Page 1

Viking Installation Guide

Viking Range Corporation

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-VIKING1 (845-4641)

or visit the Viking Web site at

vikingrange.com

F20518A EN

Professional Built-In Gas

Thermal-Convection Ovens

(091108J)

Page 2

Table of Contents

DANGER

WARNING

CAUTION

IMPORTANT

–Please Read and Follow

Warnings & Important Safety Information _______________________________________________3

Dimensions (30”W.) __________________________________________________________________6

Specifications (30”W.) ________________________________________________________________7

Dimensions (36”W.) __________________________________________________________________8

Specifications (36”W.) ________________________________________________________________9

Cutout Dimensions (30”W.) __________________________________________________________10

Cutout Dimensions (36”W.) __________________________________________________________11

Clearance Dimensions ______________________________________________________________12

Electrical & Gas Requirements _______________________________________________________12

General Information ________________________________________________________________14

Installation (30”W.)__________________________________________________________________15

Door Removal (30”W.)___________________________________________________________15

Connecting Gas & Electrical (30”W.) ______________________________________________16

Final Installation (30”W.) _________________________________________________________17

Door Replacement & Adjustment (30”W.)__________________________________________18

Installation (36”W.)__________________________________________________________________19

Door Removal (36”W.)___________________________________________________________19

Connecting Gas & Electrical (36”W.) ______________________________________________20

Final Installation (36”W. Single) ___________________________________________________21

Final Installation (36”W. Double) __________________________________________________22

Optional Center Trim Installation (36”W. Double) ___________________________________24

Door Replacement & Adjustment (36”W.)__________________________________________24

Final Preparation ___________________________________________________________________25

Performance Checklist ______________________________________________________________26

Service & Registration _______________________________________________________________27

• Before beginning, please read these

instructions completely and carefully.

• DO NOT remove permanently affixed

labels, warnings, or plates from product.

This may void the warranty.

• All local and national codes and ordinances

must be observed. Installation must

conform with local codes or in the absence

of codes, the National Fuel Gas Code ANSI

Z223.1 NFPA54-latest edition.

• The installer must leave these instructions

with the consumer who should retain for

local inspector’s use and for future

reference.

In Canada: Installation must be in accordance

with the current CAN/CGA B149.1 & 2 Gas

Installation codes and/or local codes. Electrical

installation must be in accordance with the

current CSA C22.1 Canadian Electrical Codes

Part 1 and/or local codes.

In Massachusetts: All gas products must be

installed by a “Massachusetts” licensed

plumber or gasfitter. A “T” type handle

manual valve must be installed in the gas

supply line to the appliance.

Your safety and the safety of others is

very important.

We have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that

can kill or hurt you and others.

All safety messages will be preceded by

the safety alert symbol and the word

“DANGER,” “WARNING” or “CAUTION.”

These words mean:

Hazards or unsafe practices

which WILL result in severe personal

injury or death

Hazards or unsafe practices

which COULD result in severe personal

injury or death

Hazards or unsafe practices which

COULD result in minor personal injury or

property damage

All safety messages will identify the

hazard, tell you how to reduce the chance

of injury, and tell you what can happen if

the instructions are not followed.

3

Page 3

DANGER

DANGER

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

IMPORTANT

–Please Read and Follow

Fire/explosion hazard.

IF THE INFORMATION IN

THIS MANUAL IS NOT

FOLLOWED EXACTLY, A

FIRE OR EXPLOSION MAY RESULT

CAUSING PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

• DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

–DO NOT try to light any appliance.

–DO NOT touch any electrical switch.

–DO NOT use any phone in your

building.

–Immediately call your gas supplier from

a neighbor’s phone.

–Follow the gas supplier’s instructions.

–If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be

performed by a qualified installer, service

agency, or the gas supplier.

Chemical hazard.

To avoid risk of property

damage and/or personal injury

or death; this appliance is not

to be used as a heating source.

• Benzene is a chemical which is part of

the gas supply to this cooking product,

which is consumed in the flames during

combustion. Exposure to a small

amount of benzene is possible if a gas

leak occurs. Formaldehyde and soot are

by-products of incomplete combustion.

• This appliance contains or produces

chemicals which can cause serious

injury or death and which are known to

the state of California to cause cancer,

birth defects or other reproductive harm.

To reduce the risk from substances in

the fuel or from fuel combustion make

sure this appliance is installed,

operated, and maintained in accordance

to the instructions in this document.

Moving hazard.

To avoid risk of severe

personal injury; this appliance

requires two or more personnel

while handling and moving. Possible

use of appliance moving devices is

recommended.

DO NOT use the handle or oven door to

lift the oven. Remove door before

installation to ensure that it is

not used to lift the unit.

NEVER use this appliance as a space

heater to heat or warm the room. Doing

so may result in carbon monoxide

poisoning and overheating of the oven.

Gas leak hazard.

To avoid risk of personal injury

or death; leak testing of the

appliance must be conducted

according to the manufacturer’s

instructions. Before placing appliance in

operation, always check for gas leaks

with soapy water solution.

• DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

The use of cabinets for storage above

the oven may result in potential

fire or burn hazard.

The misuse of the oven door(s) (e.g.

stepping, sitting, or leaning on them)

can result in hazards or injuries and

damage to the product.

Electrical shock hazard.

To avoid risk of electrical shock,

personal injury or death; verify

your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

No attempt should be made to operate

the appliance during power failure.

4

5

Page 4

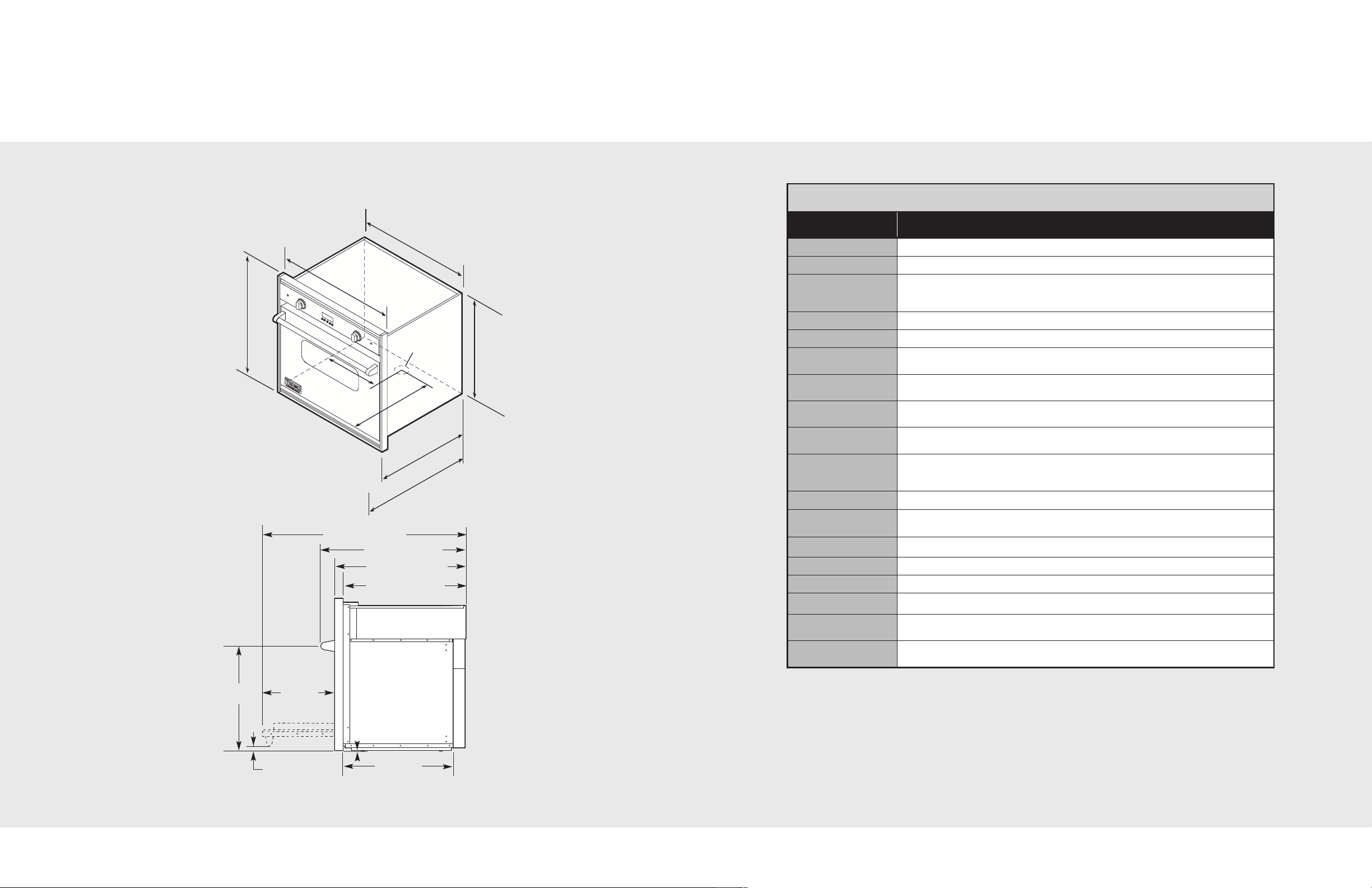

Dimensions (30”W.)

2

4

-

7

/

8

”

(

6

3

.

2

c

m

)

2

1

-

5

/

1

6

”

(

5

4

.

1

c

m

)

1

3

-

1

/

4

”

(

3

3

.

7

c

m

)

2

7

-

3

/

8

”

(

6

9

.

5

c

m

)

2

6

-

7

/

8

”

(

6

8

.

3

c

m

)

2

9

-

1

/

2

”

(

7

4

.

9

c

m

)

3

0

-

1

/

2

”

(

7

7

.

5

c

m

)

Gas inlet

3

1

”

(

7

8

.

7

c

m

)

18-5/8”

24-7/8” (63.2 cm)

27-3/8” (69.5 cm)

43-1/2” (110.5 cm)

(47.3 cm)

1/8”*

(.3 cm)

17-3/16”

(43.6 cm)

1/2”

(1.3 cm)

23-1/2 ” (60.0 cm)

Gas inlet

21-5/16”

(54.1 cm)

Specifications (30”W.)

Built-In 30”W. Gas Oven

Description

Overall width

Built-In 30“W. Gas Oven

VGSO100

29-1/2” (74.9 cm)

Overall height 31” (78.7 cm)

Overall depth from

rear

To edge of door—24-7/8” (63.2 cm)

To end of handle bracket—27-3/8” (69.5 cm)

With door open—43-1/2” (110.5 cm)

Cutout width 28-5/8” (72.7 cm)

Cutout height 30-5/8” (77.8 cm)

Cutout depth 24” (61.0 cm) min.; unit extends into cutout 23-7/8” (60.6 cm); cord protrudes 1/2”

(1.3 cm) beyond 23” (58.4 cm)

Cutout height

from floor

17” (43.2 cm) min.

Gas requirements Shipped natural or LP/Propane gas; LP must be specified after color code; accepts

standard residential 1/2” (1.3 cm) ID gas service line.

Gas manifold

pressure

Electrical

requirements

120 VAC/60 Hz 4 ft. (121.9 cm) 3-wire cord with grounded 3-prong plug attached to

product. Flexible cord/connector must be 1/2” ID (1.3 cm). Cord must be agency

Natural 5.0” W.C.P. / Liquid propane L/P 10.0” W.C.P.

approved for use with household gas ovens.

Maximum amp usage 8.0 amps

Infrared broil

18,000 BTU Nat. (5.3 kW)

burner rating

Bake burner rating

Oven interior width

Oven interior height

Oven interior depth

Oven volume Total oven capacity—4.0 cu. ft.

Approximate

shipping weight

*Note: The AHAM Stadard for measuring oven capacity subtracts the door plug and convection baffle

dimension from the total oven volume.

One 30,000 BTU Nat./LP (8.8 kW)

23” (58.4 cm)

16-1/8” (40.9 cm)

15-3/8” (39.1 cm)

AHAM Standard 3.3 cu. ft.*

310 lbs. (139.5 kg)

*Note: Bottom of cutout to bottom of trim–used for installing warming drawer below oven.

6

7

Page 5

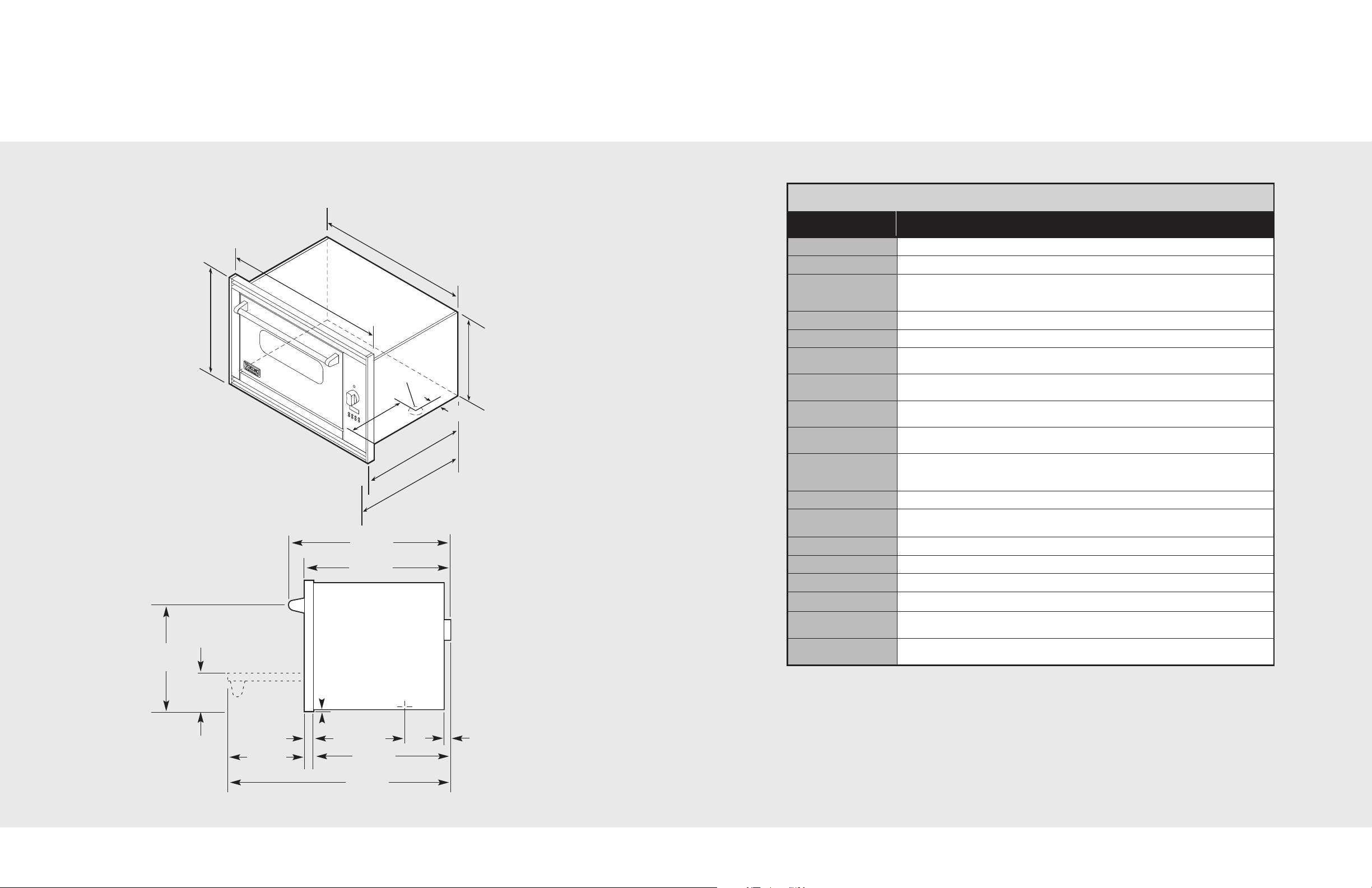

Dimensions (36”W.)

2

7

-

3

/

8

”

(

6

9

.

5

c

m

)

3

3

-

3

/

4

“

(

8

5

.

7

c

m

)

1

1

-

7

/

8

“

(

3

0

.

2

c

m)

3

5

-

1

/

4

”

(

8

9

.

5

c

m

)

2

3

”

(

5

8

.

4

c

m

)

2

2

-

1

/

2

”

(

5

7

.

2

c

m

)

2

5

-

1

/

4

”

(

6

4

.

1

c

m

)

2

-

1

/

8

“

(

5

.

4

c

m

)

Gas inlet

39-7/8”

(101.3 cm)

1/4”*

(.6 cm)

27-3/8”

(69.5 cm)

25-1/4”

(64.1 cm)

5-13/16”

(14.8 cm)

1-3/8”

(3.5 cm)

14-5/8”

(37.1 cm)

23-7/8”

(60.6 cm)

Gas inlet

11-7/8”

(30.2 cm)

2”

(5.1 cm)

19-3/16”

(48.7 cm)

Specifications (36”W.)

Built-In 36”W. Gas Oven

Description

Overall width

Overall height 23” (58.4 cm)

Overall depth from

rear

Cutout width 33-7/8” (86.0 cm)

Cutout height 22-5/8” (57.5 cm)

Cutout depth 24” (61.0 cm) min.; unit extends into cutout 23-7/8” (60.6 cm); cord protrudes 1/2”

Cutout height

from floor

Gas requirements Shipped natural or LP/Propane gas; LP must be specified after color code; accepts

Gas manifold

pressure

Electrical

requirements

Maximum amp usage 8.0 amps

Infrared broil burner

rating

Bake burner rating

Oven interior width

Oven interior height

Oven interior depth

Oven volume Total oven capacity—3.6 cu. ft.

Approximate

shipping weight

*Note: The AHAM Stadard for measuring oven capacity subtracts the door plug and convection baffle

Built-In 36“W. Gas Oven

VGSO166

35-1/4” (89.5 cm)

To edge of door—25-1/4” (64.1 cm)

To end of handle bracket—27-3/8” (69.5 cm)

With door open—39-7/8” (101.3 cm)

(1.3 cm) beyond 23” (58.4 cm)

17” (43.2 cm) min.

standard residential 1/2” (1.3 cm) ID gas service line.

Natural 5.0” W.C.P. / Liquid propane L/P 10.0” W.C.P.

120 VAC/60 Hz 4 ft. (121.9 cm) 3-wire cord with grounded 3-prong plug attached to

product. Flexible cord/connector must be 1/2” ID (1.3 cm). Cord must be agency

approved for use with household gas ovens.

18,000 BTU Nat. (5.3 kW)

15,000 LP (4.4 kW)

Two 15,000 BTU Nat./LP (4.4 kW) (each)

24-1/8” (61.3 cm)

13-3/4” (34.9 cm)

17-1/8” (43.5 cm)

Measure to AHAM standards 3.3 cu. ft.*

257 lbs. (115.7 kg)

dimension from the total oven volume.

*Note: Bottom of cutout to bottom of trim–used for installing warming drawer below oven.

8

9

Page 6

Electrical outlet

to be located in

shaded area on

rear wall

2

4

”

(

6

1

.

0

c

m

)

m

i

n

.

24”

(61.0 cm) min.

2

4

”

(

6

1

.

0

c

m

)

m

i

n

.

3

3

-

7

/

8

”

(

8

6

.

0

c

m

)

D

i

m

e

n

s

i

o

ns

s

am

e

as

b

e

l

o

w

Dimensions same

as below

D

i

m

e

n

s

i

o

ns

s

am

e

as

b

e

l

o

w

3

”

(

7

.

6

c

m

)

d

i

a

.

2

-

1

/

8

”

(

5

.4

c

m

)

2

2

-

5

/8

”

(

5

7

.

5

c

m

)

2

-

1

/2

”

(

6

.

4

c

m

)

2-1/2”

(6.4 cm)

2

-

1

/2

”

(

6

.

4

c

m

)

1

7

”

(

4

3

.

2

c

m

)

m

i

n

.

3

0

”

(

7

6

.

2

c

m

)

R

e

c

o

m

m

e

n

d

e

d

Electrical outlet

to be located in

shaded area on

rear wall

2

4

”

(

6

1

.

0

c

m

)

m

i

n

.

24”

(61.0 cm) min.

2

4

”

(

6

1

.

0

c

m

)

m

i

n

.

3

3

-

7

/

8

”

(

8

6

.

0

c

m

)

3

”

(

7

.

6

c

m

)

d

i

a

.

2

-

1

/

8

”

(

5

.

4

c

m

)

2

2

-

5

/

8

”

(

5

7

.

5

c

m

)

1

1

-

7

/

8

”

(

3

0

.

2

c

m

)

3

”

(

7

.

6

c

m

)

3

-

1

/

2

”

(

8

.

9

c

m

)

3-1/2”

(8.9 cm)

3

-

1

/

2

”

(

8

.

9

c

m

)

1

7

”

(

4

3

.

2

c

m

)

m

i

n

.

3

0

”

(

7

6

.

2

c

m

)

R

e

c

o

m

m

e

n

d

e

d

3

”

(

7

.

6

c

m

)

3

-

1

/2

”

(

8

.

9

c

m

)

3-1/2”

(8.9 cm)

3

-

1

/2

”

(

8

.

9

c

m

)

Gas inlet

location

Gas inlet

location

Gas inlet

location

1

1

-

7

/

8

”

(

3

0

.

2

c

m

)

Gas inlet

location

Gas inlet

location

Gas inlet

location

Cutout Dimensions (30”W.)

2

4

”

(

6

1

.

0

c

m

)

m

i

n

.

1

-

1

/

2

”

(

3

.

8

c

m

)

3

”

(

7

.

6

c

m

)

d

i

a

.

1

4

-

1

/

4

”

(

3

6

.

2

c

m

)

3

0

-

5

/

8

”

(

7

7

.

8

c

m

)

Electrical outlet to be located

in shaded area on rear wall

Gas inlet

location

3

”

(

7

.

6

c

m

)

2

8

-

5

/

8

”

(

7

2

.

7

c

m

)

2

1

-

5

/

1

6

”

(

5

4

.

1

c

m

)

1

7

”

(

4

3

.

2

c

m

)

m

i

n

.

3

0

”

(

7

6

.

2

c

m

)

R

e

c

o

m

m

e

n

d

e

d

Cutout Dimensions (36”W.)

30”W. Cutout

10

36”W. Single

Cutout

Installation Options:

36”W. Double

Cutout

Double Stack: Use IKD-VGSO kit or DCT-VGSO-SS center trim (sold seperately).

Double Side-by-side: Repeat single cutout with 1-1/2” (3.8 cm) min. between openings.

11

Page 7

CAUTION

Clearance Dimensions

CAUTION

CAUTION

WARNING

Electrical & Gas Requirements (cont.)

Note: Door handle of oven should be 36”

(91.4 cm) above the floor.

Note: The grounded electrical socket should

be placed above or below cutout(s).

To prevent possible damage to cabinets

and cabinet finishes, use only moisture

resistant materials and finishes that will

withstand temperature up to 190°F

(88°C). When cabinets are covered with

laminates, an appropriate heat-resistant

adhesive must be used. Consult your

manufacturer for proper specifications.

in a potential burn hazard. Combustible

items may ignite, metallic items may

become hot and cause burns.

Burn hazard.

To avoid risk of personal injury;

the use of cabinets for storage

above the appliance may result

Electrical & Gas Requirements

Electrical Requirements

Check your national and local codes

regarding this unit. These ovens require

3-wire, 120 VAC/60 Hz. See “Connecting

Gas & Electrical” section for grounding

instructions.

Electrical shock hazard.

To avoid the risk of electrical

shock, personal injury or death;

verify electrical power is turned

off at the breaker box and gas supply is

turned off until the oven is installed and

ready to operate, installation by an

authorized installer only.

These ovens are designed specifically for

natural gas or liquid propane (LP) gas. It is

shipped from the factory adjusted for use

with natural or propane (LP) gas. Before

beginning installation verify that the

model is compatible with the intended

gas supply.

Manual shut-off valve:

This installer-supplied valve must be installed

in the gas service line before the appliance

in the gas stream and in a location where it

can be reached quickly in the event of

an emergency.

In Massachusetts: A “T” handle type

manual valve must be installed in the gas

supply line to the appliance.

Pressure Regulator:

• All heavy-duty, commercial type cooking

equipment must have a pressure regulator

on the incoming service line for safe and

efficient operation, since service pressure

may fluctuate with local demand. External

regulators are not required on this oven

since a regulator is built into each unit at

the factory. Under no condition bypass

this built-in regulator.

• Manifold pressure should be checked with

a manometer, natural gas requires 5.0”

W.C.P. and LP gas requires 10.0” W.C.P.

Incoming line pressure upstream from the

regulator must be 1” W.C.P. higher than

the manifold pressure in order to check

the regulator. The regulator used on these

ovens can withstand a maximum input

pressure of 1/2” PSI (14.0” W.C.P.). If the

line pressure is in excess of 1/2” PSI

(14.0” W.C.P.), a step down regulator

will be required.

• The appliance must be disconnected from

the gas supply piping system during any

pressure testing of that system.

Flexible Connections:

If the unit is to be installed with flexible

couplings and/or quick-disconnect fittings,

the installer must use a heavy-duty AGA

design-certified flexible connector of at least

1/2” (1.3 cm) ID NPT (with suitable strain

reliefs) in compliance with ANSI Z21.41

and Z21.69.

Rigid Connections:

30”W.

• Incoming gas from the service supply is

brought from an intake pipe (not supplied)

to the back center of the unit through the

shut-off valve (not supplied) to the

regulator. (See “Cutout Dimensions”

section for gas inlet location.)

36”W.

•

Incoming gas is brought from an intake

pipe (not supplied) to the lower right

center of the unit to the pressure

regulator. The only connection

necessary is from the service supply,

through the shut-off valve (not supplied)

to this intake pipe (not supplied) to the

regulator.

section for gas inlet location.)

(See “Cutout Dimensions”

In Canada: CAN 1-6, 10-88 metal

connectors for gas appliances and CAN

1-6.9 M79 quick disconnect devices for use

with gas fuel.

In Massachusetts: This appliance must be

installed with a 36” (3-foot) long flexible

gas connector.

Before placing the oven into operation,

always check for gas leaks with a soapy

water solution or other acceptable

method. DO NOT USE AN OPEN FLAME

TO CHECK FOR LEAKS.

Gas Connection

The gas supply (service) line must be the

same size or greater than the inlet line of the

appliance. This oven uses a 1/2” (1.3 cm) ID

NPT (Sch40) inlet. Sealant on all pipe joints

must be resistive to LP gas.

IMPORTANT: Any conversion required

must be performed by your dealer or a

qualified licensed plumber or gas service

company. Please provide the service person

with this manual before work begins.

12

13

Page 8

2

1

2

3

2

2

1

4

5

NOTICE

1

Door Removal (30”W.)

NOTICE

General Information

READ AND FOLLOW ALL WARNING

AND CAUTION INFORMATION WHEN

INSTALLING THIS APPLIANCE.

• All openings in the wall behind the

appliance or in the floor under the

appliance should be sealed.

• Keep appliance area clear and free from

combustible materials, gasoline and other

flammable vapors.

• Disconnect the electrical supply prior to

servicing or cleaning.

• When removing the appliance for cleaning

or service, disconnect AC power supply

and carefully remove the appliance by

pulling forward.

• Electrical requirements are listed in the

product specifications under the “Electrical

& Gas Requirements” section.

Recommendations for Unpacking

• Products are shipped on pallets with foam

footings and corrugated inner-packing and

exterior hoods.

• Products are anchored to the pallet using

metal straps that are screwed to the

bottom of the product and the pallet.

• DO NOT remove protective packaging

until you are ready to perform the

installation.

• To remove the packaging, first remove the

staples located at the bottom perimeter of

the corrugated cover.

• Remove the corrugated cover by lifting it

off the product and remove the innerpacking.

• Detach the product from the metal anchor

strip by removing the attachment screw.

Installation (30”W.)

DO NOT use the handle or oven door to

lift the oven. Remove door before

installation to ensure that it is not used to

lift the unit. DO NOT lift or carry the door

by the handle.

Removing the door must be done by your

dealer, a qualified licensed plumber, or

certified gas installer.

Remove wooden brace on front of pallet.

• Do not obstruct the flow of combustion and

ventilation air.

Moving, Handling, and Unpacking

Remove and discard all packing materials,

including cardboard and tape on the outside

and inside of the ovens.

Some stainless steel parts may have a plastic

protective wrap which must be peeled off.

The interior should be washed thoroughly

with hot, soapy water to remove film

residues and any dust or debris before being

used, then rinsed and wiped dry. Solutions

stronger than soap and water are rarely

needed.

Recommendations for Moving

• The appliance is heavy – use extreme care

when handling!

DO NOT use the handle or oven door to

lift the oven. Remove door before

installation to ensure that it is not used to

lift the unit. DO NOT lift or carry the door

by the handle.

Removing the door must be done by your

dealer, a qualified licensed plumber, or

certified gas installer.

• Only proper equipment should be used to

move products.

• ALWAYS take steps to protect flooring at

the installation location when moving

products.

Open door completely. Place pin in pin hole.

Note: Two pins included.

Close until pins stop door.

Remove hinge trim screws. Take off hinge trim.

Lift door up and out.

Note: Do not lift door using handle.

14

15

Page 9

1

2

3

4

5

6

Note: Refer to “Electrical & Gas

Requirements” section for proper

installation information.

Connecting Gas & Electrical (30”W.)

DANGER

WARNING

1

Final Installation (30”W.)

Gas leak hazard.

To avoid risk of personal injury

or death; leak testing of the

appliance must be conducted

according to the manufacturer’s

instructions. Before placing appliance in

operation, always check for gas leaks

with soapy water solution.

• DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

Electrical shock hazard.

To avoid the risk of electrical

shock, personal injury or death;

verify your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

Remove racks.

Unscrew pallet screws from side of oven.

Connect gas and electrical. Before placing appliance in

operation, always check for gas leaks. This must be

performed by your dealer, a qualified licensed plumber,

or gas service company.

16

Lift oven into position.

Attach screws to the side of the framing.

Note: Four screws (two on each side).

(Screws not included.)

Push oven straight into cabinet.

Replace racks.

17

Page 10

1

2

2

20°

1

2

3

NOTICE

1

2

3

4

Door Replacement & Adjustment (30”W.)

CAUTION

Replace door.

Open door completely. Reinstall hinge trim plates.

Note: Screw holes may need to be re-aligned.

Door Removal (36”W.)

Installation (36”W.)

DO NOT use the handle or oven door to

lift the oven. Remove door before

installation to ensure that it is not used to

lift the unit. DO NOT lift or carry the door

by the handle.

Removing the door must be done by your

dealer, a qualified licensed plumber, or

certified gas installer.

Open door approximately 20°, then slowly pull upward

until the door stop pops out of door socket.

To avoid risk of personal injury or property

damage, verify door stops are engaged

before removing door.

Take out pins.

Note: To adjust door turn adjustment screw

clockwise (up) or counterclockwise (down).

18

Close door.

Gently close until the door rests against one of the stop

notches.

Slide door completely from hinge arms.

19

Page 11

123

456

1

Note: Refer to “Electrical & Gas

Requirements” section for proper

installation information.

Connecting Gas & Electrical (36”W.)

DANGER

WARNING

Final Installation (36”W. Single)

Gas leak hazard.

To avoid risk of personal injury

or death; leak testing of the

appliance must be conducted

according to the manufacturer’s

instructions. Before placing appliance in

operation, always check for gas leaks

with soapy water solution.

• DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

Electrical shock hazard.

To avoid the risk of electrical

shock, personal injury or death;

verify your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

Lift oven into position.

Push oven straight into cabinet.

Connect gas and electrical. Before placing appliance in

operation, always check for gas leaks. This must be

performed by your dealer, a qualified licensed plumber,

or gas service company.

20

Remove all knobs, push buttons, and bezels on the

right control panel.

Insert four wood screws, (included with the oven),

through the cabinet side flange into the cabinet.

Remove lower access panel, side trim, and

control panel.

Replace lower access panel, side trim, and

control panel.

21

Page 12

7

8

1

3

2

9

10

Connect gas line and check

for leaks.

11

12

1

2

2

1

3

3

2

1

3

4

1

2

5

6

Final Installation (36”W. Double)

Note: Purchase necessary gas kit – IKD-VGSO.

Final Installation (36”W. Double) (cont.)

Install upper oven as described on page 21, “Final

Installation” (36”W. single).

Remove access panel from oven side and

pipe plug from pipe tee.

Place bottom oven on a protected area near the

cabinet. Remove 2” hole knockout from oven top.

Attach male connector to pipe tee. Feed flex tubing

through 2” hole and attach to the male connector.

Remove all knobs, push buttons, bezels, and lower

access panel, side trim, and control panel.

Attach 8” pipe nipple through lower oven cabinet to

upper oven pipe tee. Attach female connector to pipe

nipple. Attach flex tubing to female connector.

Remove control box, disconnecting the

three harness connectors.

Replace access panel.

22

Push lower oven straight into cabinet.

Reconnect three harness connectors and

replace control box.

Replace side trim, control panel, lower

access panel, control panel knobs,

push buttons, and bezels.

23

Page 13

Optional Center Trim Installation (36”W. Double)

option

1

option

2

1

3

1

2

2

Note: With purchase of DCT-VGSO-SS center trim kit.

Install mounting brackets.

Insert center trim piece over mounting brackets.

Door Replacement & Adjustment (36”W.)

Final Preparation

1. Some stainless steel parts may have a

plastic protective wrap, which must be

peeled off. All stainless steel body parts

should be wiped with hot soapy water

and with liquid cleaner designed for this

material. If build-up occurs, do not use

steel wool, abrasive cloths, cleaners or

powders! If it is necessary to scrape

stainless steel to remove encrusted

materials, soak with hot, wet cloths to

loosen the material, then use a wood or

nylon scraper. DO NOT use a metal knife,

spatula, or any other metal tool to scrape

stainless steel! Scratches are almost

impossible to remove.

2. The interior of the oven should be washed

thoroughly with hot, soapy water to

remove film residues and installation

debris before being used for food

preparation, then rinsed and wiped dry.

Solutions stronger than soapy water are

rarely needed.

Place door onto hinge arms.

Pull door stops up and slowly slide door down.

24

25

Page 14

Performance Checklist

OVEN

LIGHT

OVEN FUNCTION

OFF

BAKE

SET

OVEN

BROIL

CONV.

BROIL

CONV.

BAKE

TEMPERATURE

OFF

400

200

300

500

BROIL

MIN/SEC

TIMER

BAKE

TIMER

START

TIME

CLOCK

OVENOVEN

LIGHTLIGHT

OFFOFF

BROILBROIL

CANCELCANCEL

CLOCKCLOCK

TIMERTIMER

COOKCOOK

TIMETIME

BROILBROIL

HI/LOWHI/LOW

DOWNDOWN

BAKEBAKE

TEMPTEMP

UPUP

BAKEBAKE

CONVECTIONCONVECTION

BAKEBAKE

CONVECTIONCONVECTION

BROILBROIL

Electronic

Timing Center

Electronic

Timing Center

Off/On

Indicator light

Interior

Oven Light Control

Temperature

Control

Oven Function Selector

Oven Function Selector

Oven Light Button

VGSO100

VGSO166

Service & Registration

A qualified installer should carry out the

following checks:

1. Check oven bake function–bake burner on

full power. Tubular bake burner should

reignite on both sides. Convection bake

function–bake burners the same with the

convection fan on.

2. Check oven broil function–infrared broil

screen should glow. Covection broil function

is the same with convection fan on.

3. Check air shutter adjustment; sharp blue

flame, no yellow tipping, no sooting, no

flame lifting.

4. Check for gas leaks (odor) at all gas

conversions.

5. Check convection fan switch and fan

operation.

6. Check light switch and light operation.

7. Check for proper fit of door seals.

Only authorized replacement parts may be used in performing service on the appliance.

Do not repair or replace any part of the appliance unless specifically recommended in the

manual. All servicing should be referred to a qualified technician.

Contact Viking Range Corporation, 1-888-VIKING1 (854-4641), for the nearest service parts

distributor in your area or write to:

VIKING RANGE CORPORATION

PREFERRED SERVICE

1803 Hwy 82W

Greenwood, Mississippi 38930 USA

VGSO100—The serial number and model

number for your appliance can be found by

opening the door and looking under the

control panel.

VGSO166—The serial number and model

number for your appliance can be found by

opening the door and looking under the

top trim.

Service Codes – VGSO166

The Time/Temperature digital display is

designed to alert you if there is an error or

problem in the control. If one of the following

codes occur, disconnect the electrical supply to

the oven and contact an authorized servicer.

F1- Shorted probe

F2- Open probe

F3- Controller malfunction

Record the following information indicated below. You will need it if service is ever required.

Model number ____________________________________________________________________________________

Serial number _____________________________________________________________________________________

Date of purchase __________________________________________________________________________________

Date installed ______________________________________________________________________________________

Dealer's name _____________________________________________________________________________________

Address ___________________________________________________________________________________________

26

These installation instructions should remain with the unit for future reference.

27

Loading...

Loading...