000 ft.

EXHAUST: Installation under an exhaust hood is

required.

Note: When used as counter units, the Tall Back risers/shelves are not available. Tall backs are for units with oven or cabinet base only. Viking

Commercial products are not approved or recommended for residential use.

Note: In line with company policies, Viking Range Corporation reserves the right to change material and specifications without notice.

Viking Range Corporation, Commercial Division 1511-C E. Orangethorpe Ave. Fullerton, California 92831 (877) 307-8877 vikingcommercial.com

REV. 03/2010

page 2 of 2

Loading...

Loading...