Page 1

Viking Installation Guide

Viking Range Corporation

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-VIKING1 (845-4641)

or visit the Viking Web site at

vikingrange.com

F20508

Professional Freestanding

30” Electric Range

(020808J)

Page 2

Table of Contents

DANGER

WARNING

CAUTION

DANGER

WARNING

WARNING

IMPORTANT

–Read and Follow!

Warnings & Important Safety Instructions _______________________________________________3

Dimensions _________________________________________________________________________4

Specifications _______________________________________________________________________5

Clearance Dimensions (Proximity to Cabinets) ___________________________________________6

Clearance Dimensions (Wood/Composite Overlay) ______________________________________7

Electrical Requirements ______________________________________________________________8

General Information__________________________________________________________________9

Installation_________________________________________________________________________10

Door Removal ______________________________________________________________10

Leg Installation______________________________________________________________11

Electrical Connection (3-wire) _________________________________________________12

Electrical Connection (4-wire) _________________________________________________14

Leveling/Adjustments/Alignment ______________________________________________16

Anti-tip Device Installation____________________________________________________17

Final Installation _____________________________________________________________18

Door Replacement and Adjustment ___________________________________________20

Final Preparation ___________________________________________________________________21

Performance Checklist ______________________________________________________________21

Service & Registration _______________________________________________________________22

• Before beginning, please read these

instructions completely and carefully.

Your safety and the safety of others is

very important.

We have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that

can kill or hurt you and others.

All safety messages will be preceded by

the safety alert symbol and the word

“DANGER,” “WARNING” or “CAUTION.”

These words mean:

Hazards or unsafe practices

which WILL result in severe personal

injury or death

Hazards or unsafe practices

which COULD result in severe personal

injury or death

• The installer must leave these instructions

with the consumer who should retain for

local inspector’s use and for future reference.

In Canada: Installation must be in accordance

with the current CSA C22.1 Canadian

Electrical Codes Part 1 and/or local codes.

Electrical shock hazard.

To avoid risk of electrical shock,

personal injury or death; verify

your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

Moving hazard.

To avoid risk of severe

personal injury; this appliance

requires two or more personnel while

handling and moving. Possible use of

appliance moving devices is recommended.

Hazards or unsafe practices which

COULD result in minor personal injury or

property damage.

All safety messages will identify the

hazard, tell you how to reduce the chance

of injury, and tell you what can happen if

the instructions are not followed.

• Do not remove permanently affixed labels,

warnings, or plates from product. This may

void the warranty.

• All local and national codes and ordinances

must be observed. Installation must

conform with local codes.

2

top left corner of the range.

• THIS RANGE CAN TIP.

• INJURIES TO PERSONS CAN RESULT.

• INSTALL ANTI-TIP DEVICE PACKED

WITH RANGE.

• SEE INSTALLATION INSTRUCTIONS.

3

Tipping hazard.

To reduce the risk of the

appliance tipping, it must be

secured by a properly installed

anti-tip bracket(s). To make sure

the bracket has been installed

properly, look behind the range

with a flashlight to verify proper

installation engaged in the rear

Page 3

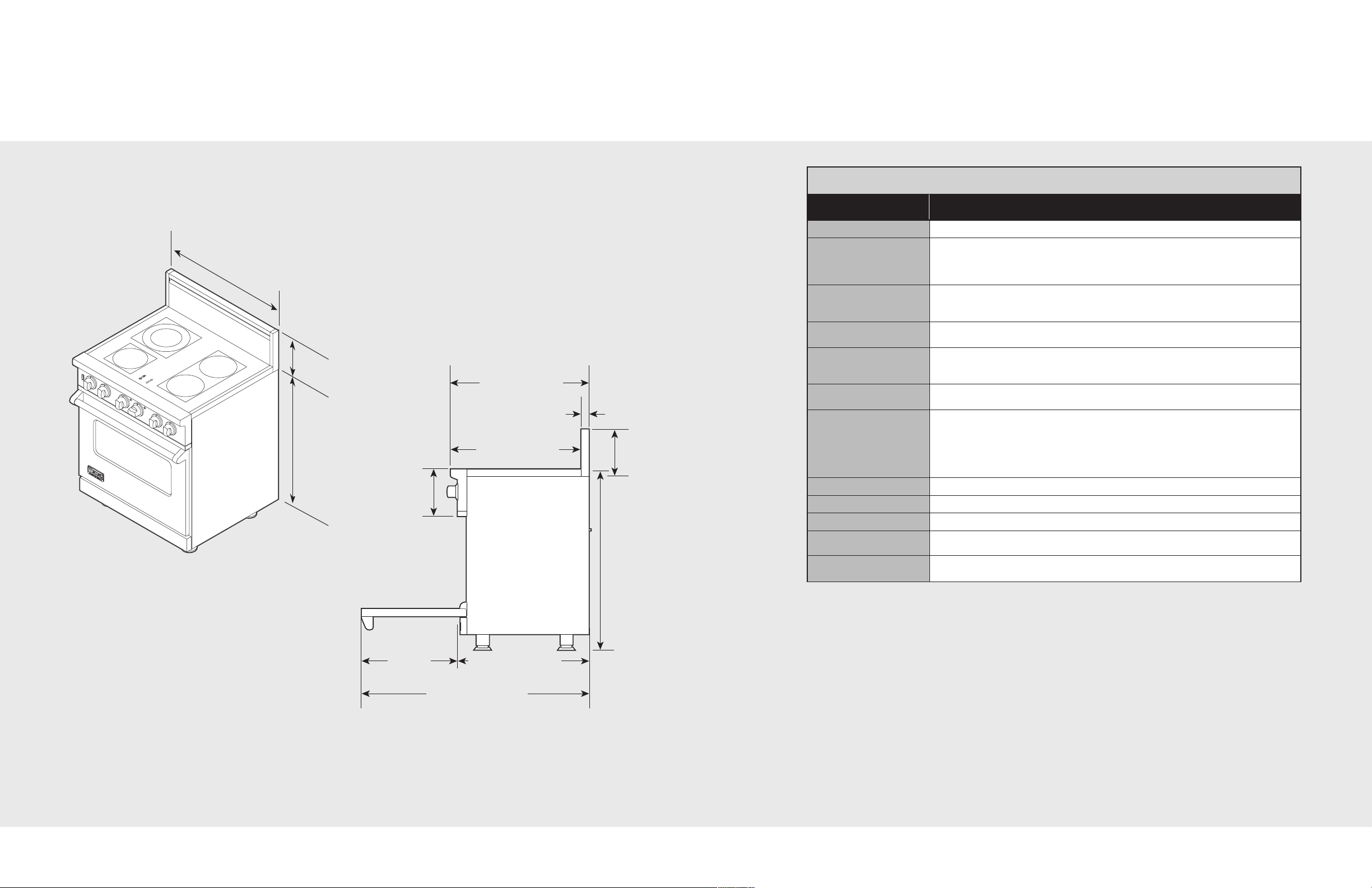

Dimensions

2

9

-

7

/

8

”

(

7

5

.

9

c

m

)

3

5

-

7

/

8

”

(

9

1

.

1

c

m

)

m

i

n

.

t

o

3

7

”

(

9

4

c

m

)

m

a

x

.

8

”

(

2

0

.

3

c

m

)

*

25-3/4” (65.4 cm)

45-1/8” (114.6 cm)

19-3/8”

(49.2 cm)

8-1/8” (20.6 cm)

26-7/16” (67.2 cm)

1-5/8”

(4.1 cm)

8”

(20.3 cm)

35-7/8”

(20.3 cm) min.

to

37”

(94 cm) max.

28-1/16” (71.2 cm)

Specifications

Electric 30” Range

*Note: Unit shown with standard 8” (20.3 cm) backguard.

Electric 30” Range

Description

Overall width

Overall height To top of glass frame

Overall depth from

rear

Additions to base

height

Electrical

requirements

Maximum amp usage 240V—59.0 amps

Surface element rating

Left front

Left rear (dual element)

Right front

Bridge

Right rear

Oven interior width

Oven interior height

Oven interior depth

Oven volume Total oven capacity—4.7 cu. ft.

Approximate

shipping weight

Minimum clearances from adjacent combustible construction

• Cooking surface and below, i.e., 36” (91.4 cm) and below

o Sides—0”

o Rear—0” with backguard or highshelf;0” with island trim and noncombustible rear wall; 6” (15.2 cm) with island

trim and combustible rear wall.

• Above cooking surface, i.e. above 36" (91.4 cm)

o Sides—6” (15.2 cm)

o Within 6” (15.2 cm) side clearance, wall cabinets no deeper than 13” (33.0 cm) must be minimum 18” (45.7 cm)

above cooking surface.

o Wall cabinets directly above product must be minimum 36” (91.4 cm) for open top burners above cooking surface.

240-208 VAC, 60 Hz electrical connection box on product, connect with locally

supplied 3-wire, flexible cord or “pigtail” rated 60 amp 125-250 VAC minimum.

Cord must be agency approved for use with household electric ranges.

To end of side panel—24-5/16” (61.8 cm)

To end of landing ledge—28-1/16” (71.3 cm)

To end of door handle—28-11/16” (72.9 cm)

To top of island trim—add 1-1/4” (3.2 cm)

To top of high-shelf—add 23-1/2” (59.7 cm)

AHAM 16-13/16” (42.7 cm) Overall—19-1/2” (49.5 cm)

Measure to AHAM standards 4.1 cu. ft.

VESC530-4B

29-7/8” (75.9 cm)

35-7/8” (91.1 cm) min.

37” (94.0 cm) max.

Legs adjust 1-1/8” (2.9 cm)

208V—51.3 amps

1,500 watts

2,500 watts/1000 watts

1,800 watts

800 watts

1,800 watts

25-5/16” (64.6 cm)

16-1/2” (41.9 cm)

426 lbs. (193.2 kg)

4

5

Page 4

4

2

”

m

in

.

(

1

0

6

.

7

c

m

)

1

3

”

m

a

x

.

(

3

3

.

0

c

m

)

6

”

m

in

.

(

1

5

.

2

c

m

)

1

8

”

m

in

.

(

4

5

.

7

c

m

)

3

/

8

”

(

0

.

9

5

c

m

)

3

6

”

(

9

1

.

4

c

m

)

2

9

-

7

/

8

”

(

7

5

.

9

c

m

)

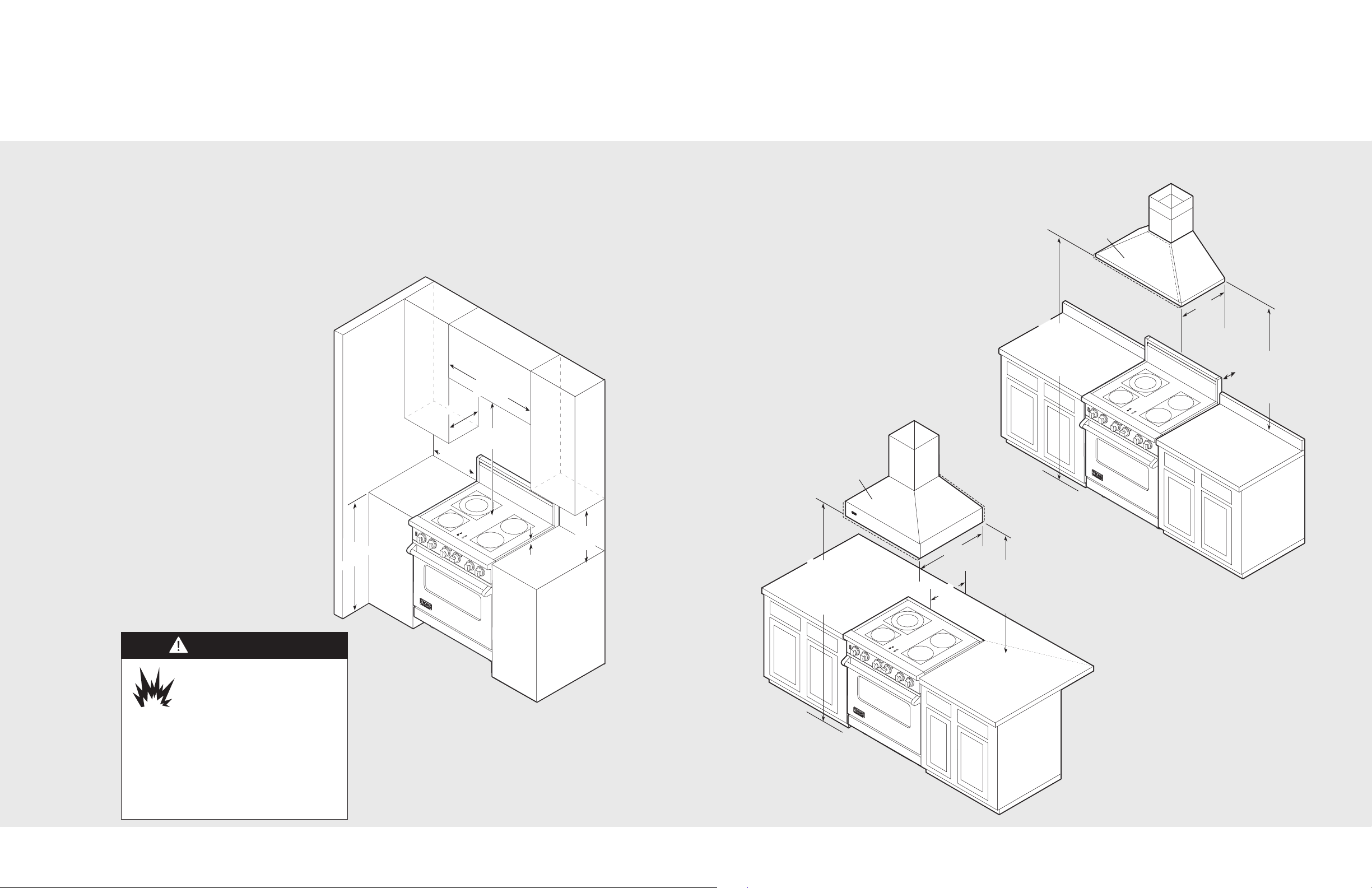

Clearance Dimensions (Proximity to Cabinets)

6

6

”

m

in

.

(

1

6

7

.

6

c

m

)

t

o

7

2

”

m

a

x

.

(

1

8

2

.

9

c

m

)

6

6

”m

in

.

(

1

6

7

.

6

c

m

)

t

o

7

2

”m

a

x

.

(

1

8

2

.

9

c

m

)

2

4

”

(

6

1

.

0

c

m

)

o

r

2

7

”

(

3

8

.

6

c

m

)

3

0

”

(

7

6

.

2

c

m

)

6

”

(

1

5

.

2

c

m

)

W

o

o

d

/

C

o

m

p

o

si

t

e

O

v

e

r

l

a

y

W

o

o

d

/

C

o

m

p

o

si

t

e

O

v

e

r

l

a

y

3

0

”m

in

.

(

7

6

.

2

c

m

)

t

o

3

6

”m

a

x

.

(

9

1

.

4

c

m

)

0

”

(

0

c

m

)

3

0

”

m

in

.

(

7

6

.

2

c

m

)

t

o

3

6

”

m

a

x

.

(

9

1

.

4

c

m

)

CAUTION

Clearance Dimensions (Wood/Composite Overlay)

• This range may be installed directly

adjacent to existing 36” (91.4 cm) high

base cabinets.

IMPORTANT: The side trim MUST be

3/8” (.95 cm) above the adjacent base

cabinet countertop. This can be

accomplished by raising the unit using

the adjustment spindles on the legs.

• Wall cabinets above the range must be a

minimum of 42” (106.7 cm) above the

range cooking surface for the full width

of the range. This minimum height

requirement does not apply if a range

hood is installed over the cooking surface.

The bottom of a standard hood should be

30” (76.2 cm) min. to 36” (91.4 cm) max.

above the countertop. This would typically

result in the bottom of the hood being

66” (167.6 cm) to 72” (182.9 cm) above the

floor. Refer to the range hood installation

instructions for additional information. These

dimensions provide for safe and efficient

operation of the hood.

• The range CANNOT be installed

directly adjacent to sidewalls, tall

cabinets, tall appliances, or other

side vertical surfaces above 36”

(91.4 cm) high. There must be a

minimum of 6” (15.2 cm) side

clearance from the range to such

combustible surfaces above the

36” (91.4 cm) counter height.

• Within the 6” (15.2 cm) side

clearance to combustible vertical

surfaces above 36” (91.4 cm), the

maximum wall cabinet depth

must be 13” (33.0 cm) and wall

cabinets within this 6” (15.2 cm)

side clearance must be 18”

(45.7 cm) above the 36”

(91.4 cm) high countertop.

Burn hazard.

To avoid risk of personal injury;

Wall Installation

Note: Minimum clearance for back wall

is 0” with backguard or high-shelf.

the use of cabinets for storage

in a potential burn hazard. Combustible

items may ignite, metallic items may

become hot and cause burns. If a cabinet

storage is to be provided the risk can be

above the appliance may result

reduced by installing a rangehood that

projects horizontally a minimum 5” (12.7 cm)

beyond the bottom of cabinets.

Note: Minimum clearance for back wall is 0” with

backguard or high-shelf.

Note: 6” (15.2 cm) min. with island trim and

Note: If a range hood is installed, wall cabinets

above the range have a different minimum

Island Installation

combustible rear wall. 0” with island trim

and non-combustible rear wall.

clearance height.

6

7

Page 5

Electrical Requirements

Electrical

connection

in this area

4-3/8”

(11.1 cm)

6”

(15.2 cm)

6”

(15.2 cm)

WARNING

General Information

Electrical Requirements

Check your national and local codes

regarding this unit. This range requires

3 wire or 4 wire, 240-208 VAC/60 Hz. See

“Electrical Connection” section for

grounding instructions. Must be fused

seperately from any other circuit.

Electric 30” Range

Electrical shock hazard.

To avoid the risk of electrical

shock, personal injury or death;

verify electrical power is turned

off at the breaker box until the range is

installed and ready to operate, installation

by an authorized installer only.

READ AND FOLLOW ALL WARNING

AND CAUTION INFORMATION WHEN

INSTALLING THIS APPLIANCE.

• All openings in the wall behind the

appliance and in the floor under the

appliance must be sealed.

• DO NOT obstruct the flow of combustion

and ventilation air.

Moving, Handling, and Unpacking

Remove and discard all packing materials,

including cardboard and tape on the outside

and inside of the range.

Range – Do not discard the anti-tip

metal bracket supplied with the

range. This is the anti-tip device and

must be installed with the unit. Refer

to “Anti-tip Device Installation”

section.

Some stainless steel parts may have a plastic

protective wrap which must be peeled off.

The interior should be washed thoroughly

with hot, soapy water to remove film

residues and any dust or debris before being

used, then rinsed and wiped dry. Solutions

stronger than soap and water are rarely

needed.

8

9

Page 6

1

1

1

2

3

2

2

4

3

CAUTION

1

2

3

4

Installation

To avoid risk of personal injury or product

damages, DO NOT use the handle or

oven door to lift the oven. Remove door

before installation to ensure that it is not

used to lift the unit. DO NOT lift or carry

the door by the handle.

Removing the door must be done by your

dealer, or a qualified licensed plumber.

Door Removal

Leg Installation

Legs are packed in styrofoam top pack.

Note: Legs should be installed near to where

appliance is to be used, as they are

not secure for long transit.

Note: It is strongly recommended

that a pallet or lift jack be used rather than tilting.

Raise unit about a foot.

couplings on all four corners

Unscrew temporary legs from

.

Open door completely. Place pins,

supplied with unit, in pin hole. For personal safety,

ONLY use pins supplied with the unit.

Remove hinge trim screws. Take off hinge trim. Identify

right and left hinge for future re-installation.

Screw legs into couplings on all

four corners.

Lower range gently to keep any undue strain from

legs and internal mounting hardware.

Close until pins stop door.

10

Lift door up and out.

11

Page 7

1

2

4

1

1

3

5

1

2

6

2

1

1

Electrical Connection (3-wire)

3

2

1

2

WARNING

WARNING

3

Note: If you have a 4-wire connection, see following section for

4-wire connection instructions.

Electrical shock hazard.

To avoid risk or electrical

shock, personal injury or death;

grounding product to the frame

of the unit may or may not be permitted

through your local codes. If ground to the

frame is not permitted then a 4 conductor

power cord must be used.

Use a 3-wire power supply cord kit rated for

60 amps – 125/250 volts with closed loop

terminals and marked for use with ranges.

DO NOT use a GFI circuit. Where local

codes do not permit grounding through

neutral, use a 4-wire power supply cord. The

cord or conduit must be secured to the

range with the strain relief bracket.

Electrical shock hazard.

To avoid risk of electrical shock,

personal injury or death; verify

your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

Attach line #1 (red) and line #2 (black)

leads to outside terminal. Attach neutral wire (white)

to center terminal on the terminal block.

Push supply cord toward terminal

block to relieve strain, reattach supply cord strain

relief bracket over supply cord.

The electrical connection is made at the

terminal block, which is located behind the

access door on the back of the range.

Remove access door.

Reattach access door.

Remove supply cord strain relief

bracket and three supply cord mounting screws

on terminal block.

12

Feed supply cord up through hole in bottom

of range back.

13

Page 8

4

1

2

5

1

2

6

1

1

3

7

1

2

8

2

1

1

3

2

1

2

Electrical Connection (4-wire)

WARNING

WARNING

2

1

3

Electrical shock hazard.

To avoid risk or electrical

shock, personal injury or death;

grounding product to the frame

of the unit may or may not be permitted

through your local codes. If ground to the

frame is not permitted then a 4 conductor

power cord must be used.

Use a 4-wire power supply cord kit rated for

60 amps – 125/250 volts with closed loop

terminals and marked for use with ranges.

DO NOT use a GFI circuit. Where local

codes do not permit grounding through

neutral, use a 4-wire power supply cord. The

cord or conduit must be secured to the

range with the strain relief bracket.

The electrical connection is made at the

terminal block, which is located behind the

access door on the back of the range.

Electrical shock hazard.

To avoid risk of electrical shock,

personal injury or death; verify

your appliance has been

properly grounded in accordance with

local codes or in absence of codes, with

the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

Remove access door.

Feed supply cord up through hole in bottom

of range back.

Attach line #1 (red) and line #2 (black)

leads to outside terminal. Attach neutral wire (white)

to center terminal on terminal block.

Attach ground lead (green)

with ground screw that was removed.

Push supply cord toward terminal

block to relieve strain, reattach supply cord strain

relief bracket over supply cord.

Remove supply cord strain relief

bracket and three supply cord mounting screws

on the terminal block.

14

Remove grounding screw. Cut-off

and discard ground strap.

Reattach access door.

15

Page 9

1

(

A)

(

A)

2

(

A

)

(A)

+

1

/

2

”

+1/2”

(

1

.

3

c

m

)

(1.3 cm)

(

A

)

+

1

/

2

”

(

1

.

3

c

m

)

3

-

5

/

8

”

3-5/8”

(

9

.

2

c

m

)

(9.2 cm)

3

-

5

/

8

”

(

9

.

2

c

m

)

3

7

1

2

3

3

/

8

”

3/8”

(

0

.

9

5

c

m

)

(0.95 cm)

3

/

8

”

(

0

.

9

5

c

m

)

4

Leveling/Adjustments/Alignment

5

6

1

2

1

WARNING

Measure the four corners in cutout area to

verify if flooring is level.

Move unit into opening.

For uneven or sloped floors, level unit with

metal shims only, as the adjustment required may

exceed the thread available in the leg.

Check that unit is level side to

side and front to back. Side trim of the high corner

must be 3/8” (0.95 cm) above countertop.

Set the high corner of range so that the top of side trim is

3/8” (0.95 cm) above countertop. Level range to high corner.

Anti-tip Device Installation

Tipping hazard.

To reduce the risk of the appliance

tipping, it must be secured by a

properly installed anti-tip bracket(s).

To make sure the bracket has been

installed properly, look behind the

range with a flashlight to verify

proper installation engaged in the

rear top left corner of the range.

• THIS RANGE CAN TIP.

• INJURIES TO PERSONS CAN RESULT.

• INSTALL ANTI-TIP DEVICE PACKED

WITH RANGE.

• SEE INSTALLATION INSTRUCTIONS.

of the anit-tip opening located on the back of range.

Measure from floor to bottom

This will be measurement (A).

If leveling is required, move unit out of opening.

Lift unit and prop on wood blocks.

16

Locate anti-tip bracket on rear wall with the top left corner at

measurement (A) plus 1/2” (1.3 cm) from the floor and 3-5/8” (9.2 cm)

from where the right side of range (facing range) is to be located.

Mark and drill holes where bracket

will be located.

17

Page 10

3

/

8

”

3/8”

(

0

.

9

5

c

m

)

(0.95 cm)

3

/

8

”

(

0

.

9

5

c

m

)

4

1

Note: Refer to range electrical

requirements section for proper

installation information.

1

2

4

Anti-tip Device Installation

2

3

(cont.)

Attach bracket with

mounting hardware provided.

Final Installation

Check that unit is level side to side

and front to back. The side trim must be 3/8” (0.95 cm)

above countertop. If unit is not level repeat steps 5-7

of “Leveling/Adjustments/Alignment” section.

Connect electrical in shaded area. See the “Electrical

Requirements” section for more information.

Install backguard.

18

Slide range into place. Be sure anti-tip

bracket slides into the anit-tip opening.

19

Page 11

NOTICE

1

1

2

2

3

2

3

4

5

Door Replacement and Adjustment

Final Preparation

Reattach door to range.

Remove pins from hole in hinges.

Open door completely. Reattach hinge trim.

Close door.

• All stainless steel body parts should be

wiped with hot, soapy water and with a

liquid cleaner designed for this material.

If buildup occurs, DO NOT use steel wool,

abrasive cloths, cleansers, or powders!

If it is necessary to scrape stainless steel

to remove encrusted materials, soak with

hot, wet cloths to loosen the material, then

use a wool or nylon scraper. DO NOT use

a metal knife, spatula, or any other

material tool to scrape stainless steel!

Scratches are almost impossible to

remove.

Performance Checklist

A qualified installer should carry out the

following checks:

h

Check top surface elements—glow red

when turned on.

h

Check hot surface indicator lights—glow

red when corresponding element is on.

h

Check oven bake function—bake element

on full power, center and outside broil

elements at partial power.

h

Convection bake function—bake and broil

elements the same with the convection fan

on.

h

Check self-clean function—door will lock

in approximately 30 seconds, the center

and outside broil elements will turn on and

the bake element will turn on at partial

power. Check broil elements through

window to make sure they are on, then

abort self-clean cycle to unlock door.

When conducting performance test,

DO NOT run self-clean cycle for more

than 10 minutes with oven racks inside

oven. This could cause them to discolor

due to the high temperature required

for self-cleaning.

If the door needs to be adjusted, loosen hinge trim screws (see step 2).

Adjust the screws located between the door and kickplate using a 5/32”

hex head allen wrench. After adjustment, tighten hinge trim screws.

20

h

Check TruConvec™ function—TruConvec

element (behind convection fan cover) on

and convection fan on.

h Check HI broil function–both broil

elements at full power.

h

Check LOW broil function—inner broil

element only.

h

Check convection broil function—both

broil elements at full power with convection

fan on.

21

Page 12

Notes

_____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________