Viking ESFR Technical Data Manual

ESFR Pre-primed Single Interlock Preaction

Cold Storage System

Technical Manual for Design, Installation,

Operation and Maintenance

March 7, 2008

Form No. F_122807

Page II

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

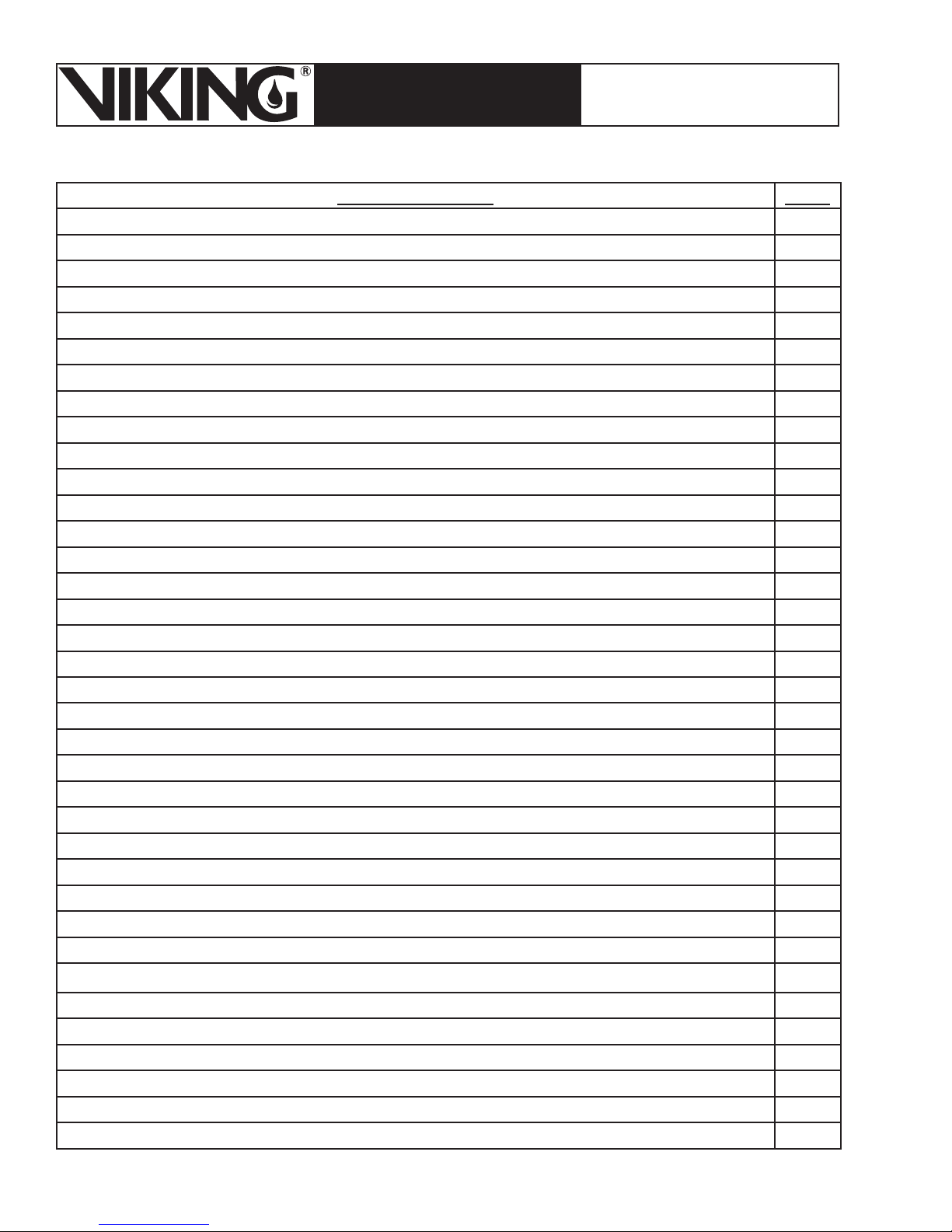

Table of Contents Page

I. SYSTEM DESCRIPTION 4

1. System Considerations 4

2. System Makeup 4

II. SYSTEM DESIGN 6

1. Hydraulic Calculations 6

2. Determining the Required Volume of Propylene Glycol 17

3. Typical Storage Arrangements 18

4. Designing the Detection System 26

III. INSTALLATION AND COMPONENT FUNCTIONS 27

1. Water Supply Control Valve 28

2. Grooved Couplings 28

3. Deluge Valve with Conventional Trim 29

A. Water Flow Pressure Switches (PS-10) 31

4. Electric Release Trim 32

®

5. Easy Riser

Check Valve with Cold Storage Trim 33

A. Cold Storage Trim with Automatic Pressure Control System 34

1. Supervisory Pressure Switch (PS-40) 34

6. Digital Pressure Switch 35

A. Description 35

B. Technical Data 35

C. Operating Modes 37

D. Installation 37

1. Electrical Connection 37

E. Inspections, Tests and Maintenance 38

7. Propylene Glycol Solution Reclaim Tank 39

®

8. Bypass Easy Riser

Check Valve with Bypass Trim 40

9. Downstream System Isolation Valve 41

10. CS-1 Tank & Pump Unit 42

A. Description 42

B. Technical Data 44

C. Installation 44

1. Handling 44

2. Location 44

3. Piping and Connections 44

4. Electrical Connections 45

5. Start Up 45

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

Page III

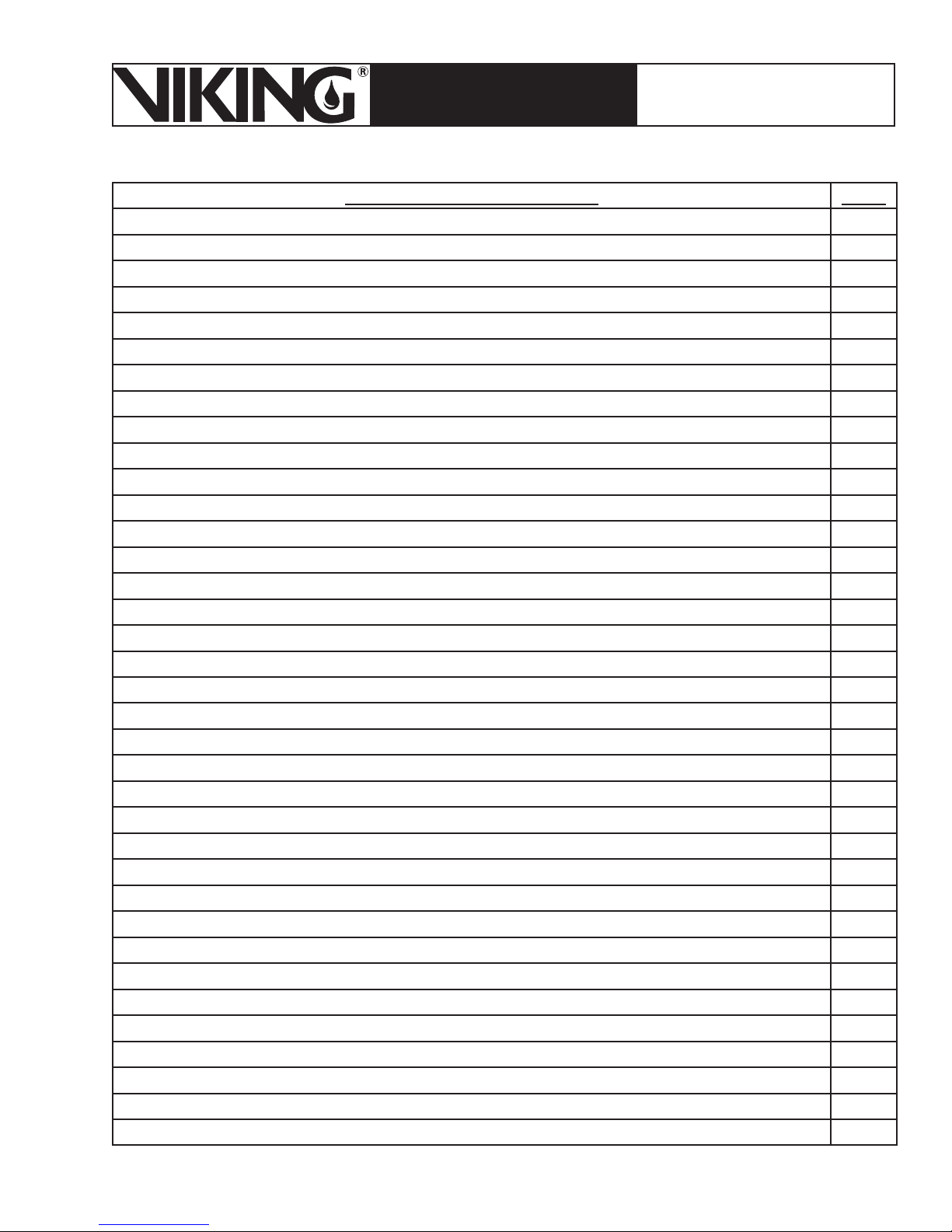

Table of Contents Continued Page

D. CS-1 Control Scheme 49

1. Pump Operation 49

2. System Solenoid Valve Operation 49

3. Level Switch Relay Coil Operation 49

E. Filling the Reservoir Tank 49

1. Gravity Fill 49

2. Pump Assist Fill 50

F. Filling Systems 50

G. Operating in Maintenance Mode: Automatic 52

H. Inspections, Tests and Maintenance 53

11. Air / Vacuum Vent 53

A. Installation 53

B. Ordering Information 54

C. Inspections, Tests and Maintenance 54

12. Firefi ghter Eliminator 56

A. Description 56

B. Technical Data 56

C. Inspections, Tests and Maintenance 56

IV. WIRING 57

1. Wiring Circuit 1 58

2. Wiring Circuit 2 59

3. Wiring Circuit 3 60

4. Wiring Circuit 4 85

V. SYSTEM OPERATION 90

Normal Condition 90

High Pressure Condition 92

Low Pressure Condition 94

Fire Condition 96

Broken Pipe Condition 98

VI. SYSTEM INSPECTIONS, TESTS AND MAINTENANCE 100

1. Solution Test Valves 102

2. Alarm Test Connection 102

3. Flow Test Valve 102

4. Service Procedures 103

APPENDIX A: ORDERING A COMPLETE SYSTEM 105

APPENDIX B: PIPING ESTIMATING TOOL 108

Page 4

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

I. SYSTEM DESCRIPTION

The Viking ESFR Pre-Primed Single Interlock Preaction Cold Storage System is a fixed fire protection

system designed for installation in refrigerated, cold storage and unheated warehouse applications

with rack storage of Class II commodity on wood pallets. This system effectively prevents frost plugs

associated with systems that supervise the piping network with air. The single interlock preaction system piping network is supervised with a propylene glycol solution. When using this system for single-,

double- and multiple-row rack storage, Viking K25.2 ESFR sprinklers are used at the ceiling only and

no in-rack sprinklers are required.

1. System Considerations

All materials installed on the system shall be compatible with propylene glycol solution.

•

Where the minimum temperature in the area being protected is 8 °F (-13.3 °C) or above,

•

Firefighter Eliminator C 35% percent by volume propylene glycol factory premixed solution

must be used.

Where the minimum temperature in the area is between 8 °F (-13.3 °C) and -21 °F (-29.4 °C),

•

firefighter Eliminator F 50% percent by volume propylene glycol factory premixed solution

must be used.

The minimum ambient temperature where the system can be used is -21 °F (-29.4 °C). This

•

is not an average temperature; it is the lowest temperature within the area.

The system piping configuration shall be designed in a tree configuration only. The

•

mains and branch lines should not be looped together. Grid systems are NOT allowed. The

piping system shall be pitched to drain completely. The branch lines shall be pitched at ¼”

per 10 ft (4 mm/m) run of pipe and the mains shall be pitched ½” per 10 ft (4 mm/m) run of

pipe.

2. System Makeup

Each Viking ESFR Pre-Primed Single Interlock Preaction Cold Storage System requires the following components for proper operation:

Water Supply Control Valve

•

Deluge Valve with Conventional Deluge Valve Trim

•

Electric Release Trim with Solenoid Valve

•

®

Primary Easy Riser

•

Control Trim

Bypass Easy Riser

•

Digital Supervisory Pressure Switch

•

CS-1 Tank and Pump Package

•

Viking VFR-400 Release Control Panel

•

Reclaim tank for Automatic Pressure Control System

•

System Reclaim Tank (Recommended)

•

AV-1 Automatic Air Vent (One for each high point recommended)

•

Firefighter Eliminator Propylene Glycol Solution

•

K25.2 ESFR Pendent Sprinklers (Viking VK510)

•

**Please see Appendix A for Material Selection

Check Valve with Cold Storage Trim including Automatic Pressure

®

Check Valve with Bypass Trim

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Page 5

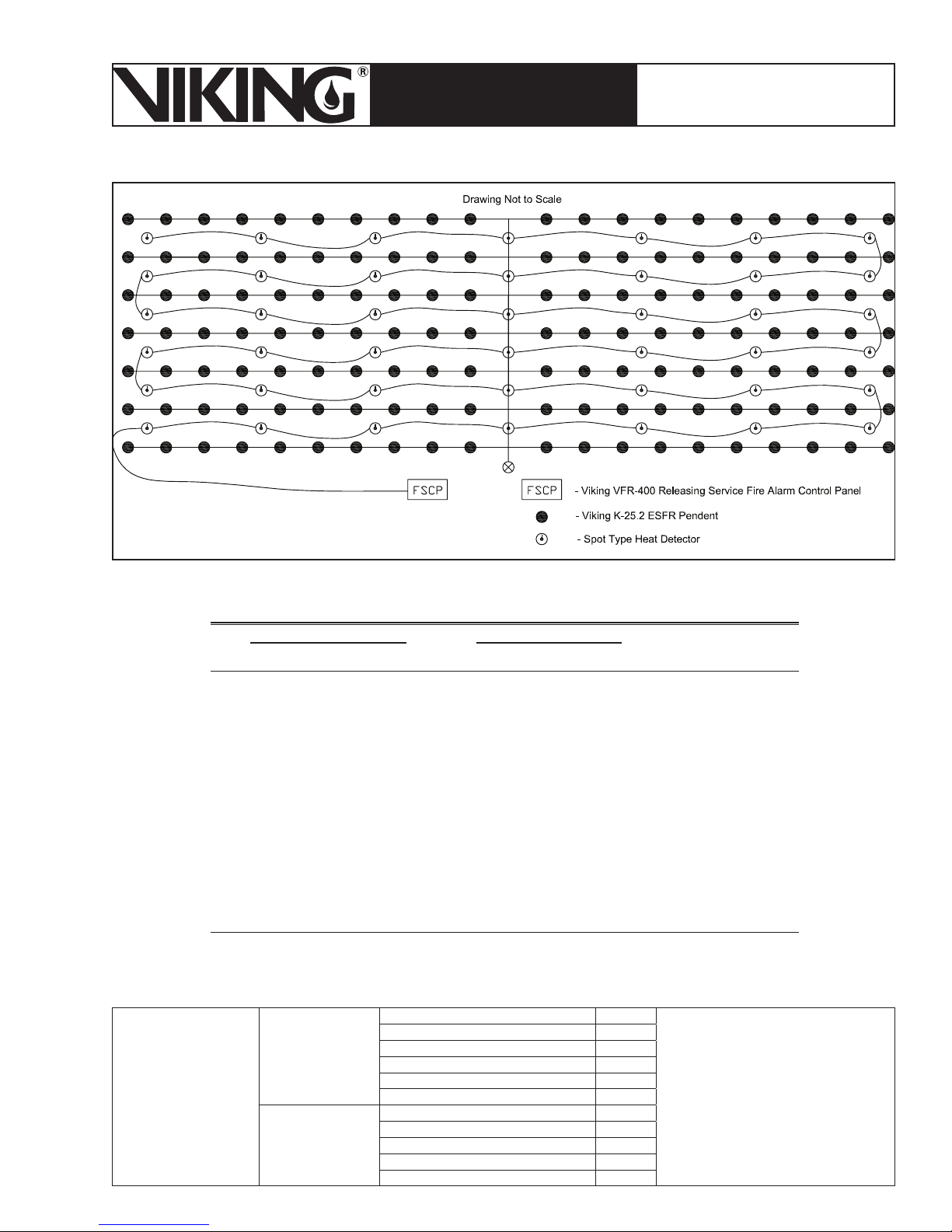

Figure 1 - Viking ESFR Pre-Primed Single Interlock Preaction

Cold Storage System

Page 6

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

This system shall be designed by qualified fire protection professionals in conjunction with the

requirements listed in this technical data, NFPA 13, and those of the authority having jurisdiction.

The system designer must read and apply all of the following design requirements.

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

II. SYSTEM DESIGN

1. Hydraulic Calculations

Two hydraulic calculations are required for the system:

The first calculation shall be with the 12 Viking VK510 K25.2 ESFR’s assuming they are flowing

water. This calculation shall include 4 sprinklers on the 3 most hydraulically remote branch lines

discharging at the minimum design pressure for the system. This calculation shall use the Hazen

Williams formula. See examples in Figures 3 & 4.

The second calculation shall include 6 Viking VK510 K25.2 ESFR’s flowing propylene glycol

solution. The calculation shall include 4 sprinklers on the most hydraulically remote branch line

and 2 sprinklers on the second most hydraulically remote branch line discharging at the minimum

design pressure required for the system. This calculation shall use the Darcy-Weisbach formula.

See examples in Figures 6-8.

Full-scale fire testing has demonstrated that the propylene glycol solution will be expelled from

the system by the time 6 sprinklers are operating in a fire condition. The 6-head sprinkler calculation using the Darcy-Weisbach formula is used to ensure that the piping has been sized properly

and the water supply is adequate for the more viscous liquid. Because the propylene glycol will

have a dramatically different viscosity at the colder temperature expected in this application, friction loss through the piping network will be significantly higher than water.

When conducting hydraulic calculations, a good rule of thumb is to increase pipe size when

friction loss has reached .3 PSI per foot of pipe. By setting up the spreadsheet described in

Appendix B, a quick estimation of the difference in friction loss will assist in determining if the

desired pipe size will be adequate. The final pipe sizes will need to be confirmed through the

actual hydraulic calculations.

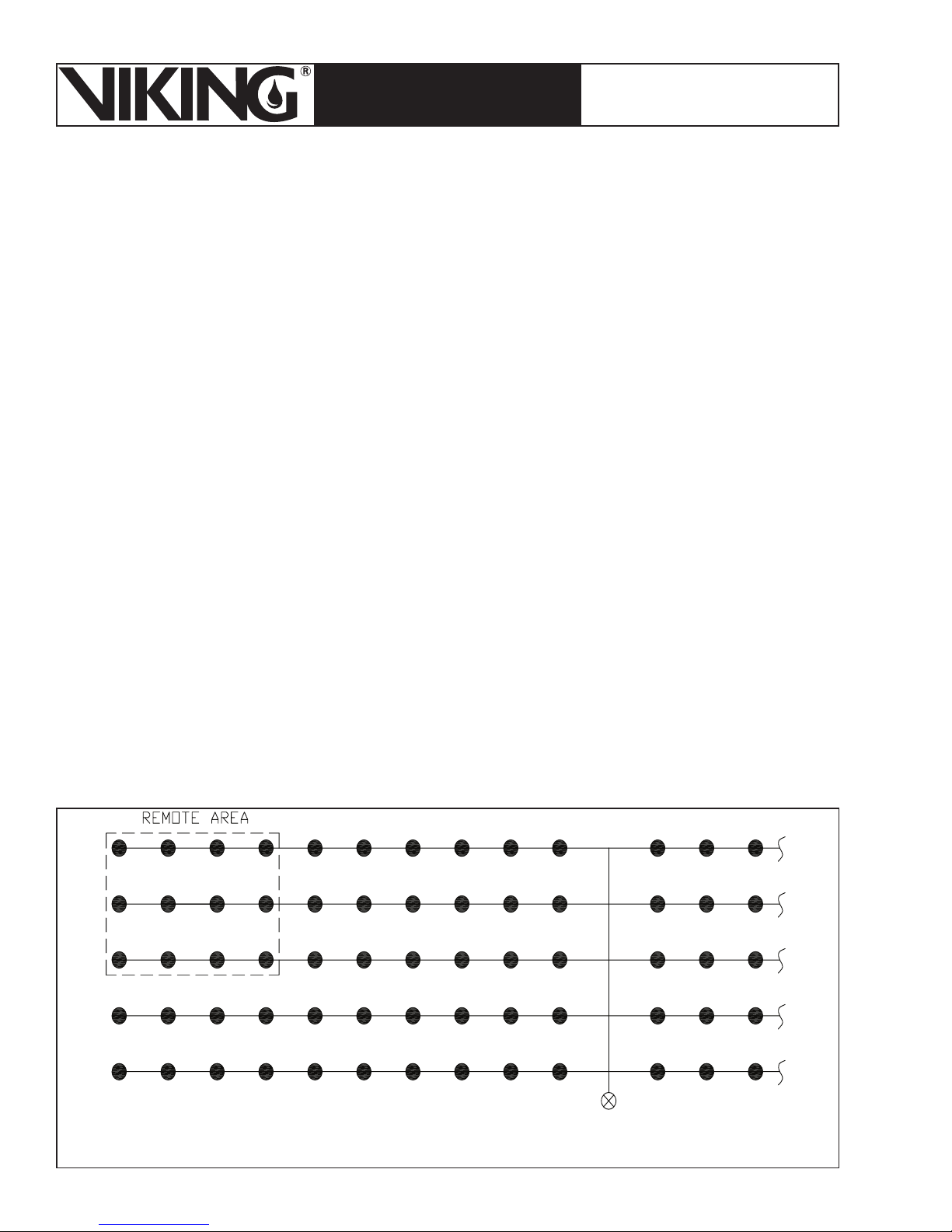

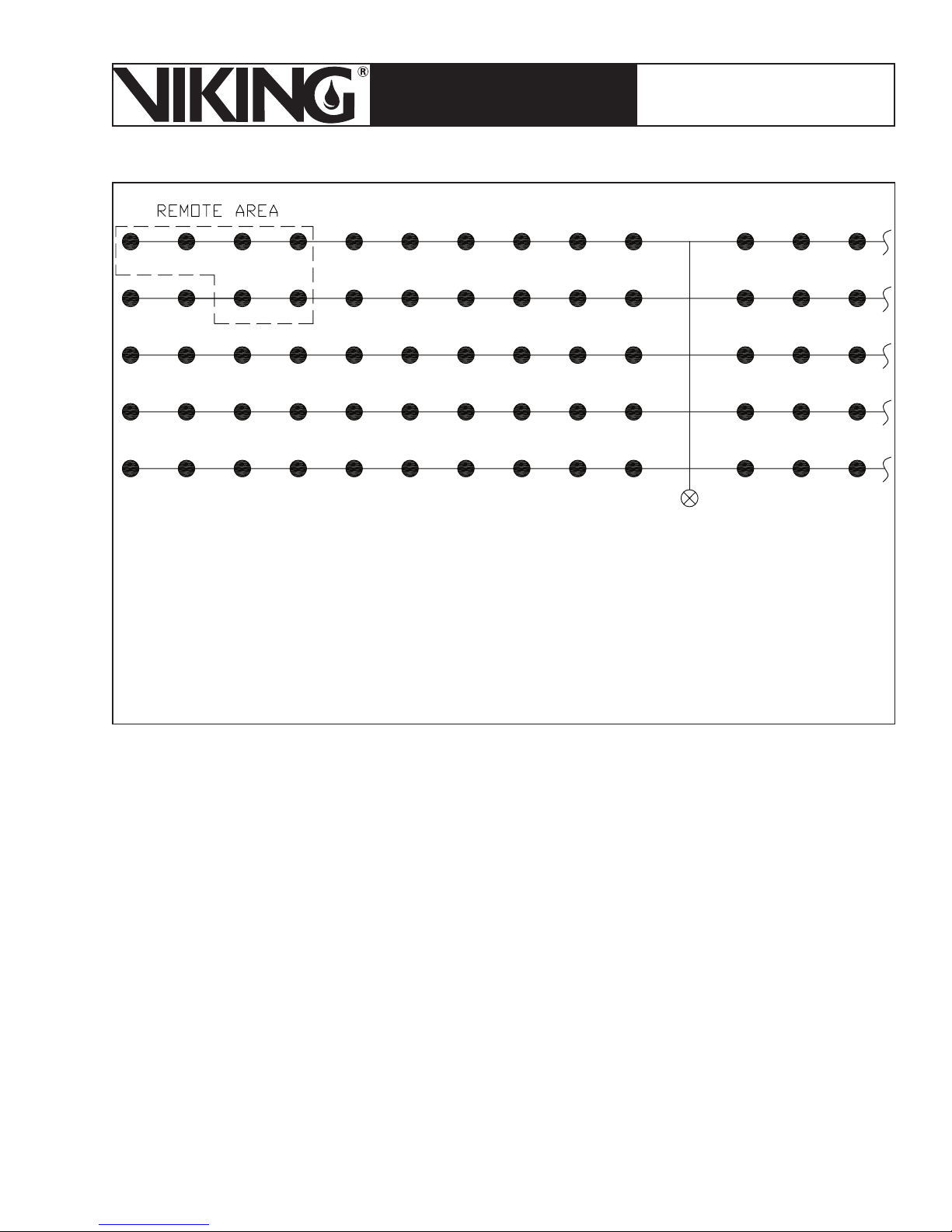

Figure 2 - Example of Remote Area for Hazen Williams Calculation

Center Feed Tree

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

CONTRACT NAME_ABC Freezer -20 Degrees Class II Commodity____________________________ SHEET__1___OF__2___

Page 7

NOZZLE

IDENT.

AND

LOCATION

STEP NO.

1 Spkr #1

FLOW IN

q

Q 195.2

2 Spkr #2

q 195.6

Q 390.8

3 Spkr # 3

q 197.6

Q 588.4

4 Spkr # 4

q 201.9

Q 790.3

To

5

Bottom of

Riser

Nipple

q

Q 790.3

q

QTPf

6 RN-1

q

Q 790.3

7RN-2

q 794.3

Q 1584.6

8RN-3

q 796.7

Q 2381.3

9

To Top of

Riser

q

Q 2381.3

To

10

Bottom of

Riser

q

Q 2381.3

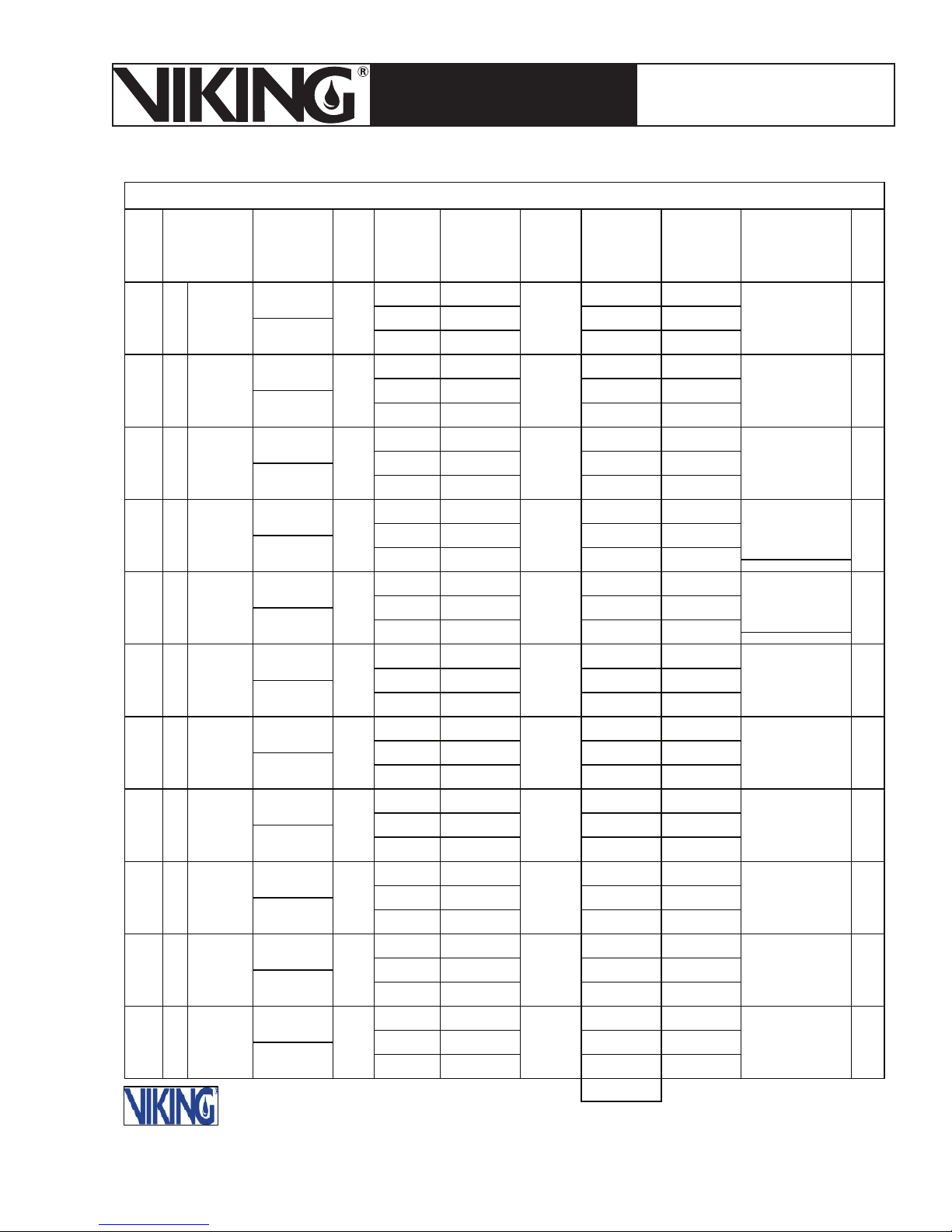

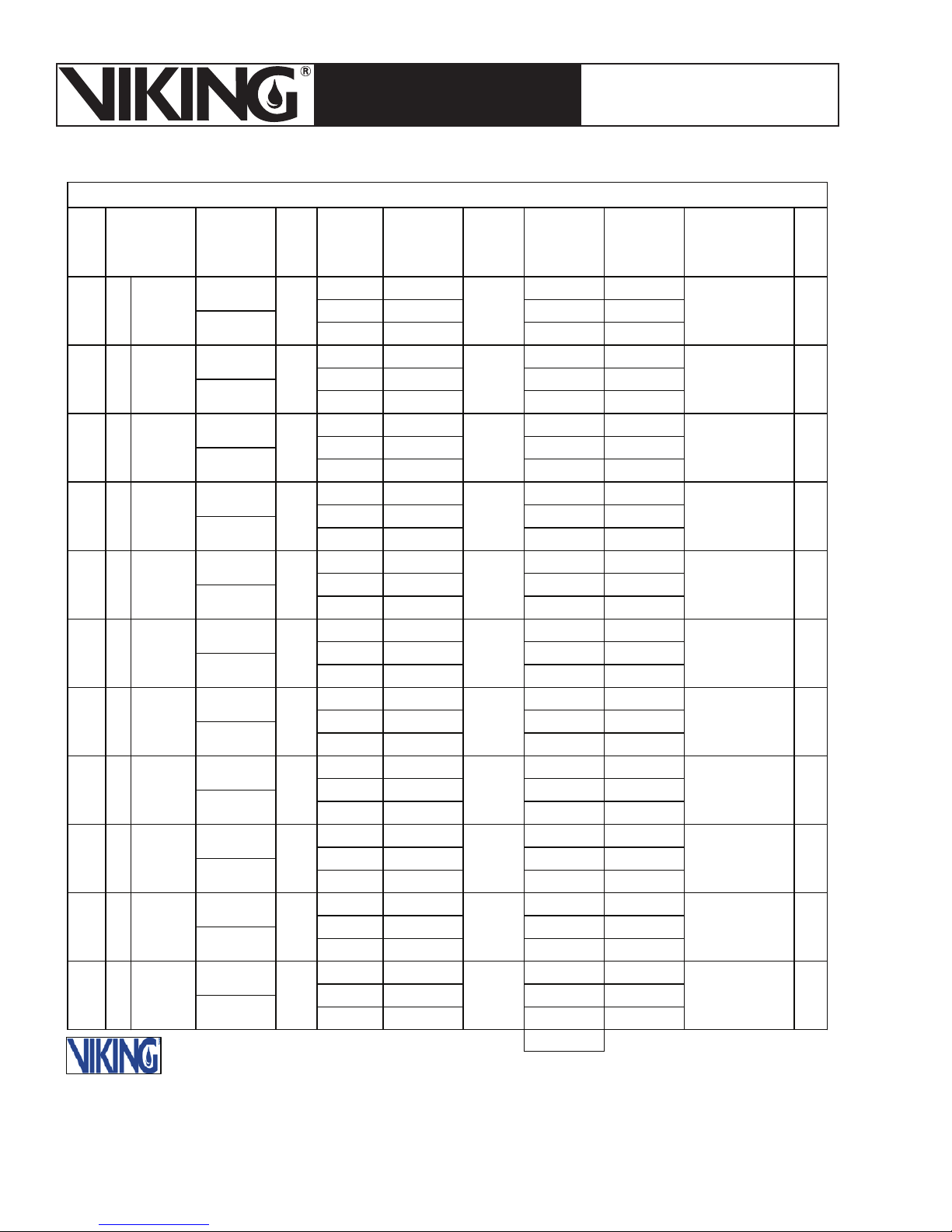

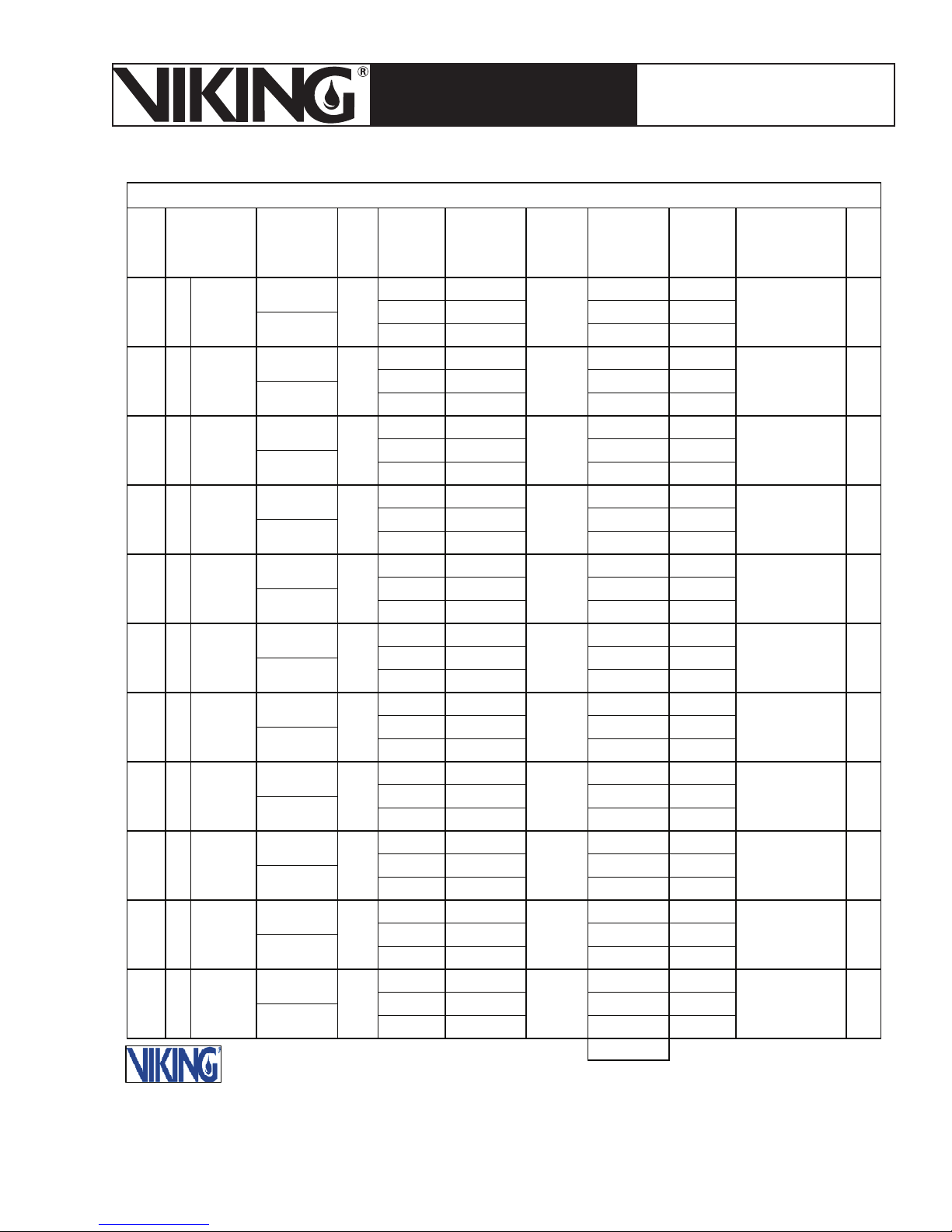

Figure 3 - Hazen Williams Example Calculation of the

25,000 ft.

G.P.M.

PIPE

SIZE

Sch 10

3"

3.26

PIPE

FITTINGS

AND

DEVICES

EQUIV. PIPE

LENGTH

L 10-0

F

T 10-0

FRICTION

LOSS P.S.I./

FOOT

C120

0.03

L 10-0

3"

3.26

F

T 10-0

0.12

L 10-0

3"

3.26

F

T 10-0

0.27

L 31-3

3"

1- Tee F 20

3.29

T 51-3

0.48

L 2-0

3"

1- Tee

3.26

T 22

0.46

L Pt 98.2

FPePv

Sch

10

6"

6.357

L 10-0

F

0.01

L 10-0

6"

6.357

F

0.06

L

6"

6.357

F

1-LTR EL L 154

6"

6.357

1-Tee

F 47

0.13

2- CHK Vl L 37

6"

1- Deluge

6.357

1- Btr Fly T 128

2

Tree System Shown in Figure 9, Sheet 1

F 91

0.13

PRESSURE

SUMMARY

Pt 60 Pt

Pe

Pf .3

Pv

Pn

Pt 60.3 Pt

Pe Pv

Pf 1.2

Pn

Pt 61.5 Pt

Pe

Pv

Pf 2.7 Pn

Pt 64.2 Pt

Pe Pv

Pf 24.6 Pn

Pt 88

PeF 20

Pf 10.2

Pt

Pv

Pn

Pt

Pn

Pt 98.2 Pt

Pe Pv

Pf .1 PnT 10-0

Pt 98.3 Pt

Pe Pv

Pf .6 PnT 10-0

Pt 98.9 Pt

Pe Pv

Pf PnT

Pt 98.9 Pt

Pe Pv

Pf 27.8 PnT 201

Pt 126.7 Pt

Pe 19 Pv

Pf 17.7 Pn

Pt 163.4

NORMAL

PRESSURE

NOTES

Viking K 25.2

Hazen Williams

60

psi Required

Q=K√P

25.2

√60

Q=195.2

√60.3

Q=25.2

Q=195.6

Q=25.2√61.5

Q=197.6

Q=25.2√64.2

Q=201.9

Fitting Adj for

Diameter

15 x 1.34 = 20

Fitting Adj for

Diameter

15 x 1.34 = 20

√P

K=Q/

K=790.3/

√98.2

K=80.12

Q=K√P

Q=80.12

√98.3

Q=794.3

Q=K√P

Q=80.12

√98.9

Q=796.7

Fittings Adj for

Diameter

Elevation 43.75

.433 x 43.75

Fittings Adj for

Diameter

The Viking Corporation

Hastings, Michigan

Litho in U.S.A. Form 3017-HB

REF. STEP

Page 8

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

CONTRACT NAME__ABC Freezer -20 Degrees Class II Commodity ________________ SHEET__2___OF__2___

NOZZLE

IDENT.

AND

LOCATION

STEP NO.

11

Hose

Stream

12 To Street

FLOW IN

G.P.M.

q 250

Q 2631.3

q

Q 2631.3

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

PIPE

SIZE

PIPE

FITTINGS

AND

DEVICES

EQUIV. PIPE

LENGTH

FRICTION

LOSS P.S.I./

FOOT

LPt

FPePv

CL-52

1-EL

8"

1 Gt vlv F 67 Pe Pv

8.385

1- Tee

TPfPn

L 100 Pt 163.4

T 167 Pf 4.5 Pn

C 140

0.02

L Pt 168

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

Pt

PRESSURE

SUMMARY

NORMAL

PRESSURE

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

NOTES

48 x 1.33 x 1.05

fittings adj

for C factor

and diameter

ystem Demand

S

gpm

2631

@

168 psi

The Viking Corporation

Hastings, Michigan

Litho in U.S.A. Form 3017-HB

REF. STEP

Figure 4 - Hazen Williams Example Calculation of the

25,000 ft.

2

tree system shown in Figure 9, Sheet 2

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Page 9

Typically, when a partial branch line is required in the hydraulic calculations, the sprinklers closer to

the cross main will be used, as shown above. The calculation of the closer sprinklers will result in less

friction loss and a smaller pressure demand on the branch line. At the cross main, a K factor for the

branch lines will need to be determined. The lower pressure requirement will result in a larger K factor and thus require more water on the partial branch line, typically making the closer sprinklers more

demanding.

Figure 5 - Example of Remote Area for Darcy-Weisbach Calculation

Center Feed Tree

Page 10

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Darcy-Weisbach Method for Calculating Friction in Piping:

Most hydraulic calculation software used in the sprinkler industry today has the option for conducting

the piping friction loss calculations with the Darcy-Weisbach method. The reason for conducting the

additional 6 sprinkler head calculation is to verify that the available water supply pressure is adequate

for the initial discharge of propylene glycol solution. The example calculations provided in Figures 68 illustrate the difference in results that can occur when calculating for the more viscous propylene

glycol solution versus the standard Hazen-Williams calculation for water illustrated in Figures 3-4.

For those not familiar with the Darcy-Weisbach method below is the basic procedure that is used to

conduct the calculation. This is intended only to provide the designer with an understanding of the

concepts of the method. It is not practical that the calculation be done by hand as this would be much

too time consuming and subject to potential errors.

2

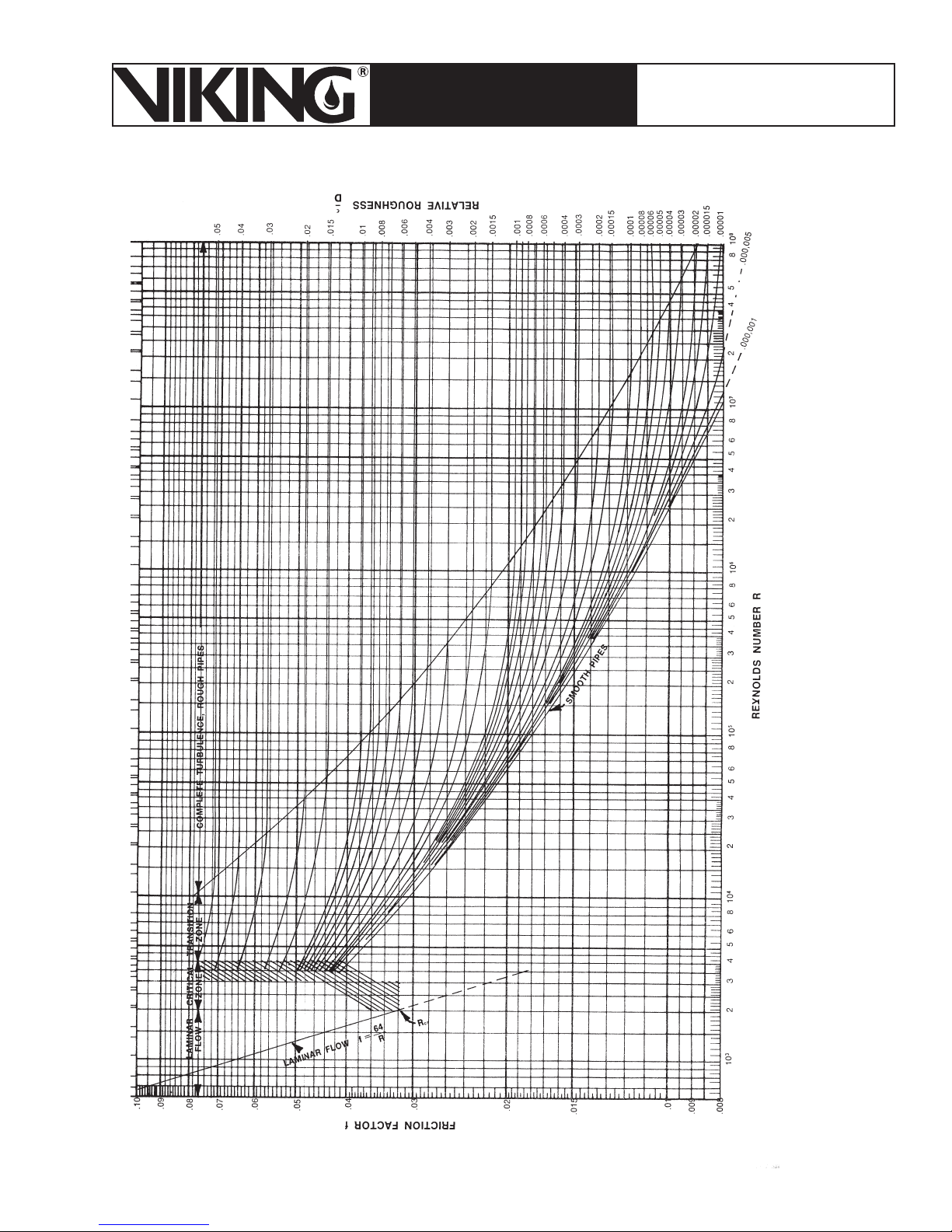

The Darcy-Weisbach Formula as found in most text is written as: h= (f) (l) (v)

h=friction loss (ft of head)

f=friction factor (from Moody Diagram-Figure 10)

l=length of pipe (ft)

v=velocity (ft/sec)

d=diameter of pipe (ft)

2

g=gravitational constant (32.2 ft/sec

)

/ (d) (2) (g)

This formula can be rearranged and simplified to:

2/d5

When the calculated Reynolds Number (Re) is >2000 =0.000216 fLρQ

When the calculated Reynolds Number (Re) is <2000 =0.000273 μLQ/d

=Friction Loss (psi)

4

=Friction Loss (psi)

Where:

Re=50.6Qρ/dμ

Q=flow (gpm)

3

ρ=density (lbs/ft

)

d=internal pipe diameter (in)

D=internal pipe diameter (ft)

L=pipe length (ft)

μ=dynamic viscosity (cps)

ε= .00033 for steel pipe

f=friction factor, If Re > 2000, use Moody Diagram (Figure 10). If Re < 2000, f = 64/Re.

Procedure:

1. Calculate Reynolds Number (Re) = 50.6Qρ/dμ

2. Calculate relative roughness of pipe = ε/D

ε= .00033 (ft)

D=internal pipe diameter (ft)

3. Use Moody Diagram (Figure 10) to find “f” if Re > 2000. If Re < 2000, f = 64/Re.

4. Use fiction loss in hydraulic calculation.

March 7, 2008

Page 11

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

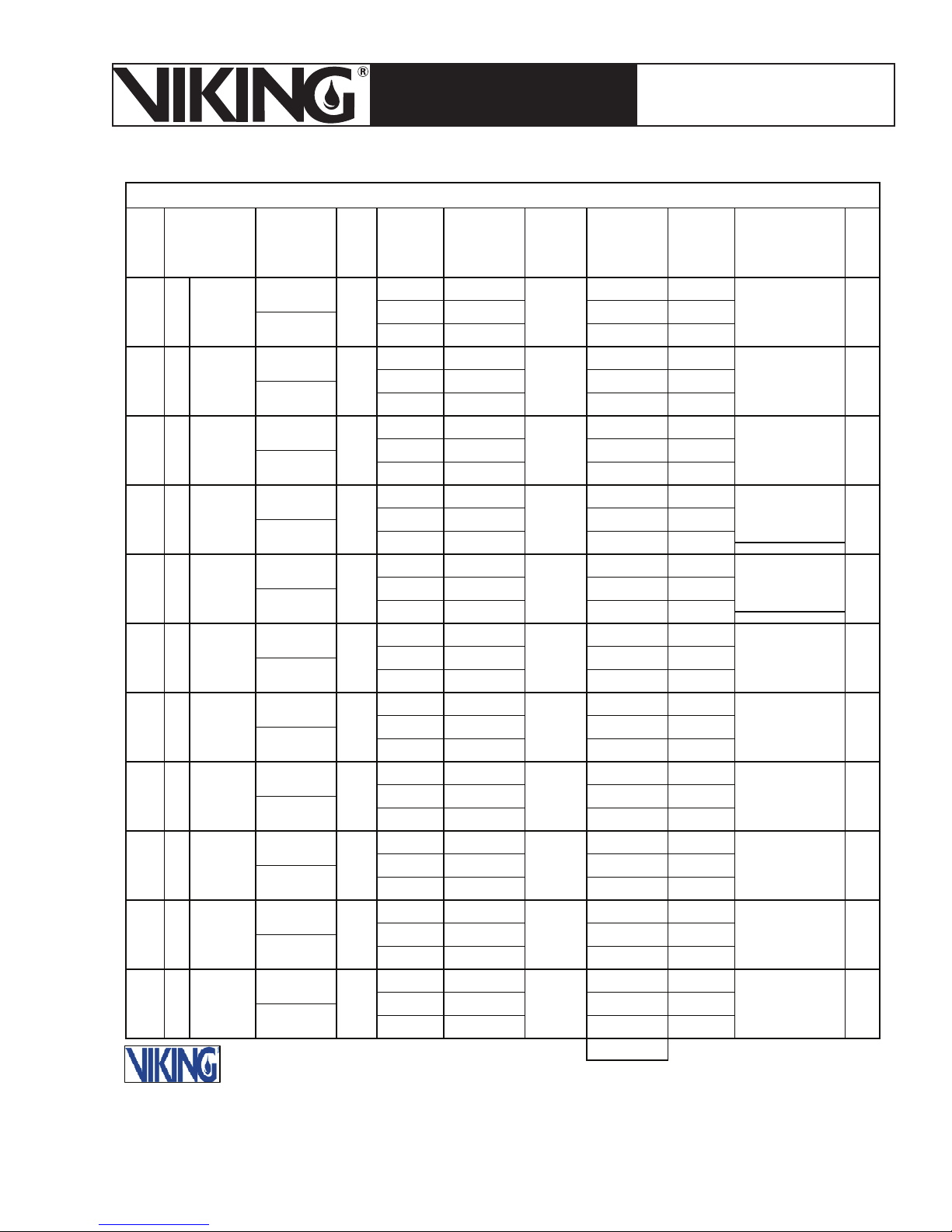

CONTRACT NAME_ABC Freezer -20 Degrees Class II Commodity___________________________ SHEET__1___OF__3___

NOZZLE

IDENT.

AND

LOCATION

STEP NO.

1 Spkr #1

2 Spkr #2

3 Spkr #3

4 Spkr #4

To

5

Bottom of

Riser

Nipple

6 RN-1

7 RN-2

8

To Top of

Riser

To

9

Bottom of

Riser

10

Hose

Stream

FLOW IN

G.P.M.

q

Q 195.2

q 196.4

Q 391.6

q 201.2

Q 592.8

q 210.6

Q 803.4

q

Q 803.4

q

Q

q

Q 803.4

q 540

Q 1343.4

q

Q 1343.4

q

Q 1343.4

q 250

Q 1593.4

PIPE

SIZE

Sch 10

3"

3.26

PIPE

FITTINGS

AND

DEVICES

EQUIV. PIPE

LENGTH

L 10-0 Pt 60

FPePv

T 10-0 Pf .8 Pn

FRICTION

LOSS P.S.I./

FOOT

0.08

L 10-0 Pt 60.8

3"

3.26

FPePv

T 10-0 Pf 3.0 Pn

0.3

L 10-0 Pt 63.8

3"

3.26

FPePv

T 10-0 Pf 6.1 Pn

0.61

L 31-3 Pt 69.9

3"

1-Tee F 20 Pe Pv

3.26

T 51-3 Pf 52 Pn

1.03

L 2-0 Pt 121

3"

1-Tee F 20 Pe Pv

3.26

T 22-0 Pf 22.6 Pn

1.03

L Pt 143.6

FPePv

Sch

10

6"

6.357

TPfPn

L 10-0 Pt 143.6

FPePv

T 10-0 Pf .4 Pn

0.04

L Pt 144

6"

6.357

FPePv

TPfPn

1- LTR EL L 154-0 Pt 144

6"

1- Tee F 47-0 Pe Pv

6.357

T 201-0 Pf 21 Pn

0.1

2- Chk Vl L 37 Pt 165

1- Deluge F 91 Pe 19 Pv

1- Btr Fly T 128 Pf 12.8 Pn

0.1

L Pt 196.8

FPePv

TPfPn

Pt 196.8

PRESSURE

SUMMARY

NORMAL

PRESSURE

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

NOTES

Viking K 25.2

y Weisbach

Darc

psi Required

60

Q=K√P

√60

25.2

Q=195.2

Q=25.2√60.8

Q=196.4

Q= 25.2√63.8

Q=201.2

Q=25.2√69.9

Q=210.6

Fitting Adj for

Diameter

15 x 1.34 = 20

Fitting Adj for

Diameter

15 x 1.34 = 20

K=Q/√P

√143.6

K=803.4/

K=67

Q=K√P

√144

Q=45

Q=540

K 45 from

Sheet 3 of 3

Fitting Adj for

Diameter

Elevation 43.7

.433 x 43.75

19

Fittin

Diameter

The Viking Corporation

Hastings, Michigan

Litho in U.S.A. Form 3017-HB

psi

g Adj for

5

REF. STEP

Figure 6 - Darcy-Weisbach Example Calculation of the

25,000 ft.

2

Tree System Shown in Figure 9, Sheet 1

Page 12

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

CONTRACT NAME_ABC Freezer -20 Degrees Class II Commodity__________________________ SHEET__2___OF__3___

NOZZLE

IDENT.

AND

LOCATION

STEP NO.

11 To Street

FLOW IN

G.P.M.

q

1593.4 1-Tee T

PIPE

SIZE

CL-52

8"

8.385

PIPE

FITTINGS

AND

DEVICES

1-El L 1

1- GT Vl F 67 Pe Pv

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

EQUIV. PIPE

LENGTH

00 Pt 196.8 Pt 48 x 1.33 x 1.05

167 Pf 6.4

LPt 20

FRICTION

LOSS P.S.I./

FOOT

C 140

0.03

PRESSURE

SUMMARY

3.2

NORMAL

PRESSURE

Pn

Pt

NOTES

Fittings Adj

Adj for C Factor

and Diameter

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

Pt

ystem Demand

S

1593 gpm

@

203 psi

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

LPt

Pt

FPePv

TPfPn

Pt

The Viking Corporation

Hastings, Michigan

Litho in U.S.A. Form 3017-HB

REF. STEP

Figure 7 - Darcy-Weisbach Example Calculation of the

2

25,000 ft.

Tree System Shown in Figure 9, Sheet 2

March 7, 2008

Page 13

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

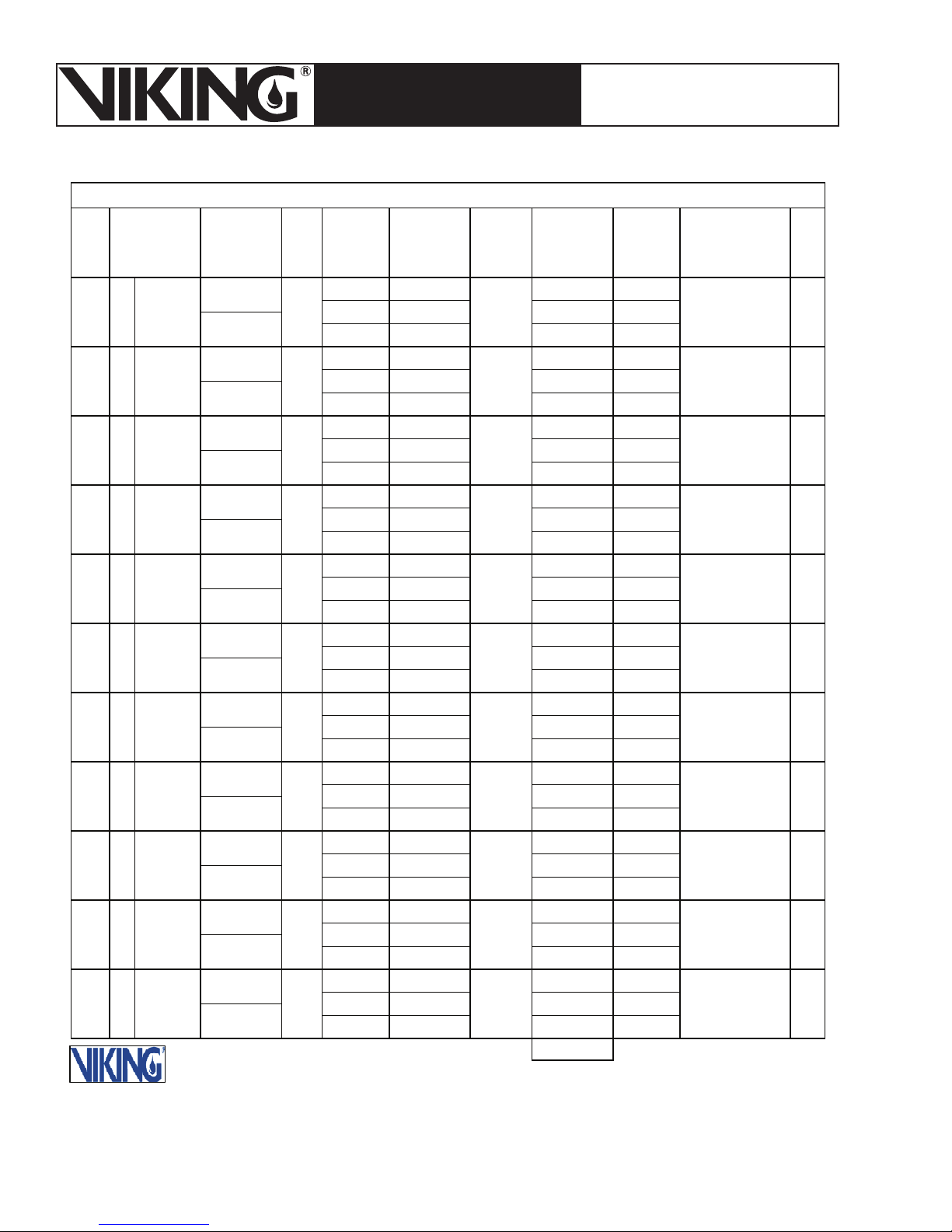

CONTRACT NAME__ABC Freezer -20 Degrees Class II Commodity___________________________ SHEET__3___OF__3___

NOZZLE

IDENT.

AND

LOCATION

STEP NO.

12 Spkr #5

13 Spkr#6

FLOW IN

G.P.M.

q

Q 195.2 T 10-0 Pf .8

q 196.4

Q 391.6

PIPE

SIZE

Sch

10

3"

3.26

3"

3.26

PIPE

FITTINGS

AND

DEVICES

1-Tee F 20-0 Pe Pv

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

Q

q

EQUIV. PIPE

LENGTH

L 10-0 Pt 60 Pt

FPePv

L 28-9 Pt 60.8

T 48-9 Pf 14.9 Pn

L Pt 75.7

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

TPfPn

LPt

FPePv

QT

FRICTION

LOSS P.S.I./

FOOT

PRESSURE

SUMMARY

0.08

0.3 Diameter

Pf Pn

Pt

NORMAL

PRESSURE

Pn

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

Pt

NOTES

Q=K√P

Q=25.2√60

Q=195.2

Q=K√P

Q=25.2√60.8

Q=195.2

Fittin

g Adj for

K=

Q/√P

K=391.6/

The Viking Corporation

Hastings, Michigan

Litho in U.S.A. Form 3017-HB

K=45

√75.7

REF. STEP

Figure 8 - Darcy-Weisbach Example Calculation of the

25,000 ft.

2

Tree System Shown in Figure 9, Sheet 3

Page 14

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

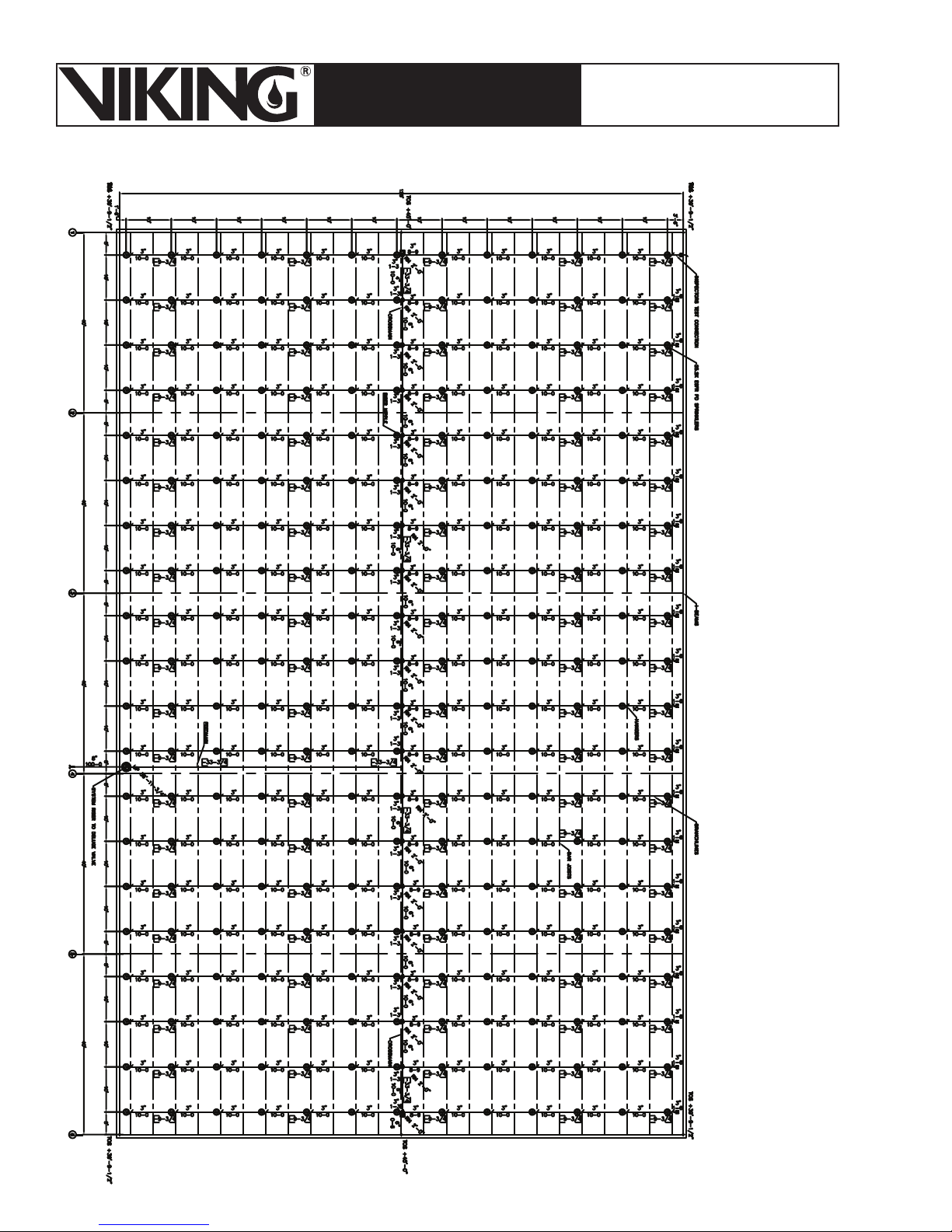

Figure 9 - Plan

View of 25,000

Square Foot

System

March 7, 2008

Page 15

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 10 -

Moody Diagram

Page 16

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

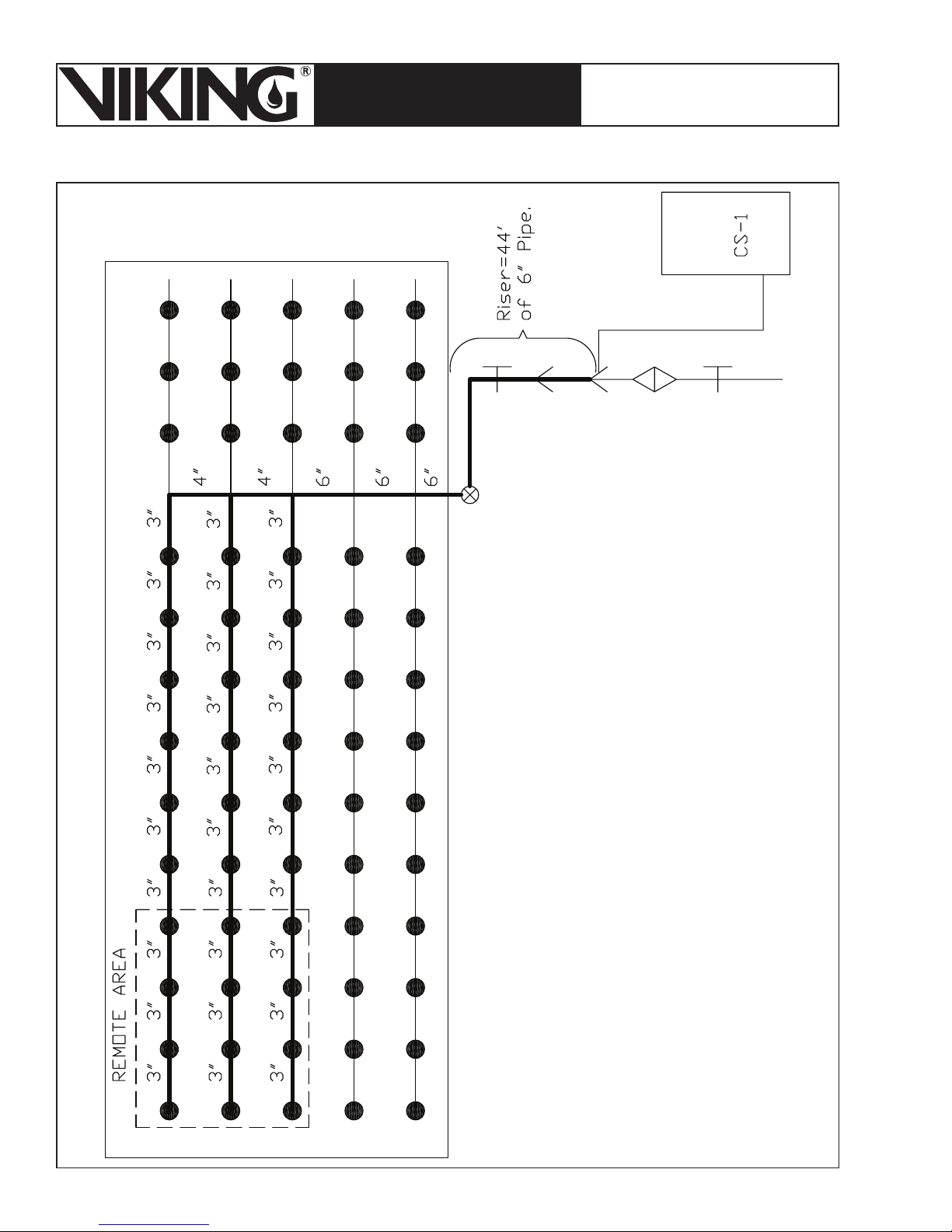

Figure 11 - Calculating the

Propylene Glycol Volume

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

Page 17

2. Determining the Required Volume of Propylene Glycol

The system design area (12 sprinklers: 4 on each of the 3 hydraulically most remote branch lines)

and bulk main to the primary Easy Riser® Check Valve (lines in bold) at the base of the riser is

limited to a total volume of 1,100 gallons.* Additional mains and sprinkler lines attached to the

sprinkler system, but not in the direct path to the base of the riser, do not need to be considered

in the volume restriction.

The actual volume of propylene glycol solution for the sprinkler system is determined by adding

all the sprinkler piping together. Additional propylene glycol is added to this total for the CS-1

Tank and supply lines to the riser.

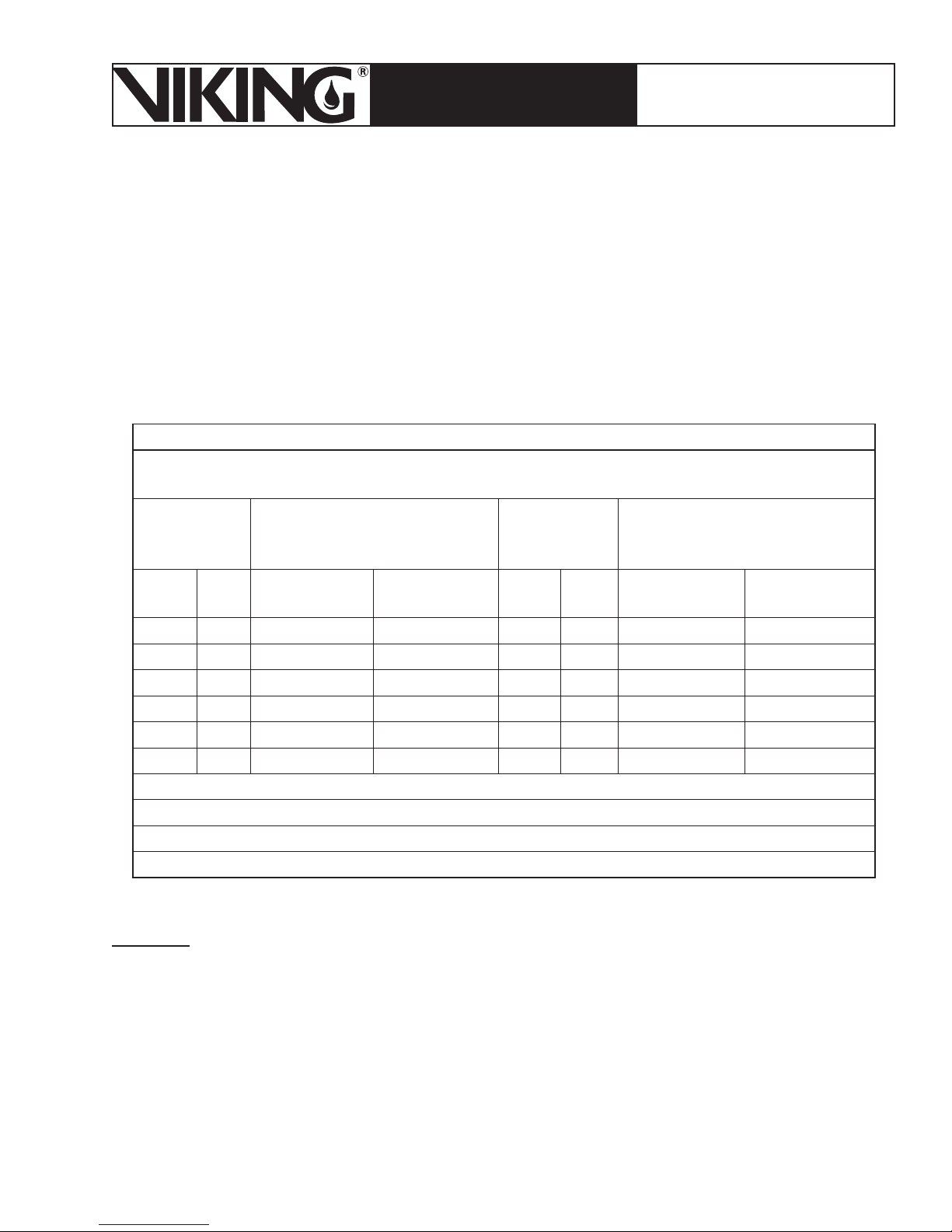

Table 1

From NFPA 13 - Table A.7.2.3 -

Capacity of 1 ft. of Pipe (Based on Actual Internal Pipe Diameter)

Nominal

Pipe

Pipe

Diameter

in. mm

Schedule 40

(gal)

Schedule 10

(gal)

3/4 20 0.028 - 3 80 0.383 0.433

1 25 0.045 0.049 3½ 90 0.513 0.576

1¼ 32 0.078 0.085 4 100 0.660 0.740

1½ 40 0.106 0.115 5 125 1.040 1.144

2 50 0.174 0.190 6 150 1.501 1.649

2½ 65 0.248 0.283 8 200 2.66

For SI units, 1 in. = 25.4 mm; 1 ft. = 0.3048 m; 1 gal = 3.785 L.

a

Schedule 80.

b

0.134 wall pipe.

c

0.188 wall pipe.

Nominal

Pipe

Diameter

in. mm

Pipe

Schedule 40

(gal)

a

Schedule 10

(gal)

b

c

2.776

Example:

Assume 100 ft² spacing, 10 ft between the sprinklers and 10 ft between the branch lines.

•

Schedule 10 Pipe.

•

3” Pipe = 300’ x .433 = 129.9 gal.

4” Pipe = 20’ x .740 = 14.8 gal.

6” Pipe = 74’ x 1.649 = 120.0 gal.

Total Volume = 247 gal.

* Note: Based on the installation history of this system, systems near 25,000 ft2 in area, with long runs on feed main, typically

begin to approach the 1,100 gallon restriction, or begin to demand excessive pressures in the Darcy-Weisbach calculation.

This history can be used as an estimating tool, however, the actual system volume must be calculated.

Page 18

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

3. Typical Storage Arrangements

Definitions:

Class II Commodity - A Class II commodity shall be defined as a noncombustible product that

is in slatted wooden crates, solid wood boxes, multiple layered corrugated cartons or equivalent

combustible packaging material with or without pallets.

Longitudinal Flue Space - The space between the rows of storage perpendicular to the direction of loading.

Transverse Flue Space - The distance between rows of storage parallel to the direction of loading.

L = Longitudinal Flue Space

T = Transverse Flue Space

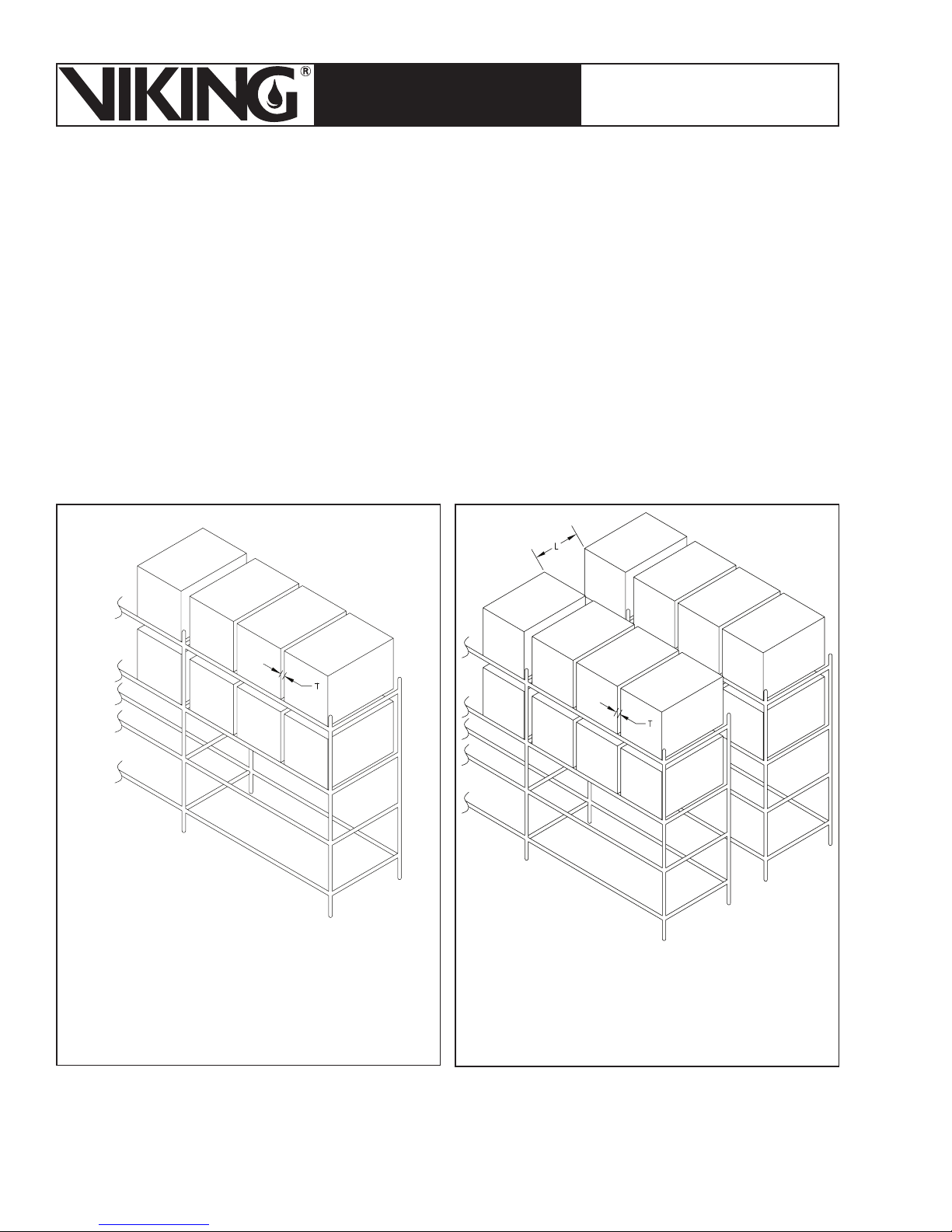

Figure 12 - Single Row Rack Storage

Racks that have no longitudinal fl ue space

and that have width up to 6 ft, and aisles at

leas 3½ ft from any other storage.

Figure 13 - Double Row Rack Storage

Two single row racks placed back to back

having a combined width up to 12 ft with

aisles at least 3½ ft on each side.

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

Page 19

Figure 14 - Multiple Row Rack

Storage

Racks greater than 12 ft (3.7 m) wide or single or double row racks separated by aisles less

than 3½ ft (1.07 mm) wide having an overall width greater than 12 ft (3.7 m).

Notes:

The system is acceptable for use with Class I and Class II commodities only.

1.

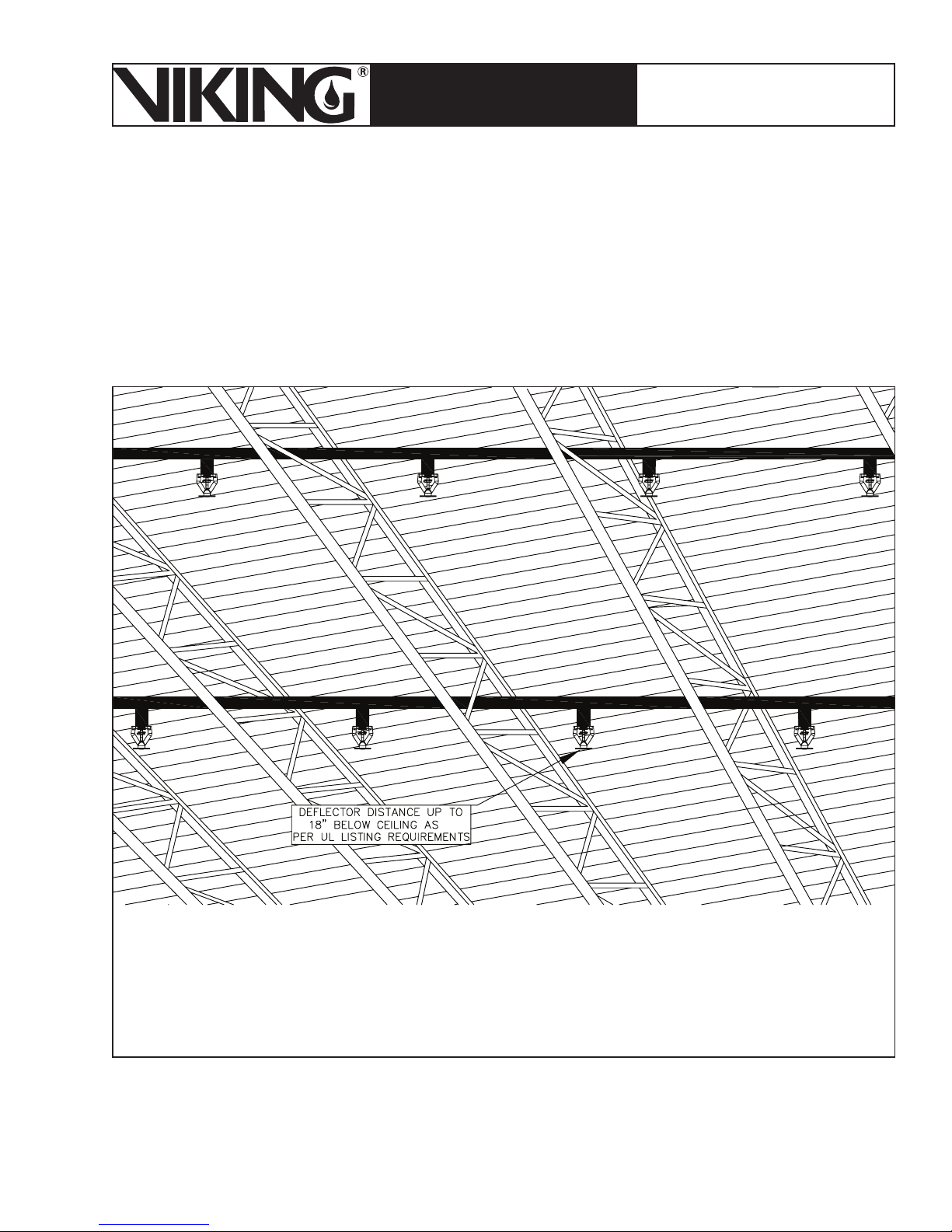

For use with a maximum 50% by volume propylene glycol and water antifreeze solution with

2.

a maximum ceiling height of 40 ft (12.2 m) and a maximum Class II commodity height of 35 ft

(10.7 m) with a maximum deflector distance below the ceiling of 18” (457 mm). The minimum

starting pressure is 40 PSI (2.76 Bar).

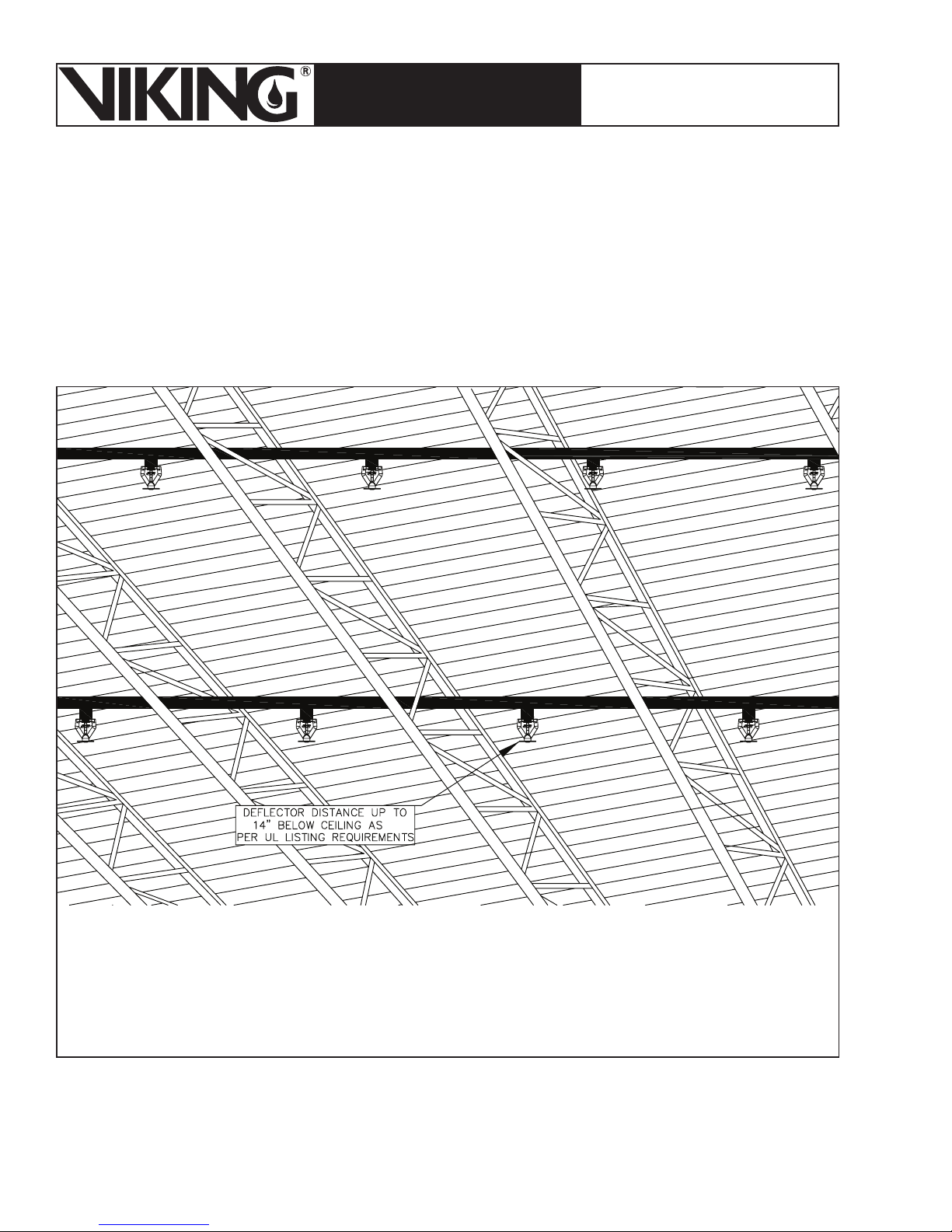

For use with a maximum 50% by volume propylene glycol and water antifreeze solution with

3.

a maximum ceiling height of 45ft-3 in (13.8 m) and a maximum Class II commodity height

of 40 ft (12.2 m) with a maximum deflector distance below the ceiling of 14” (356 mm). The

minimum starting pressure is 60 PSI (4.14 Bar).

The VK510 ESFR’s shall be ordinary temperature 165 °F (74 °C) except where required to

4.

be intermediate temperature 205 °F (96 °C) due to close proximity to heating sources as

described in NFPA 13.

The system shall be designed so that the maximum operating pressure does not exceed 175

5.

PSI (12 Bar) at the ESFR sprinklers.

Only wood pallets are acceptable.

6.

Page 20

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 15 - Maximum ceiling height of 45 ft-3 in and a maximum height

of 40 ft with a maximum deflector distance below the ceiling of 14”

March 7, 2008

Page 21

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 16 - Maximum ceiling height of 40 ft and commodity height of

35 ft with a maximum deflector distance below the ceiling of 18”

Page 22

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Table 2 - NFPA 13 Table A5.6.3.1, 2007 Edition

Table A.5.6.3.1 Examples of Class I Commodities Table A.5.6.3.1 Continued

Alcoholic Beverages

Cartoned or uncartoned

- Up to 20 percent alcohol in metal, glass, or ceramic containers

Appliances, Major (e.g., stoves, refrigerators)

- Not packaged, no appreciable plastic exterior

trim

Batteries

Dry cells (nonlithium or similar exotic metals)

- Packaged in cartons

Automobile

- Filled*

Bottles, Jars

Empty, cartoned

- Glass

Filled noncombustible liquids

- Glass, cartoned

- Plastic, cartoned [less than 5 gal (18.9 L)]

- Plastic, PET

Filled noncombustible powders

- Glass, cartoned

Canned Foods

In ordinary cartons

Cans

Metal

- Empty

Cement

Bagged

Coffee

Canned, cartoned

Fertilizers

Bagged

- Phosphates

File Cabinets

Metal

- Cardboard box or shroud

Fish or Fish Products

Frozen

- Nonwaxed, nonplastic packaging

Canned

- Cartoned

Frozen Foods

Nonwaxed, nonplastic packaging

Fruit

Fresh

- Nonplastic trays or containers

-With wood spacers

Ice Cream

Meat, Meat Products

- Bulk

- Canned, cartoned

- Frozen, nonwaxed, nonplastic containers

Metal Desks

-With plastic tops and trim

Milk

- Nonwaxed-paper containers

- Waxed-paper containers

- Plastic containers

Motors

- Electric

Nuts

- Canned, cartoned

Paints

Friction-top cans, cartoned

- Water-based (latex)

Plastic Containers

- Noncombustible liquids or semiliquids in plastic containers less than 5 gal (18.9 L) capacity

Poultry Products

- Canned, cartoned

- Frozen, nonwaxed, nonplastic containers

Salt

Bagged

Syrup

Drummed (metal containers)

Transformers

Dry and oil fi lled

Wire

Bare wire on metal spools on wood skids

*Most batteries have a polypropylene case and,

if stored empty, should be treated as a Group A

plastic. Truck batteries, even where fi lled, should

be considered a Group A plastic because of their

thicker walls.

March 7, 2008

Page 23

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Table 3 - NFPA 13 Table A.5.6.3.2, 2007 Edition

Table A.5.6.3.2 Examples of Class II Commodities Table A.5.6.3.2 Continued

Alcoholic Beverages

Up to 20 percent alcohol in wood containers

Appliances, Major (e.g., stoves)

Corrugated, cartoned (no appreciable plastic trim)

Baked Goods

Cookies, cakes, pies

- Frozen, packaged in cartons*

Batteries

Dry cells (nonlithium or similar exotic metals) in

blister pack in cartons

Bottles, Jars

Filled noncombustible powders

- Plastic PET

Boxes, Crates

Empty, wood, solid walls

Fertilizers

Bagged

- Nitrates

Fish or Fish Products

Frozen

- Waxed-paper containers, cartoned

- Boxed or barreled

Frozen Foods

Waxed-paper containers, cartoned

Leather Hides

Baled

Light Fixtures

Nonplastic

- Cartoned

Marble

Artifi cial sinks, countertops

- Cartoned, crated

Meat, Meat Products

- Frozen, waxed-paper containers

- Frozen, expanded plastic trays

Pharmaceuticals

Pills, powders

- Glass bottles, cartoned

Nonfl ammable liquids

- Glass bottles, cartoned

Photographic Film

- Motion picture or bulk rolls of fi lm in polycarbon-

ate, polyethylene, or metal cans; polyethylene

bagged in cardboard boxes

Plastic Containers

Noncombustible liquids or semiliquids (such as

ketchup) in plastic containers with nominal wall

thickness of L/4 in. (6.4 mm) or less and larger

than 5 gal (18.9 L) capacity

Poultry Products

Frozen (on paper or expanded plastic trays)

Powders (ordinary combustibles - free fl owing)

In paper bags (e.g., fl our, sugar)

Salt

Packaged, cartoned

Shock Absorbers

Metal dust cover

Signatures

Book, magazines

- Solid array on pallet

Syrup

Barreled, wood

Wire

- Bare wire on wood or cardboard spools on

wood skids

- Bare wire on metal, wood, or cardboard spools

in cardboard boxes on wood skids

- Single- or multiple-layer PVC-covered wire on

metal spools on wood skids

- Insulated (PVC) cable on large wood or metal

spools on wood skids

Wood Products

Solid piles

- Lumber, plywood, particle board, pressboard

(smooth ends and edges)

*The product is in a plastic-coated package in a

corrugated carton. If packaged in a metal foil, it can

be considered Class I.

Page 24

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

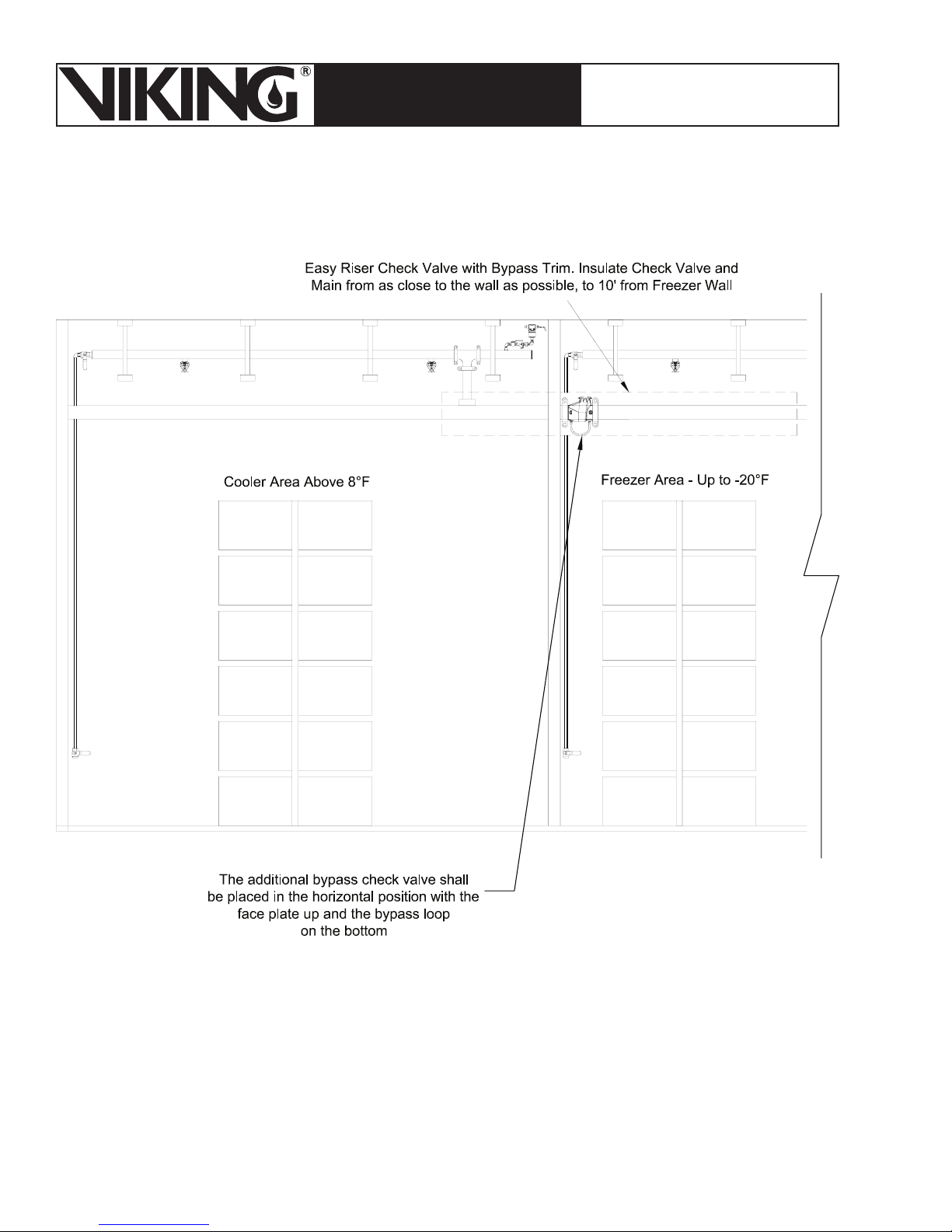

Figure 17 - Adjacent Freezer and Cooler

Where the building has separate cooler and freezer areas, it will be necessary to install additional

bypass check valves to prevent thermal transfer and frosting from one area to another.

March 7, 2008

Page 25

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Page 26

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

4. Designing the Detection System

The detection system shall consist of low temperature “spot” type heat detectors, air sampling

smoke detection or beam smoke detection. Linear heat detection is not suitable for this system

and shall not be used.

Viking does not have a preferred manufacturer of initiating devices. Spot heat detectors are

typically not subject to compatibility issues with the release control panel. Viking considers all

listed and approved spot type heat detectors that the manufacturer determines is appropriate for

cold storage applications acceptable. The detection system shall be designed to allow the heat

detectors to operate prior to the Viking K25.2 ESFR sprinklers by selecting a lower temperature

rating and RTI for the heat detector. (NFPA 13 defines an ESFR Sprinkler as having a thermal

element with an RTI of 50 (meters sec.½) or less.) The heat detector manufacturer shall be contacted for the heat detector RTI information.

Air sampling systems are also considered acceptable for activation of the ESFR Cold Storage

System, and should be designed in accordance with the manufacturer’s instructions.

The detection system shall be designed in accordance with the requirements of NFPA 72.

5.6.2.3 Marking: Heat-sensing fire detectors shall be marked with their listed operating temperature. Spot-type heat detectors shall also be marked with their RTI (response time index). The

RTI marking requirements shall have an effective date of July 1, 2008.

5.6.5.5.1 On ceilings 10 ft to 30 ft (3 m to 9.1 m) high, heat detector linear spacing shall be

reduced in accordance with Table 5.6.5.5.1 prior to any additional reductions for beams, joists,

or slope, where applicable.

5.6.5.5.2 The minimum spacing of heat detectors shall not be required to be less than 0.4 times

the height of the ceiling.

Table 4 - Detector Classification from NFPA 72

Table 5.6.2.1.1 Temperature Classifi cation for Heat-Sensing Fire Detectors

Temperature

Classifi cation

Low* 100-134 39-57 80 28 Uncolored

Ordinary 135-174 58-79 115 47 Uncolored

Intermediate 175-249 80-121 155 69 White

High 250-324 122-162 230 111 Blue

Extra high 325-399 163-204 305 152 Red

Very extra high 400-499 205-259 380 194 Green

Ultra high 500-575 260-302 480 249 Orange

*Intended only for installation in controlled ambient areas. Units shall be marked to indicate maximum ambient installation

temperature.

Temperature Rating Range Maximum Ceiling Temperature Color

° F ° C ° F ° C

Code

March 7, 2008

Page 27

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 18 - Detection System

Table 5 - Spacing Reductions from NFPA 72

Table 5.6.5.5.1 Heat Detector Spacing Reduction Based on Ceiling Height

Ceiling Height Above Up to and Including Multiply Listed

mftmft

Spacing by

0 0 3.05 10 1.00

3.05 10 3.66 12 0.91

3.66 12 4.27 14 0.84

4.27 14 4.88 16 0.77

4.88 16 5.49 18 0.71

5.49 18 6.10 20 0.64

6.10 20 6.71 22 0.58

6.71 22 7.32 24 0.52

7.32 24 7.93 26 0.46

7.93 26 8.54 28 0.40

8.54 28 9.14 30 0.34

III. INSTALLATION AND COMPONENT FUNCTIONS

Note: All materials installed on the system shall be compatible with the propylene glycol solution.

PVC C

CPVC C

Table 6 -

Propylene

Glycol

Compatibility

Chart

Thermoplastics

Gaskets

Polyethylene (PE) B

Polyethylene Cross Linked (XLPE) A

Teflon A

ABS B

Viton A

EPDM A

Neoprene C

Buna N (Nitrile) A

Hypalon A

A = Excellent resistance

B = Fair

C = Poor

Information provided by The Noble

Company

Page 28

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

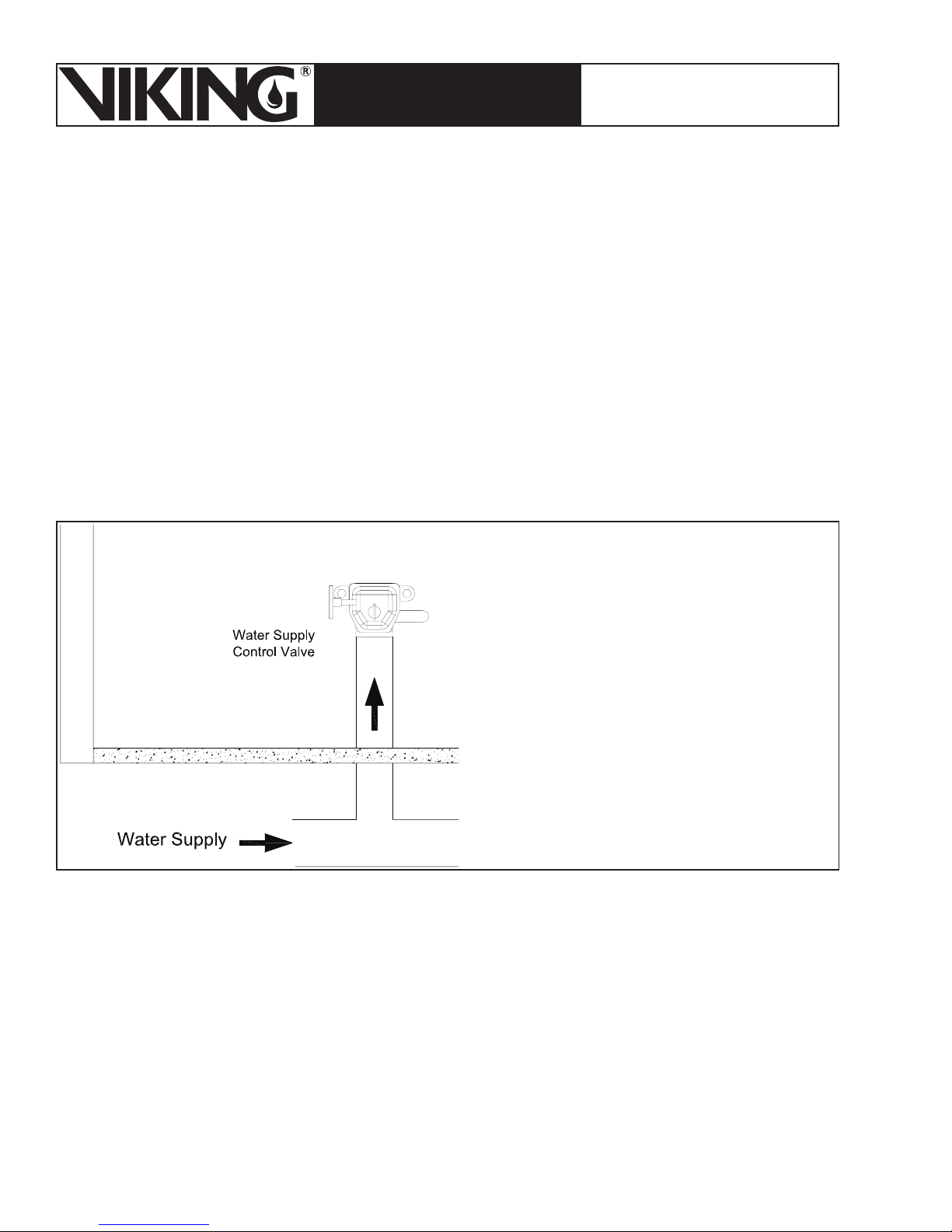

1. Water Supply Control Valve

A listed indicating valve shall be installed on the upstream side of the deluge valve. The valve

shall not close in less than 5 seconds when operated at maximum possible speed from the fully

opened position. Valves shall conform to the requirements of NFPA 13 (8.16.1.1.2 2007 ed.):

8.16.1.1.2* Supervision.

8.16.1.1.2.1 Valves on connections to water supplies, sectional control and isolation valves, and

other valves in supply pipes to sprinklers and other fixed water-based fire suppression systems

shall be supervised by one of the following methods:

Central station, proprietary, or remote station signaling service

1)

Local signaling service that will cause the sounding of an audible signal at a constantly at-

2)

tended point

Valves locked in the correct position

3)

Valves located within fenced enclosures under the control of the owner, sealed in the open

4)

position, and inspected weekly as part of an approved procedure

Figure 19 - Water

Supply Control Valve

2. Grooved Couplings

In order to prevent leaks and preserve the antifreeze solution, it is imperative that grooved pipe

ends are smooth, round, and free of burrs, flat spots, and weld seam imperfections. Also, pipes

should be capped to prevent contaminant during shipping, storage, etc. Verify that any gasket

materials used in couplings, etc. are compatible with the antifreeze solution. Refer to the antifreeze solution technical data page.

Where grooved couplings are used in the system, “flush seal” gasket, low temperature EPDM

rubber and lube are required. Gaskets: grade “E” EPDM, NSF-61 Certified, -40 °F to 230 °F (service temperature range) (-40 °F to 110 °F) recommended for water service, diluted acids, alkalys

solutions, oil-free air and many chemical services. GRUVLOK Xtrema Lubricant is required for

freezer applications. In order to pervent leaks and preserve the antifreeze solution, the grooved

pipe ends must be smooth, round, and free of burrs.

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

INTERLOCK PREACTION

COLD STORAGE SYSTEM

Page 29

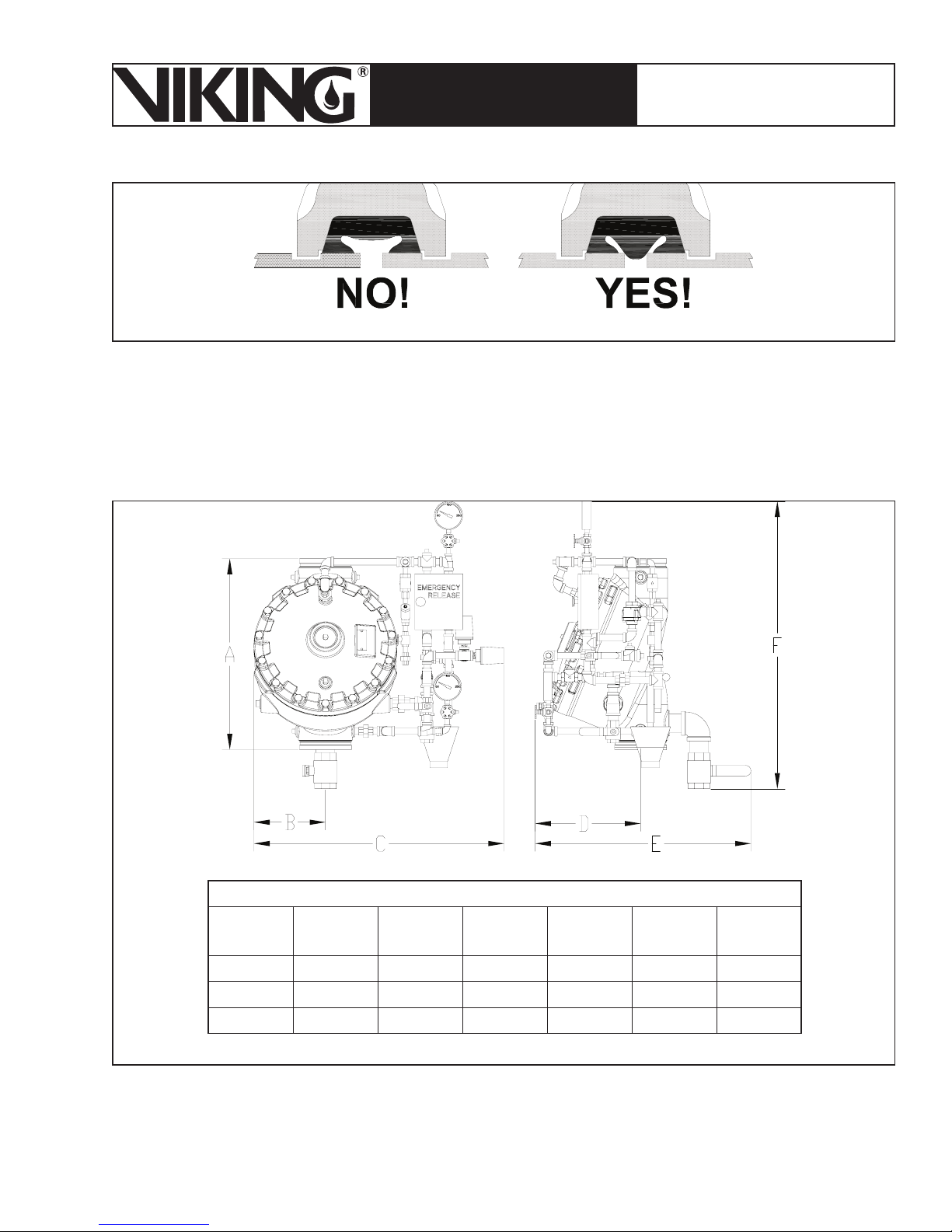

Figure 20 - Grooved Couplings

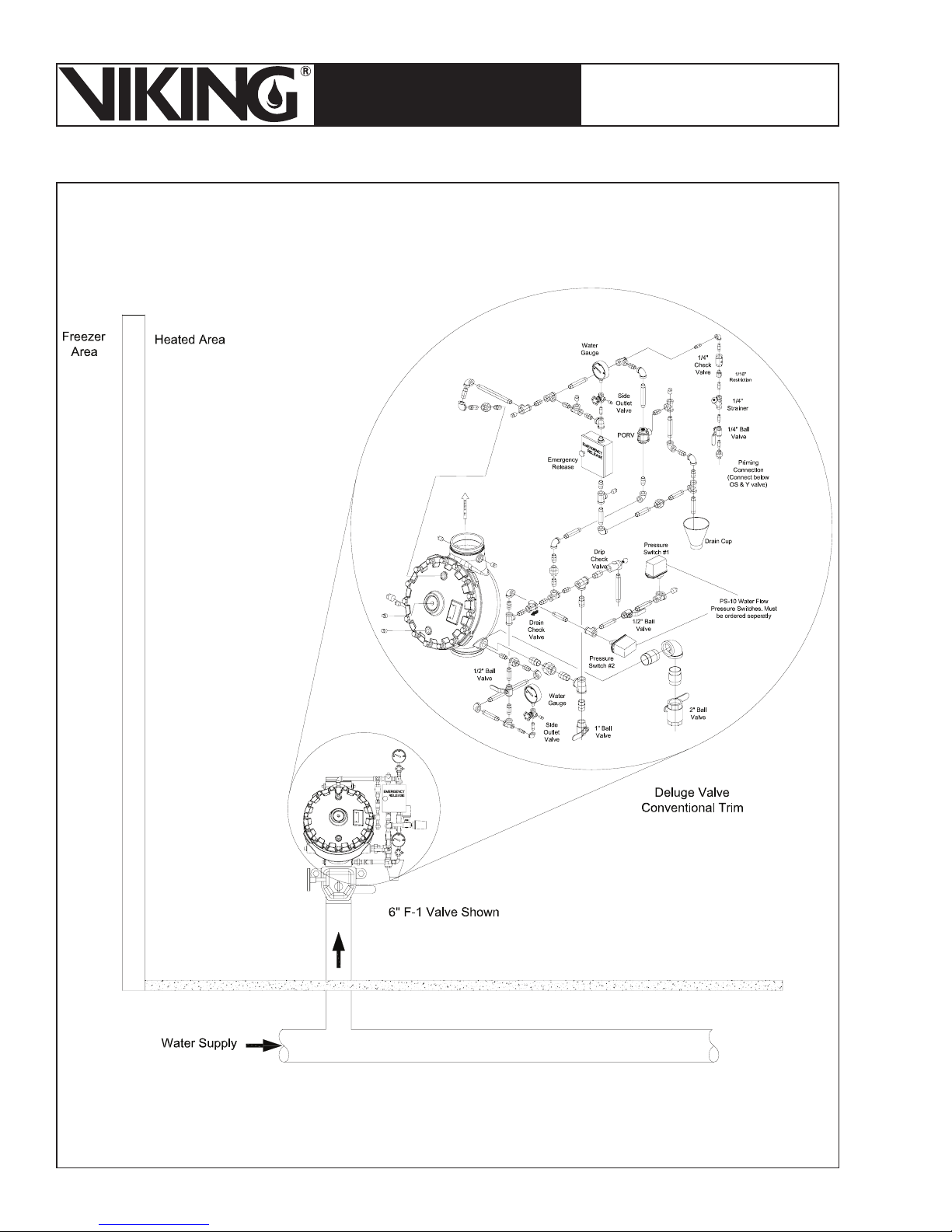

3. Deluge Valve with Conventional Trim

The ESFR Cold Storage System utilizes a Viking Model F-1 Deluge Valve. Refer to Viking

Technical data pages for Valve Specifications.

The Deluge V alve is to be installed using Deluge Valve Conventional Trim. Refer to the trim drawing on the following page for details.

Valve

Size

4” 19-1/2 7-1/4 28-1/2 13 22-7/16 34-5/8

6” 24-5/16 9-1/8 31-7/8 13-7/16 27-1/2 36-5/8

8” 29-1/2 11-1/4 35-5/16 14-1/4 19-7/8 39-1/4

Figure 21 - Valve and Trim Dimensions

ABCDEF

Page 30

March 7, 2008

ESFR PRE-PRIMED SINGLE

TECHNICAL DATA

INTERLOCK PREACTION

COLD STORAGE SYSTEM

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 22 - Deluge Valve and Trim

Loading...

Loading...