Viking F20050 EN Use & Installation Manual

F20500 EN

41010897

(081308J)

Viking Range Corporation

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-VIKING1 (845-4641)

or visit the Viking Web site at

vikingrange.com

Viking Use/Installation Guide

Undercounter/Freestanding Wine Cellars

3

GENERAL INFORMATION

UUnn ppaacckk

1. Remove banding from bottom of carton. Lift carton up and off of the wine cellar

2. Remove all tape and packaging material from the outside and inside of the cabinet.

3. Keep all carton packaging until your wine cellar has been thoroughly inspected and found to be in good condition.

AARREEAA RREEQQUUIIRREEMMEENNTTSS

1. Place unit so the front side will be completely unobstructed to provide proper air flow. The unit may be closed in

on the top and three sides, but the front

MMUUSSTT BBEE

unobstructed for air circulation and proper operation.

Installation should be such that the cabinet can be moved for servicing if necessary.

2. Unit should be in a well ventilated area with temperature above 55°F (13°C) and below 110°F (43°C). Best results

are obtained at temperatures between 65°F (18°C) and 80°F (27°C) for built-in models and 65°F (18°C) and 90°F

(32°C) for freestanding models.

3. Provisions for electricity should be determined before placing unit in proper place.

A

B

C

UUNNDDEERRCCOOUUNNTTEERR CCAABBIINNEETT CCUUTTOOUUTT

IMPORTANT - PLEASE READ AND FOLLOW

••

Before beginning, please read these instructions completely and carefully.

• Do not remove per manently affixed labels, warnings, or plates from the product. This may void the warranty.

• Please observe all local and national codes and ordinances.

• Please ensure that this product is properly grounded.

• The installer should leave these instructions with the consumer who should retain for local inspector’s use and for

future reference.

WARNING

::

TToo rreedduuccee tthhee rriisskk ooff ffiirree,, eelleeccttrriiccaall sshhoo cckk,, oorr iinnjjuurryy wwhheenn uussiinngg yyoouurr wwiinnee cceellllaarr,, ffoollllooww bbaassiicc pprreeccaauuttiioonnss iinncclluuddiinngg tthhee

ffoolllloowwiinngg::

•FOR YOUR SAFETY•

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE. THE FUMES CAN CREATE A FIRE HAZARD OR EXPLOSION.

IItt iiss yyoouurr rreessppoonnssiibbii lliittyy tt oo bbee ssuurree yyoouurr wwiinnee cceellllaarr iiss::

•located so the front is not blocked to restrict incoming or discharge air flow.

•properly leveled.

•located in a well ventilated area.

•connected to the proper kind of outlet, with the correct electric supply and grounding. A 115 volt, 60 Hz, 15 amp

fused electrical supply is required.

NNOOTTEE::

Time delay fuse or circuit breaker is recommended.

•not used by anyone unable to operate it properly.

•used only for its intended purpose.

•properly maintained.

•SAVE THESE INSTRUCTIONS•

SUFFOCATION HAZARD

Remove doors from your old refrigeration unit.

Failure to do so can result in child entrapment,

which can cause death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigeration products are still dangerous,

even if they will sit for “just a few days.” If you are getting rid of your

refrigeration product, please follow the instructions below to help prevent

accidents.

BEFORE YOU THROW AWAY YOUR OLD REFRIGERATION UNIT:

•Take off the doors.

•Leave the shelves in place so that children may not easily climb inside.

PROPER DISPOSAL OF YOUR OLD REFRIGERATION UNIT

2

DANGER

24” W. Models

15” W. Models

*Add 1/4” (.64 cm) to cutout width if door is recessed between

cabinets.

A 15” (38.1 cm)* 24” (61.0 cm)*

B

Min. 34 1/2” (87.6 cm)

Max. 35 1/8” (89.2 cm)

Min. 34 1/2” (87.6 cm)

Max. 35 1/8” (89.2 cm)

C 24” (61.0 cm) 24” (61.0 cm)

UUnn iittss CCeerrttiiffiieedd ffoorr OOuuttddoooorr UUssee -- ((ssttaaiinnlleessss sstteeeell oouutteerr ccaabbiinneett))

1. Place unit so the front side will be completely unobstructed to provide proper air flow. The unit may be closed in

on the top and three sides, but the front

MMUUSSTT BBEE

unobstructed for air circulation and proper operation.

Installation should be such that the cabinet can be moved for servicing if necessary.

2. Unit should be in a well ventilated area with temperature above 40°F (4.4°C) and below 110°F (43°C). Best results

are obtained at temperatures between 60°F (16°C) and 100°F (38°C).

3. Provisions for electricity should be determined before placing unit in proper place.

54

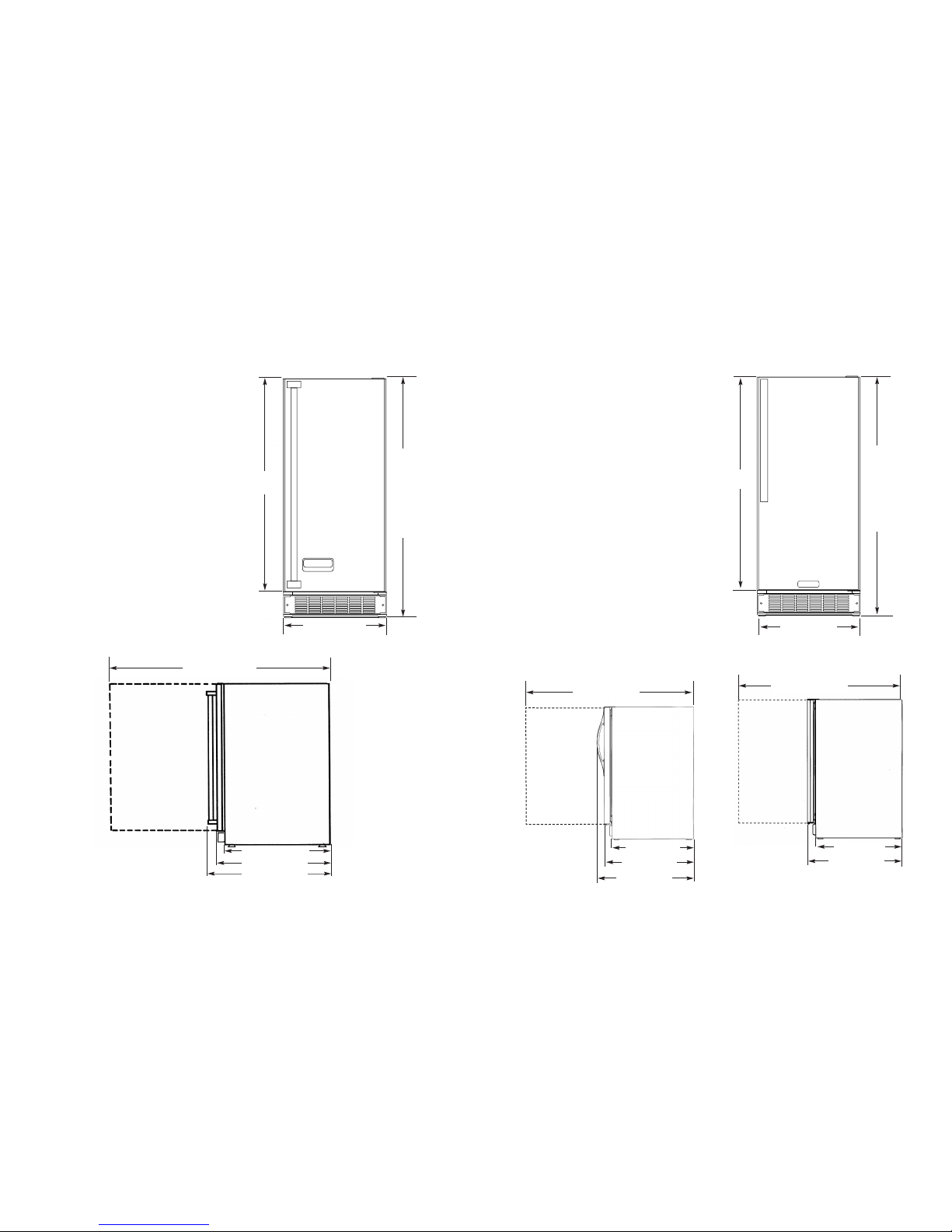

SPECIFICATIONS/DIMENSIONS

PROFESSIONAL - 15” W. Models

BBaassiicc EElleeccttrriicc DDaatta

a

•

115 VAC/60 Hz

•

Maximum amps - 3.0

•

Approximate Shipping Weight - 110 lbs. (49.5 kg)

SPECIFICATIONS/DIMENSIONS

DESIGNER - 15” W. Models

BBaassiicc EElleeccttrriicc DDaatta

a

•

115 VAC/60 Hz

•

Maximum amps - 3.0

•

Approximate Shipping Weight - 110 lbs. (49.5 kg)

Front View

Side View

30 3/4”

(78.1 cm)

Min. 34 1/4”

(87.0 cm)

to

Max. 35”

(88.9 cm)

(with leveling

legs fully

extended.)

14 3/4” (37.5 cm)

21 3/16” (53.8 cm)

23 5/8” (60.0 cm)

26 1/8” (66.4 cm)

37 3/16” (94.5 cm)

Front View

Side View

DUWC

Side View

DFUW

30 3/4”

(78.1 cm)

Min.

34 1/4”

(87.0 cm)

Max.

35”

(88.9 cm)

(with leveling

legs fully

extended.)

14 3/4” (37.5 cm)

21 3/16” (53.8 cm)

23 5/8” (60.0 cm)

24 5/8” ( 62.5 cm)

21 3/16” (53.8 cm)

23 7/16” (59.5 cm)

37 3/16” (94.5 cm)

37 3/16” (94.5 cm)

(to front of locally supplied

custom panel

7

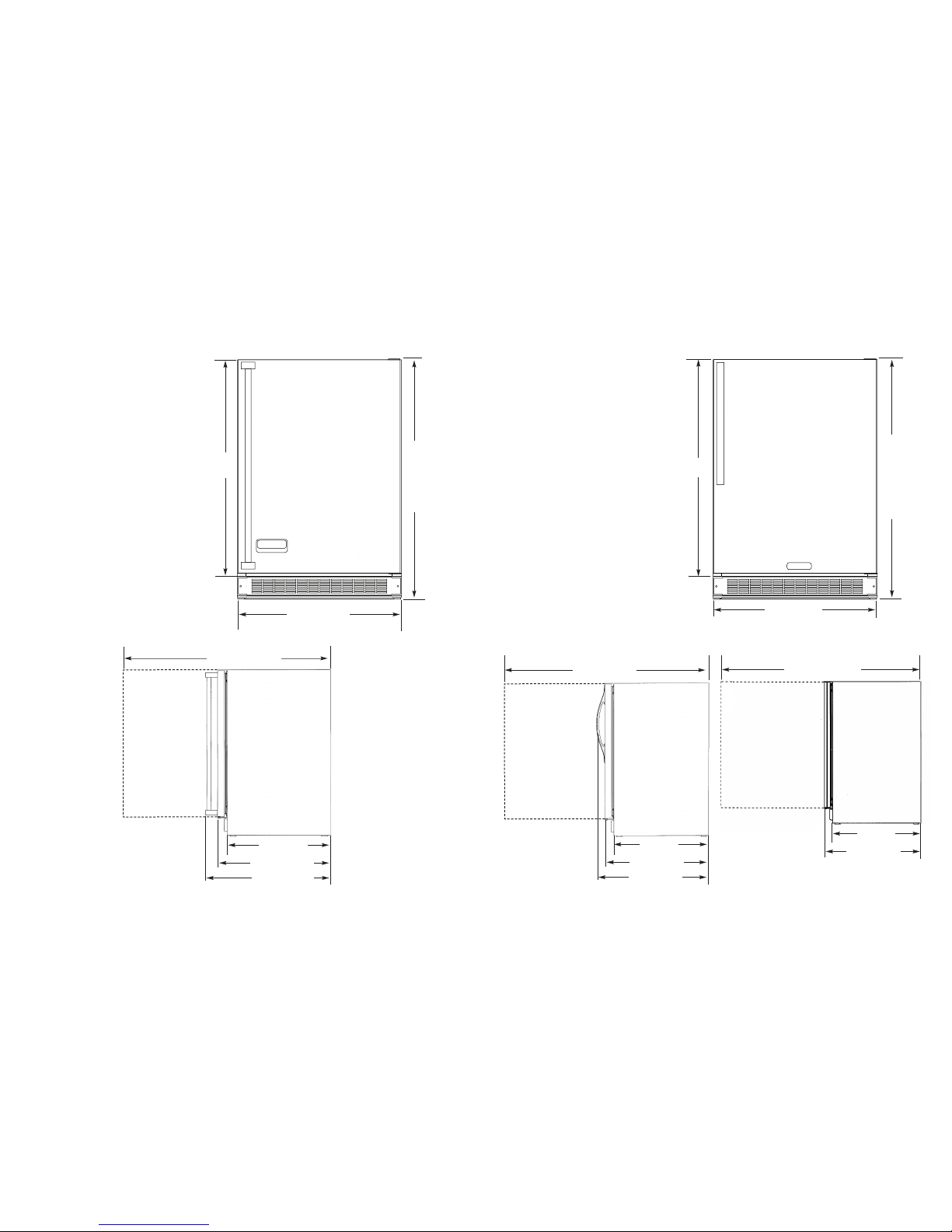

SSPPEECCIIFFIICCAATTIIOONNSS//DDIIMMEENNSSIIOONNSS

DESIGNER - 24” W. Models

BBaassiicc EElleeccttrriicc DDaattaa

•115 VAC/60 Hz

•Maximum amps - 3.3

•Approximate shipping weight - 140 lbs (63.2 kg)

Front View

30 3/4”

(

78.1 cm)

Min.

34 1/4”

(87.0 cm)

M

ax.

35”

(88.9 cm)

with leveling

legs fully

extended

23 7/8” (60.6 cm)

Side View

DUWC

22” (55.9 cm)

24 3/8” (61.9 cm)

25 3/8” ( 64.5 cm)

47 1/4” (120.0 cm)

Side View

DFUW

22” (55.9 cm)

24 3/16” (61.4 cm)

47 1/4” (120.0 cm)

(to front of locally supplied

custom panel

6

SPECIFICATIONS/DIMENSIONS

PROFESSIONAL - 24” W. Models

BBaassiicc EElleeccttrriicc DDaatta

a

•

115 VAC/60 Hz

•

Maximum amps - 3.3

•

Approximate Shipping Weight - 140 lbs. (63.2 kg)

Min. 34 1/4”

(87.0 cm)

t

o

M

ax 35”

(88.9 cm) with

leveling legs

fully

extended

30 3/4”

(78.1 cm)

23 7/8” (60.6 cm)

47 1/4” (120.0 cm)

22” (55.9 cm)

24 3/8” (61.9 cm)

26 7/8” (68.3 cm)

Front View

Side View

98

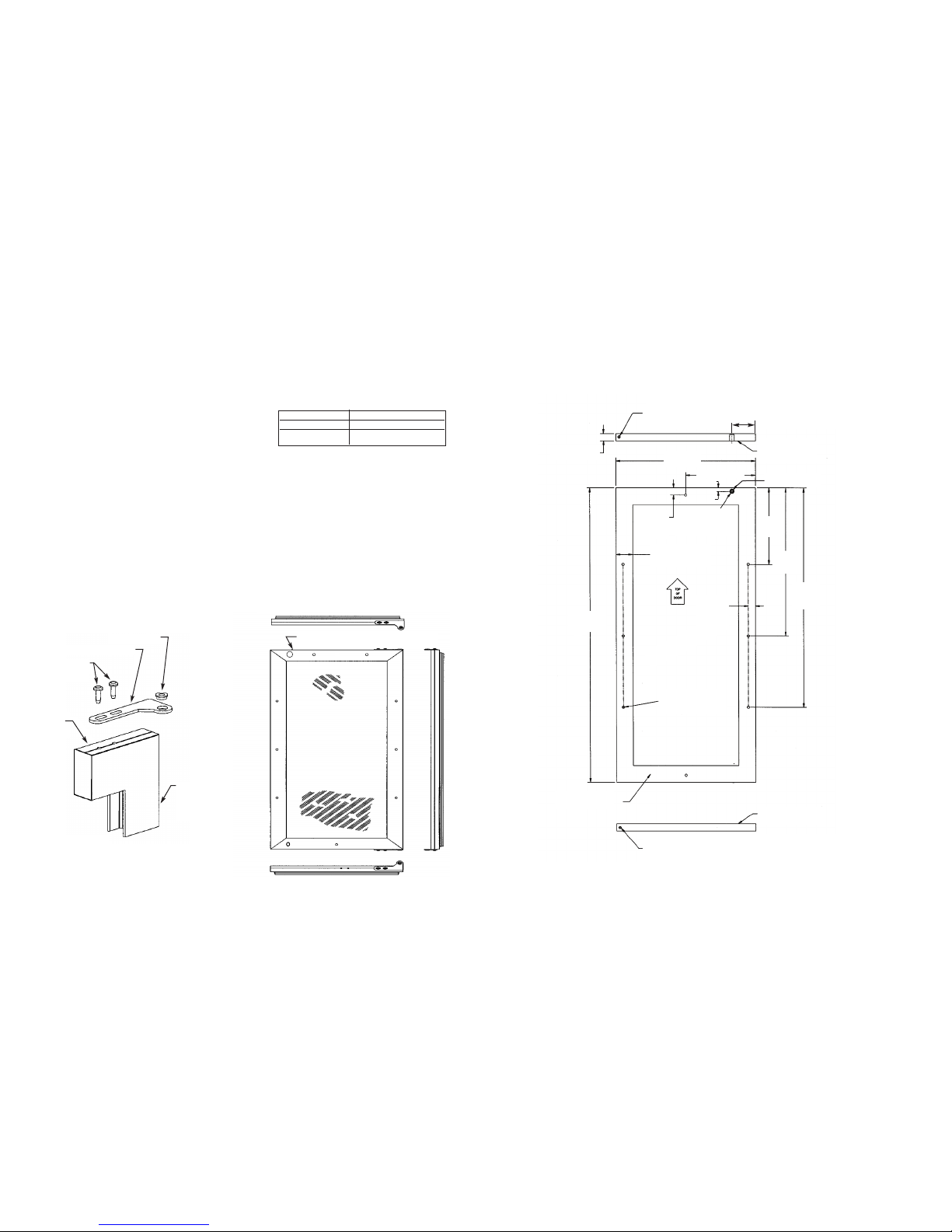

CCUUSSTTOOMM WWOOOODD FFRRAAMMEE IINNSSTTAALLLLAATTIIOONN IINNSSTTRRUUCCTTIIOONNSS

((DDFFUUWW MMooddeell))

Note: Weight of wood panel must not exceed 20 lbs.

WWoooodd SSccrreewws

s

1

. A #10 pan head wood screw should be used to properly secure the wood frame. A total of 10 screws will be needed.

2

. Only use pan head screws.

3. DO NOT select a screw that is longer than the wood thickness at

the screw locations.

4. Use recommended pilot holes for the frame material. (See chart)

WWoorrkkiinngg MMaatteerriiaall WWoooodd SSccrreeww SSiizzee ##1100

Hardwood 3/32 (0.24 cm)

Softwood 5/64 (0.20 cm)

AAsssseemmbbll iinngg DDoooorr HHiinnggee BBrraacckkeettss

(Disregard if hinge brackets are already attached)

1. Attach the top and bottom door hinge brackets to the door with the #10-32 machine screws and a 1/8” allen head

driver as shown in Figure 1 below.

2. Press in the shoulder bushings to the top and bottom door hinge brackets. Make certain that the shoulder is to the

outside of the door as shown in Figure 1 below.

3. Test fit the door to the unit to make certain door will hang correctly. The door is hung correctly when the top of the

door is parallel to the top of the unit. (See Figure 2) Adjustments can be made by loosening the door hinge

machine screws and moving the door hinge brackets on the door.

4. Tighten all four (4) machine screws after adjustments have been made.

5. Remove the door from the unit by removing the units top hinge set screw and angling the door off of the bottom

hinge pin.

Figure 1

Shoulder Bushing

Door Hinge Bracket

#10-32 Machine

Screw

Door Hinge

Screw Holes

Door Front

Surface

TTyyppiiccaall TToopp aanndd BBoottttoomm

DDoooorr HHiinnggee BBrraacckkeett

AAsssseemmbbllyy

Figure 2

This surface parallel to the unit.

(Right hinge door shown.)

Selecting and Preparing the Wood Frame - 15” W. DFUW Model

FFOORR AA 33--11//22”” TTOOEE KKIICCKK

((CCOOVVEERRSS TTHHEE EENNTTIIRREE DDOOOORR EEXXTTRRUUSSIIOONN))

((LLEEFFTT HHIINNGGEE))

1/4” X 3/8” Deep hinge screw clearance hole

-Locate and drill using door hinge hole after the door has been aligned

to the unit and when the wood is positioned on door.

1/4” X 3/8” Deep hinge screw clearance hole. Locate and drill using

door hinge hole after the door has been aligned to the unit and

when the wood is positioned on door.

M

ounting surface

(

Non-face) side

Mounting surface

(non-face) side

Mounting surface

(non-face) side

M

in. 5/8” (1.7 cm)

M

ax. 3/4” (1.9 cm)

1

4 5/16”

(

36.4 cm)

7 5/32” (18.2 cm)

23/32”

(1.8 cm) TYP

1

23/32” (4.4) cm min.

width to cover door

e

xtrusion

23/32”

(1.8 cm)

TYP

B

A

CK

V

IEW

O

F

O

V

ER

L

A

Y

PA

N

EL

30 5/16”

(77.0 cm)

Pre-drilled pilot holes 8 places

7

13/16”

(

19.8 cm)

TYP

15 5/32”

(38.5 cm)

TYP

22 1.2”

(57.2 cm)

TYP

13/16” (2.1 cm)

counterbore 7/16”

(

1.1 cm) deep

1

5/32” (1.2 cm)

D

ia. hole

15./2” (1.2 cm)

3 7/32”

(

8.1 cm)

Loading...

Loading...