Viking DFRD144, DFUR143, DFUR144, DFUW144, DUAR143 Service Manual

...

Service

Manual

This manual is to be used by qualied appliance technicians only.

Viking does not assume any responsibility for property damage

or personal injury for improper service procedures done by an

unqualied person.

2008 24 Inch

Undercounter

Refrigeration

This Base Manual covers general and

specic information including, but not

limited to the following models:

DFRD144

DFUR143

DFUR144

DFUW144

DUAR143

DUAR144

DURD144

DUWC14 4

VUAR143

VUAR144

VURD144

VUWC144

SMR-0003

July 2008

Important Information

Important Notices for Service Technicians

Viking Range Corporation will not be responsible for personal injury or property damage arising from service

performed by anyone other than Viking Factory Authorized Service Agencies. Pride and workmanship go into every

product to provide our customers with quality products. It is possible, however, that during its lifetime a product may

require service. Products should be serviced only by a qualied service technician who is familiar with the safety

procedures required in the repair and who is equipped with the proper tools, parts, testing instruments and the

appropriate service information.

IT IS THE TECHNICIANS RESPONSIBILITY TO REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE

BEGINNING REPAIRS.

All safety information must be followed as provided in this document

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power

before servicing unless testing requires power.

IM PO RTAN T: Wires removed during disassembly must be replaced on correct terminals to ensure proper

grounding and polarization.

Contact Information:

For authorized technical assistance:

Viking Technical Service

1-800-914-4799

Safety Symbols

Recognize these Safety Symbols, Words, and Labels:

DANGER-Immediate hazards which WILL result in

severe personal injury or death.

WARNING-Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION-Hazards or unsafe practices which

COULD result in minor personal injury, product or

property damage.

2 SMR-0003 © Viking Range Corporation

Table of Contents

Important Information ..................................................... 2

Important Notices for Service Technicians ................. 2

General Information ....................................................... 4

Unit Specications ...................................................... 4

Wine Cellar, Beverage Center & Refrigerated Drawers

Unit Specications ...................................................... 4

Serial Nameplate ........................................................ 4

Before Servicing ......................................................... 4

Basic Refrigeration Tools ........................................... 5

Installation .................................................................. 5

Electrical Requirements ............................................. 5

Sealed System Basics ...............................................5

Diagnostic Information ...................................................6

Low Side leaks ........................................................... 6

High Side Leaks ......................................................... 6

Restricted Capillary Tube ........................................... 6

Access Valves ............................................................ 6

Evaporator Frost Pattern ............................................ 6

Pressure and Temperature ......................................... 6

Temperature-Pressure Chart for R-134a .................... 6

Re-charging ................................................................ 7

Condenser .................................................................. 7

Compressor ................................................................ 7

Evaporator .................................................................. 8

Thermistors ................................................................ 9

Resistance versus Temperature Chart ....................... 9

User Interface Panel and Tru Protect™ System ...... 10

Starting the Unit .......................................................10

Setting the Temperature Mode ................................. 10

Adjusting the Temperature Control ........................... 10

Interior Light and Switch ........................................... 10

Sabbath Mode .......................................................... 10

Warning Alarm .......................................................... 11

Resetting the Alarms ................................................ 11

Show Room Mode .................................................... 11

Error Code Detection ............................................... 11

Error Code Detection Reference .............................. 11

Service Diagnostics Mode ........................................ 12

Software Model Number ..........................................12

Available Component Tests ...................................... 12

Ordering Parts .......................................................... 12

Troubleshooting Procedures ........................................13

Component Testing Procedures ................................... 16

Disassembly ................................................................. 19

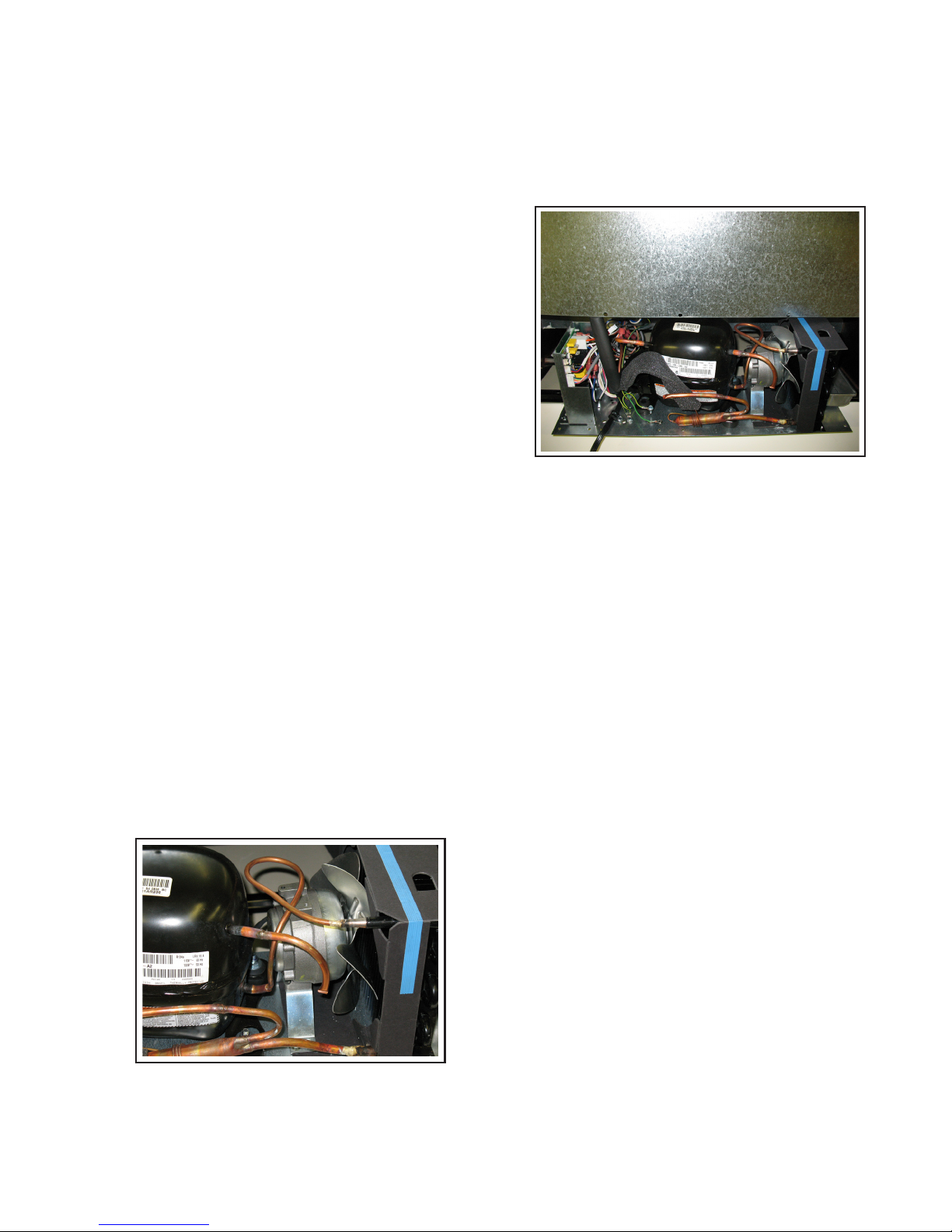

Mechanical Baseplate: ............................................. 19

Compressor .............................................................. 20

Condenser ................................................................ 21

Condenser Fan ........................................................21

Thermistors .............................................................. 21

Lights ........................................................................ 21

Wiring Diagrams and Schematics ................................ 23

Wine Cellar Wiring Schematic .................................. 23

Beverage Center Wiring Schematic ......................... 24

Refrigerated Drawer Wiring Schematic .................... 25

© Viking Range Corporation SMR-0003 3

General Information

YYYYMMDDSSSA

DETAIL "B"

YEAR

MONTH

DAY

SERIAL

ASSEMBLY SITE

MODEL NO. SERIAL NO.

BTU/HR

R134A

OZ TEST PRESSURE

"J" PSI LOW SIDE

"K" PSI HIGH SIDE

905L

LISTED

HOUSEHOLD

C

"A"

AMPSPHHZVOLTS

DETAIL "B"

"C"

"D" "E" "F"

"G"

"H"

REFRIGERATOR

GREENWOOD, MISSISSIPPI 38930 USA

VIKING RANGE CORPORATION

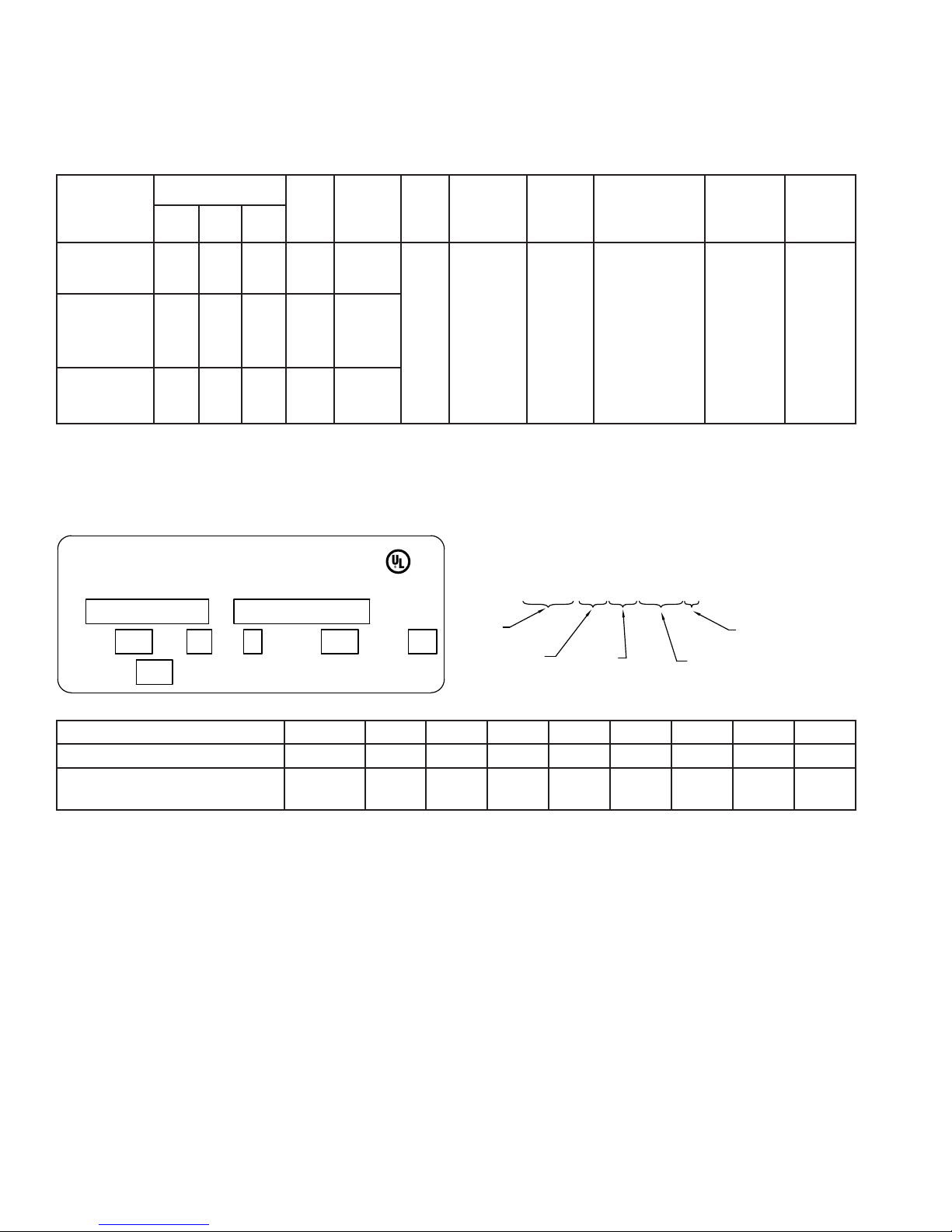

Unit Specications

The unit specications will vary among the models listed in this service manual. See chart below for unit

specications related to the model that you are servicing.

Wine Cellar, Beverage Center & Refrigerated Drawers Unit Specications

Power

Cord

Length

(ft)

Compressor

Type

System

Refrigerant

Control

Temperature

Control

Condenser

Fan Motor

Model

DFUW144

DUWC144

VUWC144

Cabinet Dimensions (in)

Height Width Depth

34 23 ⅝ 24 ¼ 166 2.8

Weight

Refrigerant

(lbs)

Charge

(oz)

Evaporator

Fan Motor

DFUR143/144

DUAR143/144

VUAR143/144

DFRD144

DURD144

VURD144

34 23 ⅝ 24 ¼ 166 3.6

34 23 ⅞ 24 ¼ 170 3.6

7 Piston type

Capillary

tube

Electronic Control

with LED display,

thermistor input,

and Tru Protect™

2.3 W 1300

RPM

12VDC

Serial Nameplate

The serial nameplate is located inside of the unit on the upper left hand wall. The serial number will need to be given

when inquiring about the unit or ordering parts. See illustration below for a sample serial tag with manufacturing date

code logic.

A B C D E F G H J K

DFUW, DUWC, VUWC 144 Detail B 115 60 1 440 3.3 2.8 140 300

DFUR, DUAR, VUAR 143/144

DFRD, DURD, VURD 144

Detail B 115 60 1 440 3.3 3.6 140 300

Before Servicing

Always disconnect power to any Viking product •

before attempting to service it. Always verify that

power has been disconnected.

If the unit has been running, use caution around the •

condenser and copper tubing. These areas may be

very hot.

Use caution around the condenser ns and •

baseplate edges. These areas are sharp.

Refrigerant is under high pressure. Always evacuate •

any system before attempting to open it.

Reasonable care and safe work methods should •

be practiced when working on any Viking product.

Never work with energized electrical equipment in

wet or damp areas.

4 SMR-0003 © Viking Range Corporation

Use an appropriate work area and location when •

performing repairs. You will nd that it is easier to

repair undercounter units if they are set on a raised

platform or workbench.

Always wear protective safety glasses and gloves •

when working on any Viking product.

Any refrigerant, whether CFC, HCFC, or HFC (R-12, •

R-22, or R-134a), must be recovered. Federal

regulations prohibit the intentional venting or release

of refrigerants during the service repair or disposal

of an appliance.

General Information

Basic Refrigeration Tools

The following list contains some of the tools required for

basic refrigeration repairs:

Hoses with R-134a couplers (must meet standards •

for handling R-134a refrigerant)

Approved and certied recovery system for R-134a•

Manifold gauge set for R-134a•

Charging cylinder with R-134a•

Weight scale (preferably in ounces to the nearest •

tenth of an ounce)

Access valves•

Small and large tubing cutter•

Brazing torch•

Swaging tools•

Multimeter•

Leak detection equipment for detection of R-134a•

Standard hand tools (assorted Phillips and standard •

screwdrivers, sockets, Allen wrenches, adjustable

wrenches, etc.)

Rivet gun and assorted rivets•

Drill motor and assorted metal drills•

Installation

Unit can be installed freestanding or built-in. The •

front of the unit must be unobstructed for proper air

circulation and operation at all times.

Area should be ventilated and without extreme •

temperatures.

Unit must be installed away from the elements of •

nature. Do NOT use the unit outdoors unless it is

U.L. approved for outdoor use; doing so may void

any warranties.

Unit must be on a • LEVEL surface capable of

supporting the loaded weight of the unit.

Sealed System Basics

The following should always be practiced with any

sealed system that has been opened. ONLY OPEN

THE SEALED SYSTEM AS A LAST RESORT AND

AS A FINAL DIAGNOSIS. Always check other areas of

operation such as wiring, airow, thermostat, etc. before

opening up the sealed system. Many times these areas

can resemble sealed system problems. The diagnosis

of a sealed system can be determined by accurate

pressure and temperature measurements. Also,

checking the evaporator frost pattern is a great way to

tell if a charge is adequate within a system.

Use a leak detection system that will detect R-134a 1.

refrigerant. Leaks need to be found on any leaking

system BEFORE the repair takes place.

The drier must be replaced anytime the sealed 2.

system is opened. Always use a new drier. Failure

to do so may cause repeated system failure in the

future.

Limit time the system is opened. 3. DO NOT EXPOSE

THE OPEN SYSTEM FOR MORE THAN 15

MINUTES. This will result in sealed system failure.

Leave replacement parts sealed and/or pressurized

until ready to install.

The compressor must be replaced if there is a low 4.

side leak. Moisture has been drawn into the system

if the unit has been running for an extended period

of time. Be sure to ush the system with dry nitrogen

gas and evacuate to 50 microns before re-charging

(see Low Side Leaks).

A new evaporator assembly must be ordered if the 5.

capillary tube is found to be plugged or severely

restricted. Restrictions cannot be ushed out.

Be sure to purge the system with dry nitrogen gas 6.

after nal brazing. This will ush out any air or

moisture that may have entered the system before

being absorbed into the ester oil.

ELECTRICAL SHOCK HAZARD-Failure to follow

these requirements could result in personal injury,

electrical shock, or re.

Electrical Requirements

115 VAC, 60 Hz., single phase power is needed•

Use an outlet with a 15 amp delayed action fuse •

or circuit breaker. DO NOT PUT A FUSE ON THE

NEUTRAL OR GROUND OF THE CIRCUIT.

Properly grounded outlet is required for this unit.•

It is recommended that a single circuit receptacle •

be used for this unit only. DO NOT USE AN

EXTENSION CORD.

© Viking Range Corporation SMR-0003 5

Diagnostic Information

Low Side leaks

Low side leaks consist of a break in the system at the

evaporator, low side (suction) return line, or accumulator.

If a leak is found in any of these areas, moisture has

probably entered the system. The compressor and drier

will have to be replaced and the system will need to be

ushed thoroughly with nitrogen gas and evacuated to

50 microns before re-charging.

High Side Leaks

High side leaks consist of a break in the system at the

condenser, high side tubing, drier, or capillary tube. If a

leak is found in any of these areas, the system can be

ushed with nitrogen gas, evacuated to 50 microns, and

re-charged.

Restricted Capillary Tube

Moisture or other contaminants that enter the system

can cause deposits in the system. These deposits will

usually collect in the capillary tube and form a restriction

that cannot be completely removed by ushing. If the

capillary tube is found to be restricted, the evaporator,

compressor, condenser, and drier should all be replaced.

Access Valves

A temporary access valve can be used to service or

evaluate the system. From these access valves, you

can evacuate, charge, and recover the system. The

access valve can be installed on the compressor’s

process tube (this will also be a low pressure side). Be

sure to cap off access valve while servicing. This will

prevent contamination of the system and/or refrigerant

from leaking. After servicing, the access valve should

be removed. A pinch-off tool can be used to close the

system to remove the access valve and then braze the

hole for the access valve to seal the system. Be sure to

leak check after brazing.

Evaporator Frost Pattern

Checking the evaporator frost pattern is a good way

to quickly diagnose simple sealed system problems.

This can be done by allowing the unit to run (at least 10

minutes) with the door open for at least 5 minutes. This

will help speed up the normal frosting of the evaporator

plate. By visually inspecting the evaporator and feeling

it with your hands, you will see and feel frost across the

plate. It is absolutely necessary for the frost to cover the

entire evaporator plate. This will ensure the system has

been charged to its specied amount or does not have

a leak. A partial frost pattern may lead to excessive run

times or even 100% run mode. This is because the frost

does not reach the area of the evaporator thermistor, so

it does not sense the temperature required to cycle the

unit off.

6 SMR-0003 © Viking Range Corporation

Pressure and Temperature

There are two ways to measure temperature of the

evaporator plate:

Use a thermocouple to measure the temperature of 1.

evaporator plate. Thermocouple must be secured to

the evaporator when taking the measurement.

If there is proper contact between the thermistor and 2.

evaporator plate, thermistor resistance value can be

corresponded to the temperature (See Thermistors).

NOTE: Temperature and pressure readings must

be taken while unit is running. Use gauge

pressure readings from the compressor’s

process tube (low side) access valve.

Pressure will vary depending upon the ambient

temperature and current stage of operation for the unit.

For example, the unit will have pressure between 0 and

5 psi just before entering the off cycle. Normal running

pressures on the low side will average 5 to 10 lbs.

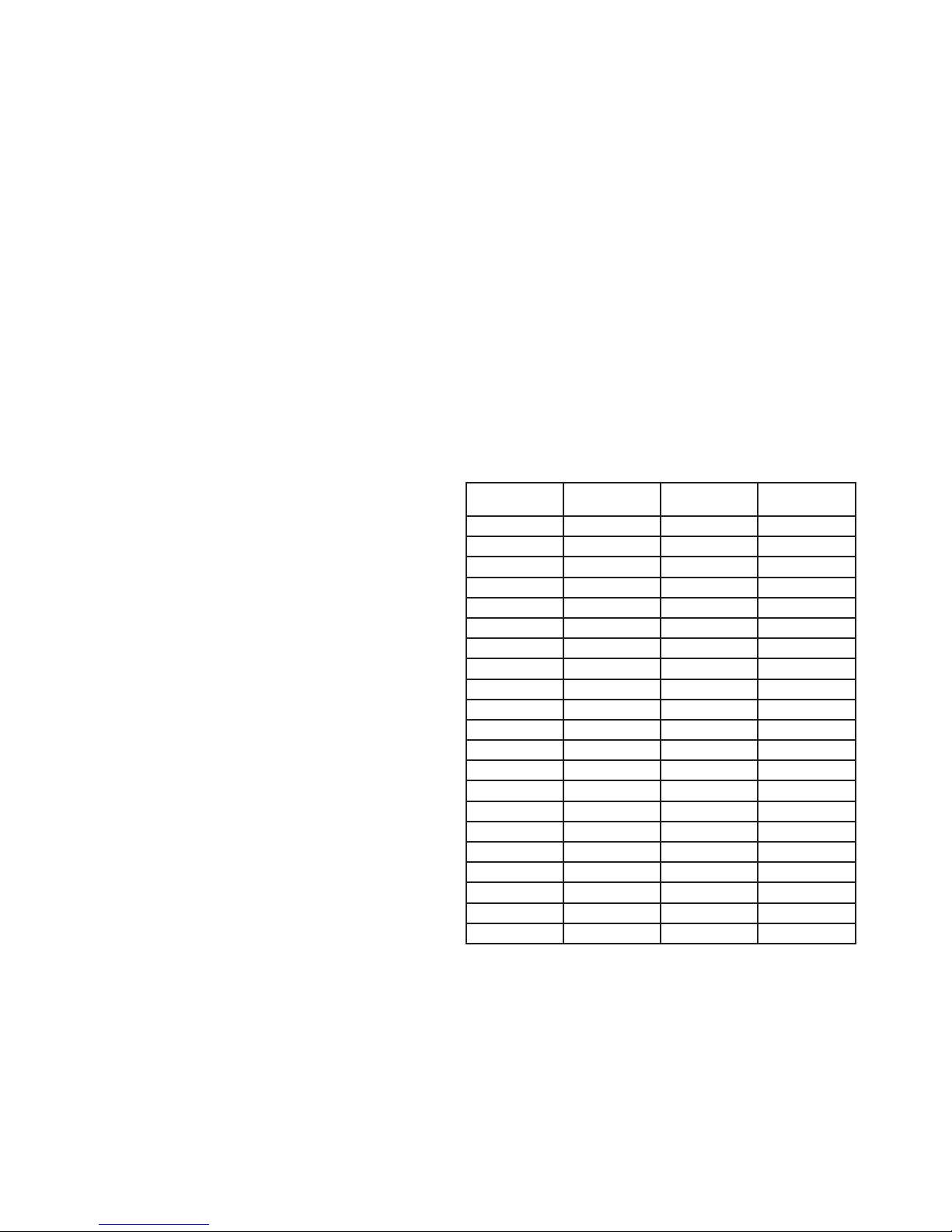

Temperature-Pressure Chart for R-134a

Degrees F Pressure (psi)

R-134a

-12 1.1 36 31.3

-8 2.8 38 33.2

-4 4.5 40 35.1

0 6.5 42 37.0

2 7.5 44 39.1

4 8.5 46 41.1

6 9.6 48 43.3

8 10.8 50 45.5

10 12.0 52 47.7

12 13.1 56 52.3

14 14.4 60 57.5

16 15.7 64 62.7

18 17.0 68 68.3

20 18.4 72 74.2

22 19.9 76 80.3

24 21.4 80 86.8

26 22.9 84 93.6

28 24.5 88 100.7

30 26.1 92 108.2

32 27.8 96 116.1

34 29.5 100 124.3

If low side pressure is below pressure in chart above,

check for the following:

A system leak1.

Capillary tube is restricted2.

Insufcient compressor (does not pump properly)3.

If low side pressure is above pressure in chart above,

check for the following:

Restricted air ow1.

Dirty condenser coil2.

Overcharged system3.

Low side leak4.

Degrees F Pressure (psi)

R-134a

Diagnostic Information

Re-charging

Re-charging of the unit should be done only after

diagnosing and repairing the system. Be sure to ush

the system with dry nitrogen gas and evacuate to 50

microns before re-charging.

The method for re-charging the unit is by weight using

vapor refrigerant. Using manifold gauge set-up, hook up

charge hoses to the access valve on the compressor’s

process tube. If any access valve is attached to the high

side process tube, remove it and then seal the tube by

brazing before charging. Charge the unit to specied

amount (see Unit Specications for charge specications

per model).

After re-charging the system, check pressures

(See Pressure and Temperature) for corresponding

temperatures and pressures. If pressures are incorrect,

check the sealed system, recover the charge, repair,

evacuate, and then re-charge.

It is normal to have some condensation or slight frost on

the suction line. Typically this will occur towards the end

of a run cycle. If the frost continues down the suction

line to the compressor, the system is overcharged. It

is important that the insulation remains on the suction

line and the capillary tube together after any repair and

that it is sealed on both ends. Be sure to replace the

refrigeration putty in the hole of the foam where the

refrigerant lines go through the back of the unit. Spread

the putty out evenly lling in the cracks to prevent air

from leaking in and out.

Condenser

The condenser is a steel tube serpentine with copper

alloy ns that removes heat from hot, high pressure

vapor from the compressor. The most common trouble is

lack of airow from either a restricted intake or exhaust

opening in the front of the unit. Lint, dust, hair, and

dirt build-up needs to be removed from the condenser

periodically to allow the unit to perform properly.

Compressor

The compressor is the heart of the refrigeration system.

However, it relies on other parts of the system to

function. Make certain that the other parts of the system

are functioning correctly before determining that the

compressor is faulty.

The following should be observed before concluding

the compressor is faulty:

Low high side pressures, warm evaporator plate, 1.

cool condenser coil, or little or very low current draw

from the unit will indicate a faulty compressor.

Check for continuity between the compressor 2.

terminals and the shell of the compressor. If

continuity is found, the compressor is faulty and will

need to be replaced.

Check for resistance between all compressor 3.

terminals. The resistance will vary from terminal

to terminal and from compressor to compressor

due to age and use. If no resistance is found, the

compressor is faulty and will need to be replaced.

© Viking Range Corporation SMR-0003 7

Diagnostic Information

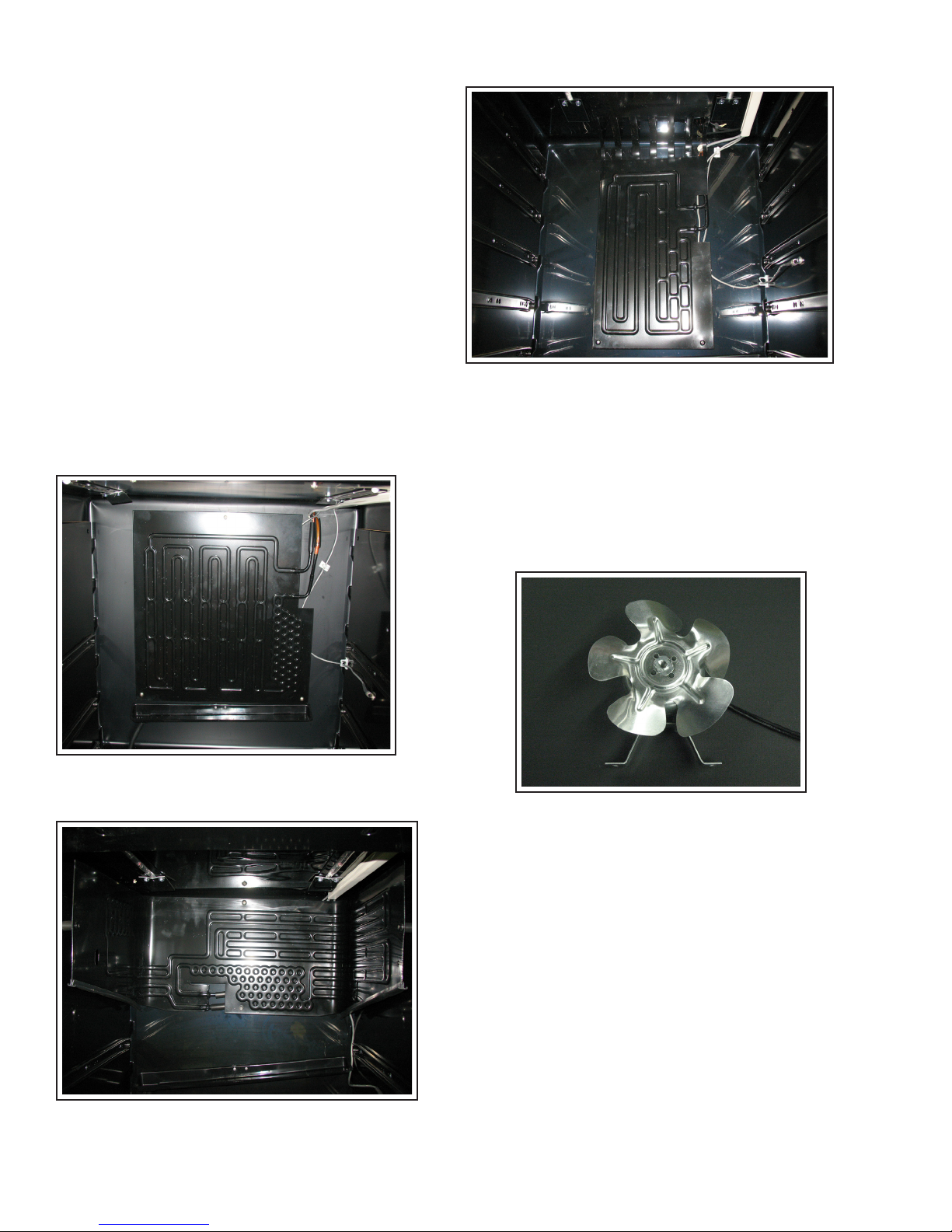

Evaporator

The evaporator uses evaporating refrigerant to remove

heat from the inside of the unit ultimately making the

interior cold. The shape and size of the evaporator may

vary among the models covered by this service manual

but the fundamentals are the same . The DFUW, DUWC,

AND VUWC use a vertical right angle evaporator plate.

The DFUR, DUAR, AND VUAR use a U-shaped plate.

The DFRD, DURD, AND VURD use a multi-purpose

evaporator plate.

It is normal for the evaporator to frost up during its run

cycle. This frost will dissipate once the unit reaches

its “cut out” temperature and the compressor and

fan stop. This condensate water will ow to the rear

of the machine in a condensate pan where it will be

evaporated from compressor and fan heat. It is very

important that the evaporator frosts in a uniform pattern

across the plate (see Evaporator Frost Pattern). A partial

frost pattern can lead to excessive run times and cooling

issues.

Evaporator plate for DFUW, DUWC, and VUWC wine

coolers

Condenser Fan

The condenser fan is used to force air over the

condenser coil. The fan will cycle on and off with the

compressor which means that when the compressor is

running so is the fan and when the compressor is not

running neither is the fan (see illustration below).

Evaporator plate for DFRD, DURD, and VURD

refrigerated drawers

Evaporator plate for DFUR, DUAR, and, VUAR

beverage centers

8 SMR-0003 © Viking Range Corporation

Make sure the motor shaft turns freely. This can 1.

be done by rotating the fan blade by hand and

observing any excessive resistance.

Check for resistance between terminals. If no 2.

resistance is found, replace the condenser fan.

Check for continuity between terminals and fan 3.

casing. If continuity is found, replace the condenser

fan.

Check current draw. Typical current draw will be 4.

0.15 amp without fan resistance. If current draw

is 0.19 amp or more, check for resistance in air

movement or objects touching the fan blade. If this

is not found, replace the condenser fan.

Loading...

Loading...